Patents

Literature

210results about How to "Regulate security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

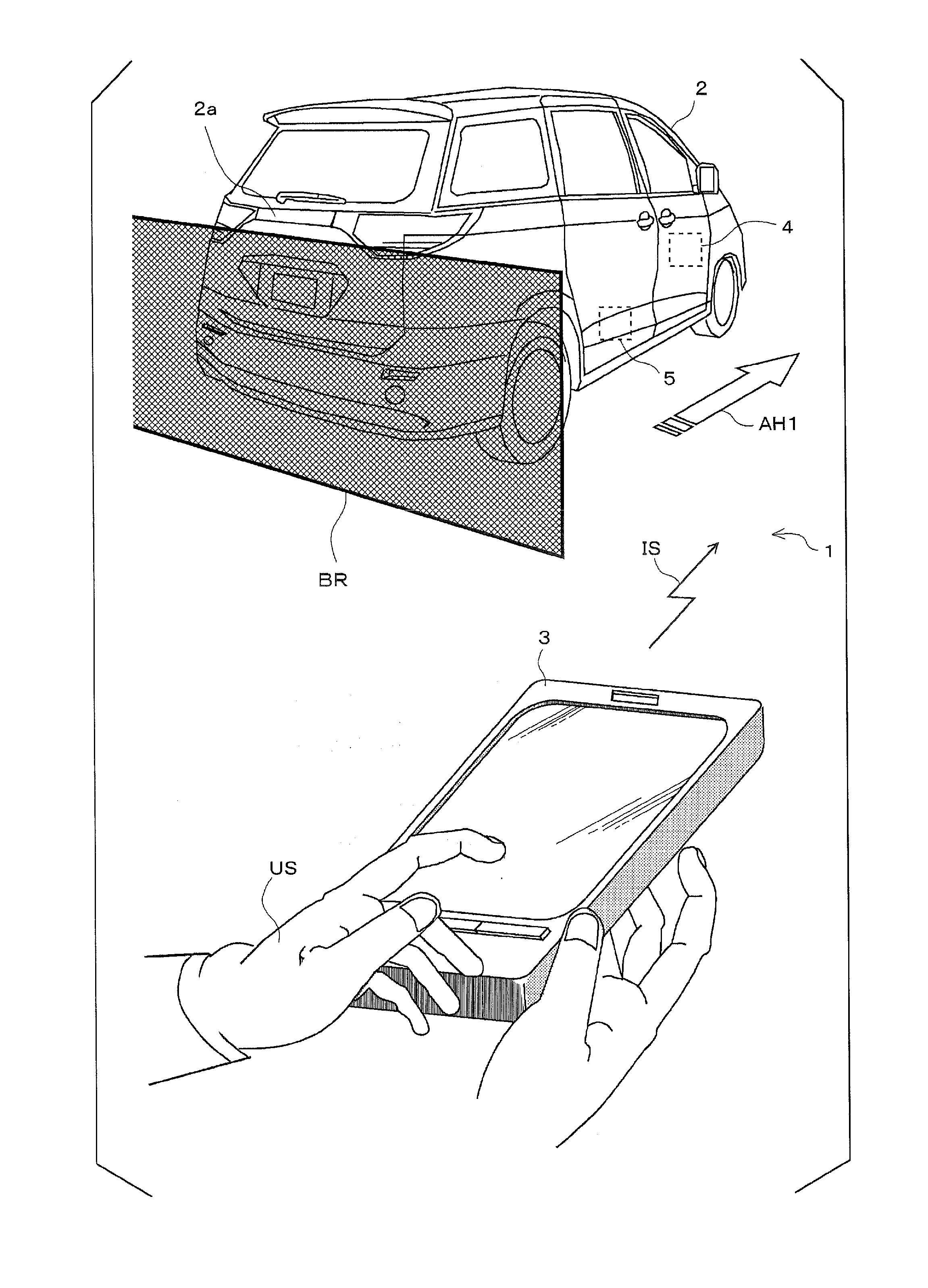

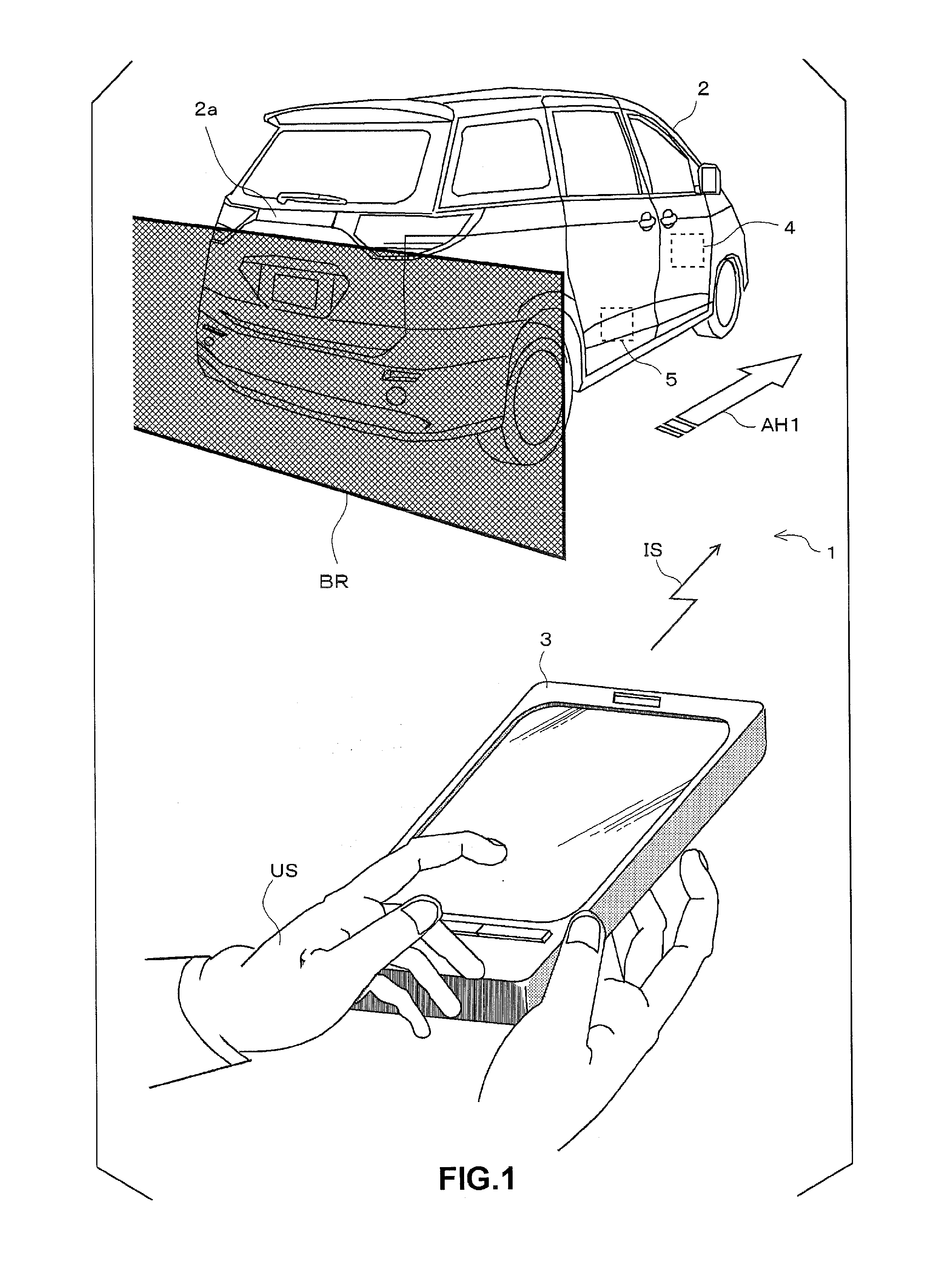

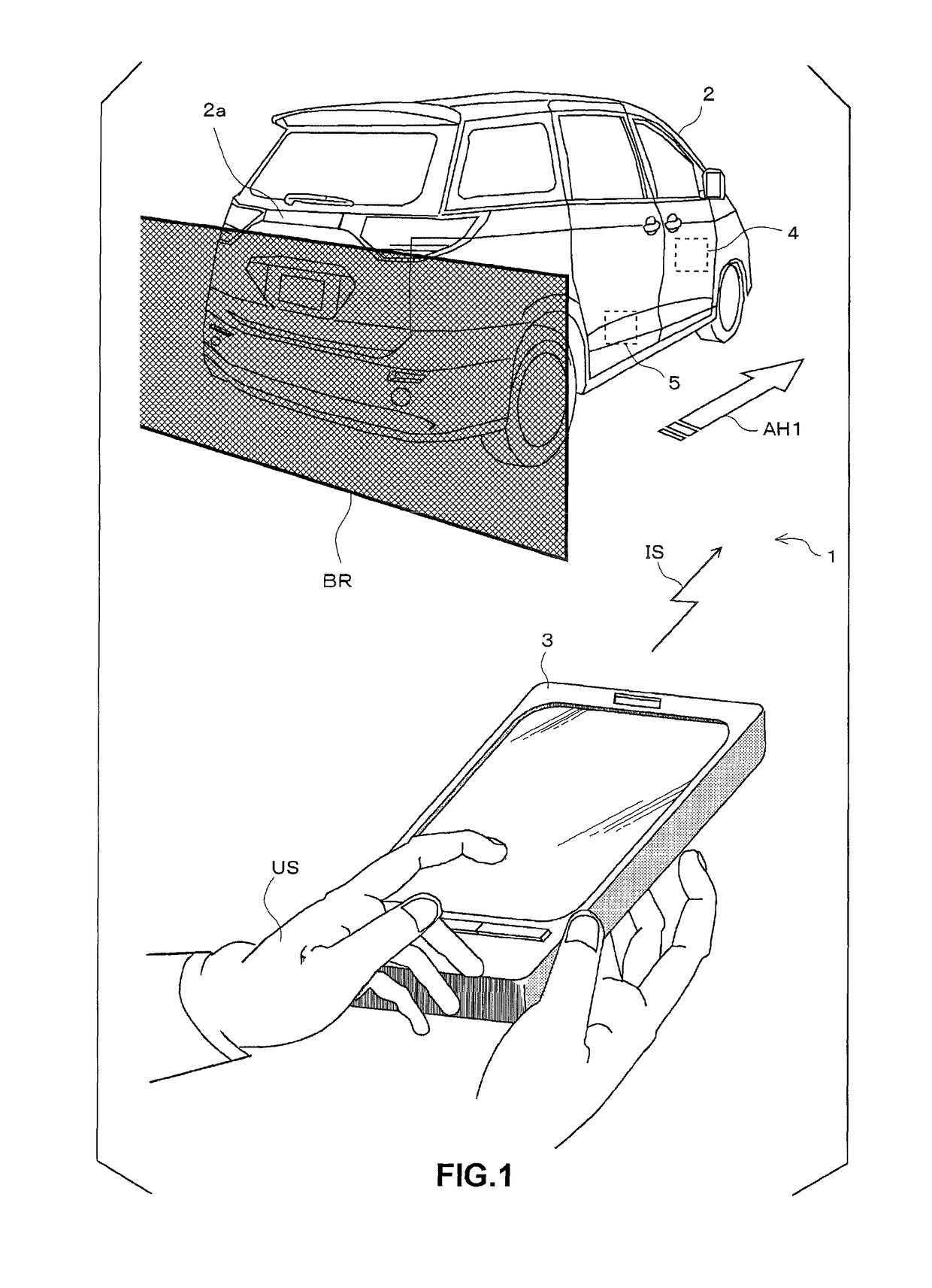

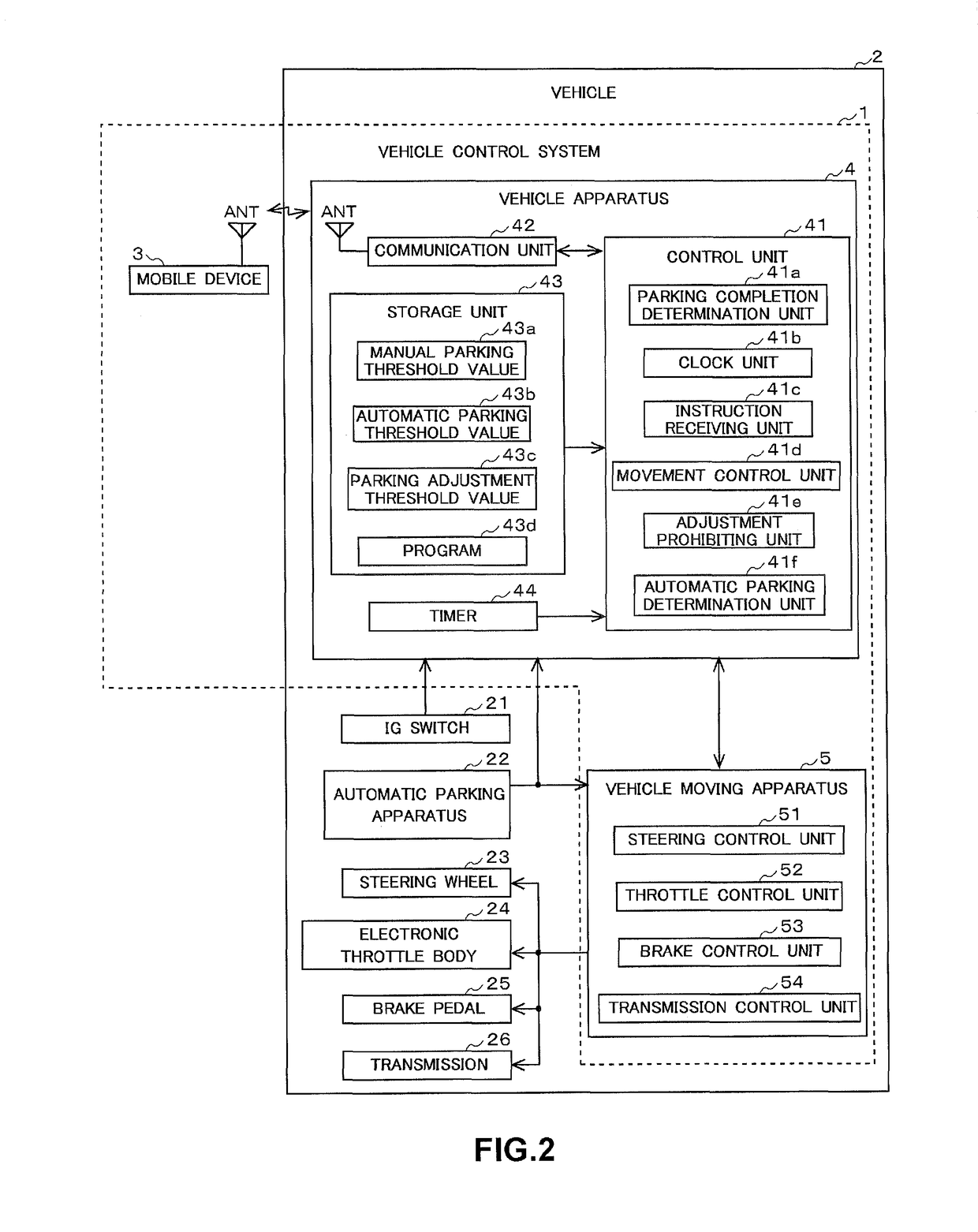

Vehicle apparatus

ActiveUS20150375741A1Improve securityProhibit some movementImage enhancementTelevision system detailsEngineeringMoving parts

A vehicle apparatus used in a vehicle measures a first elapsed time after completion of a parking operation by which the vehicle is parked in a parking region, and prohibits movement of the vehicle to adjust the parking position when the first elapsed time reaches a first predetermined time before receipt of a instruction signal by the receiver Accordingly, it is possible to improve safety by preventing the vehicle from moving out of a parking position even if the moving part is erroneously operated when the predetermined time elapses after the completion of parking operation.

Owner:FUJITSU GENERAL LTD

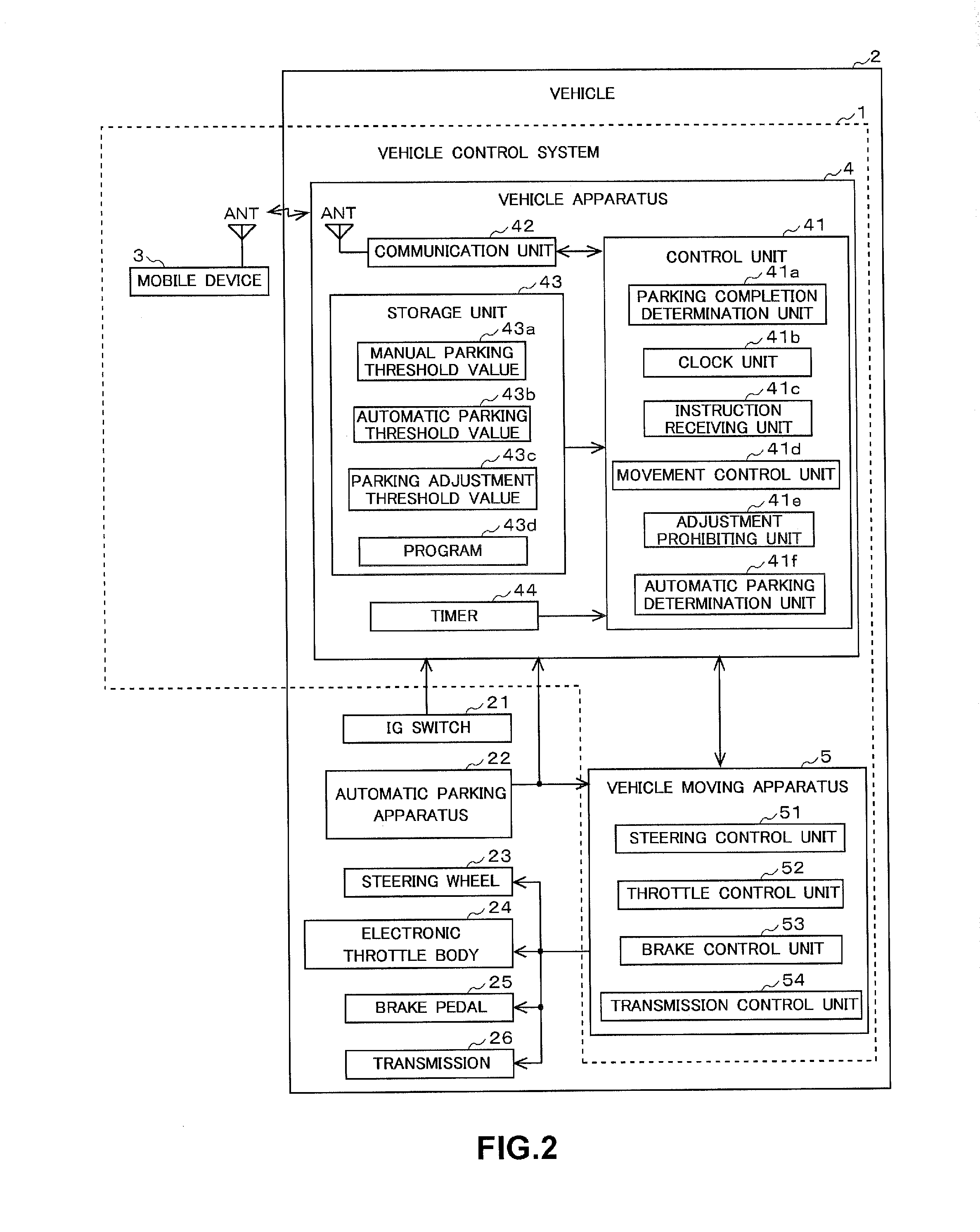

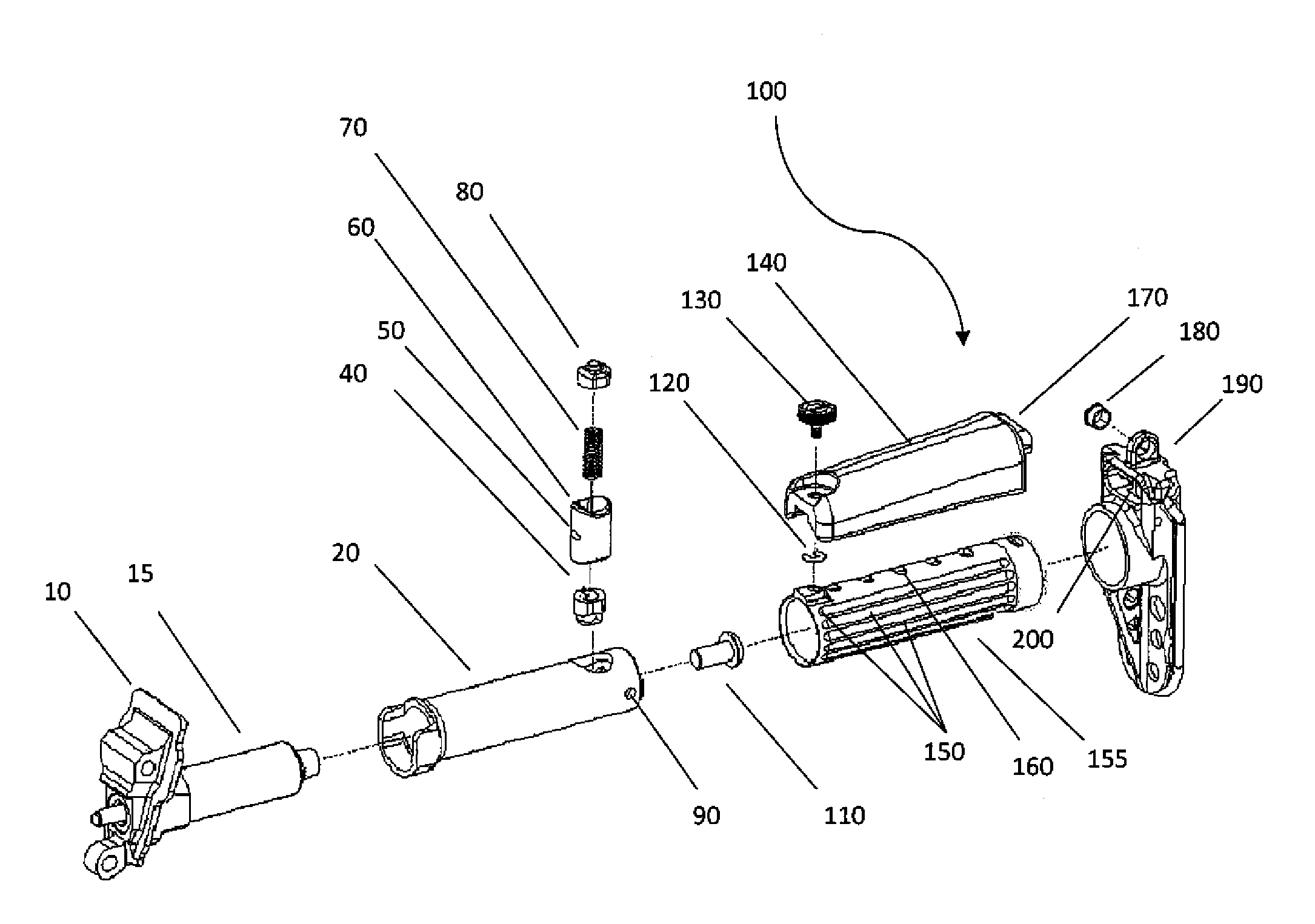

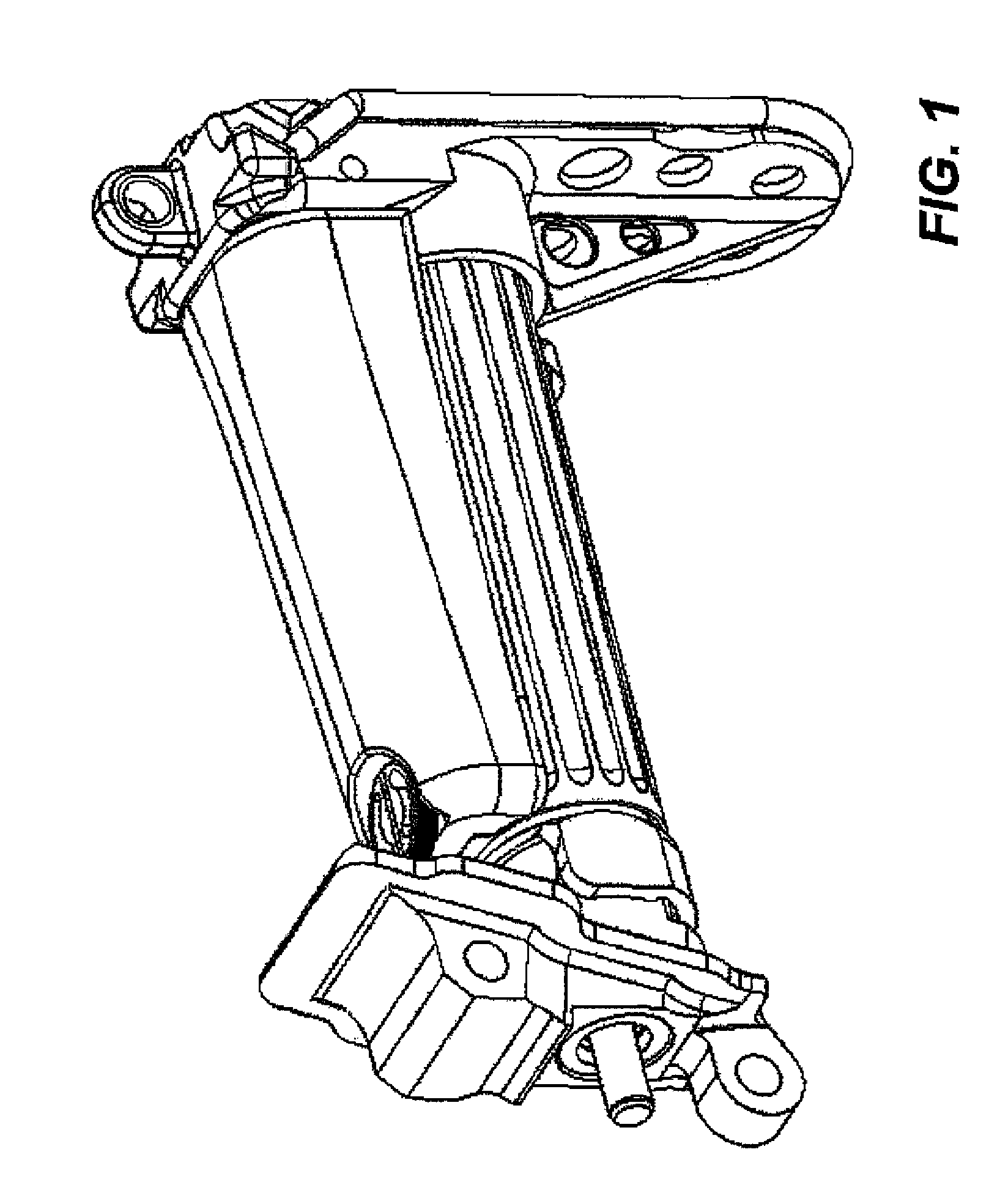

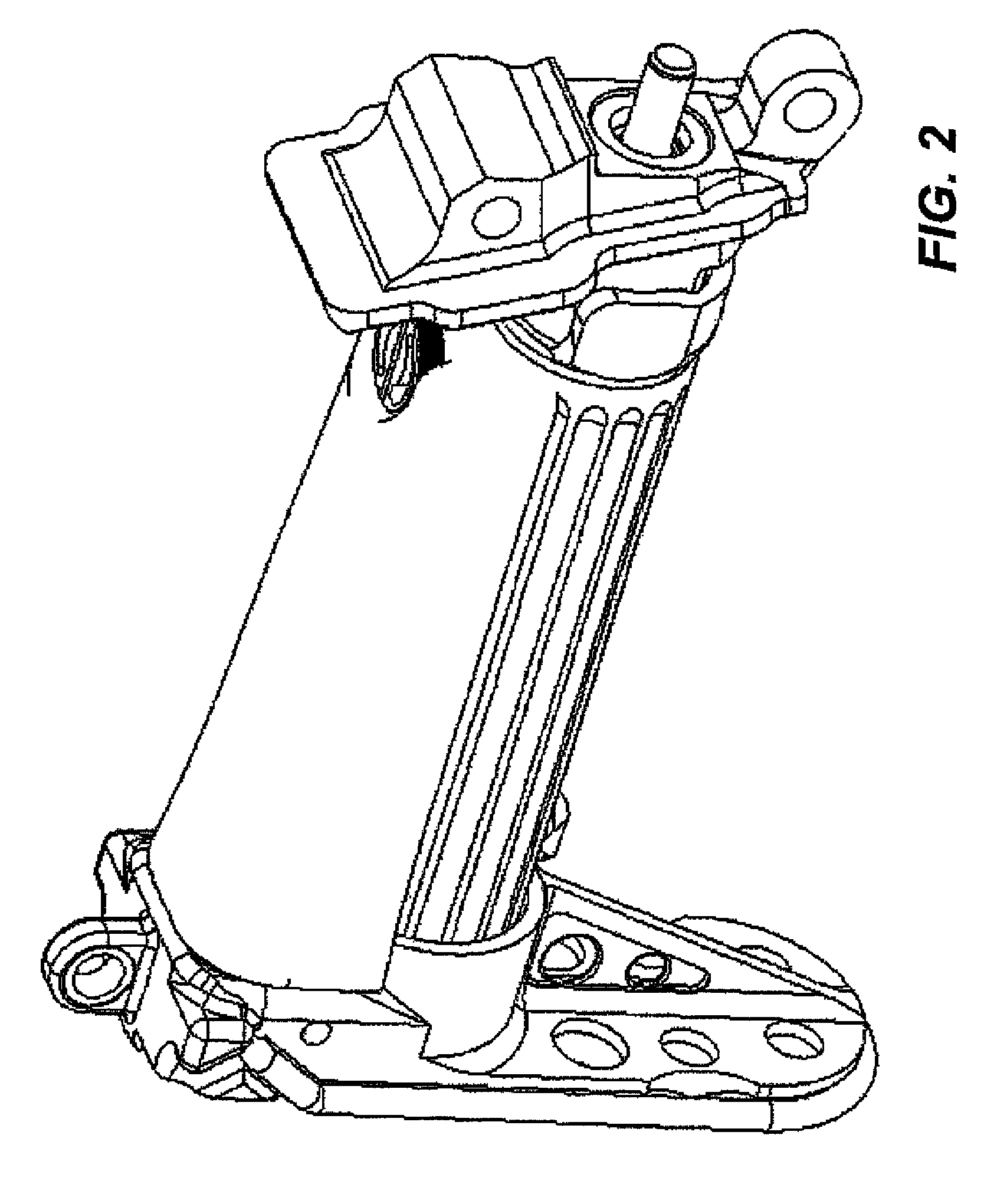

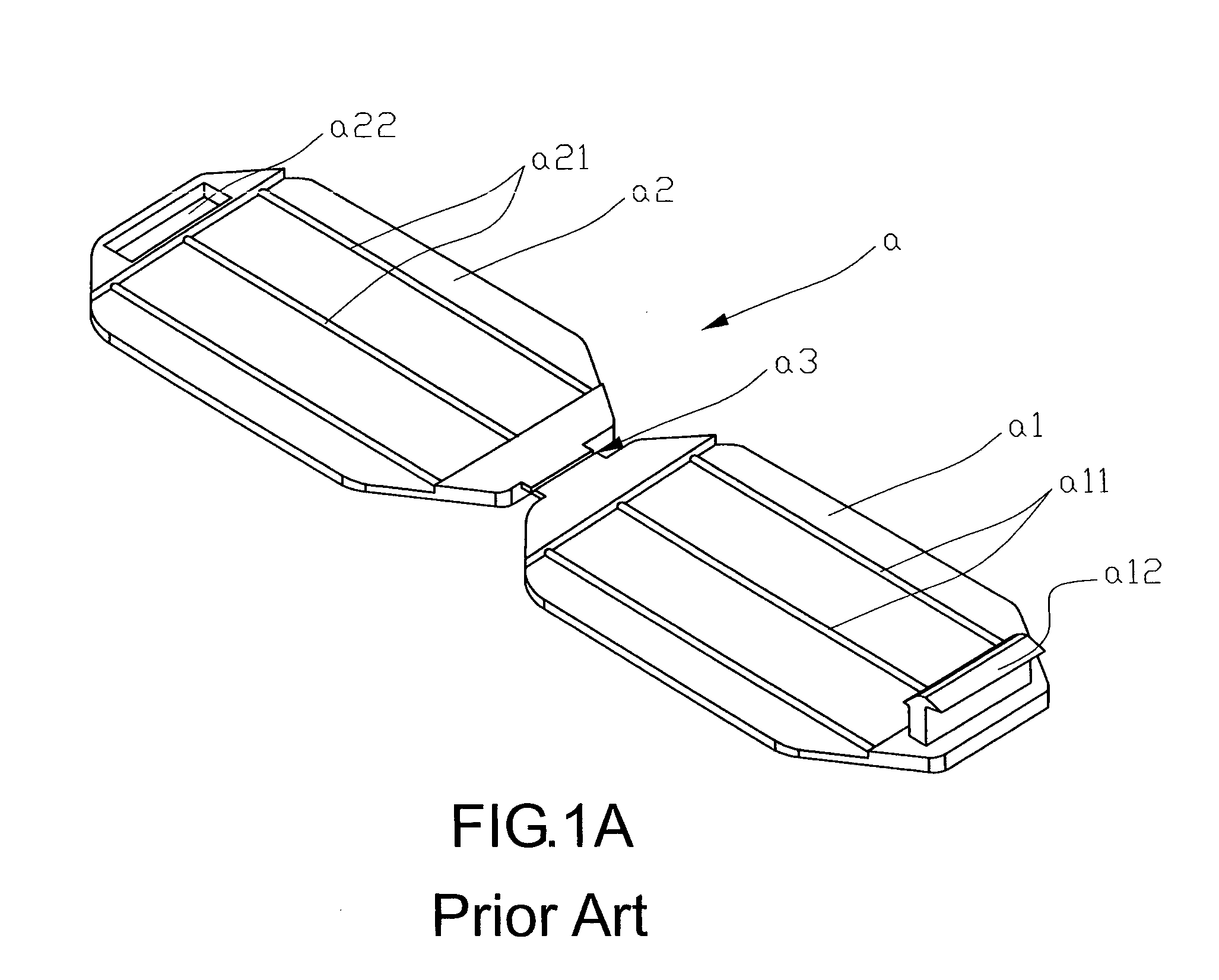

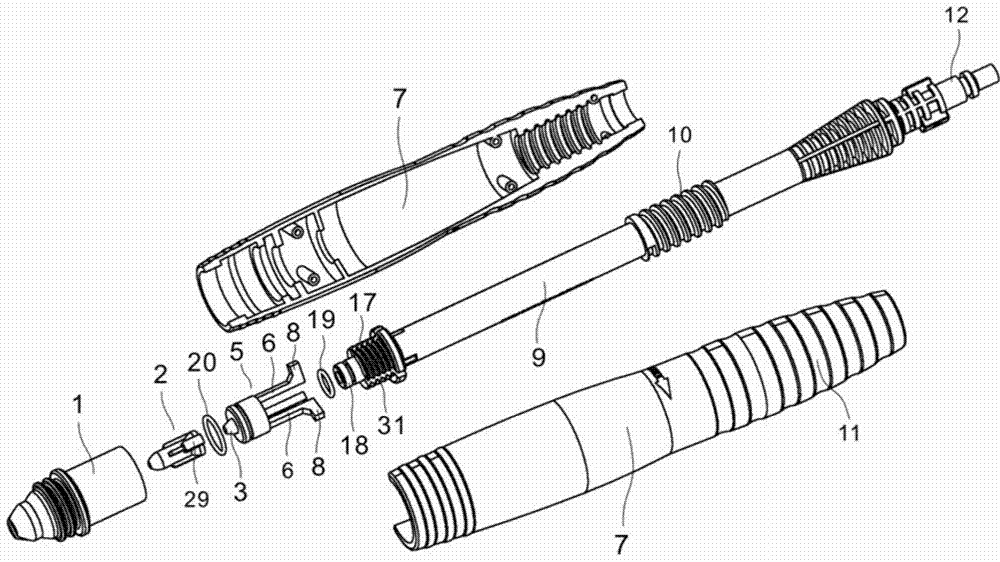

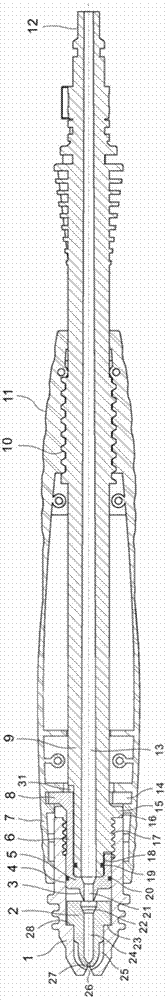

Adjustable buttstock assembly

An adjustable buttstock assembly for a hand carried weapons, wherein an inner stock extends from and slidably moves into an outer stock to provide the length adjustment and where a set of opposed spring loaded engagement pins, located in the end of the inner stock, extend through a set of discrete, opposed openings in the outer stock to securely hold the stocks in position one relative to the other. One of the engagement pins, engages into one of a series of discrete holes located in the lower side of the outer stock, while the other engages into one of a series of partial oval opening, opposed thereto, the series of partial oval openings located on the upper side of the outer stock separated by flat teeth, to form a rack, with each partial oval opening into an open channel running the length of the rack. Such that when the lower engagement pin is compressed into the lower opening in which it may be and the upper engagement pin then rotated out of the partial oval opening into the channel—the inner and outer stocks are then free to move one with respect to the other to extend or compress the adjustable buttstock. Further, the inner stock is fixed to a backplate that engages with the receiver of the weapon, and provides protection for a hydraulic buffer that engages with the receiver of the weapon and extends into the inner stock.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

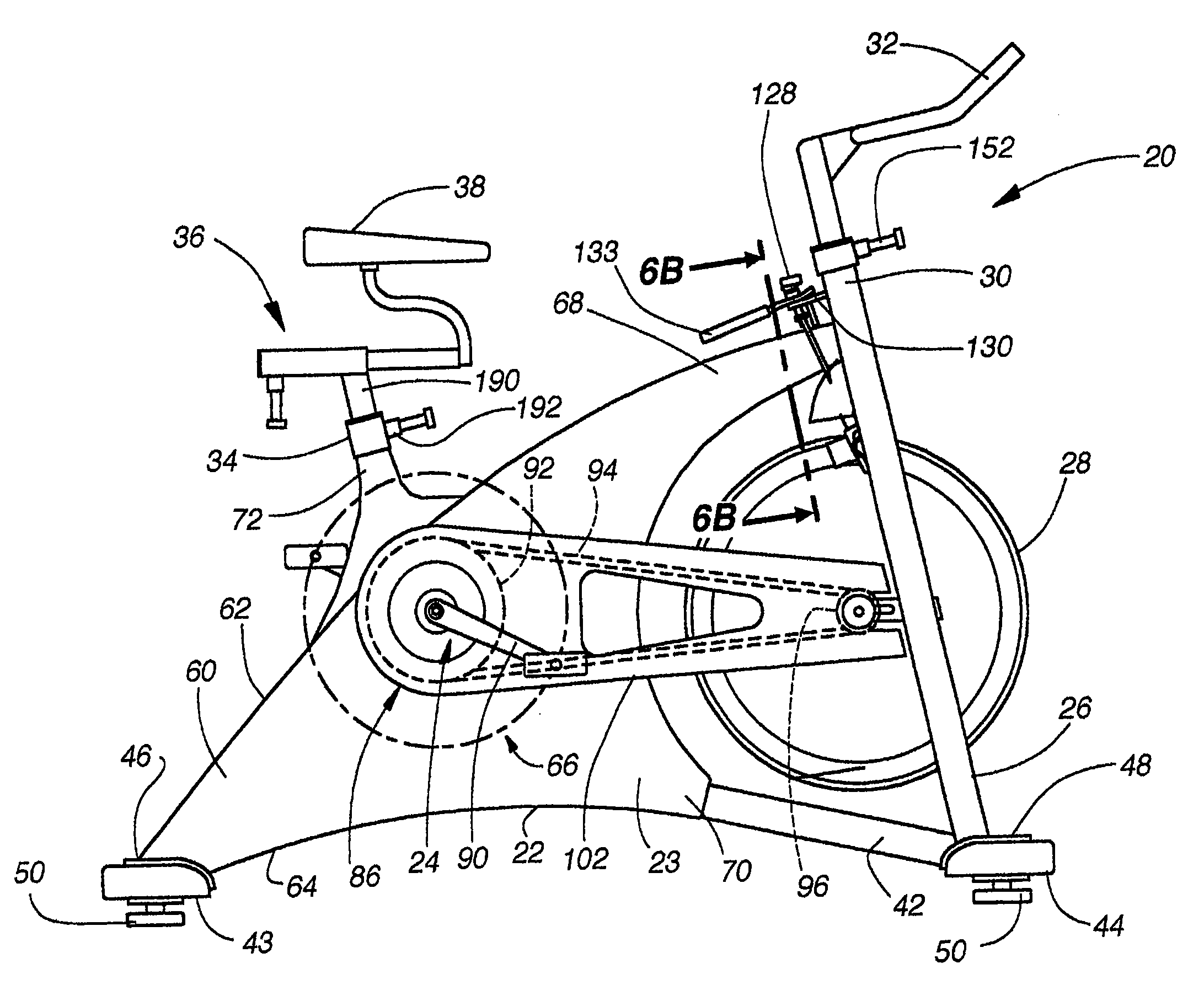

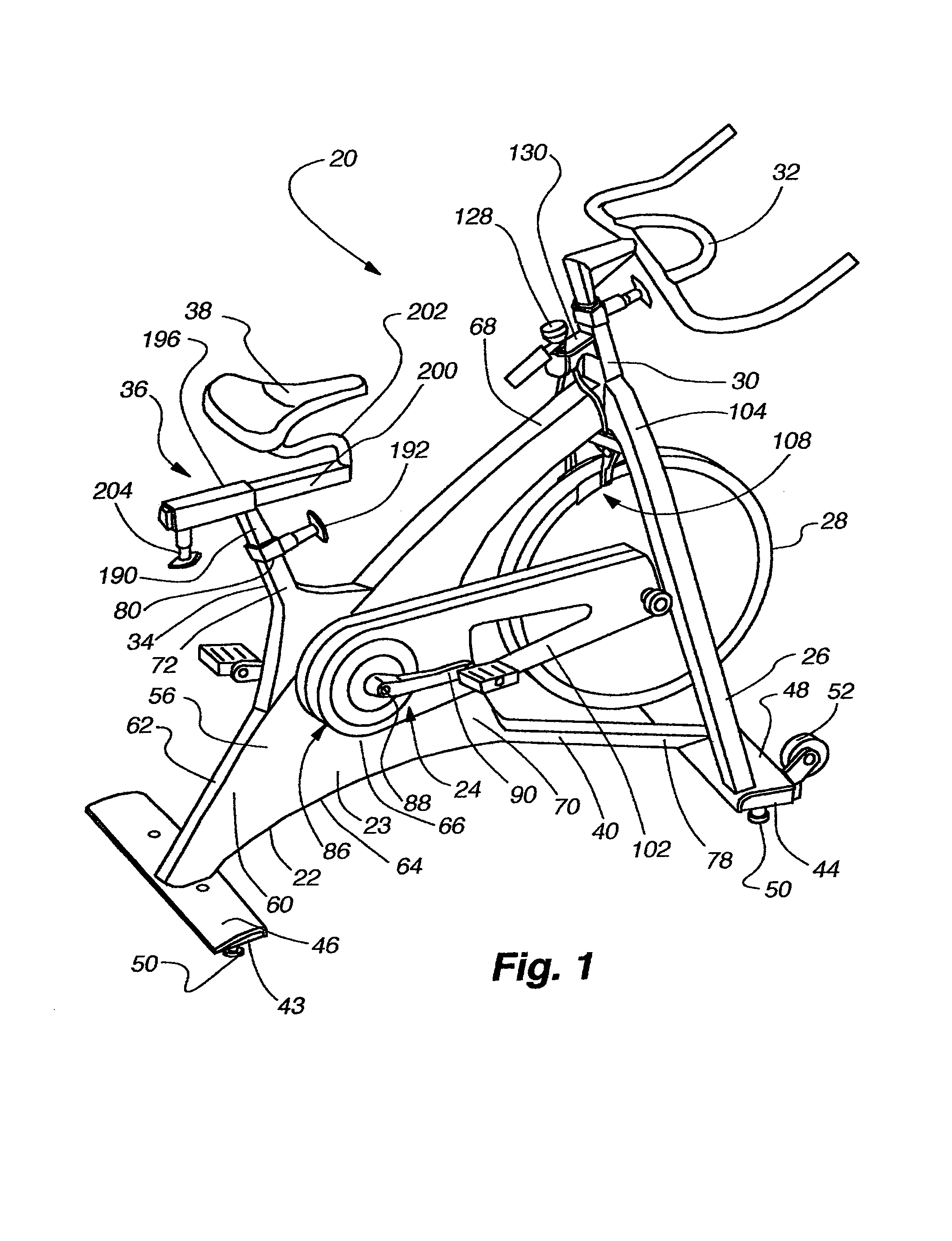

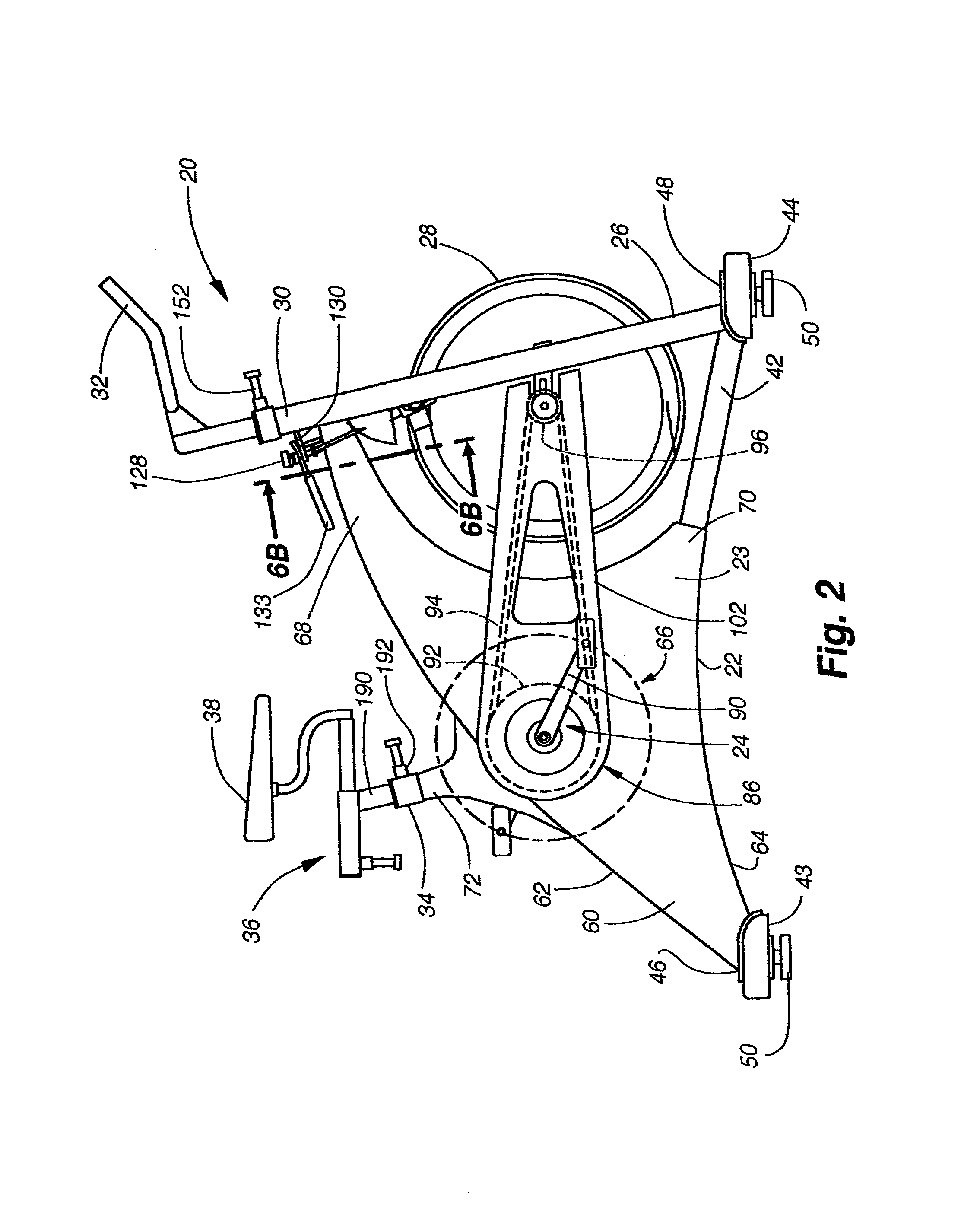

Exercise device tubing

InactiveUS7172532B2Secure adjustmentEasy to manufactureRod connectionsFrictional force resistorsPhysical exerciseIt design

A unique structure for an indoor exercise bike that provides strength in its design, as well as the flexibility to create an aesthetically appealing frame structure. The monocoque frame design, including two symmetrical halves joined together, forms a very strong, light shell that can take on a variety of shapes and sizes. The seat structure, handlebar structure, drive train and support platforms are all able to be readily attached to the primary frame structure to provide an exercise bicycle that is sturdy, easy to manufacture, and light enough to easily move when necessary.

Owner:NAUTILUS INC

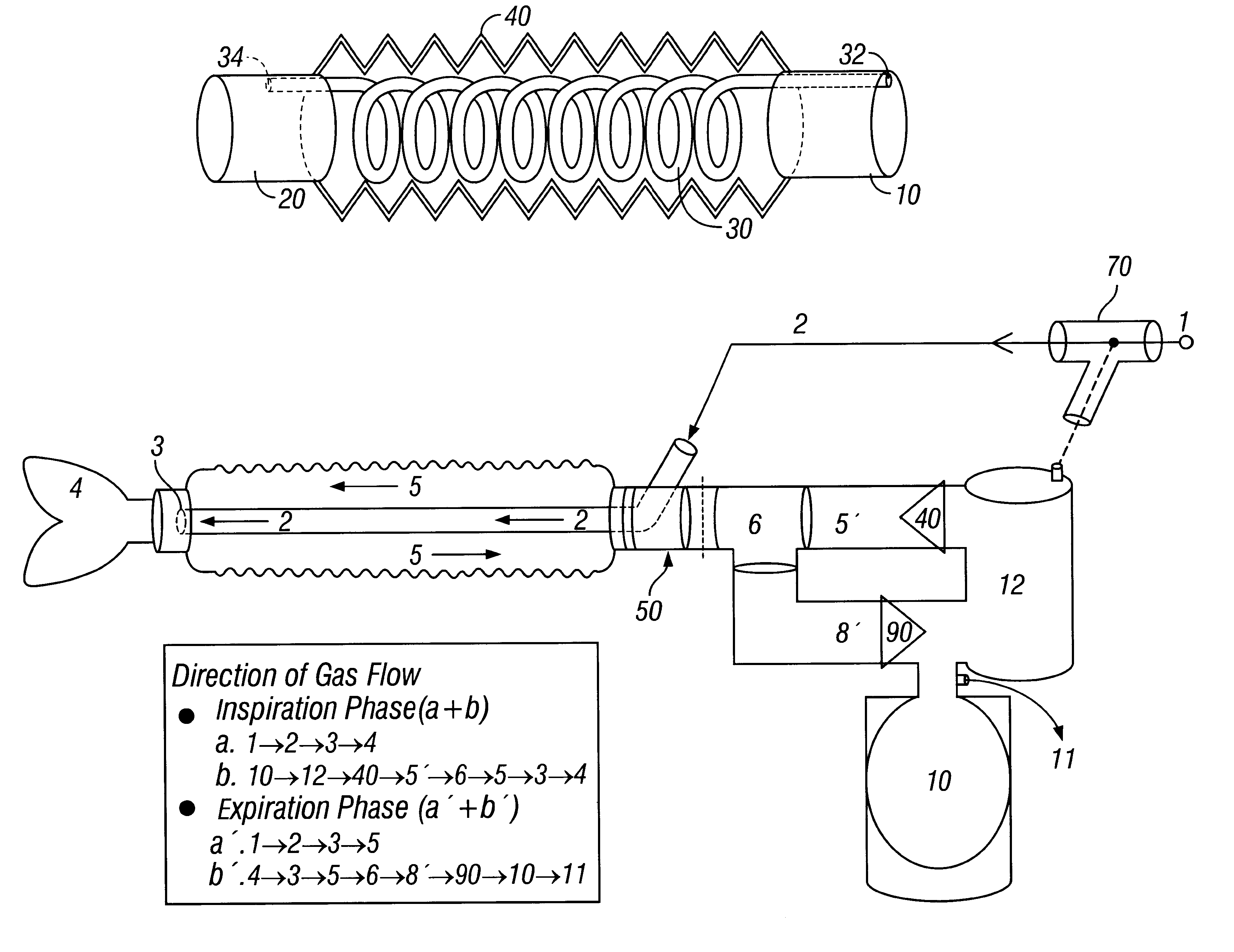

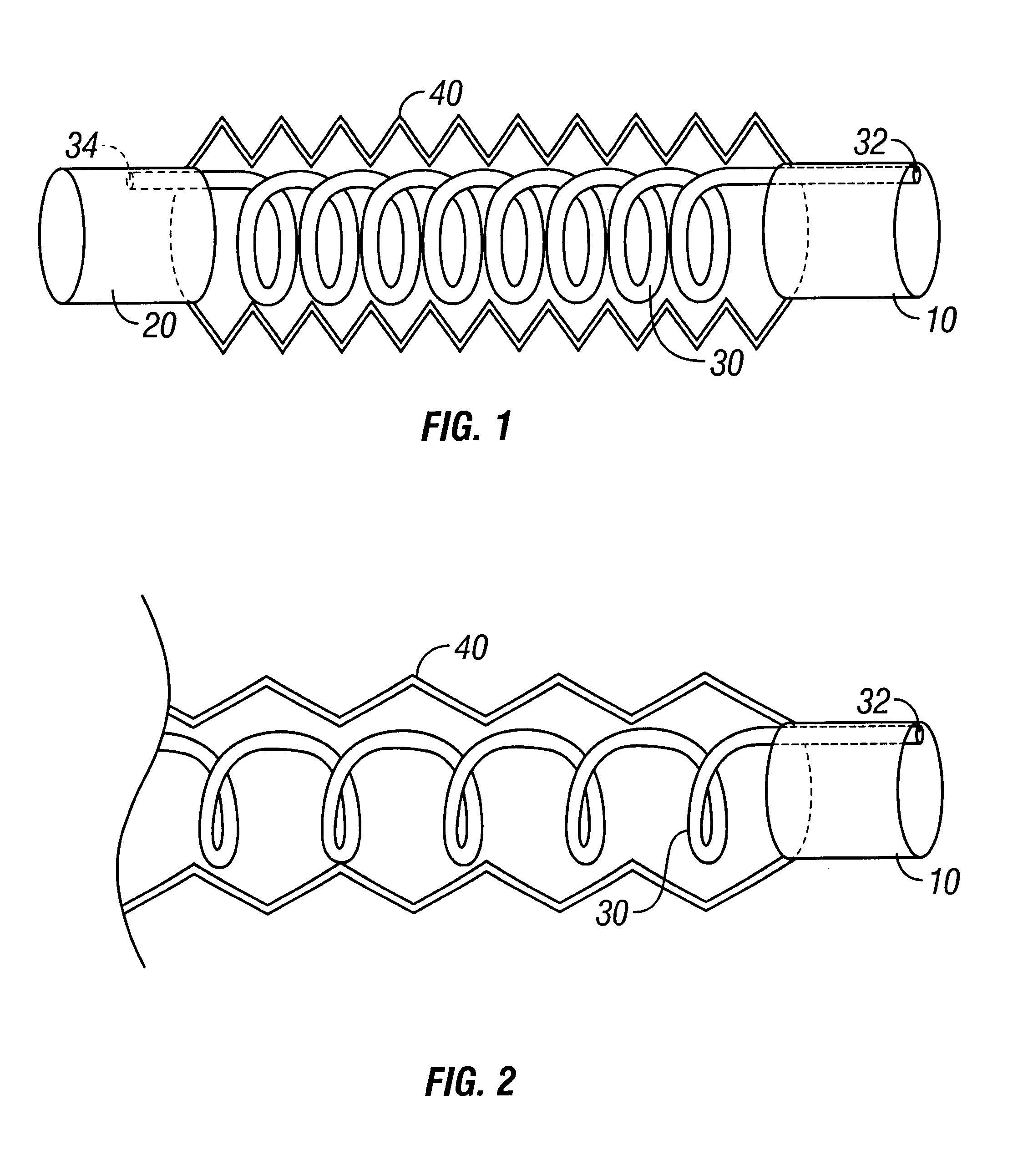

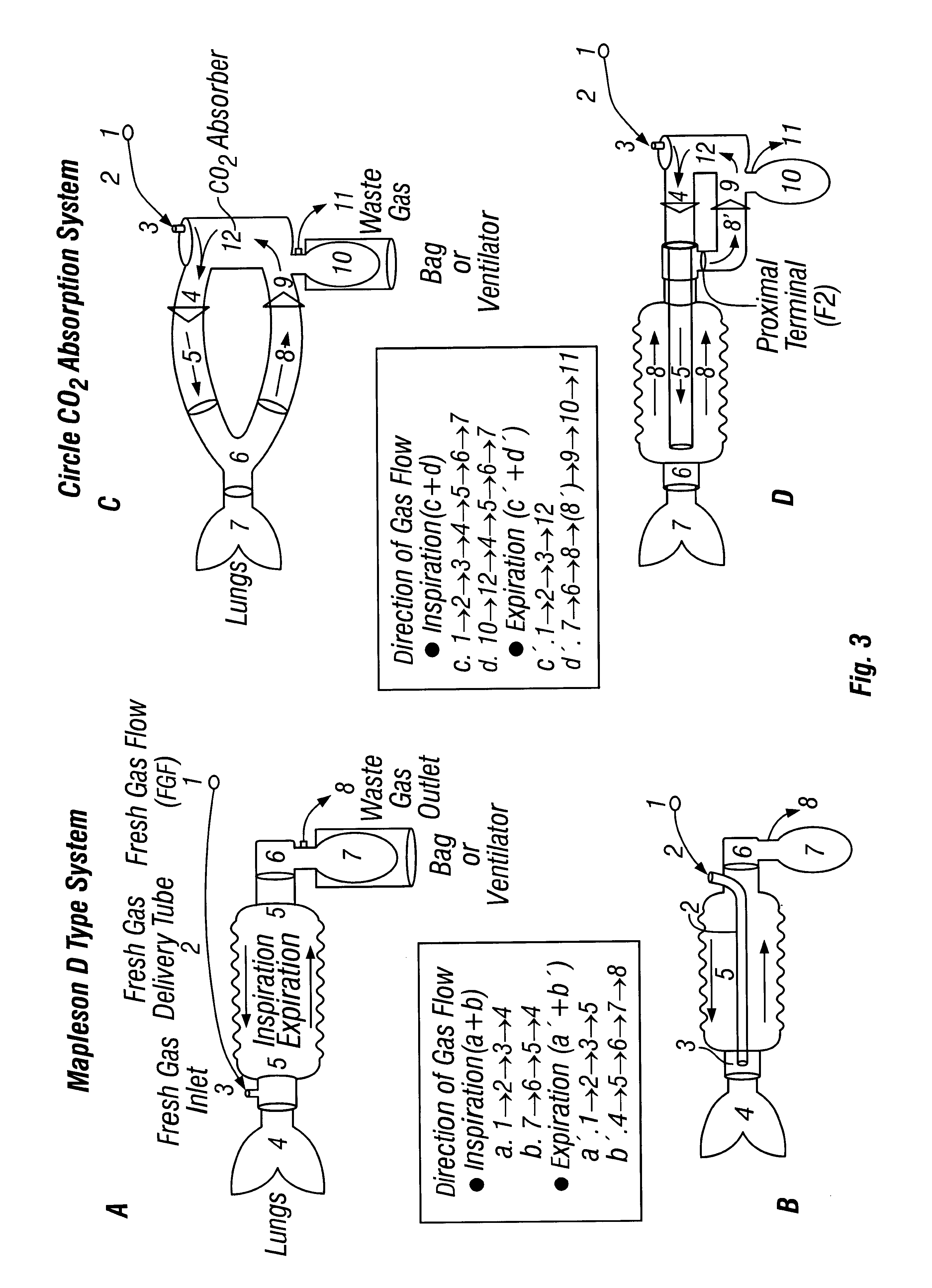

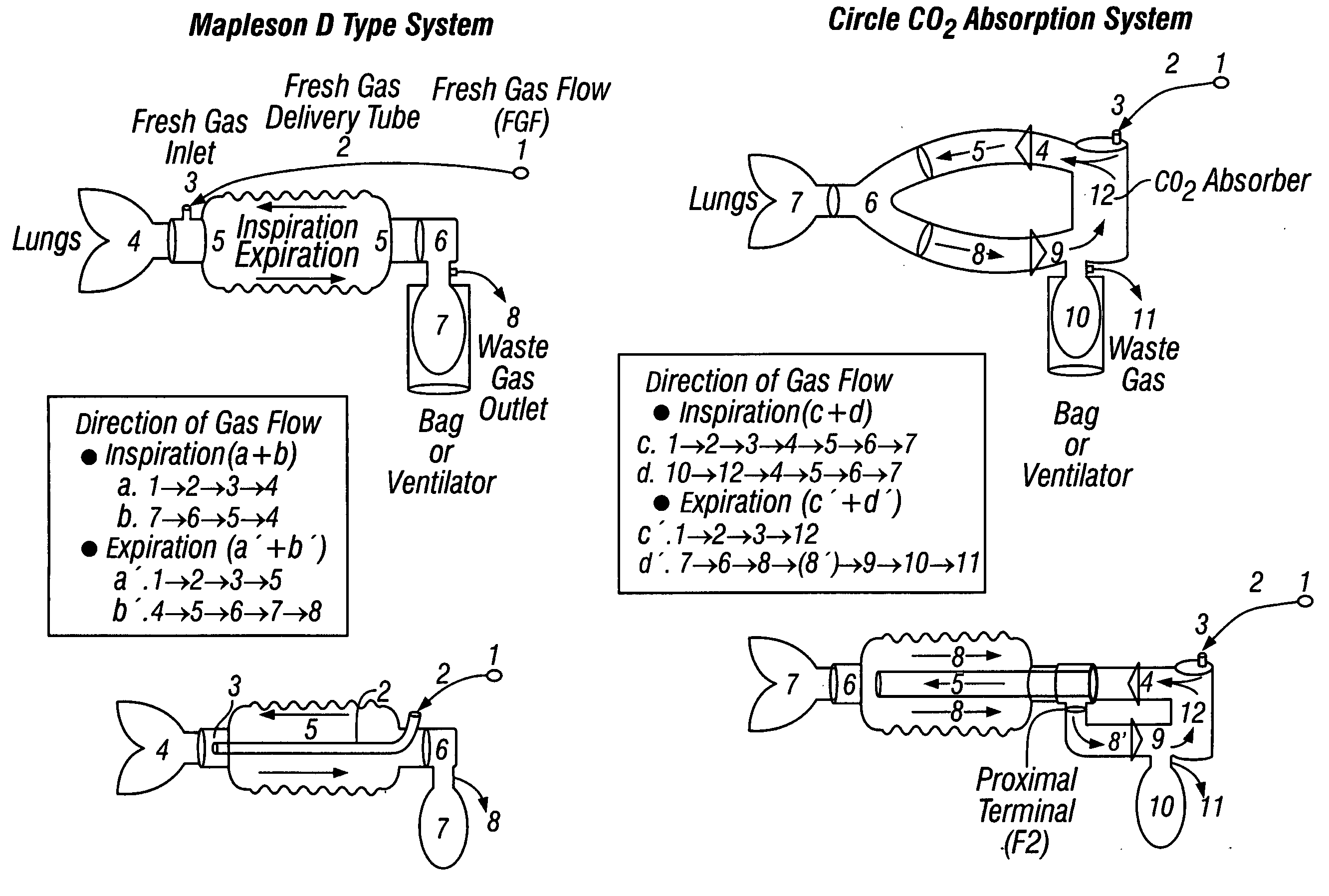

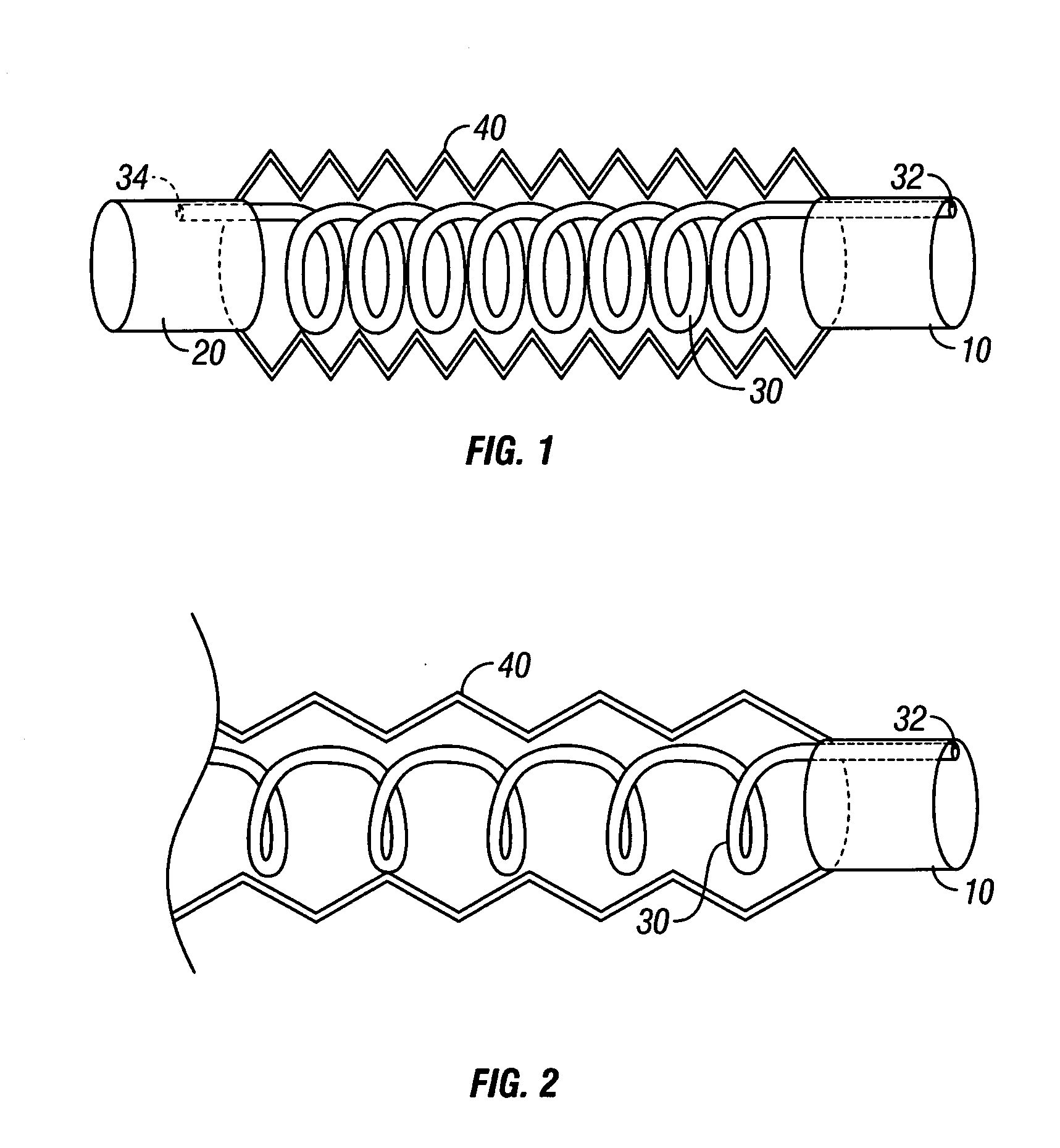

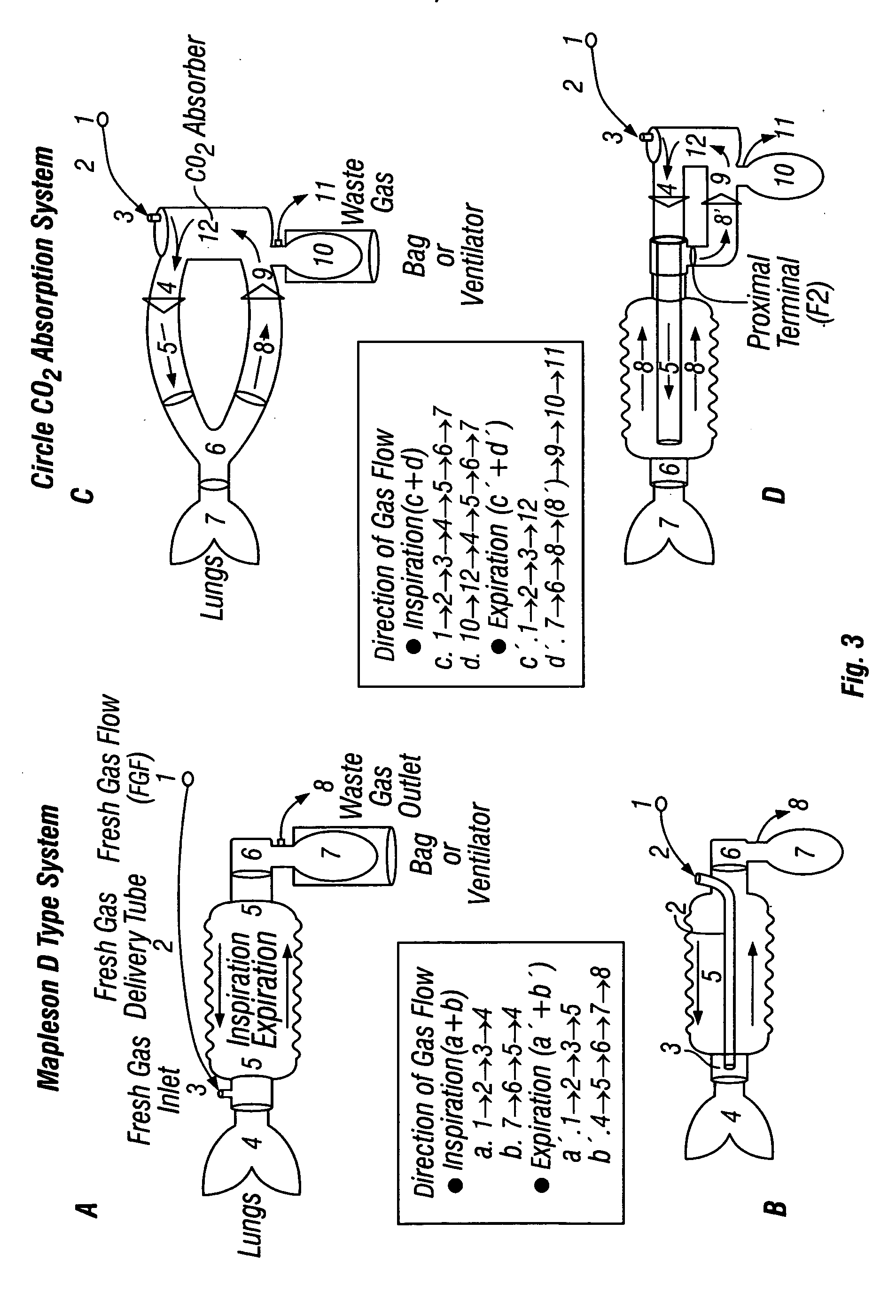

Breathing circuits having unconventional respiratory conduits and systems and methods for optimizing utilization of fresh gases

InactiveUS6874500B2Regulate securityOptimizing the utilization of anesthetic gasesRespiratorsSurgeryBreathing gasCatheter

A breathing circuit comprising first and second conduits, wherein at least one of the conduits is a non-conventional conduit. In an embodiment, a multilumen unilimb breathing circuit has first and second conduits, wherein when the proximal ends of said first and second conduits are each connected to an inlet and outlet fitting, respectively, movement of the distal end of the first conduit causes a corresponding movement of the distal end of the second conduit. In an embodiment, at least one of said conduits is coiled. In another embodiment, a coiled conduit is contained within an outer flexible conduit that is axially extendable and compressible, forming a unilimb multilumen respiratory circuit. The outer flexible conduit may be pleated to provide for non-rebounding axial extension and contraction. The multilumen respiratory circuit can provide a variable rebreathing volume. In an embodiment, at least one tube in a multilumen respiratory conduit is radially collapsible and radially expandable to a maximum radius for carrying respiratory gases to and from a patient. The methods and systems can be used to administer anesthesia and for other purposes.

Owner:AMBU AS

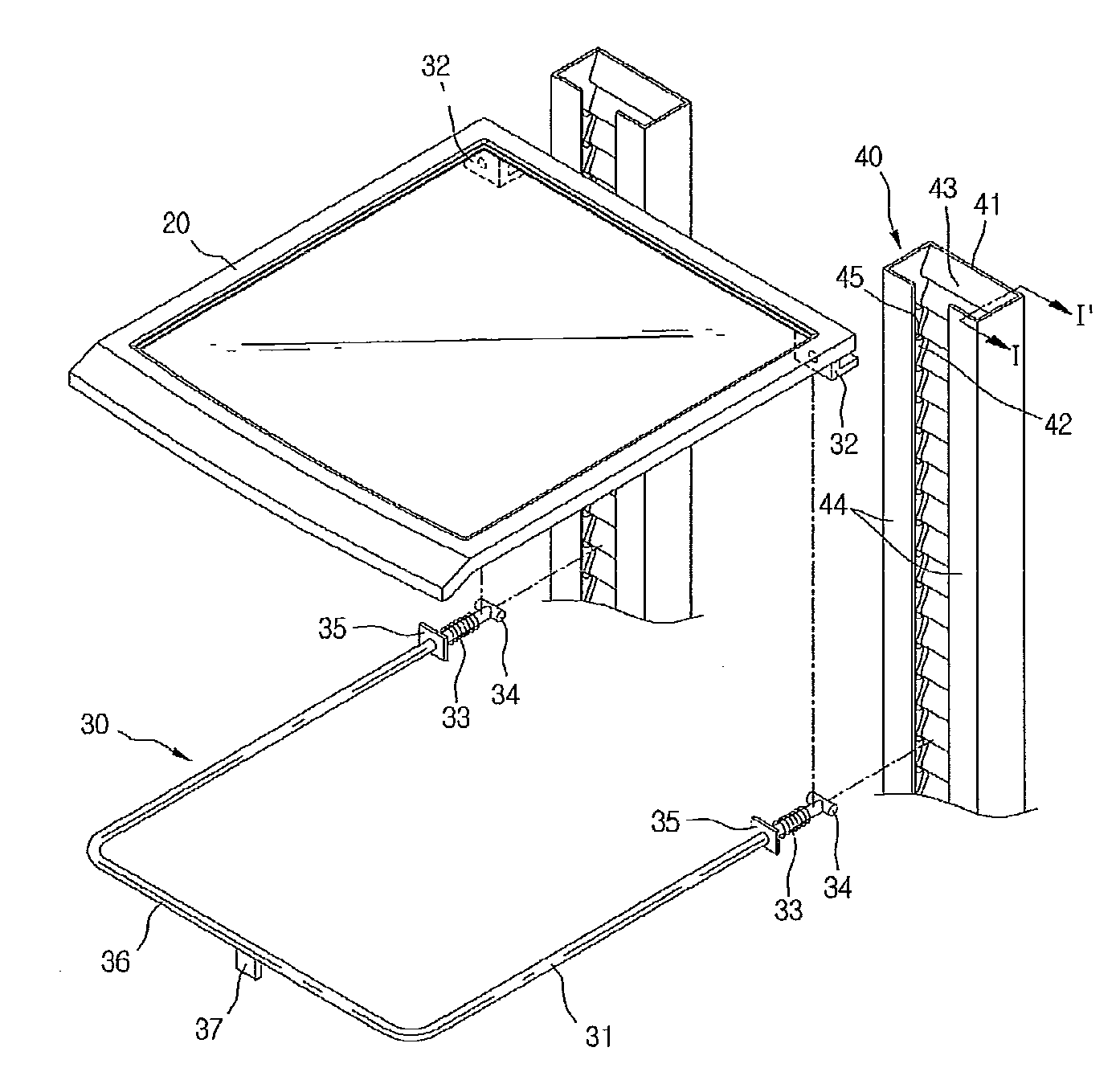

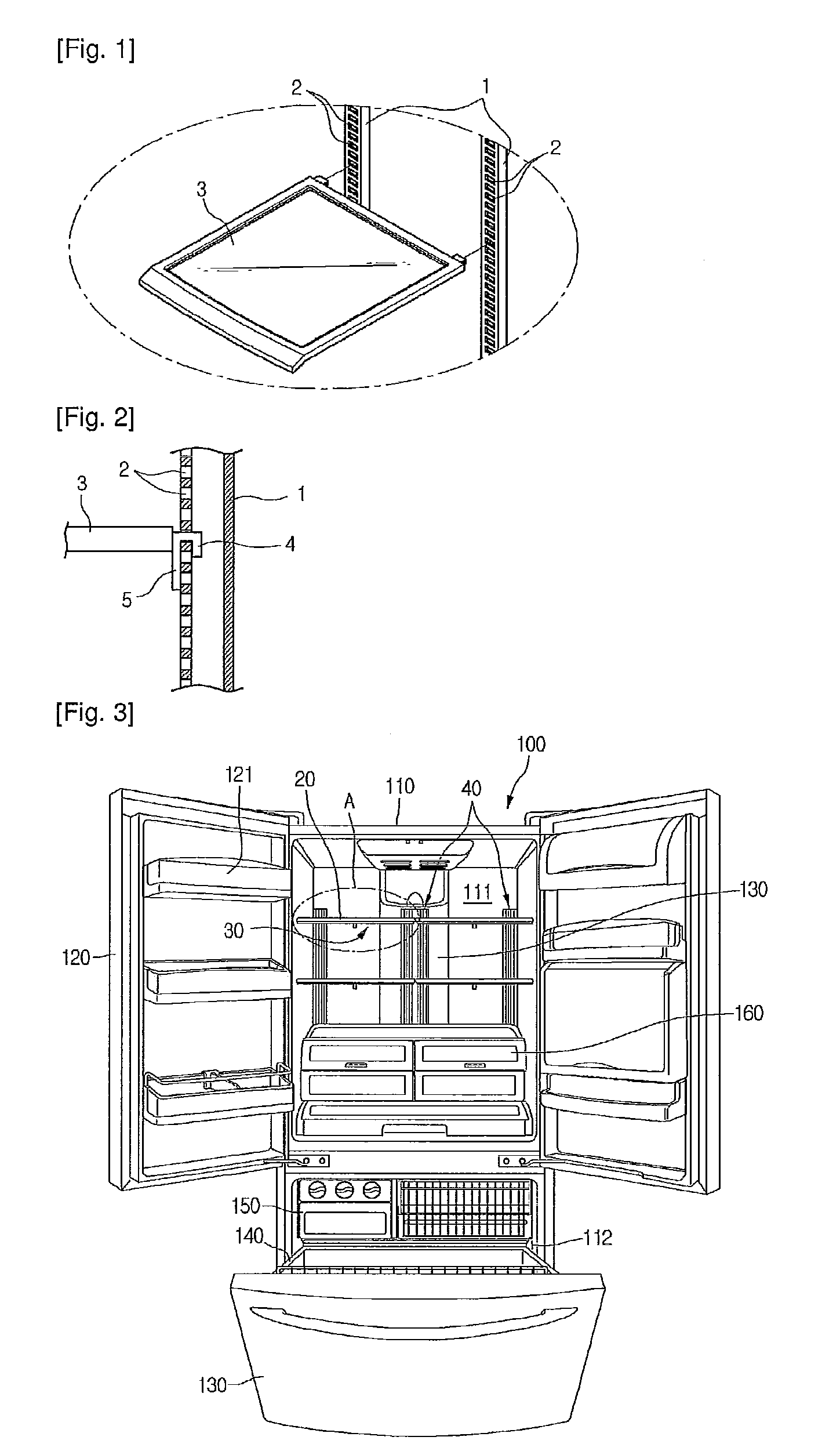

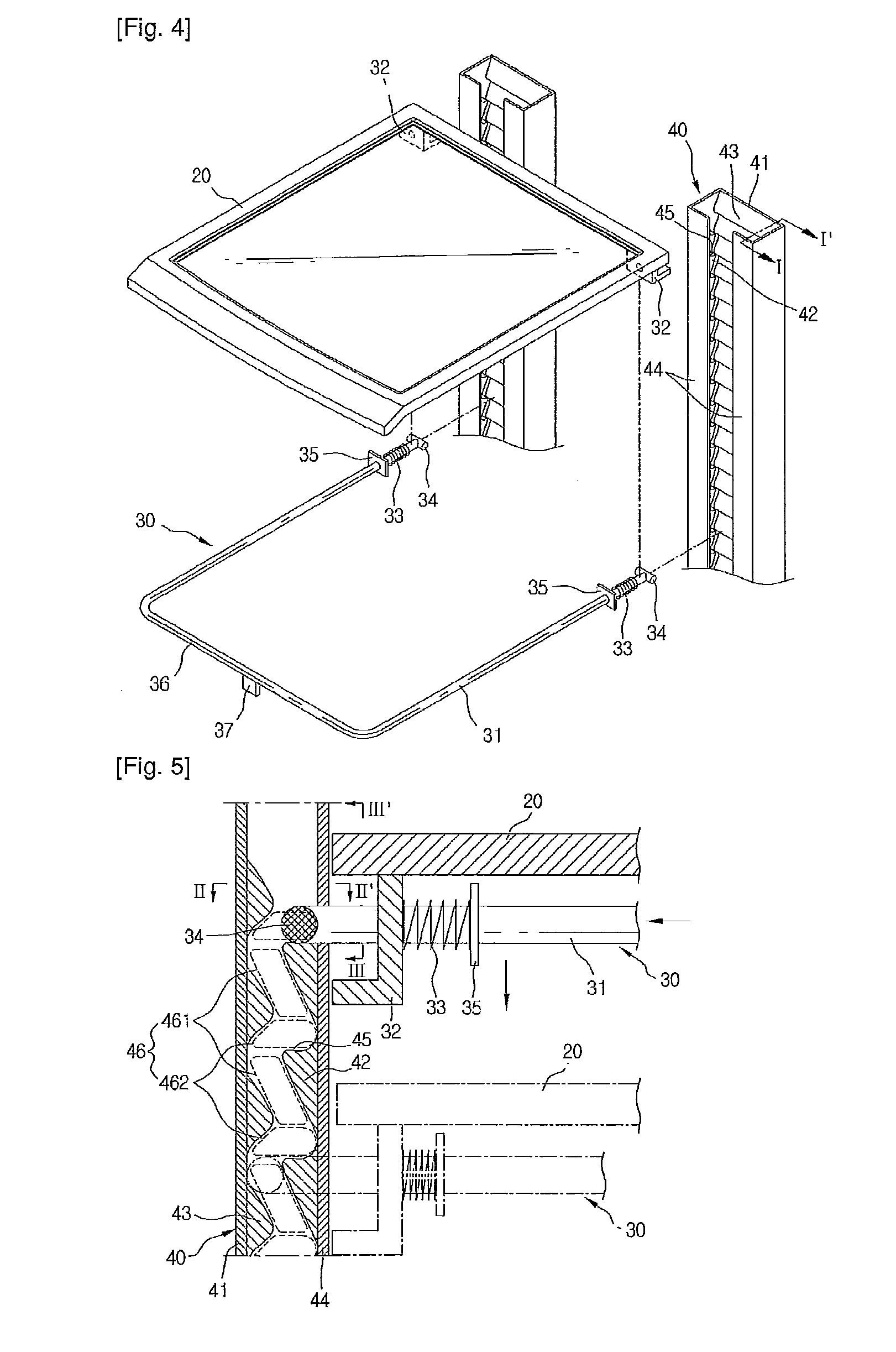

Basket for refrigerator

InactiveUS20100117502A1Improve ease of useImprove convenienceLighting and heating apparatusFurniture partsMechanical engineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

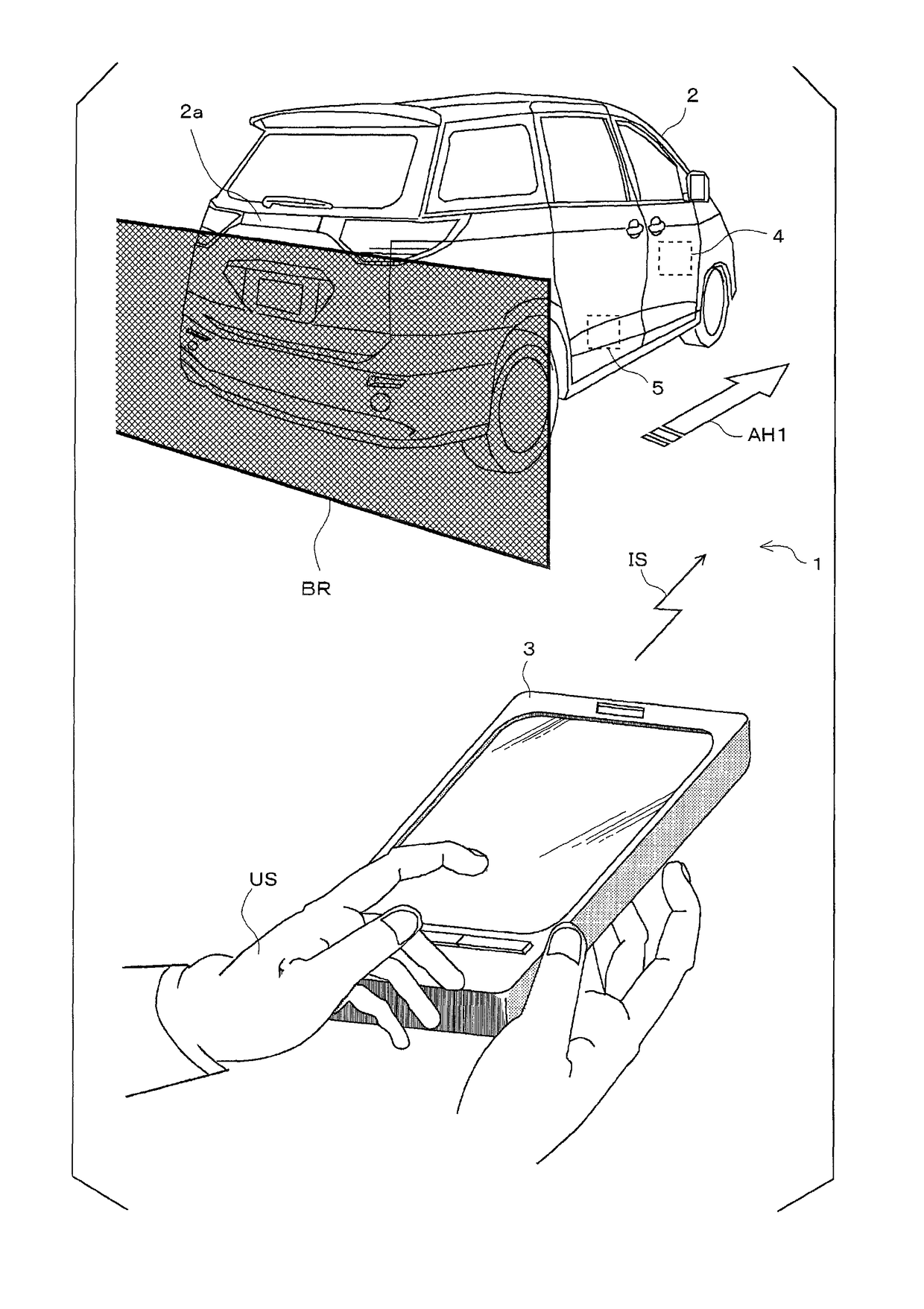

Vehicle apparatus

ActiveUS9731714B2Improve securityProhibit some movementImage enhancementImage analysisEngineeringMoving parts

A vehicle apparatus used in a vehicle measures a first elapsed time after completion of a parking operation by which the vehicle is parked in a parking region, and prohibits movement of the vehicle to adjust the parking position when the first elapsed time reaches a first predetermined time before receipt of a instruction signal by the receiver Accordingly, it is possible to improve safety by preventing the vehicle from moving out of a parking position even if the moving part is erroneously operated when the predetermined time elapses after the completion of parking operation.

Owner:FUJITSU GENERAL LTD

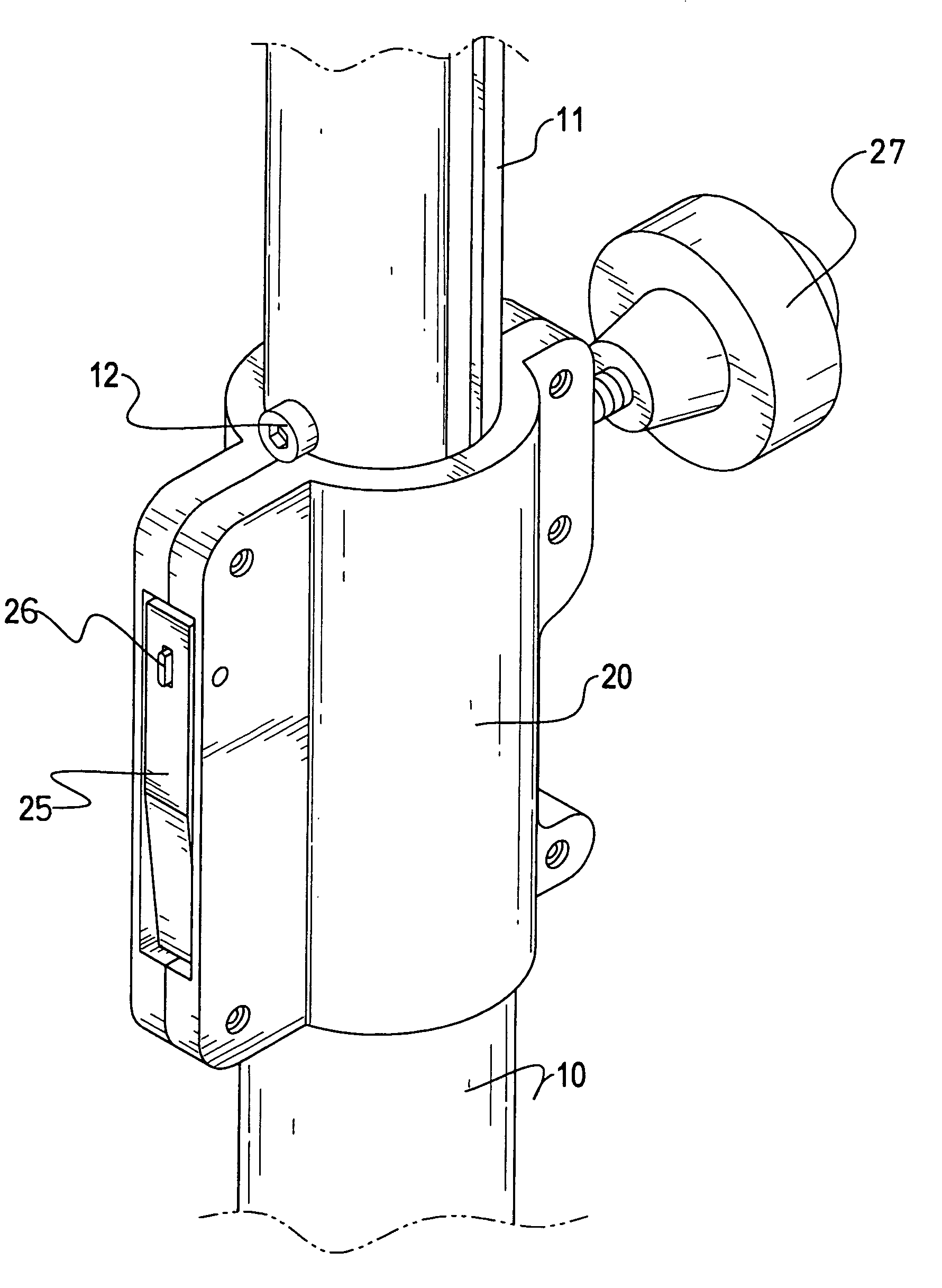

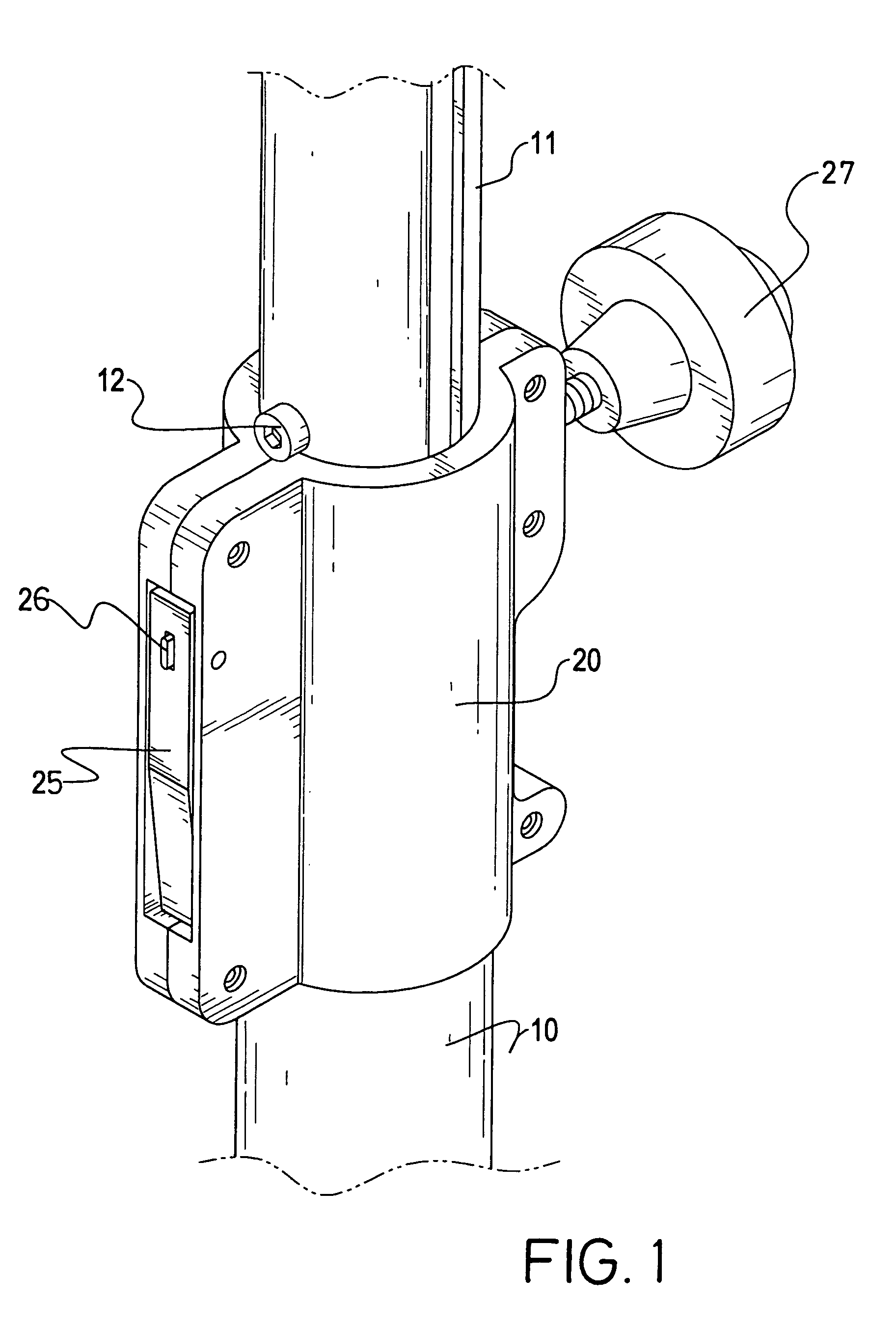

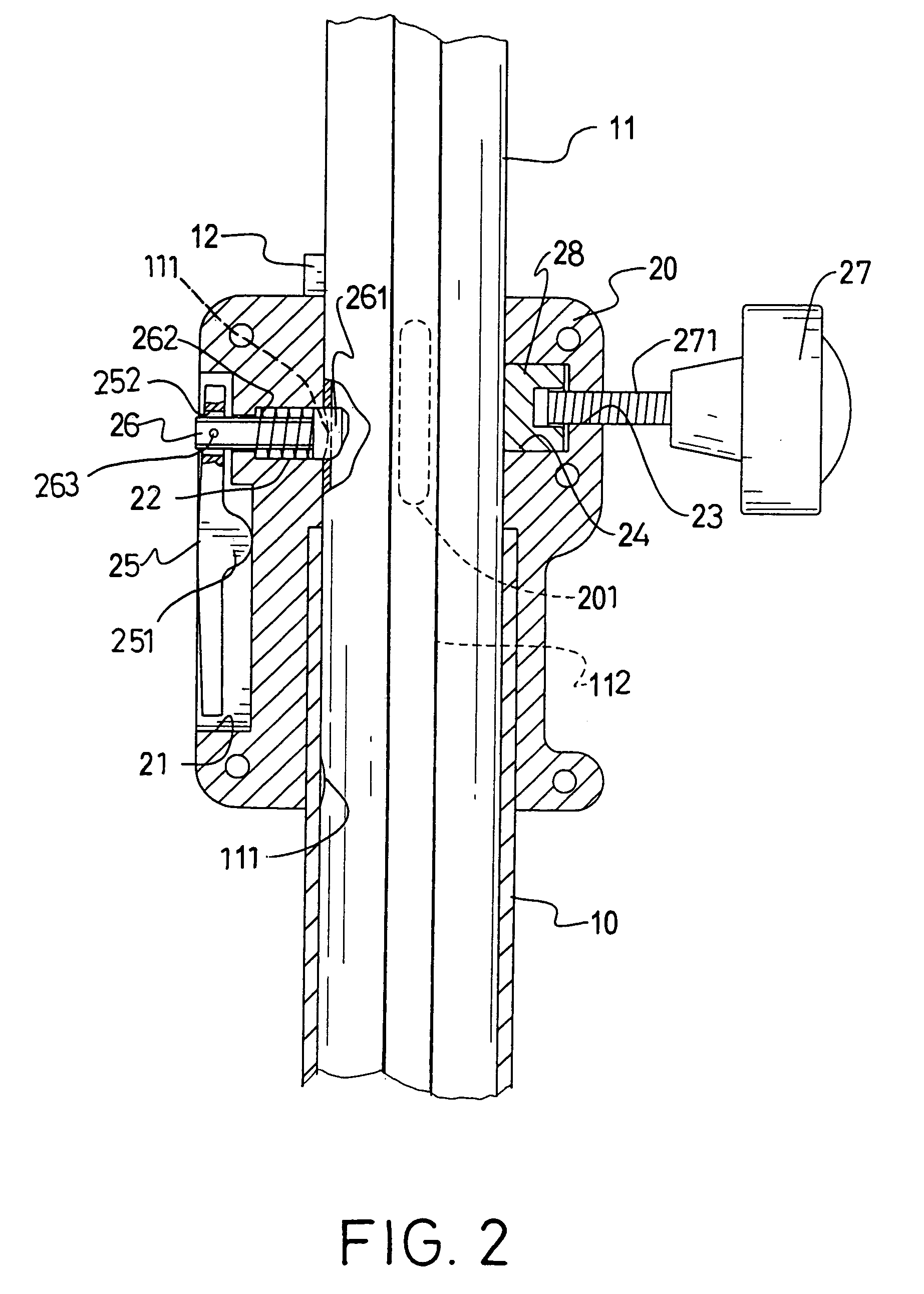

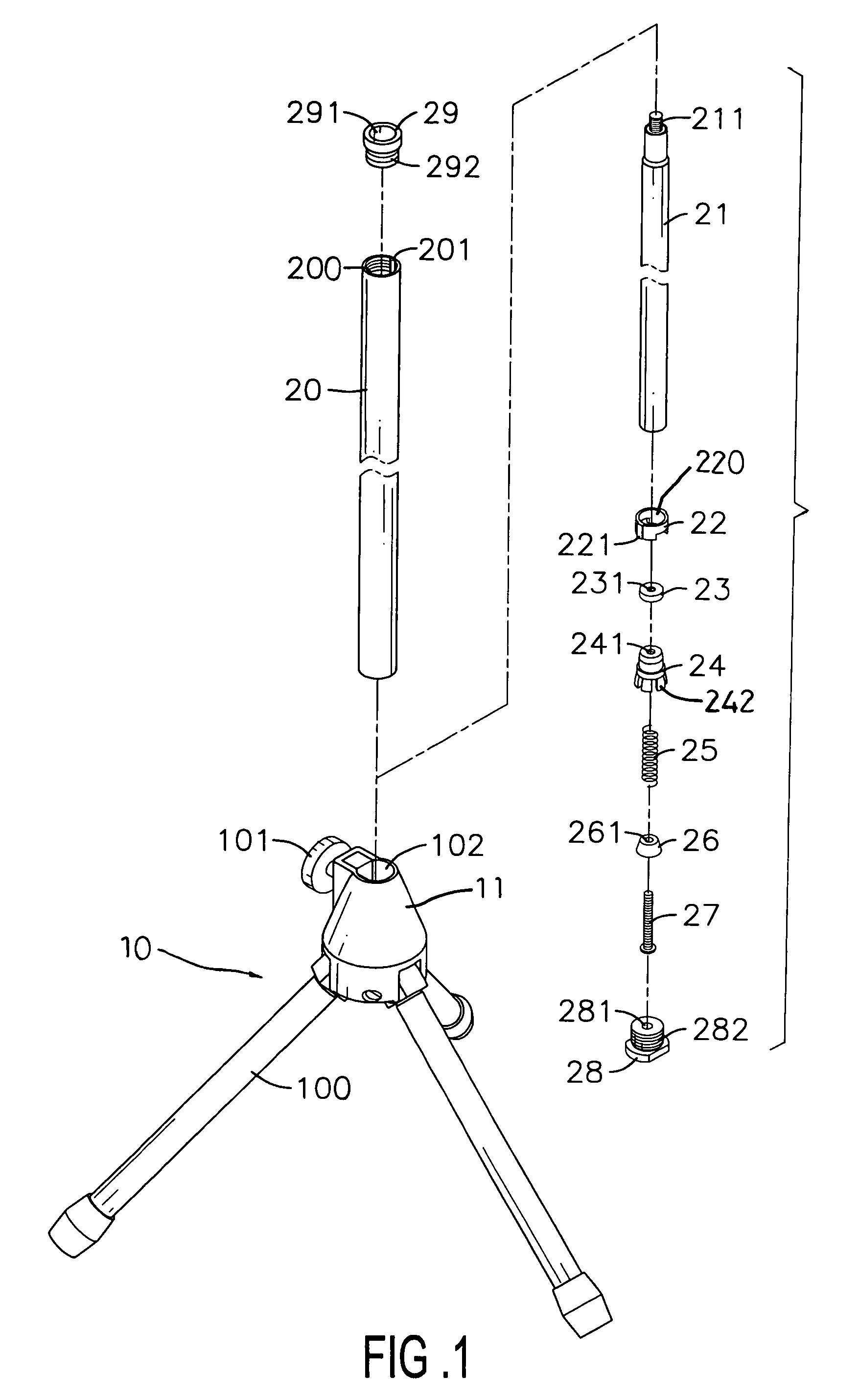

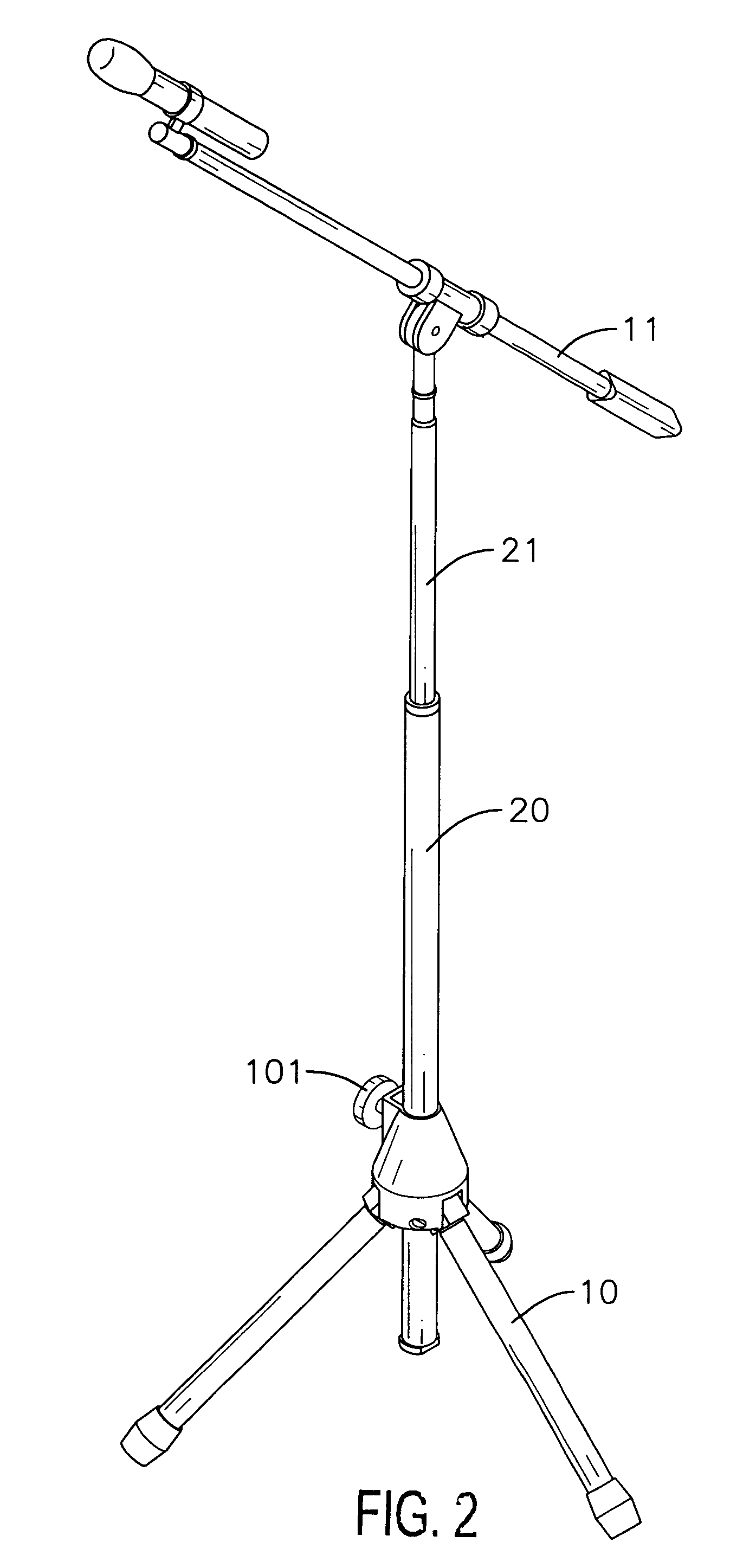

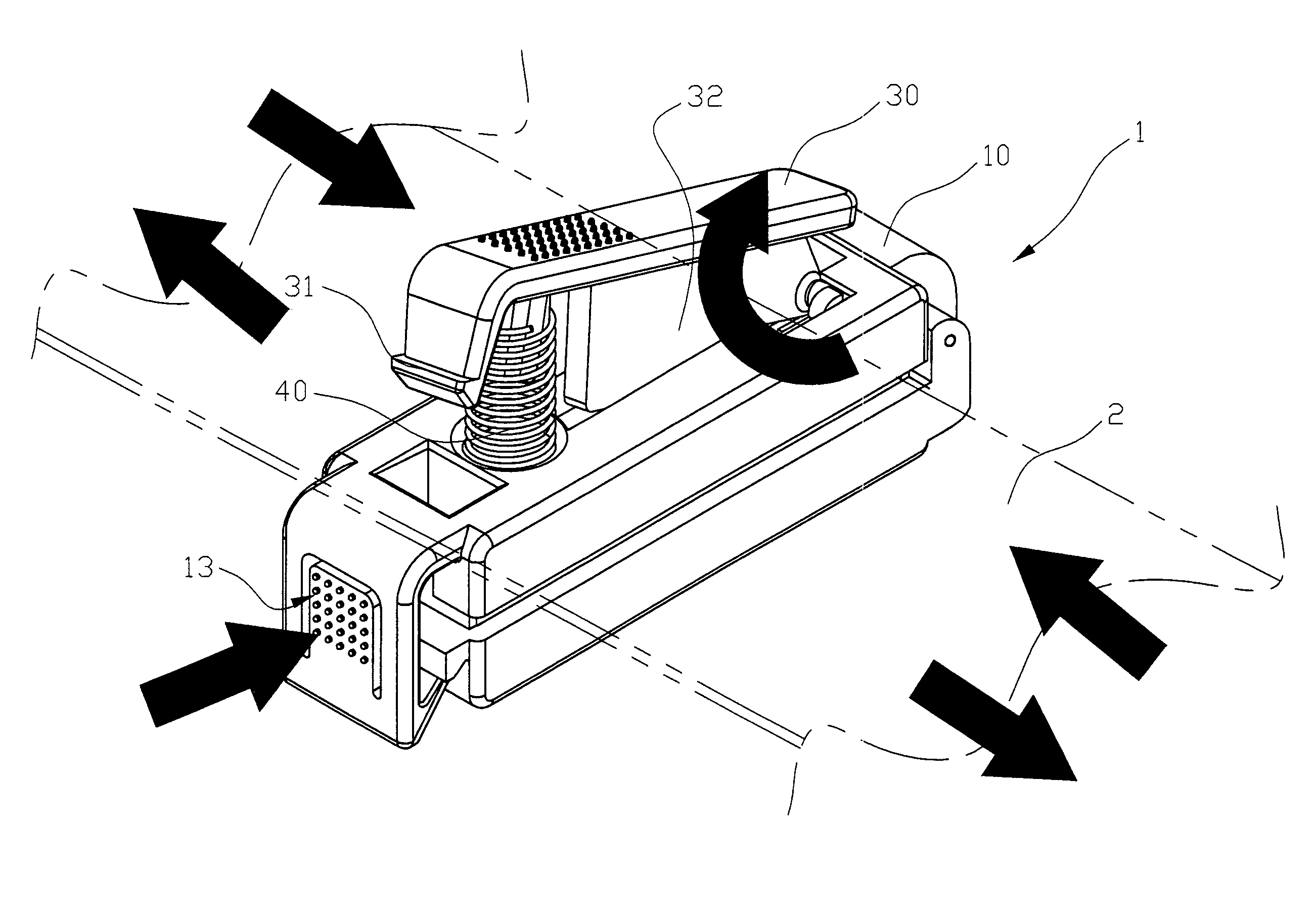

Locking device to secure a telescopic tube assembly

ActiveUS7040832B2Regulate securityEliminate dangerRod connectionsCouplings for rigid shaftsAerospace engineering

Owner:HSIEH WU HONG

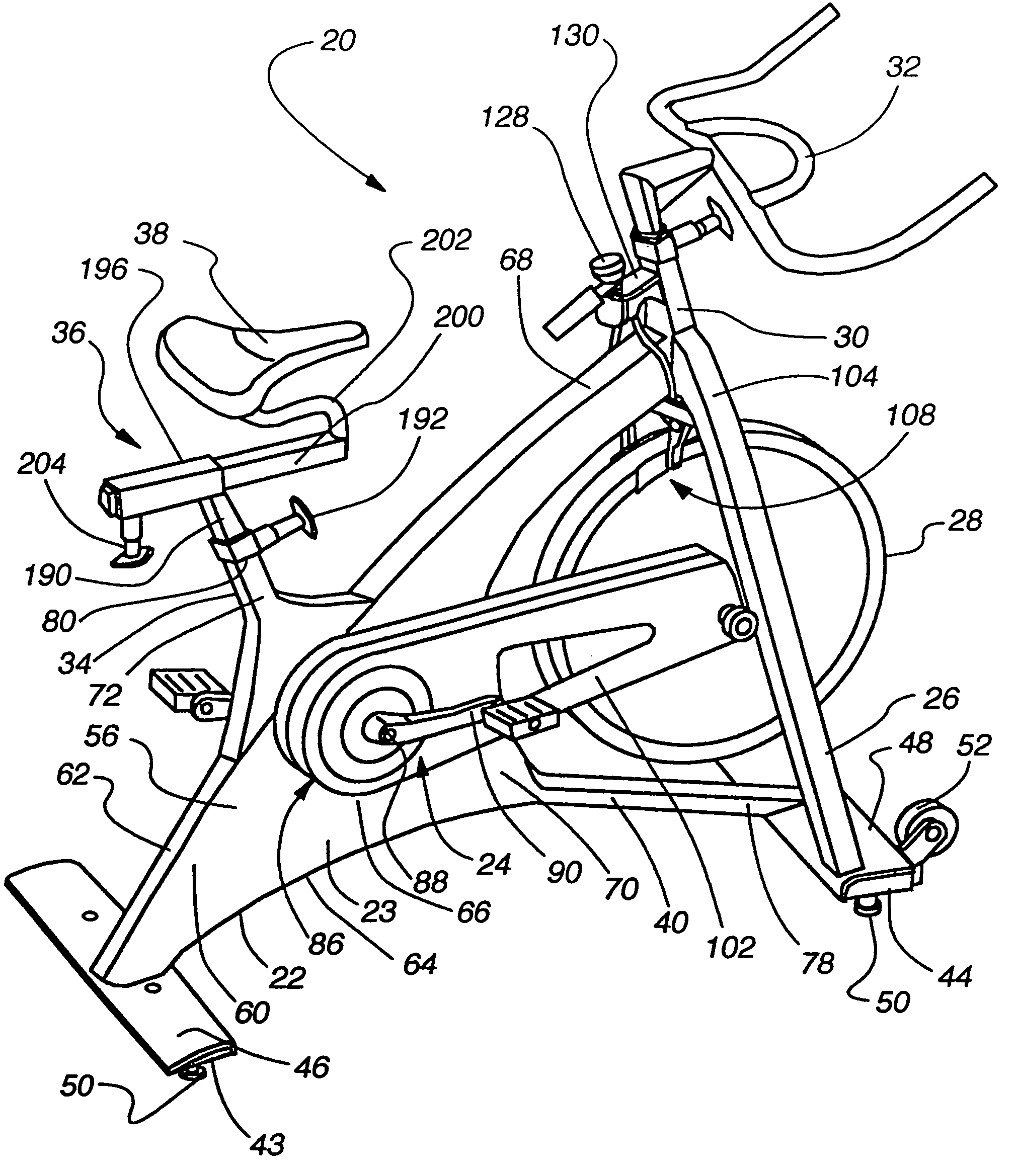

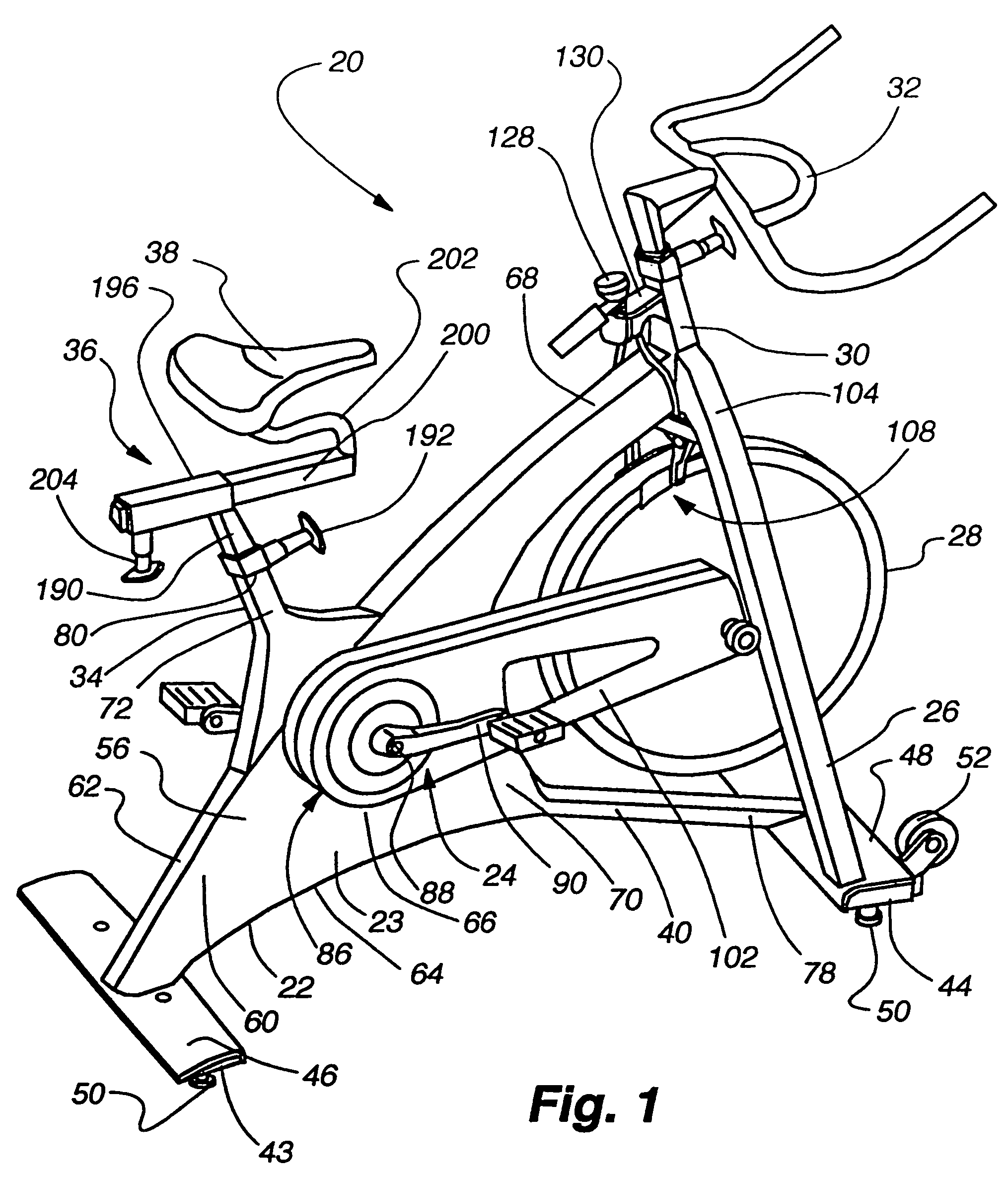

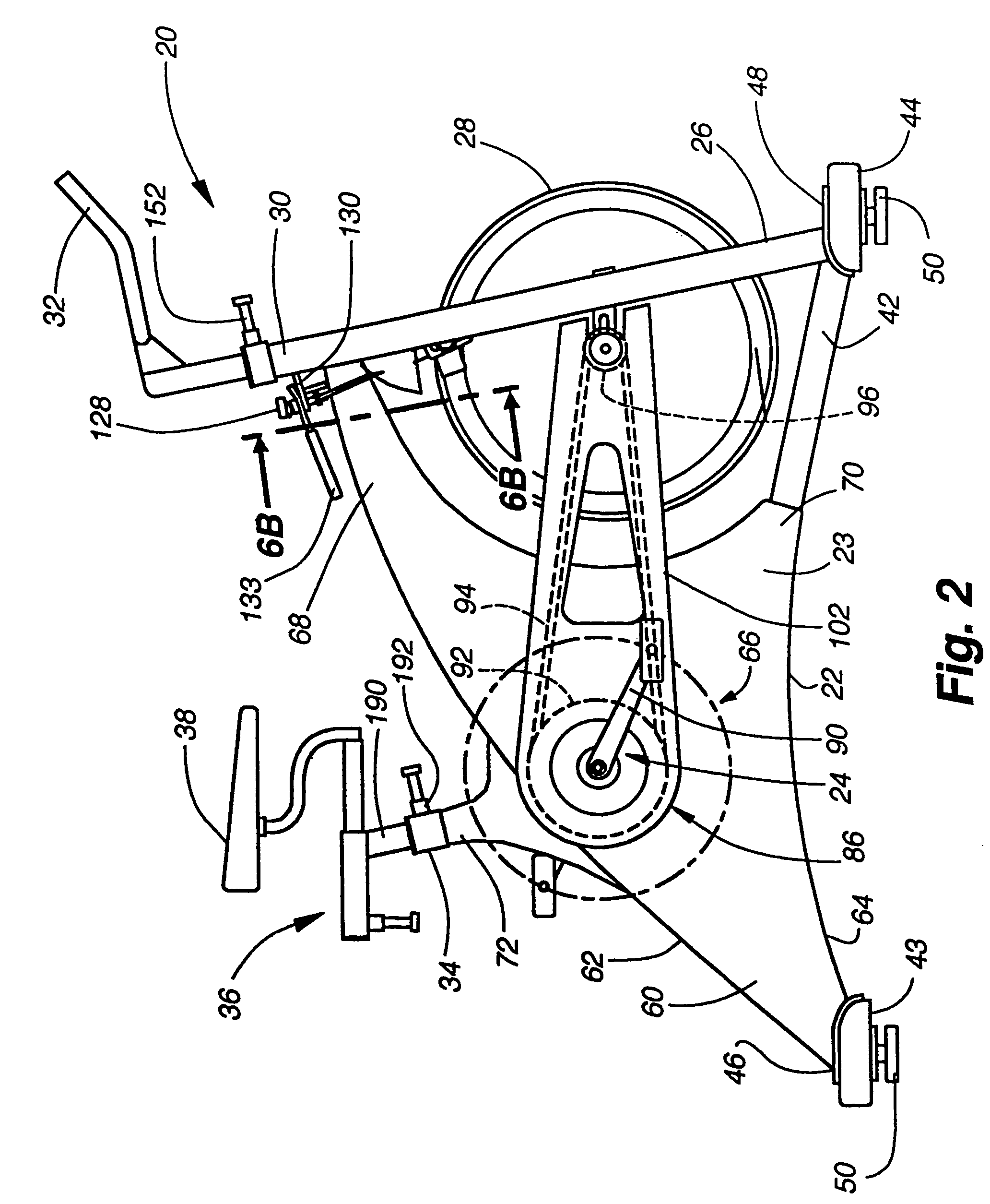

Exercise bicycle

InactiveUS7226393B2Easy to manufactureEasy to movePassenger cyclesChildren cyclesEngineeringUltimate tensile strength

A unique structure for an indoor exercise bike that provides strength in its design, as well as the flexibility to create an aesthetically appealing frame structure. The monocoque frame design, including two symmetrical halves joined together, forms a very strong, light shell that can take on a variety of shapes and sizes. The seat structure, handlebar structure, drive train and support platforms are all able to be readily attached to the primary frame structure to provide an exercise bicycle that is sturdy, easy to manufacture, and light enough to easily move when necessary.

Owner:NAUTILUS INC

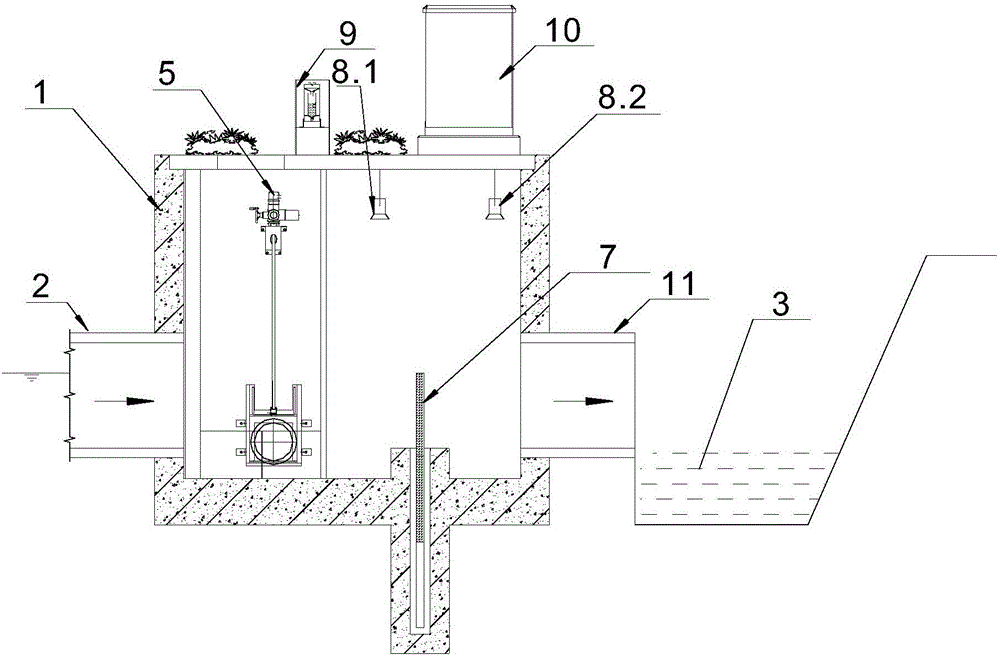

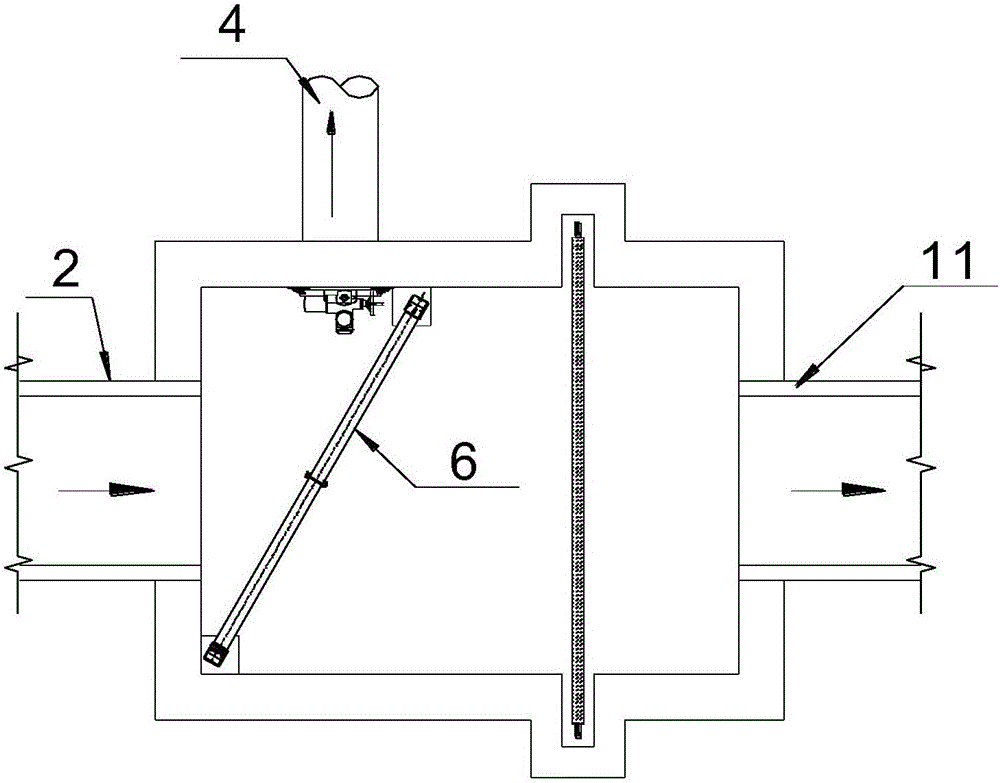

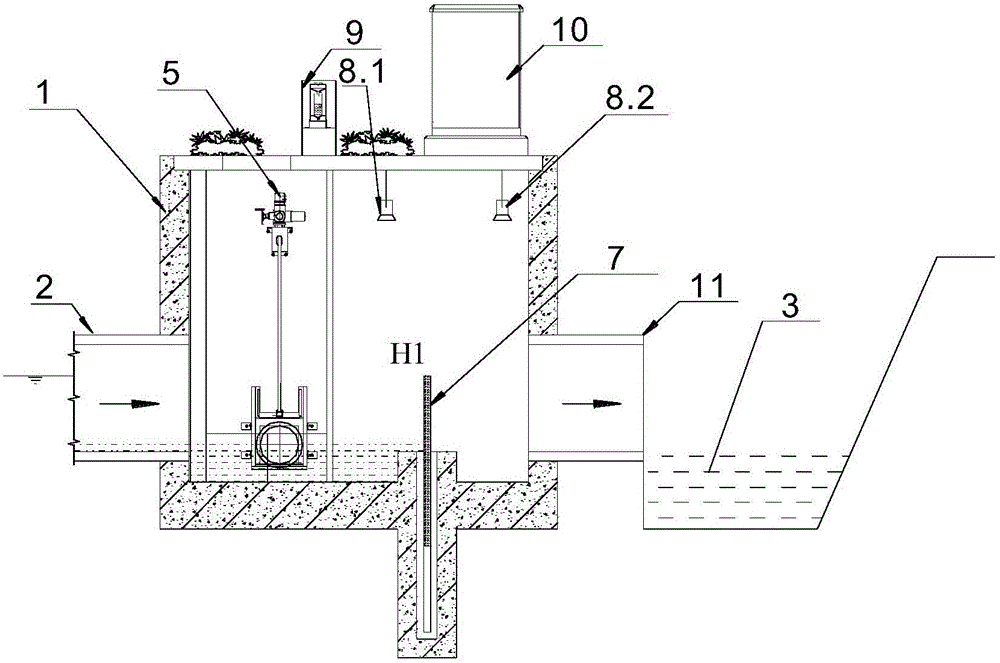

Novel anti-backflow intercepting well control method

ActiveCN105888046AEfficient separationReal-time control of interception heightSewerage structuresEngineeringNatural water

The invention discloses a novel anti-backflow intercepting well control method which comprises the steps of: carrying out initial setting: monitoring a liquid level height H in the intercepting well and on the upstream of a downward opening type weir gate in real time, monitoring a natural water liquid level height H' in real time, setting a maximum anti-backflow height of the downward opening type weir gate as Hmax, setting a top height of the downward opening type weir gate in an intercepting state as H1, and setting a safety distance of a natural water liquid level and the top height of the downward opening type weir gate as a; a, when H' is greater than H and H' is greater than H1-a, controlling the top height of the downward opening type weir gate as H'+a, when the natural water liquid level is risen, ascending the downward opening type weir gate until the top height is Hmax, and when the natural water liquid level drops, descending the downward opening type weir gate until the top height is H1; b, when H' is smaller than H, controlling the intercepting well to execute a drainage procedure. The control method disclosed by the invention is simple and effective, not only can prevent backflow, but also can safely drain and draw off floodwater, regulates and controls the intercepting height of the downward opening type weir gate in real time, is sensitive in reaction, and is rapid and safe in regulating process.

Owner:WUHAN SHENGYU DRAINING SYST

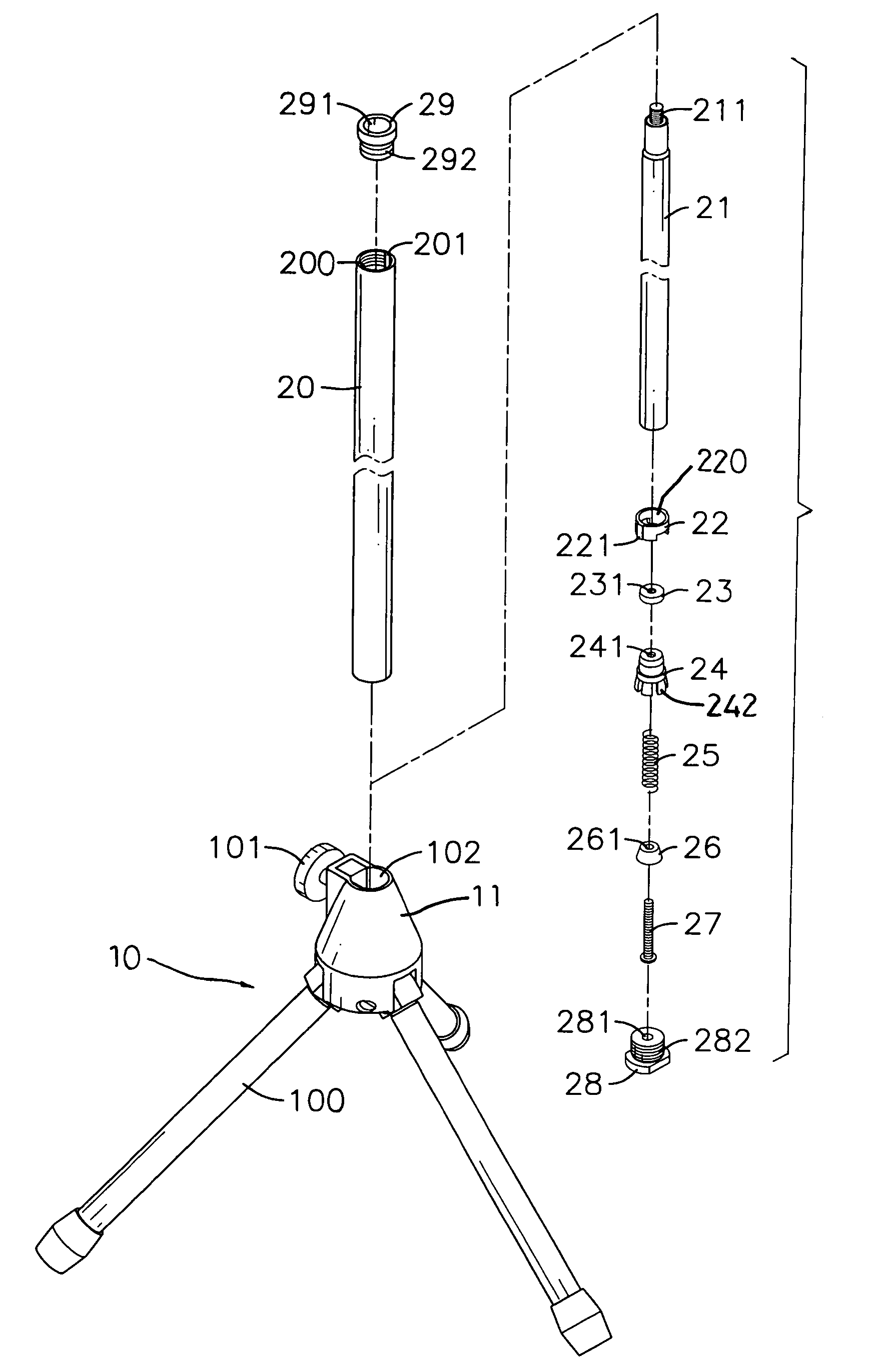

Locking device for a telescopic tube assembly

ActiveUS7007909B2Regulate securityIncrease frictionRod connectionsStands/trestlesEngineeringMechanical engineering

A locking device for a telescopic tube assembly having an outer tube and an inner tube slidably received in the outer tube includes a securing ring securable inside the inner tube, a friction element adapted to be securely mounted on one distal end of the inner tube and having legs deformably extending out and a wedge adapted to be selectively and movably received inside the outer tube to force the legs to extend toward an inner periphery of the outer tube so as to increase friction between the legs and the outer tube. Thus movement of the inner tube in the outer tube is selectively controlled.

Owner:HSIEH WU HONG

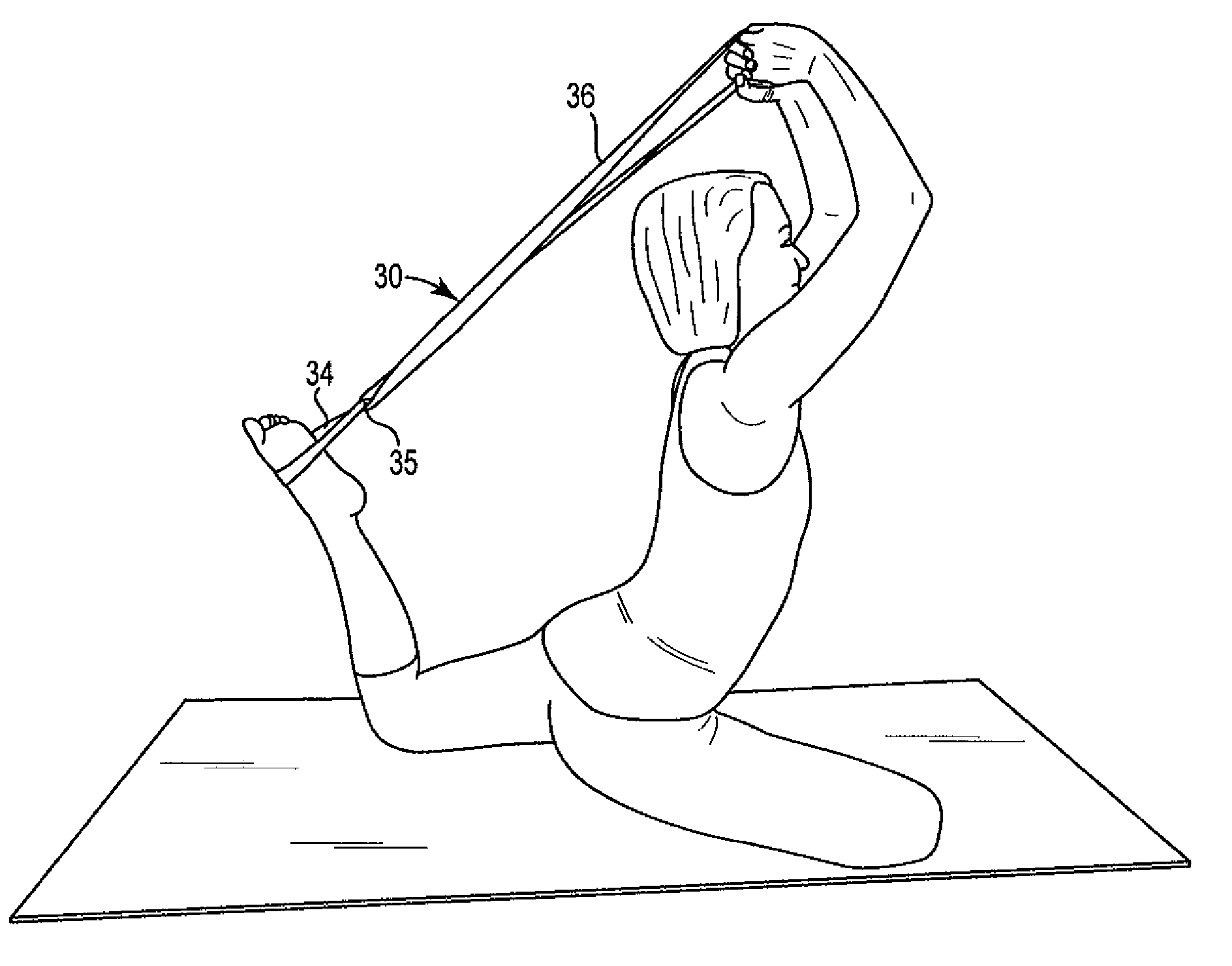

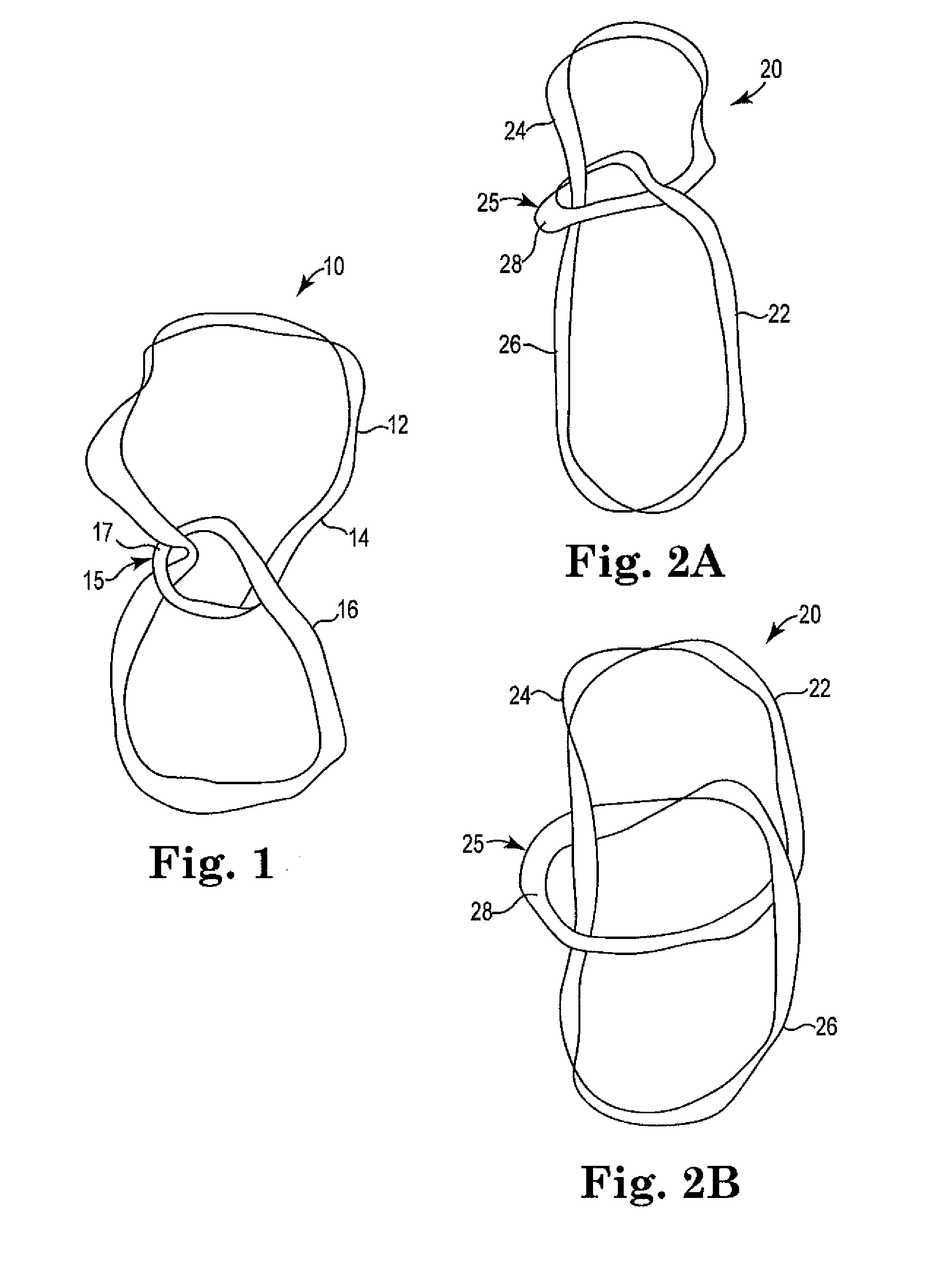

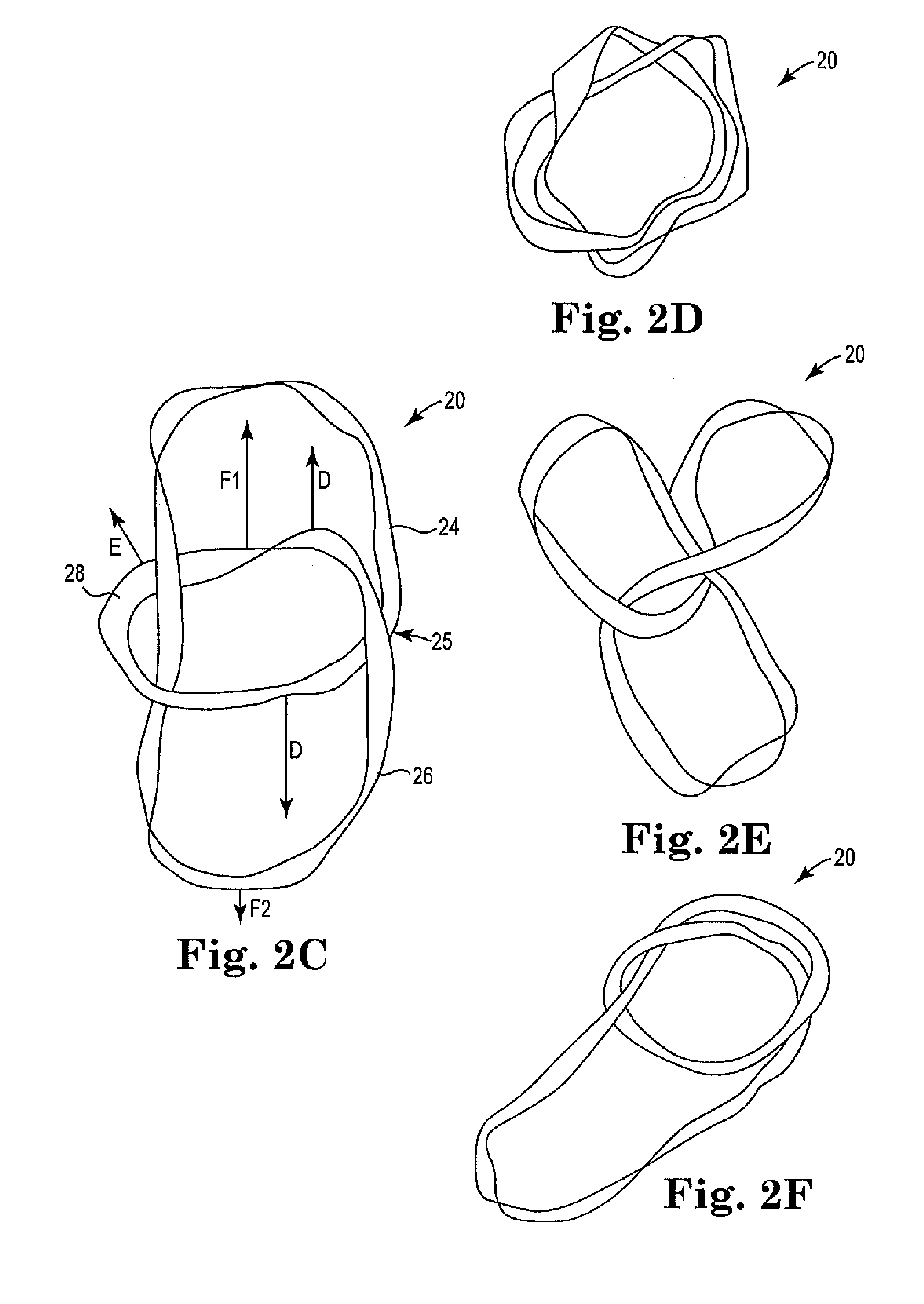

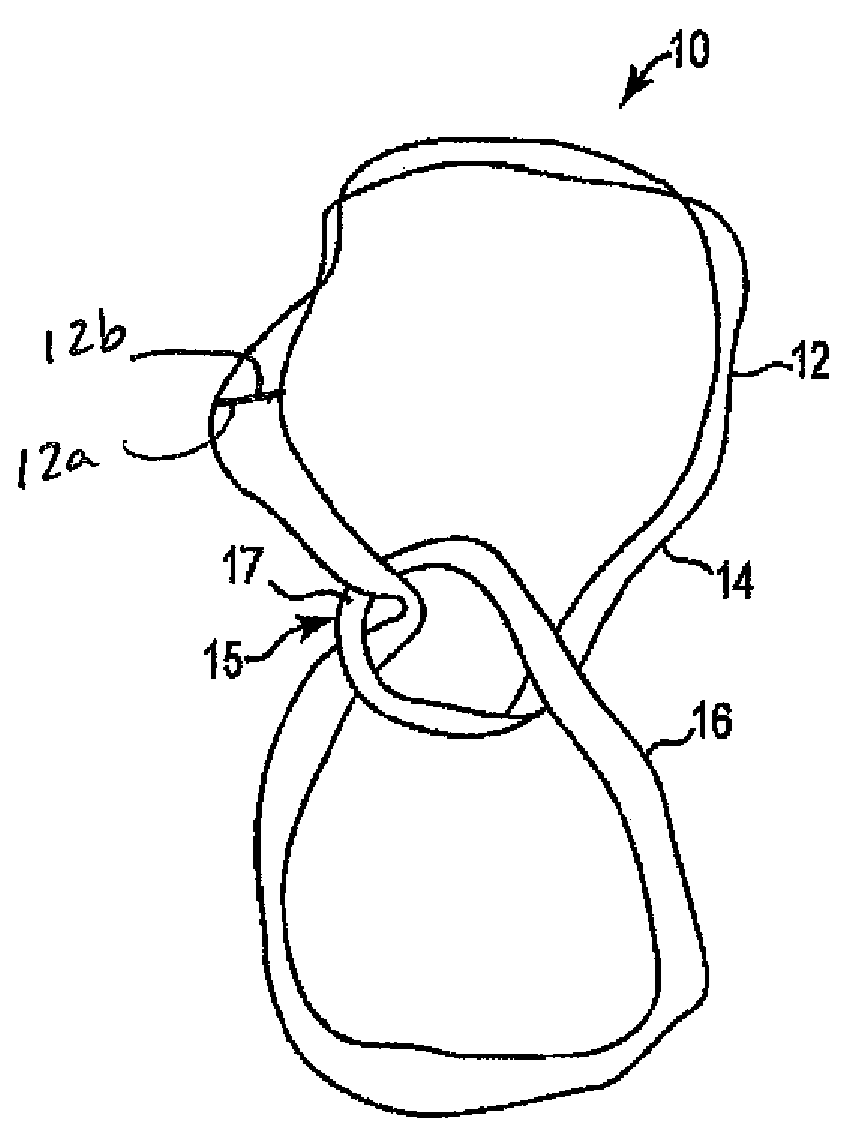

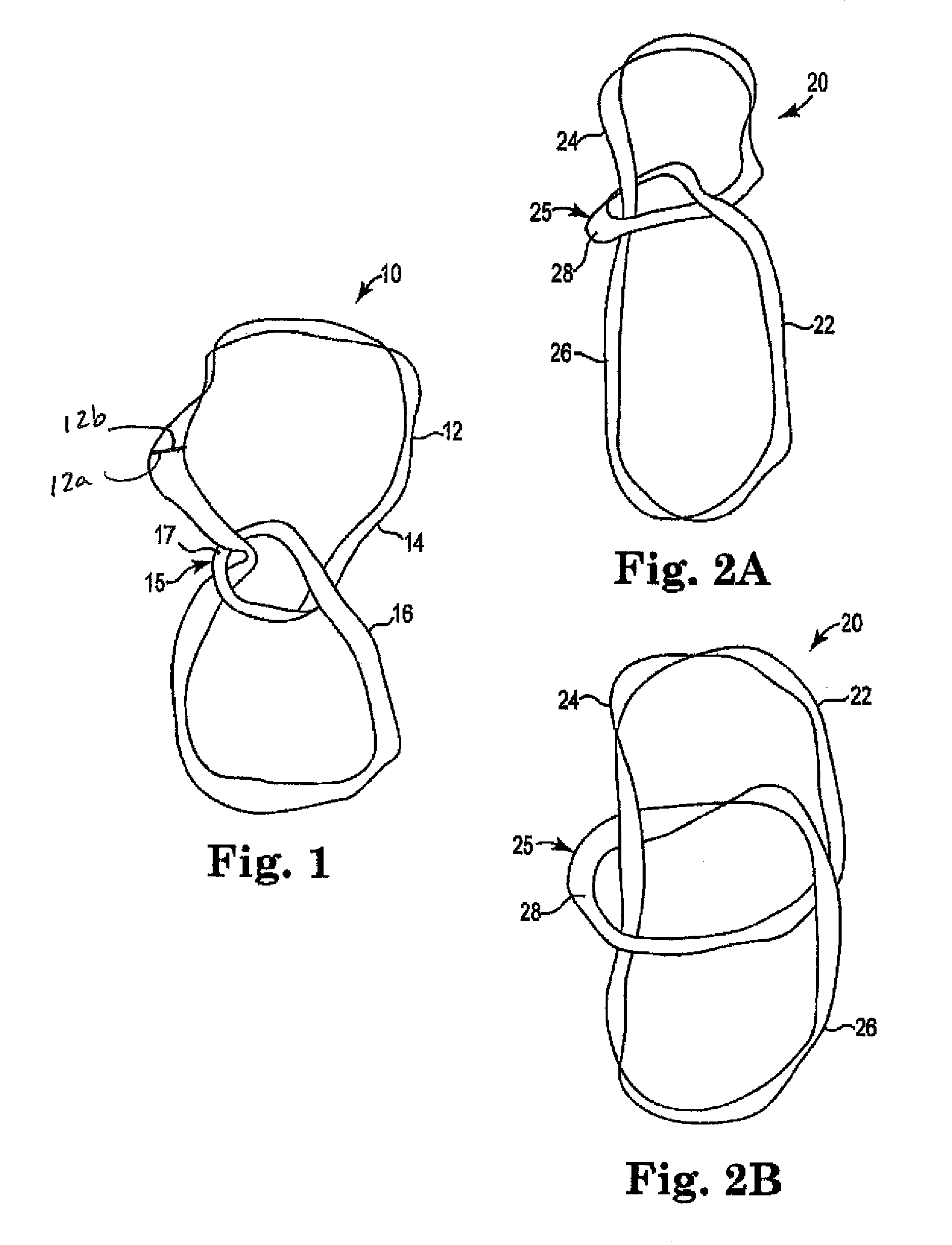

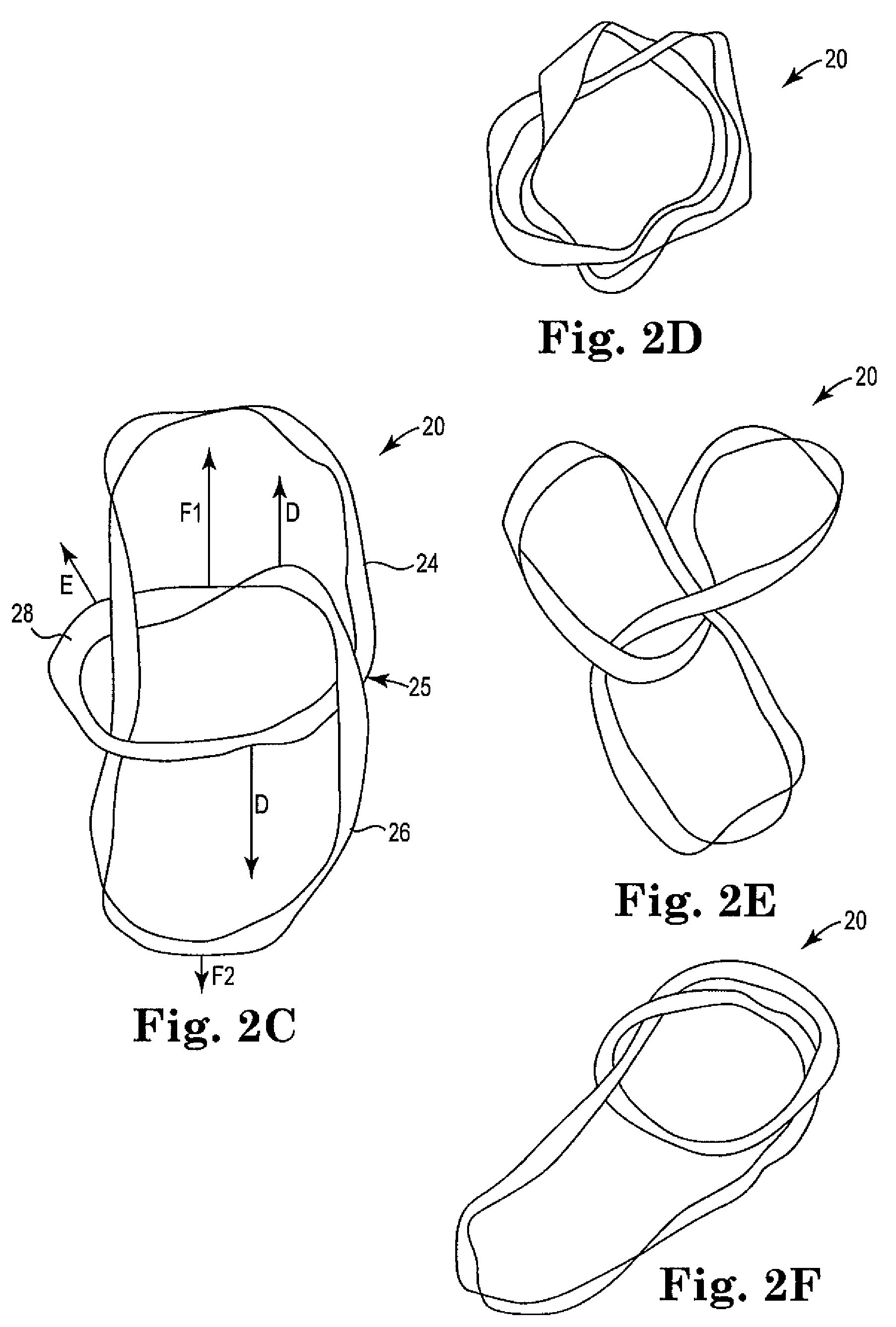

Closed loop device incorporating one or more indecomposable knots and methods of using

InactiveUS20110306477A1Easy to processSimple to useSnap fastenersTravelling sacksMuscle groupClosed loop

A flexible, closed loop device that includes at least one indecomposable knot formed that helps define a plurality of adjustable loops. The knot can be easily loosened so that the loop sizes can be adjusted. The knot is easily tightened and locked. In some embodiments, the device includes at least two indecomposable knots. The device is useful in the practice of yoga, Pilates, and other personal training exercises. The device is flexible and easily adjustable, allowing the user to more effectively target specific muscle groups. The device may additionally or alternately be used as a securing and carrying strap for items. Still further, the device may be used as a connecting device to link items together for towing, hoisting, etc.

Owner:KEEN BRIAN T +1

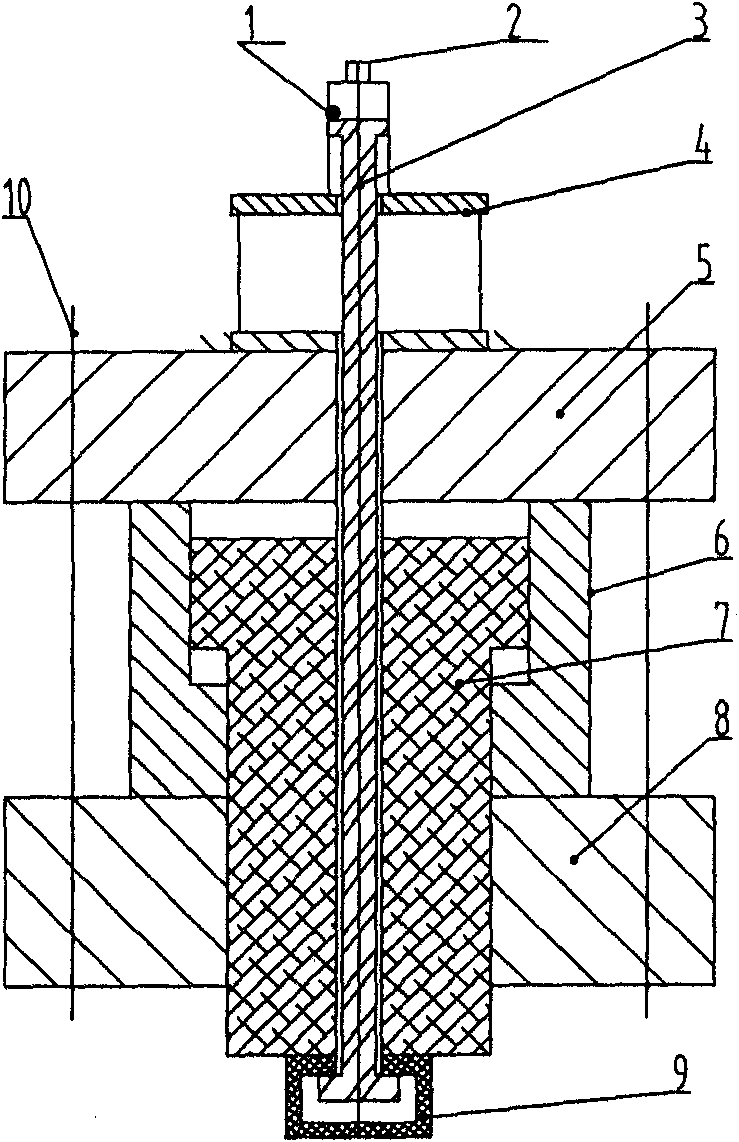

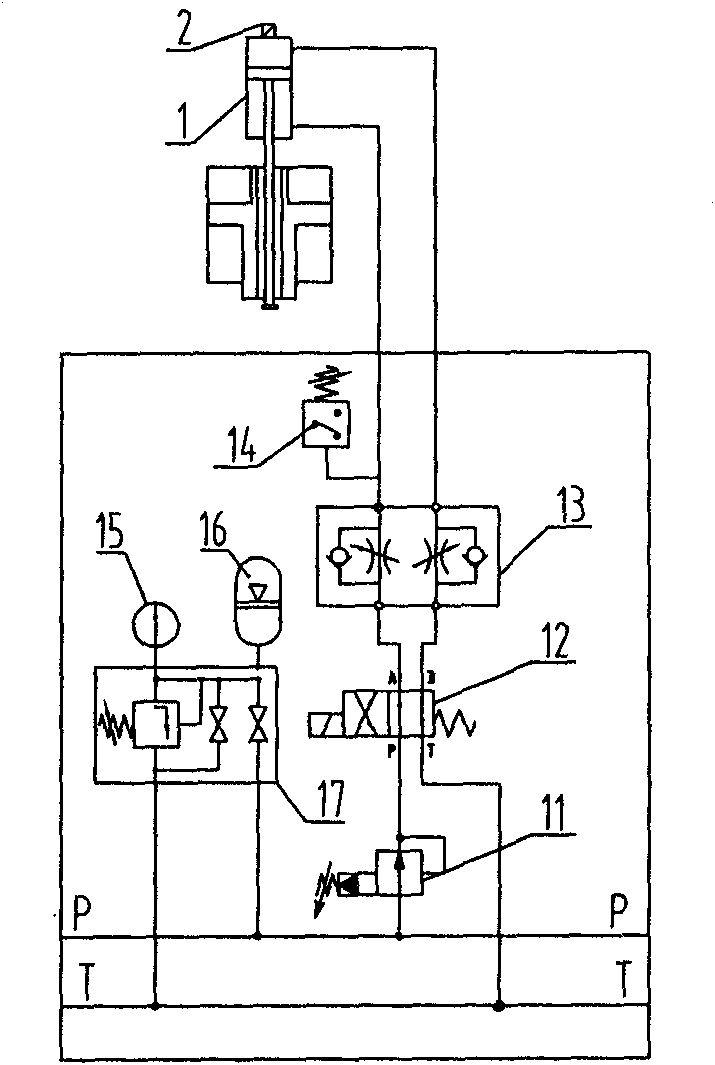

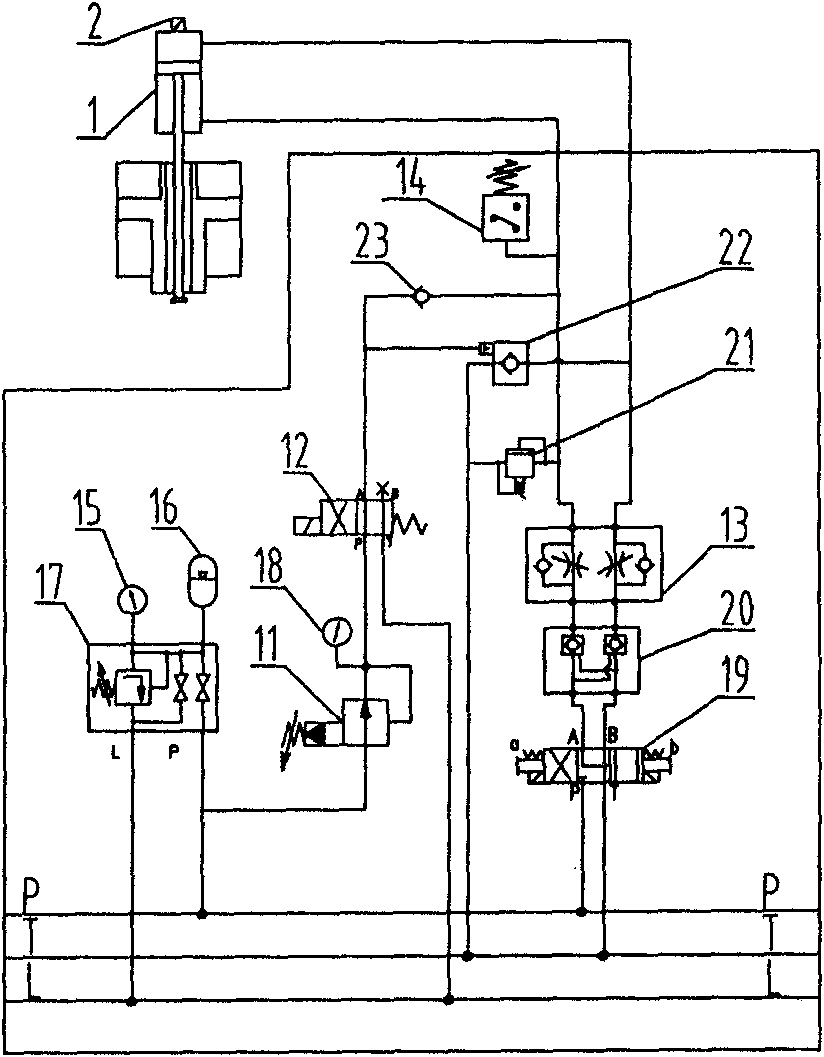

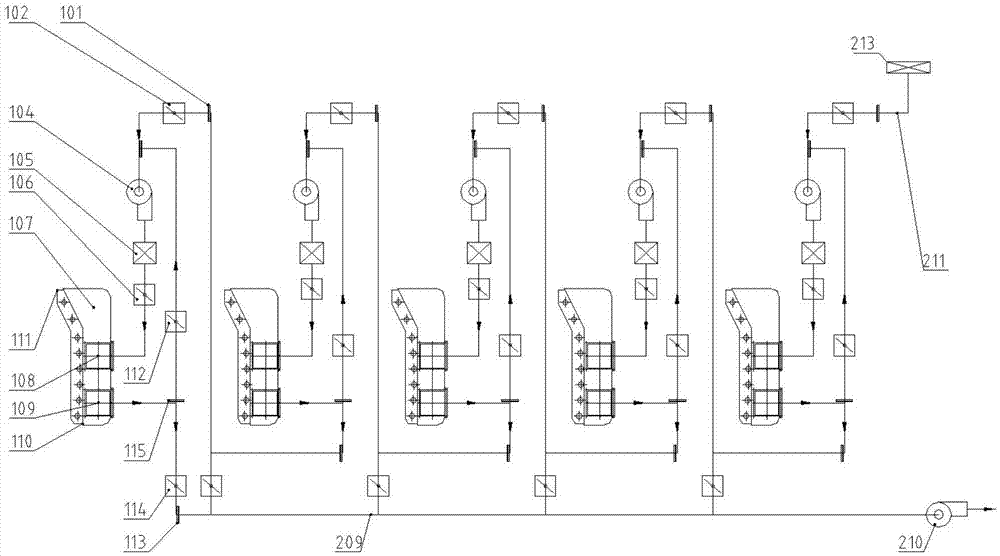

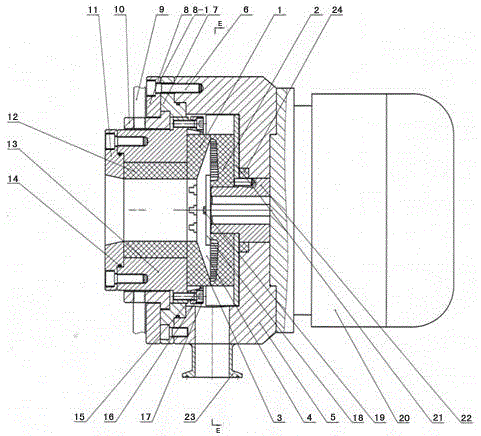

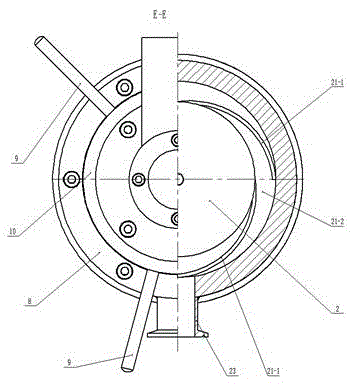

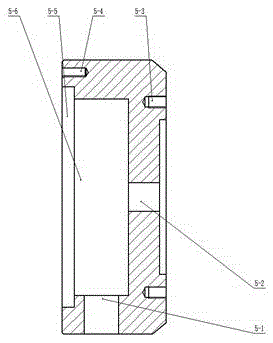

Pressure-maintaining and regulating hydraulic control system of roll balance gear

InactiveCN101869912AMonitor packing and packing pressureRegulate securityMetal rolling stand detailsMetal rolling arrangementsControl systemSafety valve

The invention discloses a pressure-maintaining and regulating hydraulic control system of a roll balance gear and relates to a hydraulic control system of a steel rolling machine. The pressure-maintaining and regulating hydraulic control system solves the problems of unreliable pressure maintenance, inconvenient equipment debugging and no pressure protection of a control loop in the prior art. The pressure-maintaining and regulating hydraulic control system is characterized in that: a hydraulic control loop comprises a pressure-maintaining loop of the roll balance gear and an adjusting loop of the roll balance gear; the pressure-maintaining loop is formed by connecting a pressure-reducing valve 11, an I-number electromagnetic directional valve 12, an energy accumulator 16, a safety valve 17, an I-number pressure meter 15, an II-number pressure meter 18 and a hydraulic oil pipe according to the conventional connecting method; the adjusting loop is formed by connecting an II-number electromagnetic directional valve 19, a one-way throttle valve 13, a pressure relay 14, a hydraulic locking valve 20, an overflow valve 21 and the hydraulic oil pipe according to the conventional connecting method; and the pressure-maintaining loop and the adjusting loop are separated and associated by using a hydraulic one-way valve 22 and a one-way valve 23.

Owner:TAIYUAN HEAVY IND

Safety belt positioning device

InactiveUS7004547B1Easy to installEasy to adjustSnap fastenersFastening devicesEngineeringBelt safety

Owner:CHENG SHENG HSIUNG

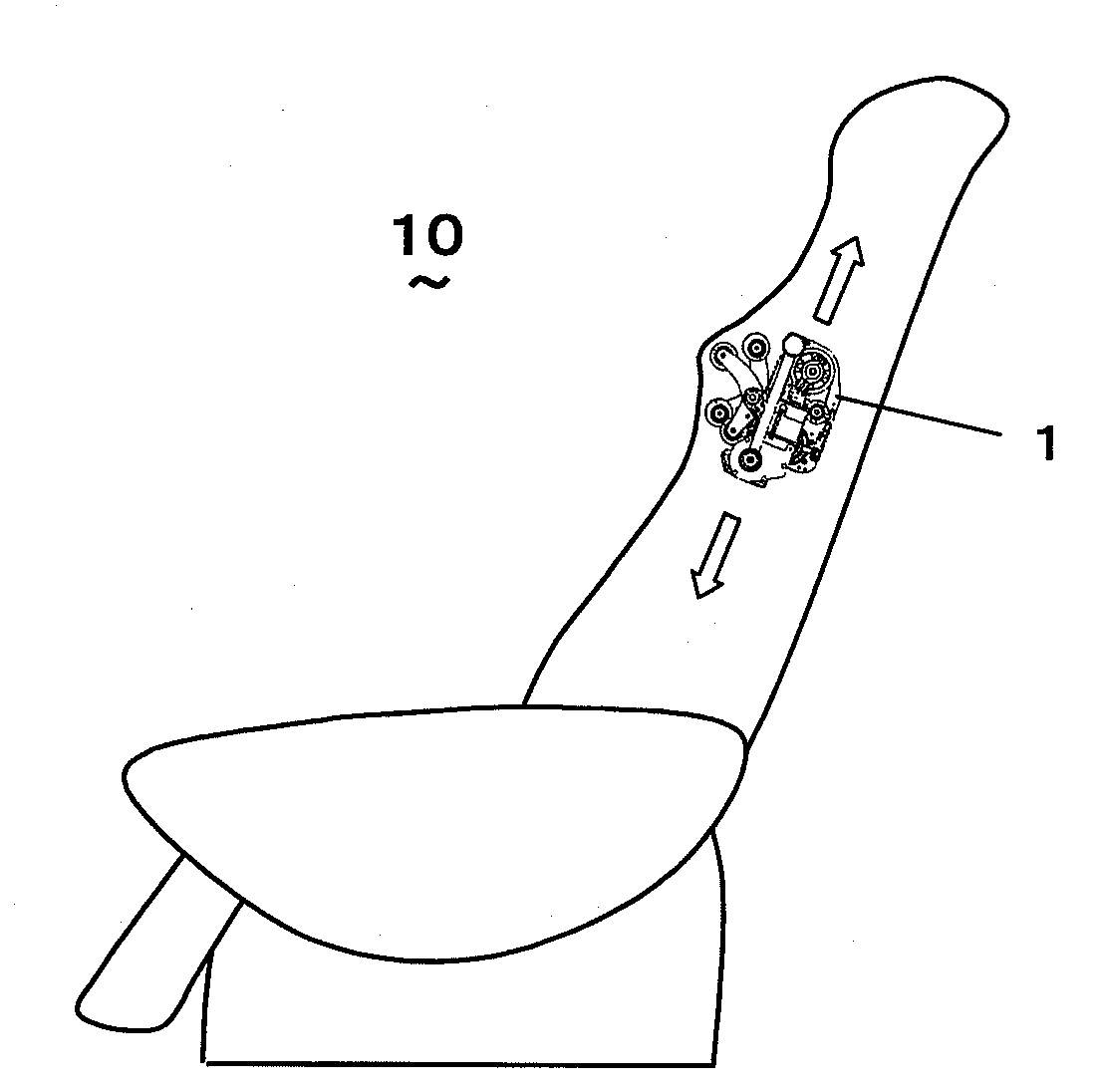

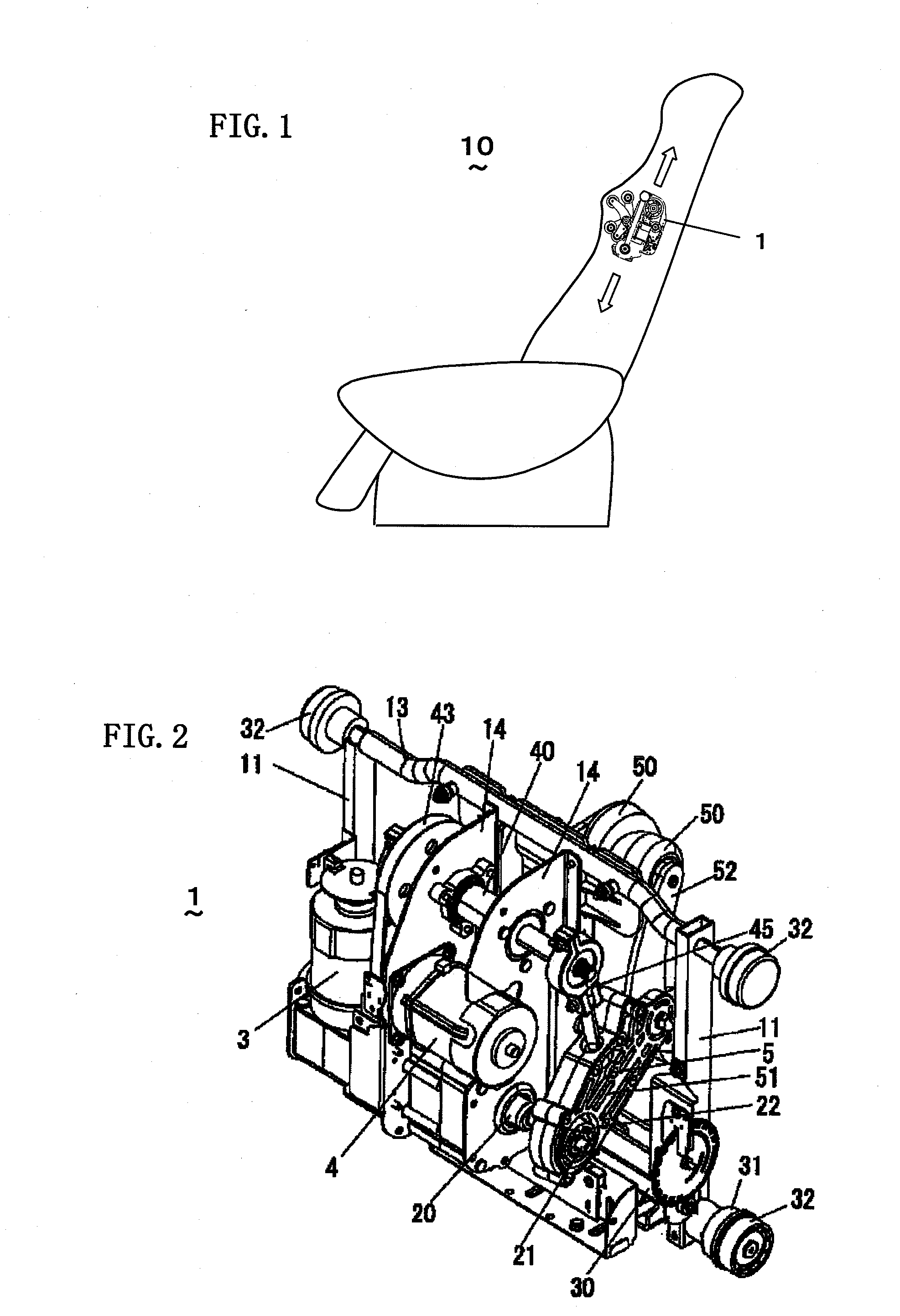

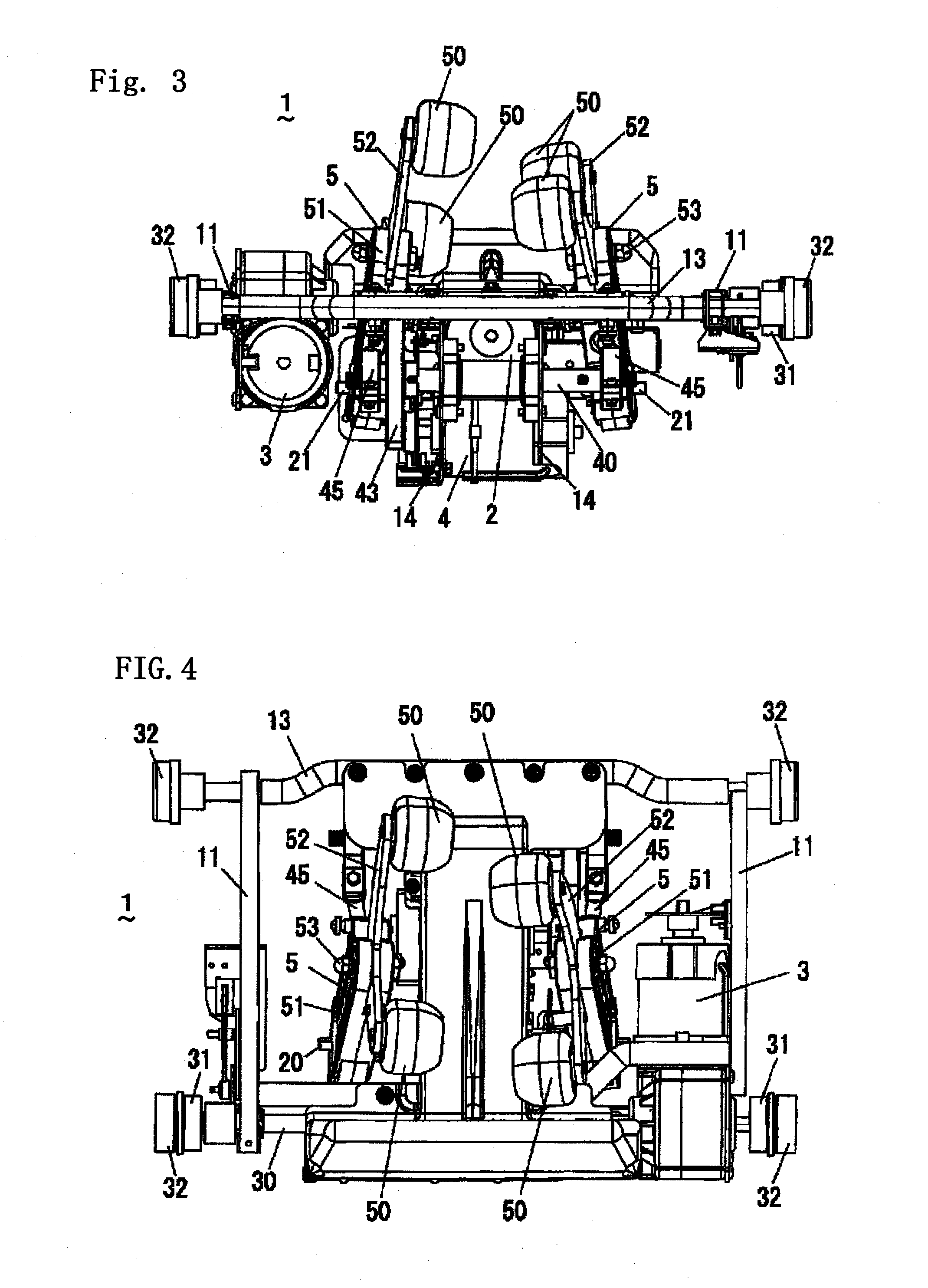

Massage machine

InactiveUS20090124940A1Great massage feelingPreventing situationChiropractic devicesVibration massageDrive shaftMassage

A massage machine comprises a drive shaft rotatably driven in forward and reverse directions; a pair of inclined shafts mounted on both ends of the drive shaft so as to have an arbitrary inclination relative to an axial direction of the drive shaft; a pair of left and right massage ball units including massage balls and rotatably connected to outer peripheral surfaces of the pair of inclined shafts, respectively; and switching means for switching an axial rotation position of one inclined shaft of the pair of inclined shafts. The massage ball units each comprise a swing arm having one end rotatably connected to the outer peripheral surface of the inclined shaft; and a support arm connected to the other end of the swing arm and having mounted thereon multiple massage balls at a vertical distance from each other. Thus, according to the massage machine, the distance from the drive shaft to the massage balls is large because of the presence of the swing arms, while the moving range of the massage balls is large because the upper and lower massage balls mounted on each support arm move in the same direction, so that a person to be treated can have great massage feeling.

Owner:PANASONIC CORP

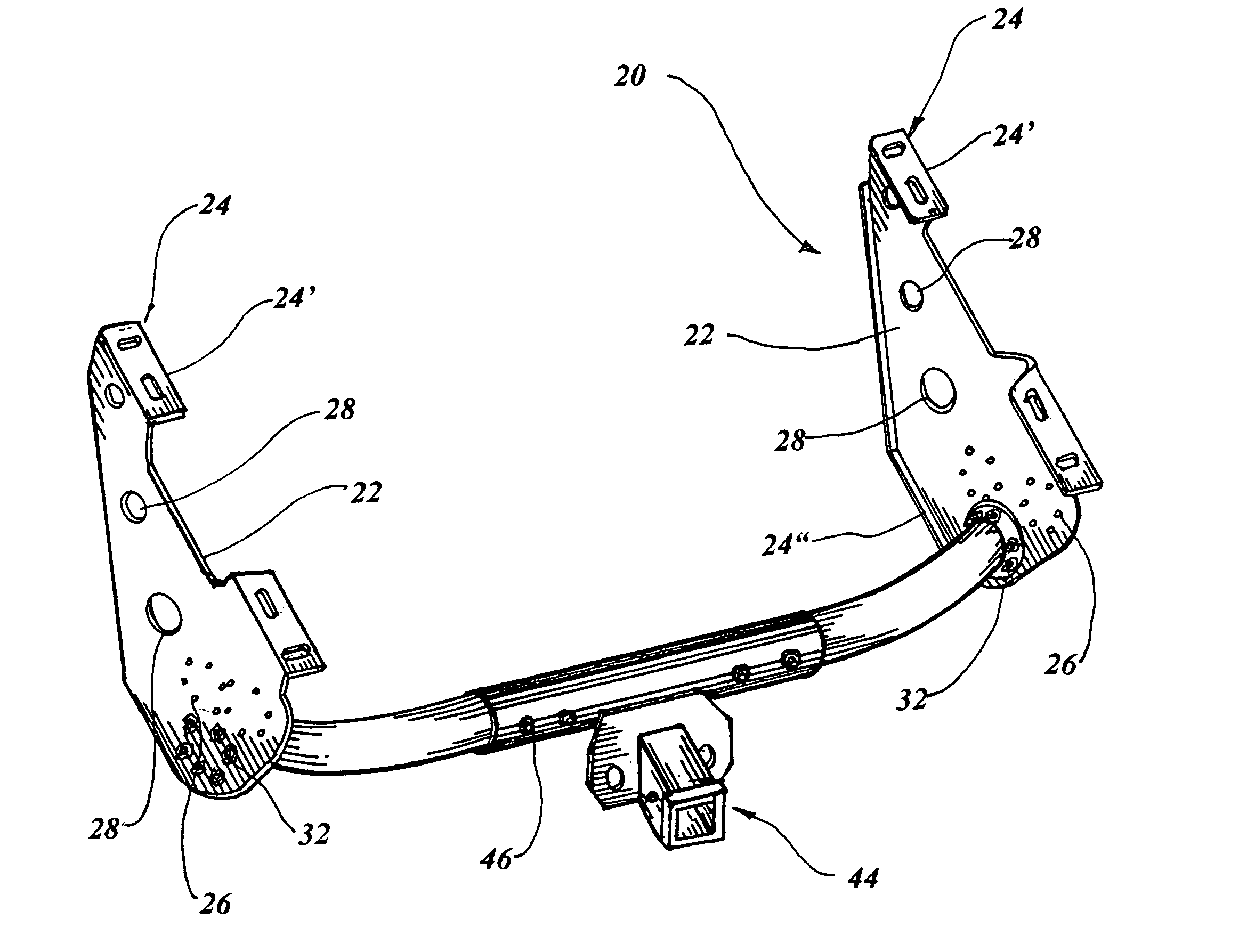

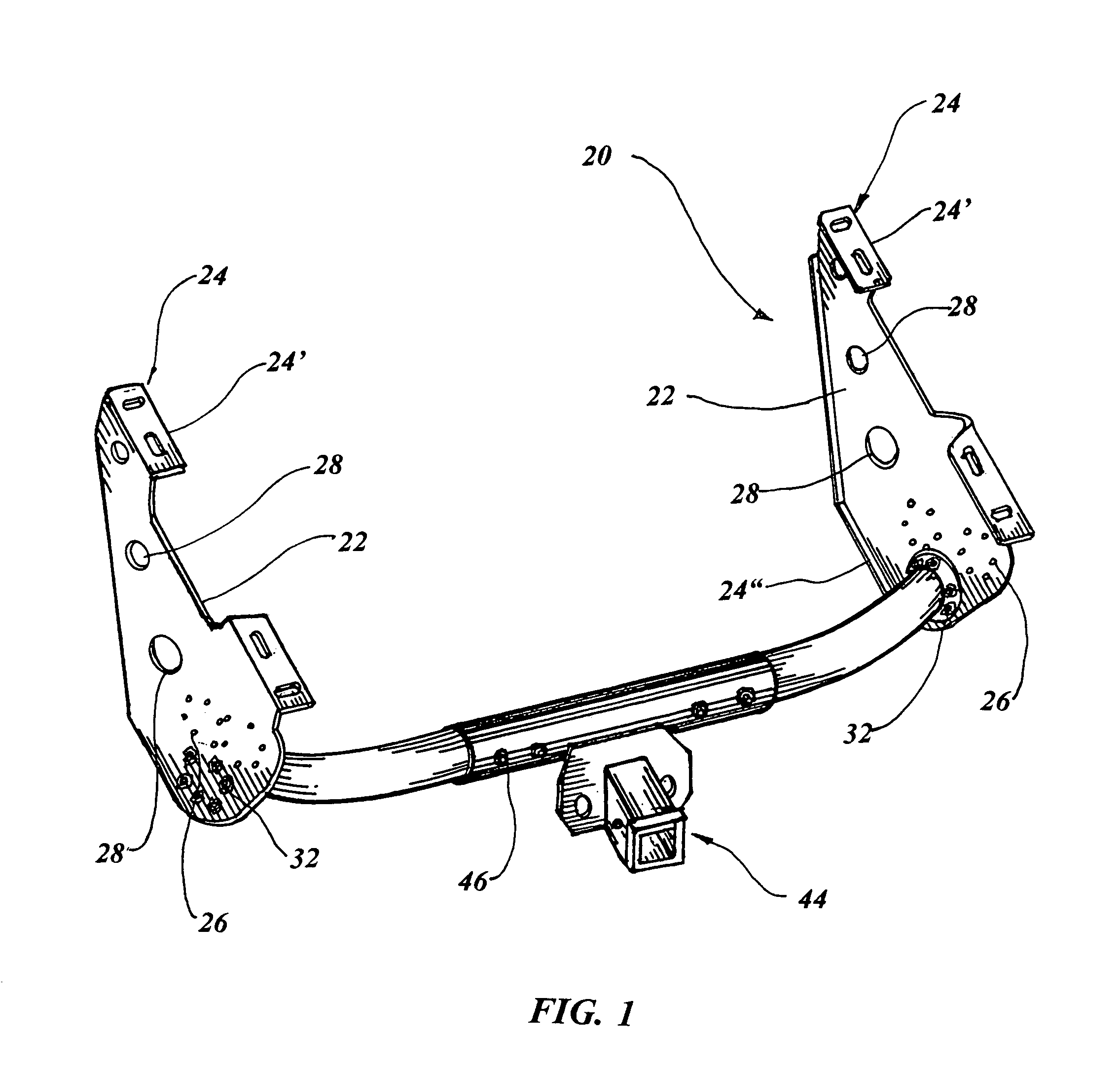

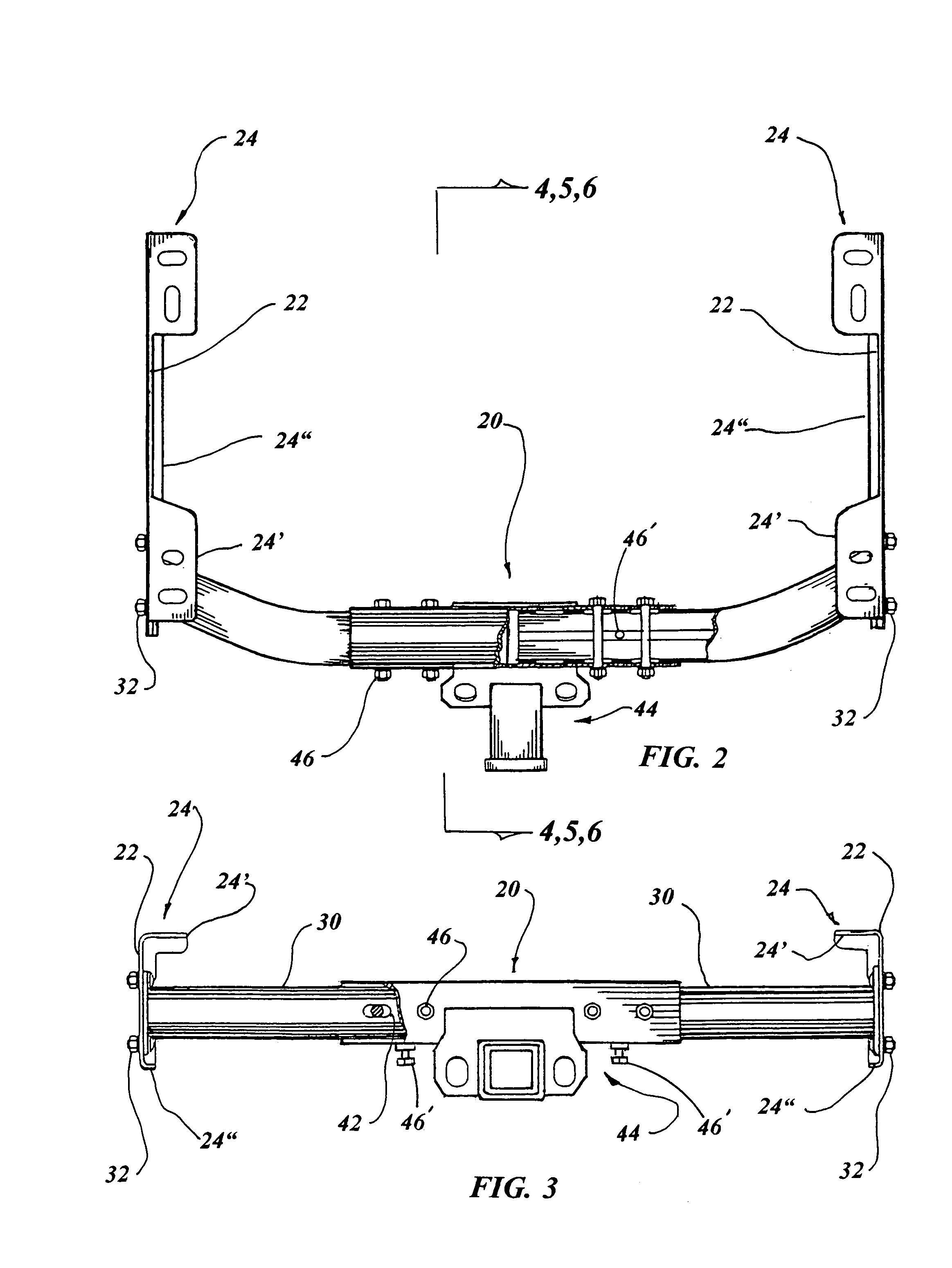

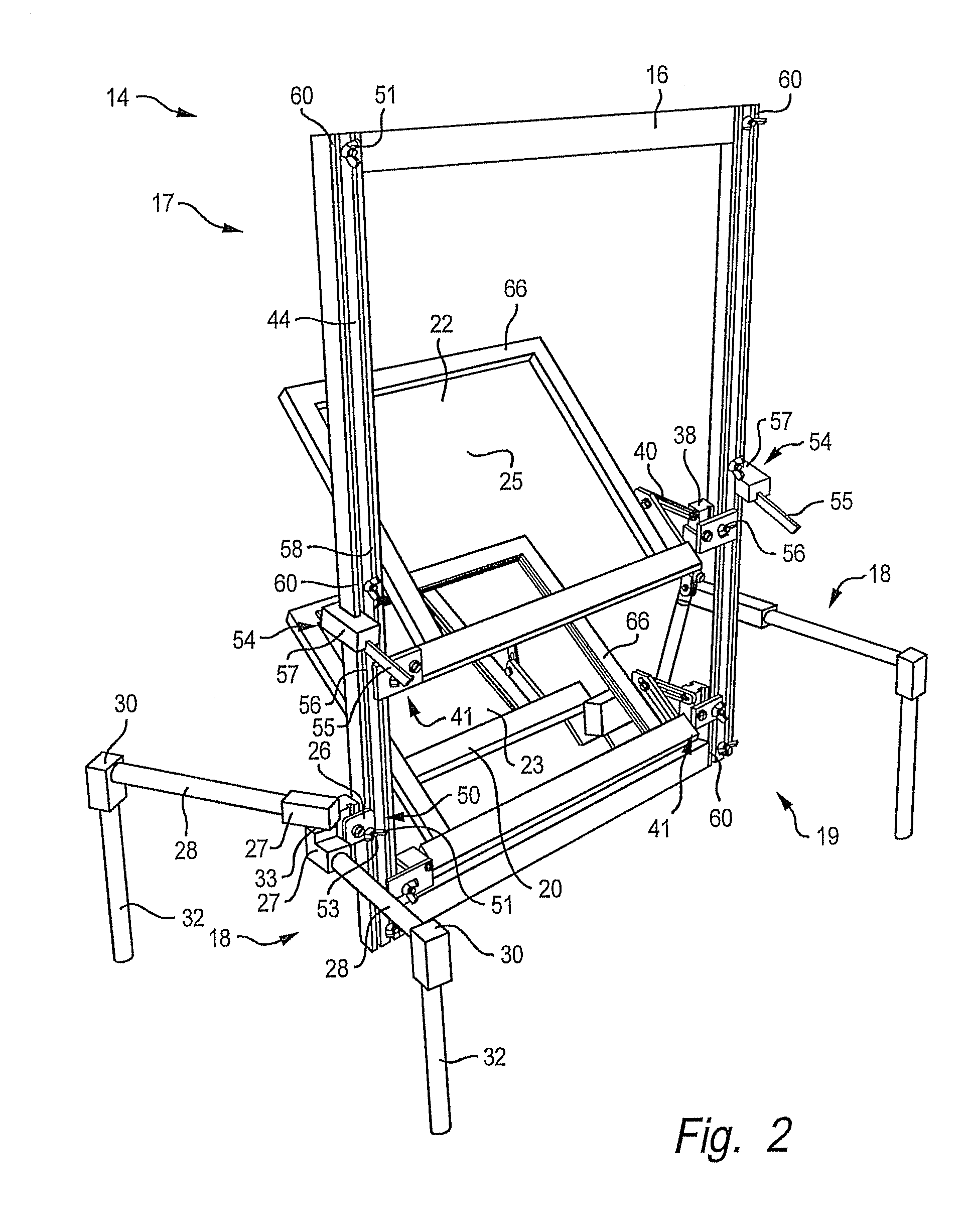

Adjustable receiver hitch

An adjustable receiver hitch (20) for receiving a hitch ball mounted, trailer ball mount that is attached onto the frame of a motor vehicle for pulling a trailer. A pair of frame mounting brackets (22) are configured for attachment onto the frame of the motor vehicle, with each mounting bracket further having flanges (24), lightening holes (28), and a plurality of bracket thru-holes (26). A pair of hitch mounting arms (30) are connected to the frame mounting brackets and interface with a selected set of the holes (28) for height adjustment of the receiver hitch relative to the motor vehicle frame. A box hitch (44) is adjustably attached onto each mounting arm by inserting the arms into a tubular sleeve (50) or (52) which is a connecting element of the box hitch. A receiver box (48) is connected on the lower surface of the tubular sleeve for receiving the hitch ball mounted on the trailer ball mount.

Owner:CHENG JOHN C +1

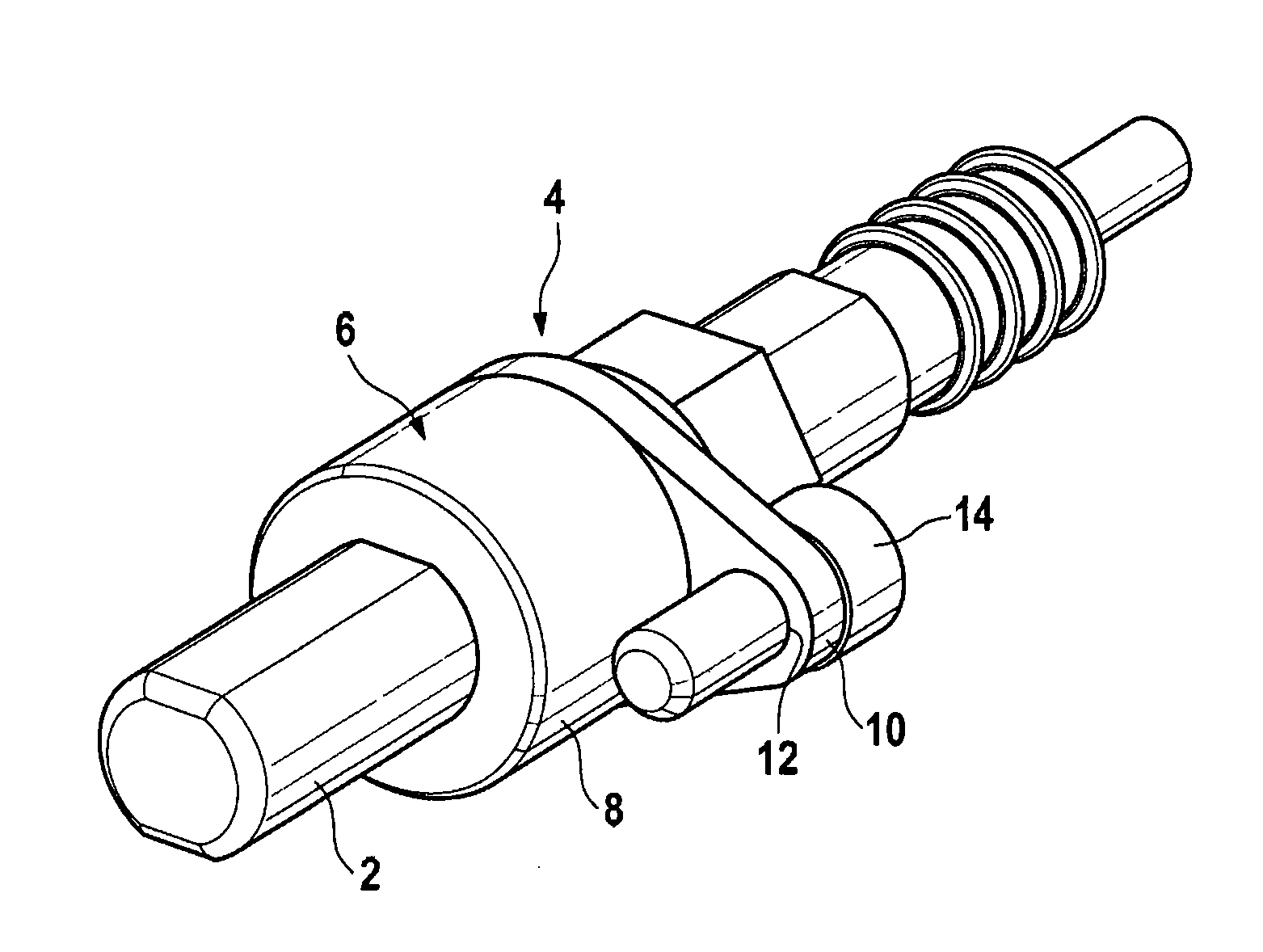

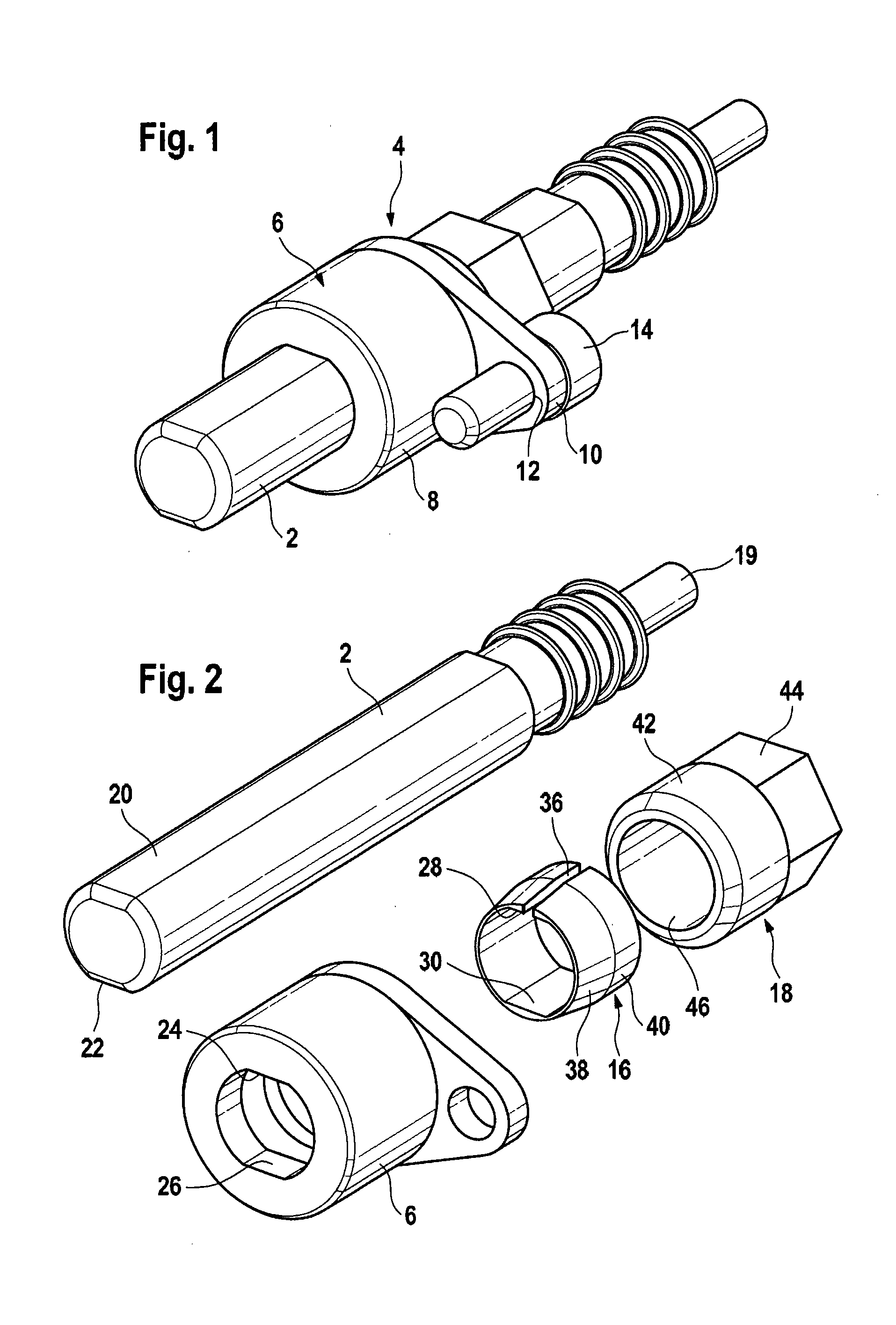

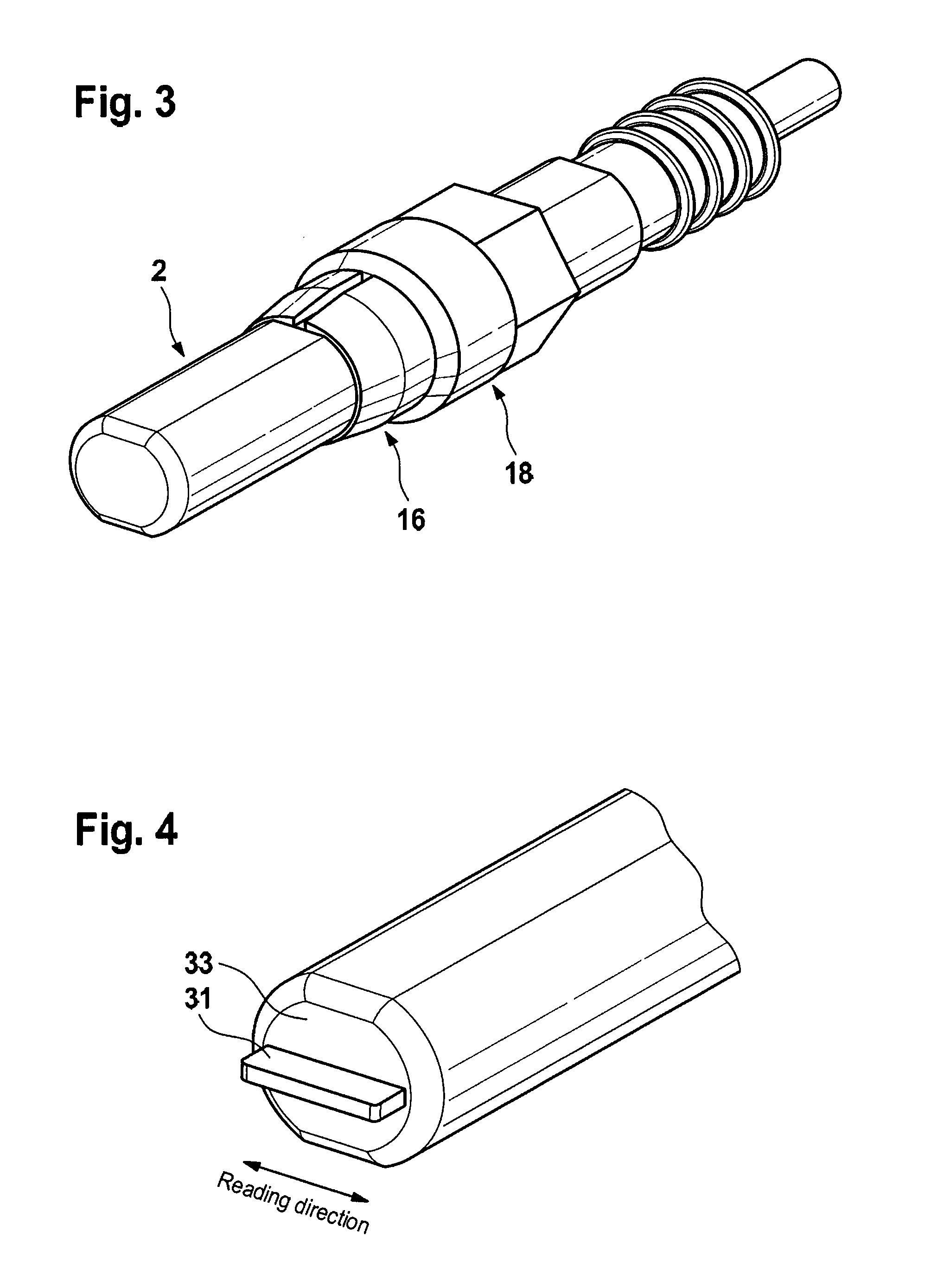

Speed sensor

InactiveUS20120112742A1Regulate securityLinear/angular speed measurementSpeed/acceleration/shock instrument detailsEngineeringEncoder

A speed sensor having a sensor housing for accommodating a magnetic field sensor element, an adapter for holding the sensor housing and a magnetic encoder. The invention provides for the speed sensor to have a device for length adaptation or air gap adjustment, and for the device to have a clamping mechanism for holding the sensor housing.

Owner:CONTINENTAL TEVES AG & CO OHG

Breathing circuits having unconventional respiratory conduits and systems and methods for optimizing utilization of fresh gases

A breathing circuit comprising first and second conduits, wherein at least one of the conduits is a non-conventional conduit. In an embodiment, a multilumen unilimb breathing circuit has first and second conduits, wherein when the proximal ends of said first and second conduits are each connected to an inlet and outlet fitting, respectively, axial extension or contraction of the second conduit causes a corresponding axial extension or contraction of the first conduit. In an embodiment, at least one of said conduits is coiled. In another embodiment, a coiled conduit is contained within an outer flexible conduit that is axially extendable and compressible, forming a unilimb, multilumen respiratory circuit. The outer flexible conduit may be pleated to provide for non-rebounding axial extension and contraction. The multilumen respiratory circuit can provide a variable rebreathing volume. In an embodiment, at least one tube in a multilumen respiratory conduit is radially collapsible and radially expandable to a maximum radius for carrying respiratory gases to and from a patient. In an embodiment, first and second conduits are formed of accordion-like pleated tubing, wherein both conduits can be connected to a proximal fitting or proximal terminal at their proximal end; in an embodiment, the first and second accordion-like pleated tubes can also be connected to a common distal fitting. The methods and systems can be used to administer anesthesia and for other purposes.

Owner:AMBU AS

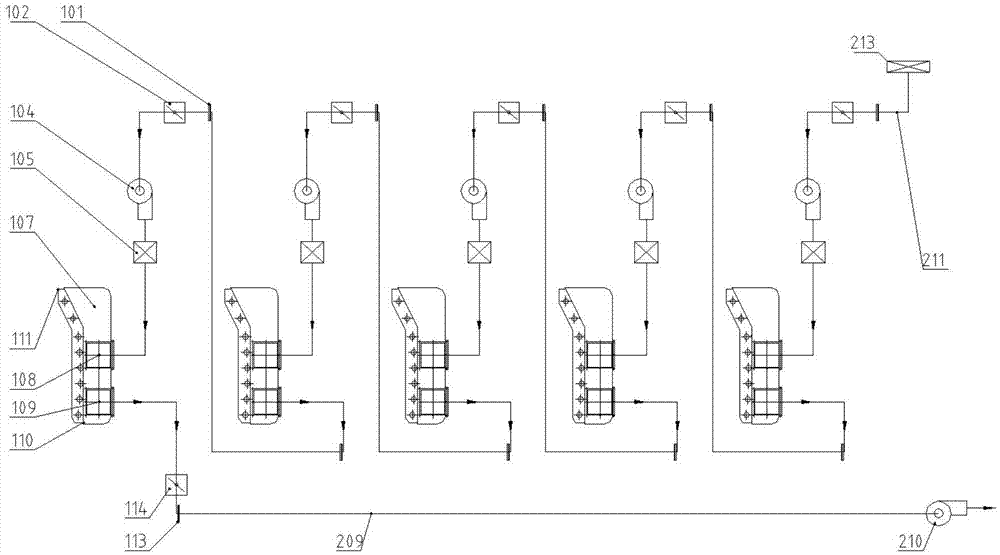

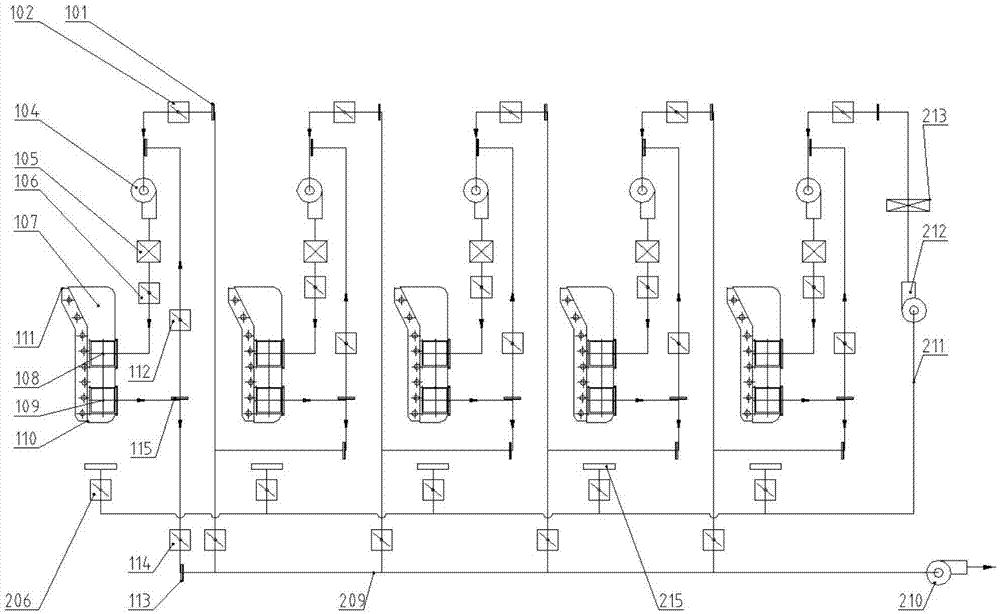

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

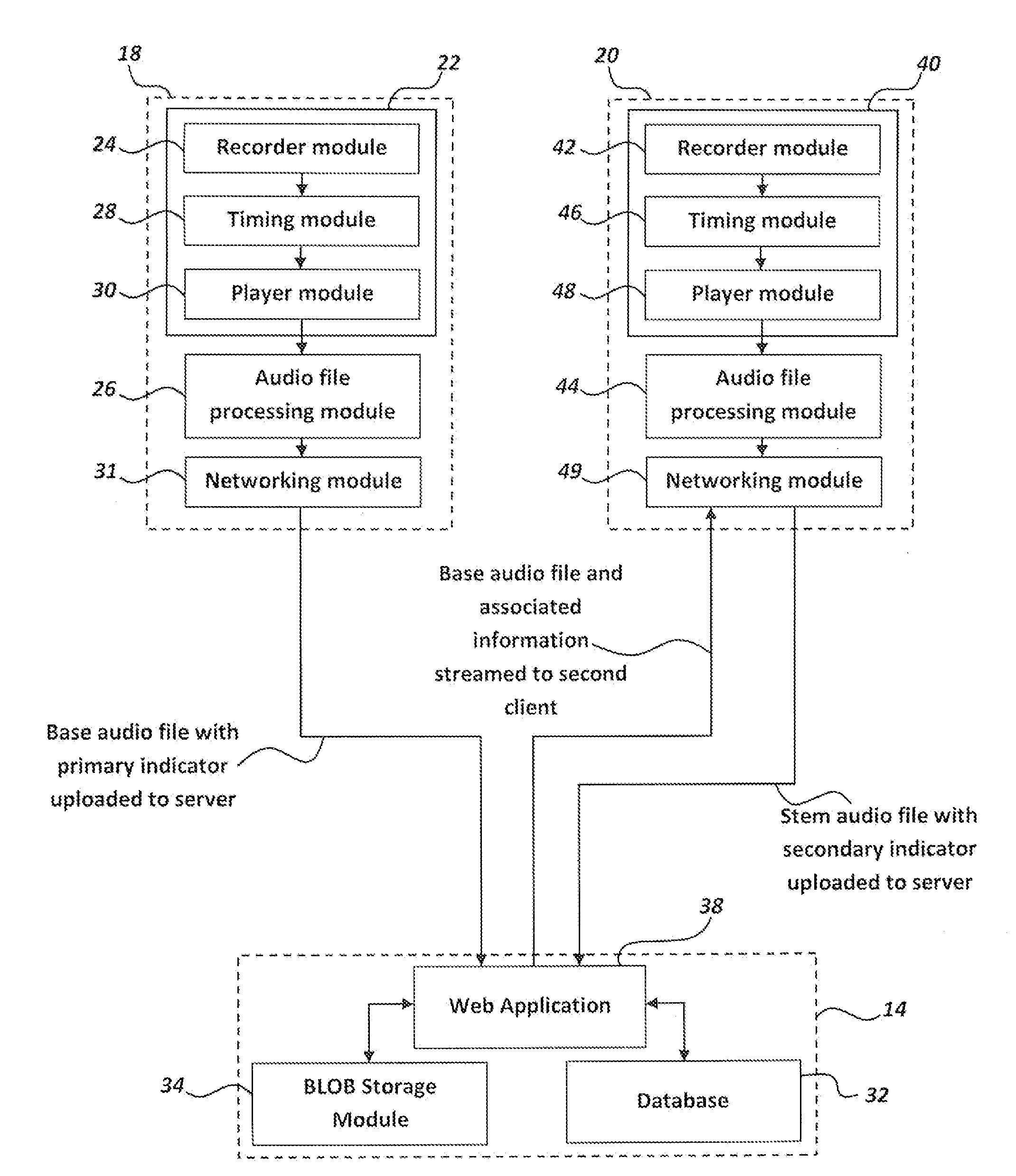

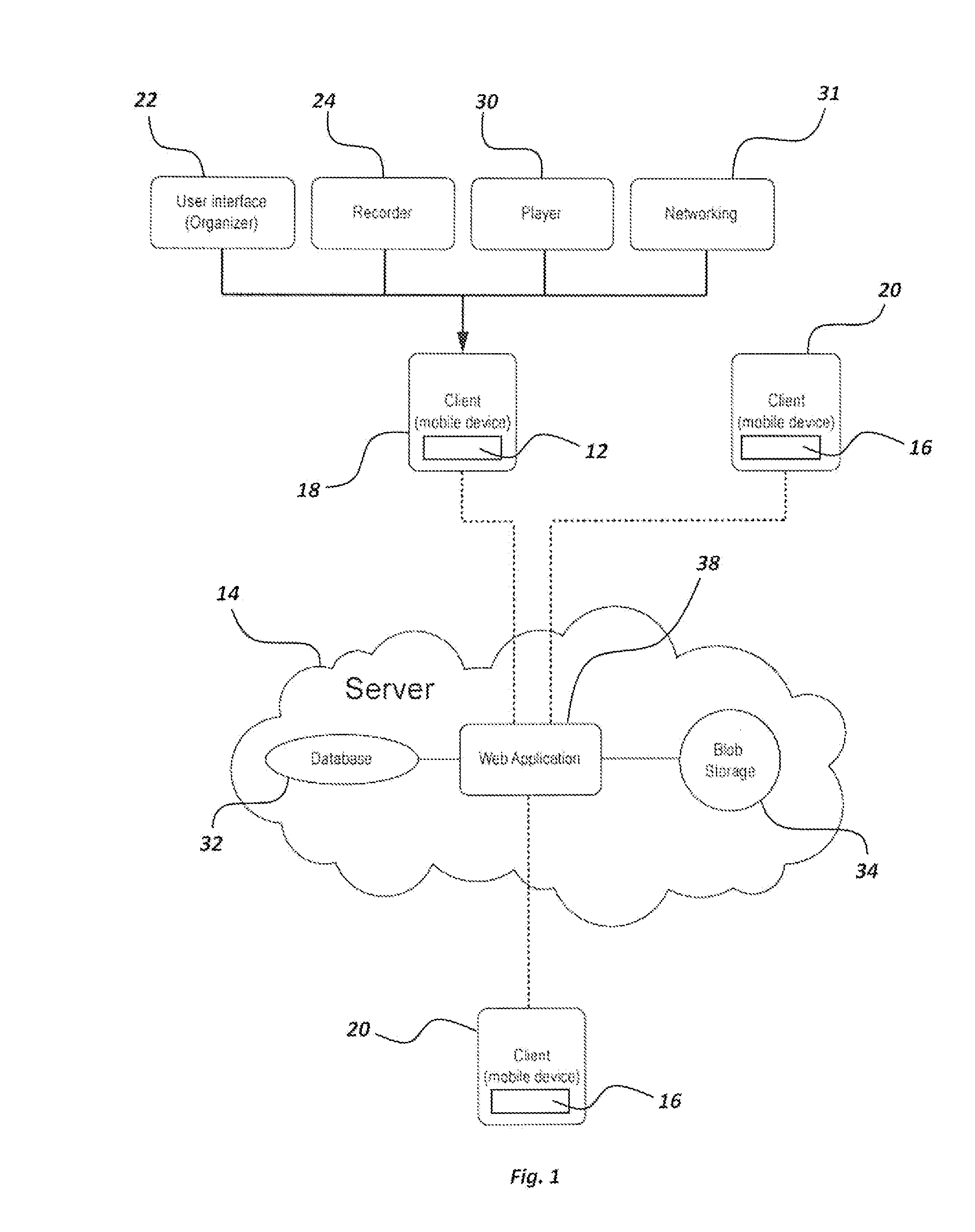

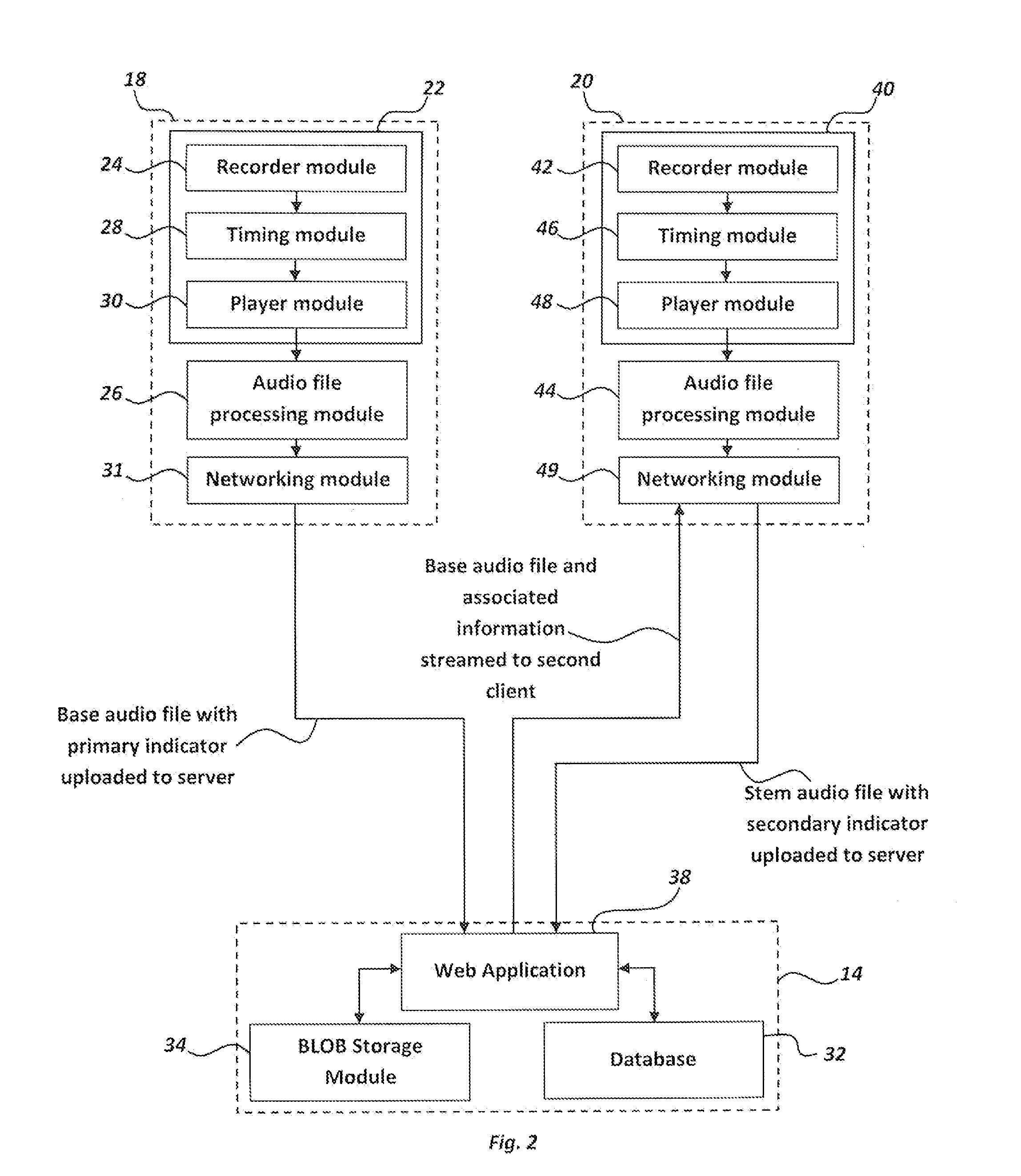

Cloud based audio recording system

InactiveUS20140289626A1Regulate securitySafe controlInput/output to record carriersDigital data processing detailsUnique identifierWorld Wide Web

The present disclosure relates to a cloud based system for compiling a series of brief recordings made by a plurality of different users sequentially to form an aggregated audio presentation. The system stores a plurality of user audio files which corresponding to a single audio presentation such as a song, conversation or presentation. Each brief recording is assigned a unique identifier indicating the corresponding presentation and the user that recorded the brief recording before the brief recording is uploaded to a server for storage. The plurality of brief recordings can be aggregated at the server into a single audio presentation that can be streamed back to users. Alternatively, the plurality of brief recordings can remain separate, wherein the plurality of brief recordings can be transmitted piecemeal to users in the order indicated by the unique identifiers to simulate an aggregated audio presentation.

Owner:CLOUDECK

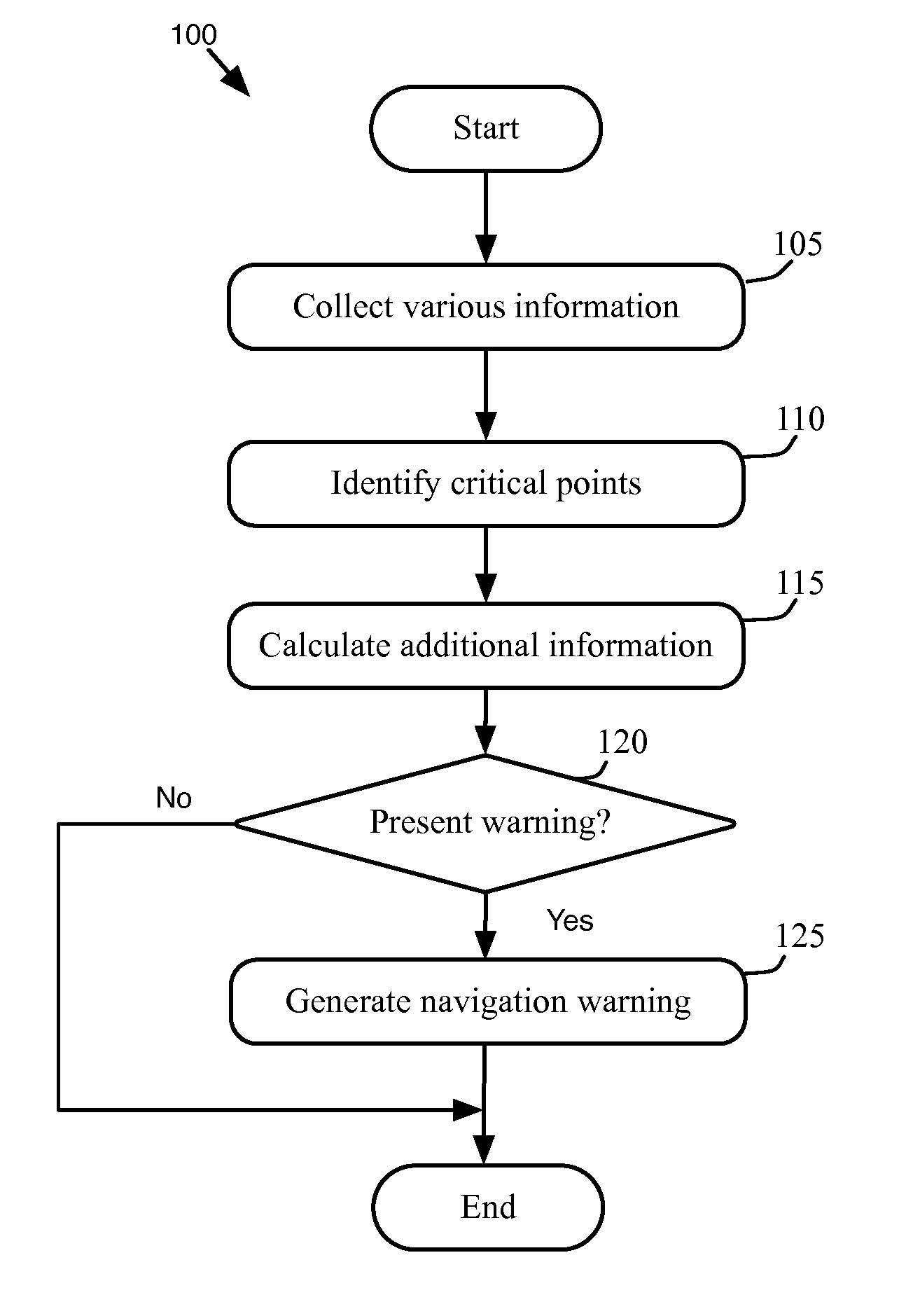

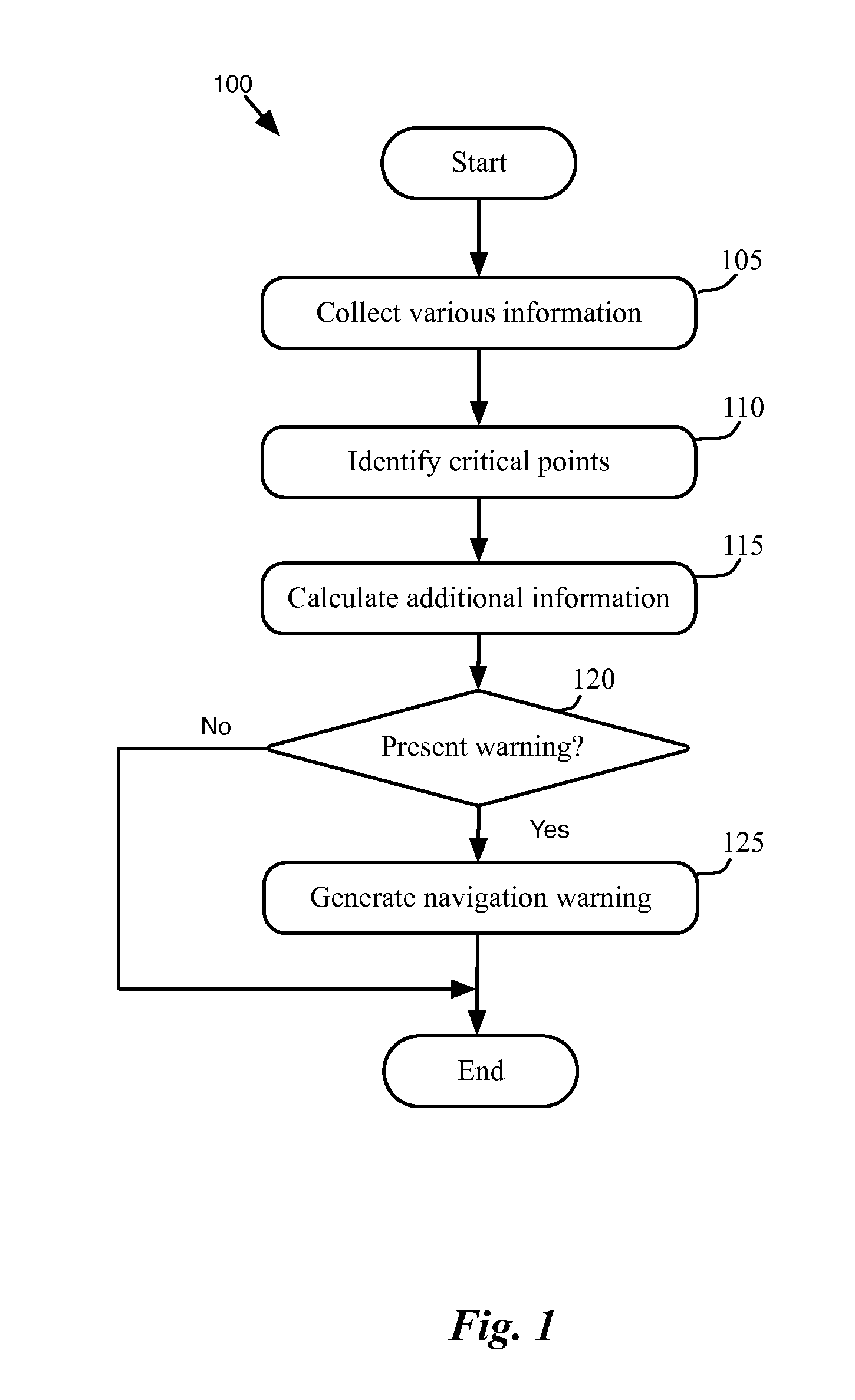

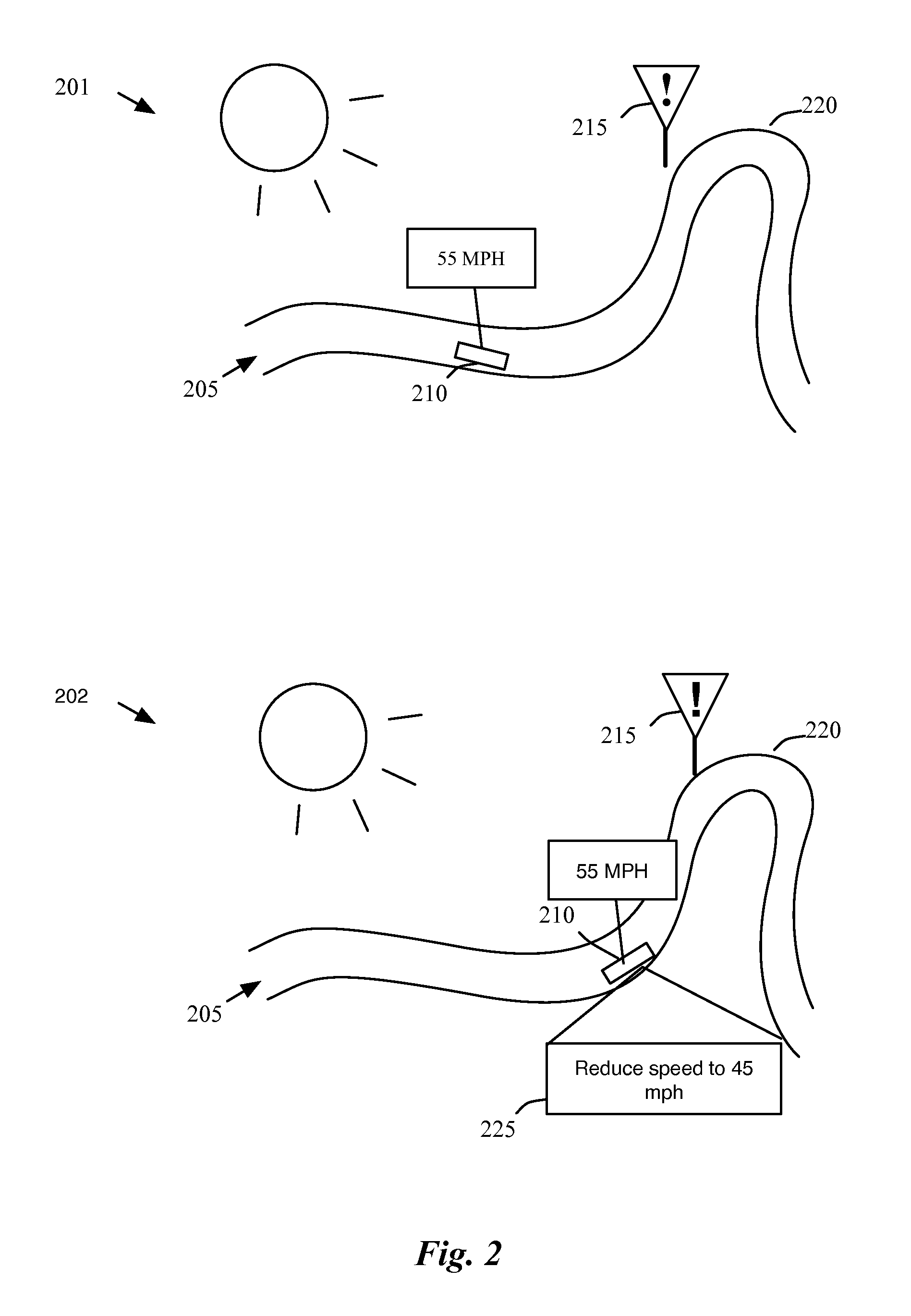

Method and apparatus for providing dynamic warnings for navigations

ActiveUS20160091323A1Enough timeRegulate securityInstruments for road network navigationCalculated dataApplication software

A navigation application that provides a dynamic set of warnings based on a set of collected and calculated data. The navigation application collects a series of data and identifies a set of critical points along the route. The navigation application analyzes the collected data to determine whether to provide a navigation warning to the user. The navigation application uses the collected data to determine whether a navigation instruction for the critical point should be modified to account for different driving conditions. Finally, the navigation application of some embodiments determines a timing for when a navigation instruction should be provided to the user, ensuring that the instruction is presented to the user with sufficient time to safely adjust their behavior.

Owner:APPLE INC

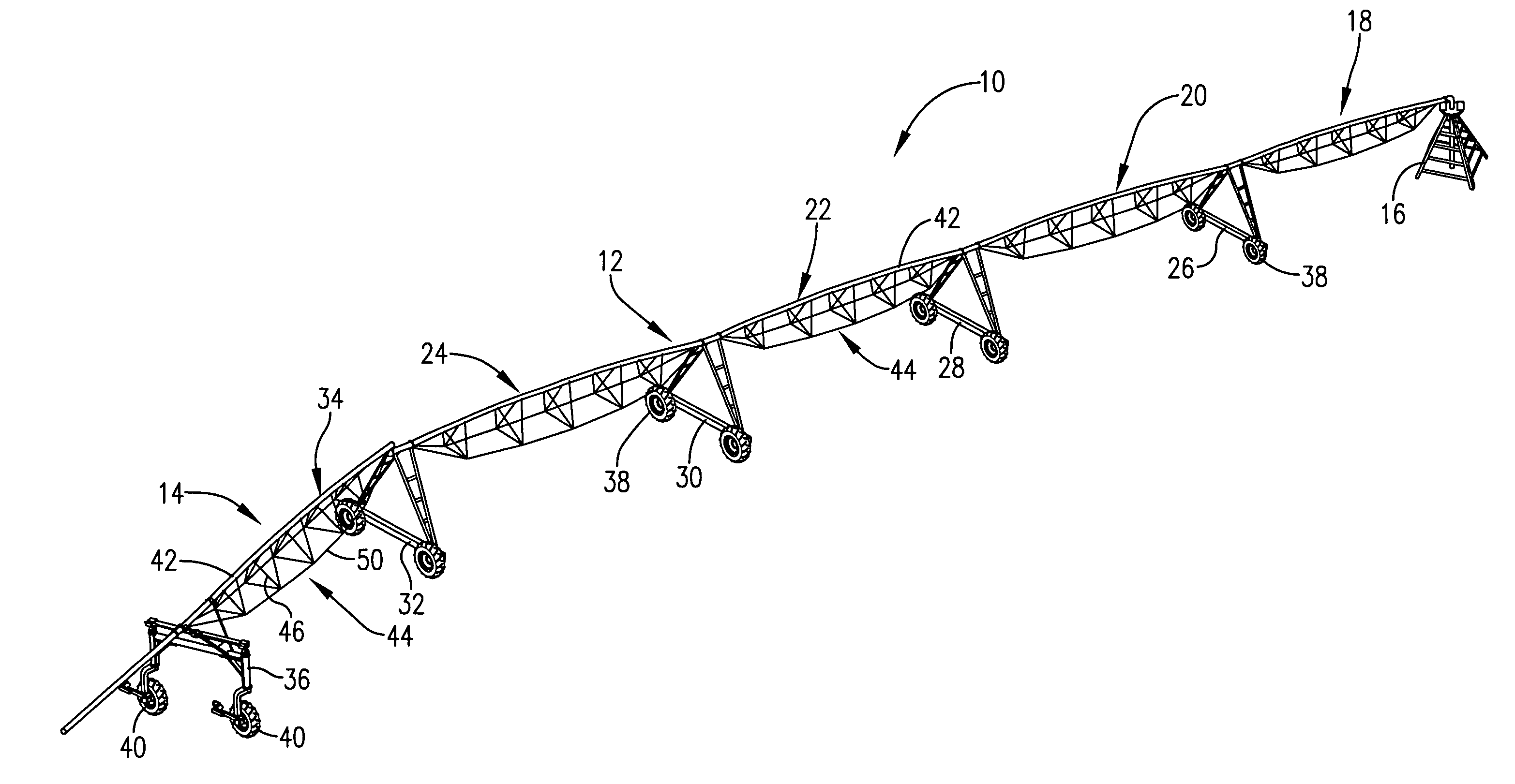

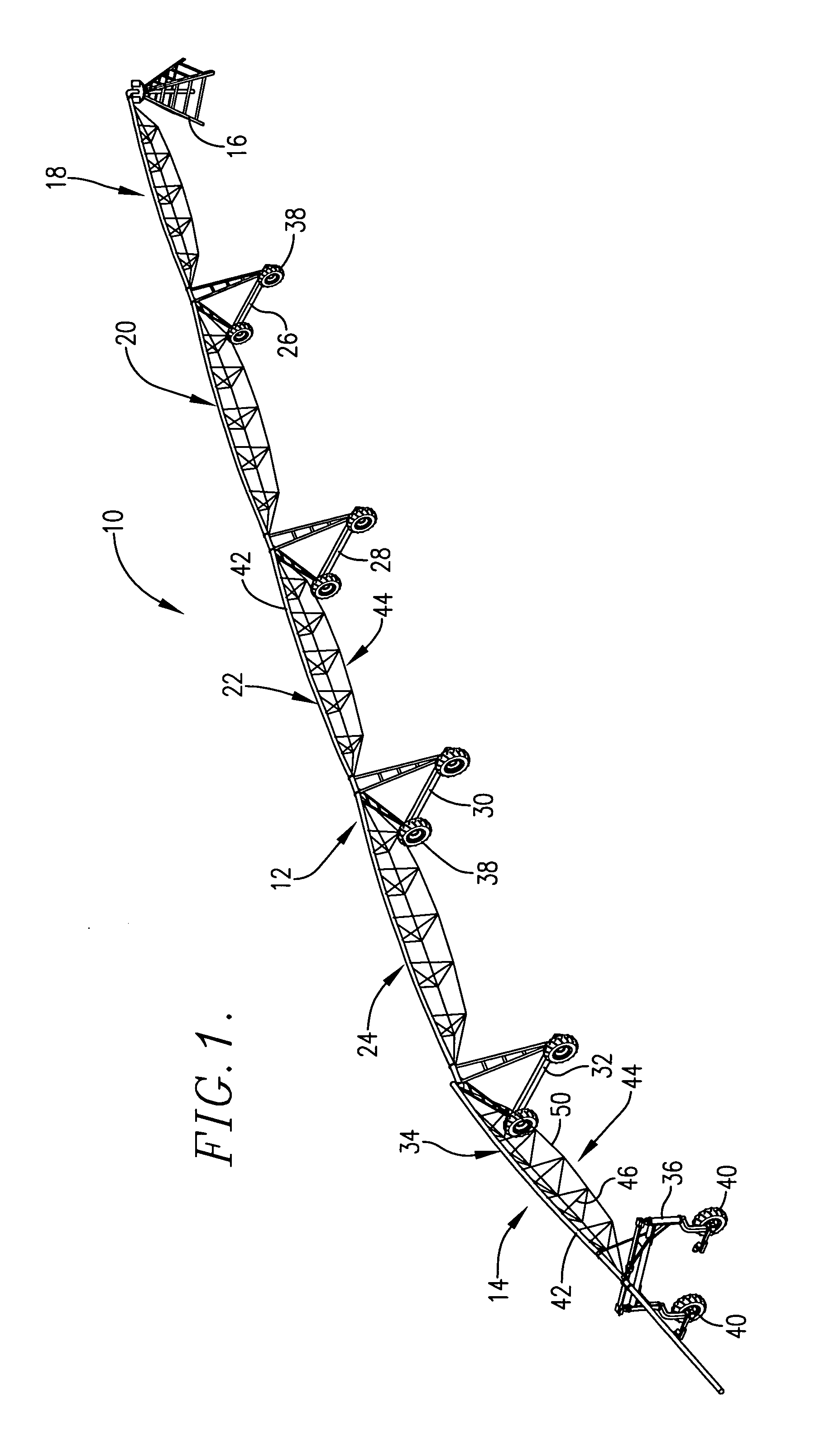

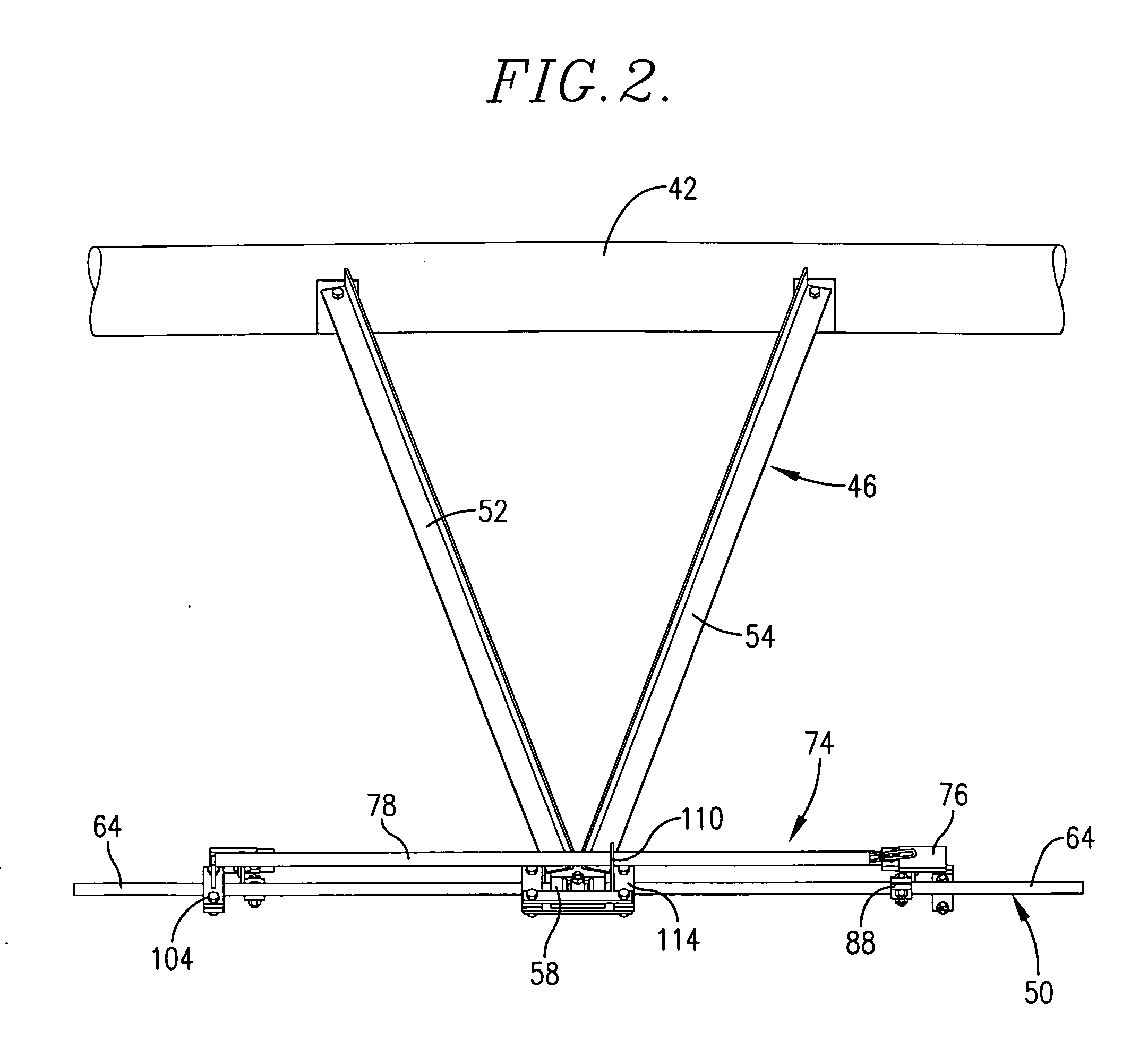

Truss rod safety for irrigation spans

InactiveUS20060237564A1Adjusting sensitivity of safetyRegulate securityWatering devicesMovable spraying apparatusAgricultural irrigationEngineering

A compression safety for a span of an agricultural irrigation system detects changes in the condition of truss rods associated with the framework of the span. When one portion of the truss rod assembly goes slack relative to another, such condition is detected by the safety to shut down the entire system. In a preferred embodiment, the safety is mounted at one of the V-braces forming part of the truss framework below the water conduit of the span. Truss rods are connected to and extend in opposite directions from the V-brace, one of such rods supporting a switch of the safety and the other supporting the switch actuator of the safety. The actuator comprises a long tubular member that is supported intermediate its ends by a fulcrum mount at the apex of the V-brace so that the operating lever of the switch is actuated by the actuator when it rocks about the fulcrum in response to a predetermined level of tension changes in the two truss rods.

Owner:LINDSAY CORP

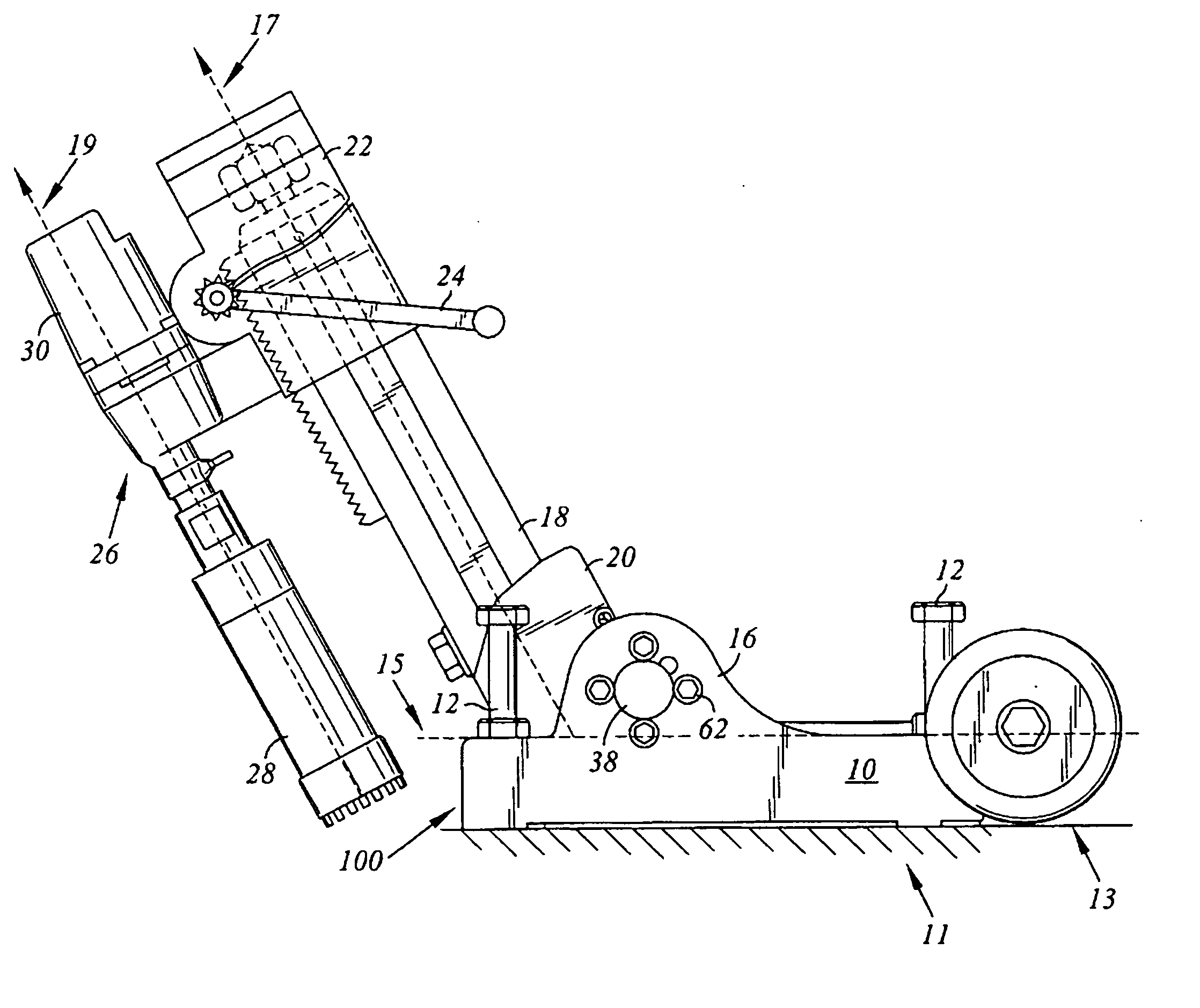

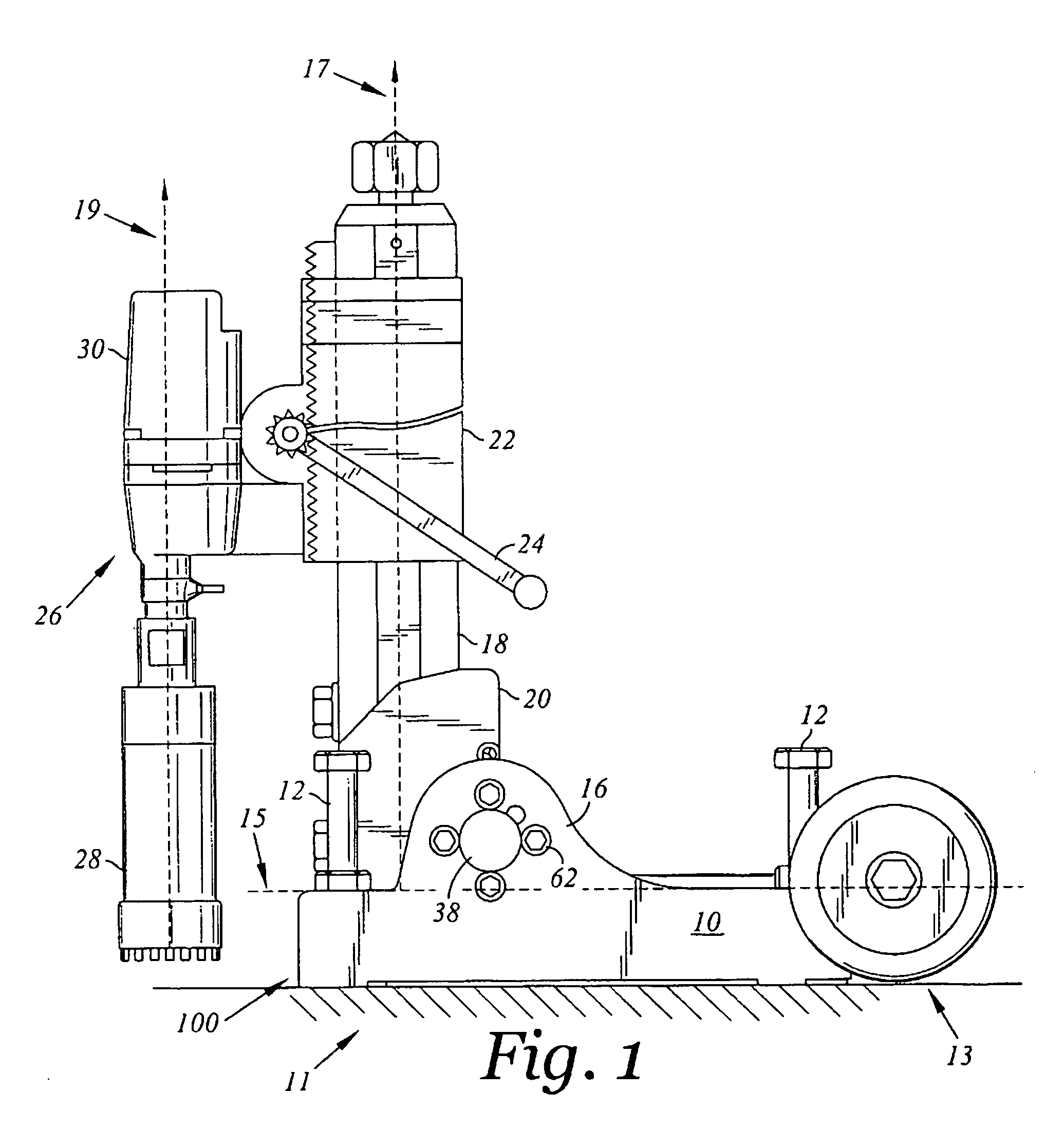

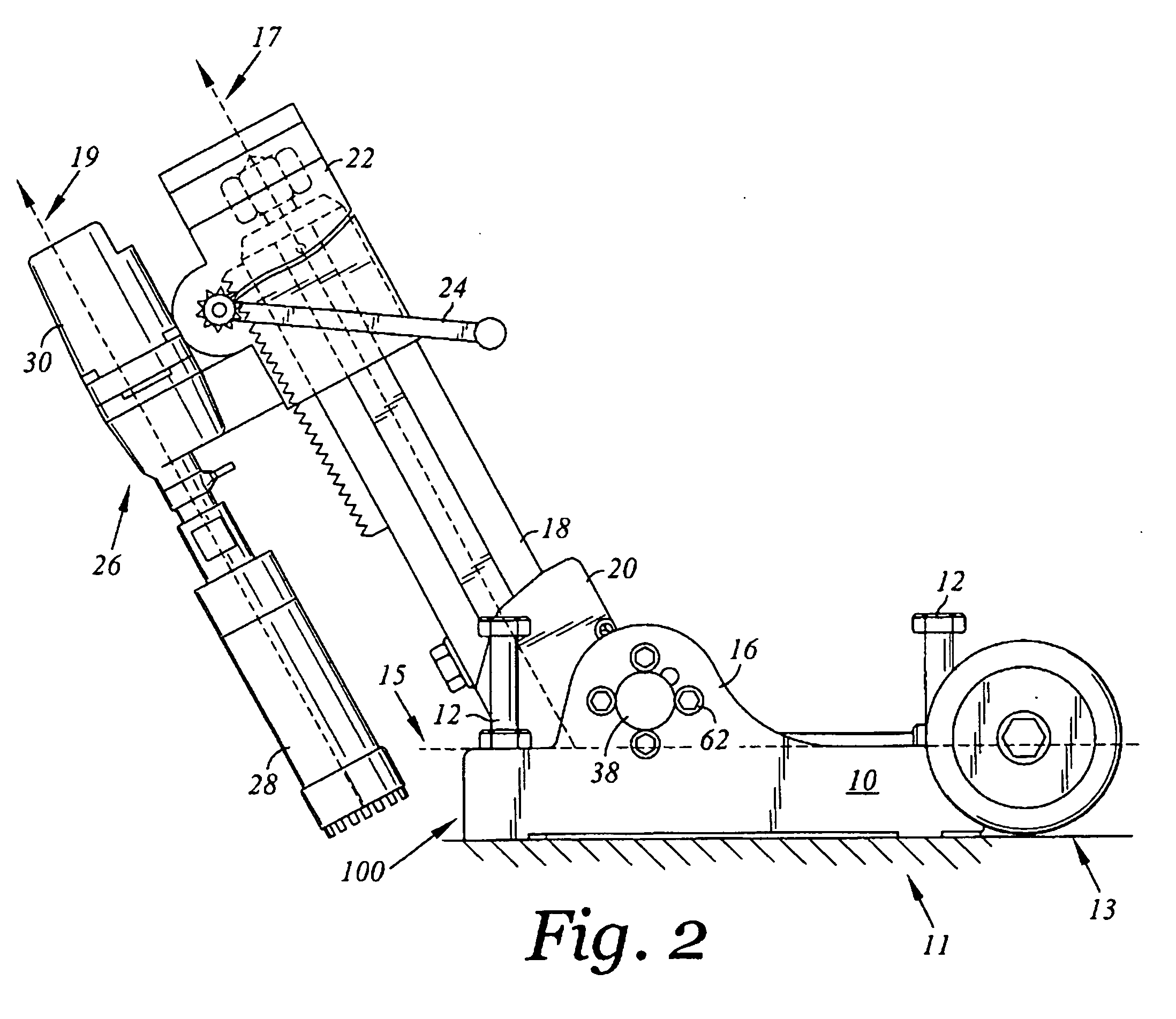

Core drill assembly with the ability to control angle of drilling

InactiveUS20060285932A1Regulate securityDrilling/boring measurement devicesThread cutting machinesEngineeringAngular direction

A core drill assembly provided for drilling on a surface at select angles capable of drilling both away from and towards the base. The surface that the core drill assembly is deployed upon defines a surface plane. The core drill assembly comprises a base deployable upon a surface. The base having first and second opposing ends and a base axis extending from the first end of the base to the second end parallel to the surface plane. The core drill assembly including a stand defining a stand longitudinal axis intersecting the base axis. The stand is pivotally connected to the base and angularly positionable between acute and obtuse angles defined between the stand longitudinal axis and the base axis with respect to an angular direction away from the surface plane towards the base axis. A drill motor including drill bit is coupled to the stand.

Owner:CABEL

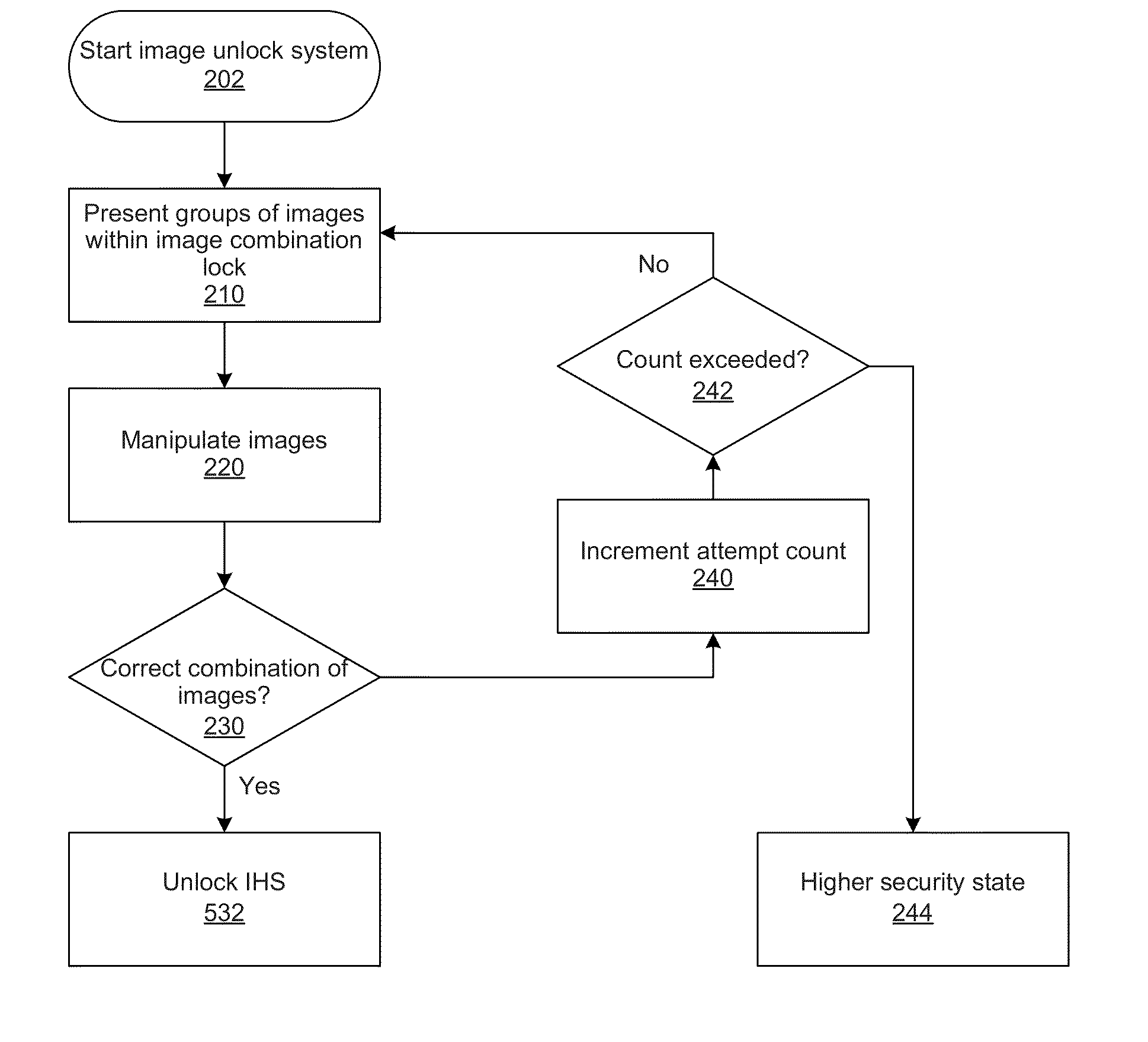

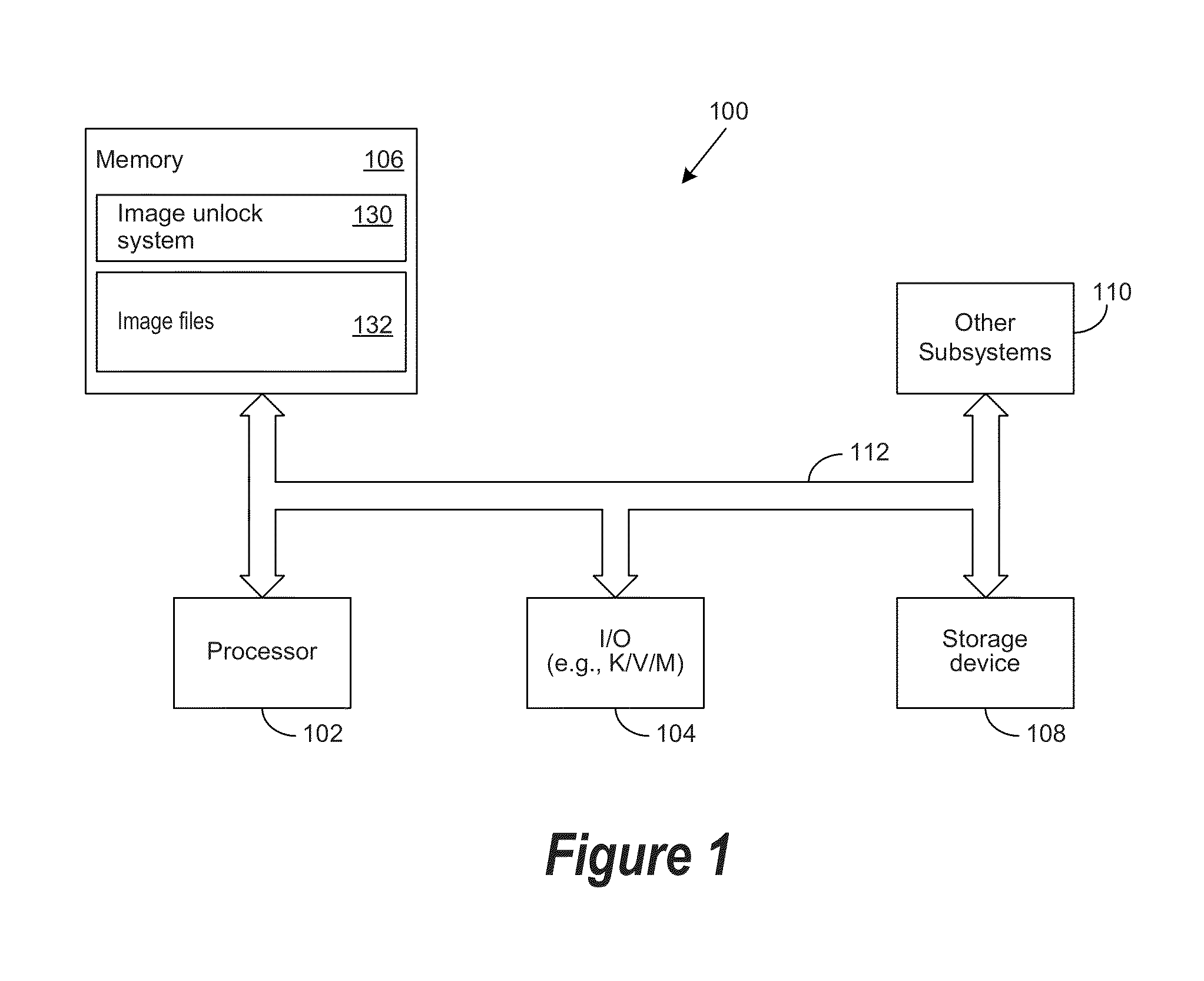

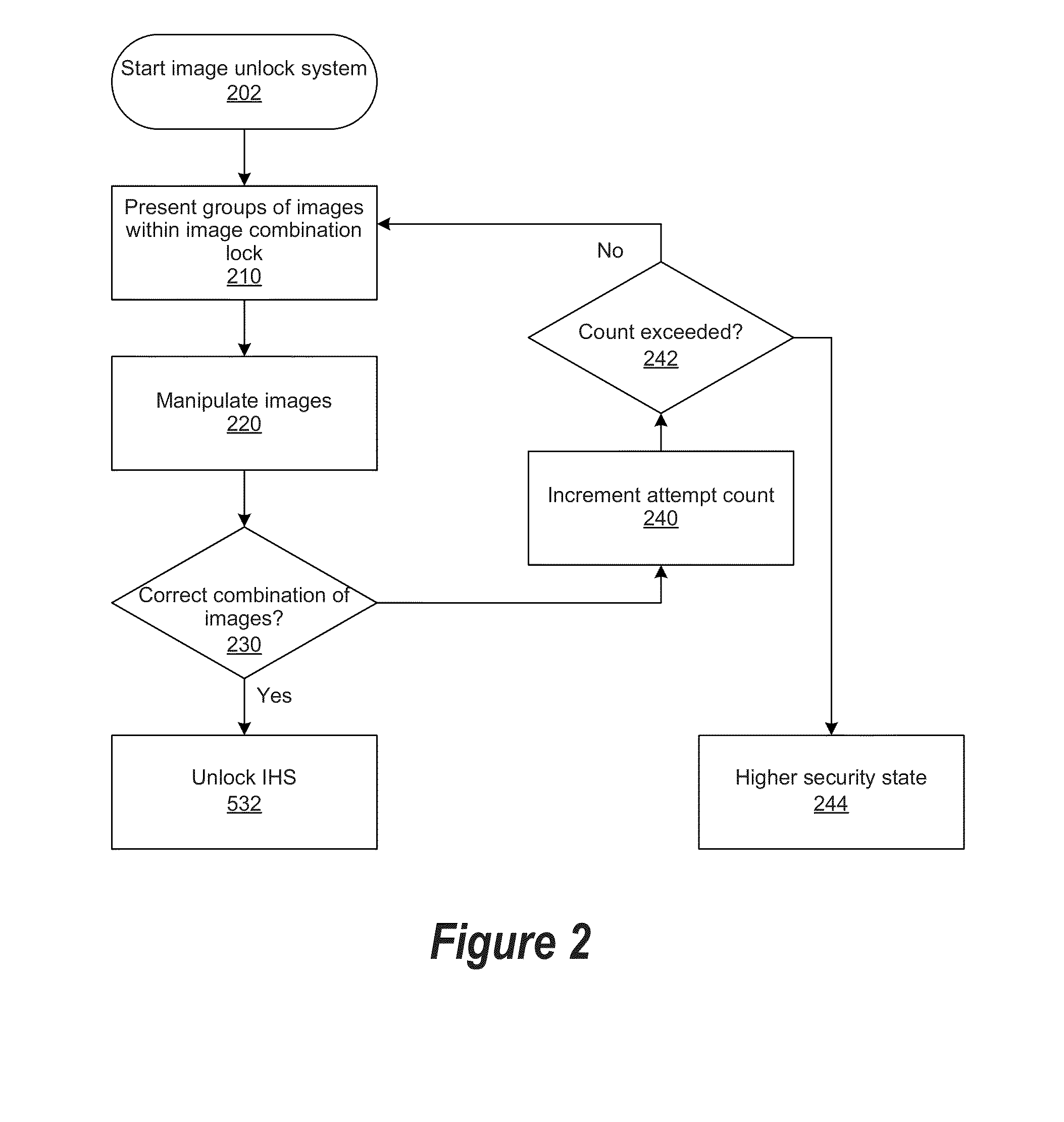

Photo Combination Lock

ActiveUS20130174247A1Regulate securityDigital data processing detailsUnauthorized memory use protectionInternet privacyDatabase access

A simple, customizable and intuitive virtual combination unlock method and system. More specifically, an unlock system and method is disclosed which includes a virtual combination lock, where the virtual combination lock includes several rows of user-selectable images such as pictures or icons as the virtual combination wheels. In certain embodiments, the images are accessed via the user's database. To unlock the device, the user touches and drags pre-selected images into alignment with each other. Security can be adjusted by changing the number of images that need to be aligned to unlock the device.

Owner:DELL PROD LP

Ceramic pipe grinder for food grinding processing

A ceramic pipe grinder for food grinding processing solves the problems that in the prior art, the idle grinding area is large, the material discharge resistance is large, the grinding efficiency is low, the processing capacity is small, the processing effect is poor, the wear-resisting property of grinding discs is poor, the service life is short, and the application range is narrow. The ceramic pipe grinder is characterized in that a movable grinding disc and a semi-open type vane wheel are installed at the shaft end of a motor shaft extending into a shell, a fixed grinding disc is installed in a fixed grinding disc installation clip clutch, the joint surfaces of the fixed grinding disc and the movable grinding disc inwards form an internally-concave cone-shaped grinding cavity, a fixed grinding disc adjusting seat is connected with an adjusting nut in a threaded mode, the internally-concave conical surface of the fixed grinding disc is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of the movable grinding disc is provided with material guide grooves and trapezoid teeth. The ceramic pipe grinder for food grinding processing has the advantages that the fixed grinding disc and the movable grinding disc have the synergistic action of extruding, smashing, shearing and grinding on foodstuffs, the wear-resisting property is good, the manufacturing cost is low, the service life is long, the whole machine production efficiency is high, the production capacity is large, and the requirements for ultra-fine processing, dry material slurrying and industrialized continuous production can be met.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

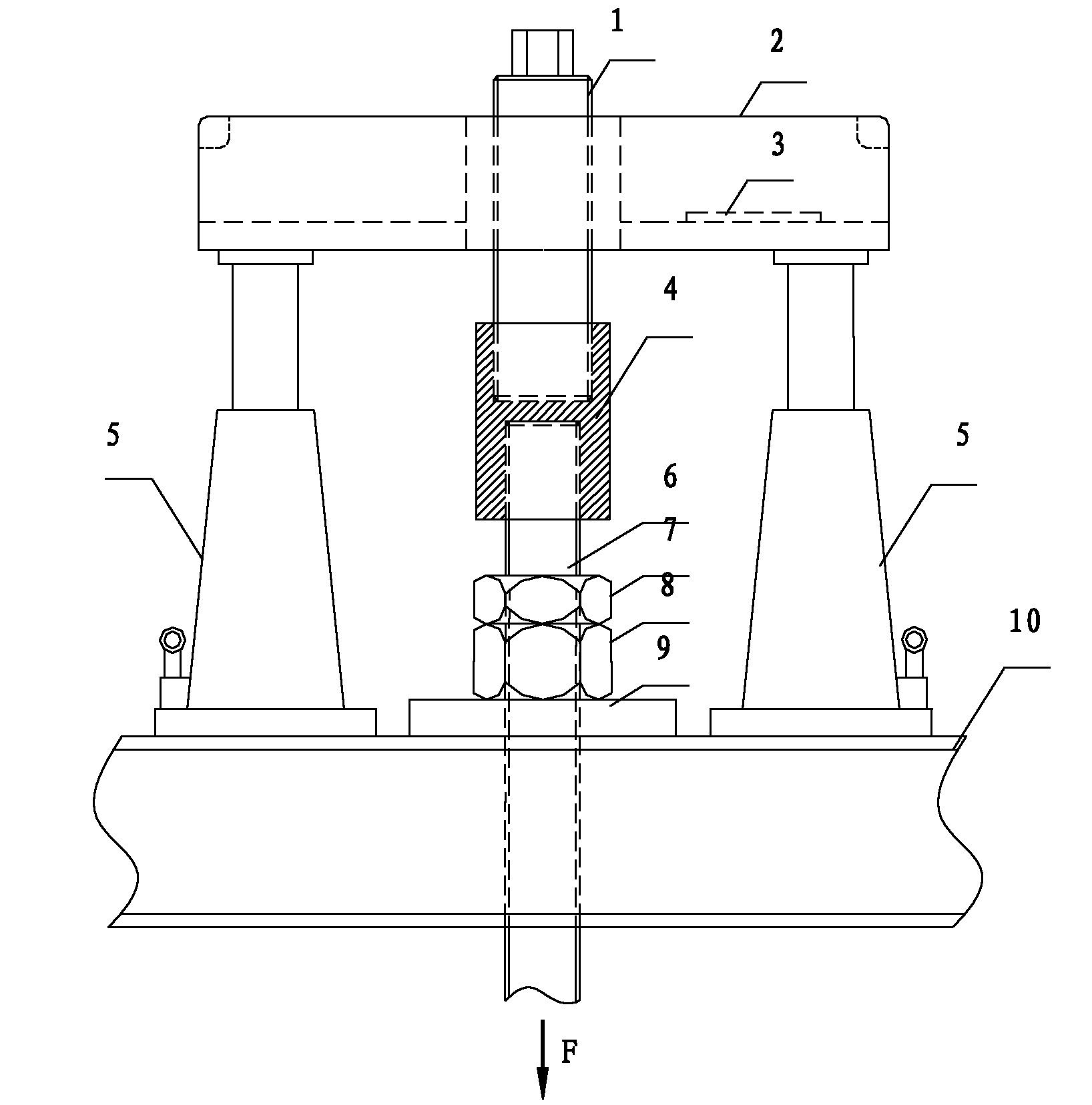

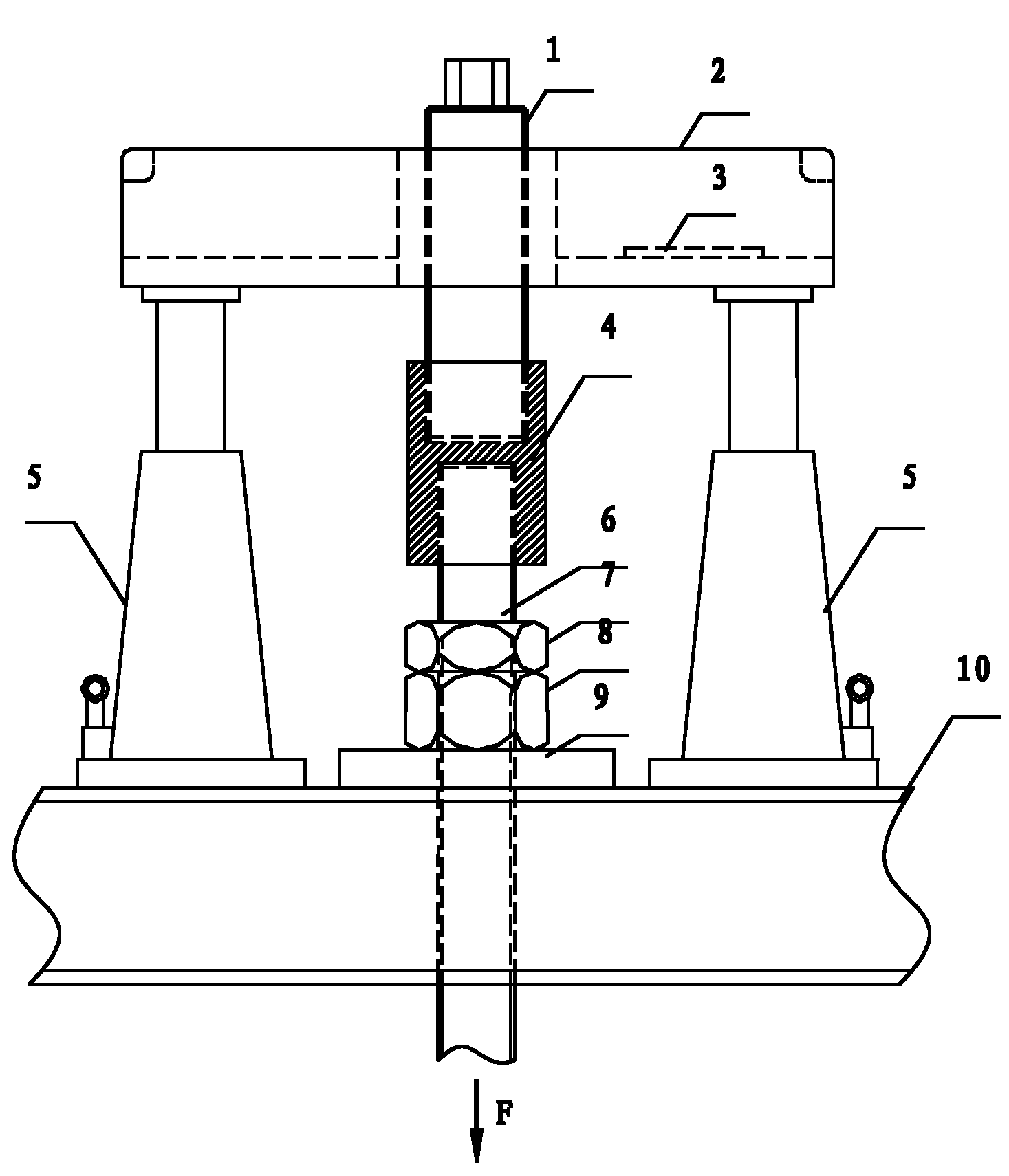

Force adjusting device of high-loading rigid hanger

InactiveCN102079480AEliminate difficultyLow efficiencyLoad-engaging elementsScrew threadHigh loading

The invention discloses a force adjusting device of a high-loading rigid hanger which comprises a height adjusting pull rod and a crane boom, wherein the crane boom is connected with the height adjusting pull rod in a screw thread mode; a hanger rod of the rigid hanger to be adjusted is connected with the height adjusting pull rod through a connecting nut in a screw threaded mode; and a hydraulicjack is arranged at two sides of the height adjusting pull rod under the crane boom. According to the invention, the defects that applied force adjustment for the traditional high-loading rigid hanger is very difficult, can not be removed, and even the hanger boom and the nut screw thread are easy to damage in the adjustment process are eliminated, the high-loading rigid hanger is a labor-saving,efficient and safe mechanical device, especially the batch high-loading rigid hanger have the characteristics of convenience and rapidness, efficiency and labor reservation when the applied force is adjusted.

Owner:XIAN THERMAL POWER RES INST CO LTD

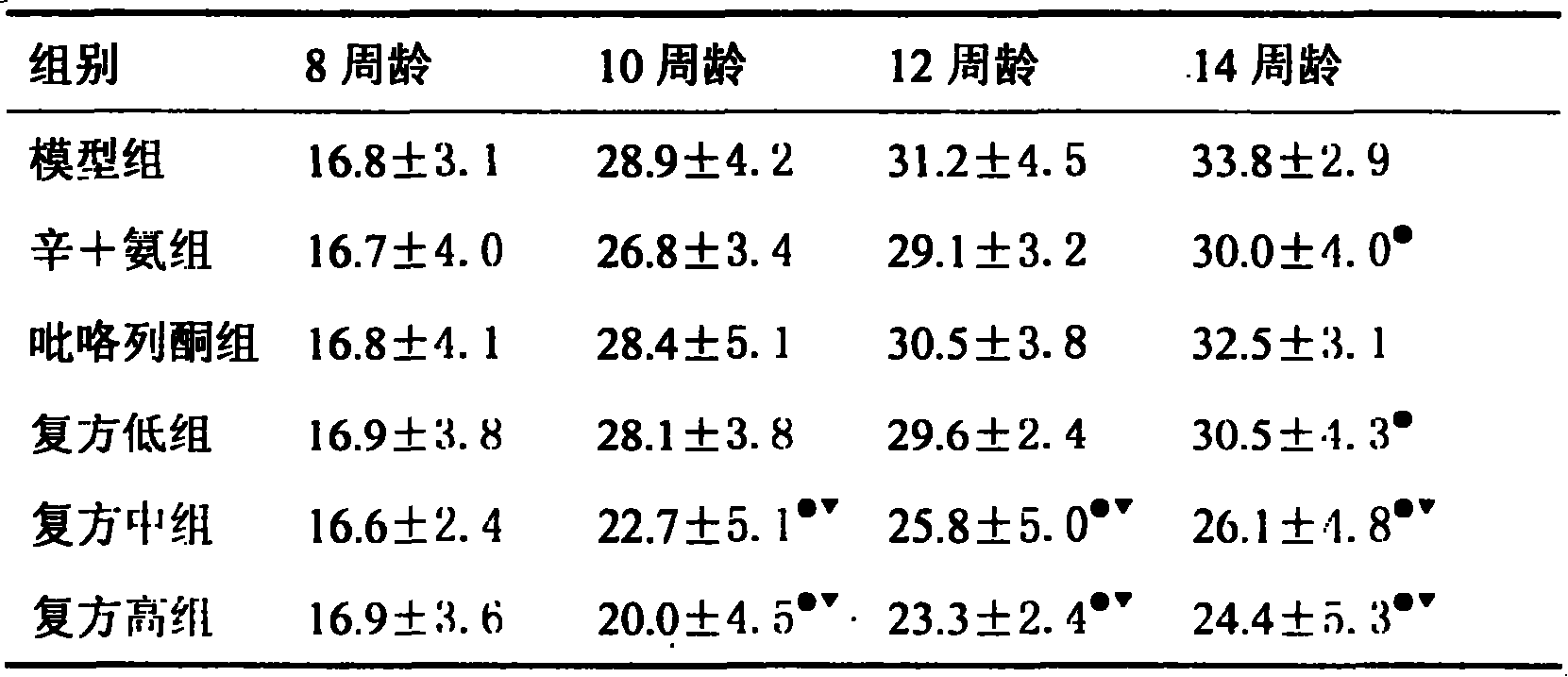

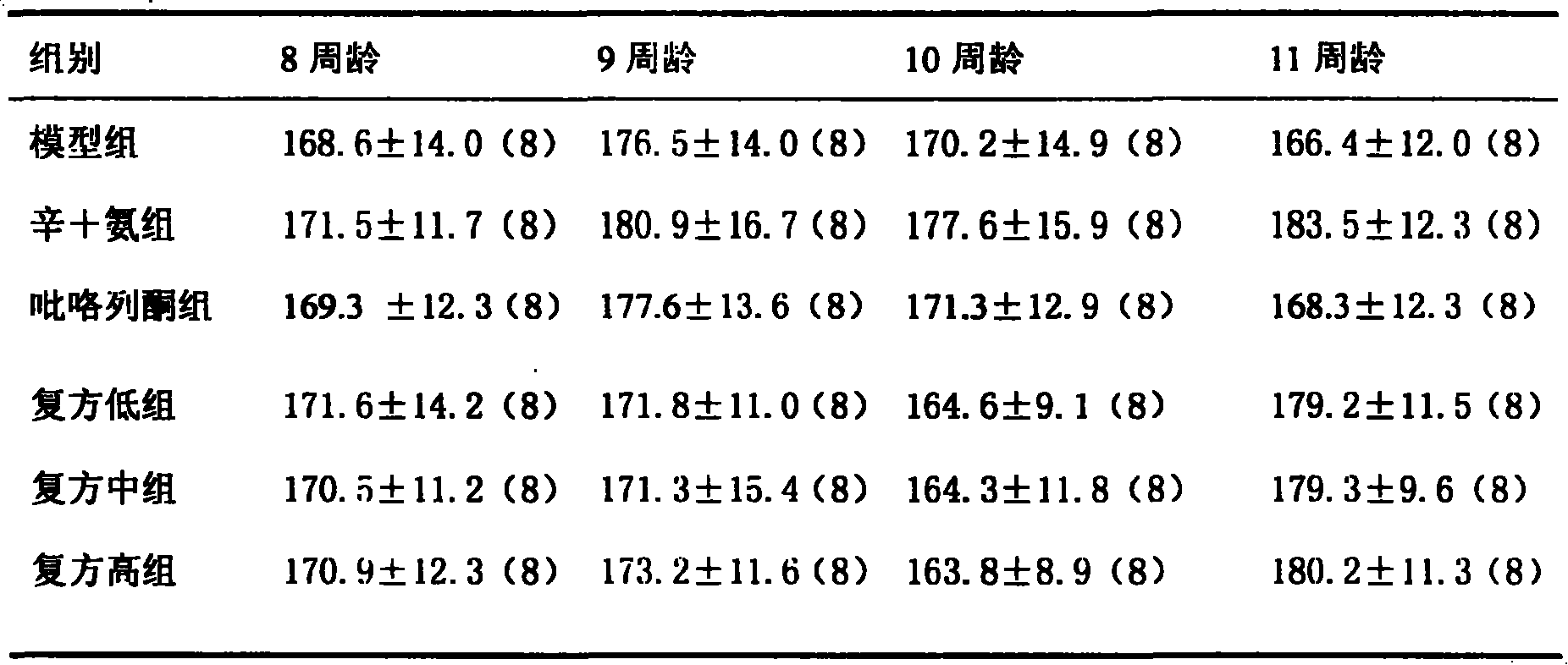

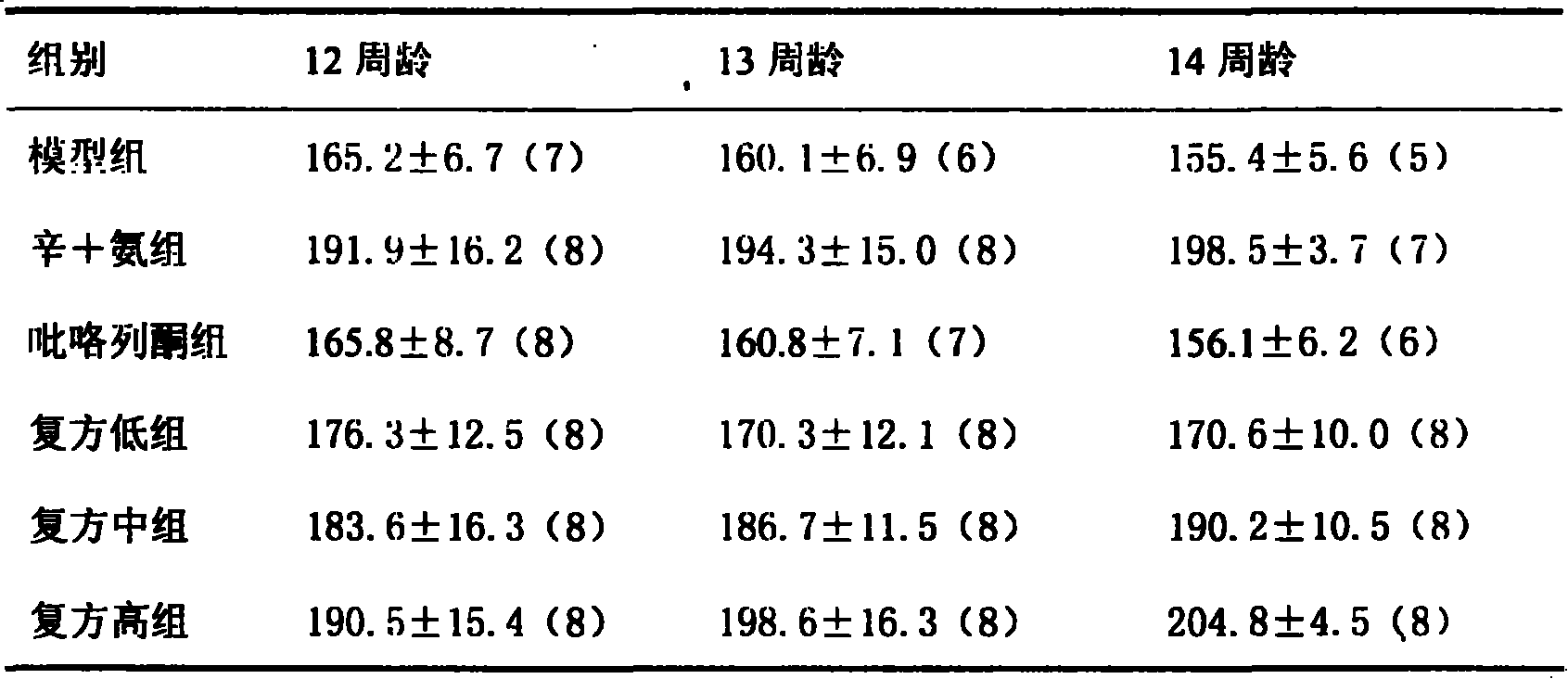

Medicine compounds for treating hypertension

ActiveCN101229372AGood treatment effectReduce incidencePharmaceutical non-active ingredientsHeterocyclic compound active ingredientsTreatment hypertensionLong term survival

The invention provides a medical composite for treating hypertension and a preparation thereof. The medical composite comprises antihypertensive drug, HMGCoA reductase inhibitor and insulin sensitizer. The medical composite of the invention not only can effectively reduce blood pressure, but also has good effect on the treatment and prevention of hypertension complications. The long term survival of patients can be improved obviously.

Owner:LUNAN PHARMA GROUP CORPORATION

Closed loop device incorporating one or more indecomposable knots and methods of using

InactiveUS8454484B2Easy to processSimple to useSnap fastenersTravelling sacksMuscle groupClosed loop

A flexible, closed loop device that includes at least one indecomposable knot formed that helps define a plurality of adjustable loops. The knot can be easily loosened so that the loop sizes can be adjusted. The knot is easily tightened and locked. In some embodiments, the device includes at least two indecomposable knots. The device is useful in the practice of yoga, Pilates, and other personal training exercises. The device is flexible and easily adjustable, allowing the user to more effectively target specific muscle groups. The device may additionally or alternately be used as a securing and carrying strap for items. Still further, the device may be used as a connecting device to link items together for towing, hoisting, etc.

Owner:KEEN BRIAN T +1

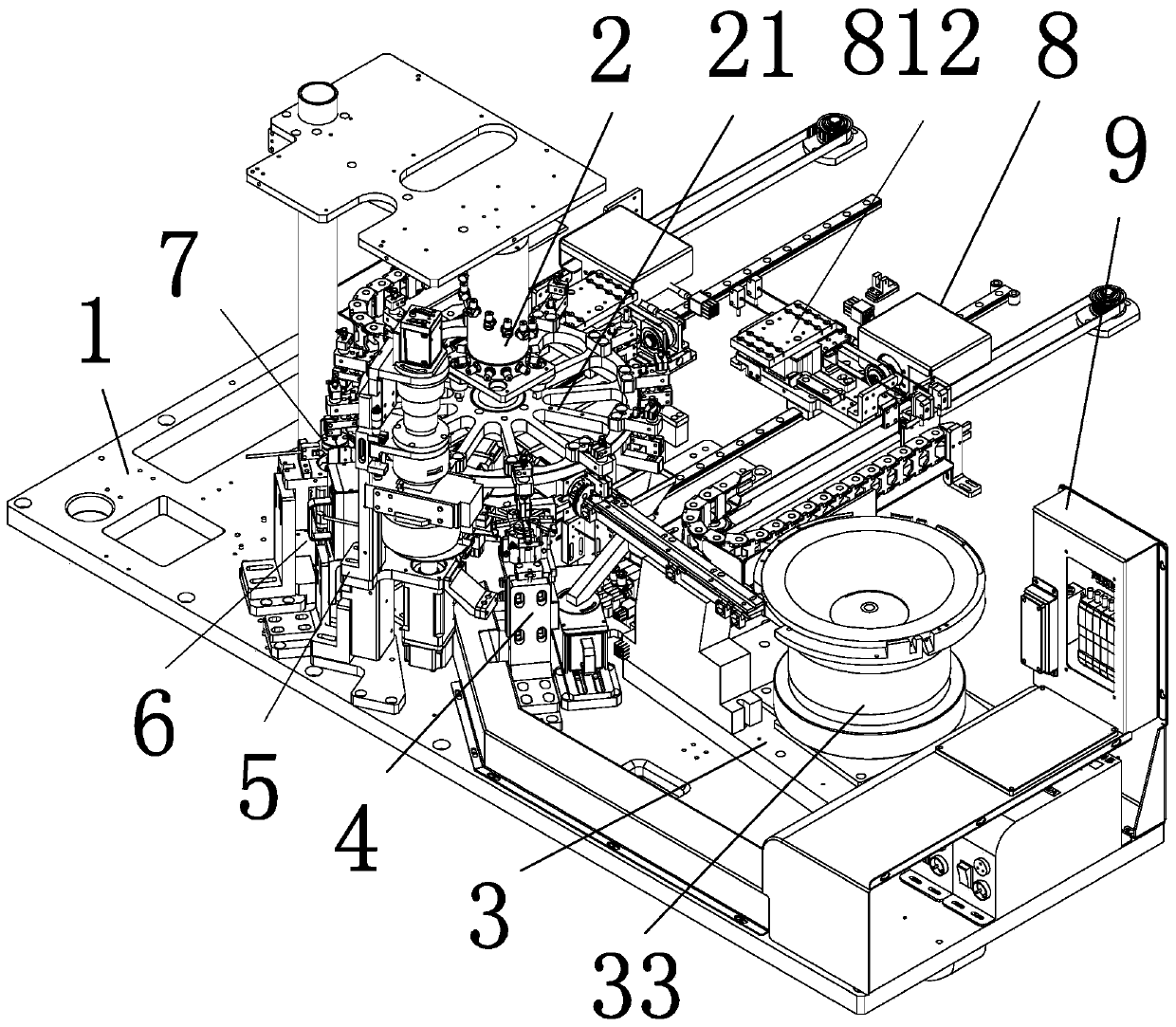

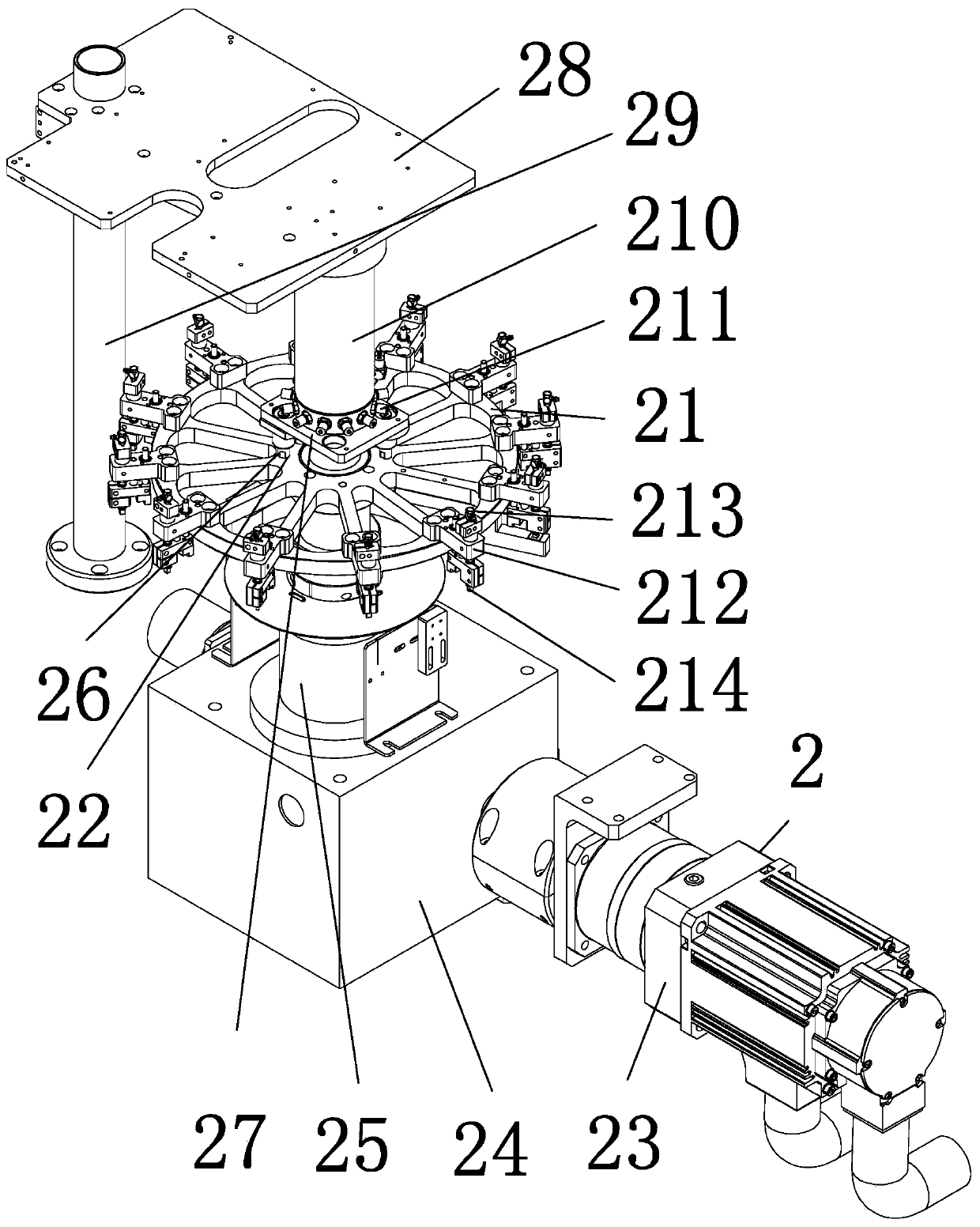

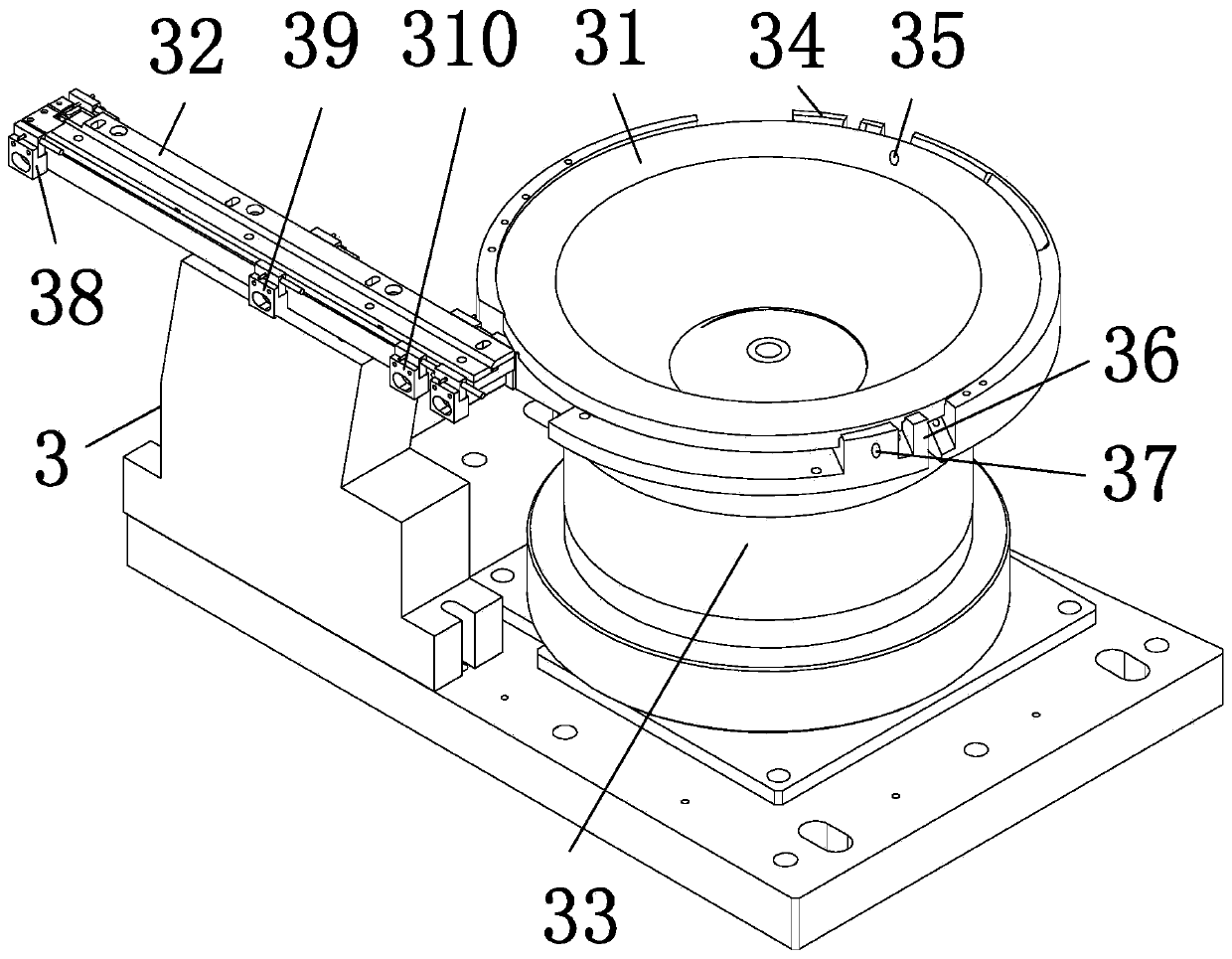

Rotating disc type chip feeding device and core feeding method

ActiveCN110371596AReduce labor intensityImprove securityConveyor partsRotary conveyorsEngineeringUltimate tensile strength

The invention relates to a rotating disc type chip feeding device which comprises a base, a rotating disc type translocating device, and a vibration fixed surface discharging device, chip positioningdevices, chip marking visual detection systems, defective chip storing devices, chip rotating devices and shuttle transporting devices which are distributed along the circumference of a rotating discin sequence, wherein the rotating disc type translocating device is arranged on the base and is provided with the rotating disc. The rotating disc type chip feeding device is capable of continuously feeding chips, the labor intensity of operating personnel is lower, and the safety is higher.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

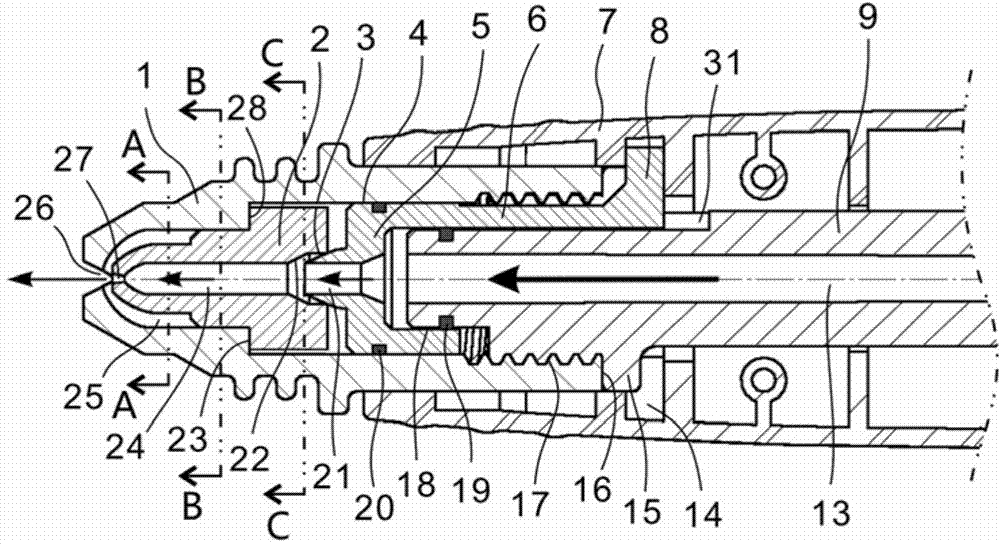

High-low pressure spray nozzle component for high-pressure cleaning equipment

ActiveCN104492620ASimple structureCompact structureSpray nozzlesCleaning using liquidsStraight tubeSpray nozzle

The invention relates to a high-low pressure spray nozzle component for high-pressure cleaning equipment. The high-low pressure spray nozzle component comprises a water outlet straight tube, a low-pressure spray nozzle, a high-pressure spray nozzle, a bypass path and a slide valve, wherein one end of the water outlet straight tube is connected with a supply tube of the high-pressure cleaning equipment, the other end of the water outlet straight tube is connected with the spray nozzle component; the low-pressure spray nozzle is connected with the water outlet straight tube; the high-pressure spray nozzle is positioned inside the low-pressure spray nozzle; the bypass path surrounds the high-pressure spray nozzle and leads to the low-pressure spray nozzle; the slide valve capable of moving along the axial direction of the water outlet straight tube is arranged between the water outlet straight tube and the high-pressure spray nozzle; when the slide valve moves forwards and attaches to the spray nozzle component of the high-pressure spray nozzle closely, the spray nozzle component is positioned at a high-pressure position, when the slide valve slides backwards to gradually leave the high-pressure spray nozzle, the spray nozzle component is started to be converted to the low-pressure position from the high-pressure position. The high-low pressure spray nozzle component for the high-pressure cleaning equipment disclosed by the invention has the advantages of being simple in structure, reliable, easy to realize, quick and convenient in speed regulation, safe, good in cleaning effect, and the like.

Owner:SUMEC HARDWARE & TOOLS

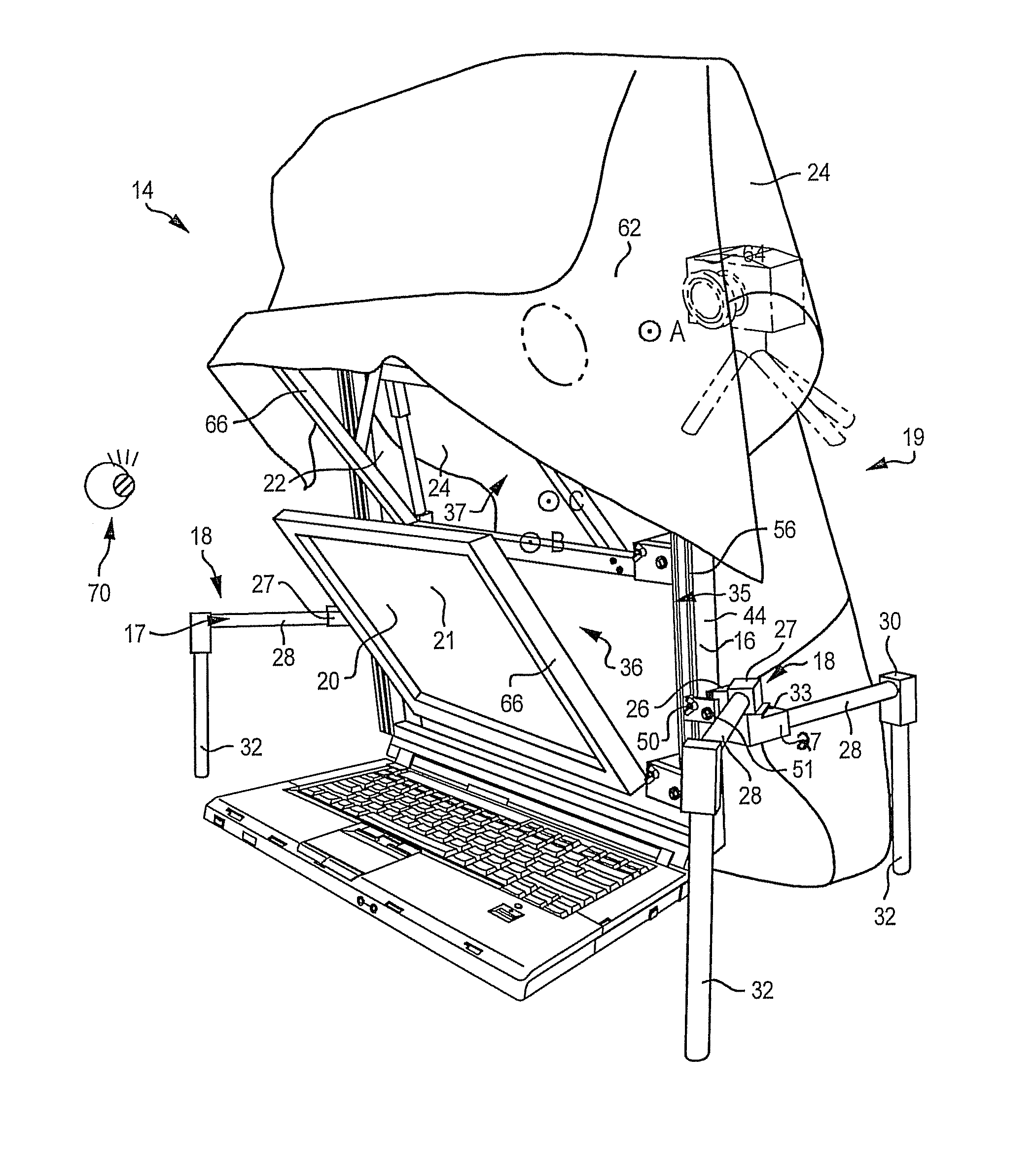

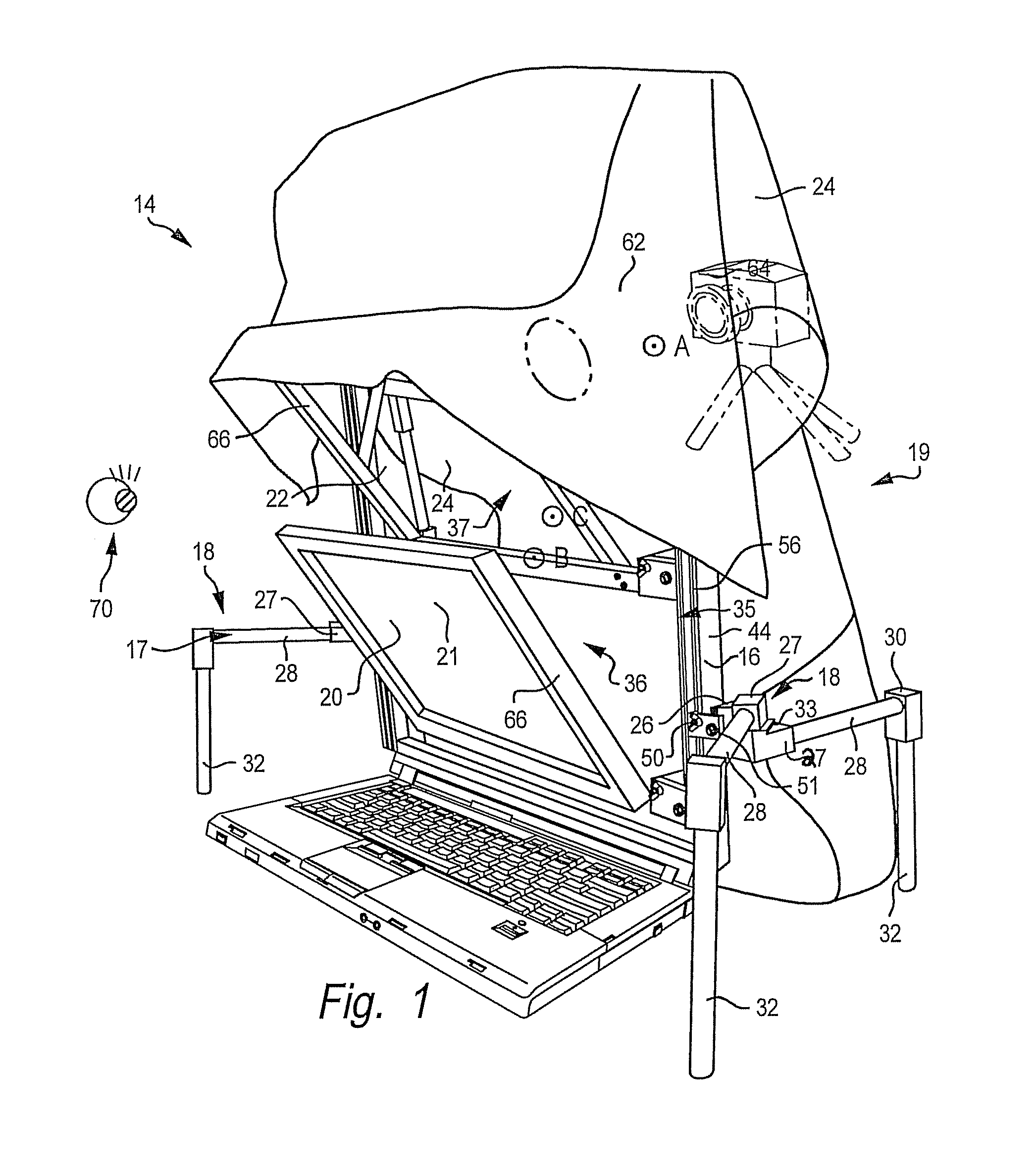

Prompting device

InactiveUS20100182513A1Easy to foldEasy to storeTelevision system detailsColor television detailsComputer monitorVideo capture

The prompting device has a frame, a plurality of reflective panes, and support members and may be used on a desktop by a home or small business user to read a script in a natural manner while speaking to a camera or other video capturing device. In the preferred embodiment, the frame has a user side and a camera side, and is lightweight and readily collapsible such that it may be easily stored when not in use. A collecting pane reflects an image onto a viewing pane, so as to create a displayed image which may be viewed by a user. The viewing pane is generally transparent allowing a user to be recorded or photographed through the viewing pane. In another embodiment the prompting device has an opaque cover. The support assemblies are adjustable in height and the panes have an adjustable angle. In another embodiment the support assemblies are hangers. In another embodiment the image is an image reflected from a computer monitor and may be scrolling text.

Owner:DEOTTE RICHARD WILLIAM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com