Patents

Literature

184results about "Leather degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

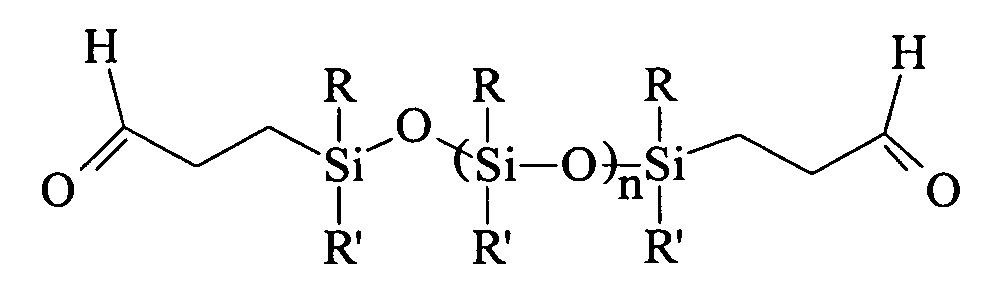

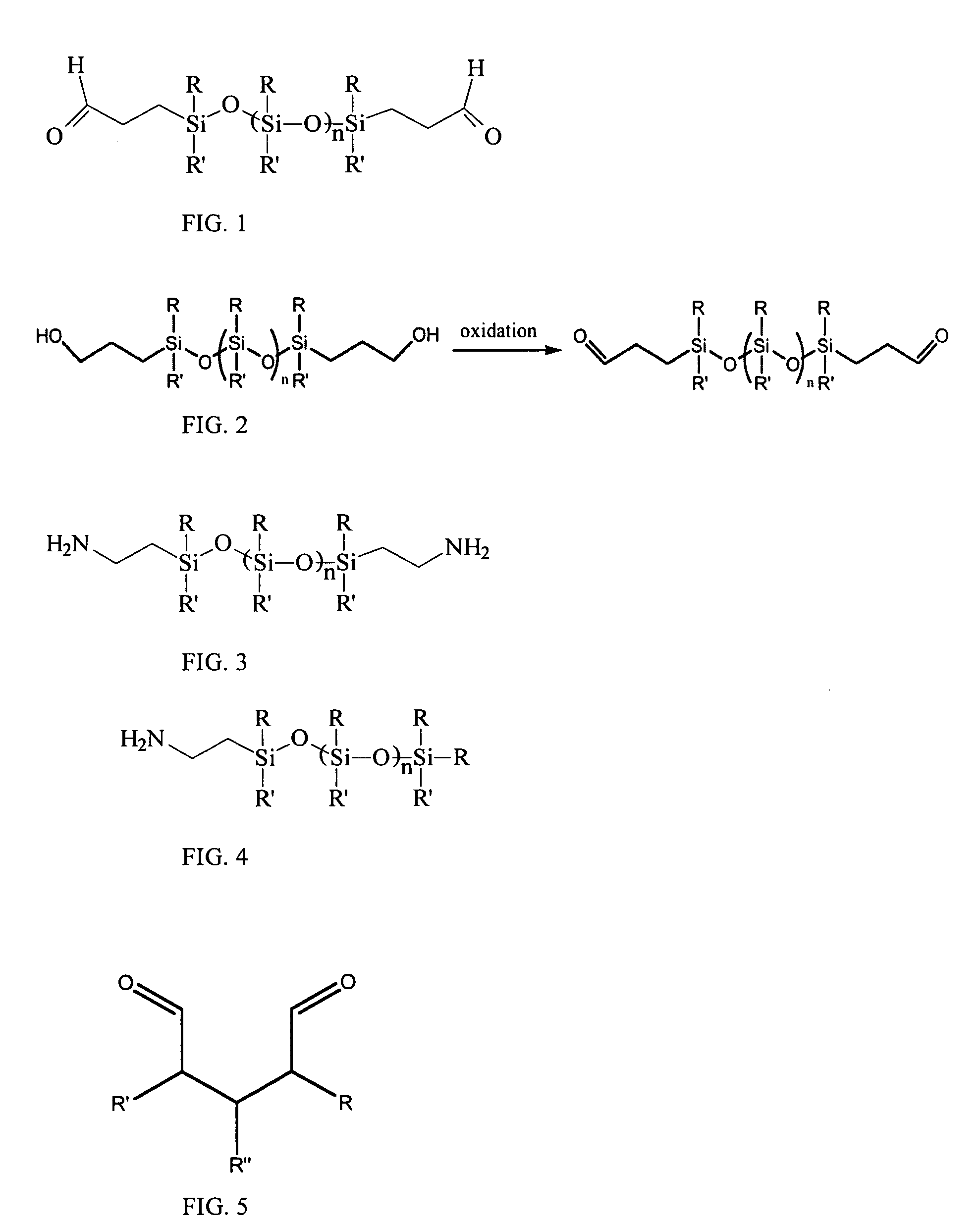

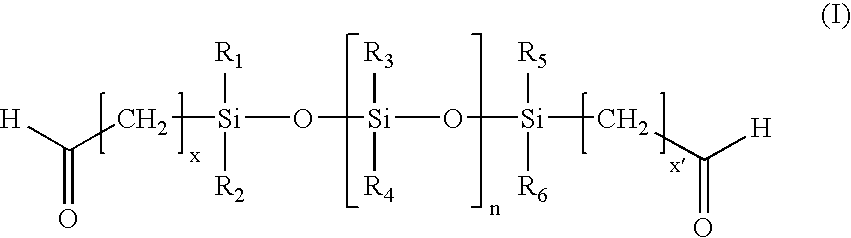

Anti-calcification treatments for heart valves and vascular grafts

InactiveUS20060047343A1Reduces calcification potentialReduce calcificationSuture equipmentsHeart valvesCalcificationProsthesis

The present invention provides processes for fixation of biological tissue and / or post-fixation treatment of such tissue that result in modified tissues with reduced susceptibility to in vitro calcification when used in prosthetic devices. The invention also relates to calcification resistant biological tissue and to methods of using such tissue.

Owner:OVIATT HENRY W +1

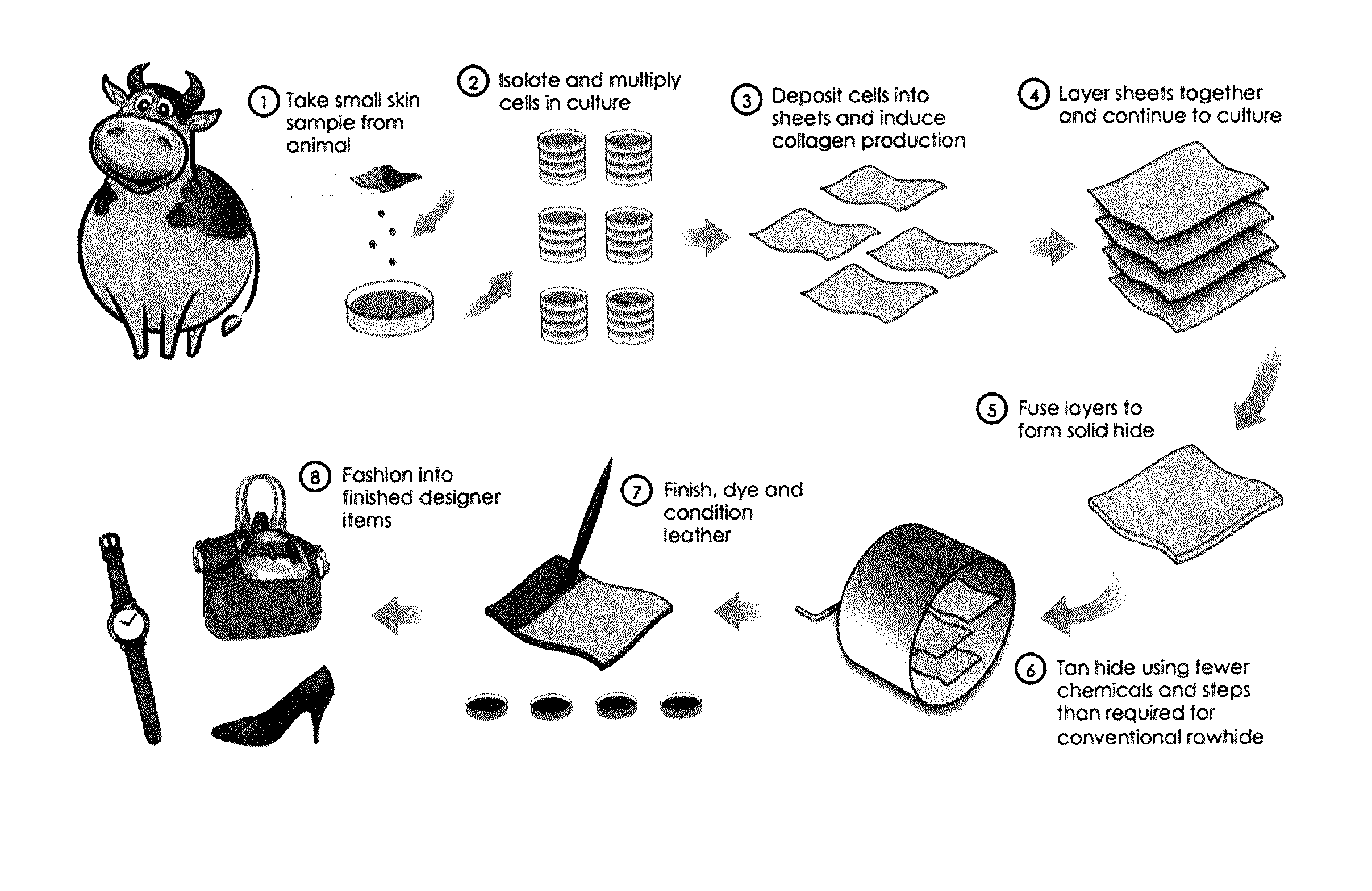

Engineered leather and methods of manufacture thereof

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

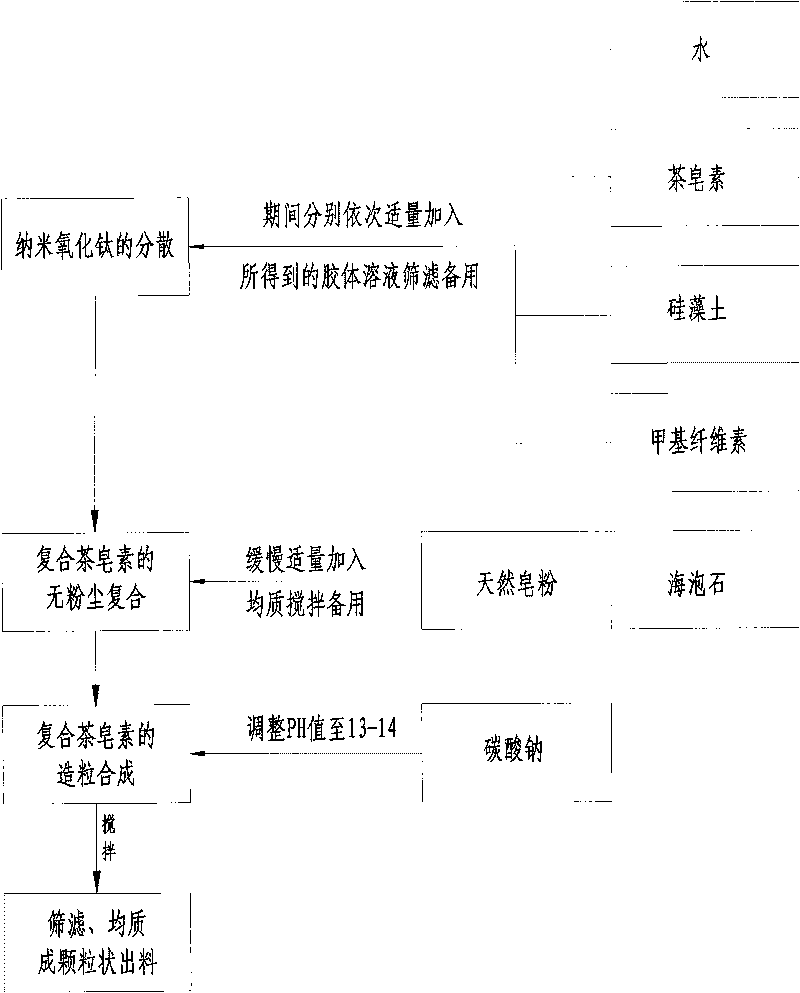

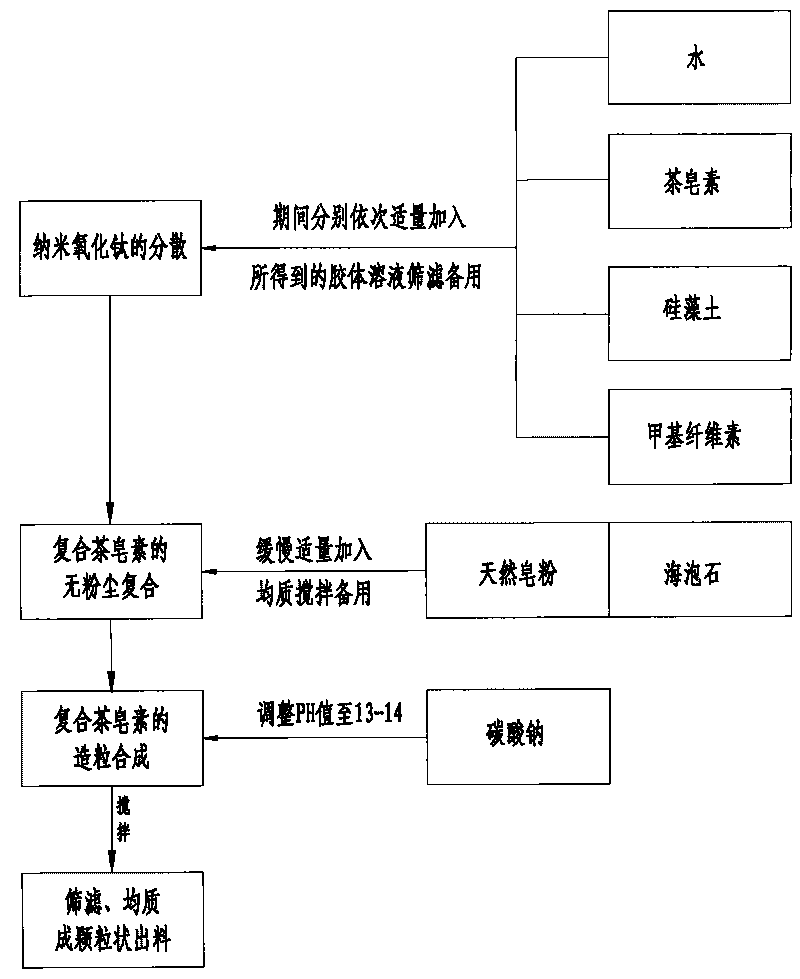

Composite tea saponin, preparation method thereof and use thereof

ActiveCN101736574AProductivityEasy to useSoap detergents with organic compounding agentsPulp bleachingChemical industryTitanium oxide

The invention relates to composite tea saponin, a preparation method thereof and use thereof. The composite tea saponin is prepared by mixing a proper a mount of water with raw materials including 1 to 3 percent of nano titanium oxide, 12 to 18 percent of tea saponin, 1 to 5 percent of methylcellulose, 23 to 45 percent of natural soap powder, 3 to 5 percent of infusorial earth, 6 to 12 percent of sepiolite and 5 to 10 percent of sodium carbonate. The preparation method mainly comprises: nano titanium oxide dispersion, dust-free compounding, granulation and synthesis, wherein the finished product is homogenized by a sieve and discharged in form of grains. The tea saponin can replace one or both of caustic soda and hydrogen peroxide as a finishing agent for use in the fields of textile, leather, paper making, sewage treatment and daily chemical industry. The preparation method can meet the original technical requirements of production and processing industries on the use of the caustic soda and the hydrogen peroxide, simplify technical process, avoid equipment corrosion and material damage, improve product quality, discharge waste water in an environmentally-friendly manner, ensure safety of human bodies, reduce production cost, save energy, labor and time and realize ecological, environmentally-friendly and safe production.

Owner:SHANGHAI JINTANG TEXTILE NEW MATERIALS TECHCO

High efficiency low-foaming blue leather degreaser

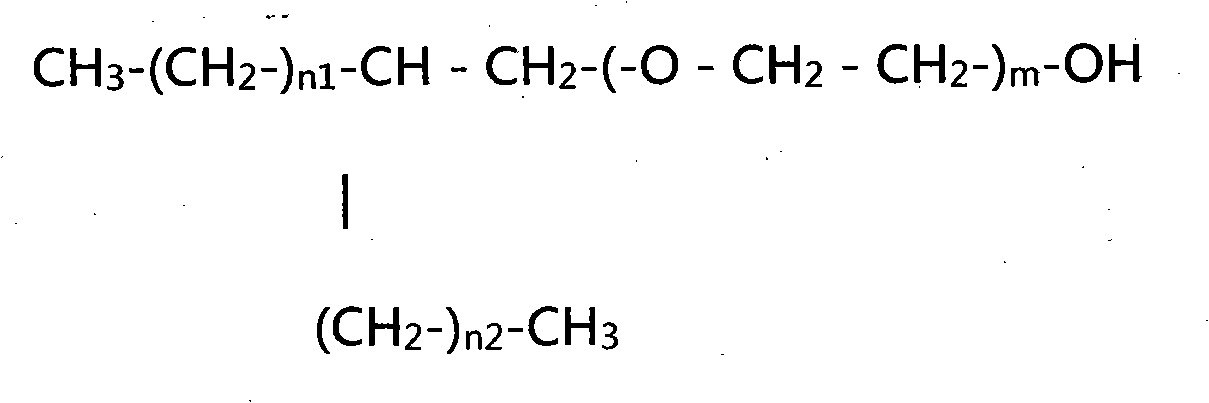

InactiveCN101831362ASuitable for a wide temperature rangeFacilitates cleaning removalNon-ionic surface-active compoundsDetergent compounding agentsWater basedKerosene

The invention relates to a degreaser used for degreasing blue leather. The degreaser is a washing composite mainly using surfactant as base material and is clear and transparent microemulsion. The formula of the degreaser comprises the following components by weight percent: 20-60% of surfactant (one or two of non-ionic surfactants such as fatty alcohol polyoxyethylene ether, fatty alcohol polyoxypropylene ether and alkanolamide, 10-40% of solvent (one or two of toluene, xylene, turpentine, C8-C12 of solvent oil, trichloroethylene, tetrachloroethylene and solvent kerosene), 0-5% of cosolvent ( one or two of ethanol, n-propanol, isopropanol and ethylene glycol monobutyl ether, 0-10% of acidic lipase, 0-2% of defoaming agent and 40-60% of water. The application temperature of the microemulsion degreaser is wide, and can be stored for long time without layering and have stable state; and the degreaser has the advantages of solvent degreasing and emulsion degreasing, the fat dissolving and cleaning functions of organic solvents and the cleaning characteristics of water-based surfactants. Therefore, the natural fat in blue leather can be reduced to less than 1%.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Fur fat removal agent

InactiveCN102660396AGood degreasing effectHigh glossOrganic detergent compounding agentsNon-ionic surface-active compoundsPreservativeSurface-active agents

The invention discloses a fur fat removal agent, and belongs to the field of detergent compositions. The fur fat removal agent comprises a non-ionic surface active agent, water-borne high polymer, silicone oil, alkali, solvent, chelant, preservatives and the balance water. The fur fat removal agent has an excellent fat removal effect to the surface and the deep layer of dermatome, removal ability to dirt on fur is high, and washed fur is high in whiteness and gloss. Due to the water-borne high polymer and the silicon oil, the content of fat of the dermatome after the oil of the dermatome is removed by the fur fat removal agent is low, and the fur is bright and smooth.

Owner:HEBEI YONGTAI LEATHER CHEM

Energy-saving and environmental-protection method for tanning raccoon fur

InactiveCN101921882AReduced hair removal rateReduced rehumidification timeTanning treatmentPre-tanning chemical treatmentMirabiliteSodium sulfate

The invention discloses an energy-saving and environmental-protection method for tanning a raccoon fur, which is characterized by adopting the following processes: (1) shunting and grouping; (2) soaking: preparing a soaking solution which contains a wetting fungicide HAC, a soaking enzyme E38, a degreasing agent S-40 and salts; (3) removing meats by water scalping; (4) re-soaking: preparing a re-soaking solution which contains the wetting fungicide HAC, Supralan80, degreasing agent S-50 and salts; stirring while throwing furs; and taking out of the furs and drying; (5) shaving and deep scalping: cutting off the pachydermia part of the fur to cause each part of the fur to have even thickness; (6) softening and pickling: preparing a softening pickling liquor which contains softening enzyme E40, sulfuric acid, Pelgrassol LP, anhydrous sodium sulfate, JFC, salts, formic acid, Eskatan GLS and fatliquoring agent FSE; throwing the furs into the softening pickling liquior for stirring; and then taking out of the furs and leaching; (7) tanning: preparing a tanning solution which contains tschermigite, JFC, salts, mirabilite, auxiliary tanning agent P-3B and fatliquoring agent FSE; stirring while throwing the furs; successively adding NovaltanPF and aluminium tanning agent AL, adding baking soda, stirring, adding the fatliquoring agent FSE and taking out of the furs; and (8) arranging for later stage. The invention has simple processes, reduces manpower consumption, improves use efficiency and saves usage amount of chemical materials and water.

Owner:HEBEI SUANG FUR & LEATHER

Process for Retanning Leather Using Hollow Microspheres

InactiveUS20090205142A1Uniform thicknessHigh tensile strengthTanning treatmentPre-tanning chemical treatmentPolymer scienceFoaming agent

A process for retanning leather has been found, which is characterized in thata) a tanned leather is treated in aqueous liquor in the presence of hollow microspheres filled with blowing agent,b) the leather obtained according to a) is dried after further optional retanning steps andc1) treated with steam at 80 to 120° C., in particular at 80 to 100° C., orc2) with infrared radiation having a wavelength of 0.7 to 100 μm,it also being possible for a finishing step b1) and / or a milling step b2) to follow at a time after the drying step b).

Owner:LANXESS DEUTDCHLAND GMBH

Crocodile belly skin tanning processing method

ActiveCN104593527ASolve problems such as flat, thin, empty and looseAvoid separationTanning treatmentPre-tanning chemical treatmentBiologyChemistry

The invention relates to a crocodile belly skin tanning processing method. The problems that fats are difficult to remove, dermatome and oracle bone are difficult to soften, scales and shells are difficult to remove, bleaching and fading effects are not good, the finished leather is flat, thin, empty and loose, and the hang drying method is improper and the like are unsolved in the existing crocodile skin tanning technology. The crocodile belly skin tanning processing method comprises the steps of soaking, fleshing, oil film scraping, degreasing and pre-liming, oil film scraping, aldehyde pre-tanning, oil film scraping, liming, oil film scraping, scale brushing, deliming, oil film scraping, united bleaching, softening, oil film scraping, combined bleaching, degreasing, oracle bond softening and bleaching, pickling and softening, tanning, shaving, degreasing, neutralizing, re-tanning, fat-liquoring, leather fluffing, dry cleaning, dyeing, hang drying and coating. The processing technology of Nile crocodile belly raw material skin is provided, and the crocodile skin is soft and plump and elastic, keeps the complete crocodile skin patterns, not only can be processed into dark leather, but also can be processed into light leather and white leather. The leather can be used for processing luggage leather, shoe leather, belt and watch strap leather and the like, and has a very high market value.

Owner:蚌埠启邦科技信息咨询有限公司

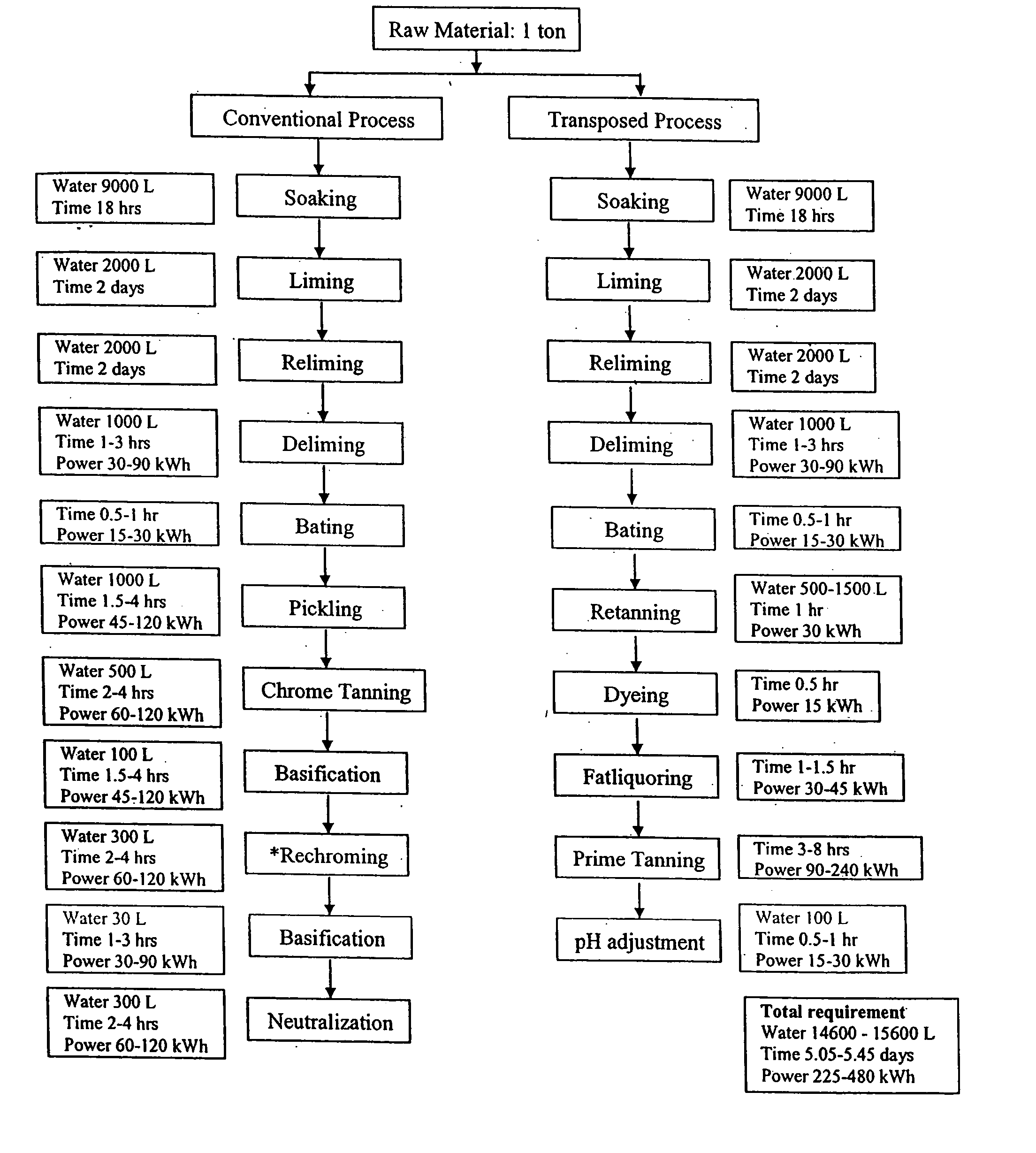

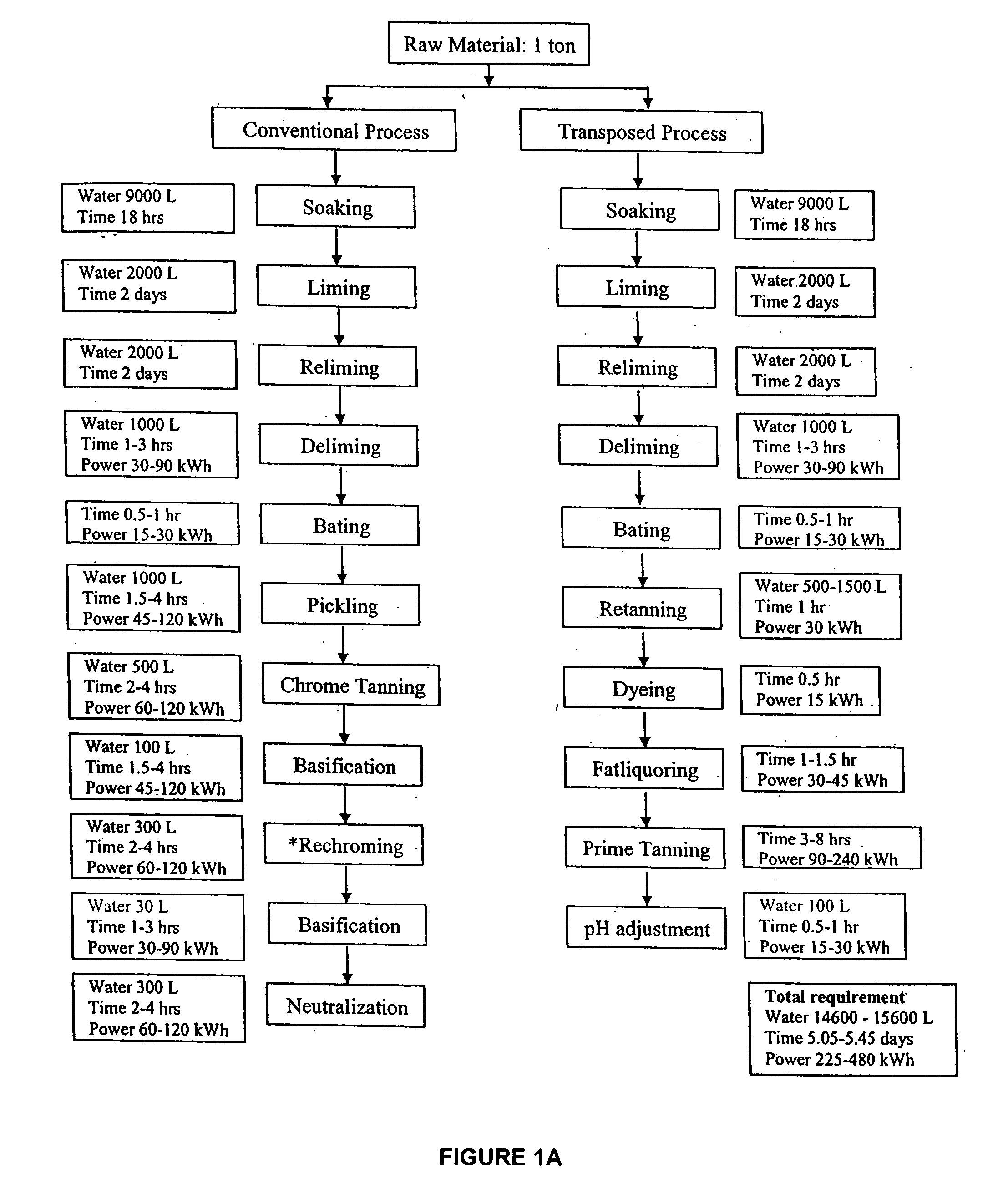

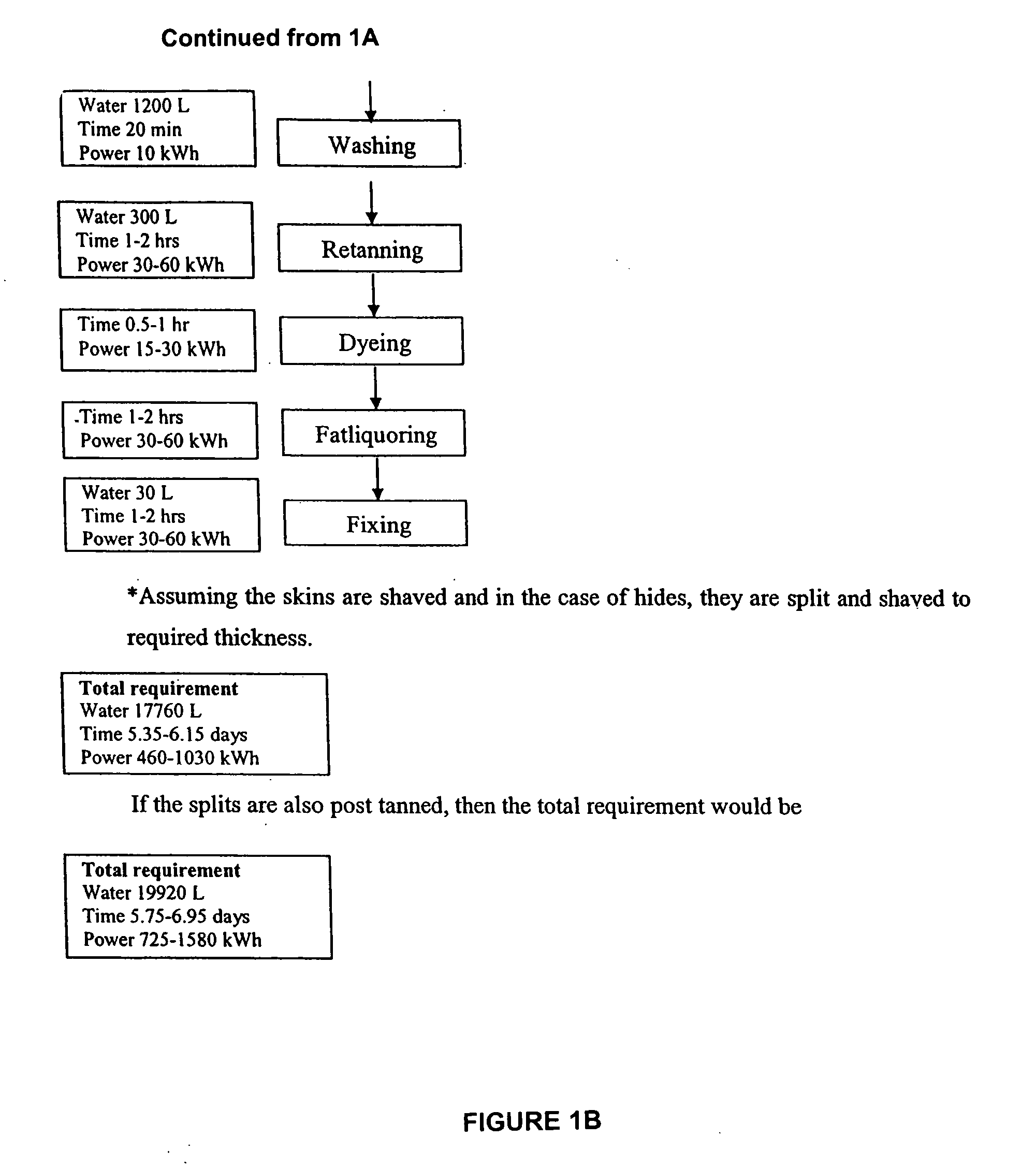

Transposed process for making leather

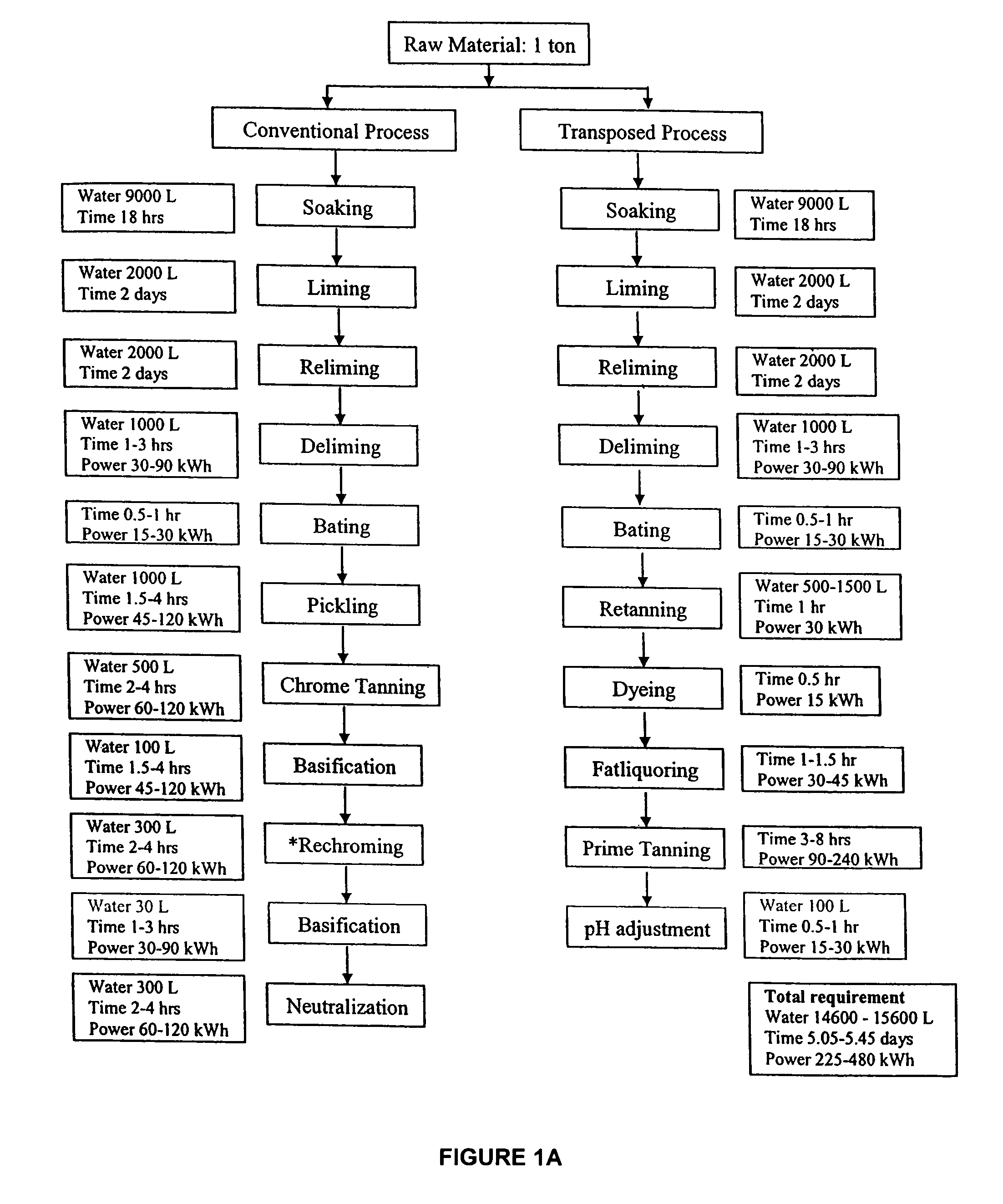

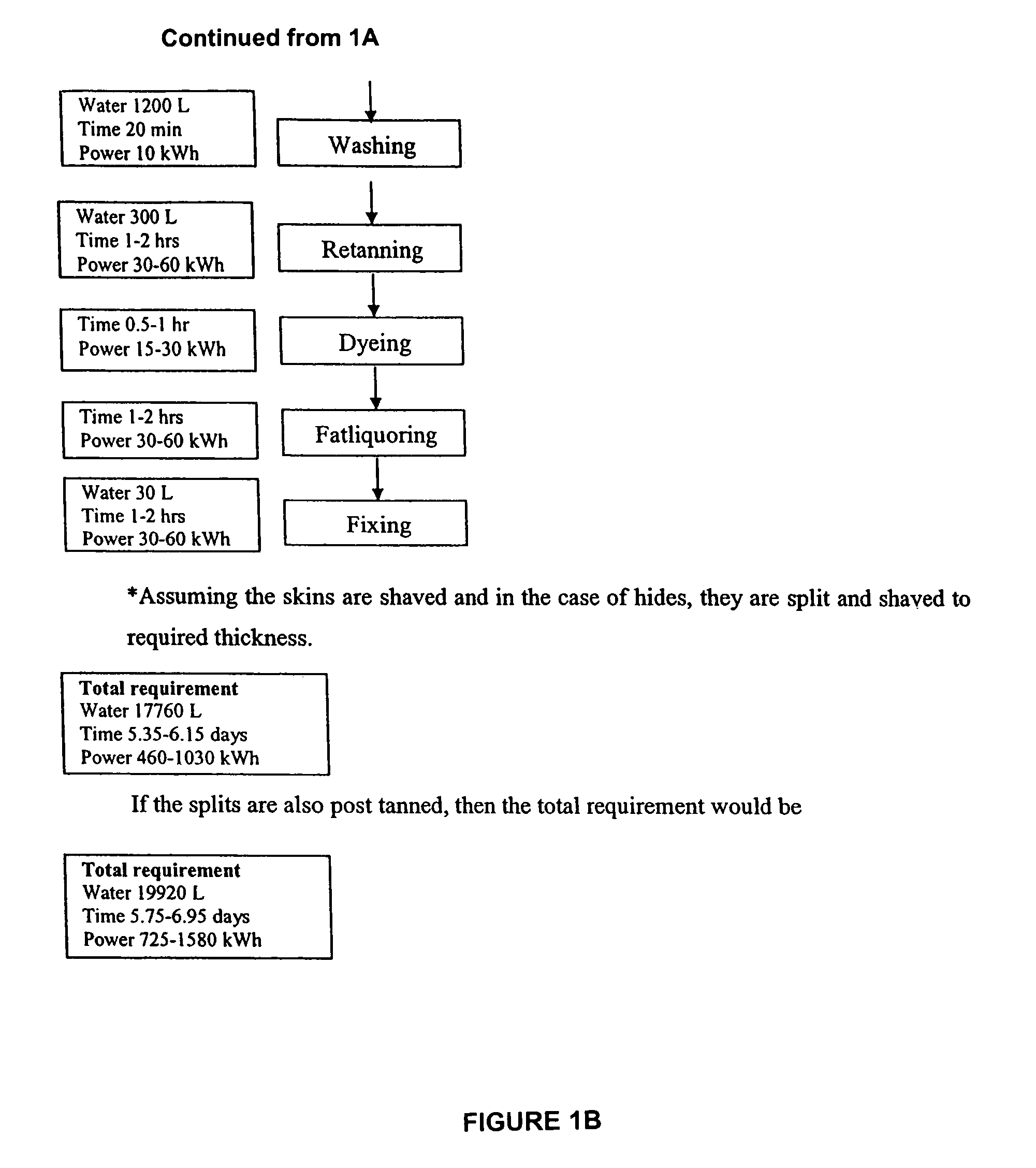

InactiveUS7033402B2Reduce the number of stepsCertain powerTanning treatmentPre-tanning chemical treatmentPulp and paper industryIndustrial engineering

The present invention relates to a novel leather making process whereby the post-tanning wet operations are done prior to tanning stage itself to make leather in eco-friendly manner in substantially shorter duration. The present process reduces the number of required steps for leather processing and the pollution load generated in comparison to conventional leather processing.

Owner:COUNCIL OF SCI & IND RES

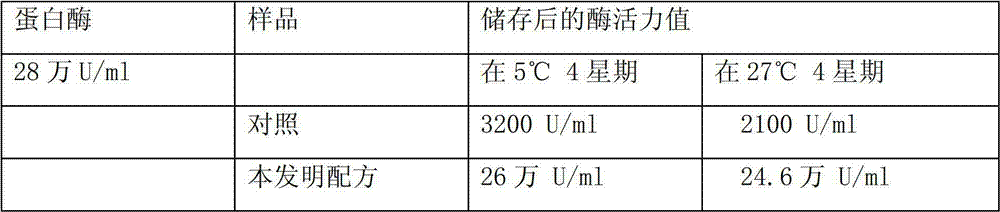

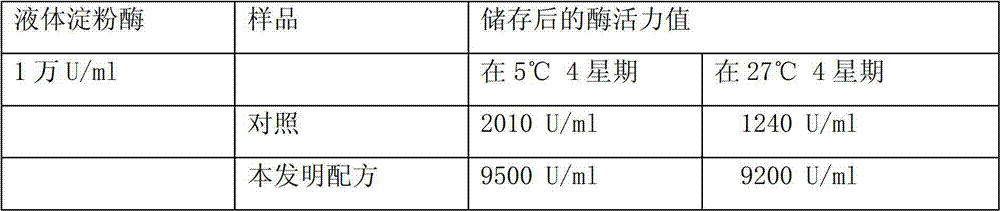

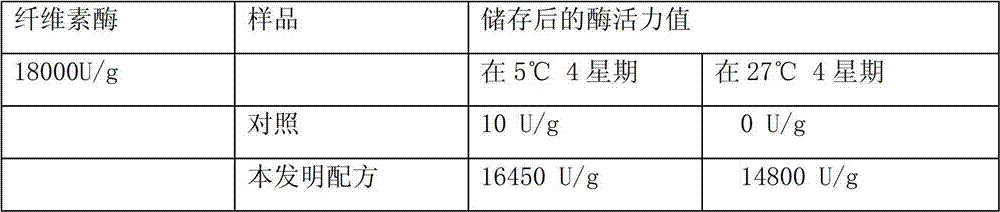

Liquid enzyme stabilizing additive and preparation method and application thereof

InactiveCN102766540AUse it wellHigh activityCosmetic preparationsOrganic detergent compounding agentsPersonal careEther

The invention provides a liquid enzyme stabilizing additive and a preparation method and application thereof. The liquid enzyme stabilizing additive comprises the following components: liquid enzyme, an ether nonionic surfactant, a linear or branched chain polymer and a surfactant. Compared with the conventional enzyme stabilizer in the prior art, the liquid enzyme stabilizing additive is environment-friendly and easy to degrade. The liquid enzyme stabilizing additive can be used for any composition containing the liquid enzyme and is particularly suitable for washing compositions, personal nursing care compositions, textile treatment compositions and the like, and the liquid enzyme can exert the using efficacy better.

Owner:SHANXI UNIV +1

Method for tanning non-metal tanned goat leather for making garment

The invention discloses a method for tanning non-metal tanned goat leather for making garment. The method adopts a combination of two non-metal tanning agents of a plant tanning agent and an organic phosphine for tanning, and simultaneously, adds a certain amount of terminal amino-dendrimers in the post period of stuffing lipid so as to greatly reduce the content of free formaldehyde in leather, wherein Ts (shrinkage temperature) is greater than or equal to 90 DEG C; and the removal rate of formaldehyde can reach up to 70 percent. The leather has good ageing resistant performance and ventilation property; and all of the other physical and mechanical performance such as tensile strength, tearing strength and the like can reach the standards of chrome tanned leather in the same type.

Owner:日照市信腾信息科技有限公司

Preparation process for pig skin top layer instep leather free of chrome tanning

ActiveCN105506196ASimple stepsImprove production efficiencyTanning treatmentPre-tanning chemical treatmentMedicine

The invention belongs to the field of instep leather preparation processes, and particularly relates to a preparation process for pig skin top layer instep leather free of chrome tanning. The preparation process comprises the following steps that from pickled skin scytoblastema, the addition quantity of additives in all the procedures is based on the mass of pickled skin, and pickling and softening, main tanning, degreasing and softening, retanning, water extruding and neutralizing, dyeing and stuffing and staking and spouting are included. The preparation process for the pig skin top layer instep leather free of chrome tanning has the advantages that the steps are simple, preparation efficiency is high, the requirement of the preparation process for equipment is low, energy saving and environment friendliness are achieved, and the prepared instep leather is resistant to wear and high temperature, full and soft.

Owner:海宁家纺产业基地投资开发有限公司

High-efficiency low-foam type degreasing agent

InactiveCN102703239AEfficient degreasing effectSurface-active detergent compositionsPre-tanning chemical treatmentFiberFatty alcohol

The invention relates to a high-efficiency low-foam type degreasing agent. The high-efficiency low-foam type degreasing agent consists of the following components in percentage by weight: 20 to 40 percent of fatty alcohol-polyoxyethylene ether, 20 to 40 percent of alkyl glycoside, and 20 to 60 percent of deionized water. Leather is degreased by using the high-efficiency low-foam type degreasing agent; and the high-efficiency low-foam type degreasing agent has the effects of deeply and efficiently degreasing the leather, can remove interfibrillar substance, is convenient and economic and is an ideal degreasing agent special for the leather.

Owner:科凯精细化工(上海)有限公司

Method for manufacturing environment-friendly ecological tanned lamb skin

ActiveCN104673943APollution hasReduce pollutionTanning treatmentPre-tanning chemical treatmentBiotechnologyBiochemical engineering

The invention discloses a method for manufacturing environment-friendly ecological tanned lamb skin. The method comprises the following steps: firstly, soaking a raw material lamb skin into water, adding degreasant and sodium carbonate in the soaking process, and removing hair and meat in the water soaking process; putting the lamb skin in water, adding degreasant and sodium carbonate for soaking and removing fat, and removing meat for the second time; putting into water for the second time to soften the lamb skin and removing fur and meat; pickling and softening, and taking out the skin and standing still for two days; tanning, taking out and standing still for two days; performing primary treatment, putting into water, adding syntans, a fatting agent and formic acid, soaking, taking out, standing for one day, performing oxidation washing and reduction bleaching, and finally finishing, thus obtaining a product. When tanned lamb skin is manufactured by using the method, environment pollution can be reduced and relevant maintenance expense for wastewater treatment and the like can be reduced, so that the production cost can be reduced and moreover the manufactured product is excellent in property.

Owner:济源澳吉尔商贸有限公司

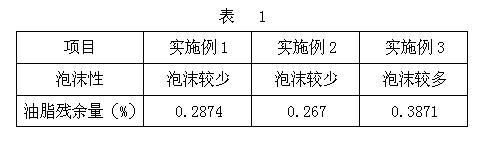

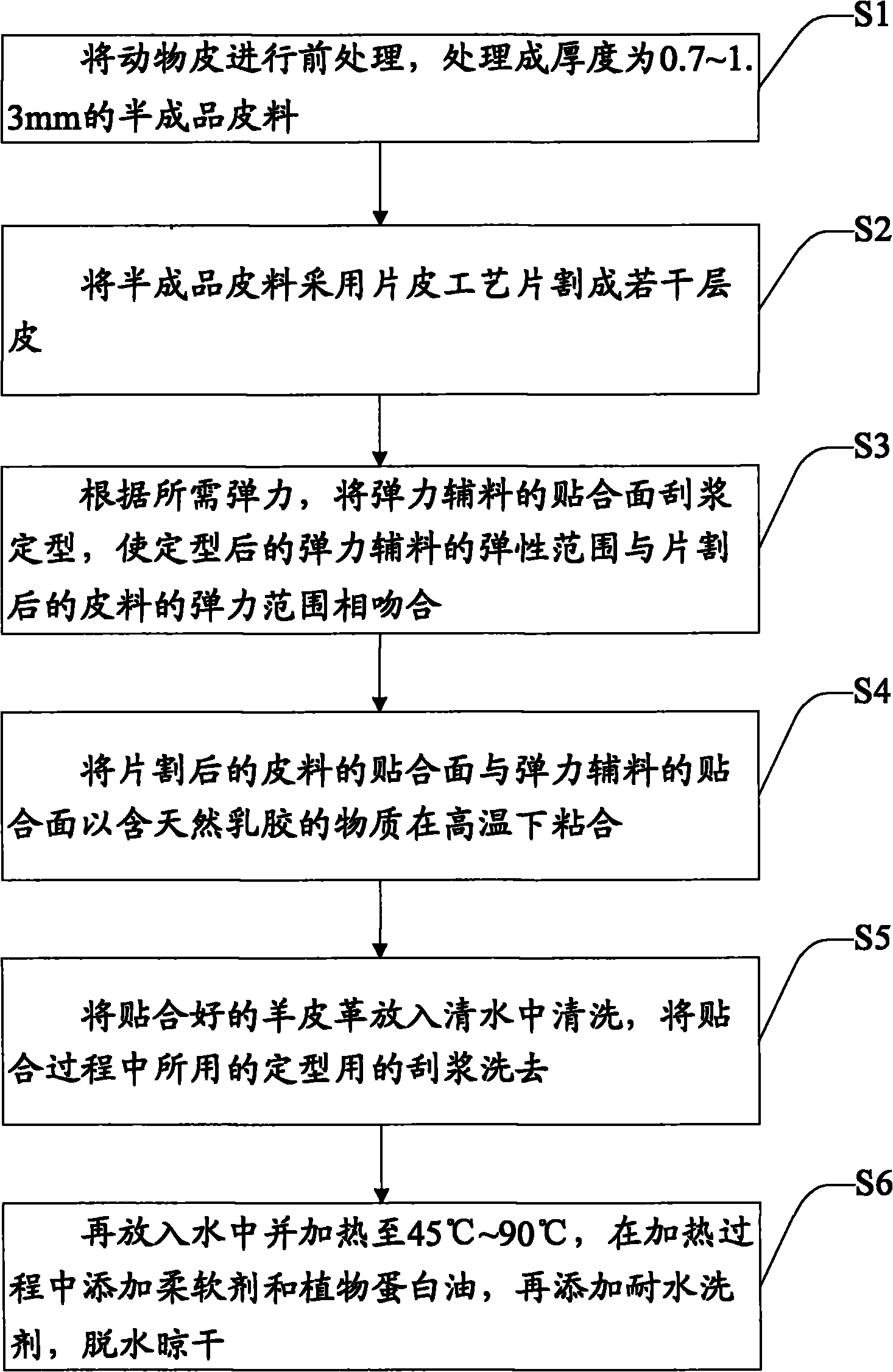

Leather material and processing method thereof

InactiveCN101956026AGive full play to the elastic propertiesIncrease elasticityLeather manufacturingComposite leathersEmulsionWork in process

The invention discloses a processing method of a leather material, comprising the following steps of: (1) pre-processing an animal skin into a semi-finished product of the leather material with the thickness of 0.7-1.3mm; (2) cutting the semi-finished product of the leather material into a plurality of layers of skins by utilizing a leather-splitting process; (3) forming scraping pulp for a binding surface of an elastic auxiliary material according to required elasticity so that the elastic range of the formed elastic auxiliary material is identical with that of the split leather material; (4) adhering the binding surface of the split leather material and the binding surface of the elastic auxiliary material at high temperature with a substance containing natural emulsion; (5) placing theadhered leather material into water for cleaning, and washing the scraping pulp for forming in the adhering process; and (6) placing into water again and heating to 45-90 DEG C, adding a softening agent and plant protein oil in the heating process, then adding a water-washing resistant agent, and dewatering and airing. The processing method of the leather material has the advantages of favorable elasticity of the obtained leather material, water-washing resistance and simple and convenient processing procedure. The invention also discloses the leather material.

Owner:谈国忠

Tan sheepskin environmental protection tanning process

InactiveCN102286647AReasonable nitration processImprove product qualityLeather manufacturingTanning treatmentAgricultural engineeringEnvironmental technology

The invention discloses an environment-friendly tanning process for Tan sheepskin, which is characterized in that it adopts the following steps: 1) spraying water to return moisture; 2) beating wool; 3) soaking in water; 4) degreasing; 5) re-immersing in water; 6) degreasing again ;7) fleshing; 8) pickling; 9) tanning; 10) standing overnight; 11) water rejection; 12) brushing with fatliquoring agent; 13) standing overnight; 14) drying; 15) still damp; 16) Dry shoveling; 17) rinsing; 18) aluminum liquid brushing; 19) drying; 20) dry shoveling; 21) storage. The present invention aims at the hardening of the leather board, hair loss of needles or excessive free formaldehyde in the prior art. After analysis, it is because the traditional process of tanning the tanned surface or nitrating with formaldehyde or aldehyde and aluminum causes the leather surface of the leather board to be tanned. Unsatisfactory, high formaldehyde content and other problems. Now the skins are degreased and then pickled, tanned, brushed with fatliquoring agent, brushed with aluminum liquid, etc., so that the tanning process of Tan sheepskin is more reasonable, the product quality is greatly improved, and the use is increased.

Owner:HUASI HLDG CO LTD

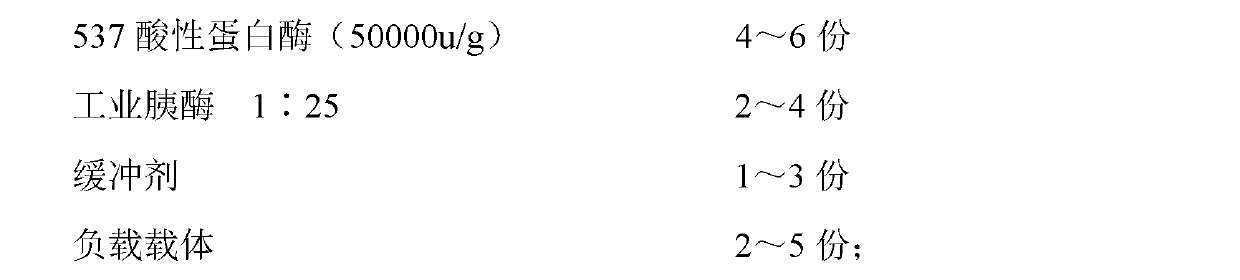

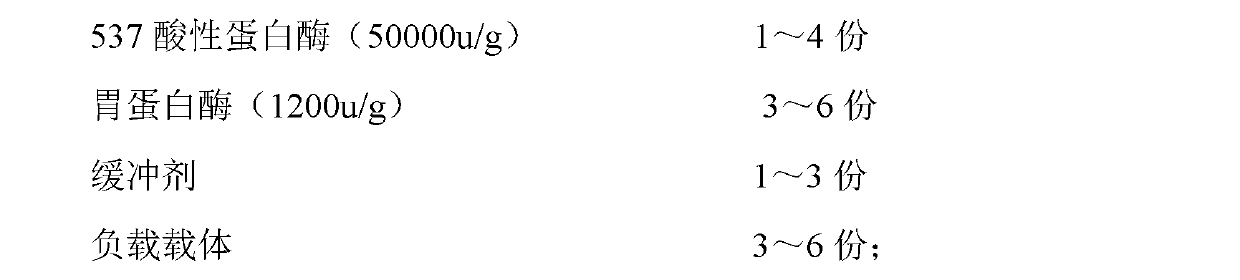

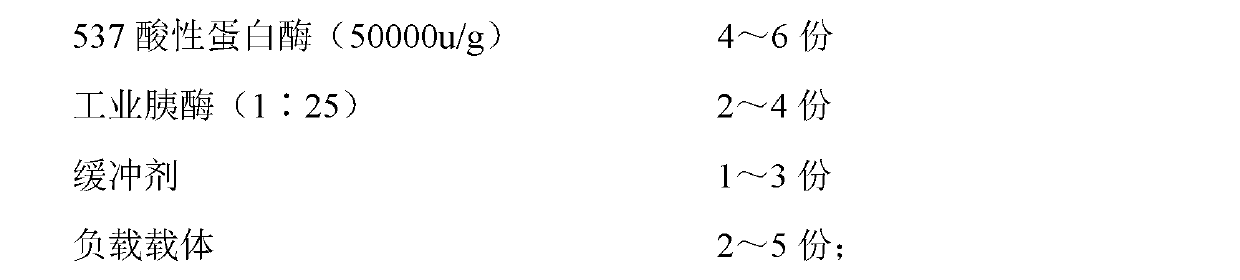

Method for processing sheepskin into fur or leather in multiple steps by using biological enzyme

ActiveCN103276117AReduce dosageLow costTanning treatmentPre-tanning chemical treatmentBiotechnologyBiochemical engineering

The invention discloses a method for performing multiple-step treatment on sheepskin by using biological enzymes, which is characterized in that industrial pancreatic enzymes, composite enzymes TA for acid pickling and softening and composite enzymes TB for acid pickling and softening are respectively used for performing softening treatment on sheepskin in an enzyme softening procedure and an acid pickling procedure; and the treated sheepskin is processed through the conventional process, thereby obtaining the very soft and lightweight sheepskin. Thus, the quality and added values of the sheepskin and products thereof are greatly improved.

Owner:SICHUAN UNIV +1

Transposed process for making leather

InactiveUS20050138738A1Load demandReduce the number of stepsTanning treatmentFibre treatmentManufacturing technologySoftware engineering

The present invention relates to a novel leather making process whereby the post-tanning wet operations are done prior to tanning stage itself to make leather in eco-friendly manner in substantially shorter duration. The present process reduces the number of required steps for leather processing and the pollution load generated in comparison to conventional leather processing.

Owner:COUNCIL OF SCI & IND RES

Method for dyeing Tan sheep skin

InactiveCN103243586AIncrease productivityQuality improvementTanning treatmentDyeing processSheep skinSecondary color

The invention discloses a method for dyeing Tan sheep skin, which comprises the following steps: softening Tan sheep skin subjected to tanning and airing, and sequentially retanning and dyeing the Tan sheep skin. The dyeing process comprises primary dyeing and secondary dyeing in a rotating drum, wherein the primary dyeing is implemented by dyeing the Tan sheep skin in the rotating drum, in which the dye amount is 1 / 2-3 / 5 of the total amount, at 30-32 DEG C for 30-35 minutes; primary color fixation is carried out after the primary dyeing; after the primary color fixation, the rest of dye is added into the rotating drum to carry out secondary dyeing at 60-65 DEG C; and after the secondary dyeing, secondary color fixation is carried out. The dyeing and color fixation are sequentially carried out twice, thereby avoiding the phenomena of nonuniform dyeing and unclear pores due to thick coating, and ensuring the uniform dyeing of the Tan sheep skin. The treatment time of the whole dyeing technique is short.

Owner:宁夏成丰农业科技开发股份有限公司

Suede leather production method

ActiveCN108165678AEnhance the feelImprove fullnessTanning treatmentPre-tanning chemical treatmentPhosphateTannin

The invention provides a suede leather production method. Suede leathers are obtained through performing water leaching, ash leaching, ash removal, acid leaching, tanning, uniform turning, retanning,neutralization, dyeing and degreasing and drying on leathers. The retanning process comprises the following steps: after 2% of acid-resistance acrylic acid and 0.5% of acid-resistance grease are usedfor treatment, pH is controlled as 3.0; and a chromium retanning agent is added for treatment. The neutralization process comprises the following steps: 150% of water, 2% of sodium formate and 2% of neutralization auxiliary are added; a rotating drum is rotated by 60 min; then, water washing is performed by 10 min; and the temperature is increased to 60 DEG C. The dyeing and greasing process comprises the following steps: 150% of water with a temperature of 40 DEG C, 1.5% of dicyandiamide tannin, 2% of amphoteric synthesized tannin, 4% of tannin extract and 2% of dye are added; the rotating drum is rotated by 50 min; 2% of sulfonated oil, 2% of phosphate and 5% of synthesized oil are added; the rotating drum is rotated by 50 min; 0.8% of formic acid is added; and the drum is stopped by 3 hours. The retanning, neutralization and greasing processes are improved to improve uniformity, hand feel, fullness, reading-writing effect and mercerization of the suede leathers.

Owner:NINGXIA JINHAI LEATHER IND

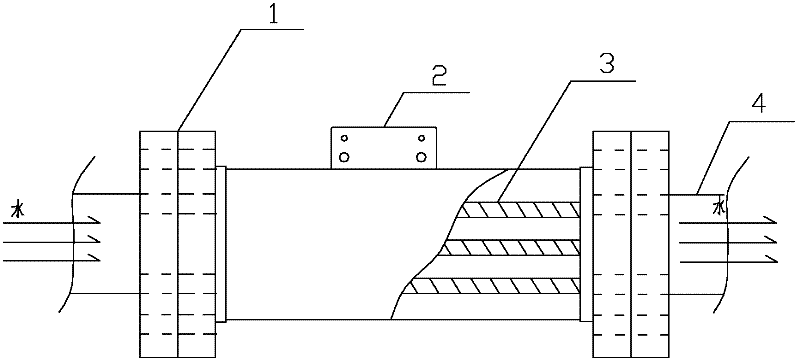

Leather making method for magnetically processing leather making water and leather chemical water solution into nanometer small-molecule water to be combined with ultrasonic wave enhancement technology

InactiveCN102583665AImprove softeningIncrease water filling speedTanning treatmentPre-tanning chemical treatmentLeather industryIndustrial waste water

The invention discloses a leather making method for magnetically processing leather making water and a leather chemical water solution into nanometer small-molecule water to be combined with an ultrasonic wave enhancement technology. The leather making method is characterized in that the magnetized nanometer small-molecule water is combined with the ultrasonic wave enhancement technology to be applied to each leather making procedure, so that the efficiency of the physiochemical process of each leather making procedure can be improved, the consumption of chemical materials is reduced, environmental pollution caused by the emission of harmful drugs and industrial wastewater is reduced to the maximum extent, the use quantity of water is greatly saved, the waste of water is decreased in the leather making process, and the production cost is reduced, so that the leather making method is a reform of the traditional leather making method and provides a new effective path for the developmentof the leather industry.

Owner:SICHUAN UNIV

Tanning method for tanning sheepskin clothing leather by hyperbranched polymer-aluminum salt tanning agent

InactiveCN103060490AIncrease shrinkage temperatureHas a tanning effectTanning treatmentPre-tanning chemical treatmentPolymer scienceMeth-

The invention relates to a tanning method for tanning sheepskin clothing leather by a hyperbranched polymer-aluminum salt tanning agent. Current chrome free tanning agents cannot completely replace chrome tanning agents for realizing better anti-hydrothermal stability of leather. The tanning method provided by the invention comprises the following steps of: pre-treating; pickling; tanning; degreasing; retanning; neutralizing; filling; oiling and drying acidic leather. The preparation method of the hyperbranched polymer-aluminum salt tanning agent used in the tanning process comprises the following steps of: mixing diethanol amine and methyl acrylate, and adding methanol to obtain an AB2 type monomer; carrying out reaction of the AB2 type monomer with trimethylolpropane, and adding para-toluenesulfonic acid for temperature rising reaction to prepare hydroxyl-terminated hyperbranched polymer; carrying out reaction of the hydroxyl-terminated hyperbranched polymer with maleic anhydride, adding para-toluenesulfonic acid to prepare an intermediate of an aqueous liquor of the hydroxyl-terminated hyperbranched polymer, and mixing and reacting the intermediate aqueous liquor with analytically pure analytically pure at normal temperature to obtain the hyperbranched polymer-aluminum salt tanning agent. The method provided by the invention is higher in shrinkage temperature and can replace the conventional chrome tanning method, so that chrome tanning pollution is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Manufacturing technology for waterproof long fur

ActiveCN107217110AEasy to cleanGood flexibilityTanning treatmentPre-tanning chemical treatmentColour fastnessManufacturing technology

The invention relates to a manufacturing technology for waterproof long fur and belongs to the technical field of two-layer leather. The manufacturing technology for the waterproof long fur comprises the following steps of water returning, retanning, basification, neutralization, dyeing, color fixing, waterproofing, washing, drying, softening and milling. According to the manufacturing technology for the waterproof long fur, water returning is conducted on leather, and ammonium sulfate and a degreasing agent are added, so that impurities in the leather are effectively removed, and the cleaning effect on the leather is good; in the subsequent retanning and basification processes, the softness of the leather is effectively strengthened through step-by-step operation, so that the leather surface is plump, the leather surface fiber fineness is enhanced, a full preparation is made for subsequent dyeing, dye completely infiltrates into leather fibers, and the color fastness is high; in addition, a filler is added, so that the bursting force of the leather is strengthened; through subsequent color fixing treatment and waterproofing treatment, the color fastness is effectively strengthened, and the waterproofness is improved; later, the impurities in the color fixing process are effectively removed through washing; and then drying, softening and milling are conducted, so that the softness of the leather is improved.

Owner:漳州香洲皮革有限公司

Kid lamb skin tanning process using amphoteric vegetable tanning agent

ActiveCN105648122AAct as a supportRealize cleaner productionTanning treatmentPre-tanning chemical treatmentFiberExtensibility

A kid lamb skin tanning process using an amphoteric vegetable tanning agent is composed of a preparatory step, a tanning step, and a finishing step; the preparatory step comprises softening collected kid lamb raw skins to restore the raw skins to the conditions of fresh skins, and removing redundant components between skin plate fibers of the raw skins; the tanning step comprises primary tanning and main tanning; in the tanning step, filling primary tanning of the skins is completed mainly by means of the characteristics of macromolecules, high filling ability, good extensibility, and stable stereostructure of the vegetable tanning agent; further, in the tanning step, tanning is carried out by using a low-astringency low-concentration vegetable tanning liquor, and after the collagenous fibers of the naked skins are primarily immobilized, permeation and filling of the tanning liquor are completed gradually to guarantee that a tannin gradually permeates into the naked skins and bonds with skin collagen; and the finishing step comprises fat-liquoring, moisture regaining, staking and shaping of the skin plates as well as hair finishing. The kid lamb skins tanned by means of the kid lamb skin tanning process using the amphoteric vegetable tanning agent has the advantages of small difference between thin and thick parts of the skin plates, full plate texture, fine piles, and locks of bent hair that is natural, has rich wonderful luster and may rival Tan-sheep kid furs.

Owner:QINGTONGXIA CITY XINGTAI FUR CO LTD

Low-VOC leather

InactiveUS8062540B2Inhibit or prevent breakageTanning treatmentOrganic compound preparationHydrogenSulfite

A natural leather is treated with a tanning agent, a re-tanning agent, a dye and a greasing agent, wherein a treatment agent for inhibiting the generation of formaldehyde and acetaldehyde from the natural leather is added to the greasing step so that the natural leather is impregnated with the treatment agent. The treatment agent includes a hydrazide compound optionally together with sodium hydrogen sulfite.

Owner:MIDORI HOKUYO CO LTD

Technique for dyeing Tan sheep skin

InactiveCN103243587AIncrease productivityQuality improvementTanning treatmentPre-tanning chemical treatmentSheep skinSecondary color

The invention discloses a technique for dyeing Tan sheep skin, which comprises the steps of softening, retanning, primary dyeing, primary color fixation, modification, secondary dyeing and secondary color fixation. The dyeing and color fixation are sequentially carried out twice, thereby avoiding the phenomena of nonuniform dyeing and unclear pores due to thick coating, and ensuring the uniform dyeing of the Tan sheep skin. The treatment time of the whole dyeing technique is short. The modification is to change the positive charges on the leather surface to enhance the electropositivity, i.e. the leather surface is positively charged, thereby being beneficial to combination with the secondary dye and laying stress on the surface.

Owner:宁夏成丰农业科技开发股份有限公司

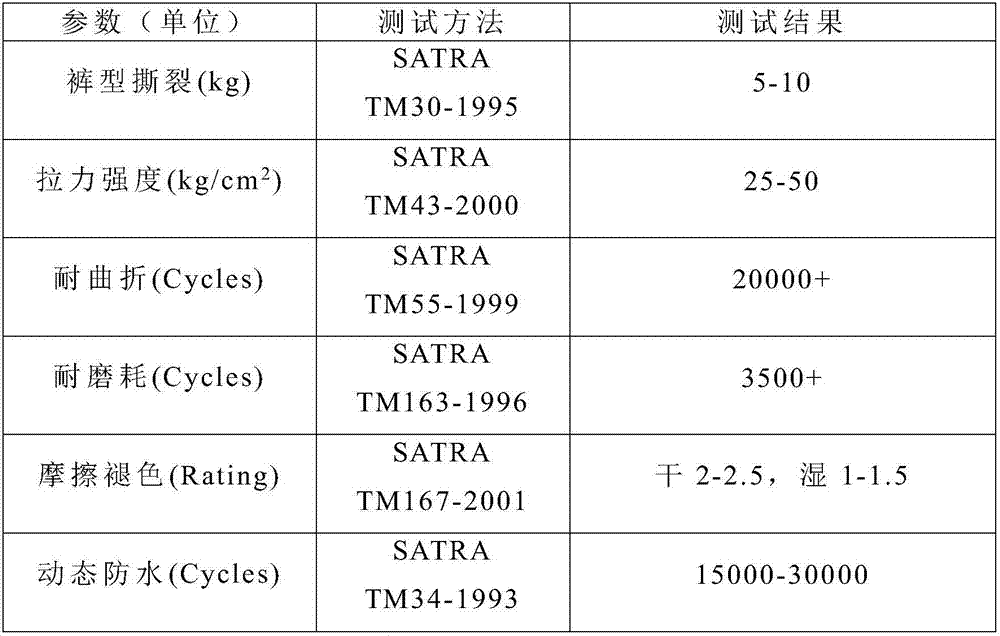

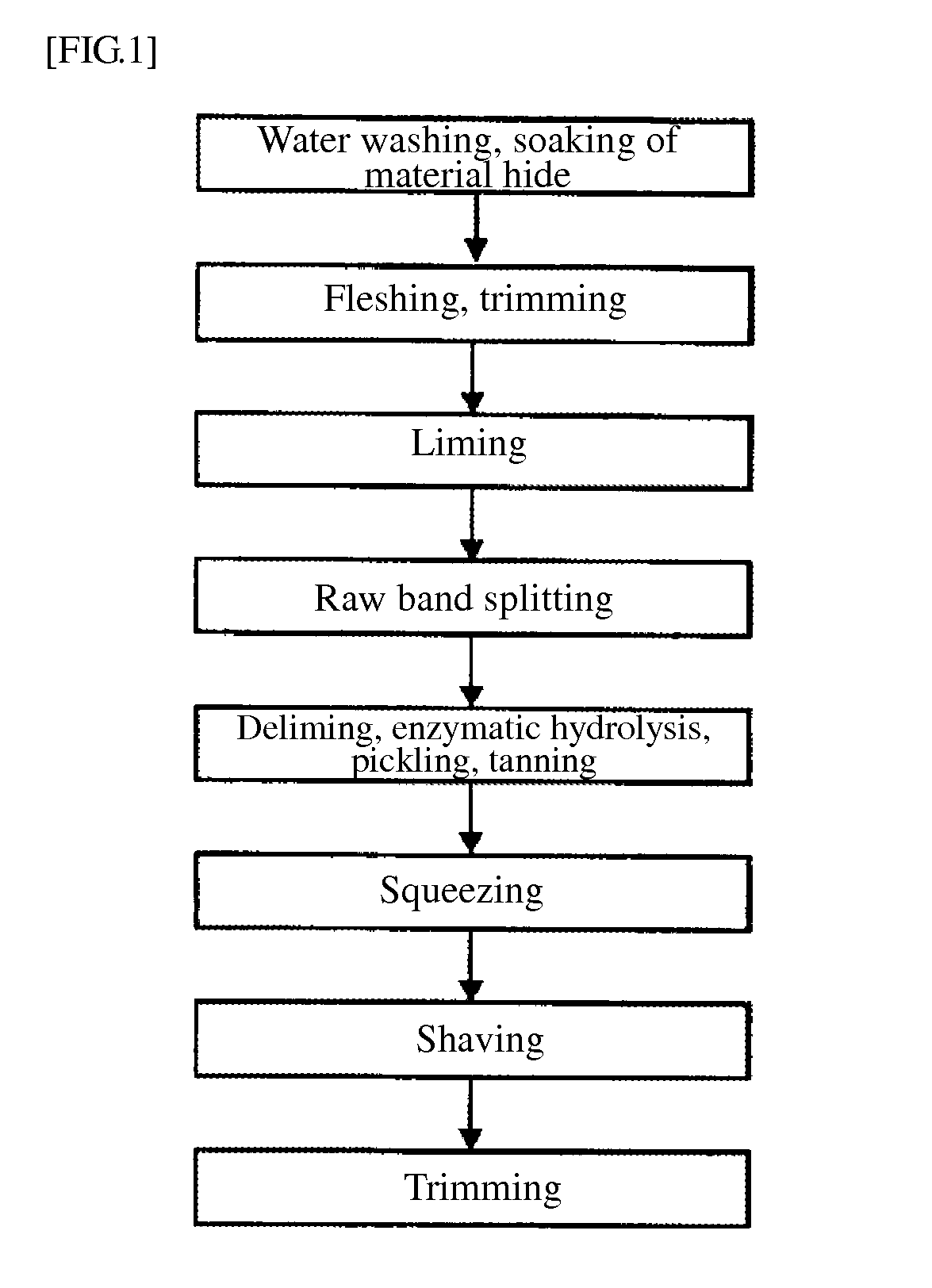

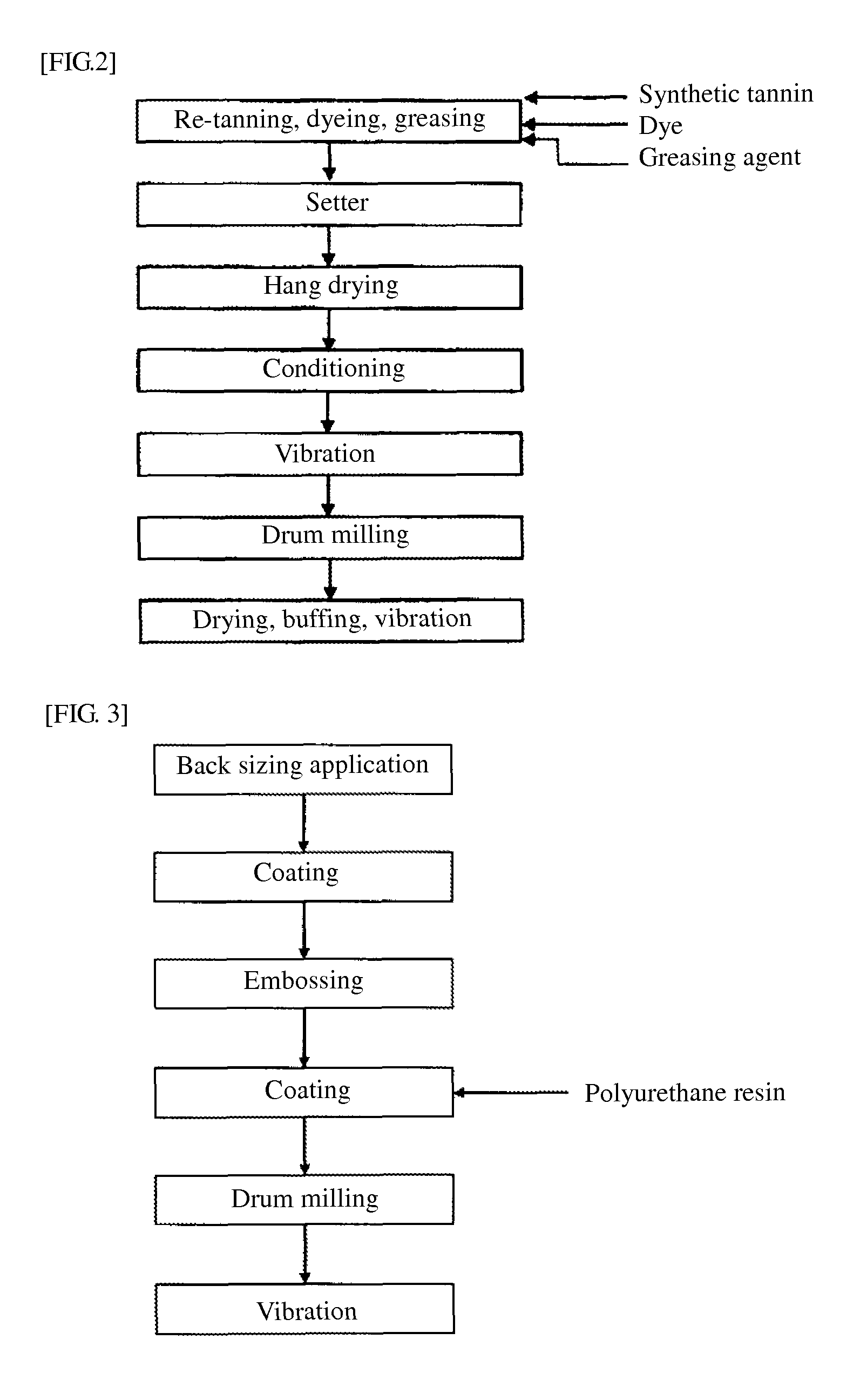

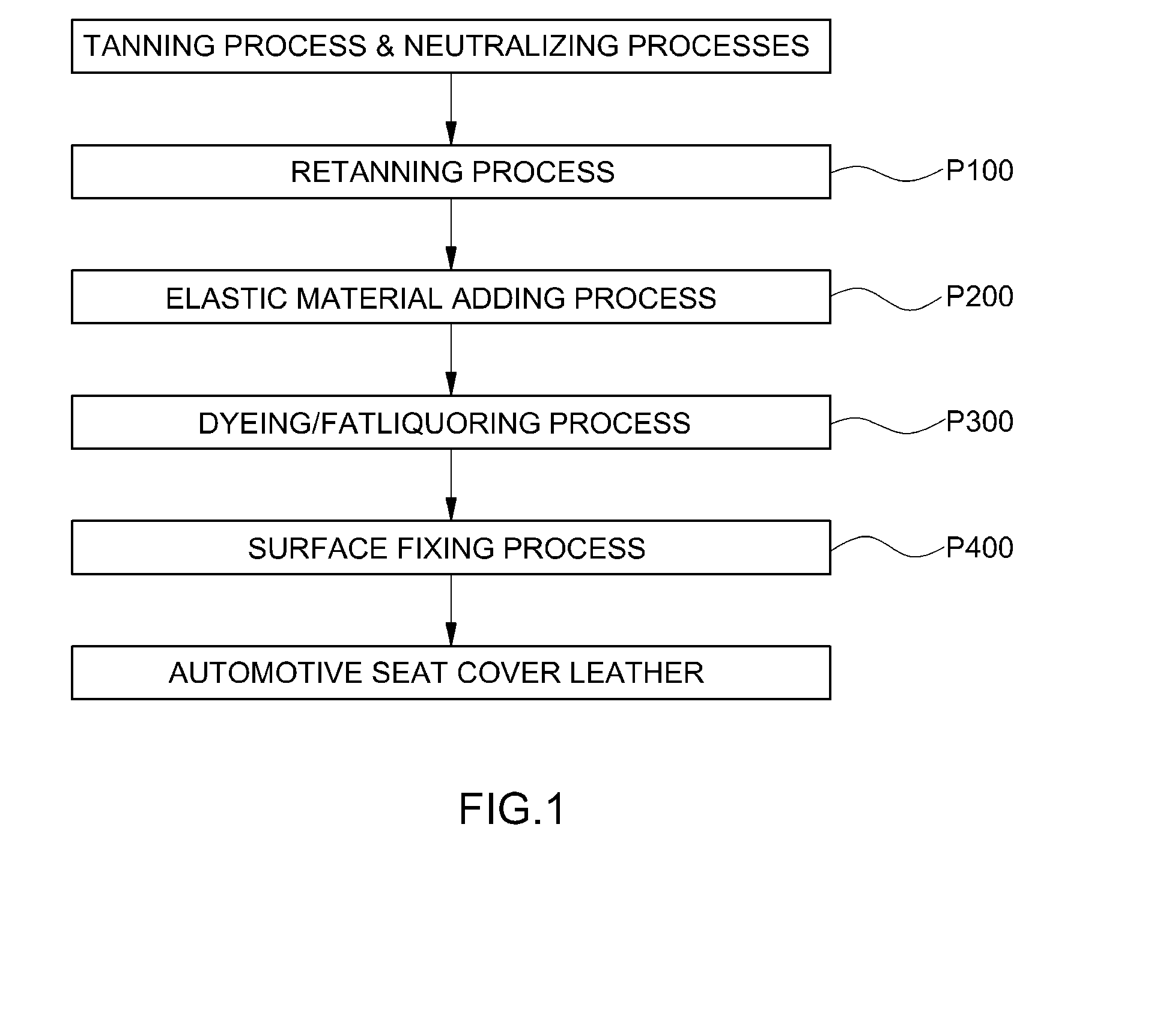

Vehicle seat cover leather having excellent durability and method of fabricating the same

InactiveUS20130263383A1Avoid wrinklesGood physical propertiesTanning treatmentFibre treatmentPliabilityEngineering

Disclosed is a method of fabricating an automotive seat cover leather. The method includes a preparing process, a tanning process, a neutralizing process, a retanning process, an elastic material adding process, a dyeing / fatliquoring process, and a surface fixing process. After the leather has gone through the tanning process and neutralizing process, the retanning process adds a tanning agent to the leather. The elastic material adding process adds a silicon-based elastic material to induce elasticity in the retanned leather. The dyeing / fatliquoring process adds a dye to the leather in which the elastic material has been added and adds an anion fatliquoring agent to the leather to provide flexibility. The surface fixing process fixes the elastic material, dye, and fatliquoring agent on and in the leather.

Owner:HYUNDAI MOTOR CO LTD +1

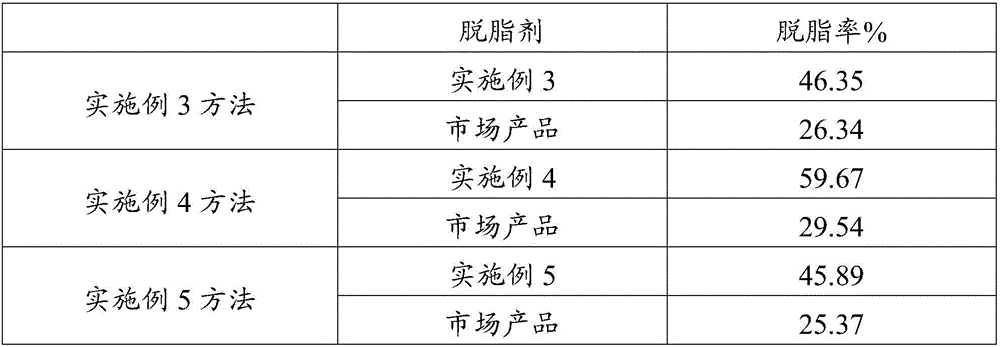

Composite lipase degreasant and application

ActiveCN106350620AHigh degree of degradationEasy to eluteLeather degreasingAnimal skinPOLYOXYETHYLENE ETHER

Relating to the technical field of leather degreasing, the invention provides a composite lipase degreasant and application. The composite lipase degreasant is prepared from, by weight, 15-25 parts of lipase and 10-15 parts of surfactant. The lipase is neutral lipase or alkali lipase; the surfactant is a sulfonate surfactant, polyoxyethylene ether surfactant or or a plurality of sulfonate surfactants and polyoxyethylene ether surfactants. The composite lipase degreasant and application, by synergistic effects of the lipase and surfactant, enhances the degradation of lipase to grease and makes intracutaneous grease easily eluted from crust so as to reach highly efficient degreasing effects. Applicable to degreasing all kinds of animal skins, such as pigskin, sheepskin, goat skin and buffalo hide, the composite lipase degreasant and application has mild skin effects, which is economical, eco-friendly and applicable to degreasing in different procedures.

Owner:SICHUAN DOWELL SCI & TECH INC

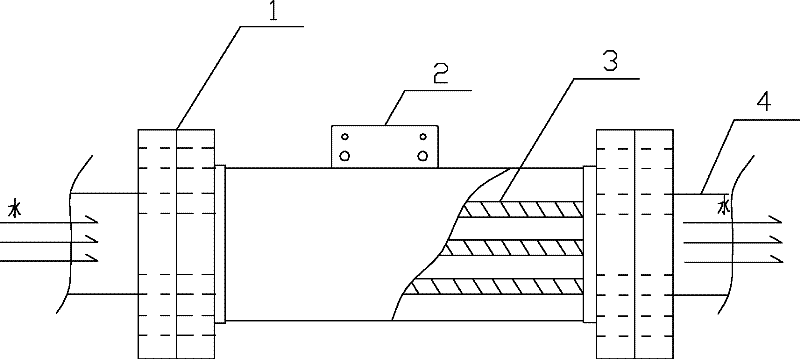

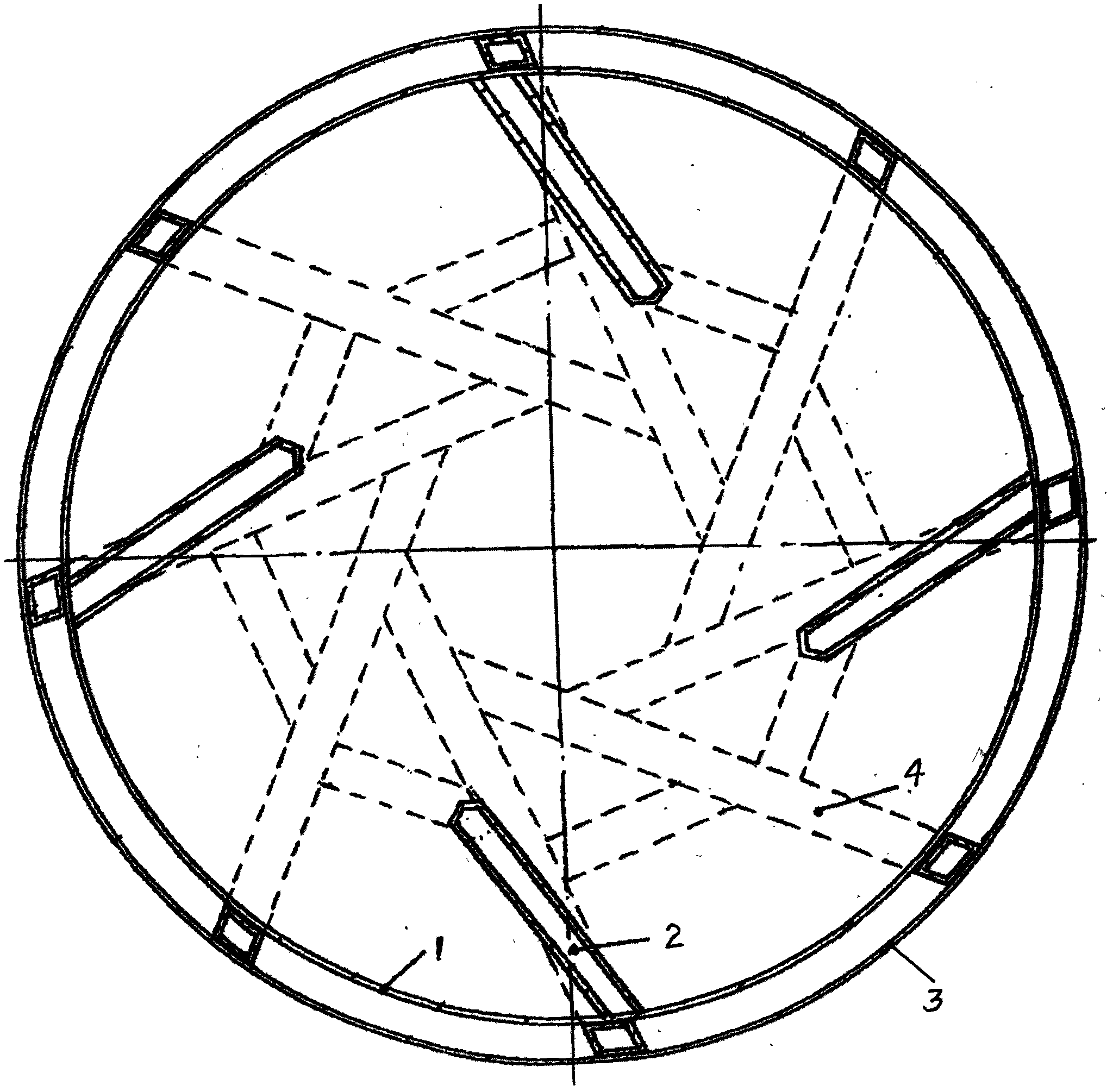

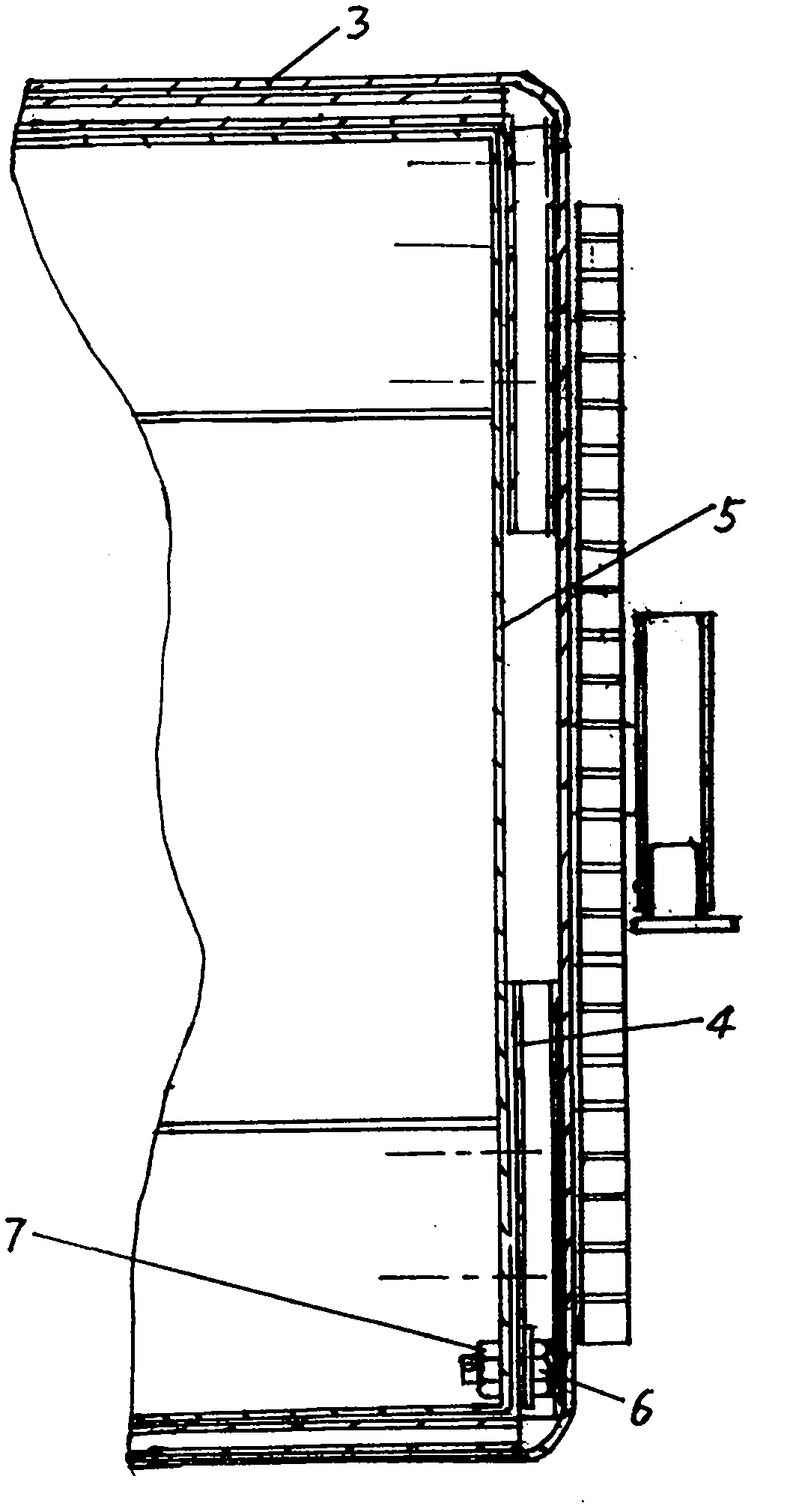

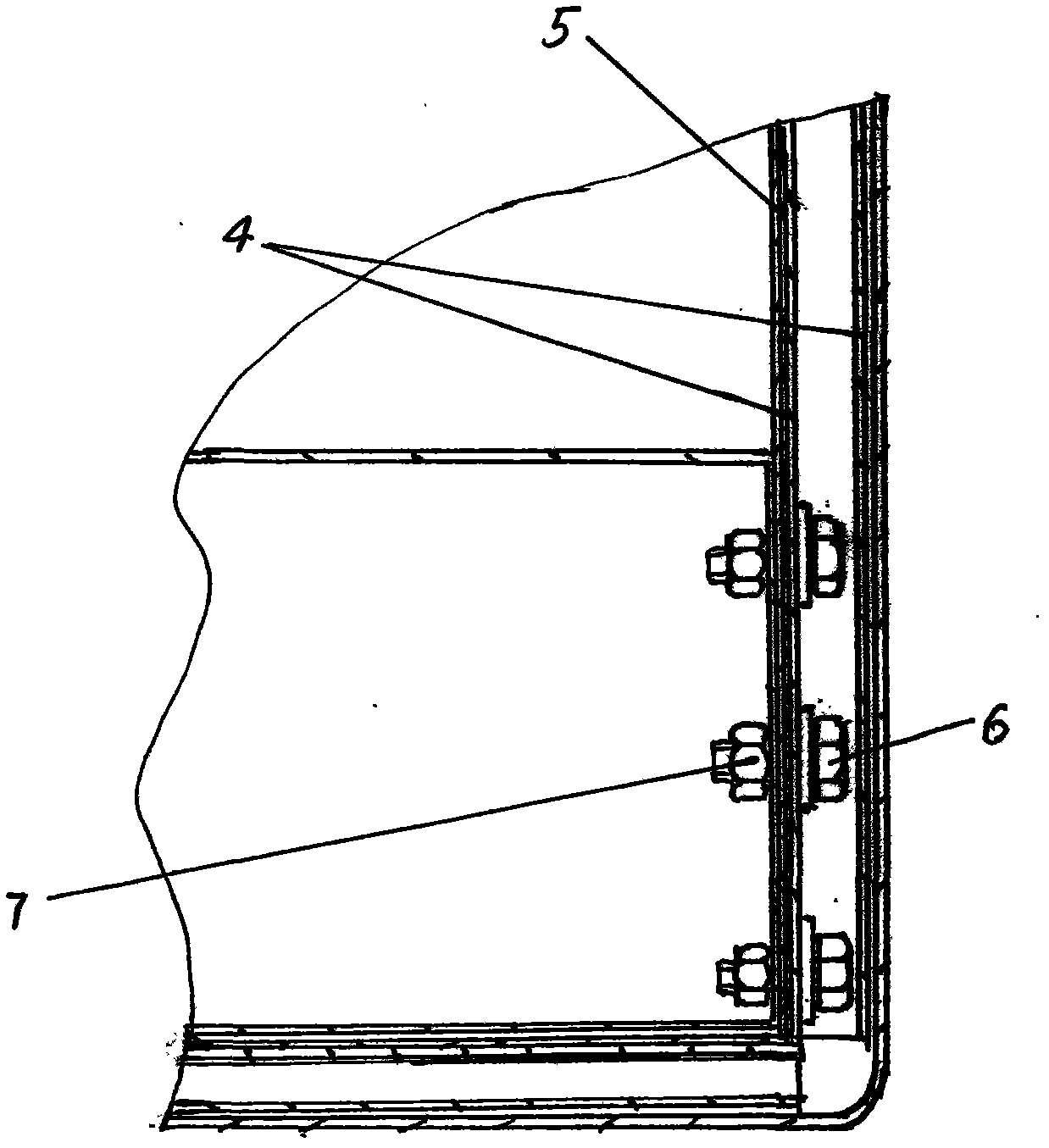

Rotary drum for improving internal baffle plate structure of drum body in leather production

InactiveCN102051420AChange the way you workHigh strengthTanning treatmentPre-tanning chemical treatmentMechanical engineeringLoading rate

The invention relates to a rotary drum for improving an internal baffle plate structure of a drum body in leather production, which is provided with a drum body. The drum body is provided with a cylindrical drum inner container and a plurality of baffle plates which are installed in the drum inner container; and the drum inner container is provided with two drum side walls and a cylindrical drum inner wall. The bottom end of each baffle plate is in closed fixation connection with the circumference surface of the drum inner wall; two side ends of each baffle plate are respectively in closed fixation connection with the two drum side walls; the height of each baffle plate is one fifth to one third of the inner circle diameter of the drum inner wall; and in the cutting plane which is perpendicular to an axis of the drum inner container, an included angle formed by each baffle plate and the inner circle tangent of the drum inner wall at the connecting position of the bottom end of the baffle plate and the drum inner wall is 50-70 degrees. Accordingly, the rotary drum can bag and splash leather and liquid together during oriented rotation, thereby improving the loading rate and the working efficiency and having good leather processing effect.

Owner:辛集巨龙皮革机械有限公司

Leather Care Using Lipophilic Fluids

InactiveUS20080248323A1Simple methodAvoid damageFibre treatmentDry-cleaning apparatus for textilesIntensive care medicineFluid system

Owner:RADOMYSELSKI ANNA VADIMOVNA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com