Patents

Literature

104 results about "Solvent degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent degreasing is a process used to prepare a part for further operations such as electroplating or painting. Typically it uses petroleum, chlorine, dry ice or alcohol based solvents to dissolve the machining fluids and other contaminants that might be on the part.

Application of micro injection molding technique for preparing tungsten-base alloy product and micro injection molding method of tungsten-base alloy powder

The invention discloses an application of micro injection molding technique for preparing a tungsten-base alloy product, which can prepare a micro tungsten-base alloy part with a mass less than 0.5g and a relative density greater than 96 percent. The invention also discloses a micro injection molding method of tungsten-base alloy powder, comprising steps of mixing, milling mixing, pelletizing, injection molding, green-ware degreasing, sintering and the like. The adhesive consists of wax, polyethylene, surface modifier and the like, wherein the modifier consists of stearic acid and organic naphthaline by a certain proportion, and the viscosity of the adhesive is dramatically reduced at a high shearing rate, thereby being favorable for filling. The invention adopts two degreasing steps of solvent degreasing and heat degreasing, wherein the first step of solvent degreasing can degrease wax of low melting point and partial surface modifier, and the second step of heat degreasing mainly degreases polymer of high melting point. The high-temperature insulation can remove the adhesive, sinter the degreased green body, improve the intensity of the green body and ensure conformality of the green bodies.

Owner:厦门博兴纳新材料科技有限公司

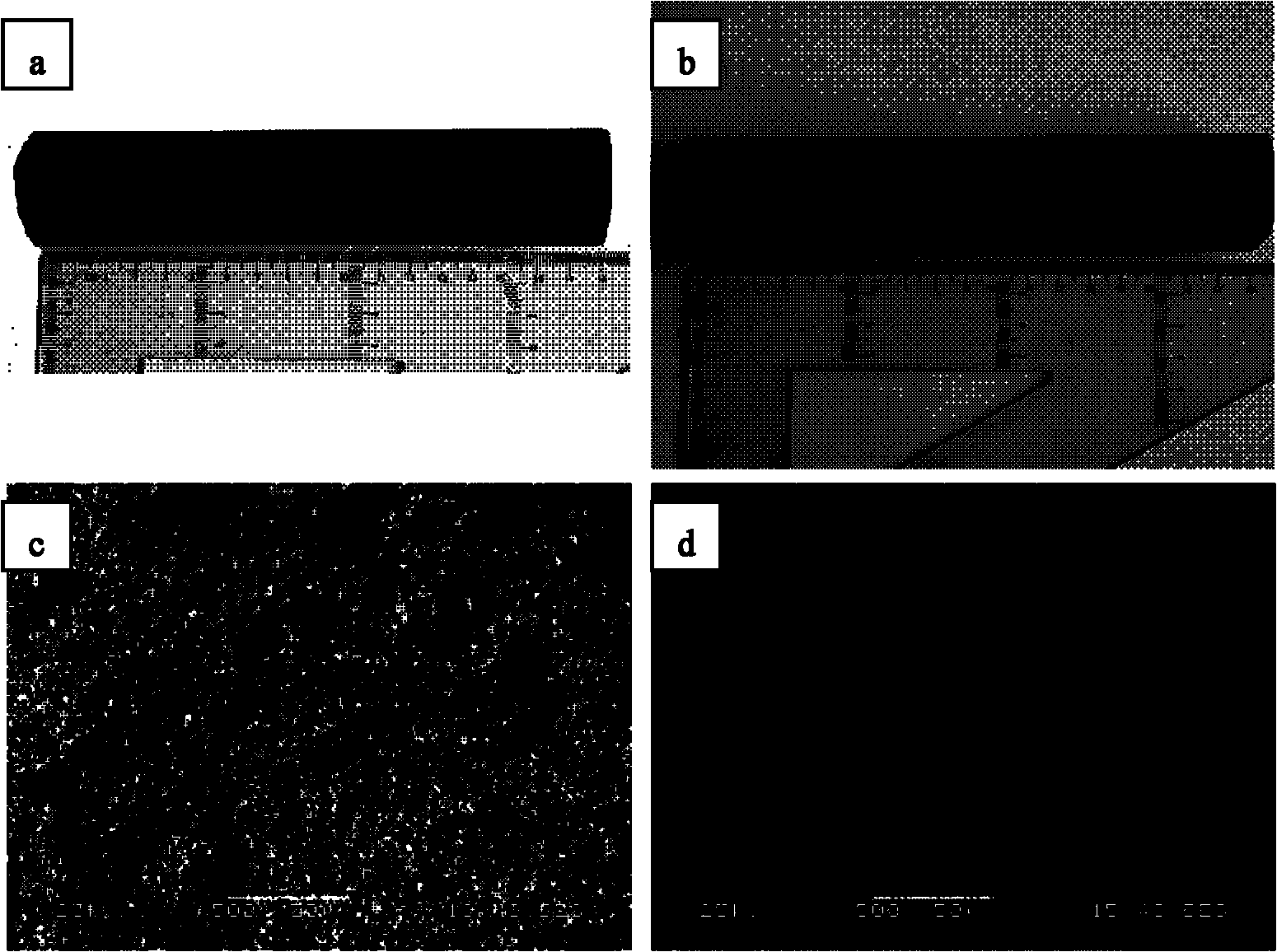

Method for synthesizing NiTi shape memory alloy porous material

InactiveCN1418974AMeet the requirements for growthMeet strength requirementsSelf-propagating high-temperature synthesisAdhesive

The method for synthesizing NiTi marmen porous body material is characterized by that it uses Ti powder and Ni powder as raw material, and includes the following steps: uniformly mixing the above-mentioned raw materials, mixing them with adhesive in mixing machine, granulating to obtain feeding material, injecting to obtain blank piece, soaking said blank piece in gasoline to remove grease, drying and placing the blank into vacuum furnace to make thermal grease removal, finally connecting one end of blank with W spiral in flame igniter, placing it into vacuum reaction synthesizer, when the degree of vacuum is higher than 1X10(-2)Pa, starting heating, after the temp. is up to defined value, starting flame igniter so as to produce self-spreading high-temp. synthesis reaction to obtain finished product.

Owner:UNIV OF SCI & TECH BEIJING

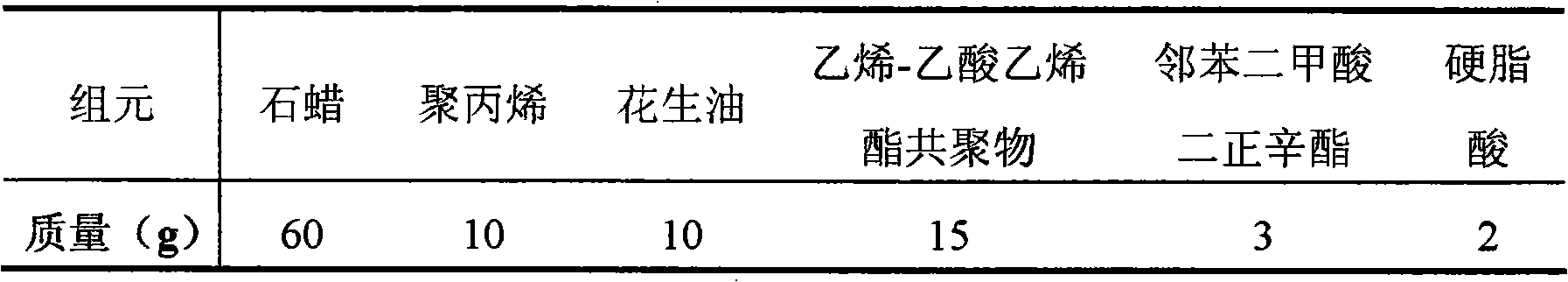

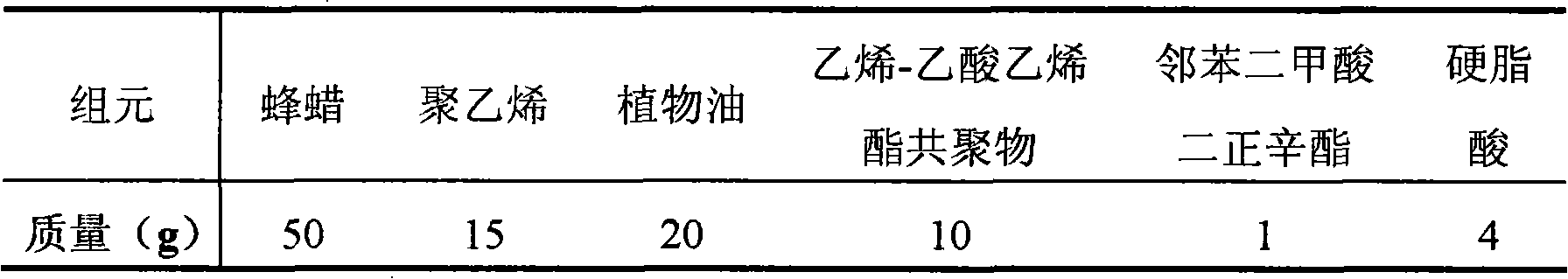

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

Preparation method of hard alloy with clad structure

The invention relates to a preparation method of a hard alloy with a clad structure, comprising the following steps of: selecting a WC-Co-based hard alloy as a base material; selecting a multicomponent alloy to which TiN, TiC and Al2O3 or TiC and TiN are added from WC-Co-based hard alloys as a cladding material; respectively obtaining a base material feed and a cladding material feed by mixing and granulating; sequentially injecting the cladding material feed and the base material feed into a mold cavity by coinjection molding to obtain a product billet; and performing solvent degreasing and hot degreasing processes on the product billet, and sintering after removing a binder to obtain the hard alloy product with the clad structure. The method provided by the invention has a simple process, simplicity of operation, short consumed time and good binding property between the shell and the base matrix, can flexibly adjust the shell thickness by selecting different shell materials and controlling the coinjection process parameters, effectively improves the mechanical and physical properties of the surface of a mechanical part, and is suitable for preparation of a hard alloy workpiece with a clad structure.

Owner:CENT SOUTH UNIV

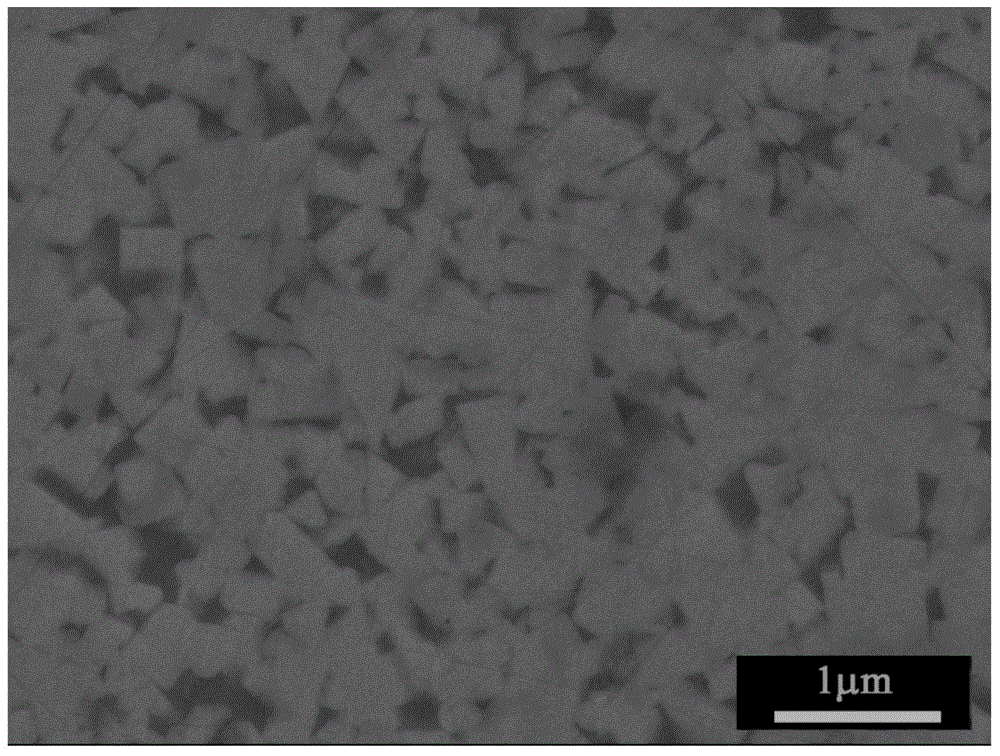

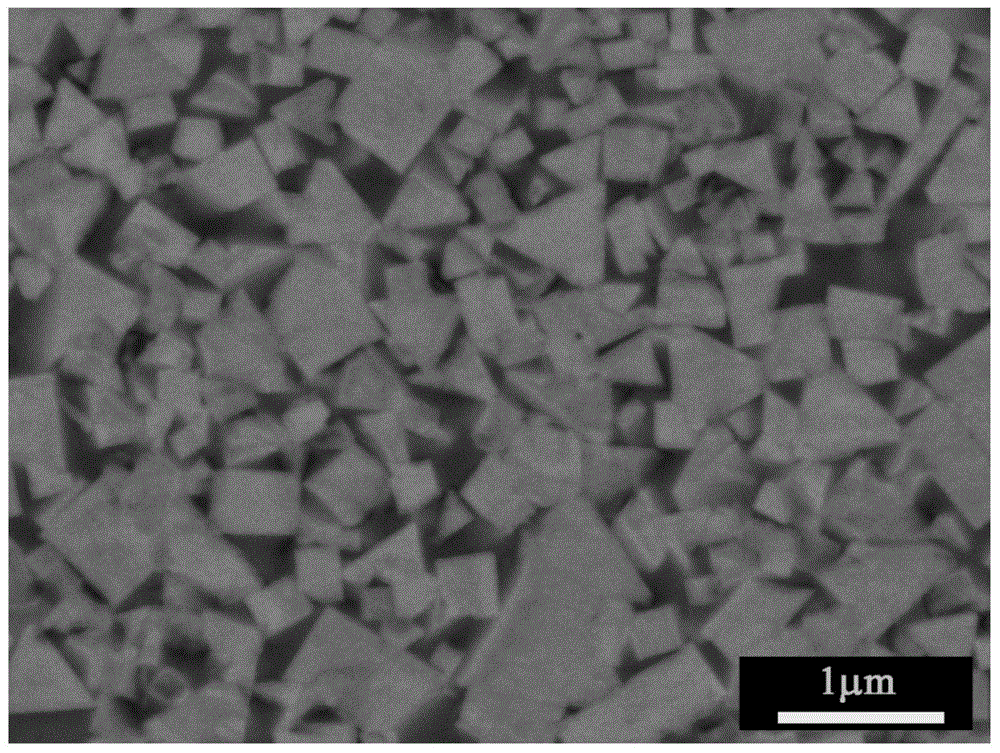

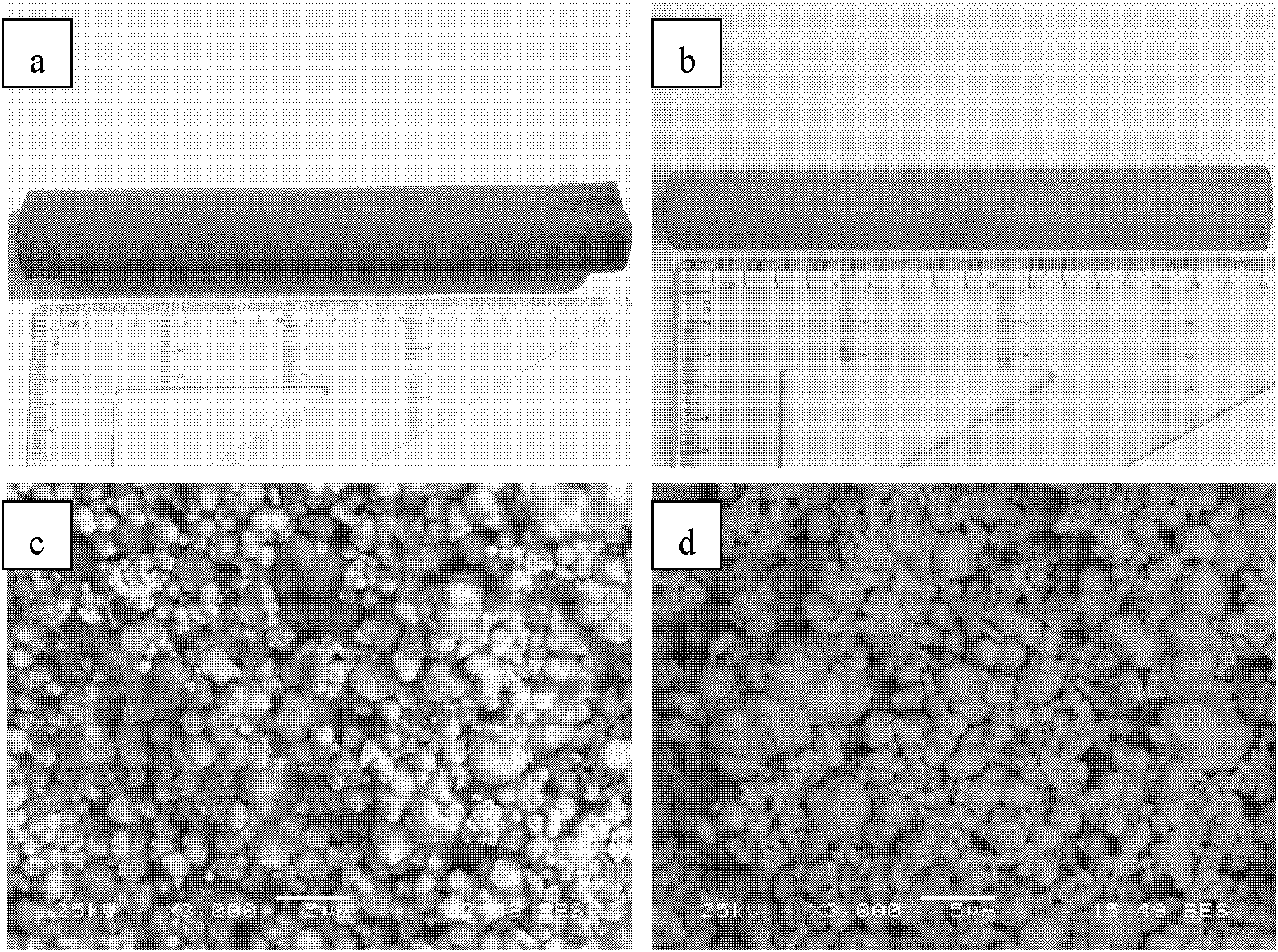

Method for preparing high-density pure tungsten product through low-temperature sintering

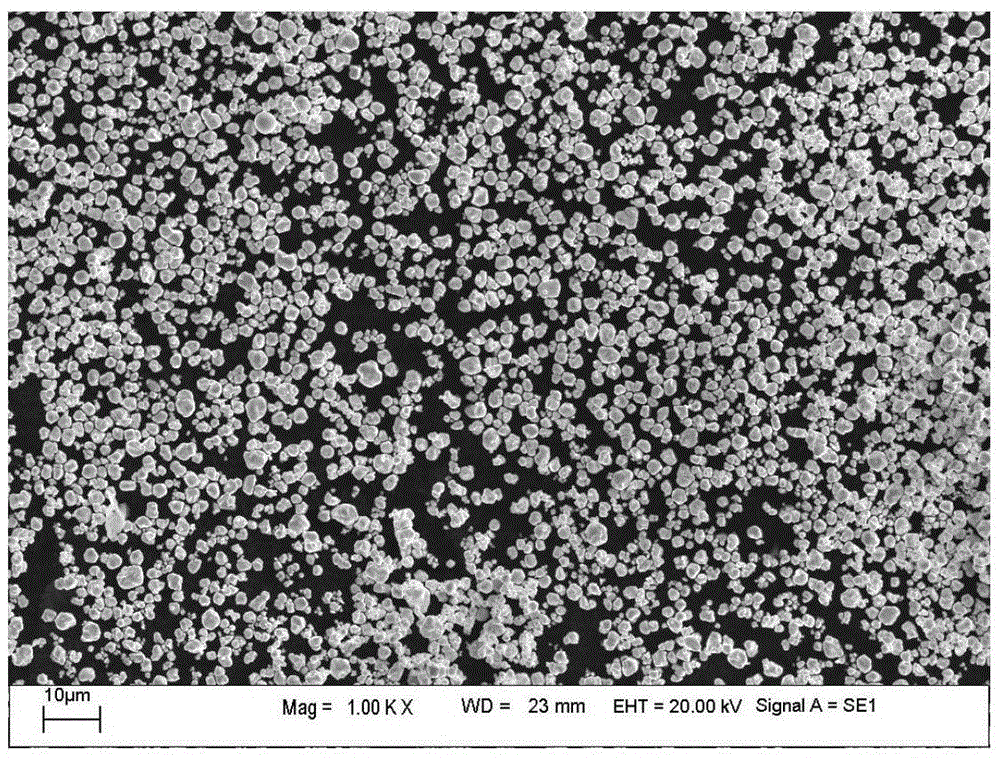

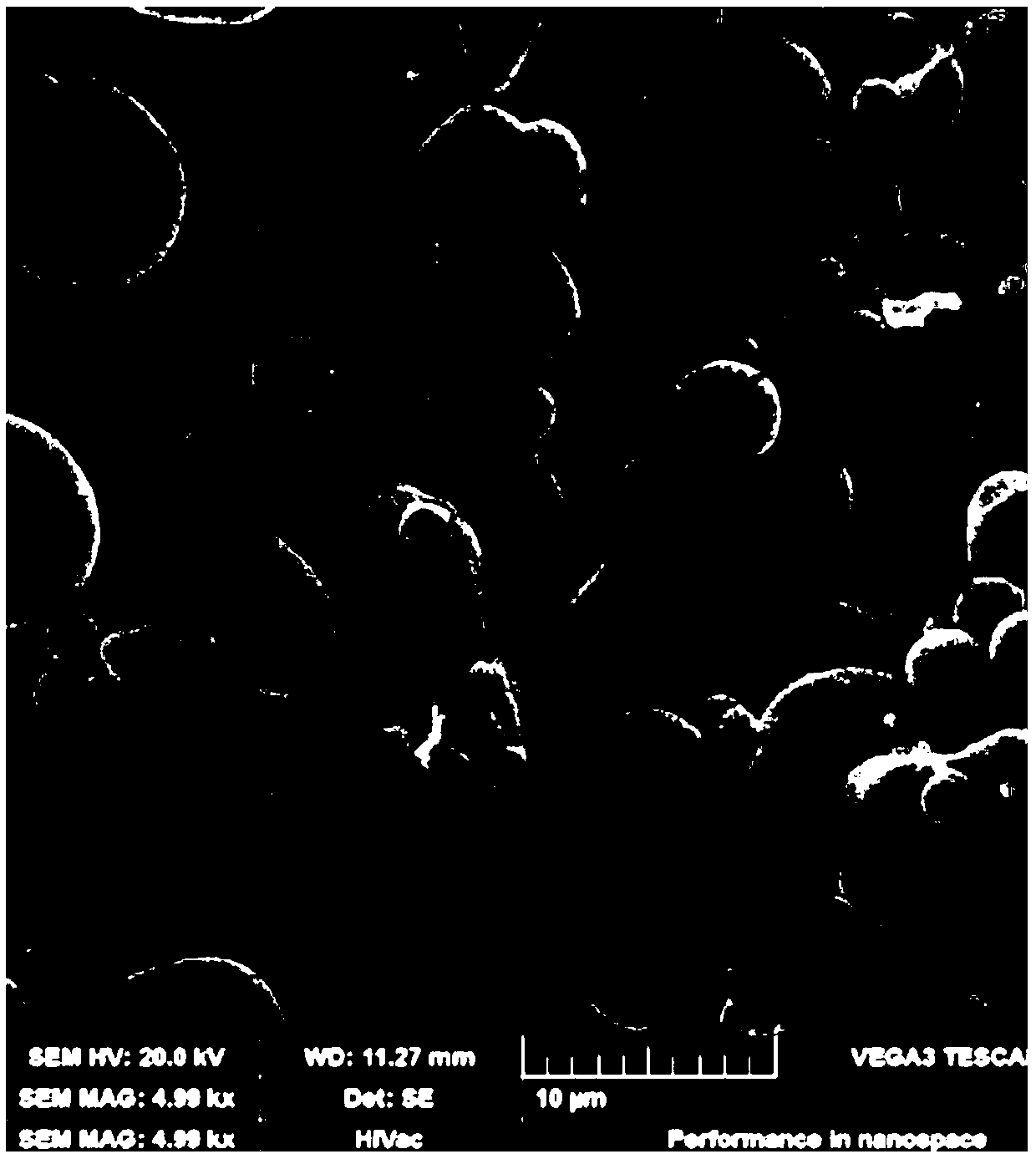

ActiveCN105478776ALower sintering densification temperatureHigh tap densityHigh densityHydrogen atmosphere

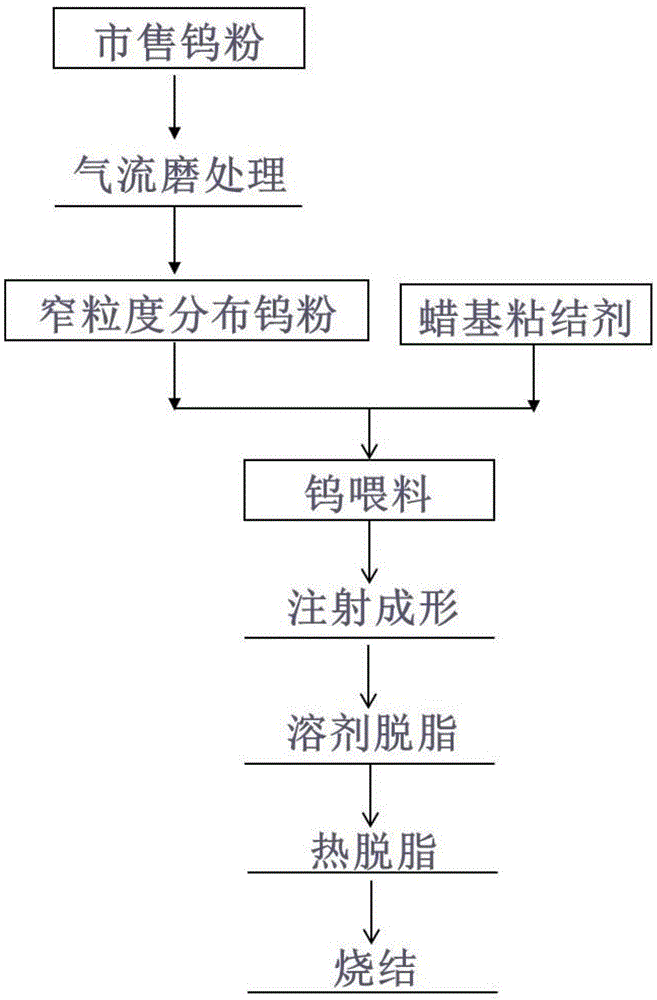

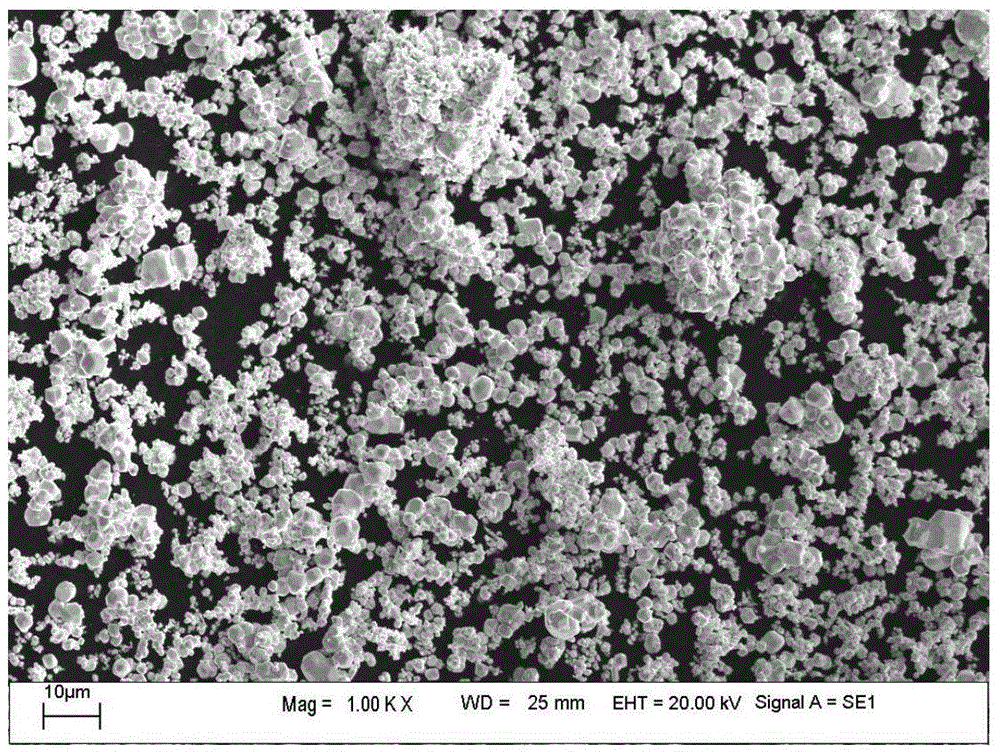

The invention provides a method for preparing a high-density special-shaped pure tungsten product through low-temperature sintering, and belongs to the technical field of powder injection molding. The method comprises the technological processes that an air flow mill is adopted for carrying out dispersing and staging treatment on commercially available high-purity tungsten powder, the treated powder and a bonding agent are evenly mixed for mixing, and even feed is obtained; the feed is subjected to injection molding to form a blank in a certain shape; and the formed blank is subjected to solvent degreasing and hot degreasing and then is sintered, and the tungsten product is obtained. Powder is subjected to dispersing and staging treatment through the air flow mill under the protective atmosphere, the powder is driven by gas to collide with each other and can be treated on a large scale, and no impurity is introduced; the particle size distribution of the treated powder becomes narrow, and the shape of particles becomes regular and is similar to a spherical shape; and loose-fitting tap density is increased, the loading amount of the injection-molded powder is correspondingly improved to 55%-70%, and the density of the pure tungsten product manufactured after sintering of the hydrogen atmosphere of 1,900 DEG C is higher than 96%.

Owner:UNIV OF SCI & TECH BEIJING

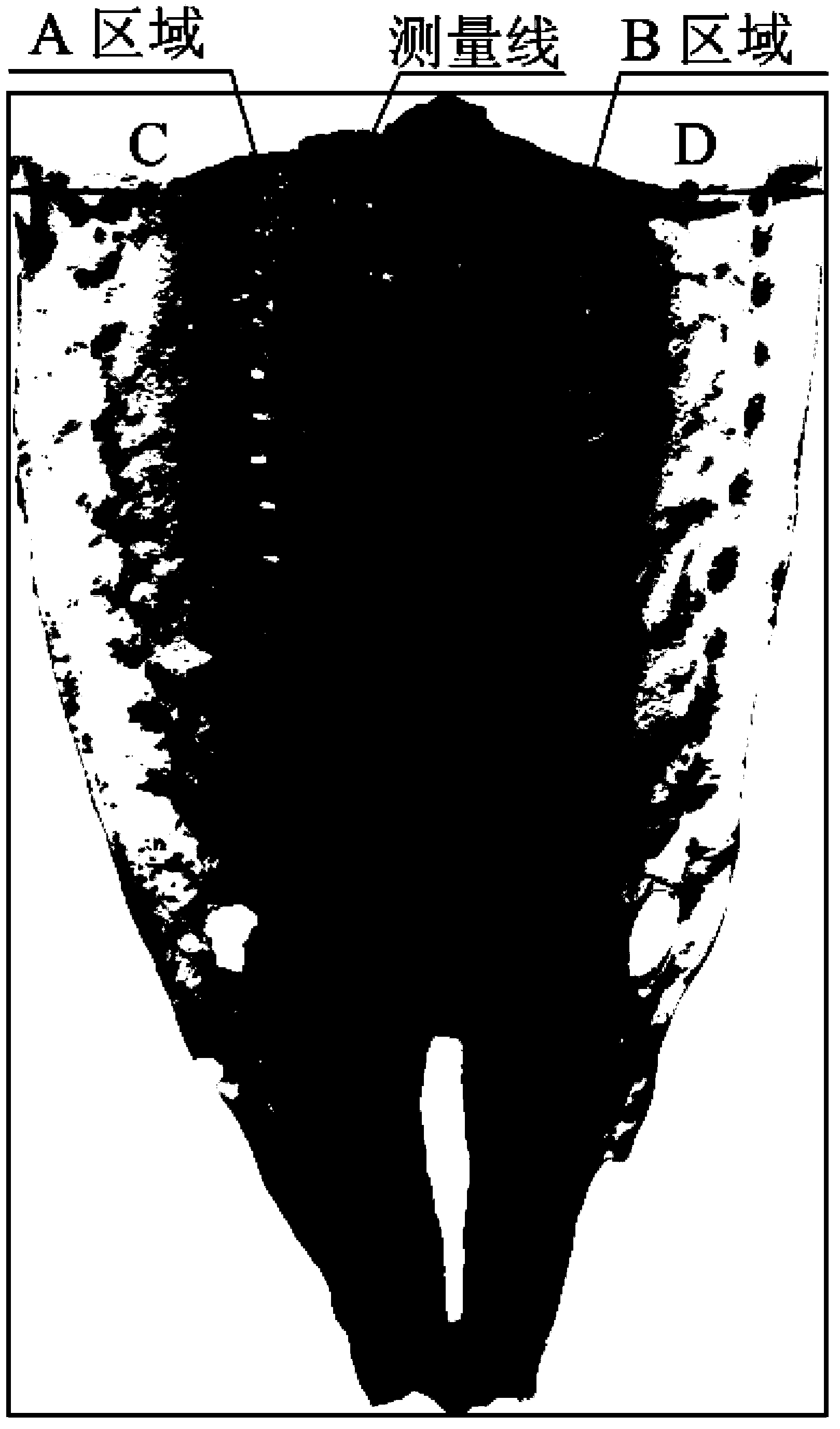

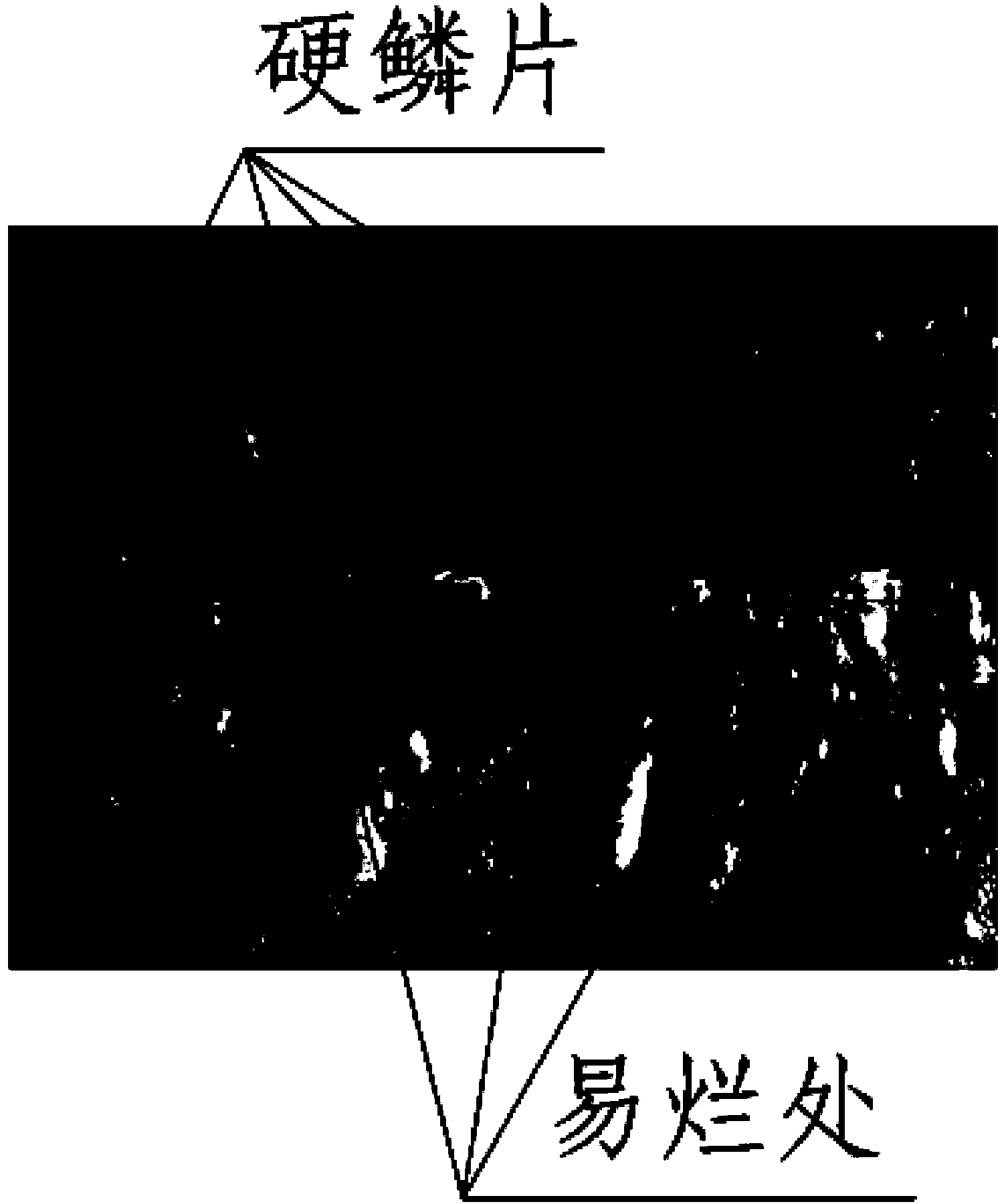

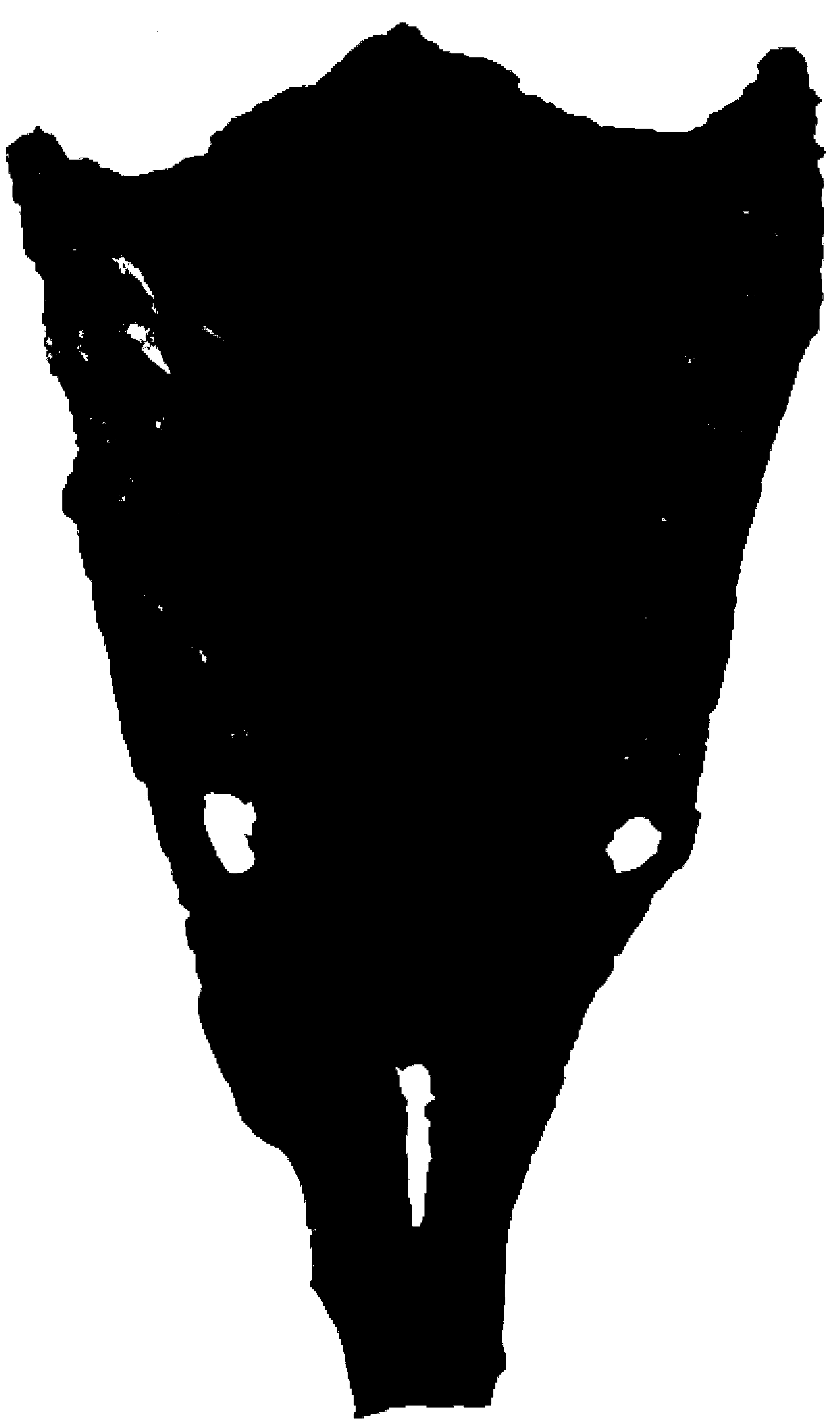

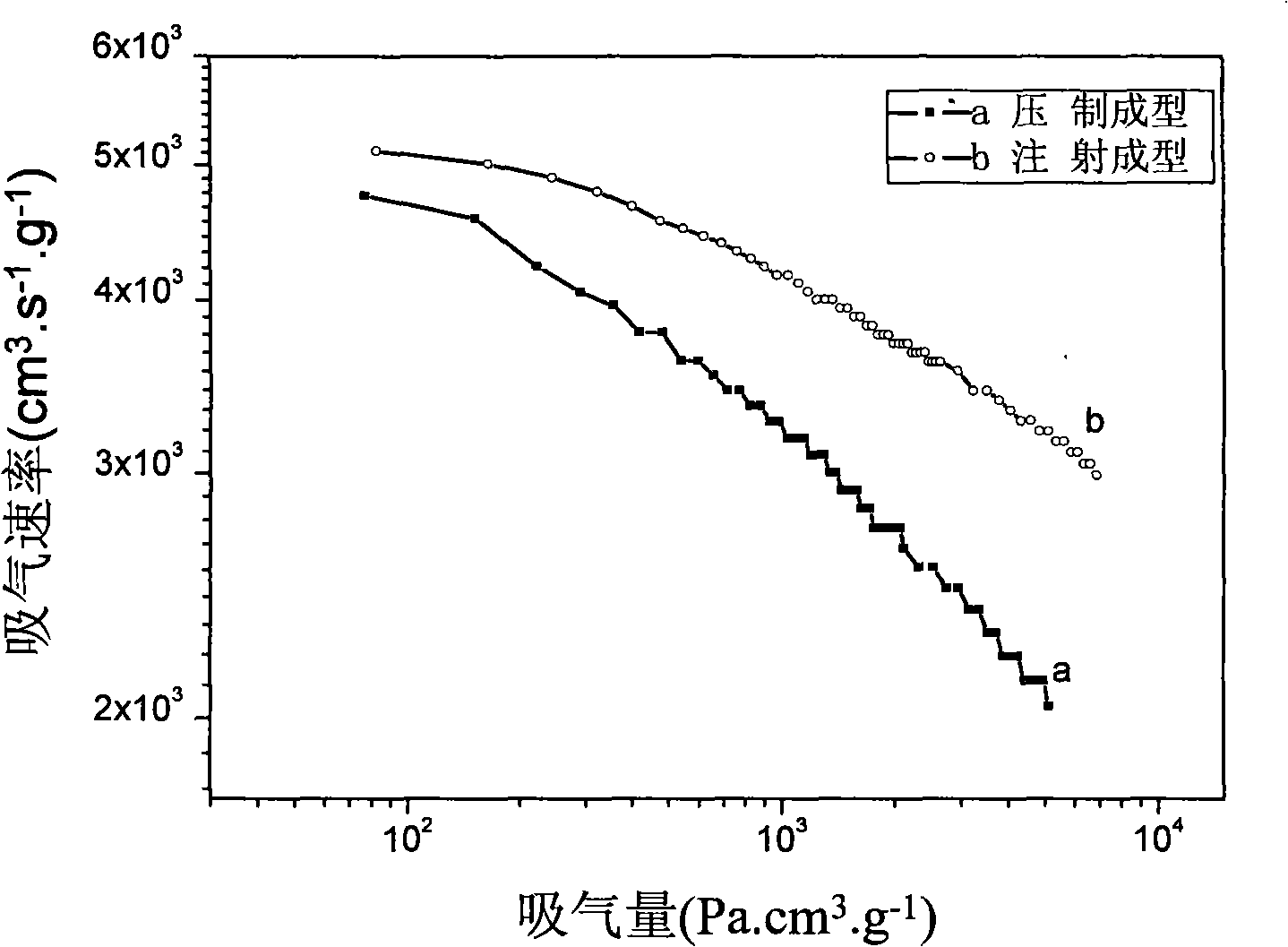

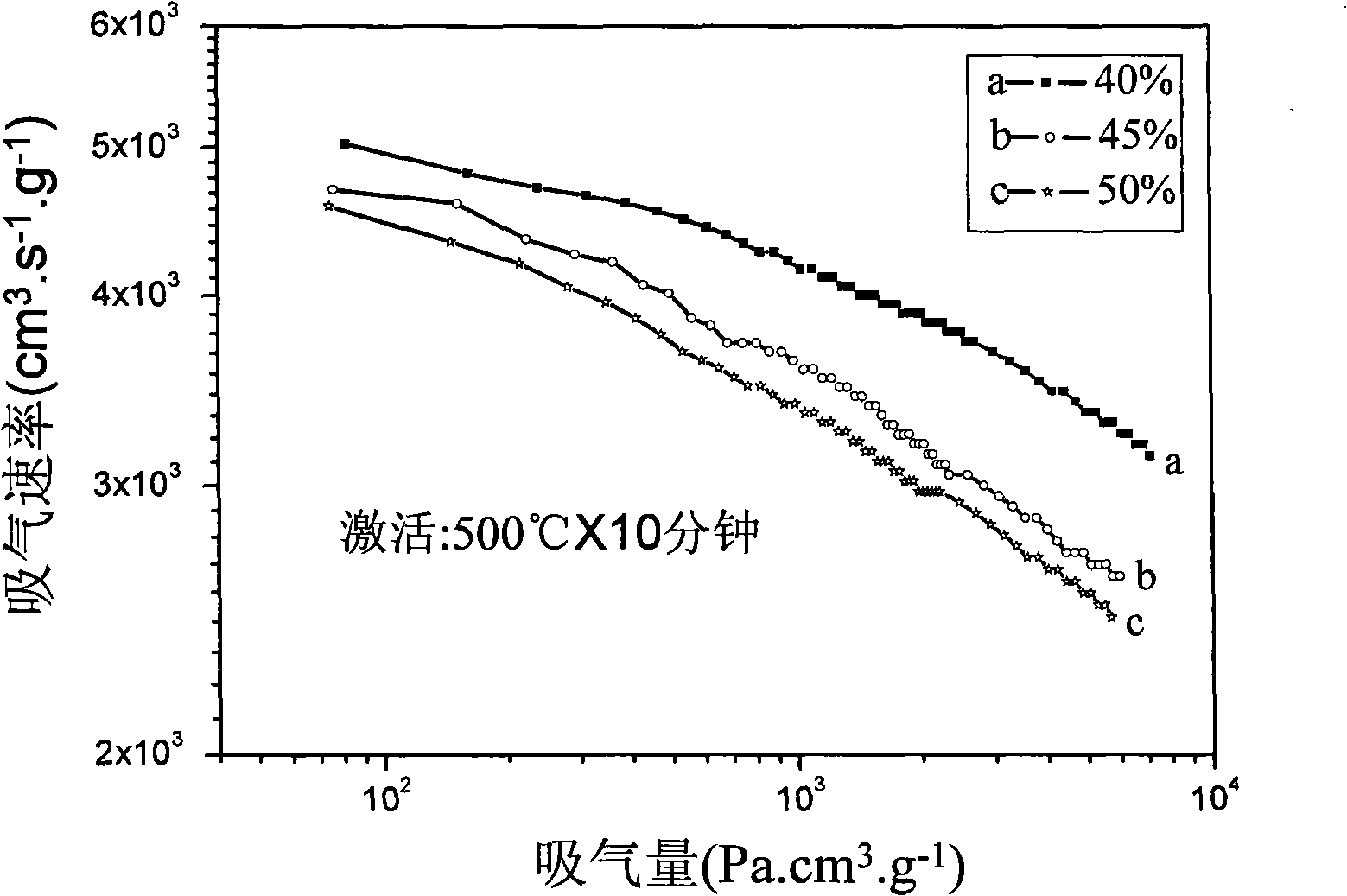

Method for preparing molybdenum and molybdenum alloys effuser by powder injection forming

A molybdenum or molybdenum alloy nozzle with very complicated shape is manufactured by powder injection molding. The molybdenum or molybdenum alloy nozzle is prepared by the following steps: mixing molybdenum or molybdenum alloy powder with a multi-component bonding agent consisting of paraffin wax, oil, low-molecule coupling agent and polymer to obtain uniform feeding material, injecting the feeding material on an injecting machine to obtain the injected blank of molybdenum or molybdenum alloy nozzle, degreasing solvent of the injected blank at a degreasing rate between 50% to 65%, pre-heating the solvent degreasing blank in a hot degreasing furnace, and high-temperature sintering the sample after hot degreasing pre-heating to obtain the molybdenum or molybdenum alloy nozzle with no deformation and stable performance.

Owner:CENT SOUTH UNIV

High efficiency low-foaming blue leather degreaser

InactiveCN101831362ASuitable for a wide temperature rangeFacilitates cleaning removalNon-ionic surface-active compoundsDetergent compounding agentsWater basedKerosene

The invention relates to a degreaser used for degreasing blue leather. The degreaser is a washing composite mainly using surfactant as base material and is clear and transparent microemulsion. The formula of the degreaser comprises the following components by weight percent: 20-60% of surfactant (one or two of non-ionic surfactants such as fatty alcohol polyoxyethylene ether, fatty alcohol polyoxypropylene ether and alkanolamide, 10-40% of solvent (one or two of toluene, xylene, turpentine, C8-C12 of solvent oil, trichloroethylene, tetrachloroethylene and solvent kerosene), 0-5% of cosolvent ( one or two of ethanol, n-propanol, isopropanol and ethylene glycol monobutyl ether, 0-10% of acidic lipase, 0-2% of defoaming agent and 40-60% of water. The application temperature of the microemulsion degreaser is wide, and can be stored for long time without layering and have stable state; and the degreaser has the advantages of solvent degreasing and emulsion degreasing, the fat dissolving and cleaning functions of organic solvents and the cleaning characteristics of water-based surfactants. Therefore, the natural fat in blue leather can be reduced to less than 1%.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Injection forming method for preparing high Niobium containing Ti-Al alloy components

A method for preparing complex shaped high-niobium titanium aluminum alloy parts with high dimension precision pertains to the field of material forming technology of high-niobium titanium aluminum intermetallic compounds. The process is that argon atomized high-niobium titanium aluminum powder and a polymer which is composed of paraffin PW with the different weight mixing ratio, low-density polyethylene LDPE, polypropylene PP and stearic acid SA are mixed and granulated by a binding agent with the load of 63 to 69 percent, the injection molding is carried out, after that, the solvent degreasing and the thermal degreasing in vacuum atmosphere are adopted for removing the binding agent, the pre-sintering is carried out at the temperature of 600 to 1000 DEG C, and the sintering is finally carried out at the temperature of 1460 to 1480 DEG C in the vacuum atmosphere for preparing the high-Nb-TiAl alloy parts. The method has the advantages that: the method can directly prepare the complex shaped high-Nb-TiAl alloy parts with high dimension precision and good performance, thus realizing the batch production of the high-Nb-TiAl alloy parts with low cost.

Owner:UNIV OF SCI & TECH BEIJING

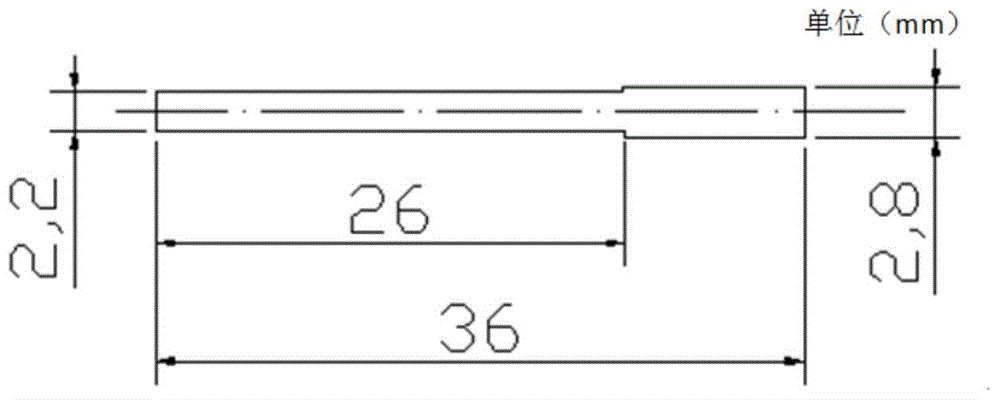

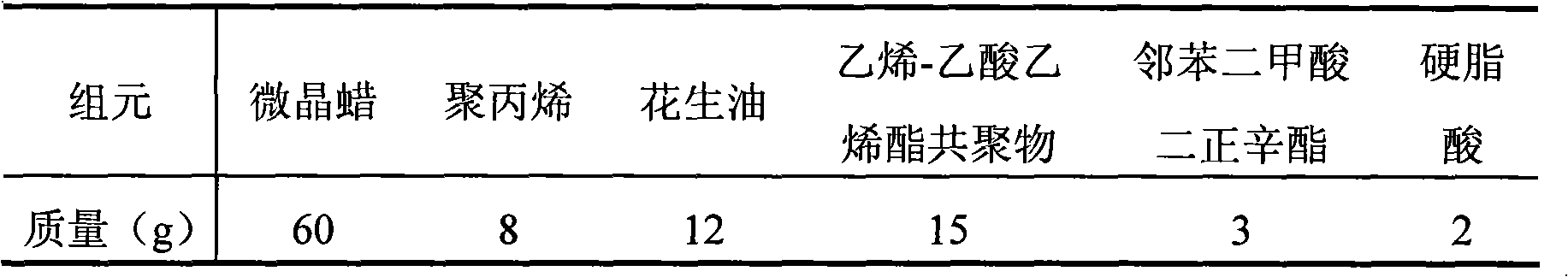

Large-length-diameter-ratio ultrafine grain hard alloy step-shaped bar and preparation method

The invention belongs to the technical field of powder metallurgy, and in particular, relates to a large-length-diameter-ratio ultrafine grain hard alloy step-shaped bar and a preparation method. The preparation method comprises the following steps: (1) ultrafine tungsten carbide powder and cobalt powder are mixed and grinded to obtain mixed powder; (2) the mixed powder and a multi-component binding agent consisting of paraffin-low molecular coupling agent-high molecular polymer are uniformly mixed to prepare a feedstock; (3) the feedstock is injected on an injection molding machine to form a molded blank; (4) the solvent degreasing and the thermal debinding are performed for the injection-molded blank in sequence; and (5) the ultrafine grain hard alloy step-shaped bar is obtained through sintering. The prepared ultrafine grain hard alloy step-shaped bar is small in alloy porosity and high in hardness and strength; and the diameter and size deviations are +-0.03 mm.

Owner:GRIMAT ENG INST CO LTD

Process for extracting alpha-crocin from fructus gardeniae

The invention relates to a process for extracting alpha-crocin from fructus gardeniae, which comprises the following steps of degreasing, aqueous extraction, tannin removal, resin adsorption, recrystallization and the like, and particularly comprises a method of degreasing by a No.4 solvent, tannin removal by polyamide resin and the recrystallization of hot water and propylene glycol. The production process has the characteristics of simplicity, convenience and low cost.

Owner:NANJING ZELANG AGRI DEV

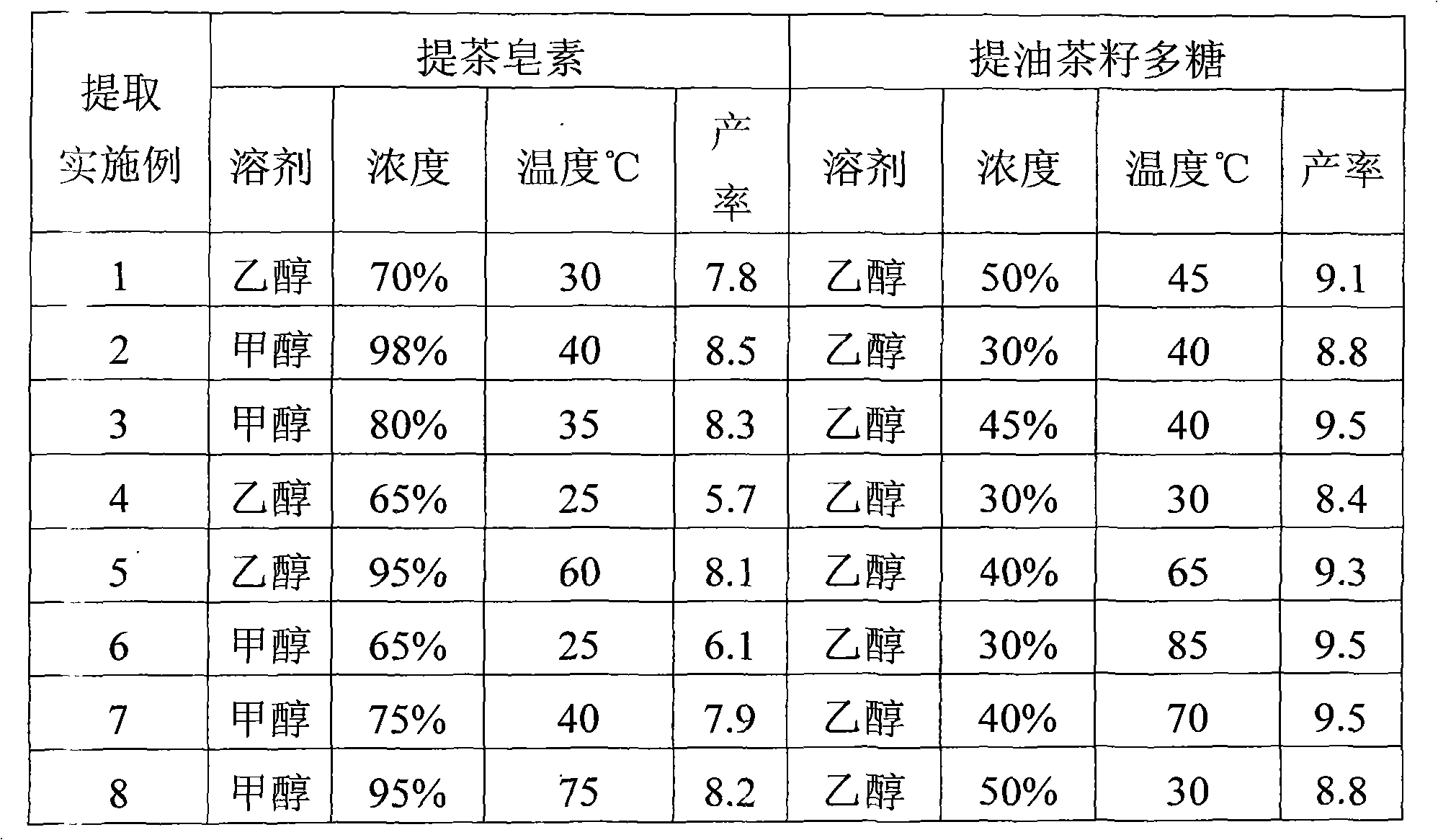

Production method and use of camellia seed polysaccharide

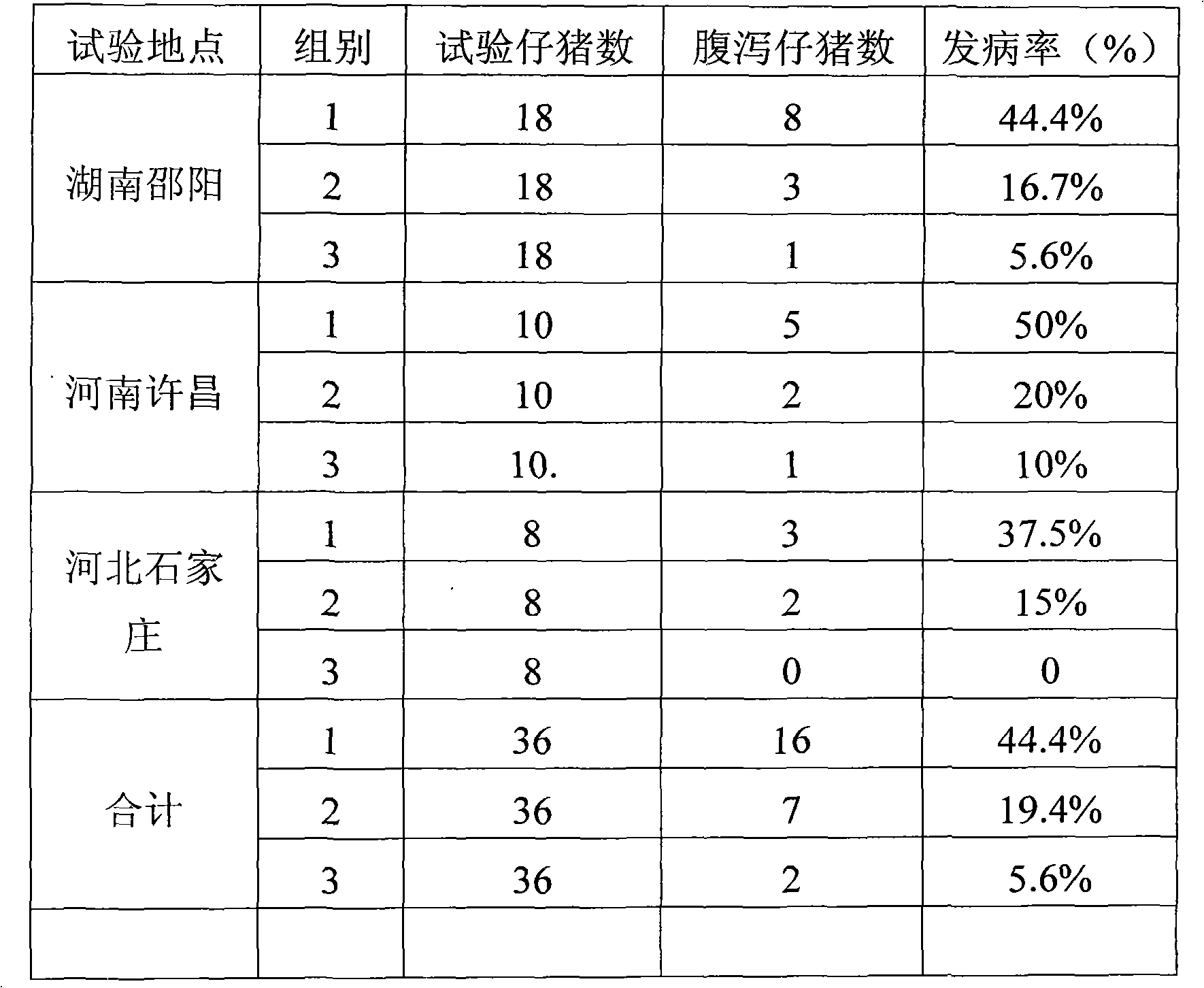

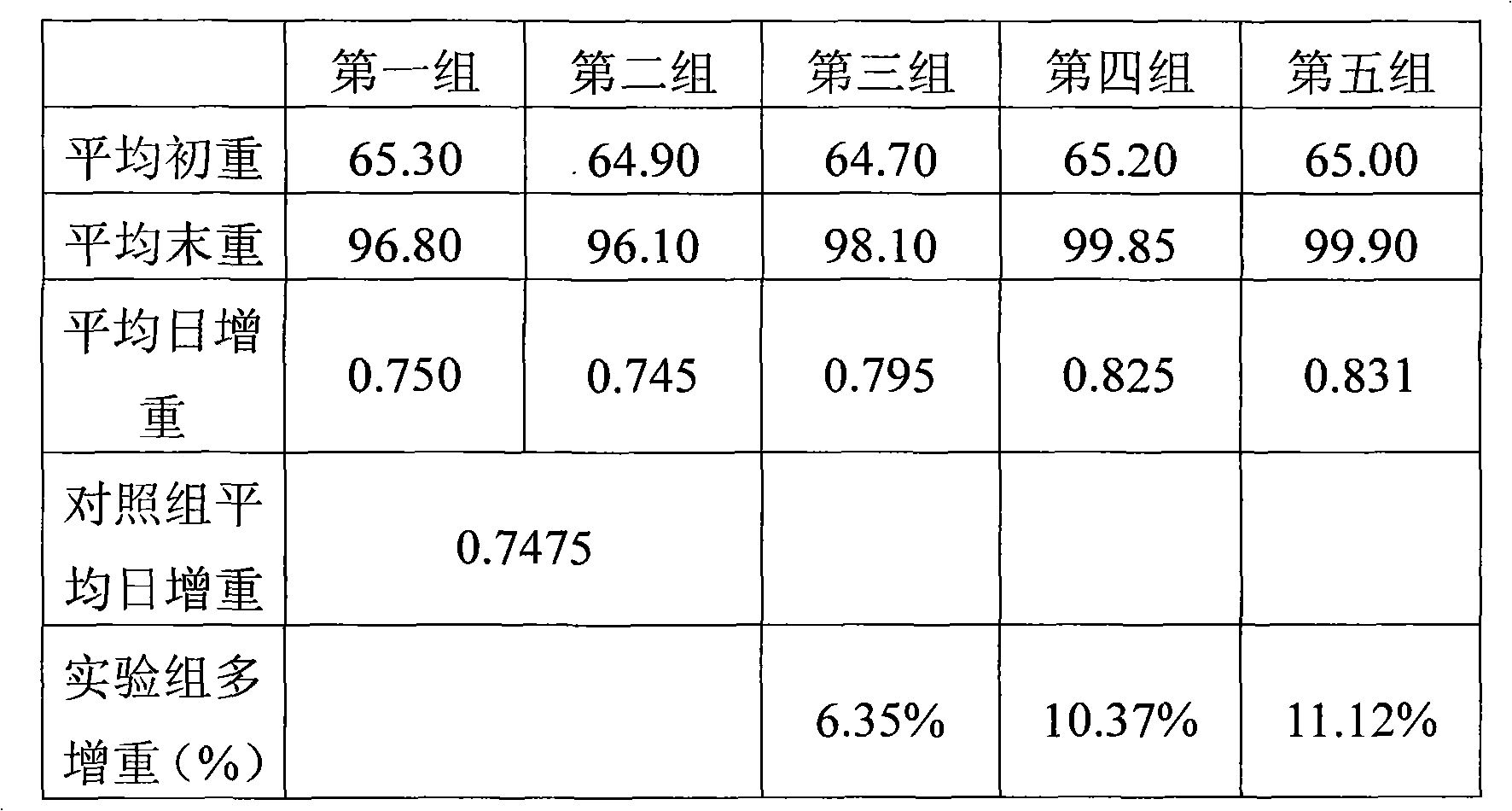

InactiveCN101602815AIncrease profitWide variety of sourcesSugar derivativesAnimal feeding stuffCamellia oleiferaSolvent degreasing

The invention provides a production method of camellia seed polysaccharide, which relates to the technical field of feed additives and agricultural waste utilization. The method comprises: subjecting camellia dregs powder after oil extraction to solvent degreasing treatment; soaking degreased cake powder in 70 to 99 percent alcohol, concentrating and drying soak solution and obtaining tea saponin; and soaking tea seed cake powder after tea saponin extraction in ethanol, concentrating and drying the soak solution and obtaining the camellia seed polysaccharide. The camellia seed polysaccharide can be directly used as animal feed additives of pigs, cattle, chickens and other poultry. Compared with the prior art, the method has the characteristics of simplicity, high extraction yield, high purity, high utilization rate of raw materials, wide raw materials source, capability of mass production, low production cost, capability of changing waste into valuables and benefit for environmental protection. The camellia seed polysaccharide can be applied as the animal feed additives of pigs, cattle, chickens and other poultry, thereby having significant social and economic benefit.

Owner:胡国田

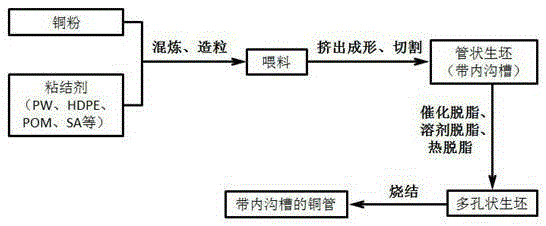

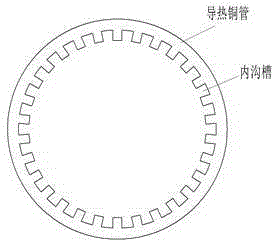

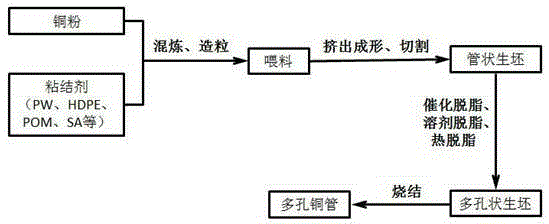

Manufacturing method of heat conduction copper pipe with inner groove

The invention relates to the field of powder metallurgy, and particularly discloses a manufacturing method of a heat conduction copper pipe with an inner groove. The method comprises the following steps that firstly, feed is prepared, a macromolecule bonding agent and copper powder are mixed evenly in an internal mixer, and pelleting is carried out to obtain the feed with the even structure; secondly, extrusion forming and cutting are carried out, the feed passes a die in a specific shape through a single screw extruder, a tubular sectional bar green body with the inner groove is obtained through extrusion, and the tubular sectional bar green body is cut to the needed length; thirdly, degreasing is carried out, and the green body is degreased through a solvent degreasing or catalysis degreasing method; and fourthly, sintering is carried out, a degreasing sintering furnace is used for thermal degreasing, the last part of bonding agent is made to be removed from the green body, and a sample is heated and sintered in the protection atmosphere to obtain the heat conduction copper pipe with the inner groove. According to the method, the advantages of the plastic extrusion forming technology and the advantages of the powder metallurgy technology are combined, and heat conduction copper pipes with inner grooves can be efficiently produced on a large scale.

Owner:SHENZHEN ELEMENT TECH CO LTD

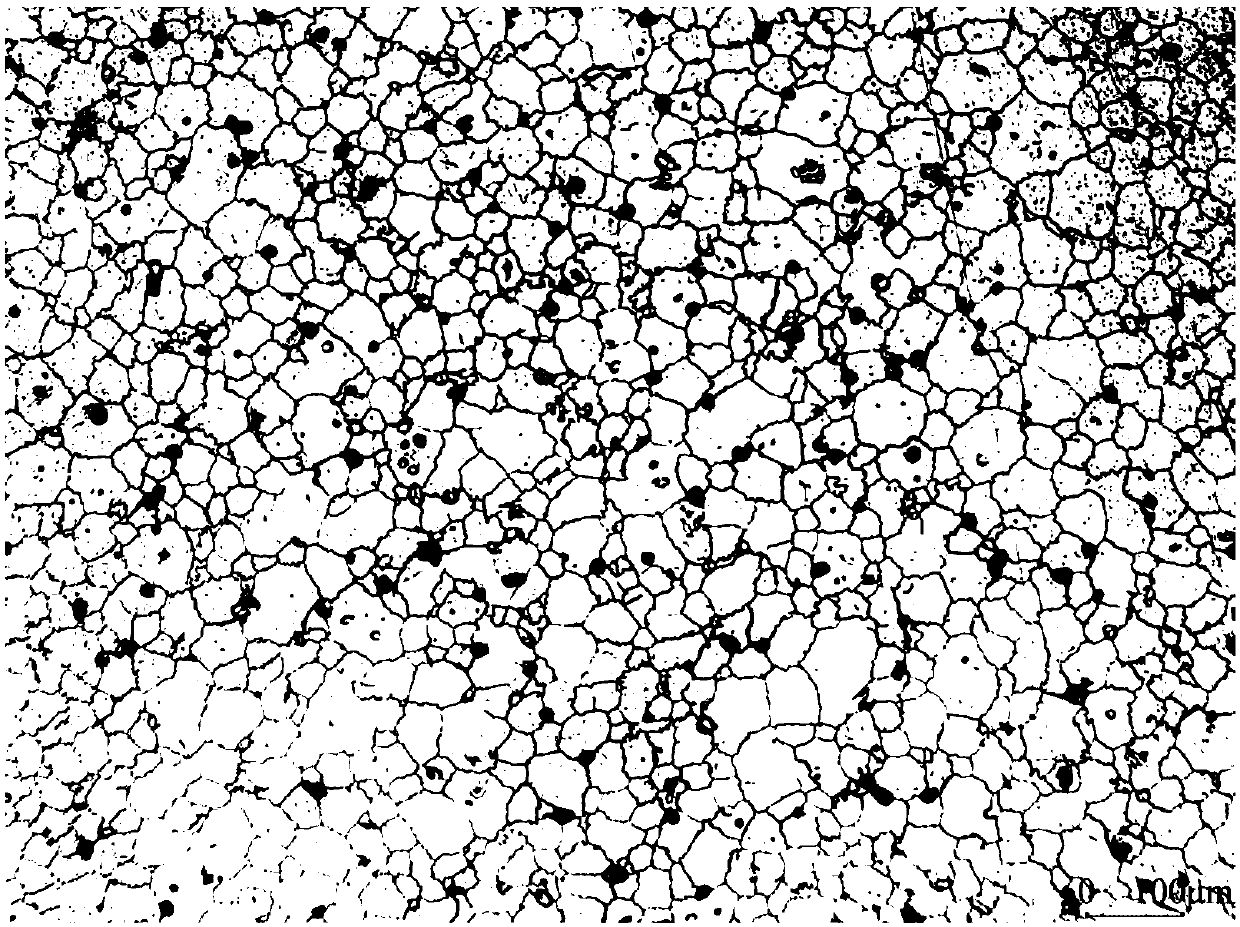

Heavy-density tungsten alloy

The invention provides a sintering process for a heavy-density tungsten alloy. The process comprises the following steps: batching: providing granular tungsten alloy feedstock; forming: injecting the tungsten alloy feedstock into a mold to form a tungsten alloy green body; solvent degreasing: placing the tungsten alloy green body in a water bath for solvent degreasing; atmosphere hot degreasing: performing atmosphere hot degreasing of the tungsten alloy green body subjected to solvent degreasing; and atmosphere sintering: performing atmosphere sintering of the tungsten alloy green body subjected to hot degreasing, and performing cooling to obtain the heavy-density tungsten alloy. The heavy-density tungsten alloy sintered according to the sintering process provided by the invention has high density, high hardness, no magnetism, low sintering temperature, low thermal expansion coefficient and the like, can meet the requirements for high temperature, high humidity, salt fog and the like, and has physical, chemical and mechanical properties approximate to those of forge pieces.

Owner:AAC PRECISE MFG TECH CHANGZHOU

Preparation method of ITO (indium tin oxide)/wool keratin solution compound functional finishing agent

InactiveCN102182061AHigh visible light transmittanceHigh UV absorptionFibre treatmentIndium TrichlorideUltraviolet

The invention relates to a preparation method of an ITO (indium tin oxide) / wool keratin solution compound functional finishing agent. The method comprises the following steps: 1) washing wool fibers with water, cleaning with detergent, degreasing with ethanol-acetone mixed solvent, crushing and adding into ion liquid, and heating and stirring to obtain a keratin ion liquid solution; 2) preparing an acetylacetone solution of indium trichloride and an ethanol solution of tin tetrachloride, and mixing the two solutions to obtain indium tin metal oxide sol; and 3) adding the indium tin metal oxide sol into the keratin ion liquid solution obtained in the step 1), and stirring and mixing to obtain the ITO / wool keratin solution compound functional finishing agent. The method provided by the invention can use fibers such as waste wool, cashmere and the like as raw materials, and is low in cost, simple to operate and easy to realize industrial production; and the compound functional finishing agent prepared by the method has the photoelectric properties such as high visual light transmissivity, high ultraviolet absorptivity, low resistivity and the like.

Owner:DONGHUA UNIV

Method for preparing porous heat conduction copper pipes through powder extrusion forming technology

The invention belongs to the field of powder metallurgy, and particularly discloses a method for preparing porous heat conduction copper pipes through the powder extrusion forming technology. The method includes the steps that firstly, feedstock preparation is conducted, wherein a macromolecule binding agent and copper powder are evenly mixed in an internal mixer, and then feedstock uniform in structure is obtained through granulation; secondly, extrusion forming and cutting are conducted, wherein the feedstock is added to a single-screw extruder, and tubular green blanks are extruded out and then cut into the required length; thirdly, degreasing is conducted, wherein degreasing is conducted on the green blanks through a solvent degreasing or catalysis degreasing method; and fourthly, sintering is conducted, wherein thermal degreasing is conducted under negative pressure through a degreasing sintering furnace according to a carrier gas degreasing method, and then samples are heated and sintered in protection atmosphere to obtain the porous heat conduction copper pipes. The advantages of the plastic extrusion forming technology and the powder metallurgy technology are combined in the method, and the porous heat conduction copper pipes with the porosity of 20% to 50% can be efficiently produced on a large scale.

Owner:SHENZHEN ELEMENT TECH CO LTD

Environment-friendly leather-producing process by using sturgeon skins

InactiveCN103436643AFeel goodFine grainTanning treatmentPre-tanning chemical treatmentSturgeonSolvent degreasing

The invention relates to a leather-producing process, and specifically relates to an environment-friendly leather-producing process by using waste sturgeon skins in a food processing process of artificially cultured sturgeons. The leather-producing process comprises the following steps of 1) group batching the sturgeon skins; 2) washing; 3) soaking; 4) liming; 5) washing; 6) deliming; 7) bating; 8) washing; 9) pickling; 10) neutralizing; 11) oxidation bleaching; 12) reduction bleaching; 13) washing; 14) dealkalizing; 15) washing: washing the dealkalized sturgeon skins with water; 16) repeat pickling; 17) tanning; 18) re-tanning; 19) drying; 20) trimming; 21) buffing; 22) solvent degreasing; 23), spin-drying; 24), drying; 25), rewetting; 26), re-tanning; 27), dyeing; 28) drying; 29) buffing; 30) finishing: spraying a coating agent on the buffed leather to obtain sturgeon leather. The sturgeon leather produced by the process has the advantages of softness, fullness, non-harsh handfeel and fine grains. The process is environment-friendly.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

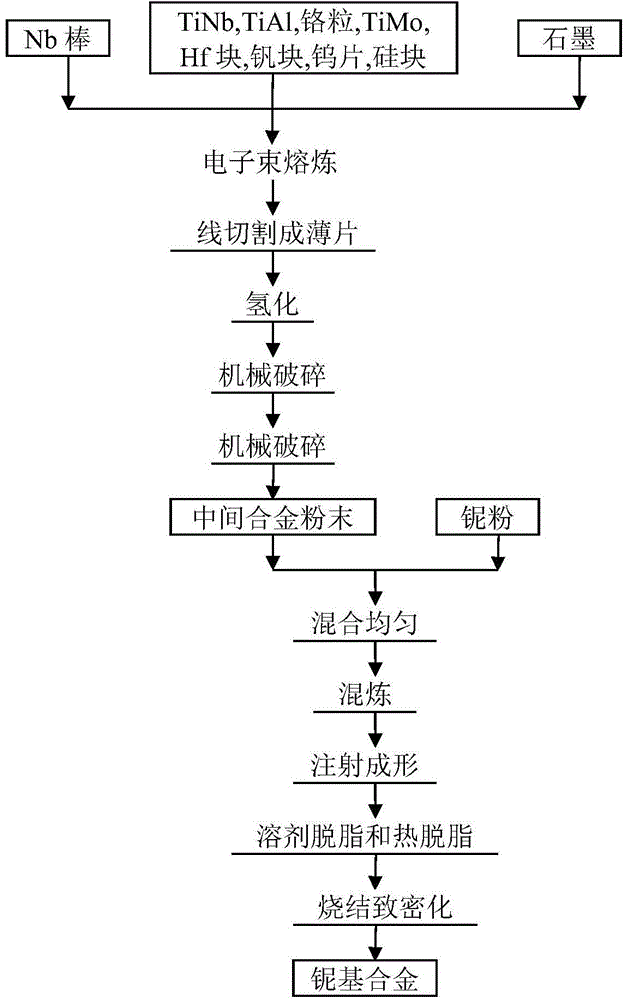

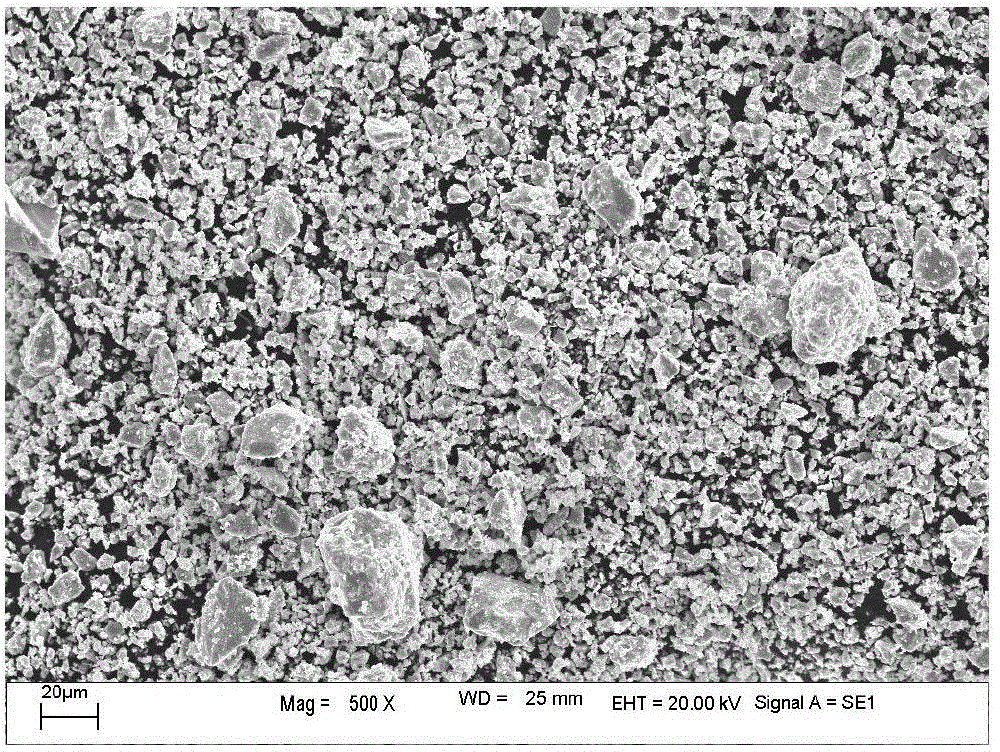

Low-cost method for preparing niobium-base alloy

The invention provides a low-cost method for preparing a niobium-base alloy, belonging to the technical field of refractory alloys. The method comprises the following steps: designing an interalloy according to the components of the target niobium-base alloy, and melting in an electron-beam melting furnace to obtain an interalloy cast ingot; after cutting the interalloy cast ingot into sheets, hydrogenating in high-purity hydrogen gas, and mechanically crushing to obtain fine-particle-size hydrogen absorption powder; carrying out partial dehydrogenation on the fine-particle-size hydrogen absorption powder in a vacuum atmosphere to obtain partially dehydrogenated interalloy powder; and uniformly mixing the partially dehydrogenated interalloy powder with niobium powder, mixing on a mixer to obtain a feed material with uniform rheological properties, forming the feed material on an injection molder, removing the adhesive by solvent degreasing and hot degreasing, and carrying out vacuum sintering to obtain the niobium-base alloy. The method has the advantages of low cost of the raw material powder and simple preparation technique.

Owner:UNIV OF SCI & TECH BEIJING

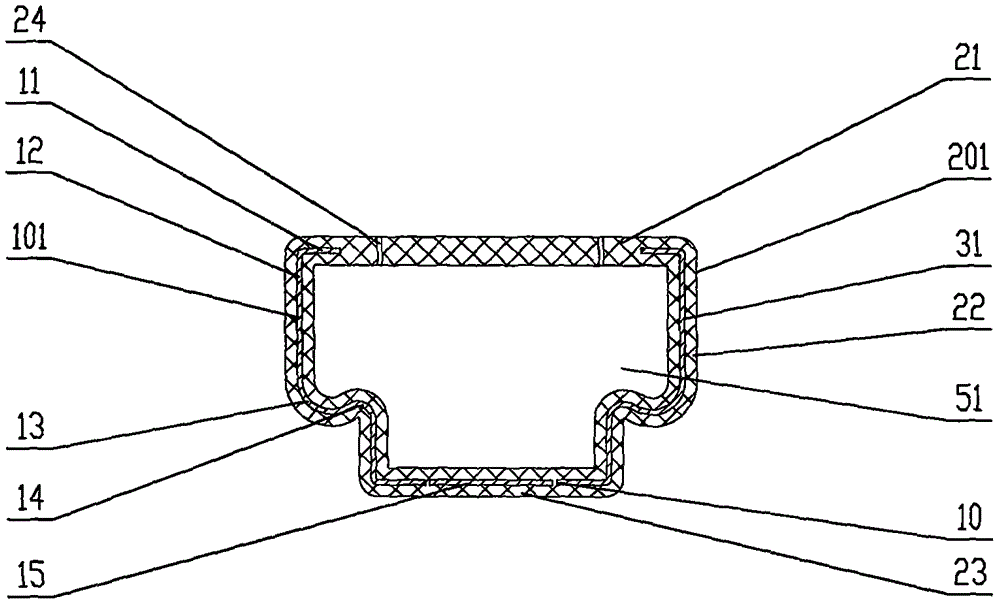

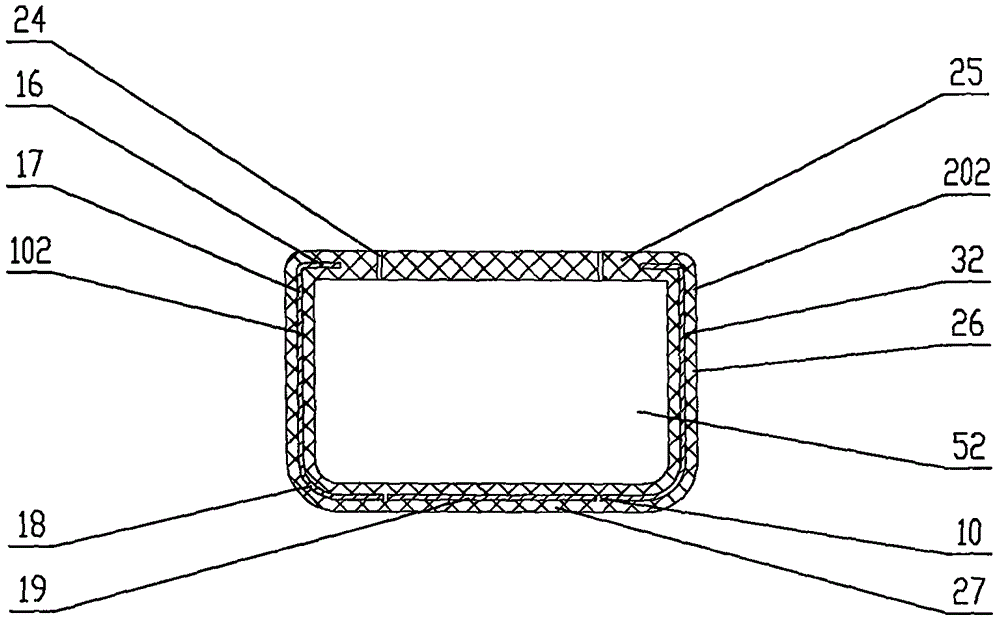

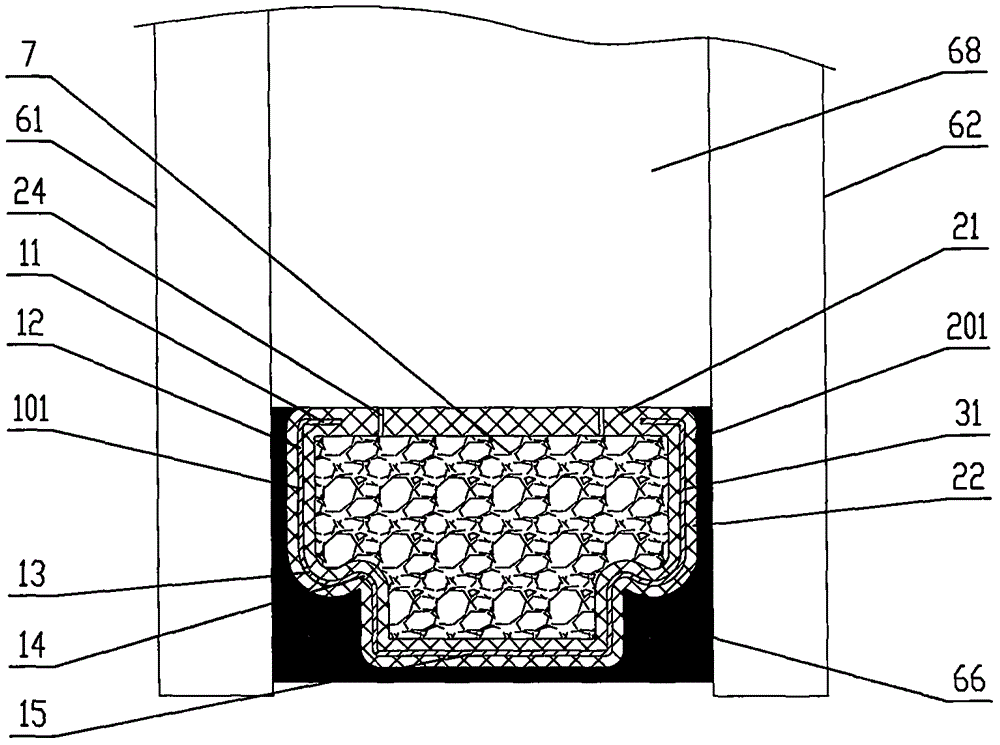

Hollow glass heat insulating strip and hollow glass

The invention discloses a hollow glass heat insulating strip and hollow glass which are mainly used for manufacturing hollow glass doors and windows and curtain walls for building heat preservation. The hollow glass heat insulating strip comprises a plastic layer, transition layers and a metal layer; the metal layer is a long strip-shaped U-shaped strip of which the upper end is provided with upper bending sections; a buffer region is a connection part of a bulging circular arc A and a recessed circular arc B or a bulging circular arc C part; solvent degreasing treatment or plasma surface degreasing treatment is performed on the metal layer before the transition layers are applied to the metal layer; the transition layers are respectively applied to the inner surface and the outer surface of the metal layer; the plastic layer wraps the transition layers; the plastic layer and the metal layer are bonded together by the transition layers. A moisture absorption molecular sieve is put in a space part of the hollow glass heat insulating strip of the hollow glass; the hollow glass heat insulating strip and cohesive glue are arranged along the circumferential edge of the glass; inert gas fills in a hollow part; the hollow glass is obviously increased in heat insulating property, sealing property and weather fastness.

Owner:DALIAN HUAGONG INNOVATION TECH

Method for regenerating wool keratin by L-cysteine

InactiveCN104861663ALow costEasy to operateMonocomponent protein artificial filamentFibre treatmentSolid componentDissolution

The invention relates to a method for regenerating wool keratin by L-cysteine. The method comprises the following steps: cleaning wool fiber, degreasing by ethanol-acetone mixed solvent, and shearing into pieces; adding the sheared wool fiber into L-cysteine composite fluid and sealing; oscillating at 65-85 DEG C for 3-8 hours, and obtaining wool keratin solution. Subsequently, performing thermal filtering, and taking filter fluid to dialyze; after dialyzing, adjusting pH value to 4.0-4.5, completely separating out keratin, centrifuging, freezing and drying solid component, and obtaining the wool keratin powder. The method for regenerating wool keratin by L-cysteine is simple and practicable; wool keratin powder with high molecular weight and high extraction ratio is prepared by adopting the dissolution of L-cysteine with low cost and precipitation of acetic acid. The prepared keratin powder is stable and can be stored for a long time; the powder can be applied to trauma medicine science; besides, the keratin powder can be dissolved by proper solvent and the keratin powder performs the composite spinning with the other polymers. The method for regenerating wool keratin is applied to the organization engineering, etc.

Owner:DONGHUA UNIV

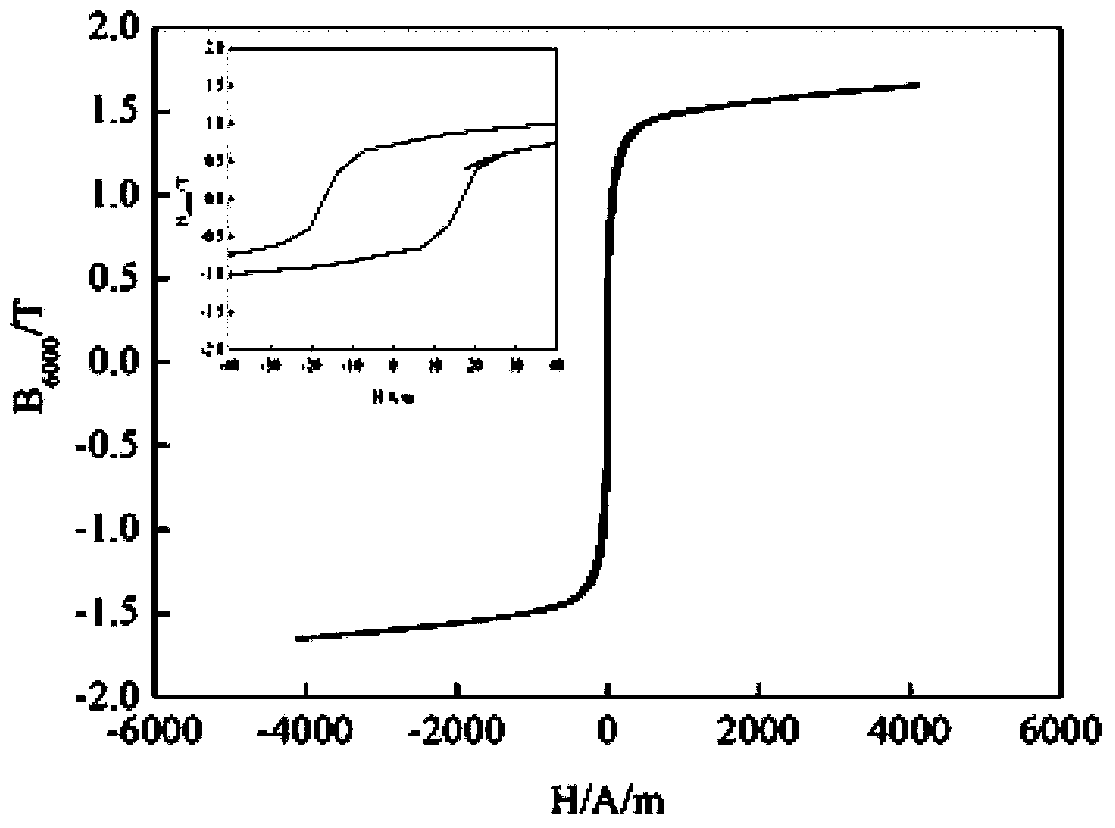

Method of producing high-performance complex-shape pure iron soft magnetic products

The invention relates to a method of producing high-performance complex-shape pure iron soft magnetic products and belongs to the field of powder metallurgy. The method includes the steps of using carbonyl iron powder as raw material, well mixing the carbonyl iron powder with proper binder to obtain well rheological feed, making the feed into complex-shape blanks by means of powder injection moulding, removing the binder from the injected blanks by solvent degreasing and thermal degreasing, sintering the degreased blanks at the temperature of 1400-1500 DEG C to obtain pure iron soft magnetic products high in density, high in performance and complex in shape. The method has the advantages that the pure iron soft magnetic products larger than 99% in density, larger than 1.75T in magnetic induction intensity B5000, smaller than 35A / m in coercivity and larger than 15mH / m in maximum magnetic permeability can be produced by powder injection moulding and phase change activated sintering; the products has the highest performance amongst pure iron soft magnetic materials produced by the existing powder injection moulding methods.

Owner:UNIV OF SCI & TECH BEIJING

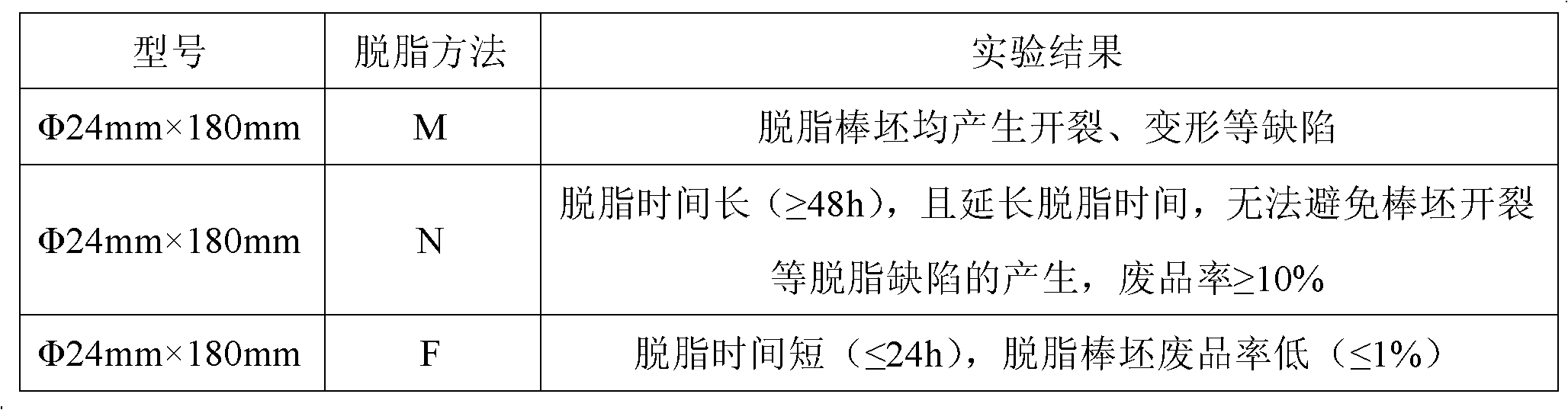

Quick zero-defect degreasing method for large-size extrusion forming blank

InactiveCN102248167AConvenient timeImprove degreasing poor shape retentionLarge sizeSolvent degreasing

The invention discloses a quick zero-defect degreasing method for a large-size extrusion forming blank, comprising the following steps of: feeding a formed blank into a solvent degreasing tank and adding a degreasing solvent at the same time, wherein the ratio of a liquid to a solid is 7:1-15:1; degreasing under the condition of constant temperature of 30-60 DEG C for 6-12h; taking out the degreased blank and drying the greased blank at the constant temperature of 30-50 DEG C for 0.5-1h; replacing the degreasing solvent and drying; repeating 2-3 times until the mass loss of a binding agent reaches 60-75 percent; and feeding a solvent greasing blank in a high-temperature degreasing furnace and raising the temperature to 600-850 DEG C in the atmosphere of vacuum or negative pressure to obtain the zero-defect large-size degreasing blank. According to the quick zero-defect degreasing method disclosed by the invention, the defects of long degreasing time of the large-size forming blank, poor degreasing shape retention and more greasing defects are overcome; in addition, two adopted degreasing processes are simple, easy to control and are widely applied in actual production.

Owner:CENT SOUTH UNIV

Injection molding process of AZ91 Mg alloy

The injection molding process of AZ91 magnesium alloy belongs to the field of magnesium alloy forming technology. The injection molding process includes the following steps: mixing AZ91 magnesium alloy powder in size of 47 micron and water soluble adhesive of PEG and PMMA in certain ratio, pelletizing, injection molding, solvent defatting and heat defatting to eliminate adhesive, and sintering at 580-620 deg.c under inert gas protection to obtain the product. The present invention has the advantages of low cost and capacity of producing magnesium alloy of complicated shape and excellent performance.

Owner:UNIV OF SCI & TECH BEIJING

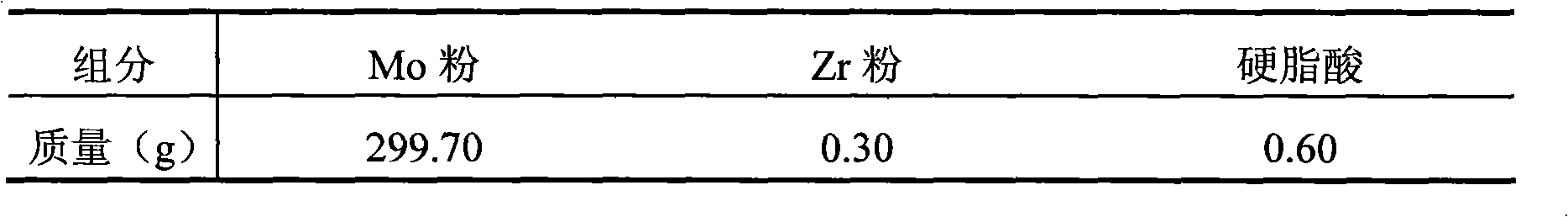

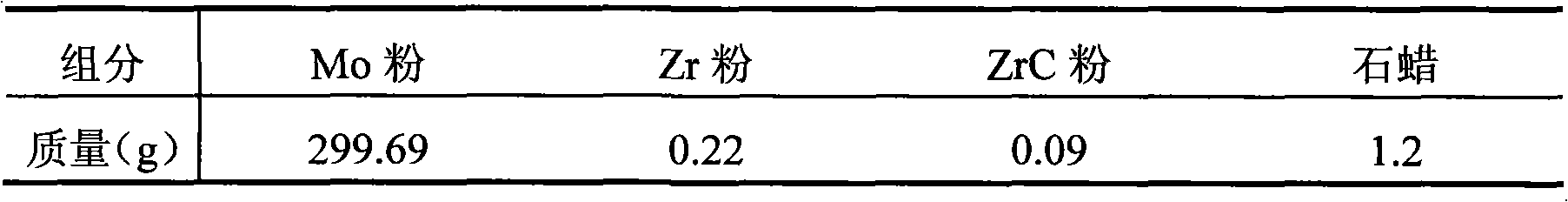

Method for producing molybdenum alloy gas vane with powder injection forming

InactiveCN101293280ALow densityImprove ductilityTurbinesOther manufacturing equipments/toolsAlloySolvent degreasing

A powder injection molding method is adopted to prepare molybdenum alloy gas vane with a complicated shape. Mechanical alloying is adopted in the invention for high performance ball grinding of Mo powder and one or multiple powders of Ti, Zr, Hf, Re, TiC and ZrC with the mass percent of 0.05-1.5%, and the even molybdenum pre-alloy powder is prepared; the molybdenum pre-alloy powder and an organic binder bond are mixed for preparing even feed, and the feed is injected through an injection machine to form a gas vane injection billet; after the gas vane injection billet is degreased by solvent, degreasing, carbon control and presintering are carried out in a thermal decreasing furnace; finally, high sintering is carried out on the samples after the samples are presintered, and the molybdenum alloy gas vane with high performance is prepared.

Owner:CENT SOUTH UNIV

Preparation method for hard alloy products by injection molding

The invention provides a preparation method for hard alloy products by injection molding. The preparation method mainly comprises the following steps: (1) mixing: hard alloy powder is mixed with adhesive to prepare an injection filler; (2) injection molding: the filler is in injection molding through an injector; (3) degreasing: solvent is degreased to remove part adhesive; (4) dewaxing and sintering: the dewaxing and the pre-sintering are performed in a sintering furnace; and (5) hot isostatic pressure sintering: the high-temperature and high-pressure sintering is performed in a hot isostatic pressure sintering furnace to obtain a compact product. The preparation method can be used for preparing the hard alloy products with various complex shapes through the injection molding process, holes can be eliminated through hot isostatic pressure sintering, and the bending strength and the fracture toughness are improved.

Owner:洛阳暖盈电子技术有限公司

Method for preparing electric vacuum suction element molded by powder injection

ActiveCN101290851AMeet shape requirementsMeet the dimensional accuracy requirementsElectric discharge tubesTube/lamp vessel degassingElectricityPorosity

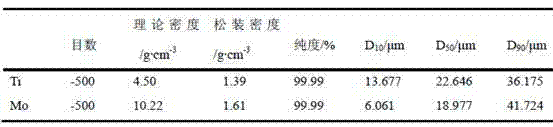

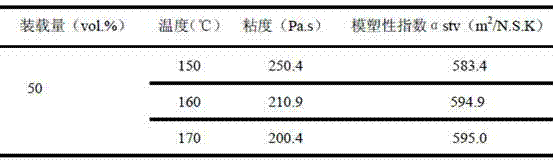

The invention provides a method for preparing an electric vacuum inspiration element by using powder injection molding, which belongs to the electric vacuum inspiration element manufacturing technical field. The preparation technology is as follows: Ti powder and Mo powder taken as raw materials are mixed in a mixer, the evenly-mixed raw material powder and adhesive are mixed according to the volume ratio, mixed in a mixing roll, cooled, then crushed into injection feedstock, and subject to the injection molding, two-step debinding process treatment is adopted to a blank formed by the injection molding, the blank formed by the injection molding undergoes solvent debinding and vacuum thermal debinding then, and finally vacuum sintering is carried out to the debound blank to prepare the vacuum inspiration element. The method has the advantages that: the method can prepare the inspiration elements with complicated shape and high dimension accuracy to meet the requirement of spaces with various shapes of various electric vacuum devices to the complicated shape and the dimension accuracy of the inspiration elements. The aperture and the degree of porosity of the product are evenly controlled, and the degree of porosity of the inspiration element can reach more than 50 percent.

Owner:GRIMAT ENG INST CO LTD

Preparation technology for high-purity medicinal soyabean lecithin

ActiveCN108066768AHigh yieldImprove the purity of phosphatidylcholinePharmaceutical non-active ingredientsMicroorganismSolvent degreasing

Different from the prior art, a preparation process for high-purity medicinal soyabean lecithin comprises the steps of solvent degreasing, solvent extracting, precipitating, filtering, low-temperaturevacuum desolventizing and drying, wherein purity of phosphatidylcholine in soyabean lecithin is greatly improved through a first solvent extraction process, a second solvent extraction process and asettling process; microorganisms are filtered through a micromembrane, so that the integral yield of high-purity medicinal soyabean lecithin is high, impurity and microorganism content is extremely low, and pharmacopeia standards are met; besides, processes such as adsorbent adsorption purification and adsorbent discoloring can be flexibly added, so that injection-grade high-purity soyabean lecithin is produced.

Owner:JIANGSU MANSHI BIOTECH

Preparation method of swing block of air compressor

ActiveCN109277574ALow costHigh tensile strengthTransportation and packagingMetal-working apparatusGas compressorAir compressor

The invention discloses a preparation method of a swing block of an air compressor. The preparation method comprises the following steps: mixing a 440C stainless steel powder matrix material with a binder to prepare a uniform feed; injecting the feed into a cavity by means of an injection molding technique to obtain a product blank; and then carrying out solvent degreasing and thermal debinding processes on the binder in the blank and carrying out sintering densification, and finally carrying out heat treatment intensification to obtain the swing block product of an the compressor. Compared with the prior art, the swing block of the air compressor produced by the metal injection molding technique has the characteristics of being high in processing efficiency, high in dimensional precision,low in production cost and easy to achieve production automation, a product which is excellent in performance and stable in quality can be prepared, the tensile strength exceeds 850 MPa which is 60%better than that of a similar product and achieves the international advanced level, and the demands of client can be met well.

Owner:湖南英捷高科技有限责任公司

Manufacturing method for copper alloy part

The invention relates to a manufacturing method for a copper alloy part. The manufacturing method comprises the following steps that firstly, mixing is conducted, copper alloy powder and a bonding agent are mixed, and injection feed is manufactured; secondly, injection forming is conducted, and the feed is subjected to injection forming through an injection machine; thirdly, degreasing is conducted and includes solvent degreasing and thermal degreasing; fourthly, sintering is conducted, and sintering densification is conducted in a sintering furnace; and fifthly, sintering post treatment is conducted, and a finished product is obtained through machining shaping. The manufacturing method overcomes the defects that in traditional preparing methods such as casting and powder metallurgy die pressing, the machining period is long, parts with the complex shapes are hard to form, size precision cannot be guaranteed, and the machining cost is high, special-shaped products with the complex appearances and the small sizes and the special-shaped parts with the complex shapes can be produced on a large scale, and the manufacturing method is suitable for industrial production.

Owner:洛阳新巨能高热技术有限公司

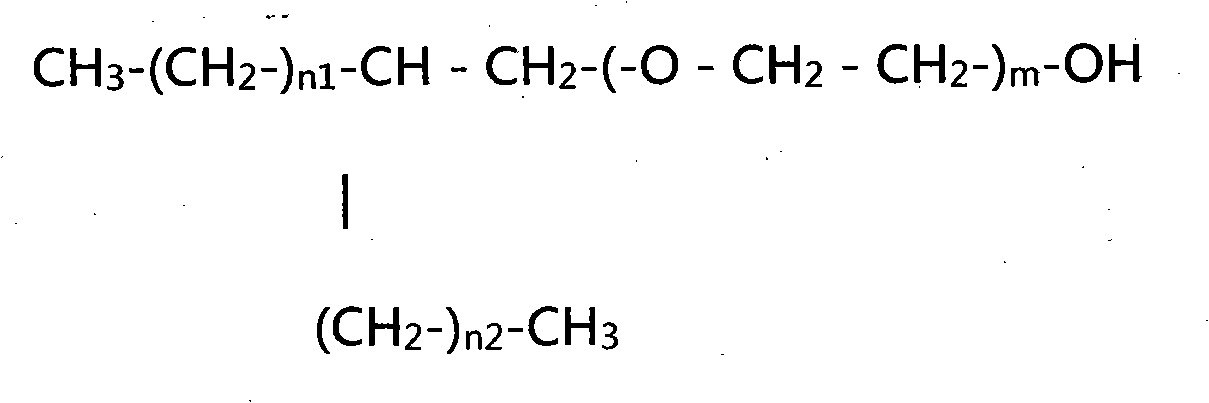

Surface-modified zirconium oxide injection molding solvent degreasing feed as well as preparation method and application thereof

The invention belongs to the technical field of zirconium oxide ceramic injection molding, and particularly relates to surface-modified zirconium oxide injection molding solvent degreasing feed as well as a preparation method and an application thereof. A feed is prepared from modified zirconium oxide powder and a binder, and the mass ratio of the modified zirconium oxide powder to the binder is (82-91): (9-18); wherein the mass ratio of a surfactant to skeleton resin to elastomer resin to a lubricating aid to a plasticizer in the binder is (3-6): (25-35): (8-15): (38-61): (3-6); after modification, the surface of the zirconium oxide powder is alkaline, and the zirconium oxide powder can be better combined with an acidic surfactant. According to the invention, the adopted binder has good compatibility, the skeleton binder has good supporting performance on the strength of a green body at a high temperature, and the binder adopts a plurality of different components, so that the use requirements of different products can be met; meanwhile, the preparation method provided by the invention is more beneficial to uniform mixing of the modified zirconium oxide powder and the binder.

Owner:长裕控股集团股份有限公司

High-strength turbocharger spray nozzle ring blade and preparation method thereof

ActiveCN109513930AHigh temperature strengthImprove performanceTransportation and packagingMetal-working apparatusInjection pressureThermal fatigue

The invention discloses a high-strength turbocharger spray nozzle ring blade and a preparation method thereof and belongs to the technical field of production of vehicle-purpose turbocharger spray nozzle ring blades. According to the high-strength turbocharger spray nozzle ring blade and the preparation method thereof, the method comprises the steps that HK30 stainless steel gas atomized powder and adhesive are adopted, wherein an enhancer accounting for 0.8-1.5 % of the weight of the stainless steel gas atomized powder is added into the HK30 stainless steel gas atomized powder; the HK30 and enhancer powder and the adhesive are weighed according to the mass ratio of (80-95)%:(20-5)% and are subjected to mixing, cooling and crushing, and then feed is prepared; the prepared feed is injectedinto an injection moulding machine, and a blank is injection moulded, wherein the injection temperature is 140-175 DEG C, the injection pressure is 60-120 MPa, and the mould temperature is 30-60 DEG C; and after the blank is subjected to solvent degreasing and heating degreasing combined treatment, treatment of presintering and sintering procedures is performed to obtain a finished product. The high-strength turbocharger spray nozzle ring blade provided by the invention is high in product size precision and surface precision, high in product thermal fatigue resistance, and long in product service life under high-temperature strength conditions.

Owner:湖南英捷高科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com