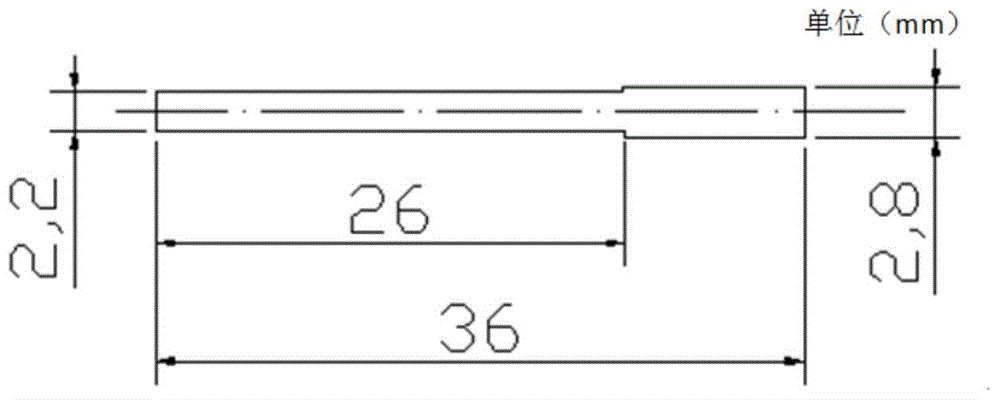

Large-length-diameter-ratio ultrafine grain hard alloy step-shaped bar and preparation method

A cemented carbide, large aspect ratio technology, applied in the field of powder metallurgy, to reduce processing difficulty, save mineral resources, and solve the effect of uneven distribution of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

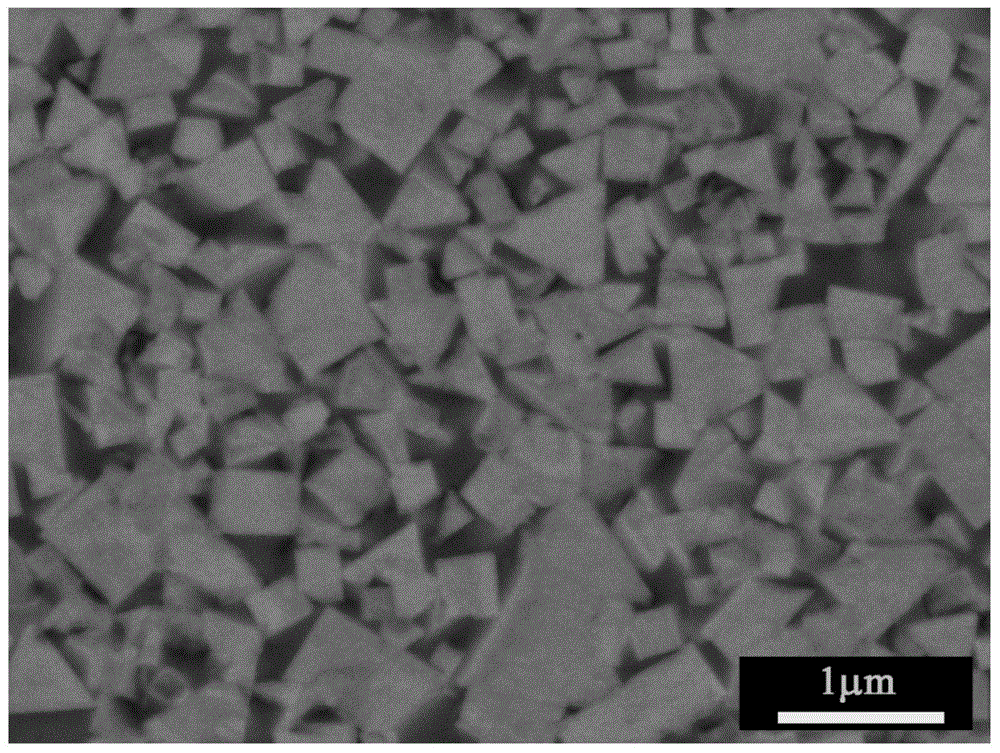

[0027] A preparation method of ultra-fine-grained WC-10Co cemented carbide stepped rod with large aspect ratio:

[0028] (1) Will contain vanadium carbide (VC, 0.35wt%), chromium carbide (Cr 3 C 2 , 0.45wt%) superfine tungsten carbide powder and cobalt powder are added in proportion to the ball mill irrigation, wet milled for 30h, vacuum dried after discharge, and sieved with 320 meshes to obtain the mixture powder; wherein the superfine tungsten carbide powder BET particle size is 0.60μm, Co content is 10%;

[0029] (2) choose each component of wax-based binder to form and the mass percentage composition of each component to be: wax is the high-purity paraffin wax of Thiel hard alloy, accounts for 63% altogether; Macromolecular polymerization is high-density polyethylene, Polypropylene and ethylene-vinyl acetate copolymer account for 30% in total; low-molecular coupling agents are stearic acid and dioctyl phthalate, accounting for 7% in total.

[0030] (3) Mix the wax-base...

Embodiment 2

[0036] A method for preparing an ultra-fine-grained WC-12Co cemented carbide stepped rod with a large aspect ratio:

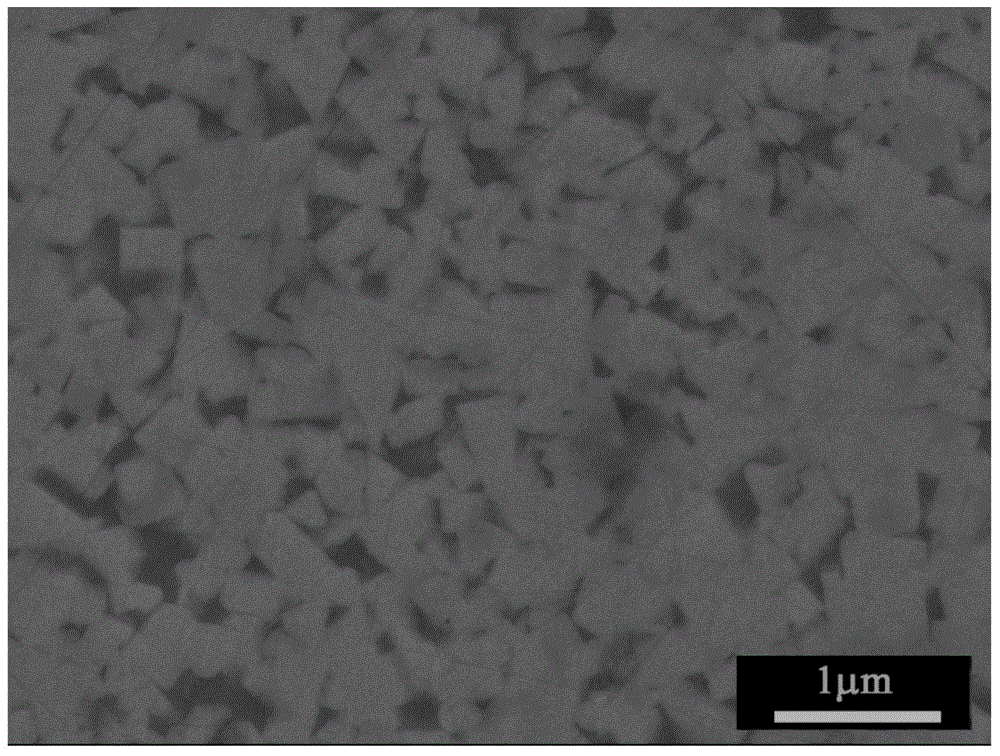

[0037] (1) will contain chromium carbide (Cr 3 C 2 , 0.35wt%) superfine tungsten carbide powder and cobalt powder are added in proportion to the ball mill irrigation, wet milled for 48h, vacuum-dried after discharging, and sieved with 320 orders to obtain the mixture powder; wherein the superfine tungsten carbide powder BET particle size is 0.32μm, Co content is 12%;

[0038] (2) choose each component of wax-based binder to form and the mass percentage composition of each component to be: wax is the high-purity paraffin wax of Thiel hard alloy, accounts for 63% altogether; Macromolecular polymerization is high-density polyethylene, Polypropylene accounts for 30% in total; low-molecular coupling agents are stearic acid and dioctyl phthalate, accounting for 7% in total.

[0039](3) Mix the wax-based binder in step (2) with the mixture powder obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com