Active calcium oxide with calcium carbide dreg as raw material, desulfurizing agent, calcium carbide raw material and preparation method of active calcium oxide

A technology of active calcium oxide and calcium carbide slag, which is applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve problems such as adverse effects on the environment, and achieve the effects of protecting the environment, improving purity and saving limestone mineral resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

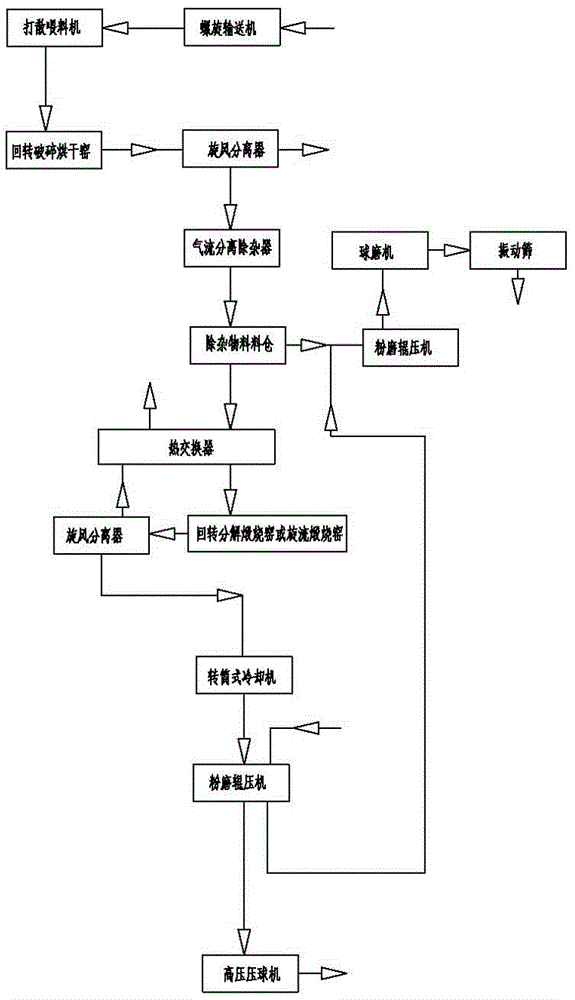

[0028] Example 1 : as attached 1 As shown, the activated calcium oxide using calcium carbide slag as raw material is obtained by the following preparation method: the first step is to obtain a primary wet slag after pressure filtering the calcium carbide slag, and the mass percentage of water in the primary wet slag is 38% to 42% , the secondary wet slag is obtained after the primary wet slag is air-dried, and the mass percentage of water in the secondary wet slag is 30% to 35% In the second step, the secondary wet slag is crushed for the first time; in the third step, the calcium carbide slag powder is obtained after drying the secondary wet slag after the primary crushing, and the mass percentage of water in the calcium carbide slag powder is 10% Following; in the fourth step, the calcium carbide slag powder is subjected to gas-solid separation to obtain solid powder and gas material, and the solid powder is passed through the air separation impurity remov...

Embodiment 2

[0029] Example 2 : this active calcium oxide with calcium carbide slag as raw material obtains by the following preparation method: the first step obtains a wet slag after pressing the calcium carbide slag, and the mass percentage of water in the wet slag is 38% or 42% , the secondary wet slag is obtained after the primary wet slag is air-dried, and the mass percentage of water in the secondary wet slag is 30% or 35% In the second step, the secondary wet slag is crushed for the first time; in the third step, the calcium carbide slag powder is obtained after drying the secondary wet slag after the primary crushing, and the mass percentage of water in the calcium carbide slag powder is 10% Following; in the fourth step, the calcium carbide slag powder is subjected to gas-solid separation to obtain solid powder and gas material, and the solid powder is passed through the air separation impurity remover to obtain the impurity removal material, and the particle size...

Embodiment 3

[0030] Example 3 : this active calcium oxide with calcium carbide slag as raw material obtains by the following preparation method: the first step obtains a wet slag after pressing the calcium carbide slag, and the mass percentage of water in the wet slag is 38% , the secondary wet slag is obtained after the primary wet slag is air-dried, and the mass percentage of water in the secondary wet slag is 30% In the second step, the secondary wet slag is crushed for the first time; in the third step, the calcium carbide slag powder is obtained after drying the secondary wet slag after the primary crushing, and the mass percentage of water in the calcium carbide slag powder is 5% ; The fourth step is to obtain solid powder and gas material after the gas-solid separation of the carbide slag powder, and obtain the impurity removal material after the solid powder is removed by the air separation impurity remover, and the particle size of the impurity removal material is 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com