Pressure-maintaining and regulating hydraulic control system of roll balance gear

A technology of hydraulic control system and balancing device, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of pressure leakage, no pressure protection function, rupture of connecting oil pipes, etc., to prevent sudden pressure rise. High, complete and rapid pressure relief, and the effect of protecting safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

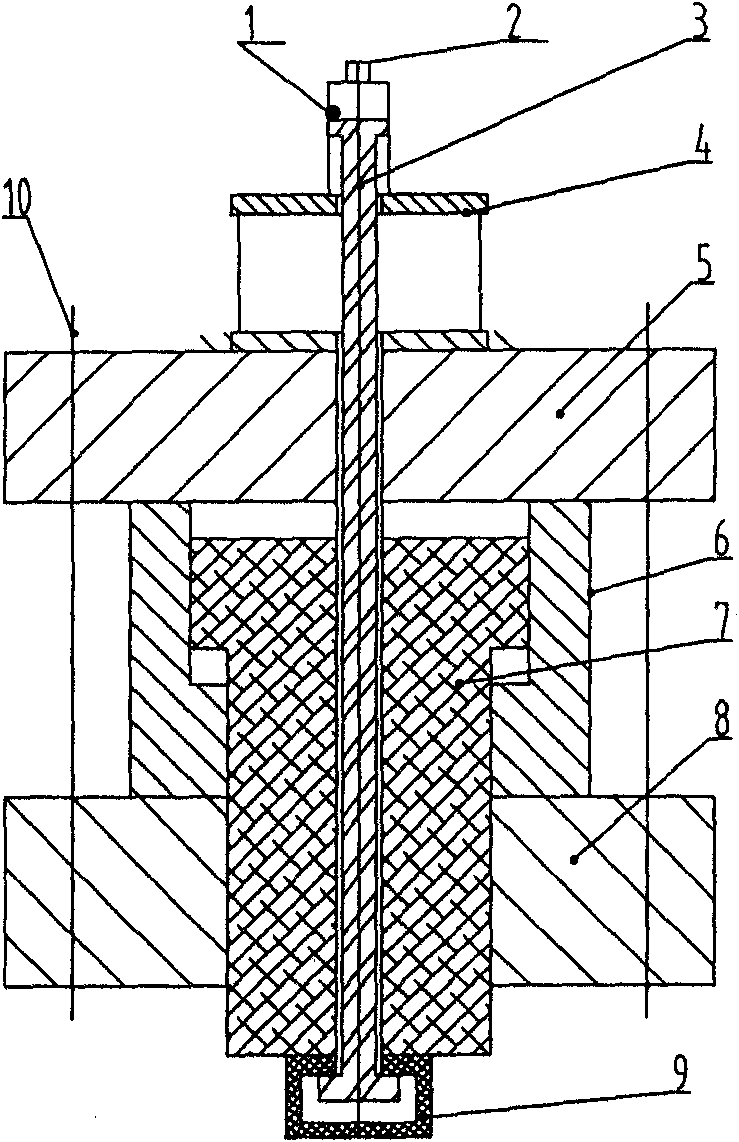

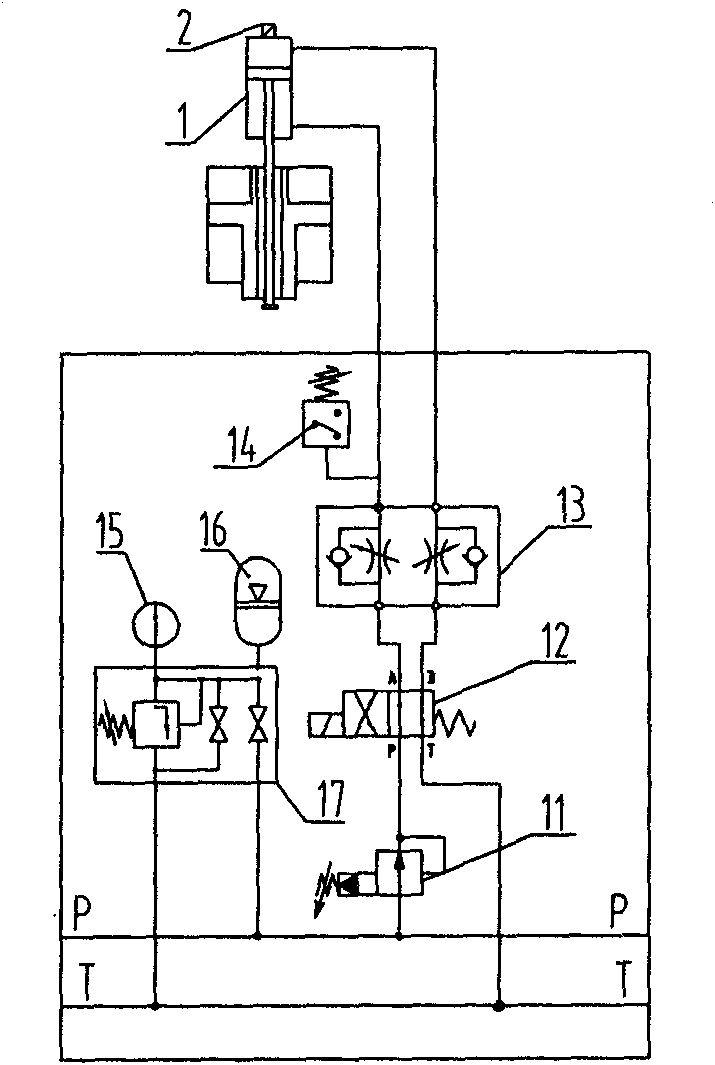

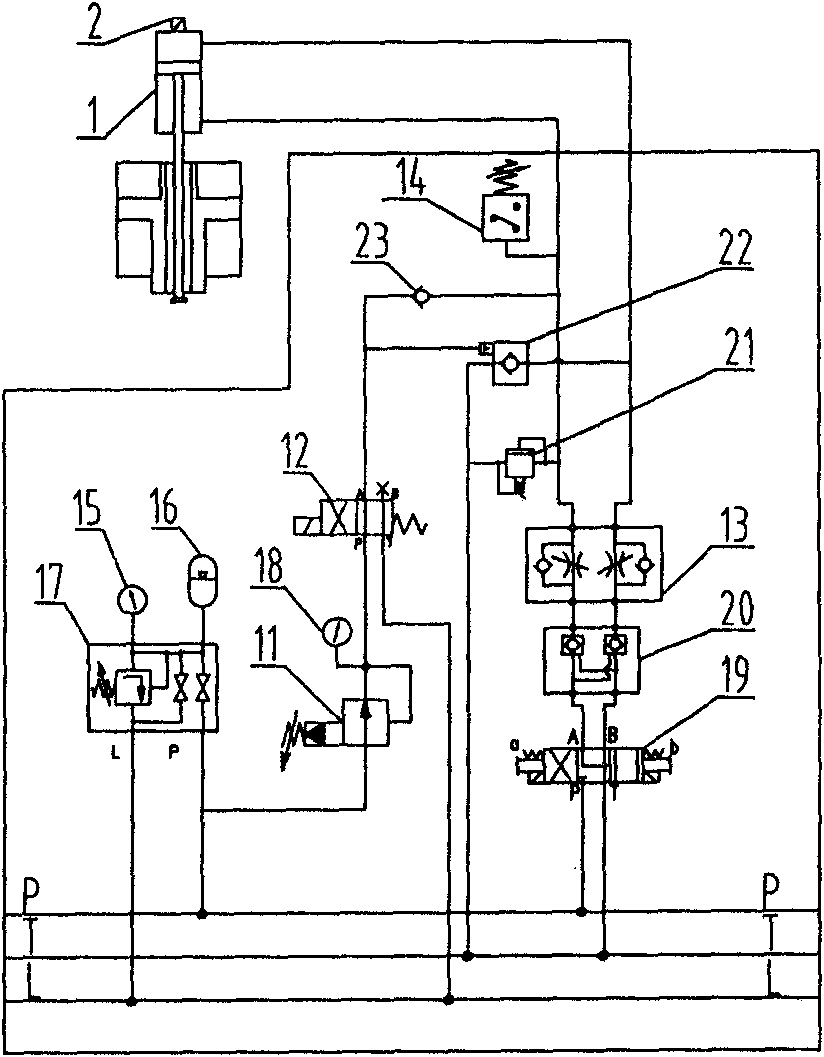

[0020] like image 3 As shown, a hydraulic control system for maintaining pressure adjustment of a roll balancing device has a balancing hydraulic cylinder 1 with a built-in displacement sensor 2, which consists of a pressure reducing valve 11, a No. No. Ⅰ pressure gauge 15, No. Ⅱ pressure gauge 18 and hydraulic oil pipes form the pressure maintaining circuit of the roll balance device according to the conventional connection method; The valve 20, the relief valve 21 and the hydraulic oil pipe form the adjustment circuit of the roll balance device according to the conventional connection method. The two control circuits can work independently, and the pressure maintaining circuit and the adjusting circuit are separated and associated by the hydraulically controlled one-way valve 22 and the one-way valve 23 . Increase the No. Ⅱ electromagnetic reversing valve 19 to ensure that the roll device stays at any position at any time, and the adjustment is convenient; increase the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com