Black tea withering method

A technology of withering and black tea, which is applied in the field of black tea withering, which can solve the problems of high aroma loss, light black tea aroma, and low nutrient loss rate, and achieve the effects of easy rolling and forming, simple withering process, and short withering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

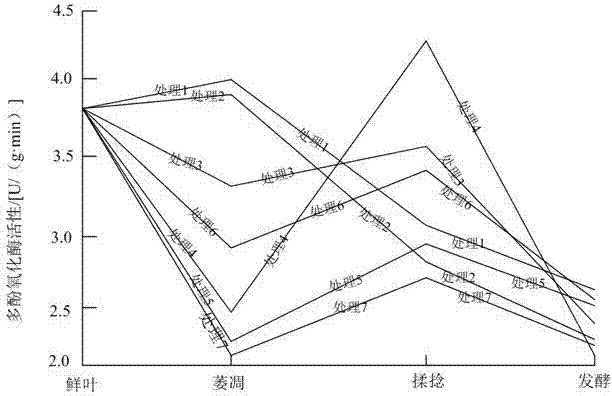

Image

Examples

Embodiment 1

[0014] Embodiment 1, a kind of black tea withering method, specifically:

[0015] (1) Picking fresh tea leaves with one bud and two leaves as raw materials for withering;

[0016] (2) Spread the fresh original leaves on the withering rack with a layer thickness of 1 cm, and send the fresh original leaves into the freezer for freezing. The temperature in the freezer is -5°C, and the freezing time is 30 minutes;

[0017] (3) Send the fresh raw leaves obtained by freezing into the evaporation chamber for instant evaporation treatment, the instant evaporation temperature is 200°C, and the instant evaporation time is 1 second;

[0018] (4) Spray a layer of wort evenly on the surface of the fresh original leaves obtained by instant evaporation, place at 26°C for 40 minutes, and then knead.

Embodiment 2

[0019] Embodiment 2, a kind of black tea withering method, specifically:

[0020] (1) Picking fresh tea leaves with one bud and two leaves as raw materials for withering;

[0021] (2) Spread the fresh original leaves on the withering rack with a layer thickness of 1.2 cm, and send the fresh original leaves into the freezer for freezing. The temperature in the freezer is -6°C, and the freezing time is 32 minutes;

[0022] (3) Send the fresh raw leaves obtained by freezing into the evaporation chamber for instant evaporation treatment, the instant evaporation temperature is 204°C, and the instant evaporation time is 1 second;

[0023] (4) Spray a layer of wort evenly on the surface of the fresh original leaves obtained by instant evaporation, place at 26°C for 42 minutes, and then knead.

Embodiment 3

[0024] Embodiment 3, a kind of black tea withering method, specifically:

[0025] (1) Picking fresh tea leaves with one bud and two leaves as raw materials for withering;

[0026] (2) Spread the fresh original leaves on the withering rack with a layer thickness of 1.3 cm, and send the fresh original leaves into the freezer for freezing. The temperature in the freezer is -7°C, and the freezing time is 35 minutes;

[0027] (3) Send the frozen fresh original leaves into the evaporation chamber for instant evaporation treatment, the instant evaporation temperature is 210°C, and the instant evaporation time is 1.1 seconds;

[0028] (4) Spray a layer of wort evenly on the surface of the fresh original leaves obtained by instant evaporation, place at 27°C for 45 minutes, and then knead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com