Patents

Literature

238results about How to "Save mineral resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

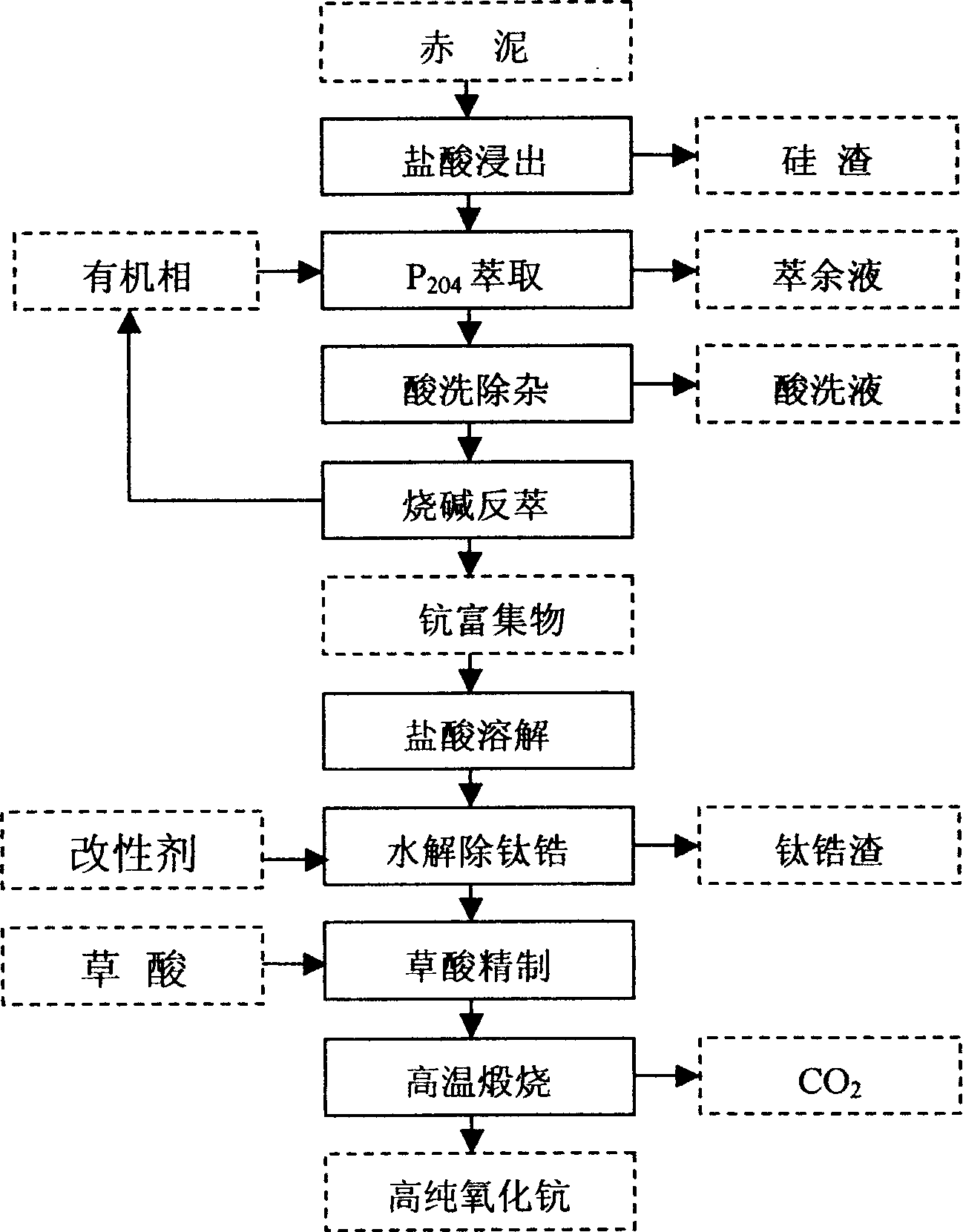

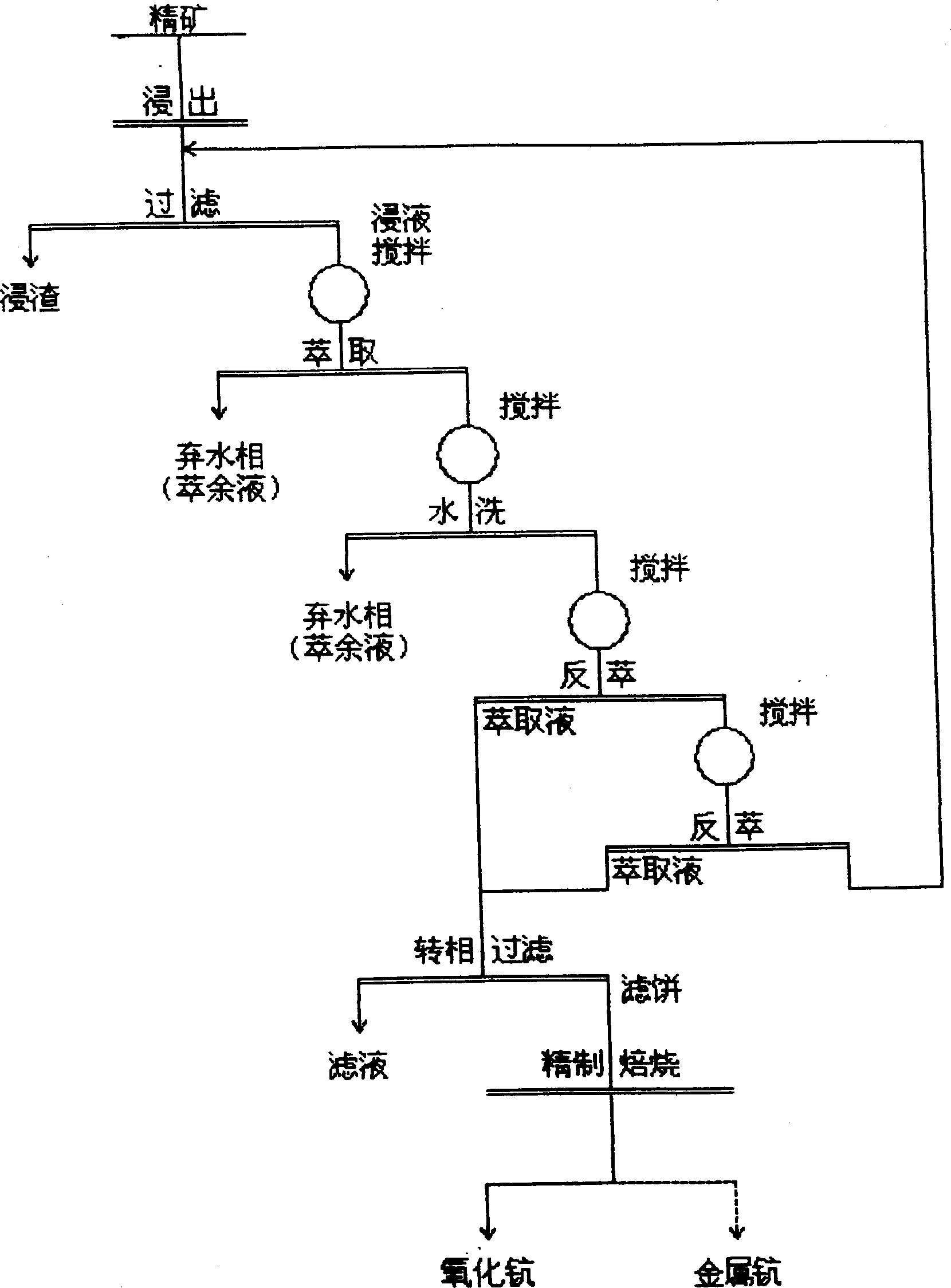

Method for extracting scandium from red mud

InactiveCN1844421AImprove protectionSimple processProcess efficiency improvementRed mudDecomposition

The invention relate to a method of extracting scandium from red mud, the method utilize the red mud that come from the process of producing aluminum oxide from alumyte, in accordance with specific characteristics of red mud, applying hydrochloric acid leach, P204 abstraction, acid-washing edulcoration, sodium-hydroxide back extraction, ammonia modifier hydrolytic decomposition zirconium and titanate in hydrochloric acid solution, oxalic acid precipitating scandium and medium temperature calcining technique, the purity of final production Sc2O3 is 99.9%. Extracting scandium from red mud change refuse into available material, save mineral resources, benefiting environmental conservation. The invention also fills up the study vacant of isolation technique in high-strength zirconium titanate and scandium.

Owner:汪友华

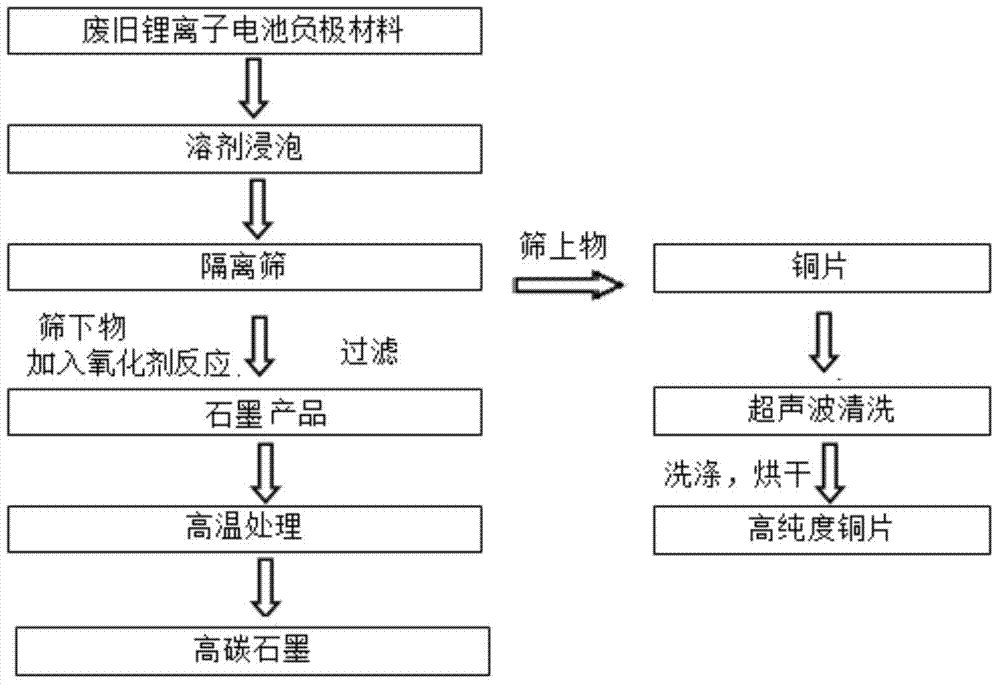

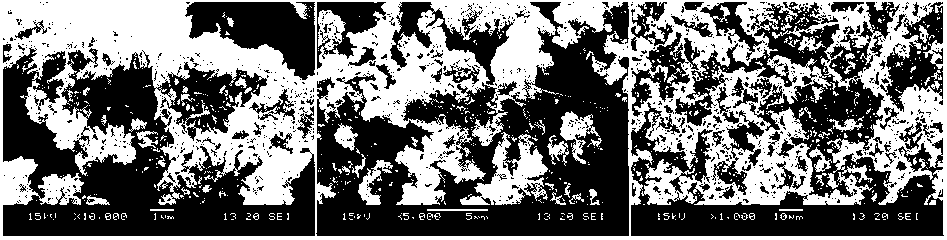

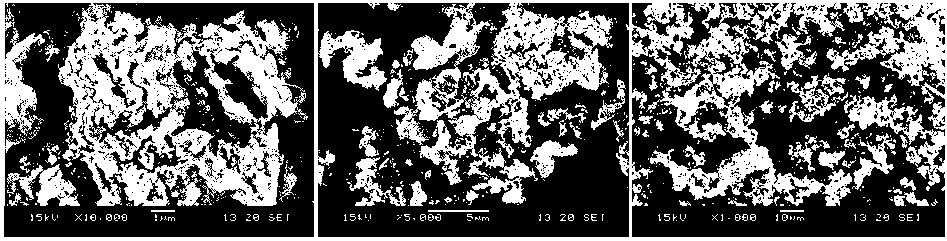

Method for separating and recycling graphite and copper sheets in negative pole materials of waste lithium ion batteries

ActiveCN103618120AReduce pollutionSimple processWaste accumulators reclaimingBattery recyclingGraphiteAdditional values

The invention discloses a method for separating and recycling graphite and copper sheets in negative pole materials of waste lithium ion batteries. The method comprises the steps of (1) separating graphite from copper sheets; (2) removing a separating solvent on the copper sheets; (3) removing impurities in crude graphite products; and (4) processing the graphite products at high temperature so as to obtain high purity copper sheets and high-carbon graphite finally. The method has simple steps, the raw materials are abundant and cheap, the recovery rate and additional value of the products are high.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

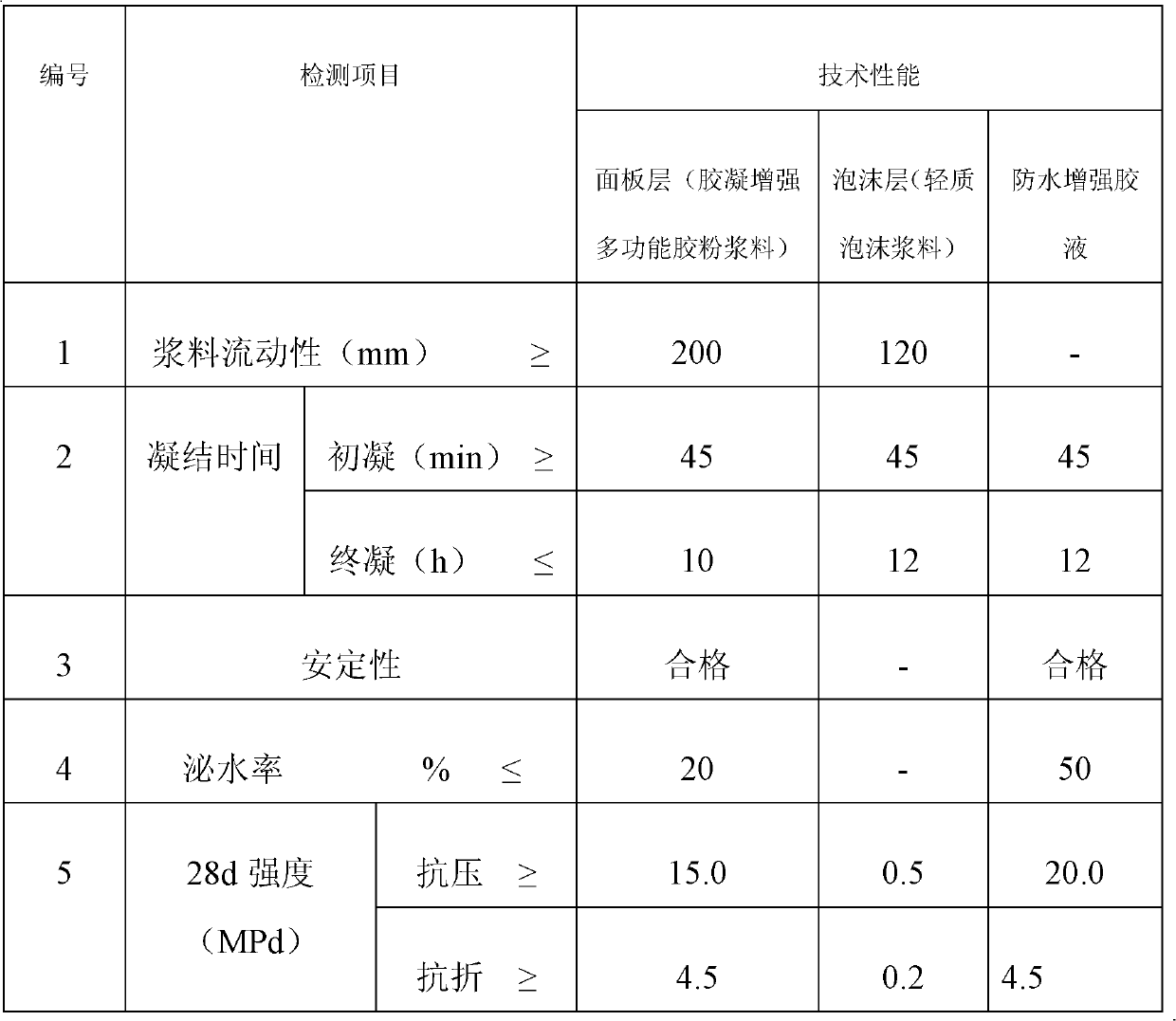

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

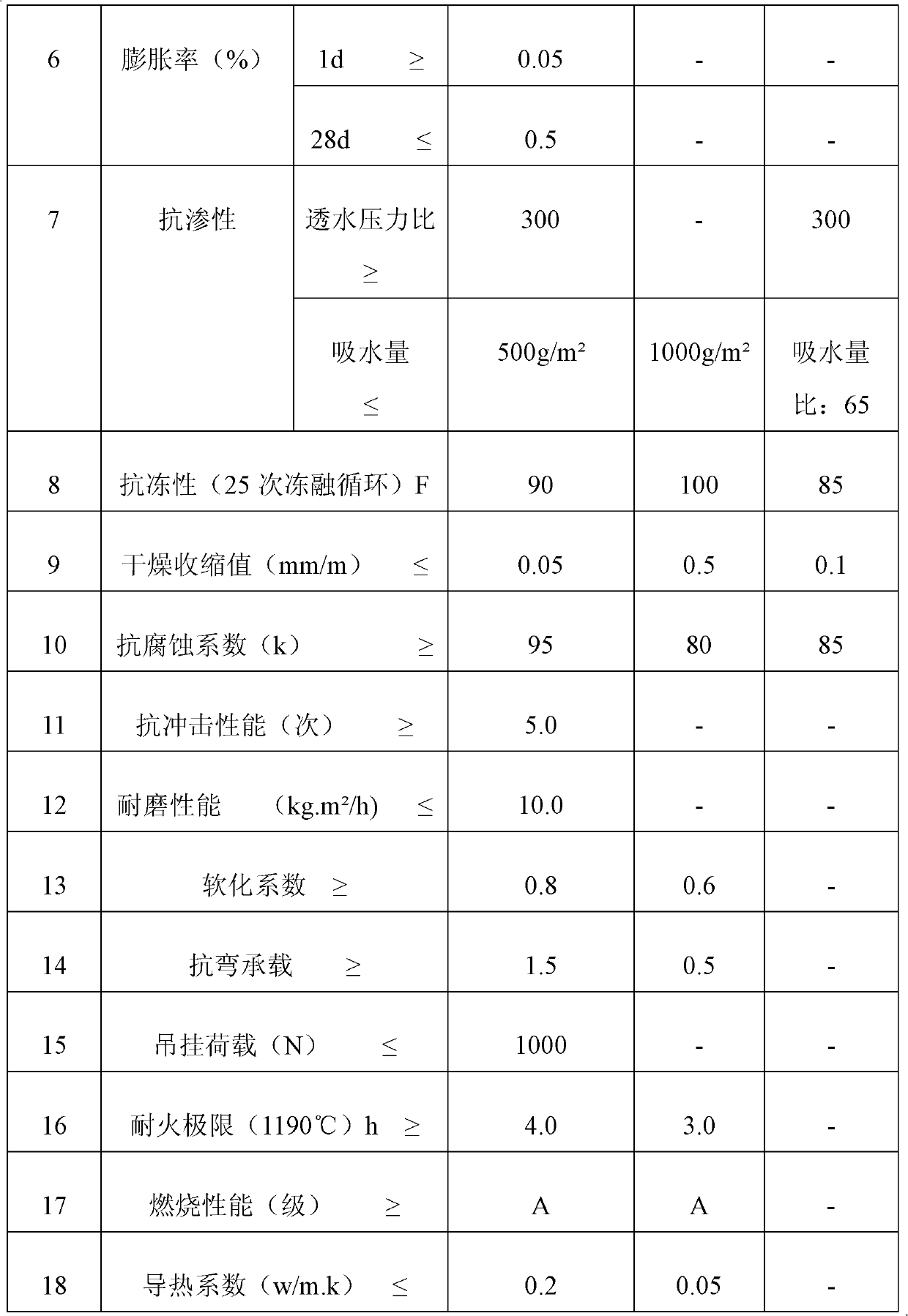

Anticorrosion expansion compacting agent composition and preparation method thereof

The invention relates to an anticorrosion expansion compacting agent composition and a preparation method thereof; the composition comprises the following components by weight: 15-35% of aluminium-containing compounds, 0-8% of zirconium-containing compounds, 2-10% of magnesium salts, 0-3% of titanium dioxide compounds, 0-6% of lithium salts, 2-6% of alkanolamine salts, 0-10% of super-plasticizers, 0-10% of solidification adjusting agents, 0-5% of acids, and the balance of carriers. The components are reacted in a reaction vessel at 80 DEG C+ / -5 DEG C for 3 hours, and then cooled to 45 DEG C+ / -5 DEG C; thermal insulation is performed for one hour; and anticorrosion expansion compacting agents of a standard type, a solidification-promoting type, or a pumping slow-solidifaction type are obtained according to the added solidification adjusting agents with different types and amounts.

Owner:苏琳

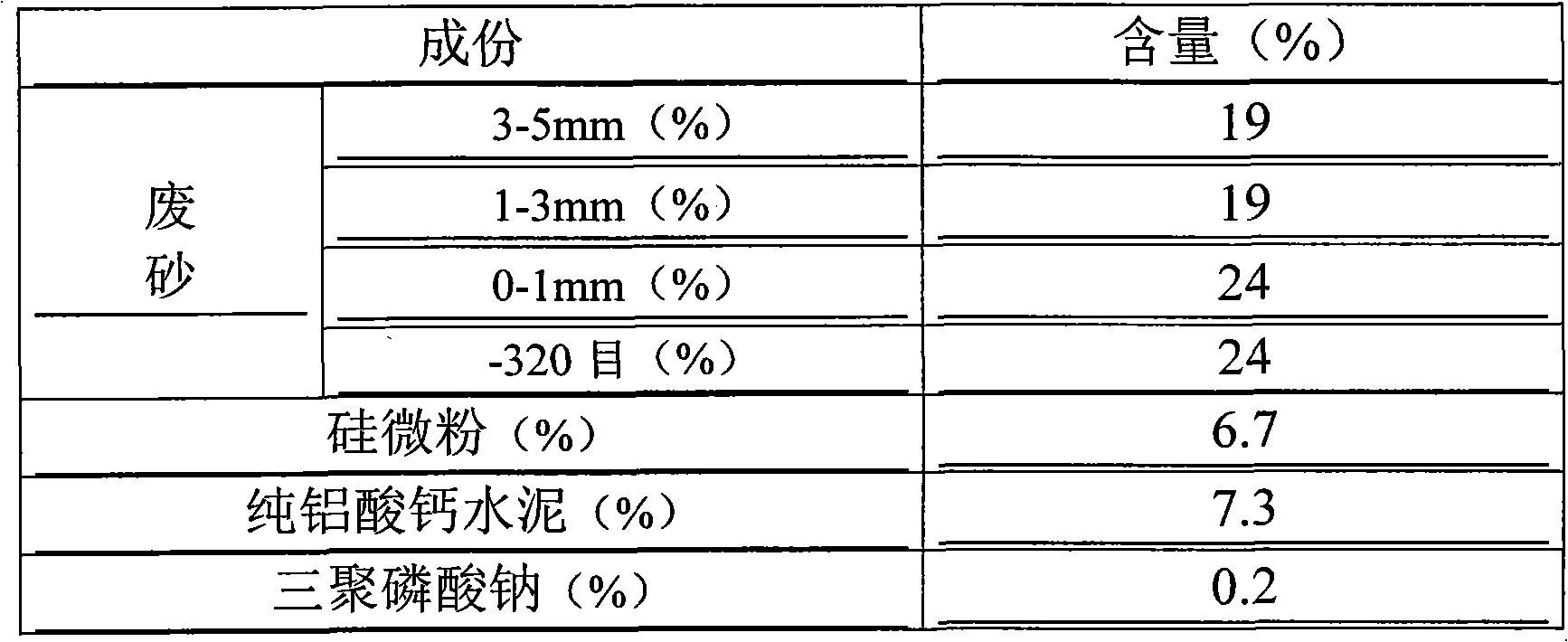

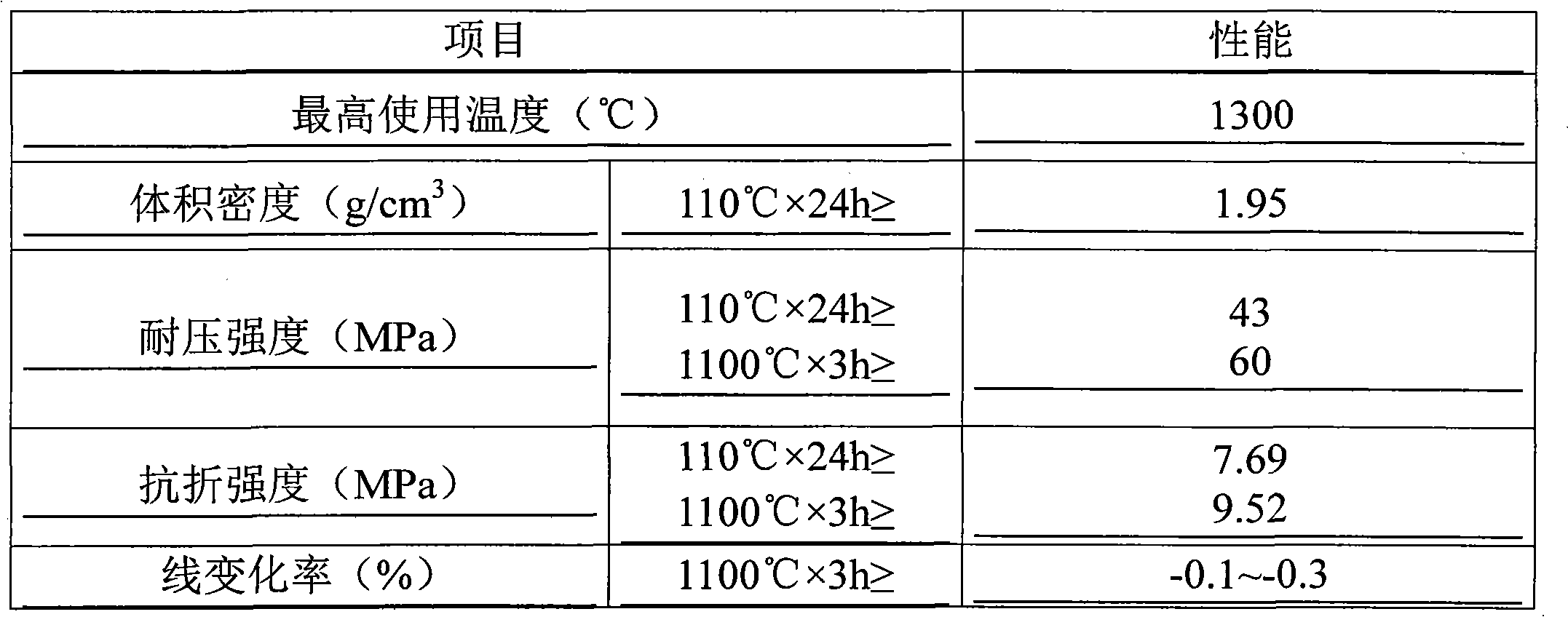

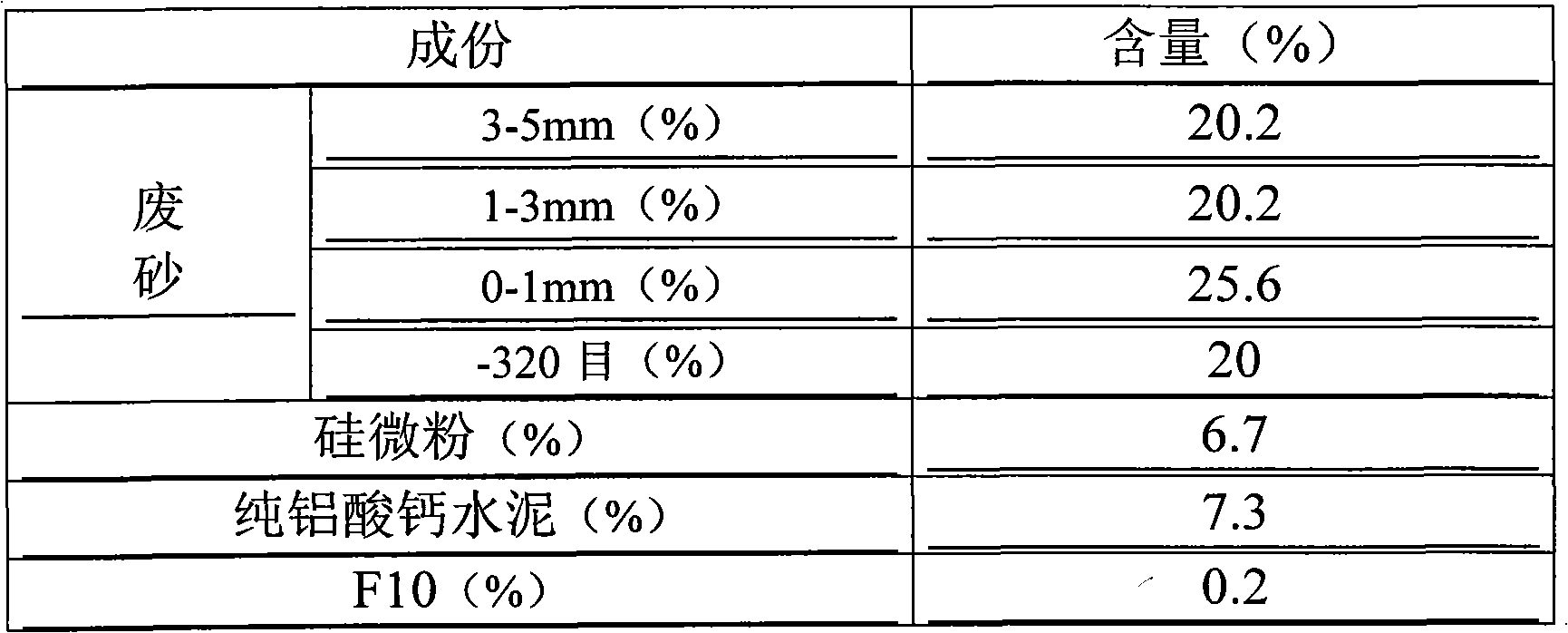

Precision casting waste sand reusing method

ActiveCN101870562AReduce manufacturing costSolve pollutionSolid waste managementSolid waste disposalMulliteRefractory

The invention relates to the waste reusing technology, in particular to a precision casting waste sand reusing method. The precision casting waste sand contains mullite, mullite sand, zirconite and zircon sand. The precision casting waste sand is cleaned, dried, crushed and screened to form aggregate and powder for a fireproof casting material; and a bonding agent and an admixture are added into the aggregate and the powder, and the components are mixed and homogenized to form the fireproof casting material. The method solves the problem that the conventional precision casting waste sand pollutes the environment.

Owner:泰州枫叶冶金设备有限公司

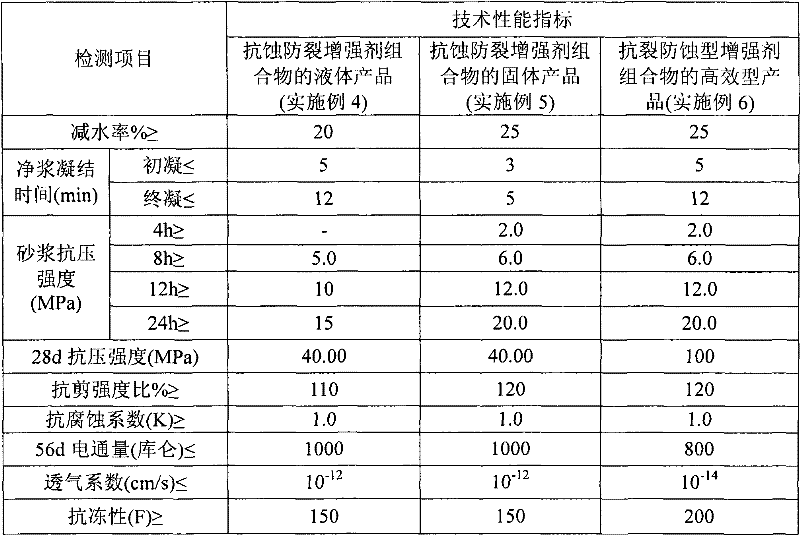

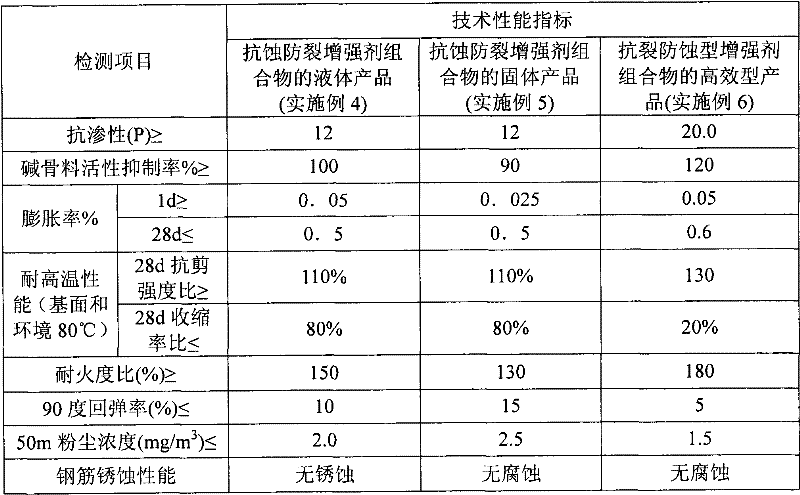

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

Aluminium-magnesia carbon brick and preparation method thereof

The invention provides an aluminium-magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the aluminium-magnesia carbon brick include 30-80 parts of waste aluminium-magnesia carbon brick grains, 3-40 parts of special grade bauxite chamotte, 3-10 parts of magnesia, 3-10 parts of magnesia-alumina spinel, 5-8 parts of graphite, 3-15 parts of micro powder additives and 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste aluminium-magnesia carbonbricks from the steel mills and then mulling the waste aluminium-magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the aluminium-magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion andservice life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

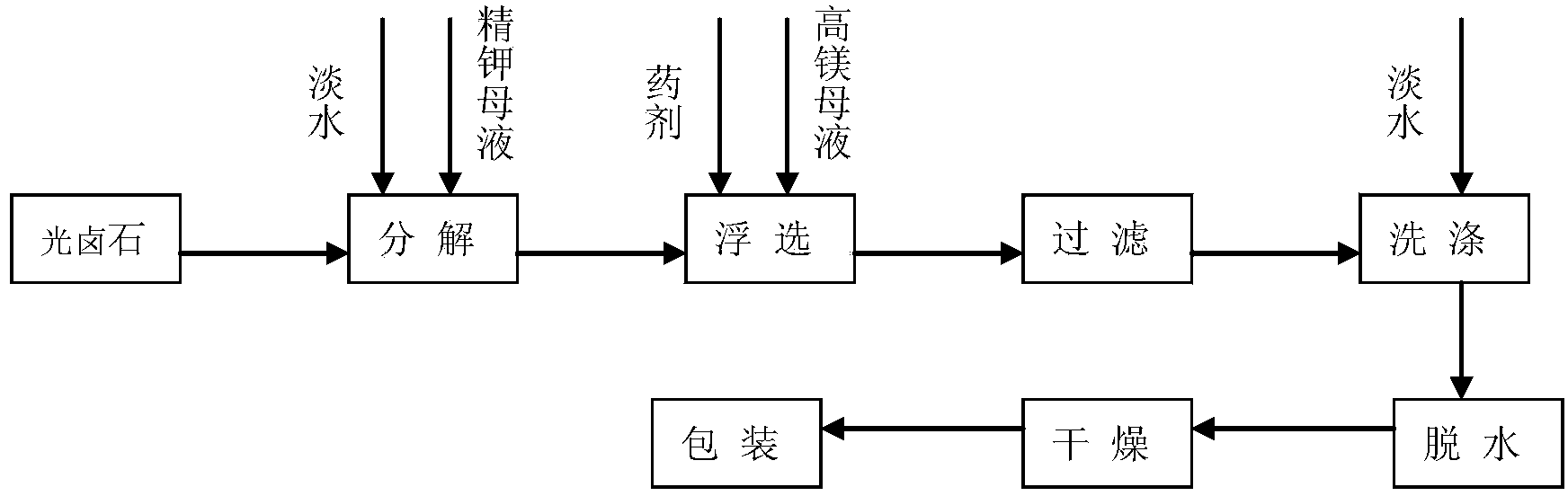

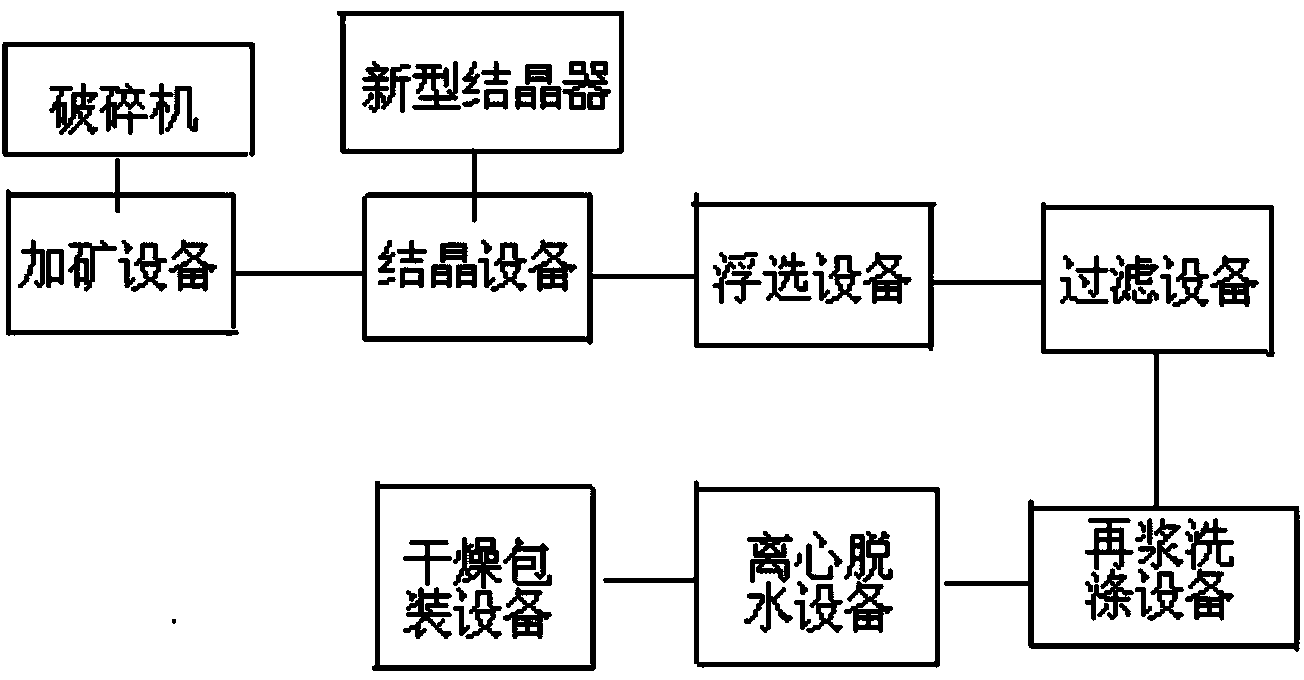

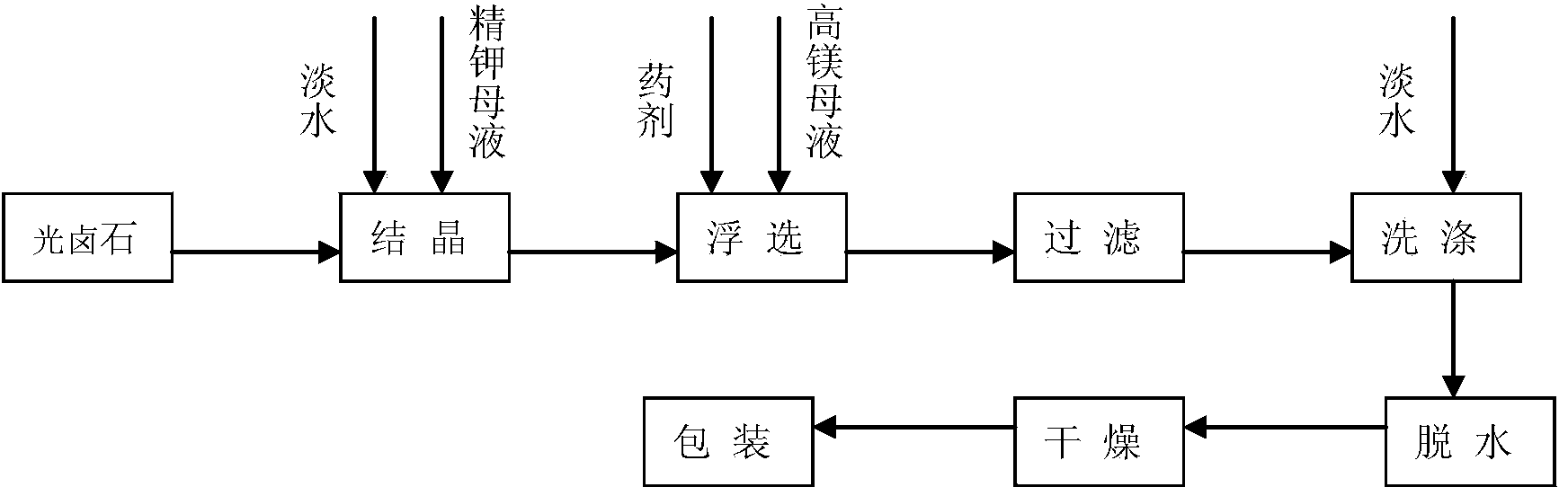

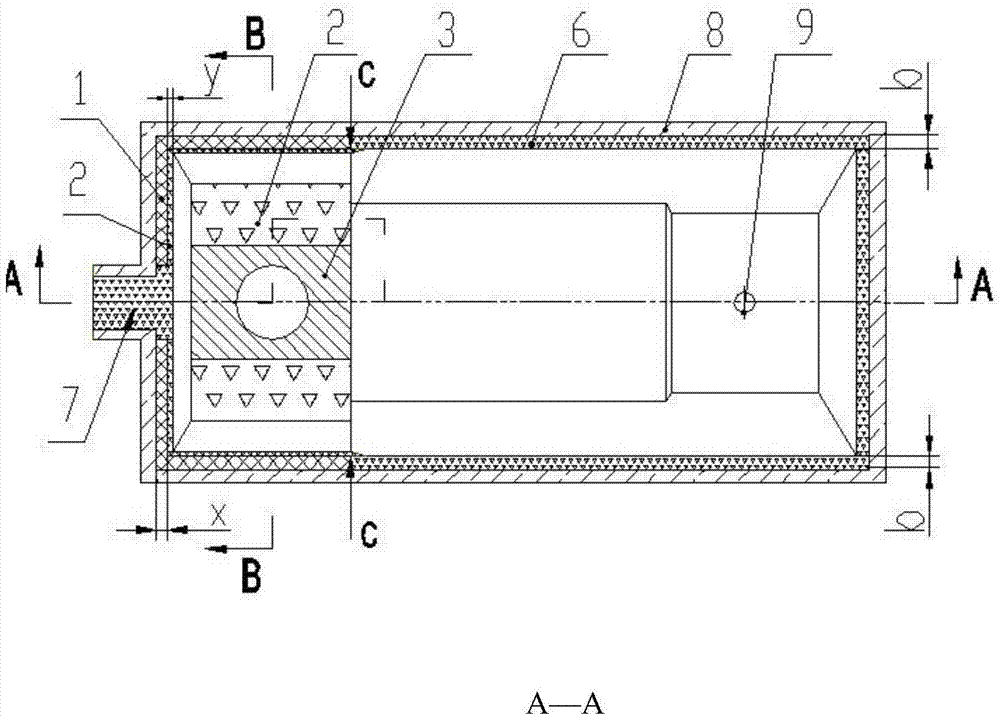

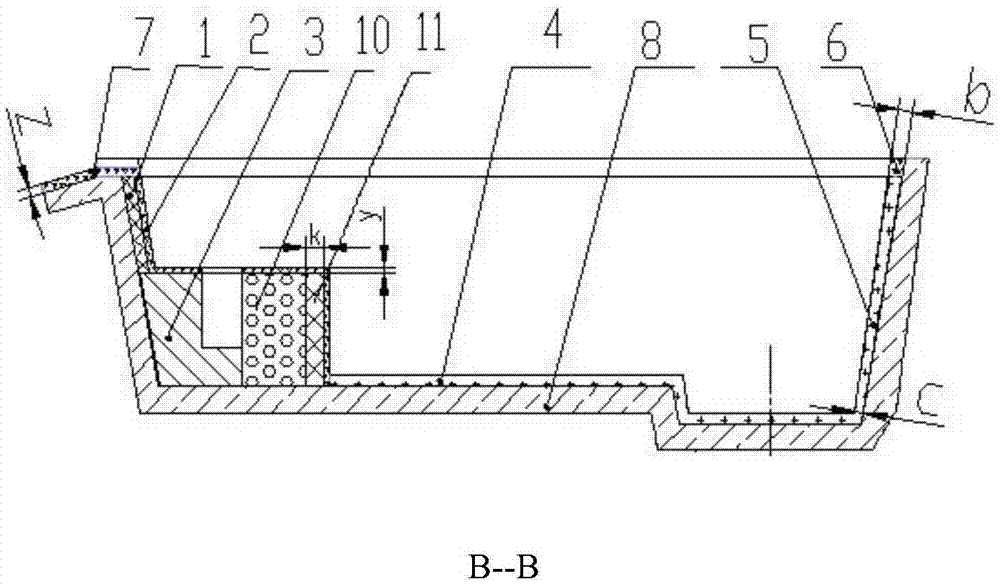

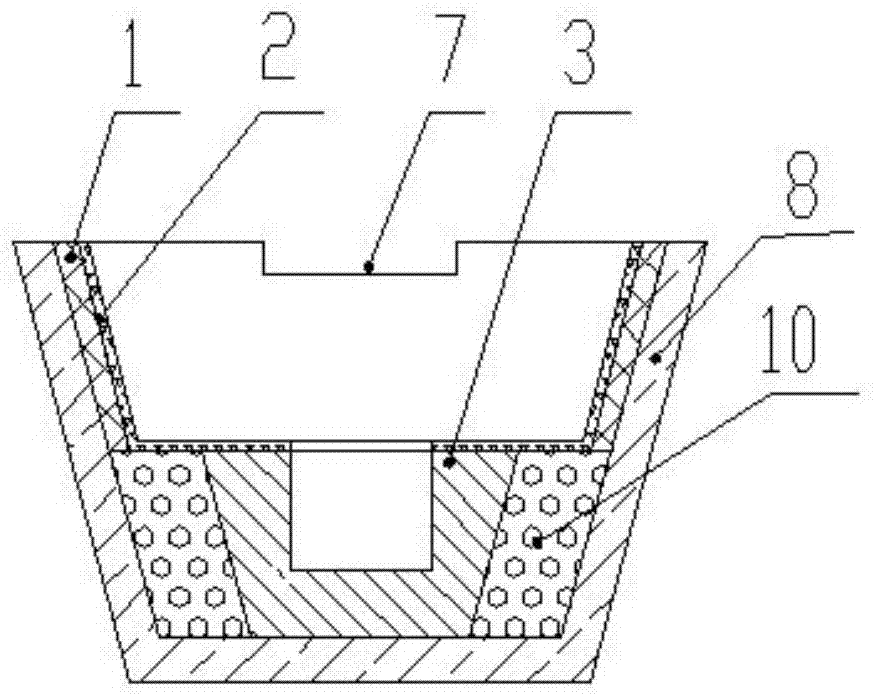

Novel system and method for producing potassium chloride by utilizing carnallite

ActiveCN104058428AHigh recovery rateRealize learning from each otherAlkali metal chloridesDecompositionFiltration

The invention discloses a novel system and method for producing potassium chloride by utilizing carnallite. The novel system for producing the potassium chloride by utilizing the carnallite comprises ore adding equipment, crystallization equipment, floatation equipment, filtration equipment, repulping and washing equipment, centrifuging and dehydrating equipment and drying and packaging equipment which are sequentially connected; a crushing machine is added on the ore adding equipment, so that a crystallization system can conveniently decompose crystals; meanwhile, in the crystallization equipment, a novel crystallizer invented by the company (described in the specification) is used for replacing carnallite decomposition equipment in the conventional cold decomposition-direct floatation technology. The novel system and method for producing the potassium chloride by utilizing the carnallite have the advantages that production technological conditions of the conventional direct floatation technology are improved, the recovery rate of potassium chloride is increased to 60%, a potassium chloride product with the purity of 90% is eliminated, the purity of the potassium chloride product is increased to 93-95%, product granularity is increased, and energy consumption is reduced.

Owner:QINGHAI SALT LAKE IND

Abandoned molding sand based mullite light heat insulating bricks and preparation method thereof

The invention relates to abandoned molding sand based mullite light heat insulating bricks and a preparation method thereof, wherein the preparation method in the technical scheme comprises the following steps: firstly mixing 45-80wt% of abandoned molded sand and 20-55wt% of special-grade alumina or alpha-Al2O3 as raw materials; then additionally adding 2-10wt% of kyanite, 5-15wt% of plasticine, 5-30wt% of pore-forming agent, 0.5-4wt% of plasticizer, 0.1-0.5wt% of bonding agent and 15-35wt% of water of the raw materials, mixing uniformly, aging for 3-10 hours, molding, drying naturally, baking at 110 DEG C for 8-12 hours, warming to 1200-1450 DEG C, and keeping the temperature for 2.5-10 hours. The abandoned molding sand based mullite light heat insulating bricks and the preparation method thereof provided by the invention have the advantages of low production cost, simple technology, energy conservation and environment friendliness and easiness for large scale production, and the prepared mullite light heat insulating bricks not only have high pressure-resistant intensity, good heat shock stability, low volume density and small heat conduction coefficient, and also have wide social and economic value.

Owner:WUHAN UNIV OF SCI & TECH

Regeneration method of steelmaking carbonic crushed brick

The invention discloses a regeneration method of steelmaking carbonic crushed bricks. The regeneration method comprises the following technical flow steps of: piling in classification; sorting; removing impurities; preprocessing; drying; crushing; screening; packing; and producing a regeneration product. Regeneration grains can be used for producing regenerated magnesia carbon bricks, aluminum-magnesium-carbon bricks, aluminum carborundum carbon bricks, tundish dry materials, aluminum-magnesium-carbon fireclay and slag-pot unfired bricks. The regeneration use rate of the carbonic crushed bricks can reach as high as 100 percent. The invention saves resources, clears garbage and protects the environment.

Owner:HUNAN XIANGGANG RUITAI TECH +1

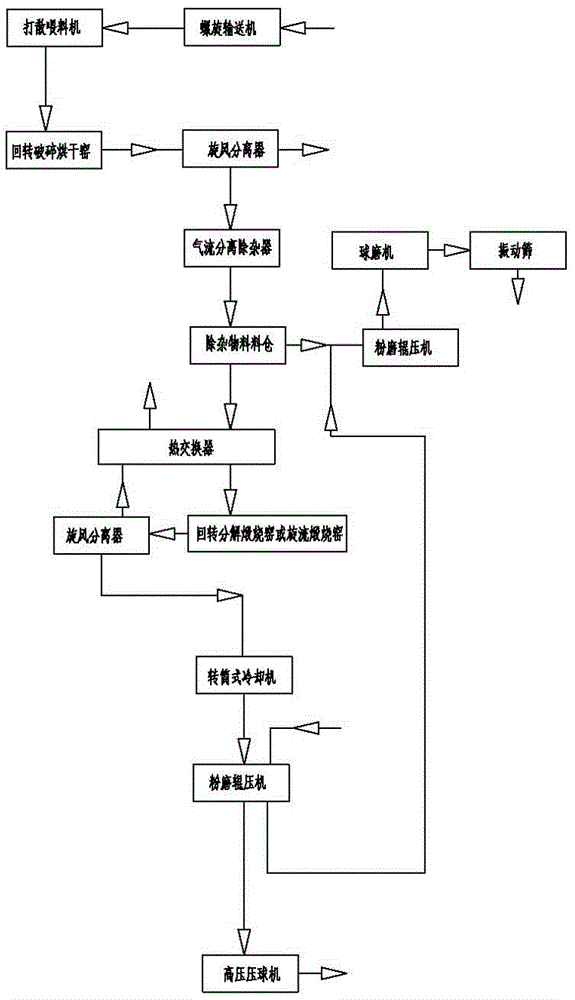

Active calcium oxide with calcium carbide dreg as raw material, desulfurizing agent, calcium carbide raw material and preparation method of active calcium oxide

ActiveCN105948091AProtect environmentReduce usageCalcium/strontium/barium oxides/hydroxidesMaterials scienceCalcium carbide

The invention relates to the technical field of active calcium oxide, desulfurizing agents, calcium carbide raw materials and preparation methods of active calcium oxide, in particular to active calcium oxide with calcium carbide dreg as a raw material, a desulfurizing agent, a calcium carbide raw material and a preparation method of active calcium oxide. The active calcium oxide with the calcium carbide dreg as the raw material is obtained through the following steps: firstly, the calcium carbide dreg is subjected to filter pressing, and primary wet dreg is obtained. According to the active calcium oxide with the calcium carbide dreg as the raw material, the desulfurizing agent, the calcium carbide raw material and the preparation method of active calcium oxide, the calcium carbide dreg is turned into wealth, accordingly, the problem of adverse influence on the environment due to stacking of a large amount of calcium carbide dreg is solved, and the environment is effectively protected; besides, utilization of mineral resources such as limestone is reduced, the mineral resources such as the limestone are saved, and the idea of harmonious development of economic development and environment protection is realized; meanwhile, according to the active calcium oxide with the calcium carbide dreg as the raw material, the desulfurizing agent, the calcium carbide raw material and the preparation method of active calcium oxide, the purity of the desulfurizing agent can be improved; moreover, the cost of the calcium carbide raw material for producing calcium carbide is lower, and industrial application prospect is realized.

Owner:新疆中泰创安环境科技股份有限公司

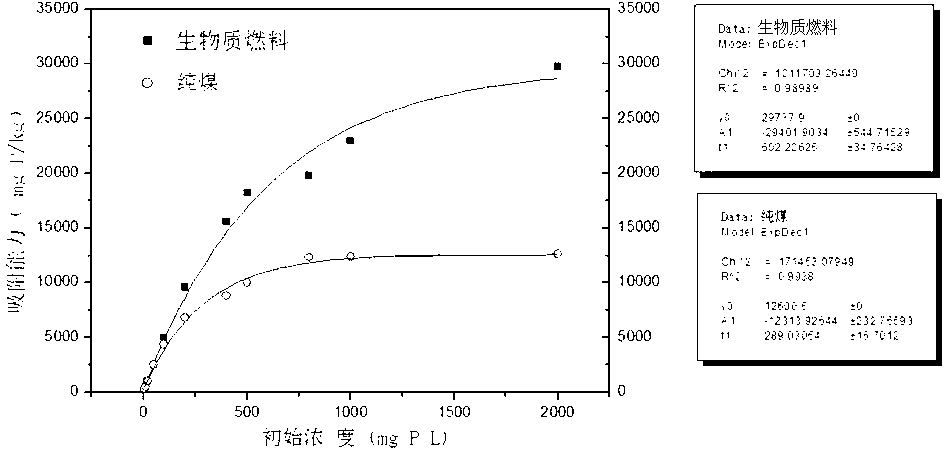

Biomass fuel based on sludge, straw and raw coal, preparation method of biomass fuel and application of fuel slag

ActiveCN102703155AReduce secondary pollutionDehydration fastBiofuelsSolid fuelsConstructed wetlandCombustion

The invention discloses a biomass fuel based on sludge, straw and raw coal, a preparation method of the biomass fuel and application of a fuel slag, and belongs to the field of resource utilization of solid waste. The biomass fuel is formed by mixing, pressing and molding the sludge, the straw and the raw coal; and the weight ratio of the sludge, the straw and the raw coal is (1-3): (1-3): 3. The preparation method comprises the following steps of: adding limestone to the dehydrated sludge subjected to application of an aluminum coagulant, wherein the mass percentage of the limestone in the sludge is 1 to 3 percent; mixing the sludge and the straw to aerobically compost; mixing the raw coal with the mixture of sludge and straw, pressing and molding to obtain the biomass fuel. After the biomass fuel disclosed by the invention is burnt, the maximum absorption capacity of the slag exceeds 25g / Kg and can be used as substitutes of filler materials for artificial wetlands. According to the biomass fuel based on sludge, straw and raw coal, the preparation method of the biomass fuel and the application of the fuel slag, water in the raw material can be hydrated quickly, heavy metals can be passivated, the emission of SO2 in combustion of the raw coal can be reduced, and the burnt slag of the biomass fuel has high contents of calcium, aluminum and Ferrum with strong absorption capacity to phosphor and can be used as a phosphorus removing agent during sewage treatment.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

All-natural insecticide

InactiveCN102217658AHigh insecticidal efficacyExtension of timeBiocideAntiparasitic agentsSolubilityMugwort

An all-natural insecticide is characterized in that: the insecticide comprises the following components by weight: 25-30 parts of Chinese mugwort leaves, 10-15 parts of philippine violet herb flowers, 10-15 parts of leaflet herbs, 8-12 parts of gleditsia beans, 15-30 parts of perilla, 8-10 parts of geranium, 10-15 parts of fennel, and 10-20 parts of chinaberry, and is prepared by water extraction, concentration, and purification. The invention has high insecticidal effectiveness, long duration, and water solubility, thoroughly substitutes the use of mineral oil as a raw material, saves mineral resources, and is convenient for use.

Owner:余来鸿 +1

Magnesia carbon brick and preparation method thereof

The invention provides a magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the magnesia carbon brick include 30-80 parts of waste magnesia carbon brick grains, 3-40 parts of magnesia grains, 6-12 parts of graphite, 5-15 parts of magnesia powder, 3-15 parts of micro powder additives, 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste magnesia carbon bricks from the steel mills and then mulling the waste magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion and service life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

Iron series colored glazes prepared from chlorite and decoration method thereof

The invention relates to iron series colored glazes prepared from chlorite and a decoration method thereof. The iron series colored glazes are prepared from chlorite mineral in Jingdezhen as a main raw material through compounding, ball milling and screening. The iron series glazes are applied to a ceramic green body, and the ceramic green body is dried and calcined at 1180-1350 DEC C by insulating for 5-120 min to obtain the colored glaze decorated ceramic product. Because the iron series colored glazes are prepared from the local chlorite in Jingdezhen as the raw material, not only are the mineral resources of feldspar, quartz and the like saved, but also the production cost of the ceramic product is greatly lowered. The different prepared colored glazes such as pea green, light greenish blue, plum green, rabbit hair, oil-spot temmoku, brown color and the like and metal luster glaze, mat glaze and the like can be widely applied to the decoration of domestic ceramics, architectural ceramics, sanitary ceramics and art ceramics.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for recycling germanium, gallium, indium and selenium in waste diode

ActiveCN102951618AReduce pollutionHigh recovery rateZinc halidesSolid waste disposalIndiumMineral Sources

The invention relates to treatment of waste metal materials, and in particular relates to a method for recycling germanium, gallium, indium and selenium in a waste diode. The recycling method comprises the following steps of: (1) crushing the waste diode; (2) separating plastic powder from metal powder; (3) oxidizing roasting; (4) recycling selenium; and (5) recycling gallium, indium and germanium. By using the method, the pollution of the diode on the environment is reduced, valuable elements of selenium, indium, gallium and germanium are recycled, and mineral resources are saved; and the method is simple to operate, lower in cost, high in recycling rate of selenium, indium, gallium and germanium elements and very high in purity of recycling products.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Reworked material working lining of continuous casting tundish and preparation method for reworked material working lining

ActiveCN105436492ASolve the problem of bulging cracks and even material collapseEasy to useMelt-holding vesselsBrickRefractory

The invention relates to a reworked material working lining of a continuous casting tundish and a preparation method for the reworked material working lining. The reworked material working lining is divided into an impact zone working lining and a non-impact zone working lining, which are internally attached to a permanent lining; the non-impact zone working lining sequentially comprises a ladle edge working lining, a ladle wall working lining and a ladle bottom working lining from top to bottom; the impact zone working lining is built by adopting waste magnesia-carbon bricks and regenerated coating material mud through a wet process; the ladle wall working lining and the ladle bottom working lining are built by adopting a regenerated dry material; an overflow port working lining and the lade edge working lining are built by adopting the regenerated coating material; a space between the two sides of a turbulent flow controller and the ladle wall permanent lining is filled by waste; and a regenerated coating material layer coats the outer surfaces of the waste magnesia-carbon bricks, the outer surface of the waste and the upper surface of the turbulent flow controller. By applying the reworked material working lining, the service life of a shaped blank continuous casting tundish reaches 33-38 hours, and refractory material cost of the regenerated material working lining is reduced by more than 60% year on year.

Owner:SHANDONG IRON & STEEL CO LTD

Method for purifying surface of tailings reservoir and ecologically restoring linear stonecrop herb

InactiveCN101767103AReduce penetrationReduce pollutionSolid waste disposalVegetationEconomic benefits

The invention relates to a method for purifying the surface of a tailings reservoir and ecologically restoring linear stonecrop herb. The method comprises the following steps of: a, purifying the superficial layer of tailings; b, covering clay; and c, afforesting vegetation. The method has the advantages of pollution abatement and ecological restoration; compared with a filling method and a solidifying method, the method saves abatement cost when used in the tailings reservoir; compared with a reclaimation method, the method saves a great number of soil resources on the basis of saving cost; compared with the common tailings reservoir, the method solves the problems of environmental pollution caused by dust because tailings are exposed in the common tailings reservoir; and the method has the advantages of convenient technology implementation, low cost, contribution to ecological balance and sustainable development of the society, and capability of achieving good economic benefit and environmental benefit.

Owner:WUHAN LITI GREENING ENG

Aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization

InactiveCN107626712ASimple processShort production processWaste processingSolid waste disposalResource utilizationSilicon alloy

The invention provides an aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization. According to the aluminum electrolysis dangerous solid waste comprehensive treatment method, other solid waste, except for waste anodes and waste aluminum dust, of aluminum electrolysis can be recycled, treatment processing is carried out through multiple procedures of primary election impurity removal, magnetic separation iron removal, flotation carbon removal, smelting reduction and the like, all aluminum electrolysis solid waste is effectively treated, renewable resources are all comprehensively utilized, and finally aluminum-silicon alloy products, electrolyte products for aluminum electrolysis, fuel powdered carbon products and the like are produced; and solidwaste treatment of the aluminum electrolysis industry is achieved, valuable resources containing aluminum, silicon, fluorine and the like are recycled and reutilized, and the good aims of protectingthe environment, saving resources and creating benefits are achieved.

Owner:陕西泰鑫有色金属综合利用有限公司

Method for smelting medium/high-carbon hard-wired steel by vanadium-titanium containing molten iron

ActiveCN102994871ASave mineral resourcesReduce smelting costManufacturing convertersSteelmakingMolten steel

The invention relates to a method for smelting medium / high-carbon hard-wired steel by vanadium-titanium containing molten iron, belonging to the technical field of metallurgy, wherein the technical scheme is as follows: vanadium-titanium containing molten iron is used as raw material; a molten iron vanadium extracting pre-processing technology is adopted in a converter steelmaking process, to produce two parts of semi-steel, and one part of the semi-steel, which is used for converter steelmaking, is referred to as steelmaking semi-steel, and the other part, which is used for recarburizing molten iron produced by the steelmaking converter, is referred to as recarburizing semi-steel; on the end point of converter smelting, a low-tensile carbon method is adopted to tap; the alloying process is recarburized little or not recarburized; after tapping, a certain amount of recarburizing semi-steel is mixed in the molten iron depending on the carbon content in the molten steel to recarburize until the molten iron carbon component is qualified, so the problems of uneven carbon element distribution in the recarburized steel, lower than 0.010% of vanadium element and lower than 0.005% of nitrogen element of the recarburizing agent are solved. By a process that the recarburizing semi-steel skips over the converter smelting and is directly turned into qualified molten steel while mixing the recarburizing semi-steel in the molten liquid to recarburize, the smelting cost of the converter smelting is directly saved.

Owner:HEBEI IRON AND STEEL

Activated waste slay composite powder and its application in cement, concrete and bake free brick

InactiveCN1493541ANon-proliferationImproved pozzolanic propertiesCement productionBuilding componentsChemical admixtureMineral Sources

An activated composite waste dregs powder used for cement, concrete and non-calcine brick is prepared from acidified zeolite powder, lead or copper dregs, carbonate stone powder, phosphate dregs (ardealite), lime dregs and powdered coal ash as basic materials. Its advantages are high property and low cost.

Owner:吴发辉

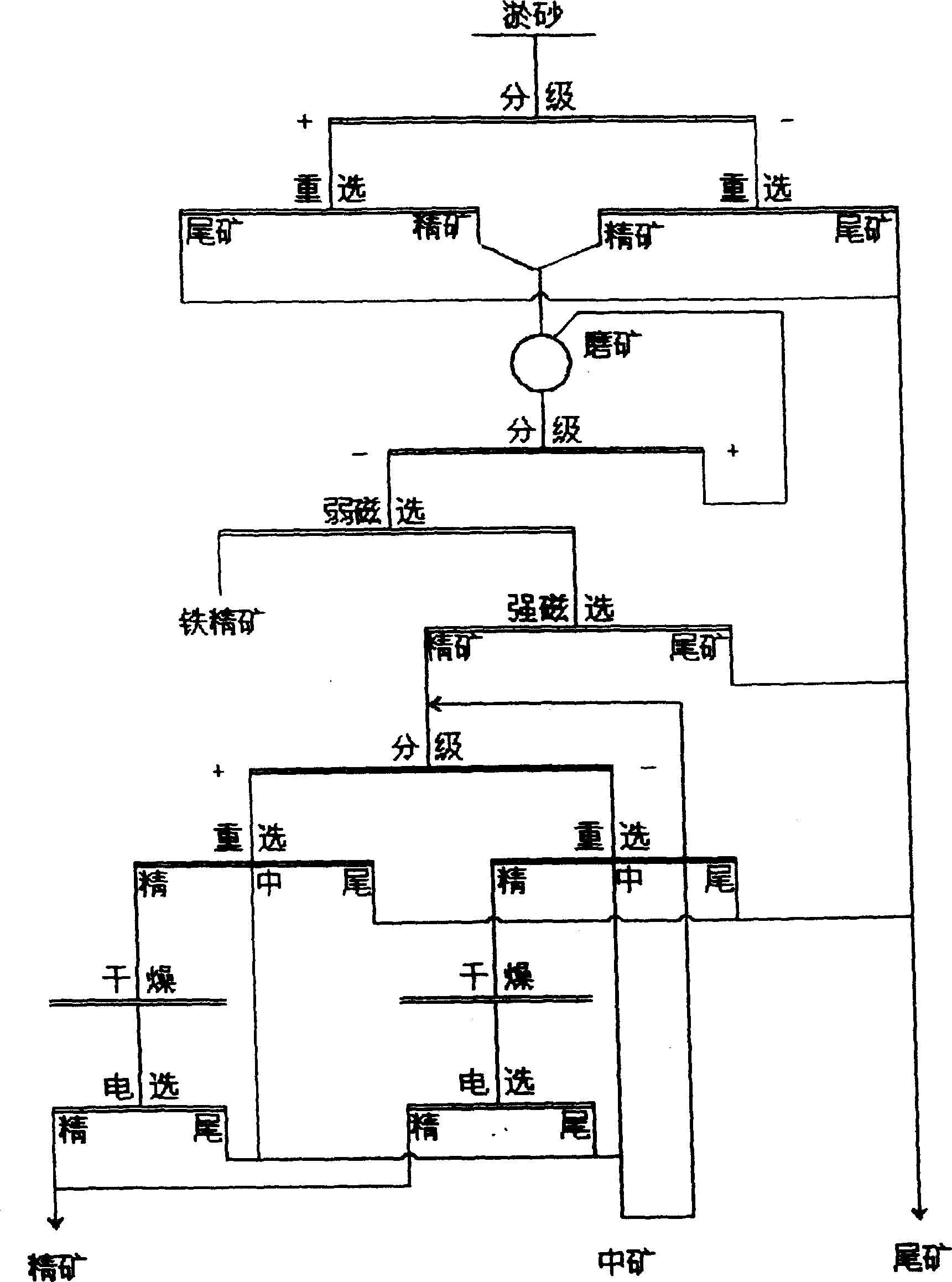

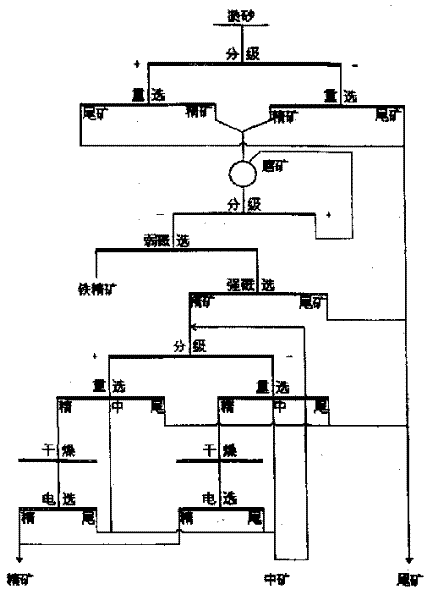

Scandium extraction method of river channel sedimentation

InactiveCN1478600AHigh puritySave mineral resourcesLiquid solutions solvent extractionWet separationElectricityMineral Sources

Owner:汪友华

Metallurgical slag sintered bricks and preparation method thereof

InactiveCN106431350AReduce energy consumptionImprove the exhaust effectCeramic materials productionClaywaresMetallurgical slagMineral Sources

The invention provides metallurgical slag sintered bricks and a preparation method thereof. The preparation method comprises the following steps: mixing metallurgical slag, clay and / or shale and an additive, which meet a preset condition, according to preset proportions; aging the mixture obtained after mixing, and then performing forming to obtain green bricks; and drying the green bricks, and then burning the green bricks in a kiln to obtain the sintered bricks. According to the preparation method provided by the invention, by controlling the preset condition of the metallurgical slag, the clay and the additive can be directly mixed with the metallurgical slag by stirring, and secondary breaking is not needed, so that the energy consumption of the preparation is greatly reduced; the metallurgical slag has a function of reducing the melting point, so that the temperature of a sintering reaction can be reduced; and by controlling factors including the content of ferric oxide in the metallurgical slag, the sintering temperature and the sintering atmosphere, sintered bricks with different colors can be obtained without adding an expensive coloring agent, so that large-scale utilization of the metallurgical slag is achieved, mineral resources are saved, and meanwhile, qualified sintered bricks are produced with low cost, low energy consumption and a high efficiency, thereby achieving comprehensive utilization of resources, and protecting the environment.

Owner:UNIV OF SCI & TECH BEIJING

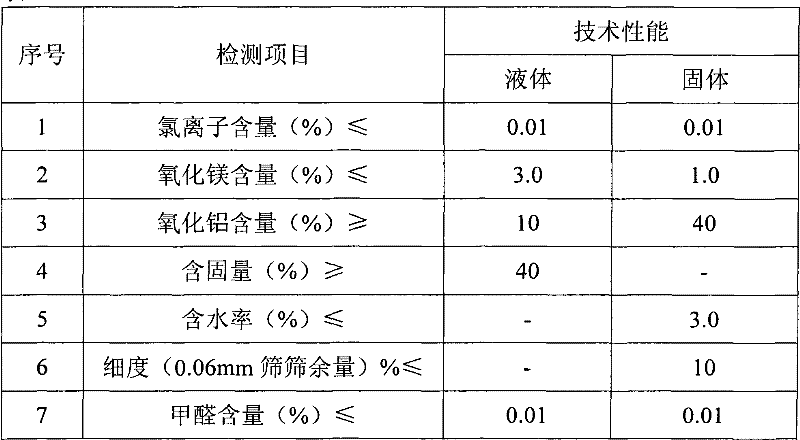

Tap hole clay for recycled material high blast furnace and preparation method thereof

The invention belongs to the field of blast furnace iron making and particularly relates to tap hole clay for a blast furnace which replaces the conventional dense raw materials and coke powder by recycled materials and a preparation method thereof. The formula of the tap hole clay comprises the following components in percentage by weight: 55 to 70 percent of recycled material, 14 to 23 percent of clay, 2 to 5 percent of asphalt, 2 to 5 percent of sericite and 12 to 16 percent of binding agent. The dense raw materials such as dense corundum, high-alumina aggregate, an SiC raw material and the like and the coke powder are replaced by the recycled materials, so that mineral resources are saved, a large amount of energy is saved, waste discharge can be reduced effectively, the production cost of the tap hole clay is lowered and remarkable economic and social benefits are achieved.

Owner:通化耐博新材料股份有限公司

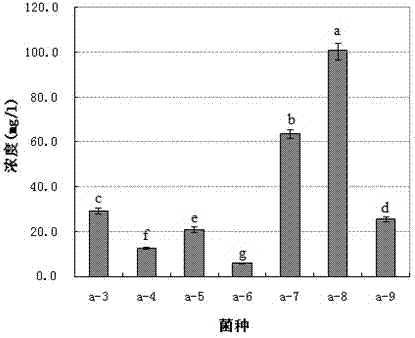

Bacillus cereus for activating soil nutrient and application of bacillus cereus

ActiveCN103173380AImprove micro-ecological environmentConducive to sustainable useAgriculture tools and machinesBacteriaNucleotideBacillus cereus

The invention discloses a bacillus cereus for activating soil nutrient and application of the bacillus cereus. The bacillus cereus is preserved in the China General Microbiological Culture Collection Center (CGMCC) on May 21, 2012 with preservation number of CGMCC No. 6127, and the 16SrDNA nucleotide sequence is shown by SEQ ID No: 1. According to the bacillus cereus, the soil nutrient can be obviously activated, the effectiveness of phosphorus and nitrogen in soil can be improved, the composition of a soil microbial community can be improved, the diversity and the evenness of the soil microbial community can be improved, the metabolic activity of the soil microbe can be improved and the like, the soil fertility can be improved, the crop growth can be promoted, the bacillus cereus is good for the agricultural sustainable development and utilization, and the bacillus cereus is wide in application prospect in the production practice.

Owner:广东润华环保产业有限公司

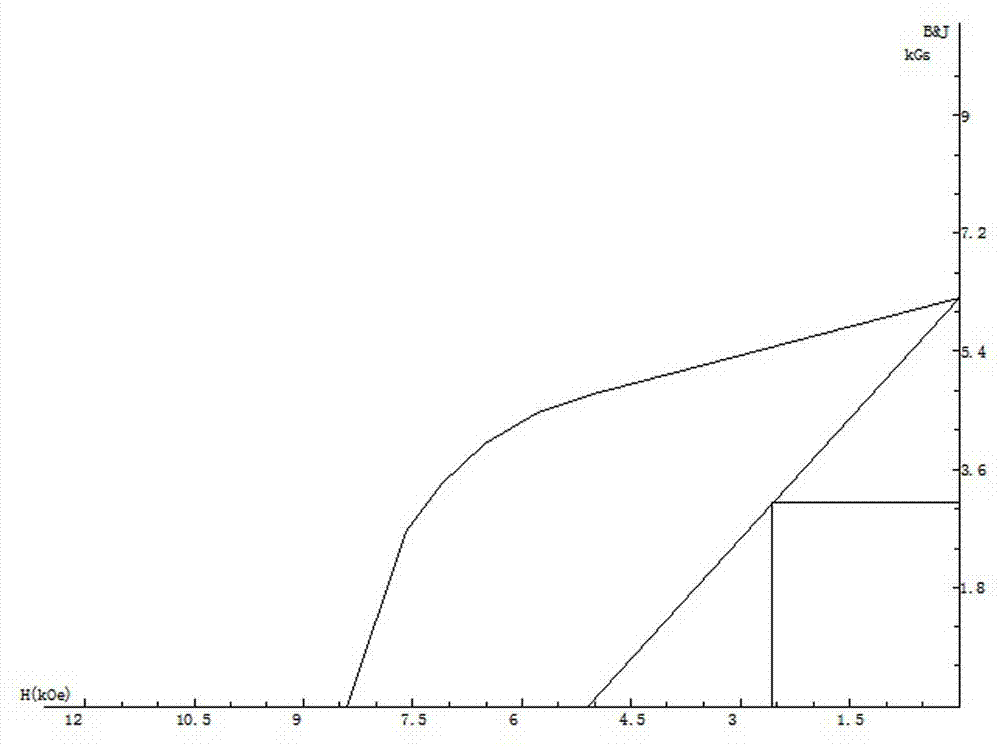

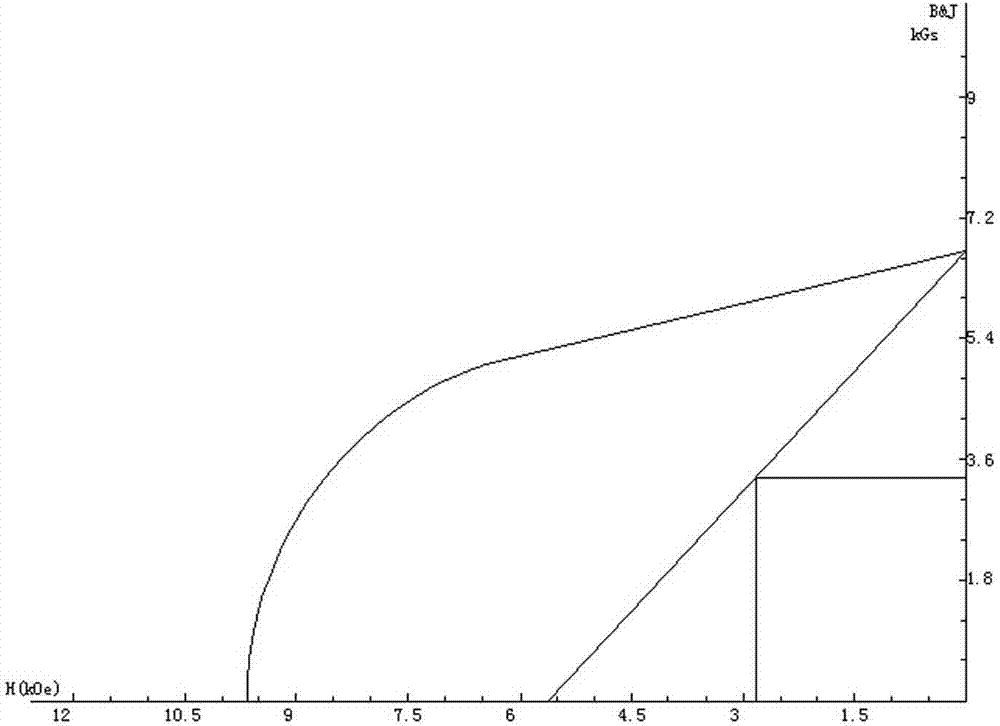

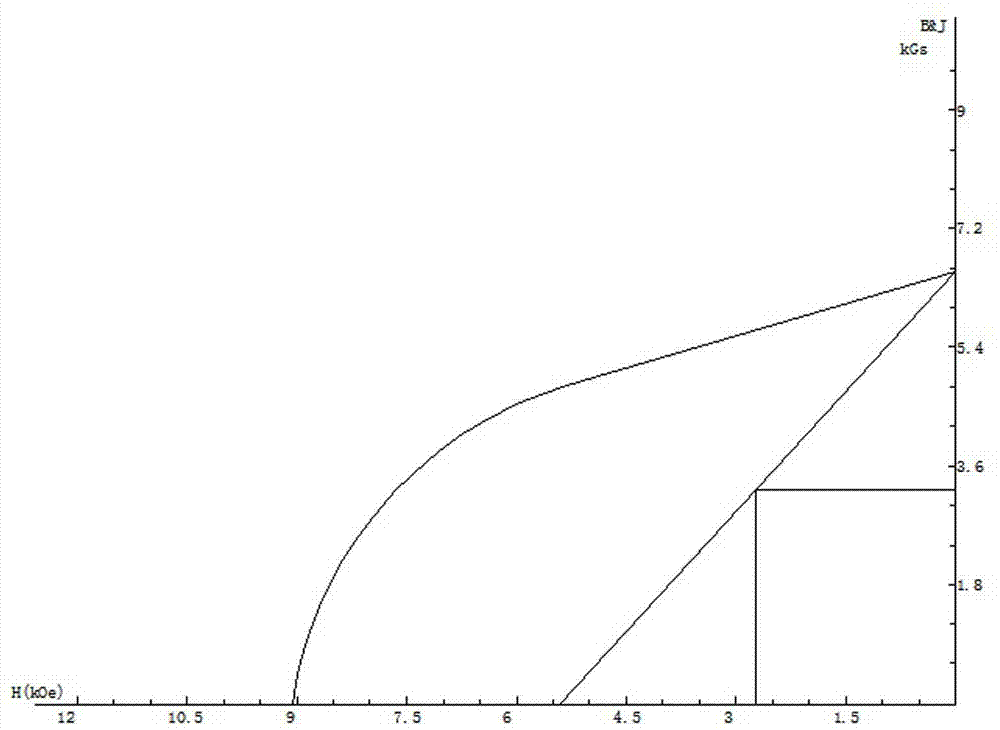

Preparation method of iron-based low-rare earth NdFeB rapid quenching permanent magnetic powder

The invention provides a preparation method of iron-based low-rare earth NdFeB rapid quenching permanent magnetic powder. The preparation method comprises the procedures of: raw material preparation, vacuum melting, vacuum rapid quenching, primary pressing, crystallization thermal treatment, powder preparation, and magnetic property and physical property detection, wherein in the raw material preparation procedure, the iron-based low-rare earth NdFeB rapid quenching permanent magnetic powder is prepared from the following raw materials in percentage by weight: 15.5-19% of praseodymium-neodymium alloy, 3-7% of lanthanum-cerium alloy, 4.5-5.5% of zirconium, 1.15-1.25% of boron, and the balance of iron, thereby forming prepared materials. The use amount of the praseodymium-neodymium alloy is reduced by 19%, the lanthanum-cerium alloy is properly added, the performance index can achieve Hcj9.592, (BH)m9.751 through proper magnetic separation, and the property of the magnetic powder can achieve 14.38MGO. By utilizing the preparation method, the best result of producing the iron-based low-rare earth NdFeB rapid quenching permanent magnetic powder through a vacuum rapid quenching manner can be realized, the economic benefits can be directly improved by about 15%, thereby striding a new pace for saving limited mineral resources.

Owner:JIANGSU JUXIN MAGNET

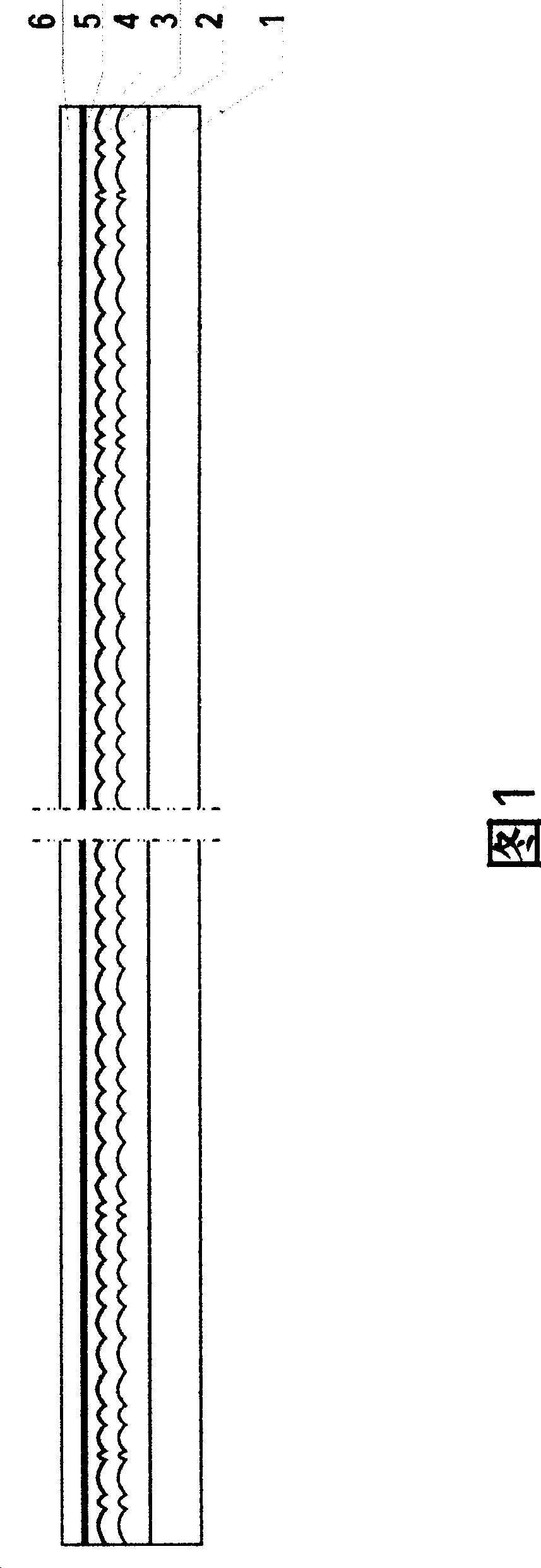

Compound film for decoration with tridimensional multicolor pattern

InactiveCN101376317ASave mineral resourcesNo smellSynthetic resin layered productsSpecial ornamental structuresComposite filmMineral Sources

A multilayer composite film with solid multicolor patterns for decorative use comprises a plastic bottom film layer. The technical proposal of the composite film is that a thermal sol layer, a metal deposition layer or a multicolor dyeing film layer with convex and concave solid patterns or solid embossing patterns, transparent double adhesive vinyl, and a transparent film layer with characters or / and patterns are arranged on the plastic bottom film layer in sequence. The invention has the advantages that the composite film adopts metal film composite materials and a multicolor printing and cold mounting process, so as to achieve the sense of metal of metal tags and the rich color change which can not be reached by the metal tags, thereby saving a large amount of mineral resources. The process produces no smell, no pollution or noise, and is more environment-friendly and beautiful compared with the chemical corrosion process for producing the traditional tag, and improves the production efficiency by more than 10 times. The invention particularly adopts the thermal sol layer with a certain thickness. In the invention, the thermal sol layer is not only a bounding layer, but also a framework layer for the metal layer composite material to form the permanent solid pattern.

Owner:赵臣

On-line hot preparation method of glass batch

InactiveCN101913752AImprove thermal conductivityIncrease the reaction areaCharging furnaceGlass productionAdhesiveRefractory

The invention discloses an on-line hot preparation method of a glass batch. The method comprises the following steps of: adding a proper quantity of adhesives to a traditional glass batch and pressing the mixture into a block material; preheating to decompose the molded block material in a firing kiln to form a sintered block consisting of silicate and silicon dioxide, immediately pulverizing the block into granules in the hot state; conveying and uniformly scattering the granules into a filling pocket; and pushing into a glass kiln for melting. The on-line hot preparation method of the glass batch can greatly improve the heat conductivity coefficient of the batch, improve the melting rate of the glass kiln, increase the glass capacity and achieve the purpose of saving energy. The compacted glass batch block reduces flying dust in the glass kiln, prolongs the service life of refractory materials, prevents the blockage of a regenerative chamber, purifies the operating environment, reduces the flying loss of the batch and stabilizes the glass component. The method ensures that the melting rate can be improved by 20-30 percent. Compared with a traditional method, the method ensures that the fuel consumed for producing the same quantity of glass can be saved by 10-20 percent.

Owner:杭州蓝星新材料技术有限公司

Kaolin high concentration ore dressing technology

InactiveCN101099940ASave Kaolin Mineral ResourcesHigh degree of mechanizationWet separationHigh concentrationQuartz

The high concentration kaolin beneficiating process includes the following steps: providing raw kaolin ore; stirring and dispersing raw kaolin ore in the presence one water and dispersant while maintaining viscosity in 7.6-78.3 comprise; desanding the dispersed kaolin ore in a screw grader; elutriating desanding obtained coarse quartz sand in a secondary screw grader and a third screw grader; and returning the ore slurry from the secondary screw grader to the raw kaolin ore stirring and dispersing step and the ore slurry from the third screw grader to the secondary screw grader. The process can ensure the ore slurry concentration within 45-55 %, is favorable to kaolin beneficiating operation and post treatment, and has kaolin mineral resource recovering rate as high as 95 % and low water consumption.

Owner:茂名市银华高岭土实业有限公司

Gangue foam concrete building block for realizing self heat insulation of walls

InactiveCN102493593ALow costConducive to high value-added comprehensive utilizationConstruction materialClimate change adaptationFoam concreteInsulation layer

Owner:CHONGQING HAIFENG CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com