Patents

Literature

112results about How to "Reduced roll change time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

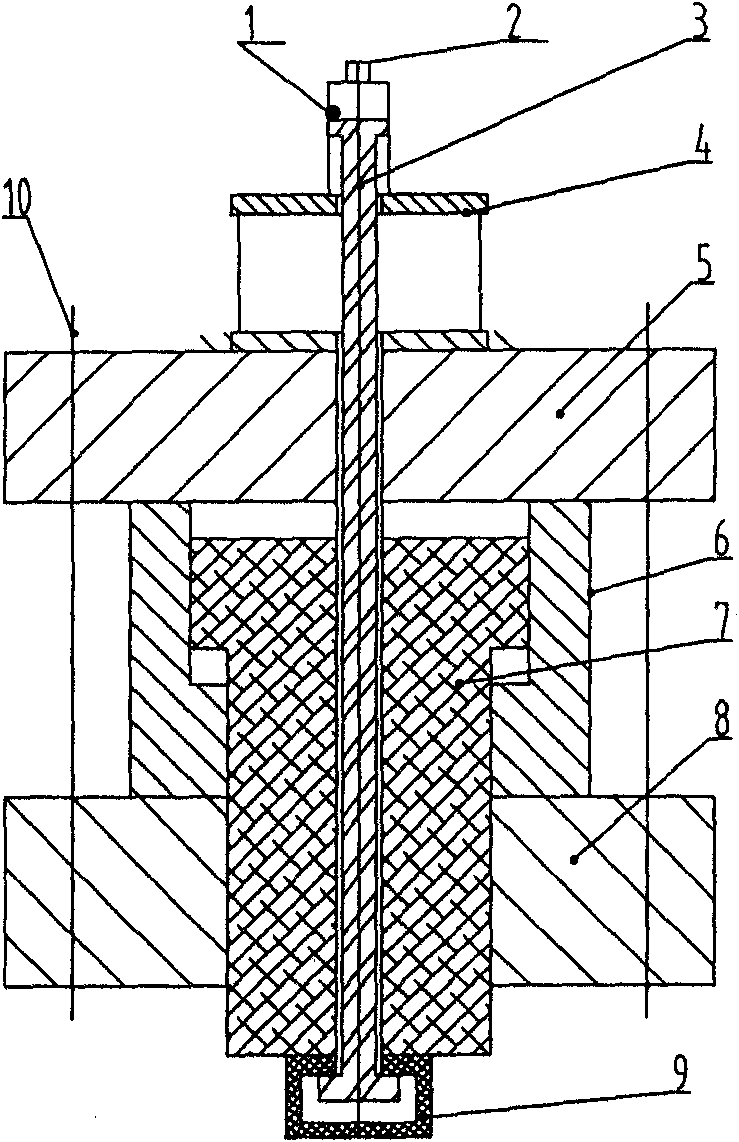

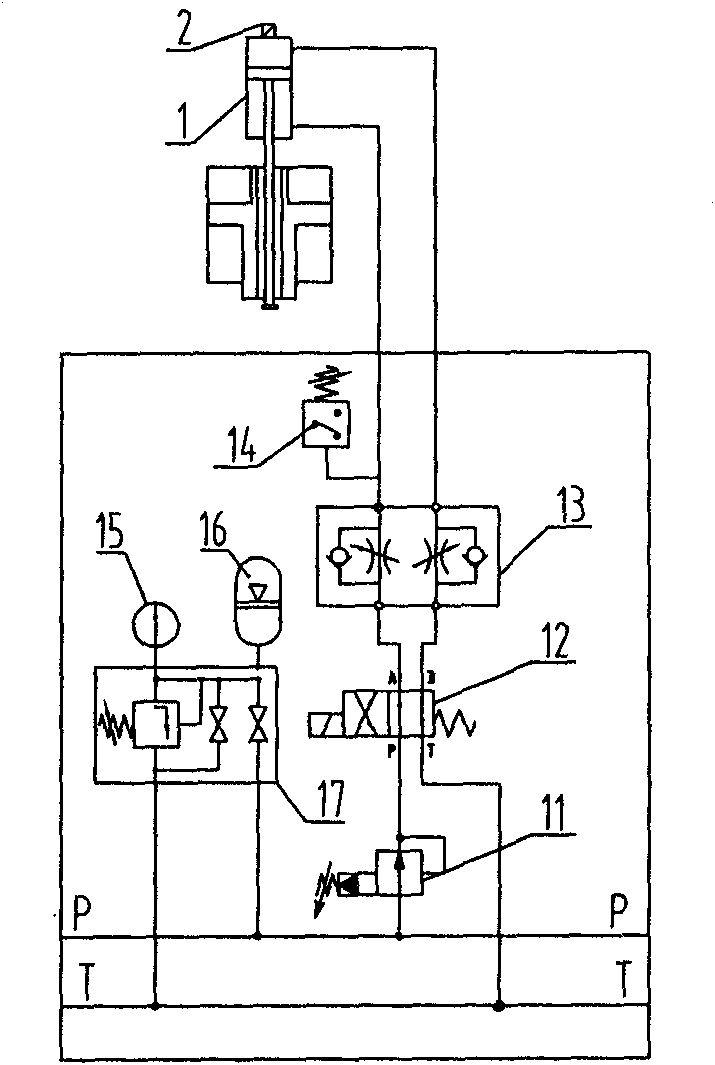

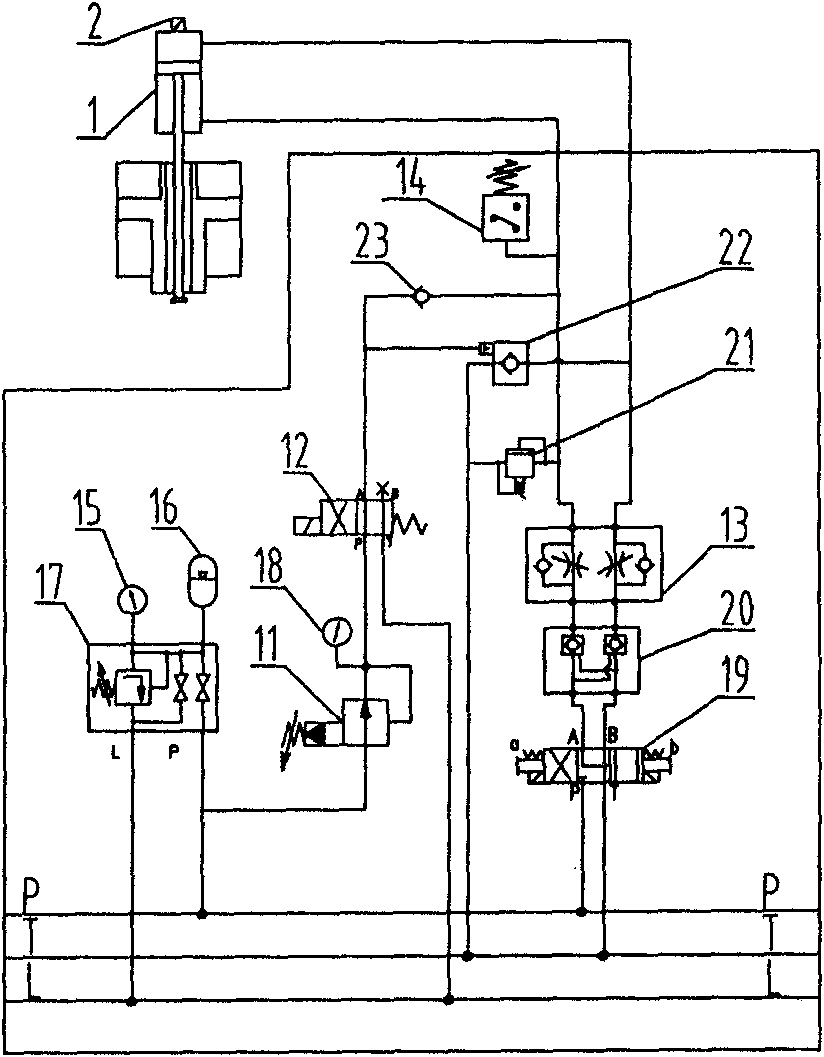

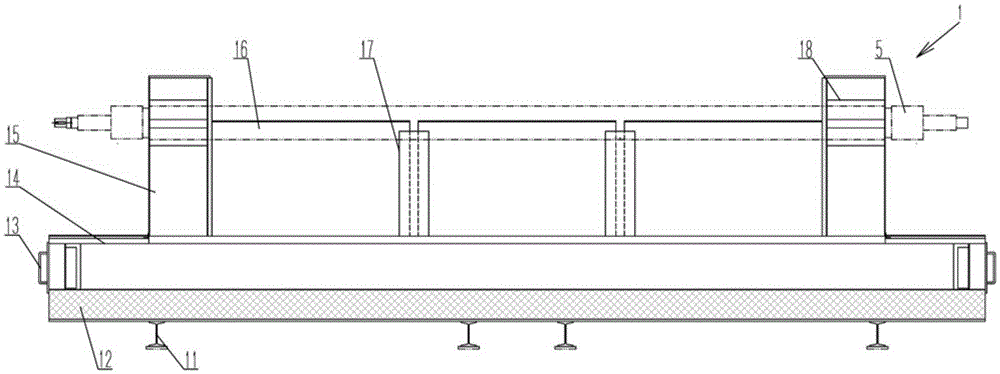

Pressure-maintaining and regulating hydraulic control system of roll balance gear

InactiveCN101869912AMonitor packing and packing pressureRegulate securityMetal rolling stand detailsMetal rolling arrangementsControl systemSafety valve

The invention discloses a pressure-maintaining and regulating hydraulic control system of a roll balance gear and relates to a hydraulic control system of a steel rolling machine. The pressure-maintaining and regulating hydraulic control system solves the problems of unreliable pressure maintenance, inconvenient equipment debugging and no pressure protection of a control loop in the prior art. The pressure-maintaining and regulating hydraulic control system is characterized in that: a hydraulic control loop comprises a pressure-maintaining loop of the roll balance gear and an adjusting loop of the roll balance gear; the pressure-maintaining loop is formed by connecting a pressure-reducing valve 11, an I-number electromagnetic directional valve 12, an energy accumulator 16, a safety valve 17, an I-number pressure meter 15, an II-number pressure meter 18 and a hydraulic oil pipe according to the conventional connecting method; the adjusting loop is formed by connecting an II-number electromagnetic directional valve 19, a one-way throttle valve 13, a pressure relay 14, a hydraulic locking valve 20, an overflow valve 21 and the hydraulic oil pipe according to the conventional connecting method; and the pressure-maintaining loop and the adjusting loop are separated and associated by using a hydraulic one-way valve 22 and a one-way valve 23.

Owner:TAIYUAN HEAVY IND

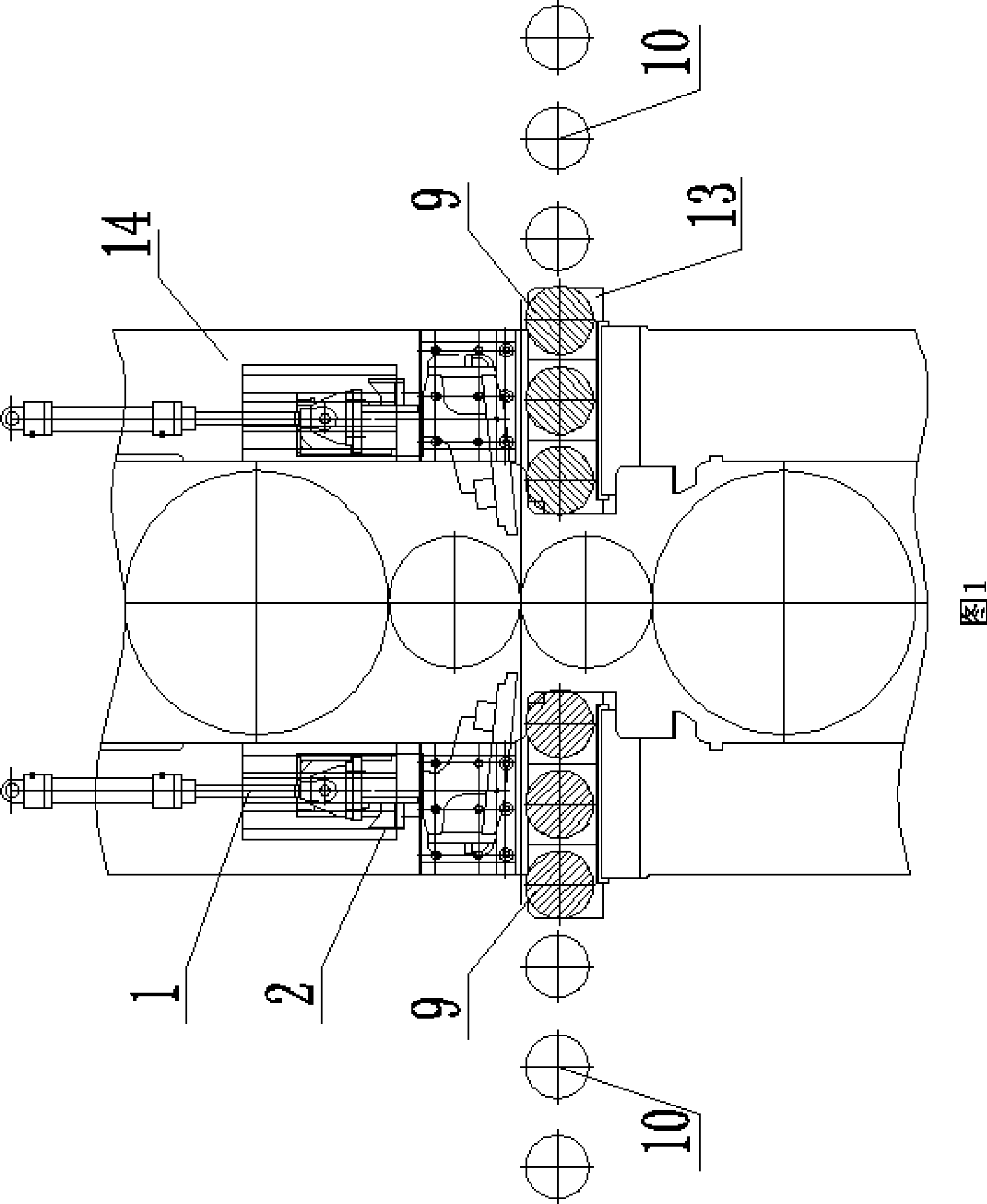

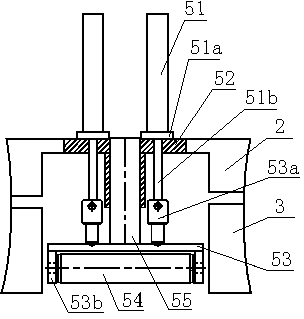

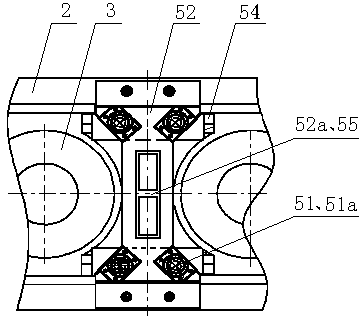

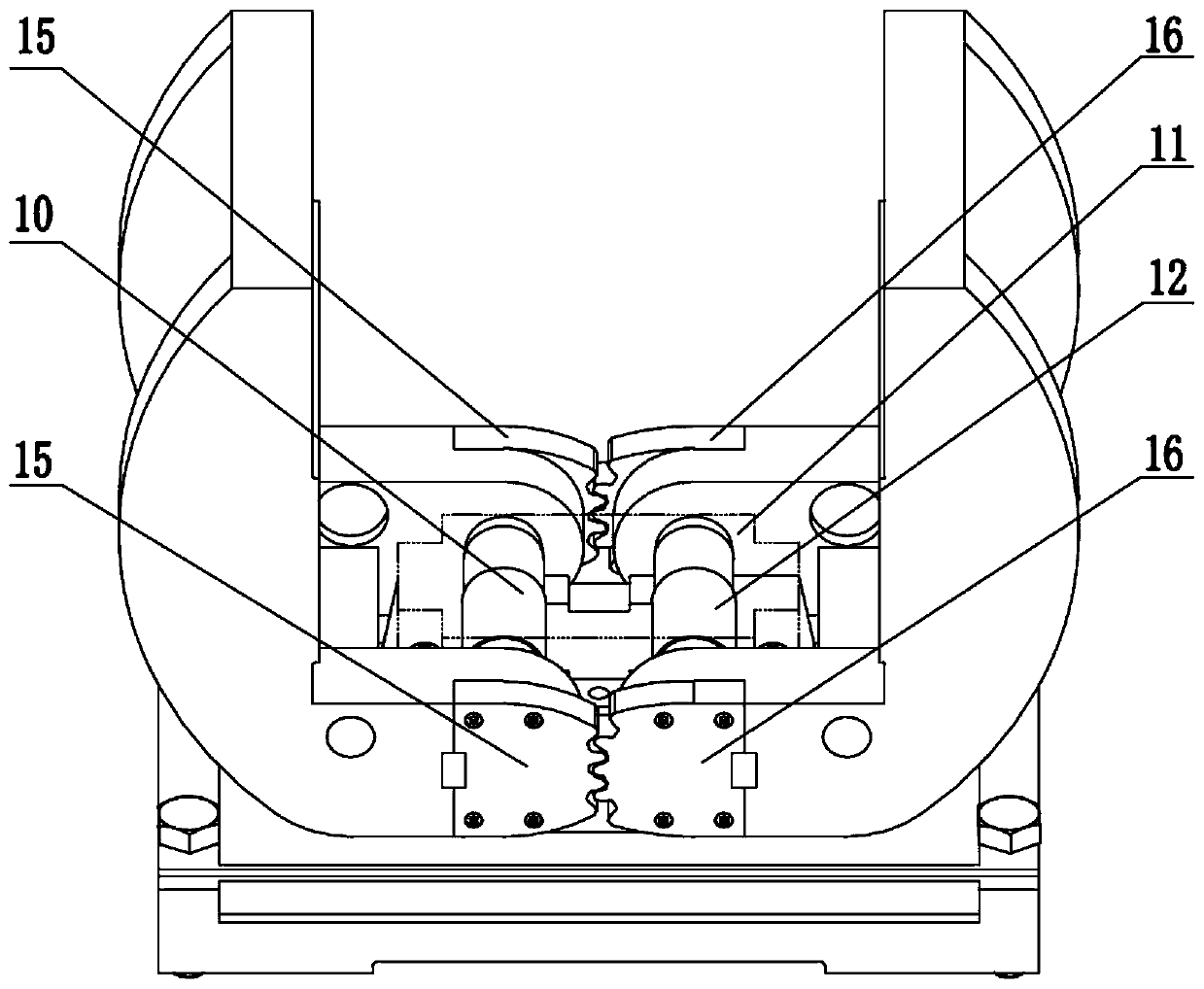

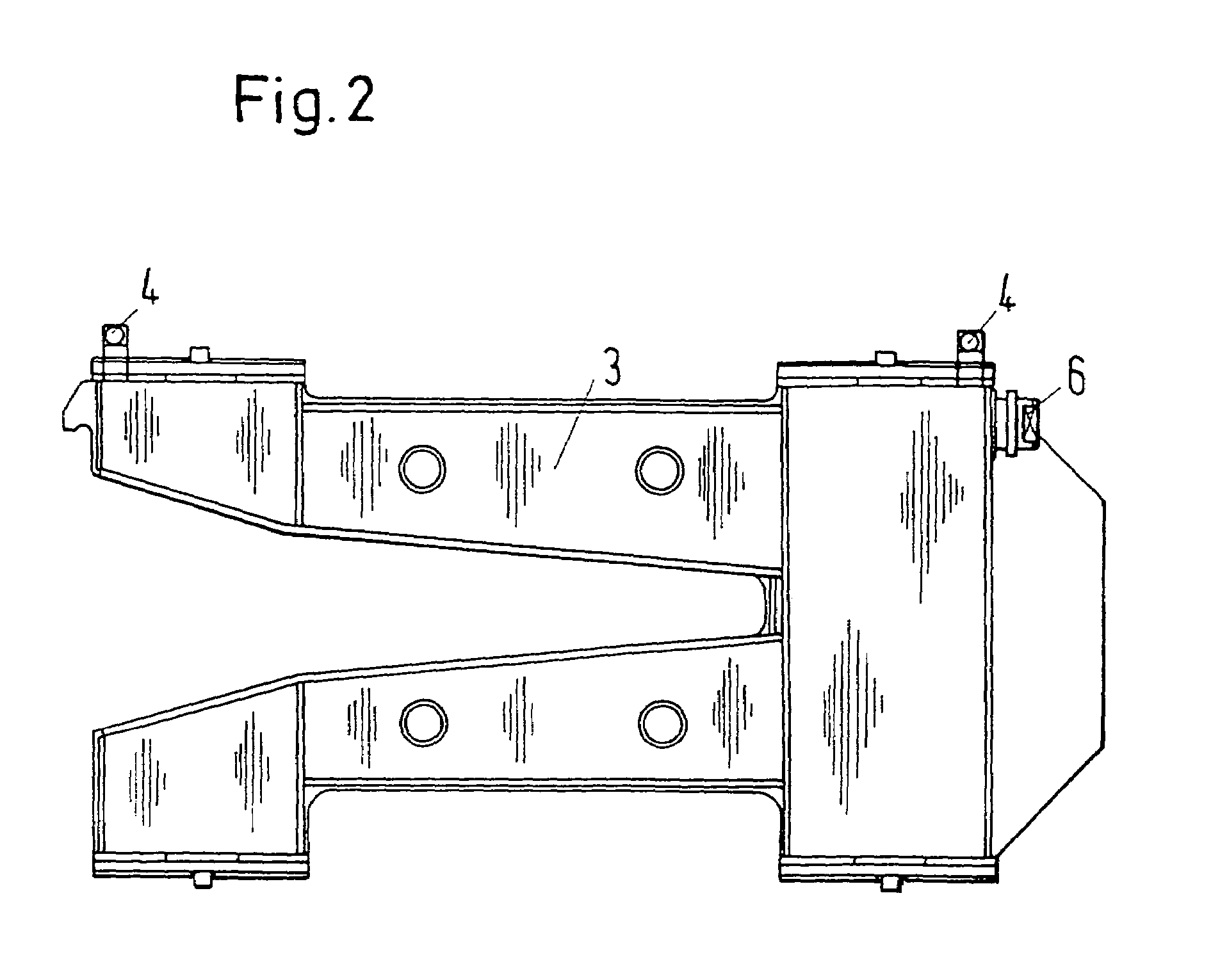

Breast-roll set replacement method and hoisting clamp thereof

ActiveCN101456036AReduced roll change timeHigh degree of automationMetal rolling stand detailsLoad-engaging elementsWork rollEngineering

The invention discloses a method for changing a breast roll of a rolling mill. The method for rapidly changing the breast roll comprises the following steps: A. placing two hangers between a guide rack and a breast roll assembly; B. connecting the hangers and the guide rack; and passing a bolt having a connecting clamping head into each hanger, screwing the bolt and being clamped at the roll body of the two adjacent breast rolls; C. lifting the breast roll assembly upwards by the hanger; D. putting the breast roll assembly down to a roll bedding rack through a guide lifting cylinder; E. separating the guide rack from the hangers; F. transporting the roll bedding rack and the breast roll assembly out of the stander by a working roll channel to finish the dismantling of the old breast roll assembly; and G. finishing the installation of a new breast roll assembly by the similar way. The invention further provides a lifting clamping tool used in the method. The method and the lifting clamping tool have the advantages of high degree of automation, simple operation, large reduction of the labor intensity of workers, convenient storage and low cost.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

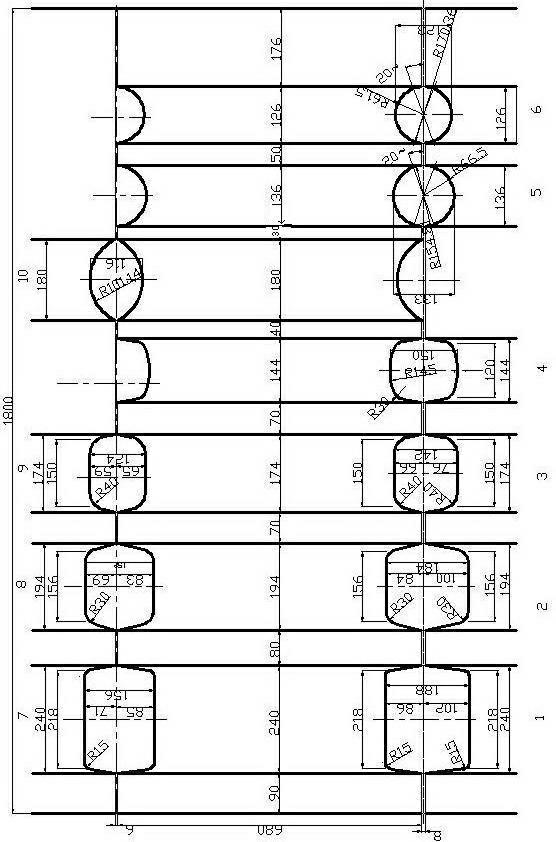

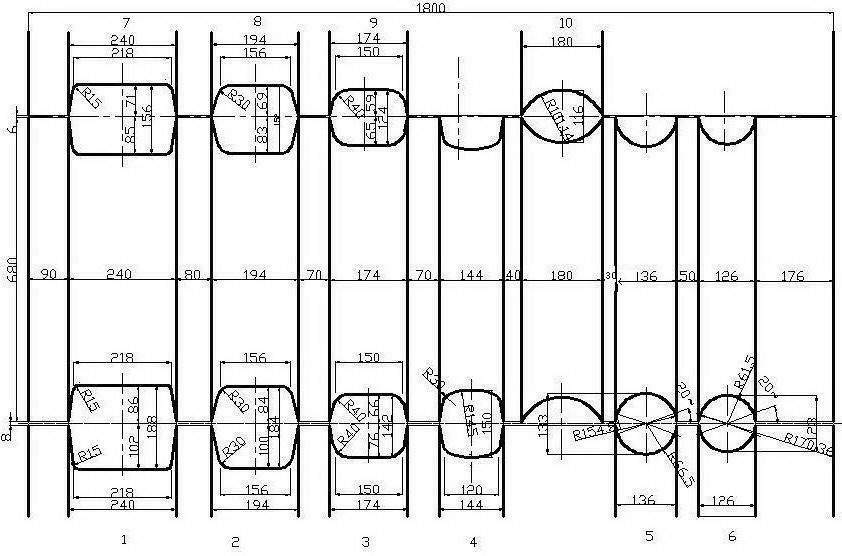

Method for rolling mill to roll round steel with diameter phi of 120mm and round steel with diameter phi of 130mm by one roller set

ActiveCN102553910AReduce labor intensityAvoid high number of rollsMetal rolling arrangementsRolling mill

A method for a rolling mill to roll round steel with the diameter phi of 120mm and round steel with the diameter phi of 130mm by one roller set includes the ten-pass design of a 650mm rolling mill and a regulating method thereof. The two types of round steel share the first, second, third, fourth and fifth passes and the eighth pass of leader passes. When in rolling of the round steel with the diameter phi of 120mm, the roller gap of the upper rolling line is 6mm, feeding is carried out after 90-degree rotation from the seventh pass to the eighth pass. When in rolling of the round steel with the diameter phi of 130mm, the roller gap of the upper rolling line is regulated to be 11mm, feeding is carried out from the fifth pass to the eighth pass after the sixth pass and the seventh pass arecast off, the third pass and the fifth pass meet the requirement for the entry width of the previous pass in the processes of rolling the round steel with the diameter phi of 120mm and the round steel with the diameter phi of 130mm simultaneously, the eighth pass meets requirements of the round steel with the diameter phi of 120mm and the round steel with the diameter phi of 130mm simultaneously,the width B of the eighth pass meets requirements of the round steel with the diameter phi of 130mm, and the height H thereof meets requirements of the round steel with the diameter phi of 120mm. By the method, the rolling mill can roll the round steel in two specifications by the same roller set, and roller changing frequency and time due to alternating of the two specifications can be reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Float glass encapsulation box and roller replacing method thereof

ActiveCN102167496ASimplify the drivetrainSave workshop spaceGlass transportation apparatusDrive shaftEngineering

Owner:BENGBU TRIUMPH ENG TECH CO LTD +2

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

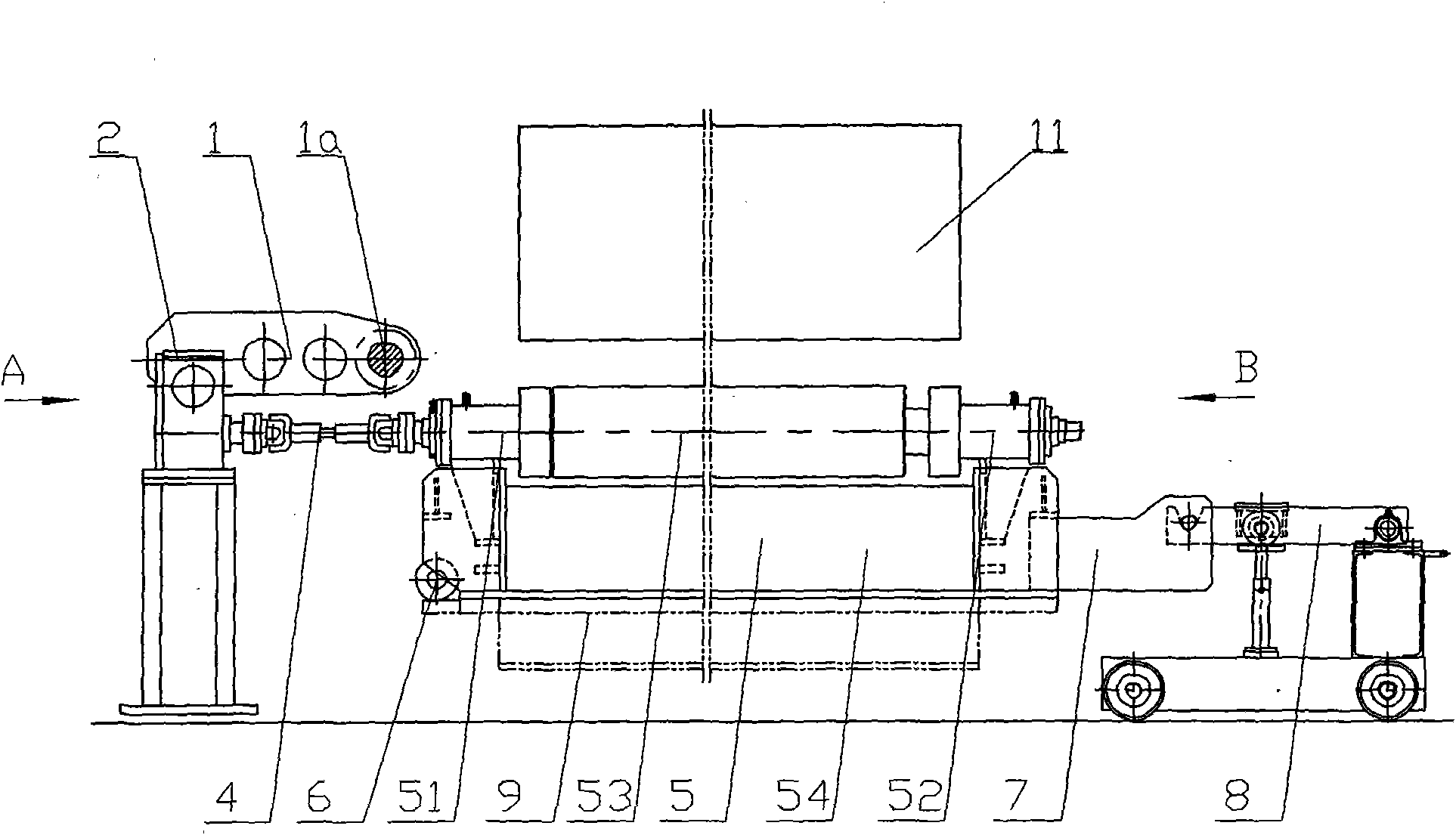

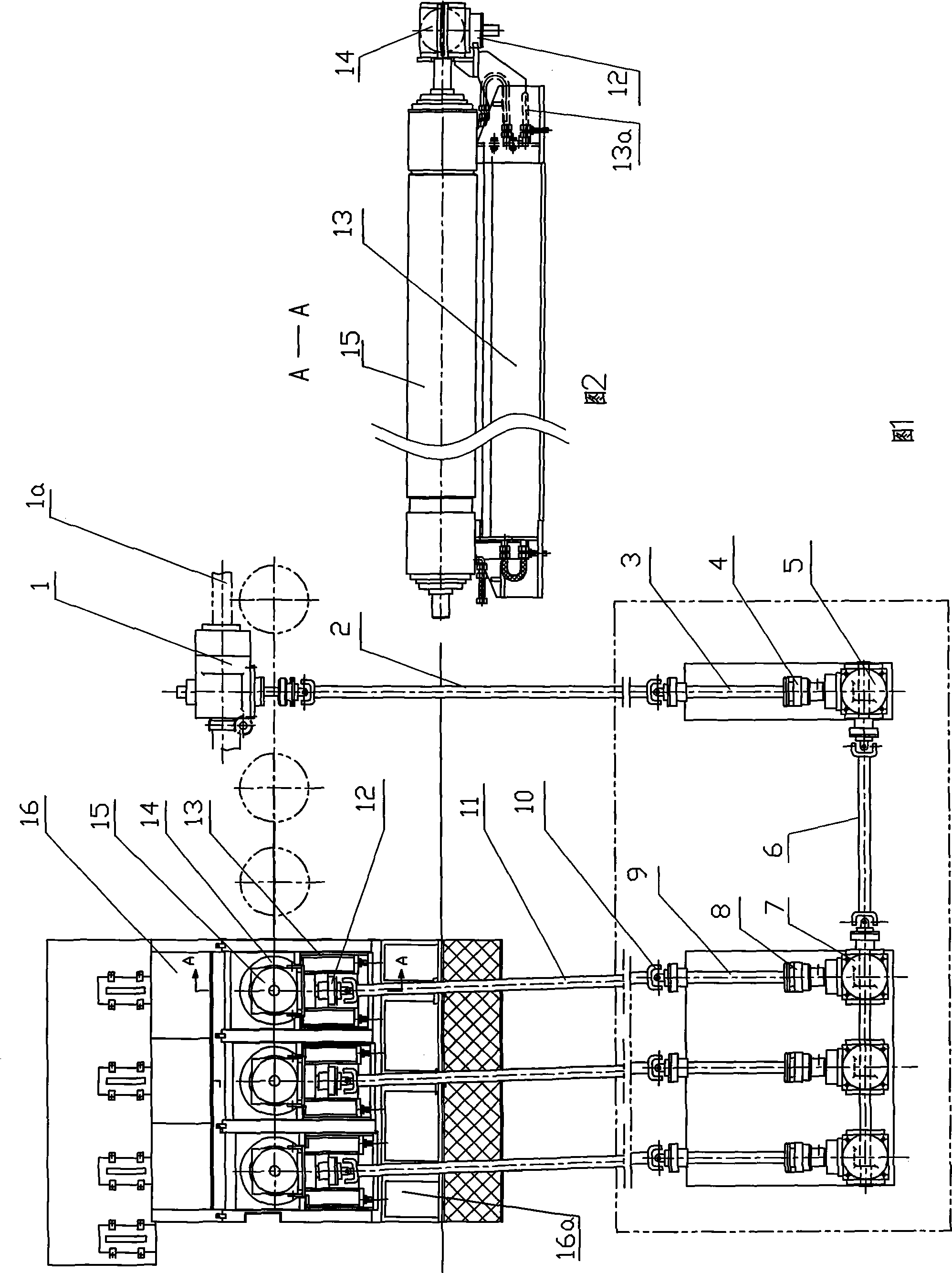

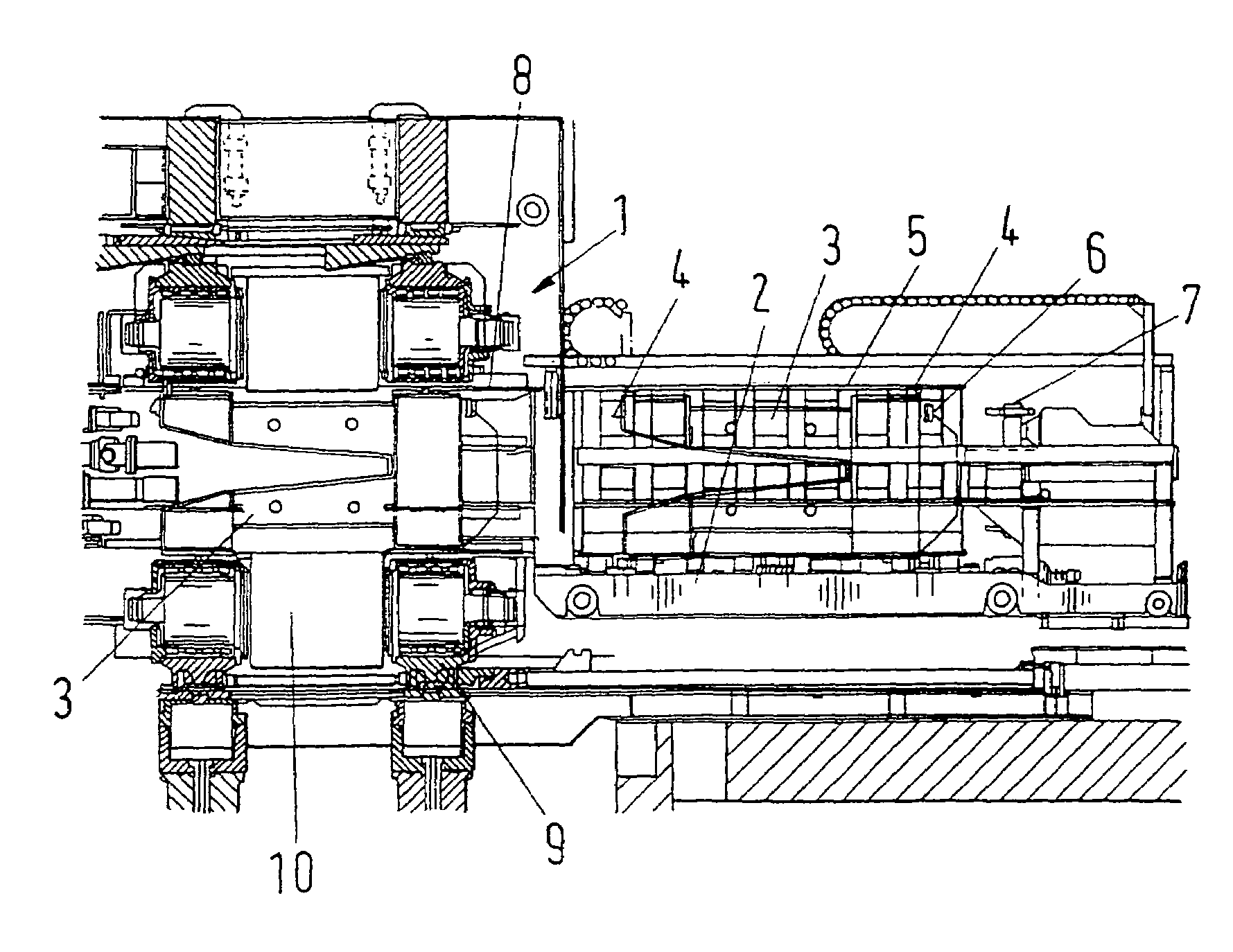

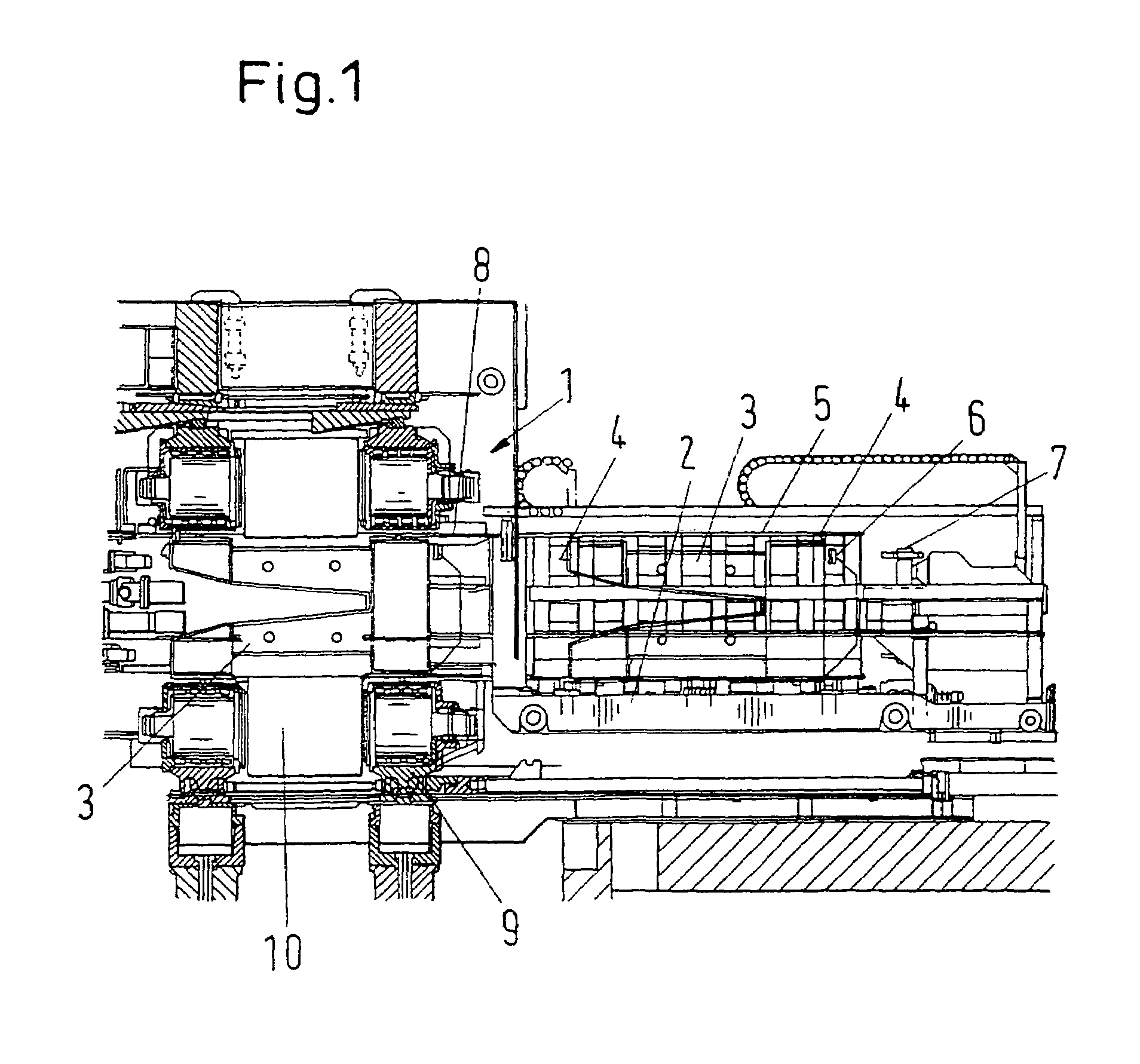

Lower transmission sealing box used for producing float glass and roller-changing method thereof

The invention relates to a lower transmission sealing box used for producing float glass and a roller-changing method thereof. The low transmission sealing box is characterized in that a gear box (1) is connected with a annealing kiln roller-way transmission shaft (1a) and connected with a steering gear (5) in a ground pit through transmission shafts (2, 3), the steering gear (5) is coaxially connected with three steering gears (7) in a ground pit through a transmission shafts (6), a steering gear (7) is connected with a steering gear (14) through transmission shafts (9, 11), and a steering gear (14) is connected with a shaft head of a transition roller (15). The transition roller (15) and a support (13) thereof are made into an integrated unit, and the integrated unit is in cooperated connection with a track in the sealing box. The invention has advantages that a transmission system is arranged in a ground pit, thereby providing full operation space for replacing the transition roller; the transition roller is made into modularized integrated unit, and the integrated unit can be drawn out for on-line replacing, thereby shortening roller-changing time and saving production cost.

Owner:CHINA TRIUMPH INT ENG +3

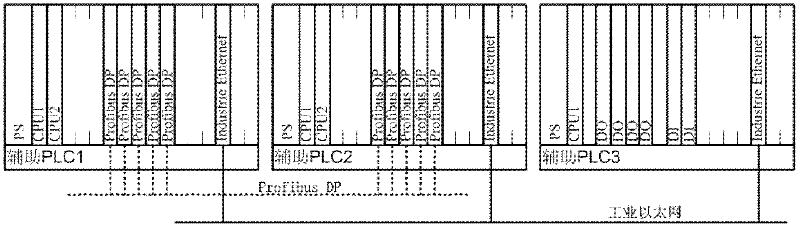

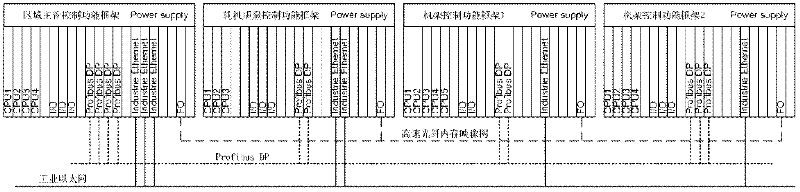

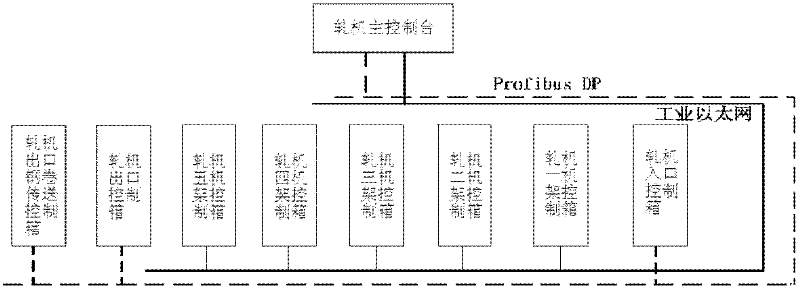

Basic automation control system for tandem cold rolling unit with five frames

InactiveCN102553937AImplement functional requirementsRealize automatic roll change functionRoll mill control devicesMetal rolling arrangementsLoop controlPerformance computing

The invention provides a basic automation control system for a tandem cold rolling unit with five frames, which comprises a PLC (programmable logic controller ) cluster, an HPC (high performance computing ) controller cluster, a field rolling mill control console, a real-time data acquisition system, a developing and debugging system and a system communication network. By the basic automation control system, automatic roll changing can be realized, roll changing time is shortened, production and maintenance can be carried out easily, and building investment and maintenance cost are reduced greatly. Since a high-speed closed-loop control function is realized, continuously high-speed production on sites is guaranteed. Since a high-speed data acquisition function is realized, the basic automation control system is capable of running safely and efficiently and meeting the requirements to millisecond-level monitoring data during fault analysis of the high-speed closed-loop control system of the tandem cold rolling unit. Since functional units are debugged and controlled to run successfully, structural uniformity of the basic automation control system after modification of programs is guaranteed. The high-speed optical fiber memory map net serves as the communication network, high-speed data exchange is realized by data caching among functional units of the HPC controller cluster, and accordingly high-speed data acquisition of the real-time data acquisition system is realized.

Owner:ANGANG STEEL CO LTD

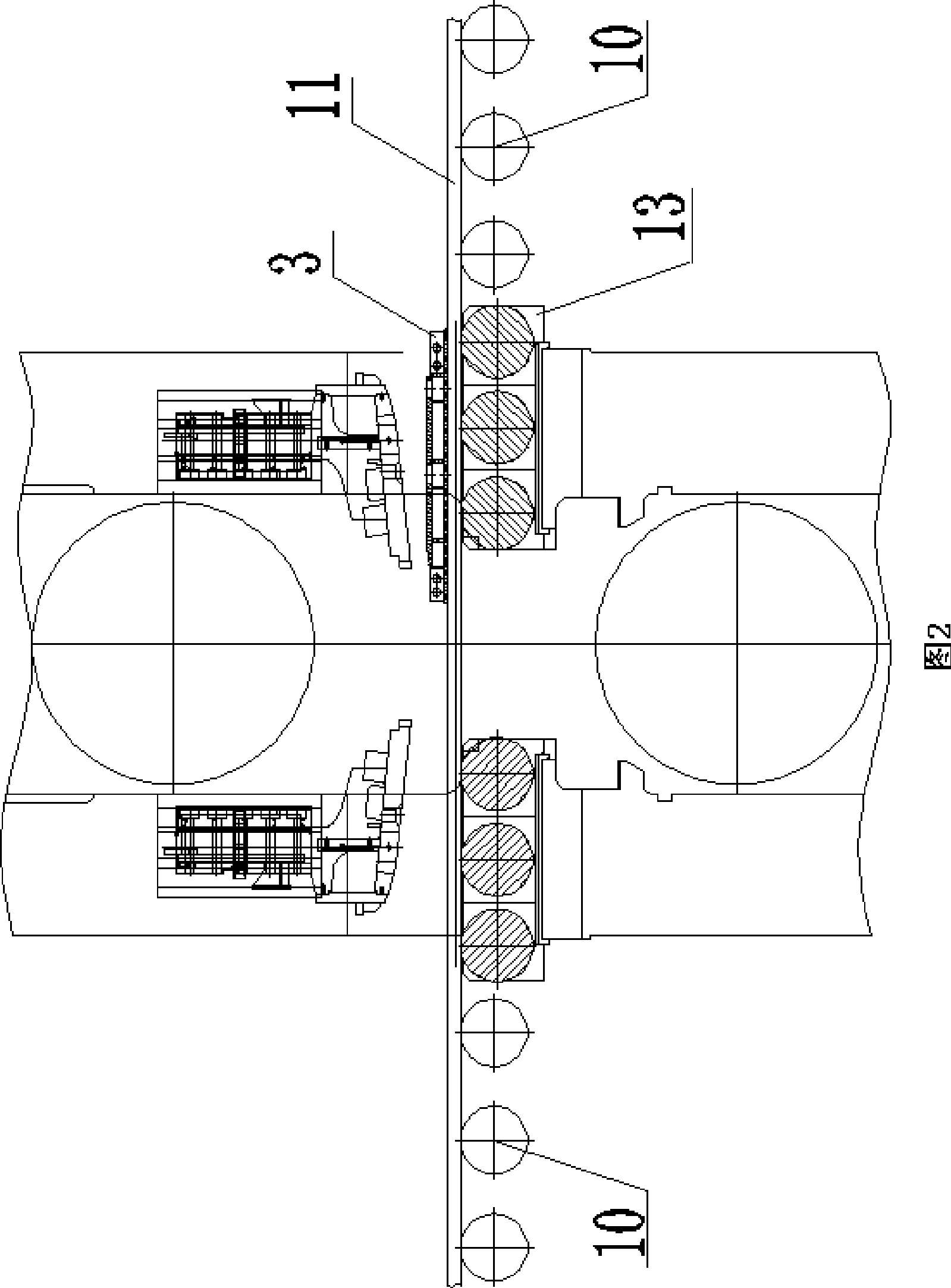

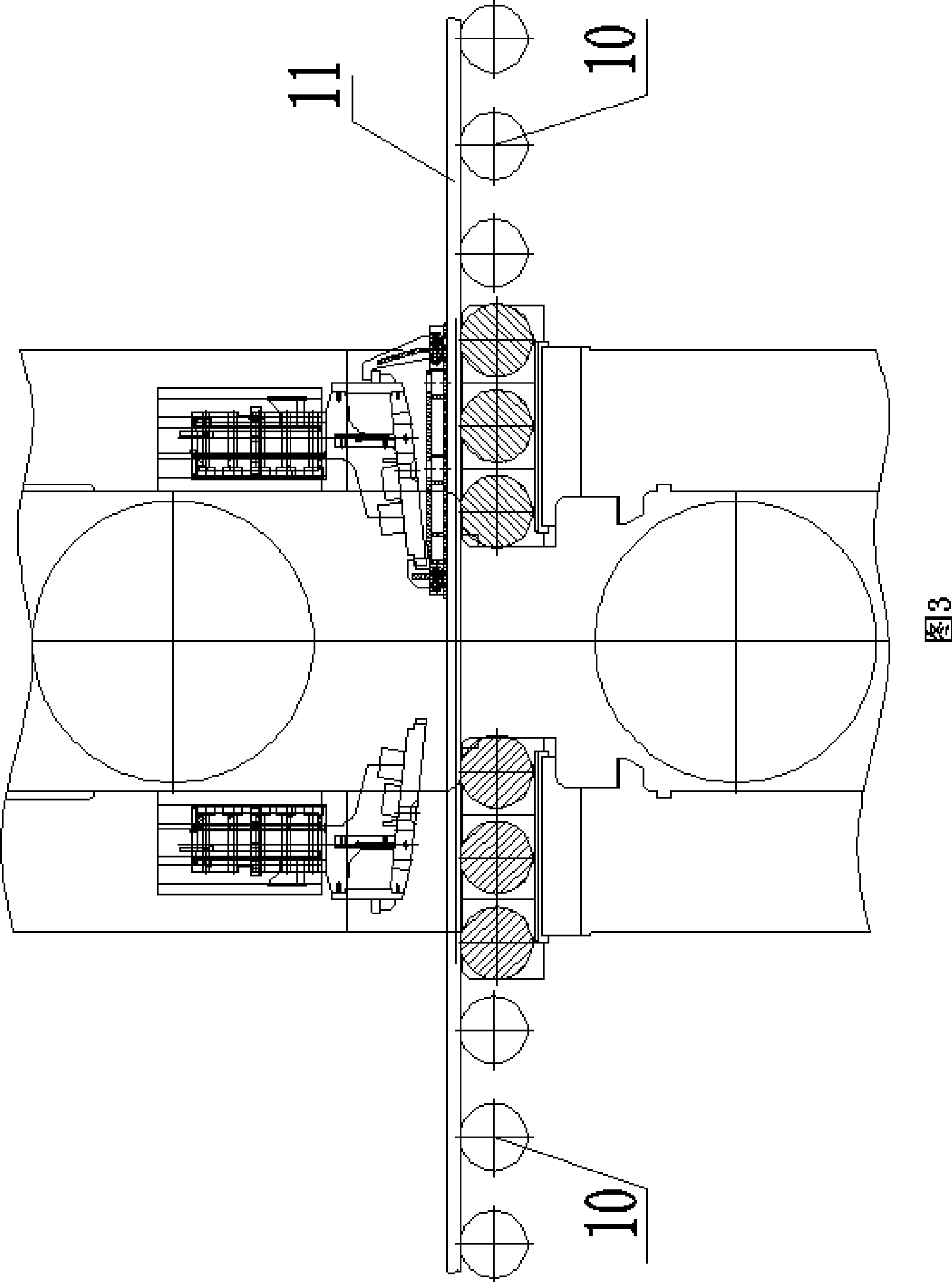

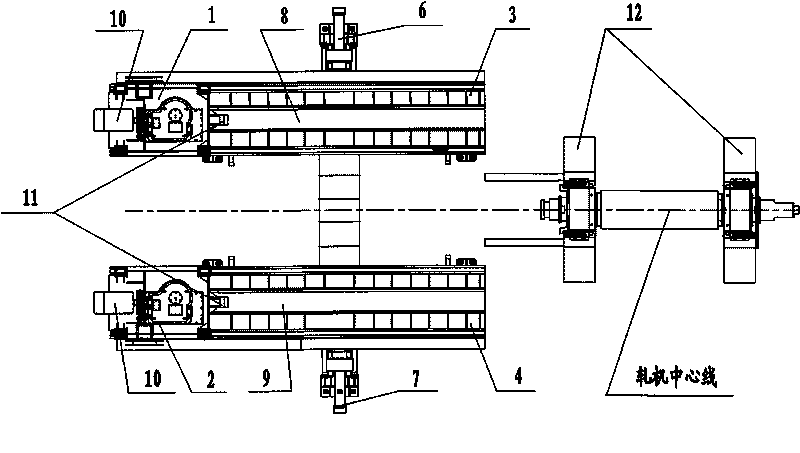

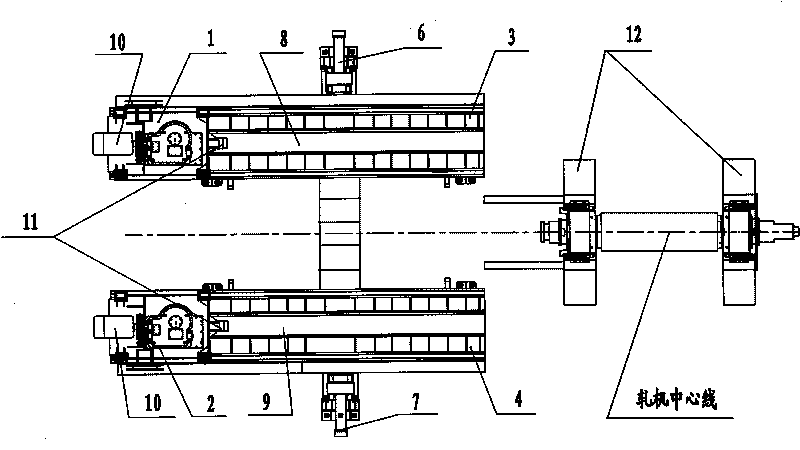

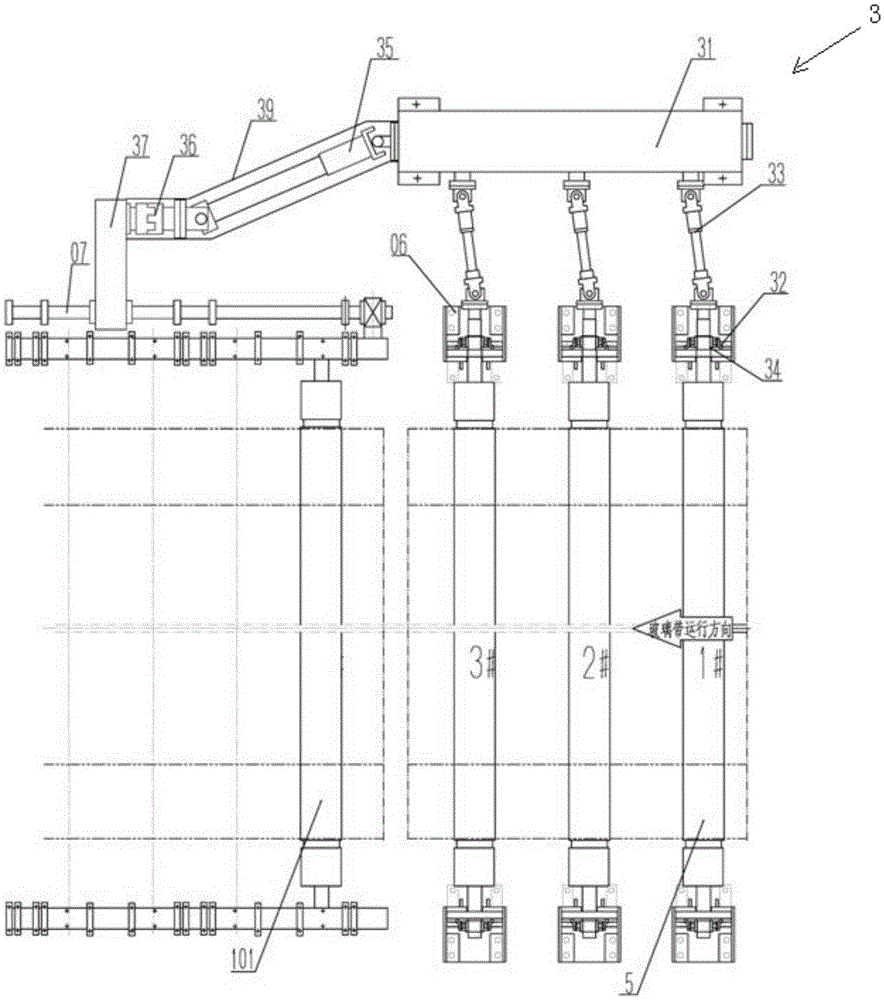

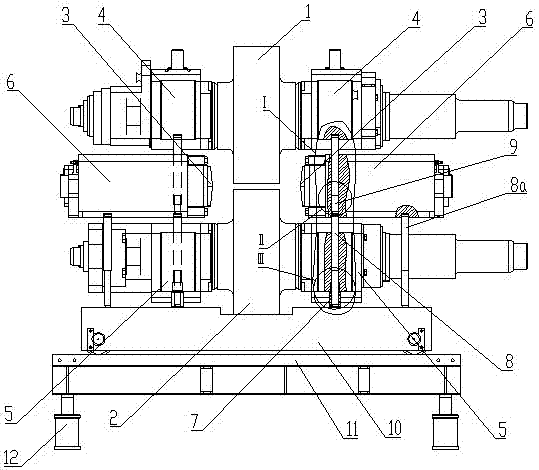

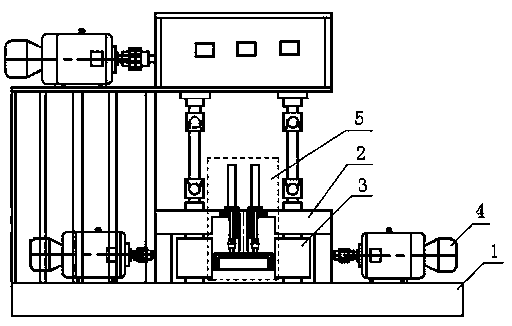

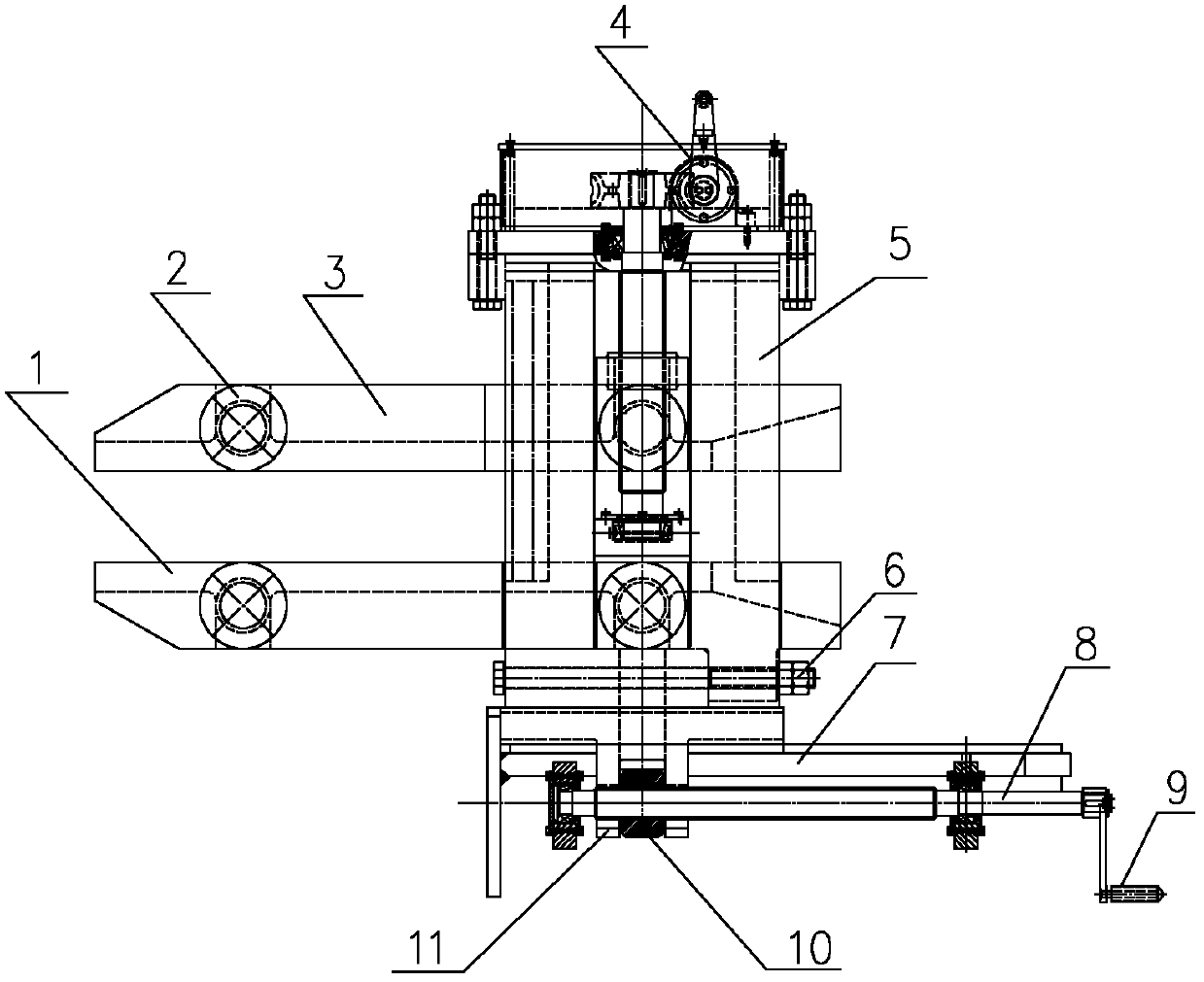

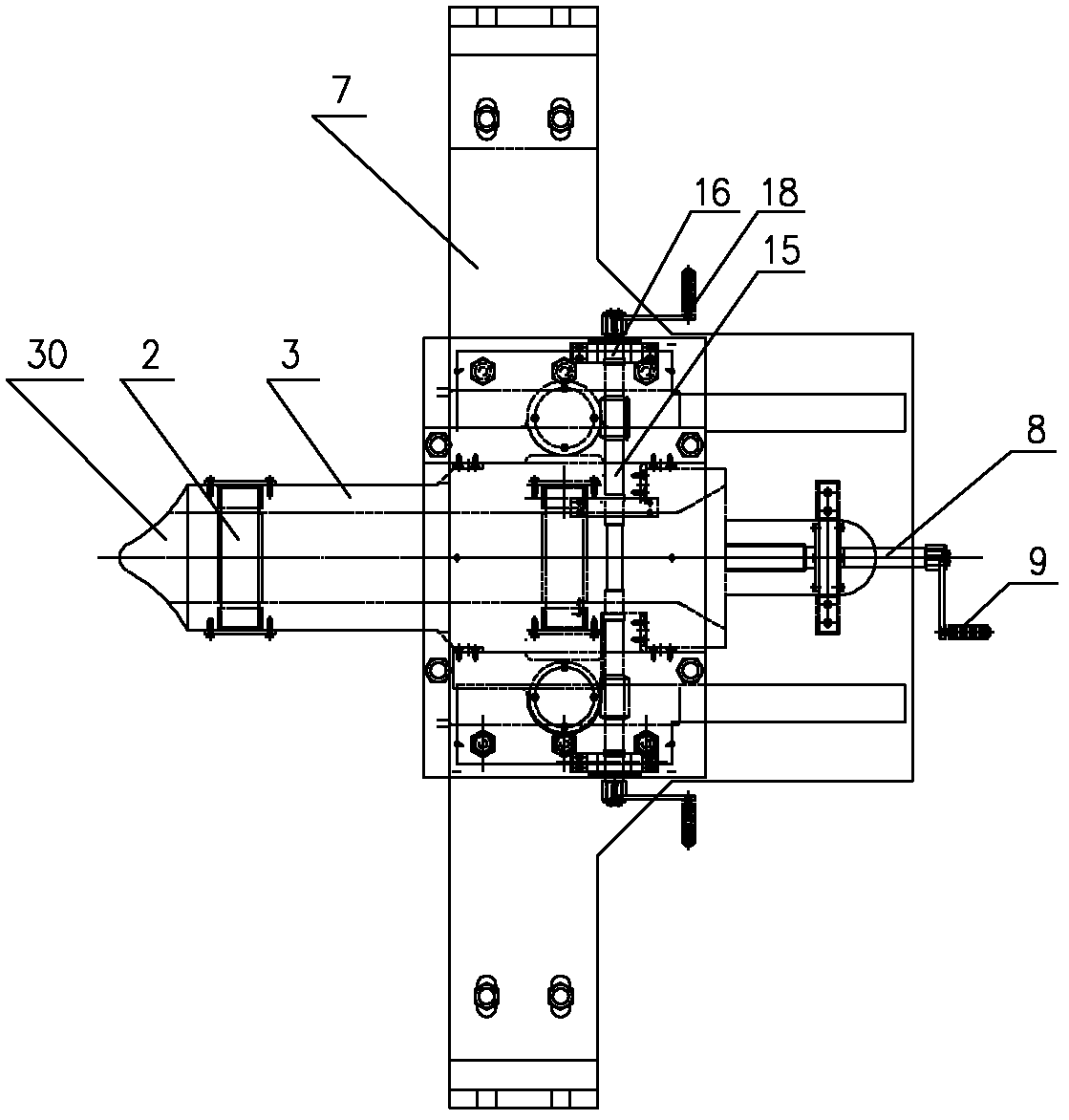

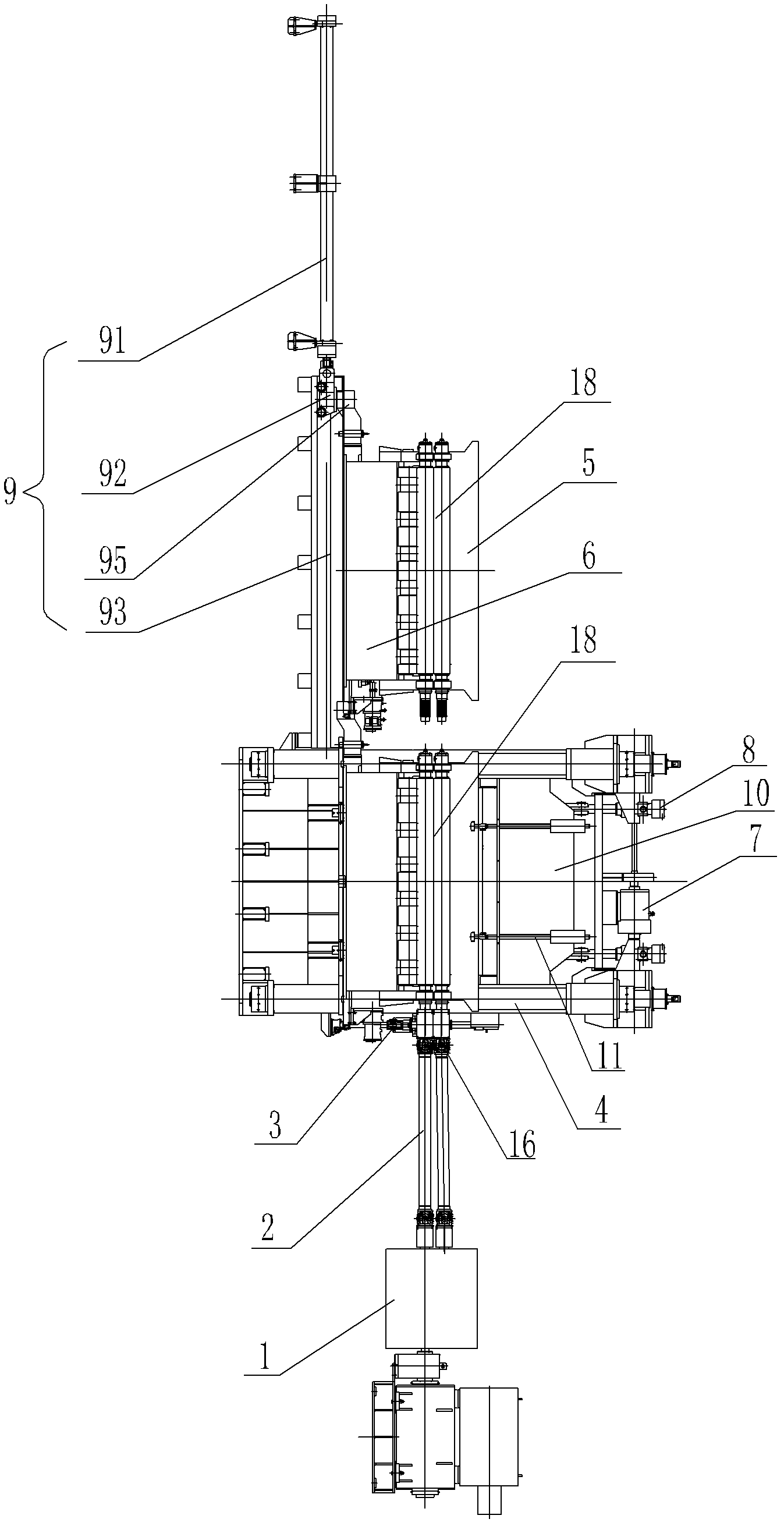

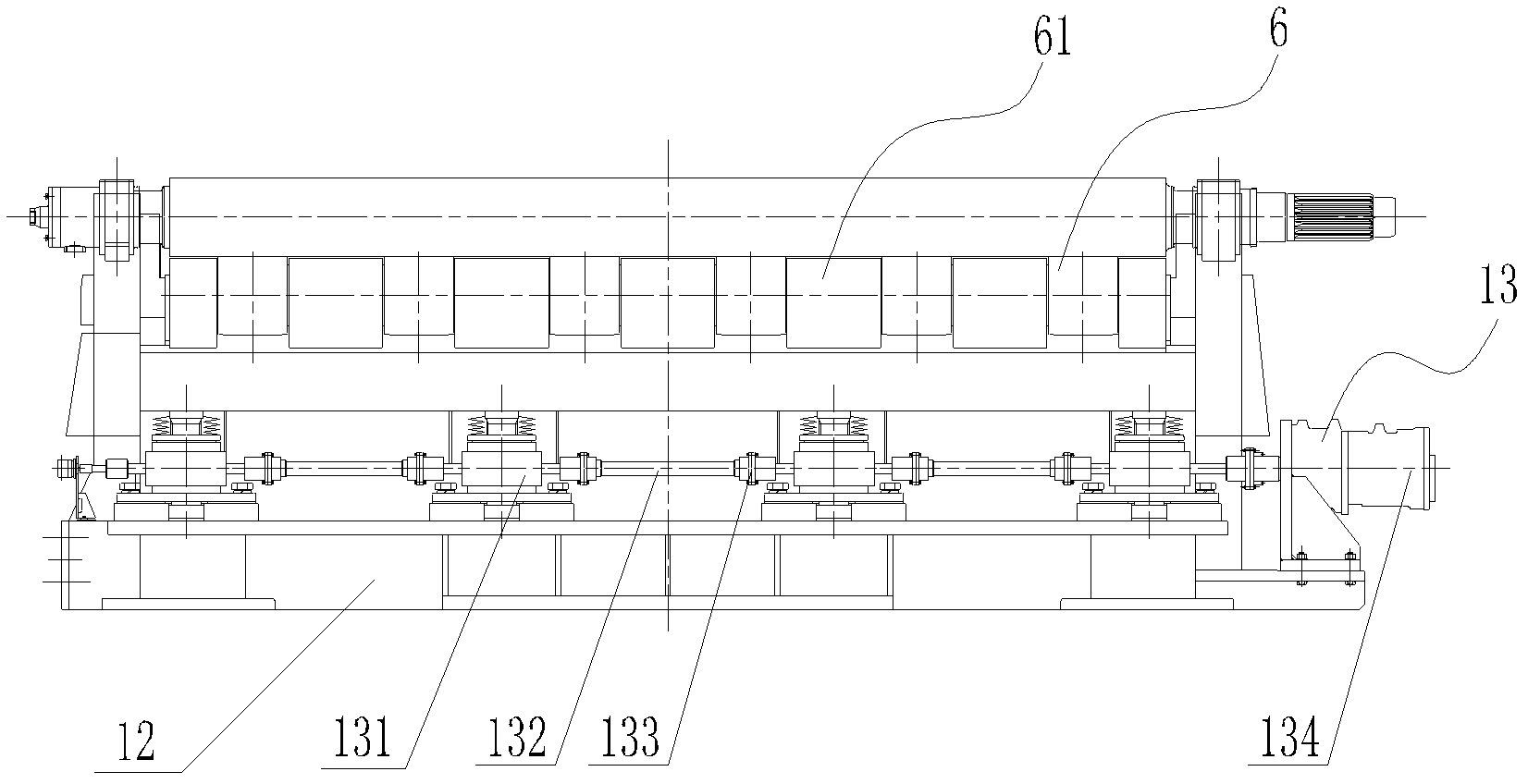

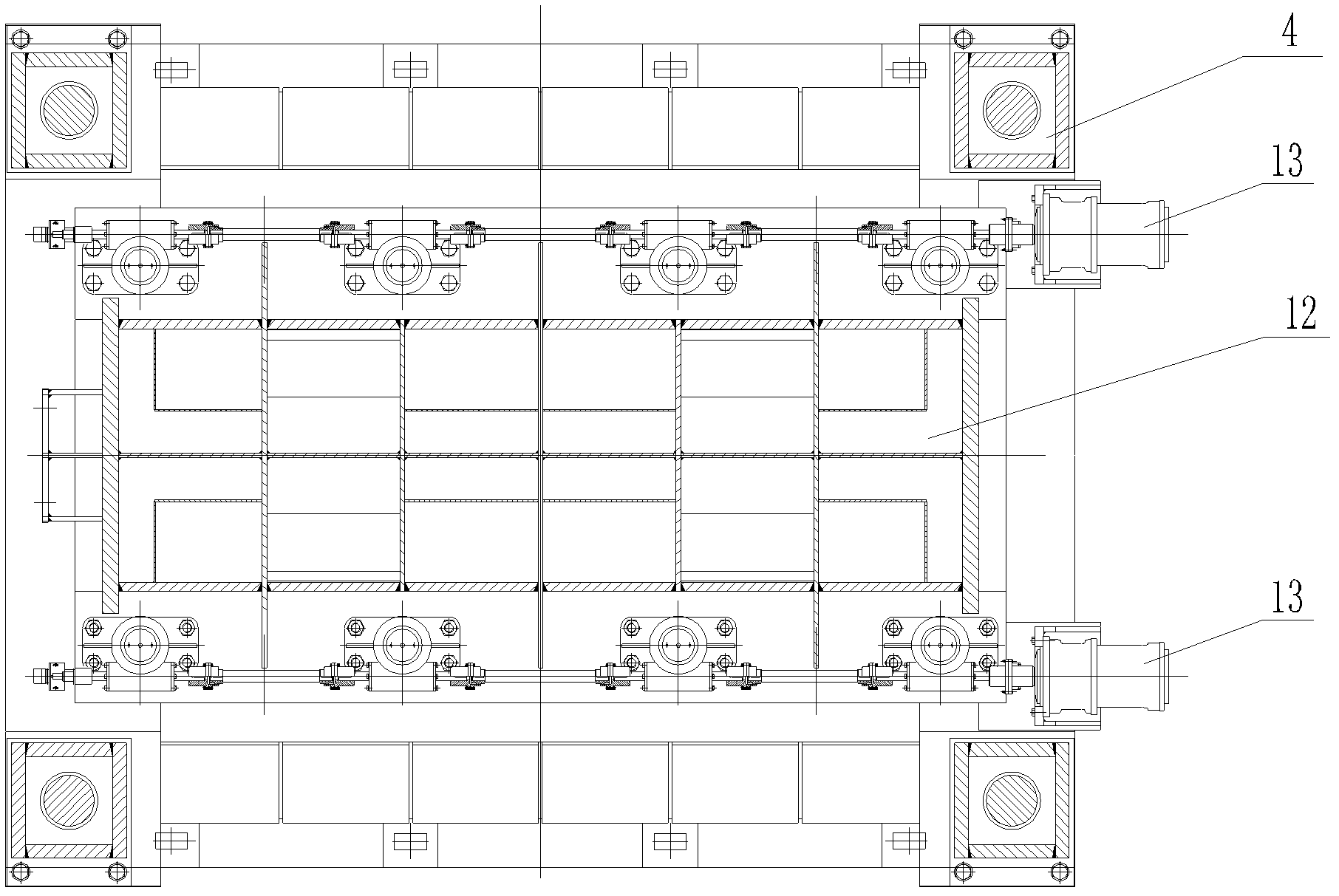

Working roll replacing device and working roll replacing method for heavy and medium plate mill

InactiveCN101733284AReduced roll change timeIncrease production capacityMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderWork roll

The invention discloses a working roll replacing device for a heavy and medium plate mill. The device comprises two roll replacing trollies, a transverse guide rail arranged outside one side of a mill stander vertically to a central line of the mill, a pair of hydraulic cylinders arranged at the two ends of the transverse guide rail and two cross travelling trollies which can move along the transverse guide rail and are connected to the pair of hydraulic cylinders respectively, wherein the two cross travelling trollies are also provided with a longitudinal guide rail in parallel with the central line of the mill respectively; and the two roll replacing trollies are arranged on the pair of cross travelling trollies respectively and can move along the longitudinal guide rail. The invention also discloses a working roll replacing method for the heavy and medium plate mill, which is executed in the working roll replacing device for the heaving and medium plate mill. The technical scheme of the working roll replacing device and the working roll replacing method for the heavy and medium plate mill of the invention can shorten the roll replacing time of a working roll and achieve high automatic degree so as to fulfill the aim of indirectly improving the production capacity of a unit.

Owner:SHANGHAI HEAVY MACHINERY PLANT

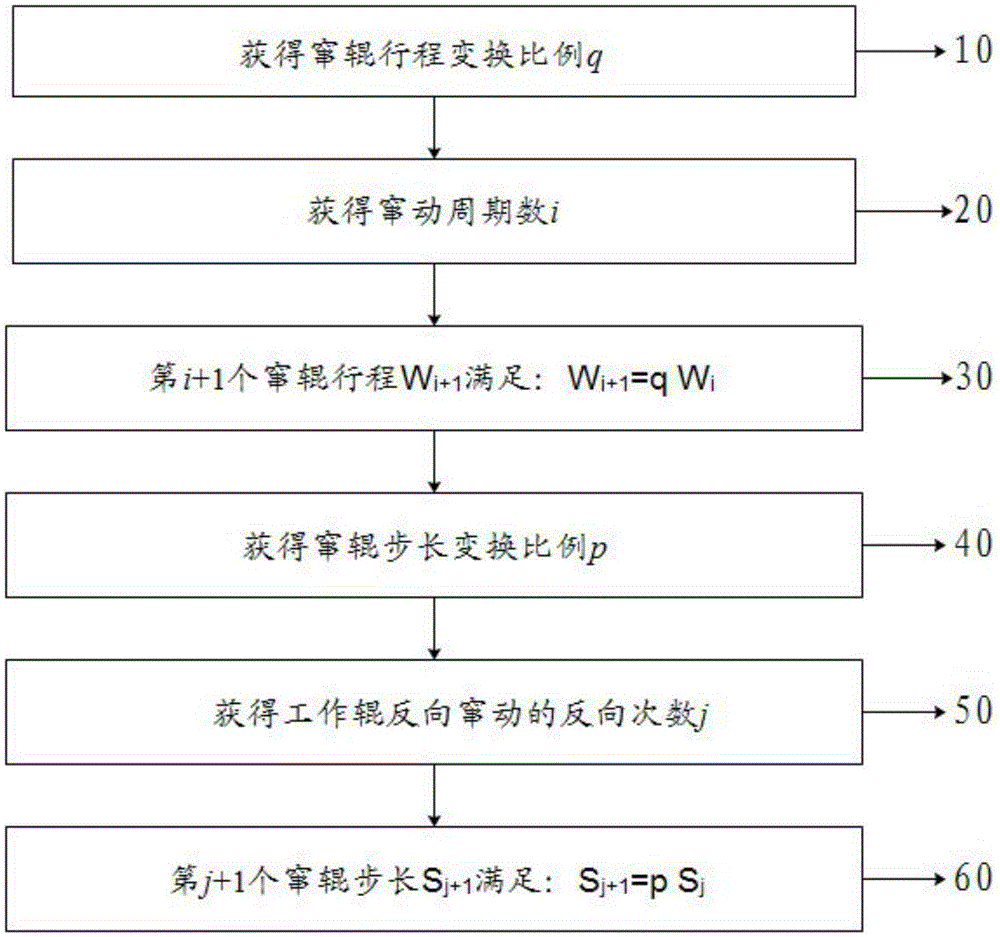

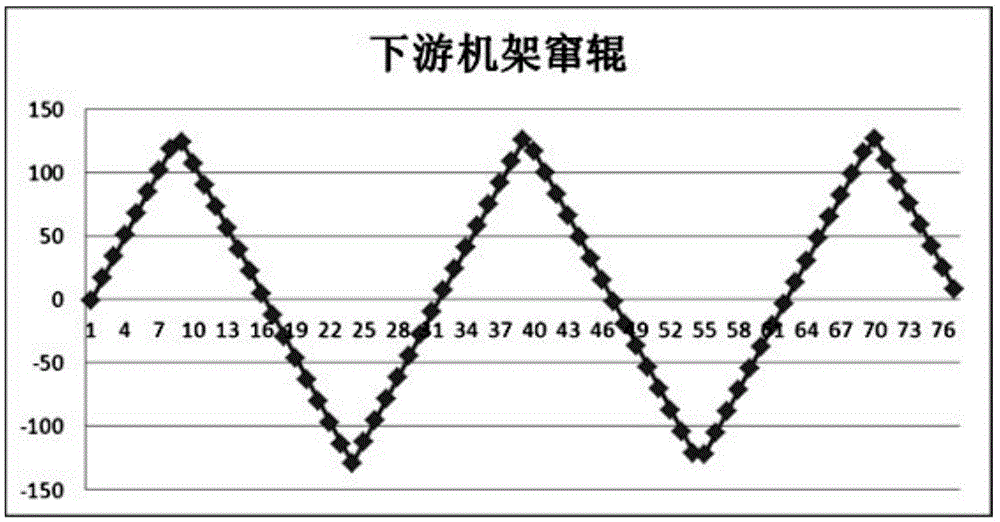

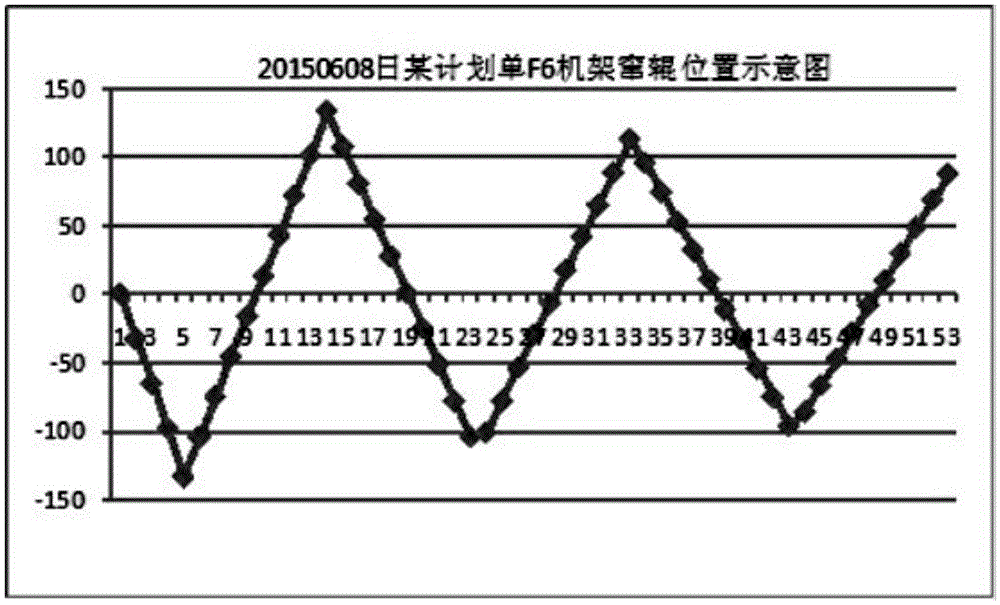

Variable-stroke and variable-step-size roll motion alternating method

InactiveCN105598182AAvoid long termAvoid contact in the same areaProfile control deviceStrip steelComputer science

The invention provides a variable-stroke and variable-step-size roll motion alternating method. The method comprises the steps that the roll motion alternating stroke transformation proportion q is obtained; the alternating cycle number i is obtained; according to the alternating cycle number i and the roll motion alternating stroke transformation proportion q, the (i+1)th roll motion alternating stroke W(i+1) is obtained, wherein W(i+1) is equal to q*Wi, wherein Wi is the roll motion alternating stroke when the cycle number is i; the roll motion alternating step size transformation proportion p is obtained; the reverse alternating number j of a working roller is obtained; according to the reverse alternating number j and the roll motion alternating step size transformation proportion p, the (j+1)th roll motion alternating step size S(j+1) is obtained, wherein S(j+1) is equal to p*Sj, and Sj is the roll motion alternating step size when the reverse alternating number is j. According to the variable-stroke and variable-step-size roll motion alternating method, the abrasion uniformity of a roller can be significantly improved, the strip steel shape quality is improved, and the planned order length is increased.

Owner:BEIJING SHOUGANG CO LTD

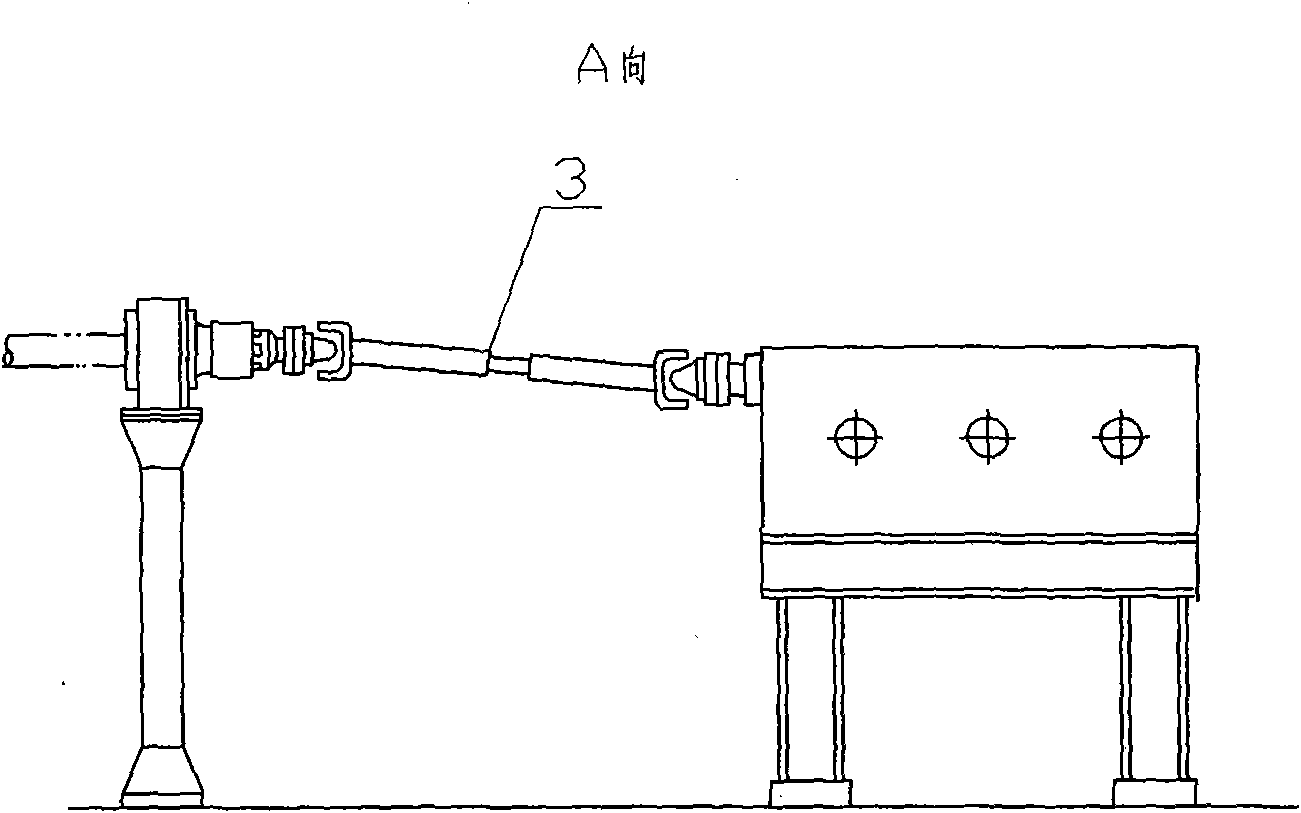

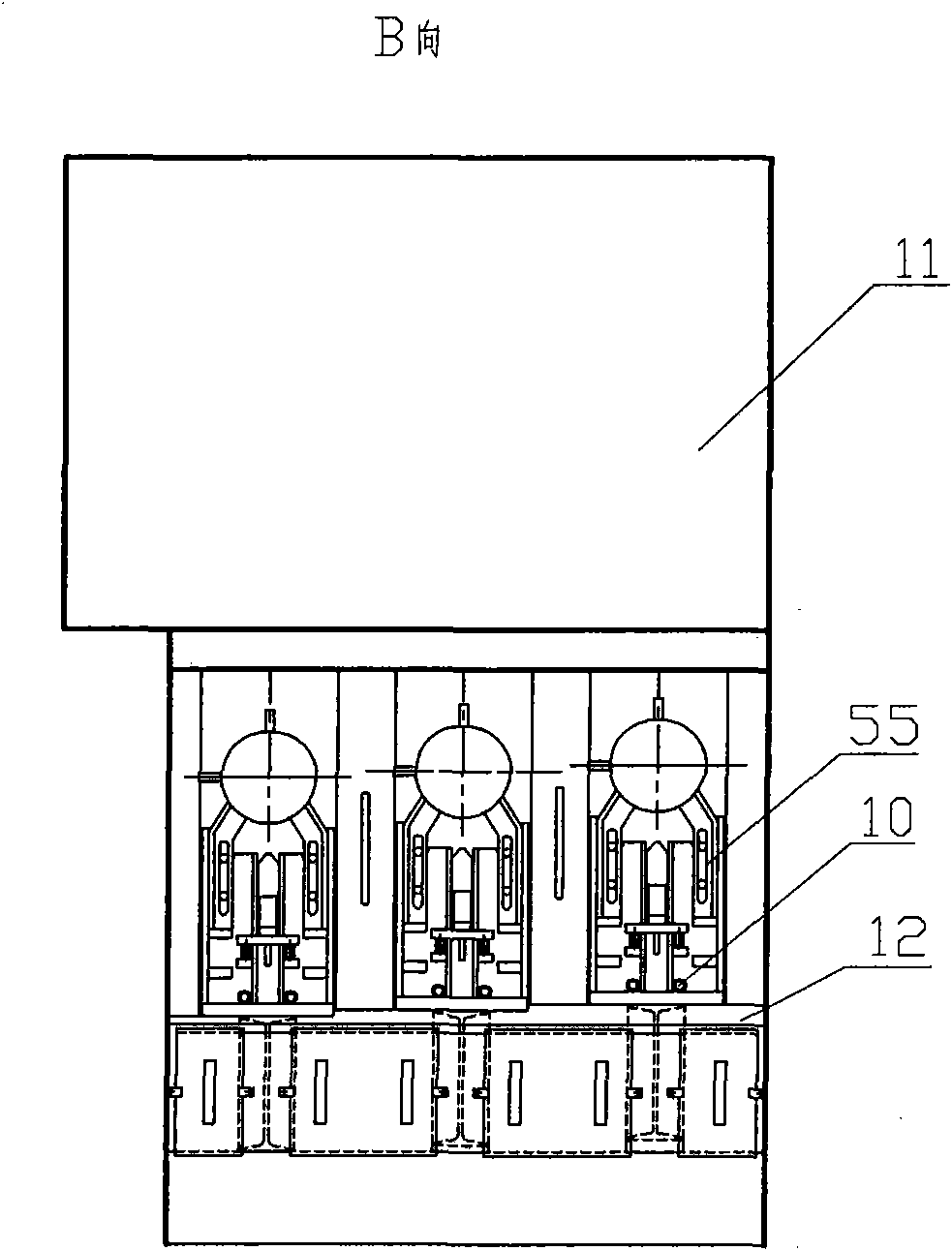

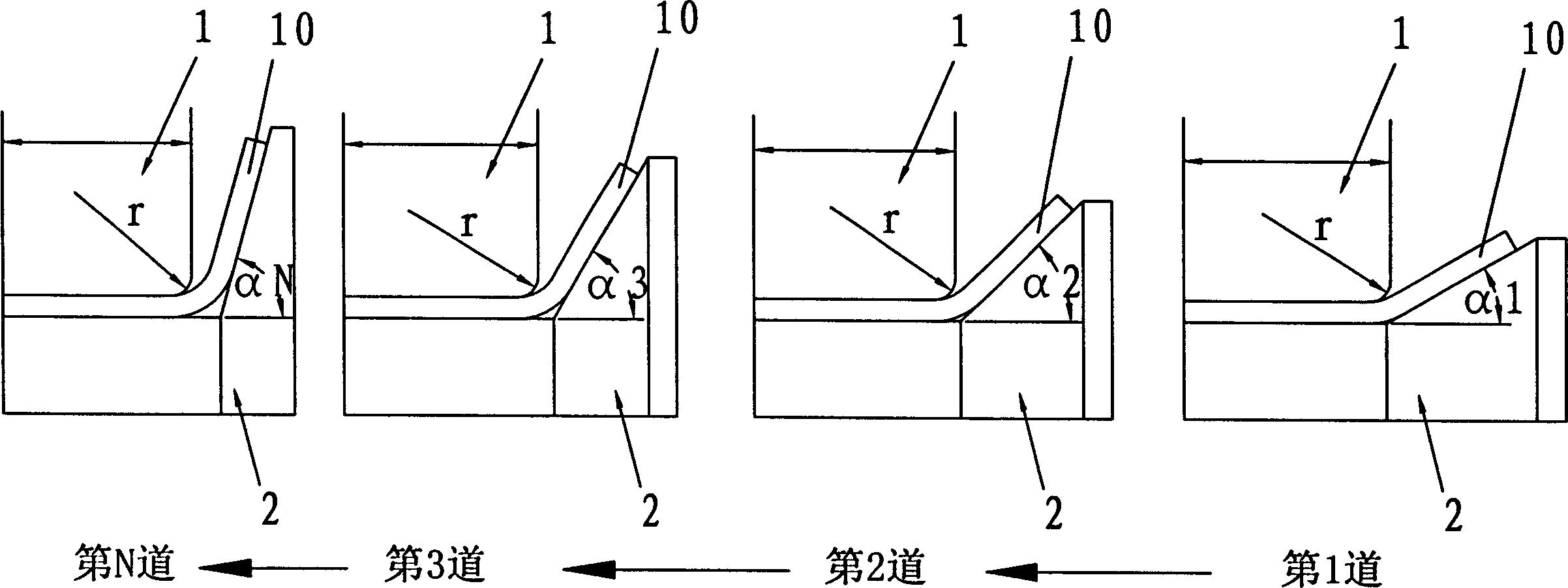

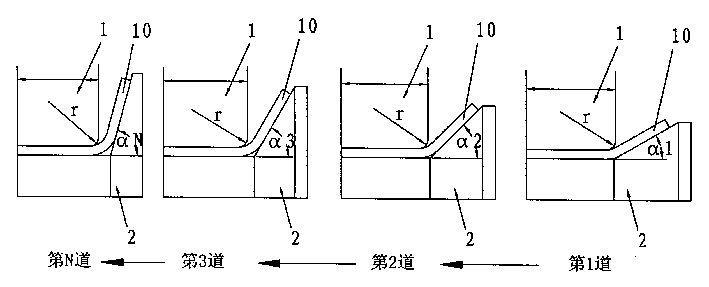

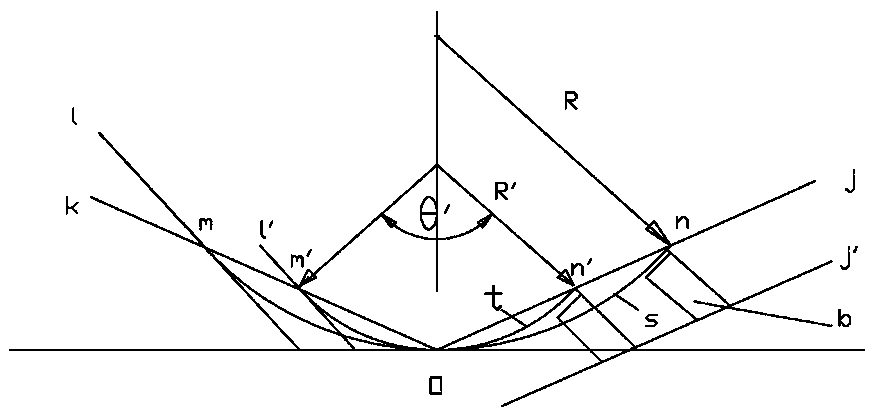

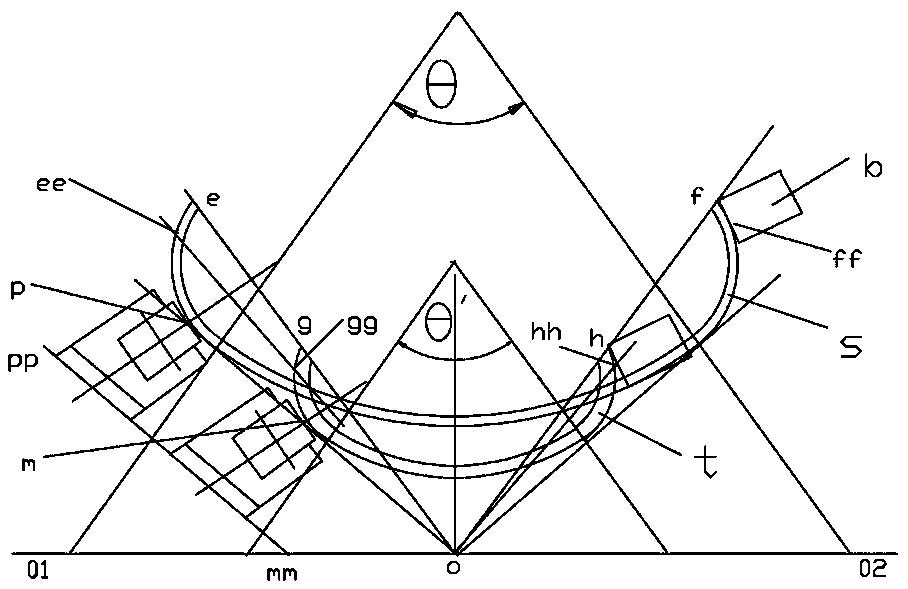

Fixed roll radian-change bending-point position cold-bending shaping process

InactiveCN1528538AReduce investmentSolve the problem of micro cracks in the cornerEngineeringThick wall

The invention is a cold-bending molding technique of fixing roller arc and changing bend-point position, according to the minimum wall thickness in set product outline, determining angular bending arc of the roller, making all the top rollers in the curves adopt the bending arc, determining the bending molding angle of the raw material plate according to inner circular arcs of the finished products of different wall thicknesses, making the unbended raw material of each angle remained on the bottom pate, making each bending point gradually move toward the bottom plate during roll bending, and finally completing the whole bending process. The molding is natural and smooth, able to effectively resolve the angular microcrack. It saves roller-changing time.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

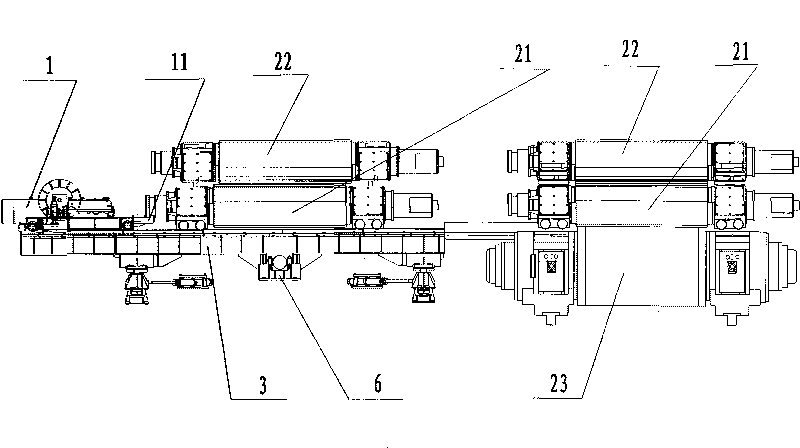

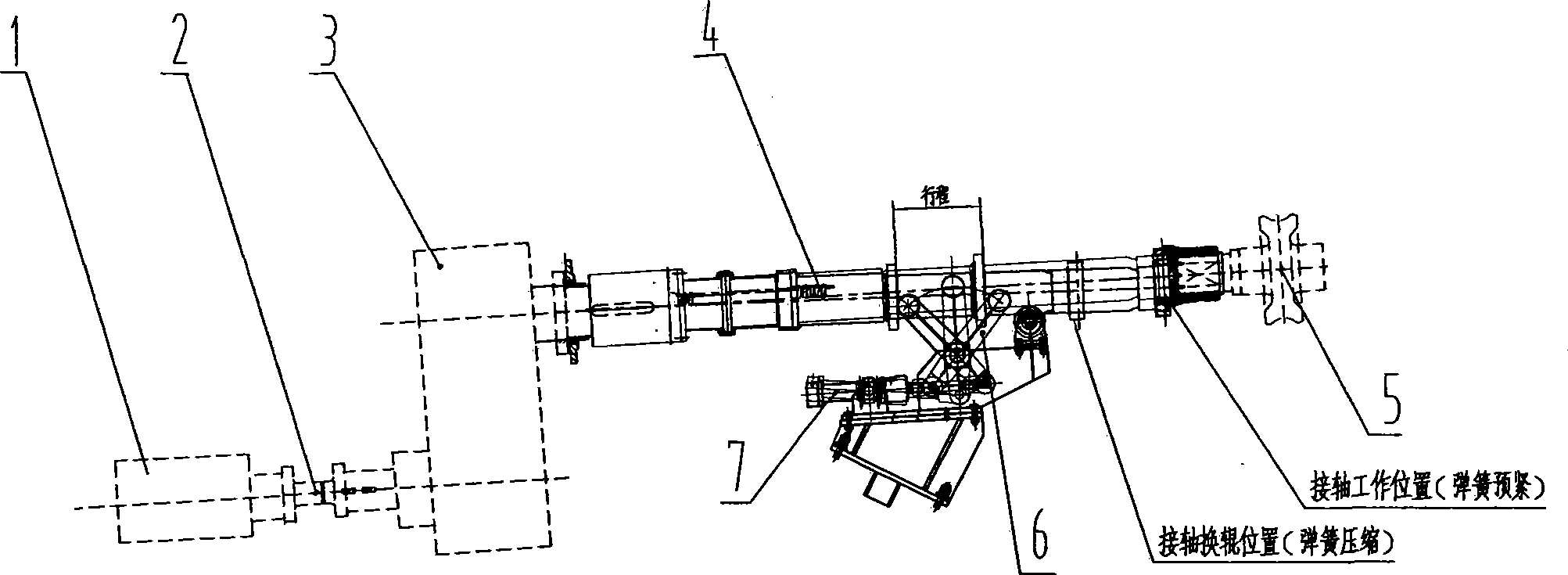

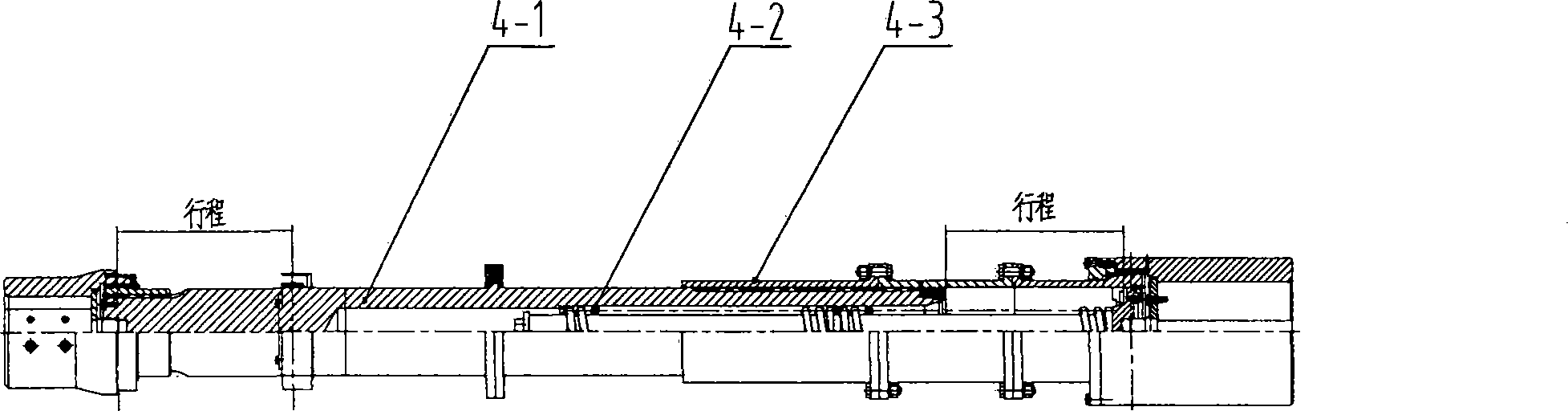

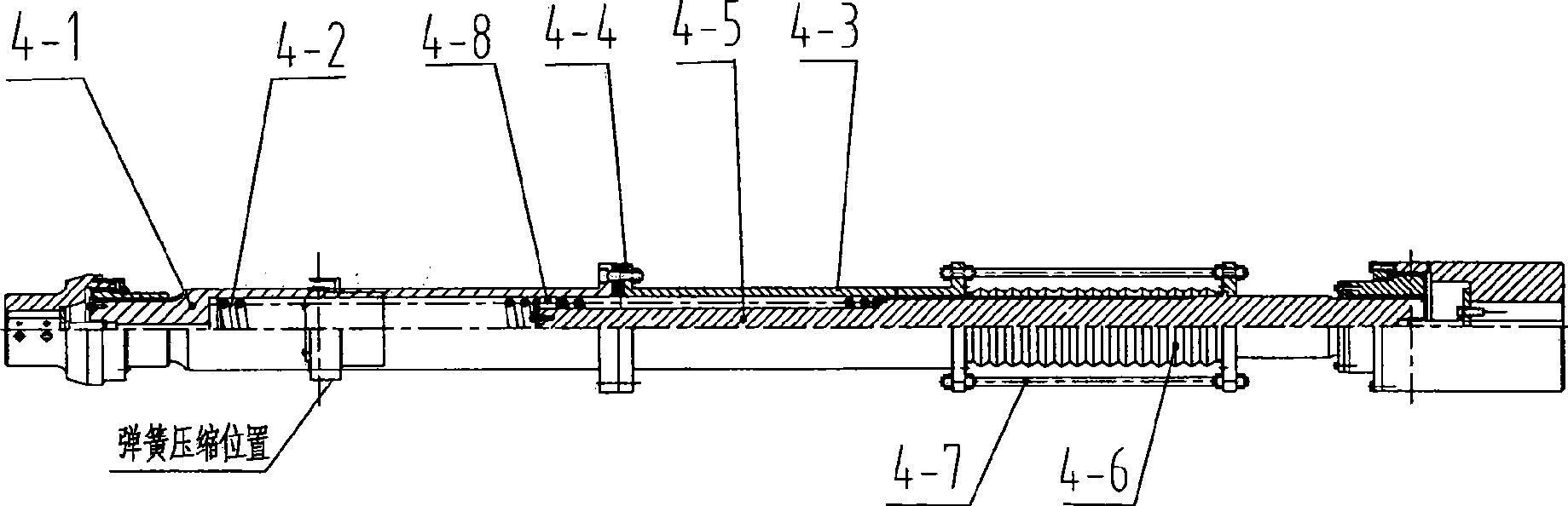

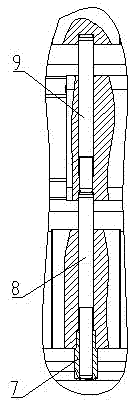

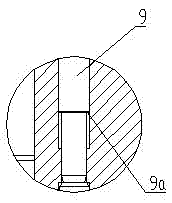

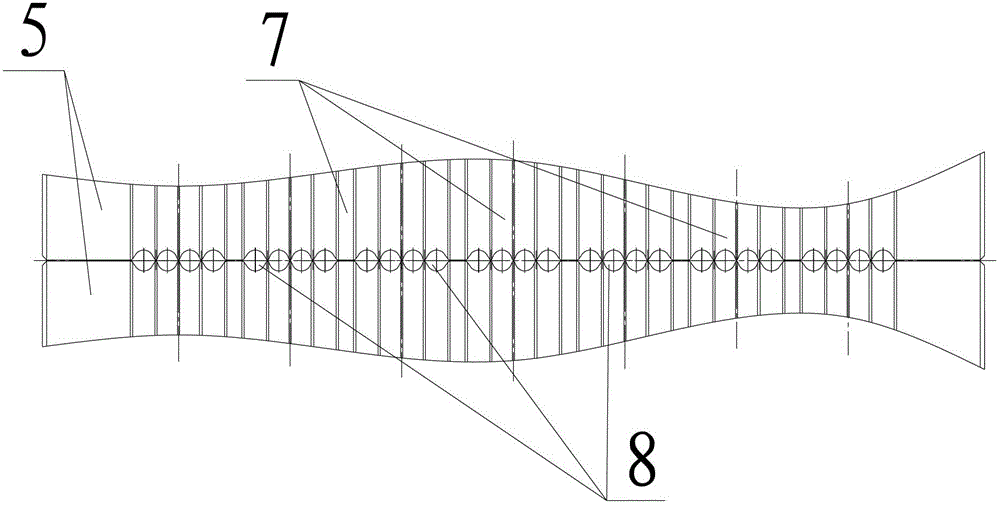

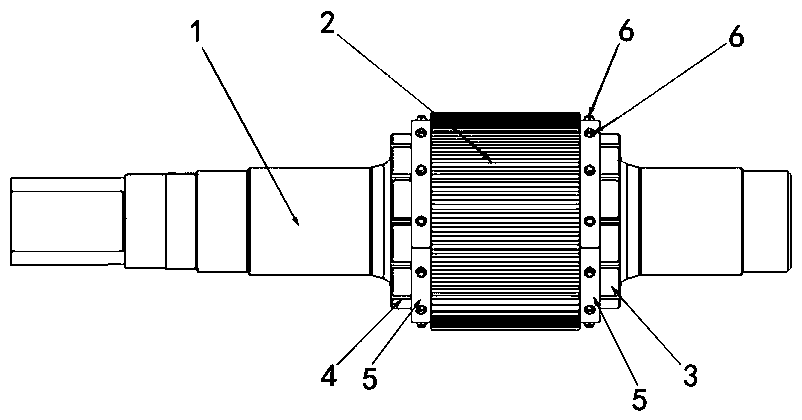

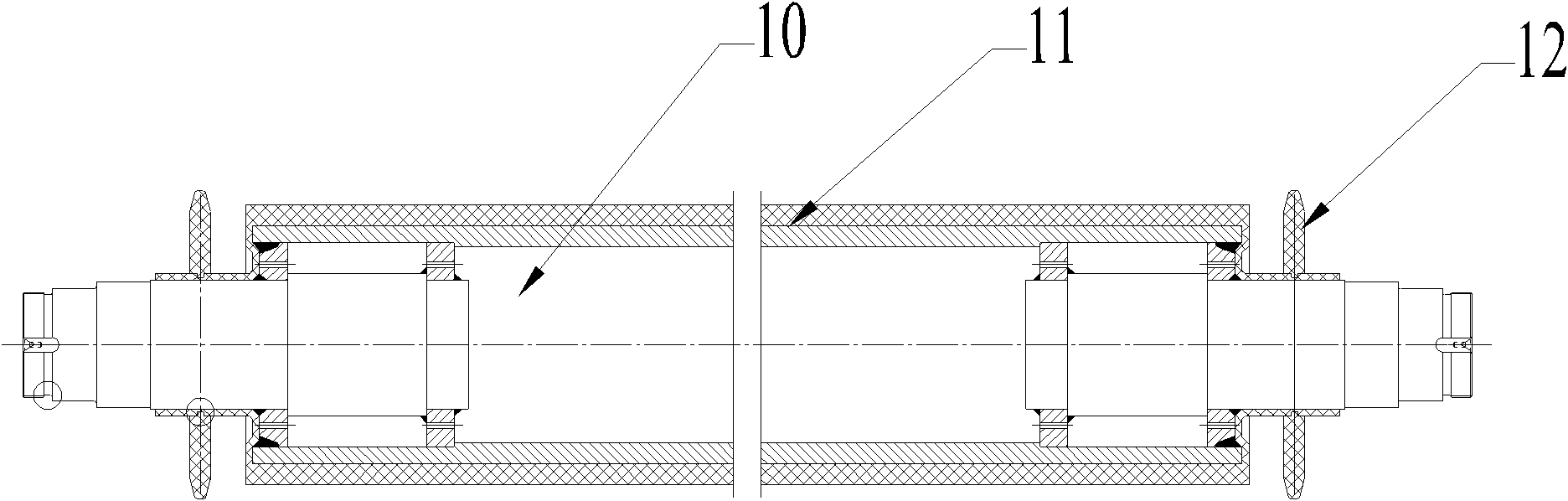

Main transmission spindle for three-roller tandem rolling tube machine

ActiveCN101439355AReduce wall thicknessIncrease stiffnessRolling mill drivesMetal rolling arrangementsEngineeringRolling mill

A main transmission connecting shaft for a three-roller continuous tube rolling mill relates to a production device of a seamless steel pipe. The invention mainly solves the problem in the prior art that roll change time of the connecting shaft is longer and unstable production factors exist so that the production rhythm of the device is affected. A movable spline shaft and an internal spline housing are connected into a sliding component by a flange; a fixed spline shaft is arranged in the sliding component; a spring is mounted between the fixed spline shaft and the sliding component; and a supporting stud is additionally arranged in the working position of the connecting shaft. The main transmission connecting shaft improves the work stability of the connecting shaft in the high-speed state, shortens the roll change time of the continuous tube rolling mill, ensures the production rhythm of the device and improves the output.

Owner:TAIYUAN HEAVY IND

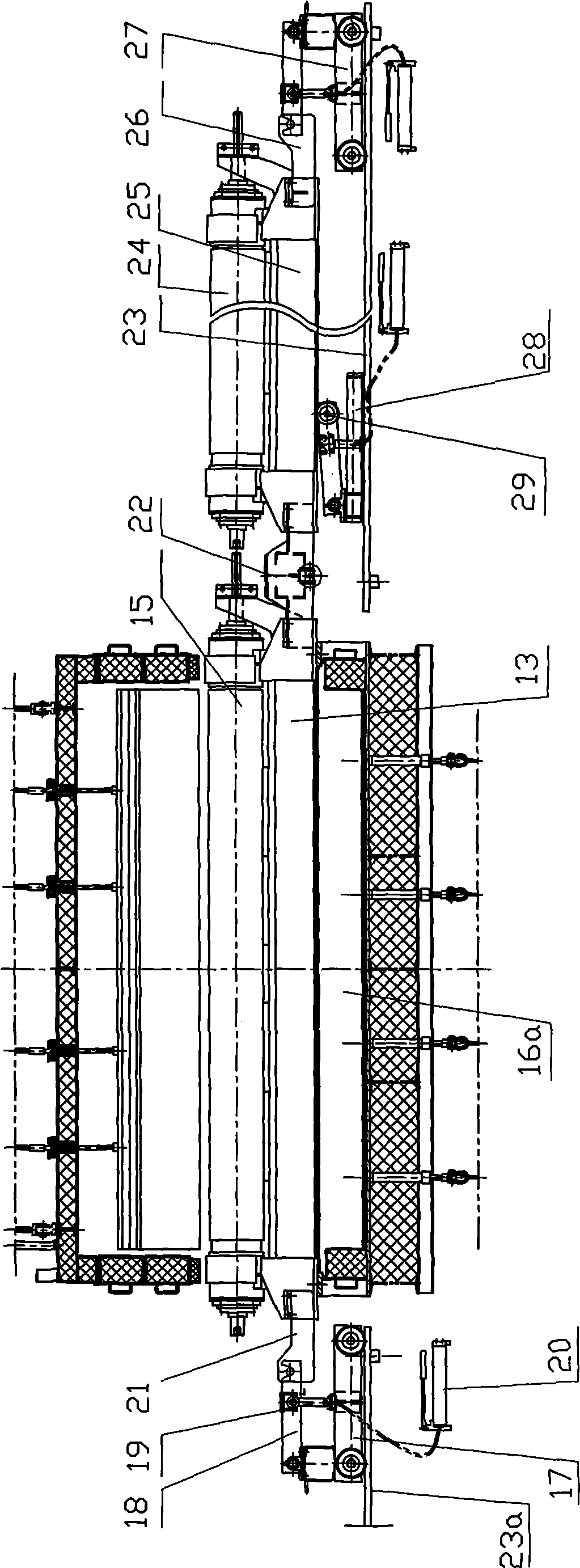

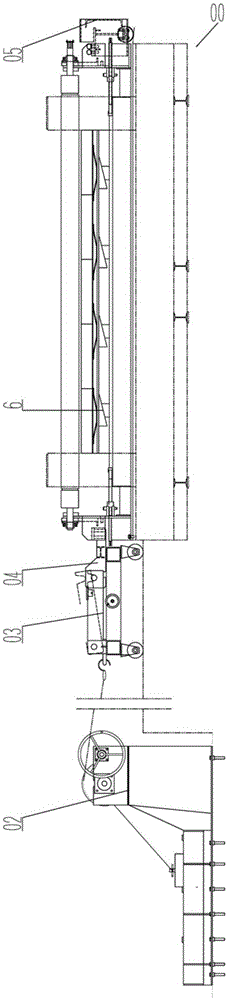

On-line roller changing device for float glass transitional roller table and roller changing method

ActiveCN105293888AEasy to replaceIncrease productionGlass transportation apparatusGlass productionSlagPulp and paper industry

The invention provides an on-line roller changing device for a float glass transitional roller table and a roller changing method. The device comprises a winch, a pull cart, a connecting rack and a roller discharging cart. According to the on-line roller changing device for the float glass transitional roller table and the roller changing method, tin rubbing devices, supports and rollers of the transitional roller table are connected into a whole through U-shaped assemblies. According to the on-line roller changing device, by adjusting the pre-changing roller positions, the tin rubbing devices, the supports and the rollers are integrally pulled out, hence, on-line roller changing is achieved, operation is easy and convenient, and roller changing time is saved; a roughing slag box is arranged to be in an open type, and changing of the rollers is facilitated. The on-line roller changing device for the float glass transitional roller table and the roller changing method are suitable for the float glass production process, the yield of glass products can be increased, the product quality of the glass products can be improved, and implementation and popularization are easy.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

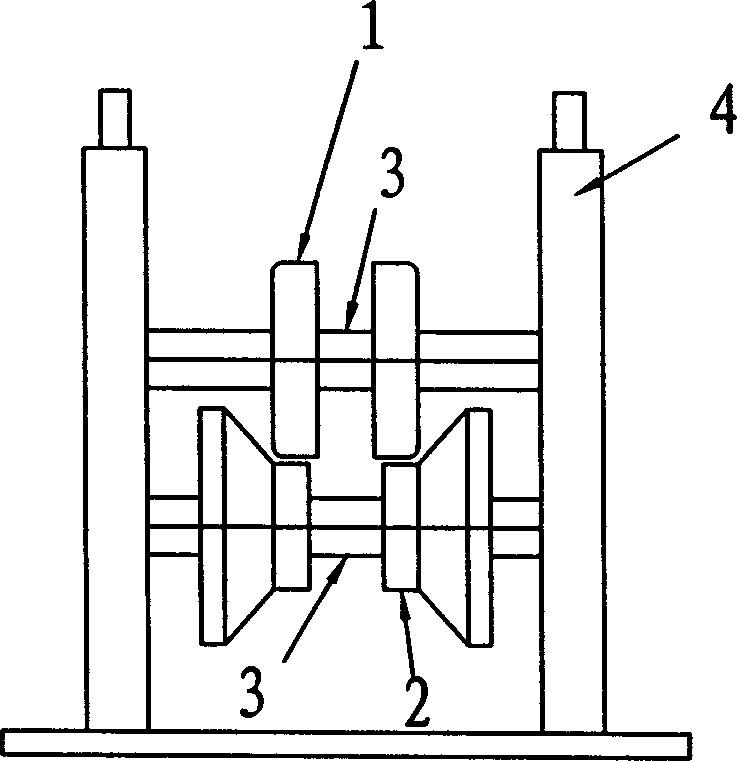

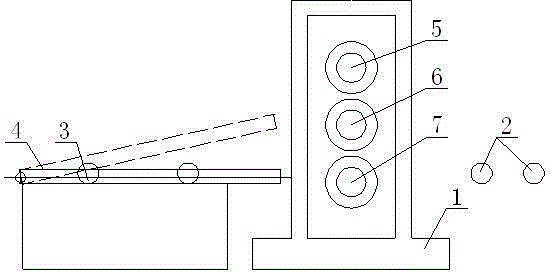

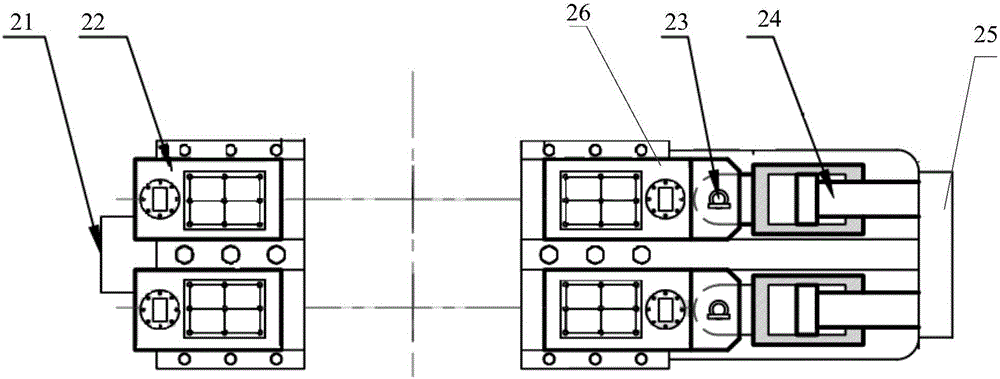

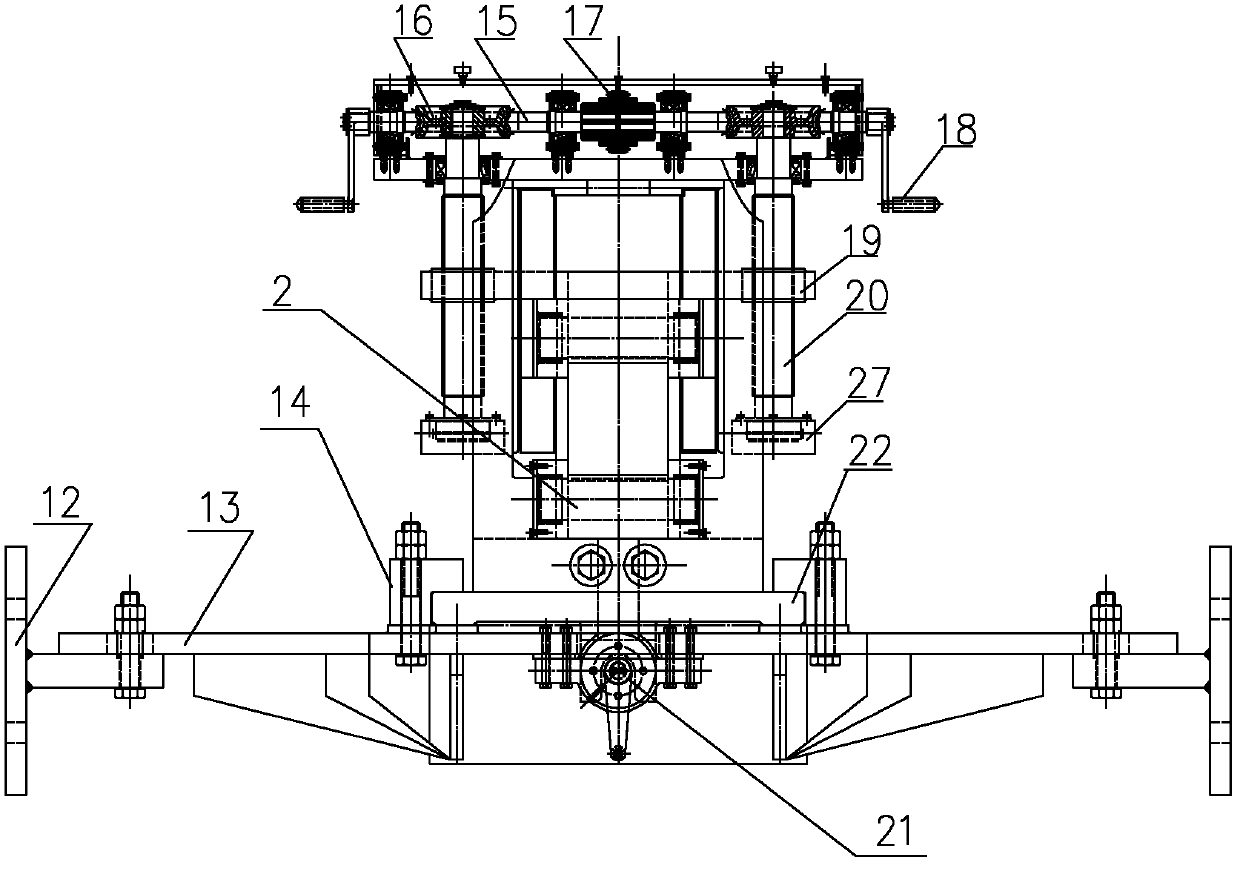

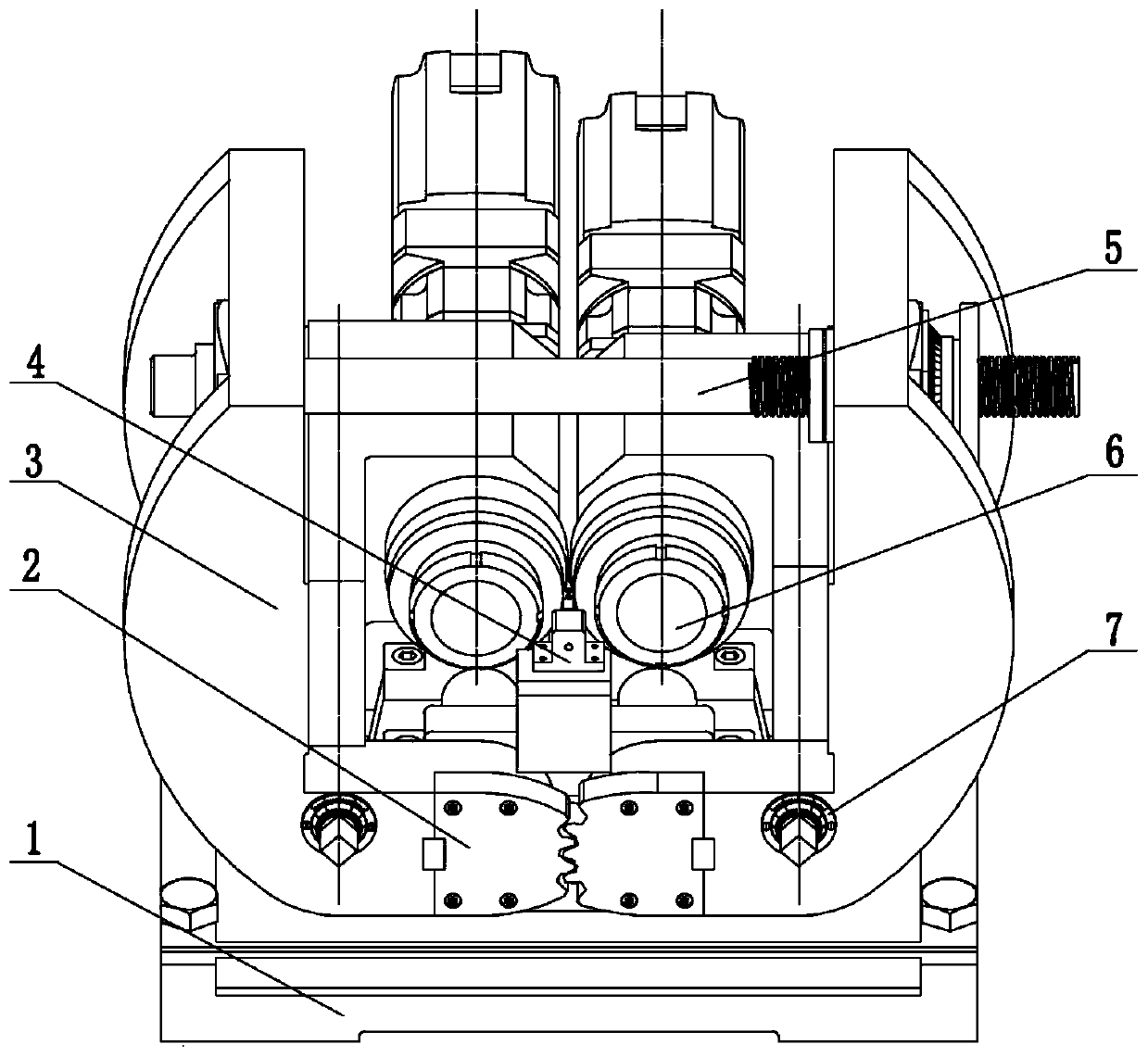

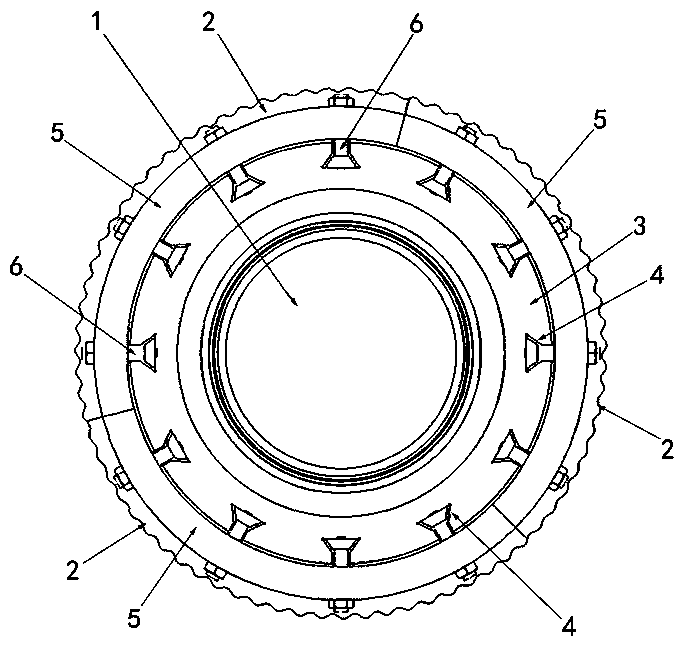

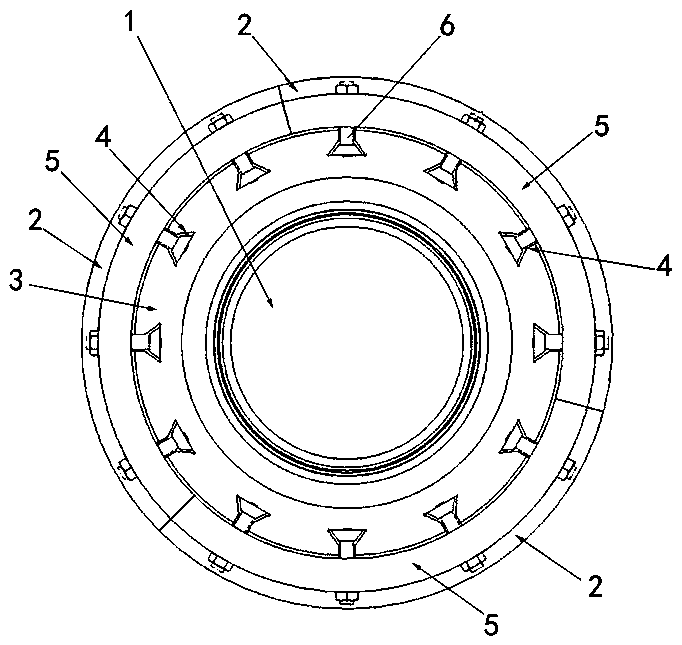

Roller set for universal mill

ActiveCN102179408AEasy to take outEasy loadingMetal rolling stand detailsRollsEngineeringExchange time

The invention discloses a roller set for a universal mill, and the roller set comprises an upper horizontal roller, a lower horizontal roller, a pair of upright rollers and a quick roller-exchanging device, wherein the upper horizontal roller is provided with two upper bearing bases; the lower horizontal roller is provided with two lower bearing bases; each upright roller is provided with a roller bearing base; and the quick roller-exchanging device comprises a lower horizontal roller positioning rod, an upright roller positioning rod, an upper horizontal roller positioning rod and a lifting roller-exchanging trolley. When the roller is needed to be exchanged, the roller-exchanging trolley lifts and then drives all the positioning rods to stretch into countersinks which are correspondingly arranged on the bearing bases, thereby realizing the reliable support positioning, integrally forming the roller set, avoiding the relative movement among rollers and abrasion of the positioning rods when the roller set is quickly moved out or loaded, and being reliable in interlocking. When the roller set is needed to work, the roller-exchanging trolley descends so as to release all the supportpositioning relationships and then the roller set can start working quickly. The roller set for the universal mill has a simple and reasonable structure and can be used for efficiently increasing thereliability and maintainability of the roller set, reducing the difficulty of roller-exchanging operation, shortening the roller-exchanging time, and increasing the production efficiency.

Owner:CISDI ENG CO LTD

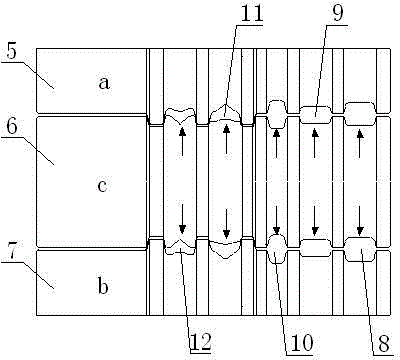

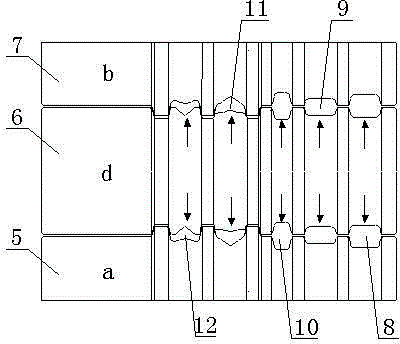

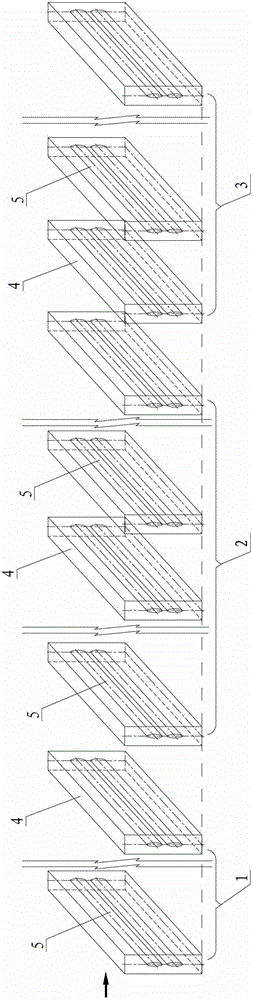

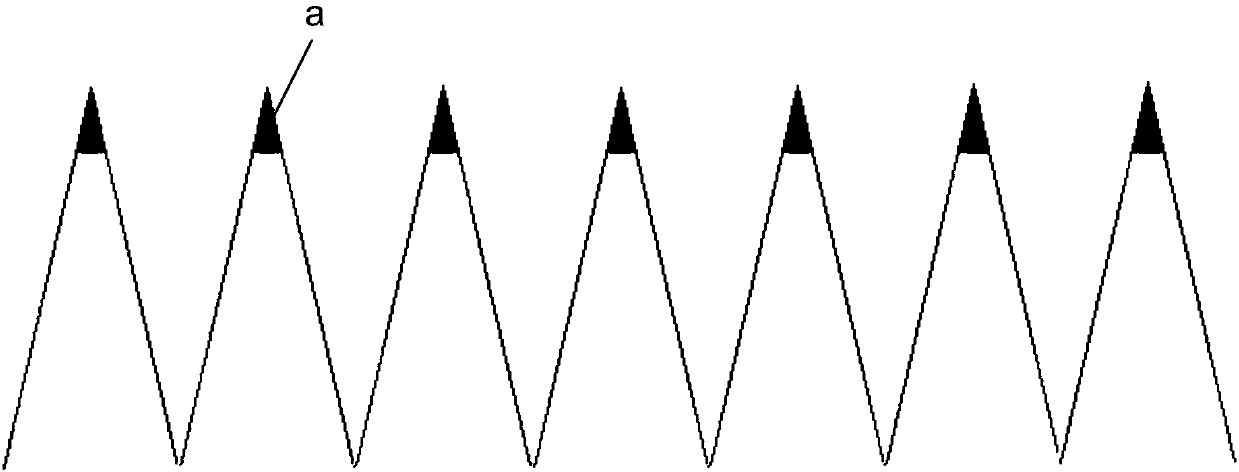

Four-roll roll-arranging type profile steel blooming mill

The invention provides a four-roll roll-arranging type profile steel blooming mill, belongs to a metal rolling mill, and particularly relates to a three-roll type steel rolling mill. A rolling mill base is provided with an upper roll a and a lower roll b, the two rolls are the same in length and roll diameter, the roll faces are each provided with 5-7 rolling grooves, and the rolling grooves are the same in position and shape. A middle roll is at least configured with a middle roller body c and a middle roll body d, the middle roll body c and the middle roll body d are the same in structure and provided with rolling grooves, and the rolling grooves correspond to the rolling grooves in the upper roll and in the lower roll. The upper roll a, the middle roll c and the lower roll b are fixed to the rolling mill base from top to bottom according to the primary roll-arranging type of the upper roll a, the middle roll c and the lower roll b, or the upper roll a, the middle roll c and the lower roll b are fixed to the rolling mill base from top to bottom according to the roll-replacing roll-arranging type of the lower roll b, the middle roll c and the upper roll a. The four-roll roll-arranging type profile steel blooming mill has the advantages that the two rolling rolls of the same structure are adopted, the two middle roll bodies of the same structure are adopted, the two rolling rolls are dispatched in an up-down mode to be used in cooperation with the two middle roll bodies, all the rolling grooves of the rolling rolls are fully utilized, the utilization rate of the rolling rolls is increased, and 1 / 3 the rolling roll cost is saved; when roll-replacing and roll-arranging are conducted, the process of transporting new rolling rolls is omitted, the roll replacing time is saved, and smooth steel rolling production is guaranteed.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

System for producing ribbed bar by quartered hot rolling production line

InactiveCN102873089AIncrease profitReduce production and operation costsRollsMetal rolling arrangementsProduction lineEngineering

The invention discloses a system for producing a ribbed bar by hot rolling, in particular a system for producing the ribbed bar by a quartered hot rolling production line, belongs to the technical field of steel rolling equipment, and provides a production system with relatively low running cost, relatively low equipment investment cost and relatively low fund occupied rate during rolling production. The system comprises at least two rough rolling machine sets, at least two medium rolling machine sets and at least two fine rolling machine sets which are sequentially arranged, wherein rollers are arranged on rolling machines; the rollers arranged on each rolling machine of the rough rolling machine set are flat and straight rollers without rolling slots; and a rolling hole consists of a radial gap between two adjacent rollers on each rolling machine.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

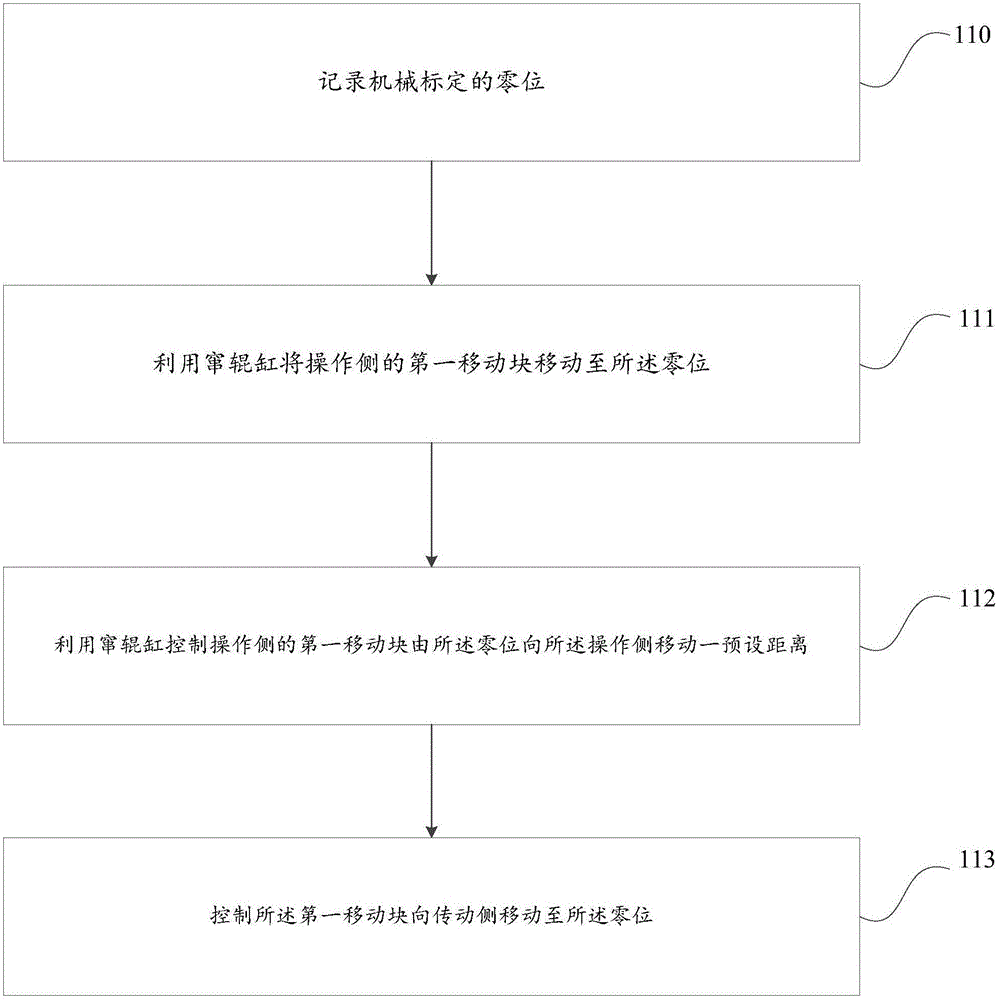

Method for eliminating zero error

ActiveCN105689397AMove to precisionEliminate zero errorMetal rolling stand detailsMetal rolling arrangementsWork rollEngineering

The invention provides a method for eliminating a zero error. The method comprises the steps that the zero position calibrated mechanically is recorded; the relative position between a magnetic ring and a magnetic ruler of each channeling roll cylinder is set to be zero; first moving blocks on an operation side are controlled by the channeling roll cylinders to move to the zero position; the first moving blocks are controlled by the channeling roll cylinders to move towards the operation side from the zero position by a preset distance; the first moving blocks are controlled to move towards a drive side to the zero position; and by means of the preset distance, it is ensured that the first moving blocks precisely move to the zero position. Thus, the zero error caused by accumulated gap values of all components can be eliminated, it is ensured that the first moving blocks and second moving blocks can precisely move to the zero position, it is ensured that clamping plate cylinders are in an opened state, a work roll can be replaced safely, rapidly and automatically, and then the roll replacement time is shortened, the work efficiency is improved, and manual operation accidents are avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Vertical rolling mill with press roll device

ActiveCN103372577APrevent rolloverIncrease productivityGuiding/positioning/aligning arrangementsMachinePiston rod

The invention discloses an vertical rolling mill with a press roll device. The vertical rolling mill comprises a base, a rolling mill body which is disposed on the base and comprises a rolling mill stand, vertical rolls and a drive system and the press roll device. The press roll device comprises oil cylinders, an upper crossbeam, a lower crossbeam, press rolls and a guide cylinder. The oil cylinder is disposed on the upper portion of the upper crossbeam. A piston rod of each oil cylinder penetrates the upper crossbeam to be connected with a connecting rod fixed on the upper portion of the lower crossbeam. Support plates are disposed on the lower portion of the lower crossbeam. The press rolls are disposed between every two support plates. The guide cylinder is disposed between the upper crossbeam and the lower crossbeam. By the press roll device, billet rollover caused by unavailable hole patterns of the vertical rolls during vertical rolling can be prevented effectively, multi-specification rolling can be achieved on the premise that rolls of a single rolling machine need not to be replaced, time for roll replacing is saved, production efficiency is increased, and production cost is lowered.

Owner:HUBEI SHILI MOLD MATERIAL

Vertical mill inlet shared induction device

ActiveCN102728628BExtended service lifeImprove physical qualityGuiding/positioning/aligning arrangementsRolling millSpare part

The invention provides a vertical mill inlet shared induction device, which consists of a fixing bracket, a guide body, an upper supporting arm, a lower supporting arm, a guide roller, a guide roller opening adjusting mechanism and a guide body horizontal movement mechanism, wherein the billet moves in a space formed by the upper and lower supporting arms and a side baffle, is guided by the guide roller and the side baffle and is correctly engaged with a rolling mill; when the milling specification is changed, an adjusting handle is rotated, the upper supporting arm drives the upper guide roller to lift to meet the novel specification requirement; the supporting arm stretches into two rollers on an inner frame, the guide plate body moves backwards in the process of replacing the rollers, and the supporting arms and the guide rollers retract the rollers and the arch of the inner frame; and therefore, the guide device is not required to be replaced in the process of replacing the rollers, the roller replacing time can be obviously shortened, the operate rate of the rolling mill is improved, the service life of the guide device is greatly prolonged, the storage and consumption of spare parts are reduced, and the production cost is reduced; and meanwhile, the scratch defect on the surface of a rolled piece can be overcome, and the quality of the finished rolled product is improved.

Owner:ANGANG STEEL CO LTD

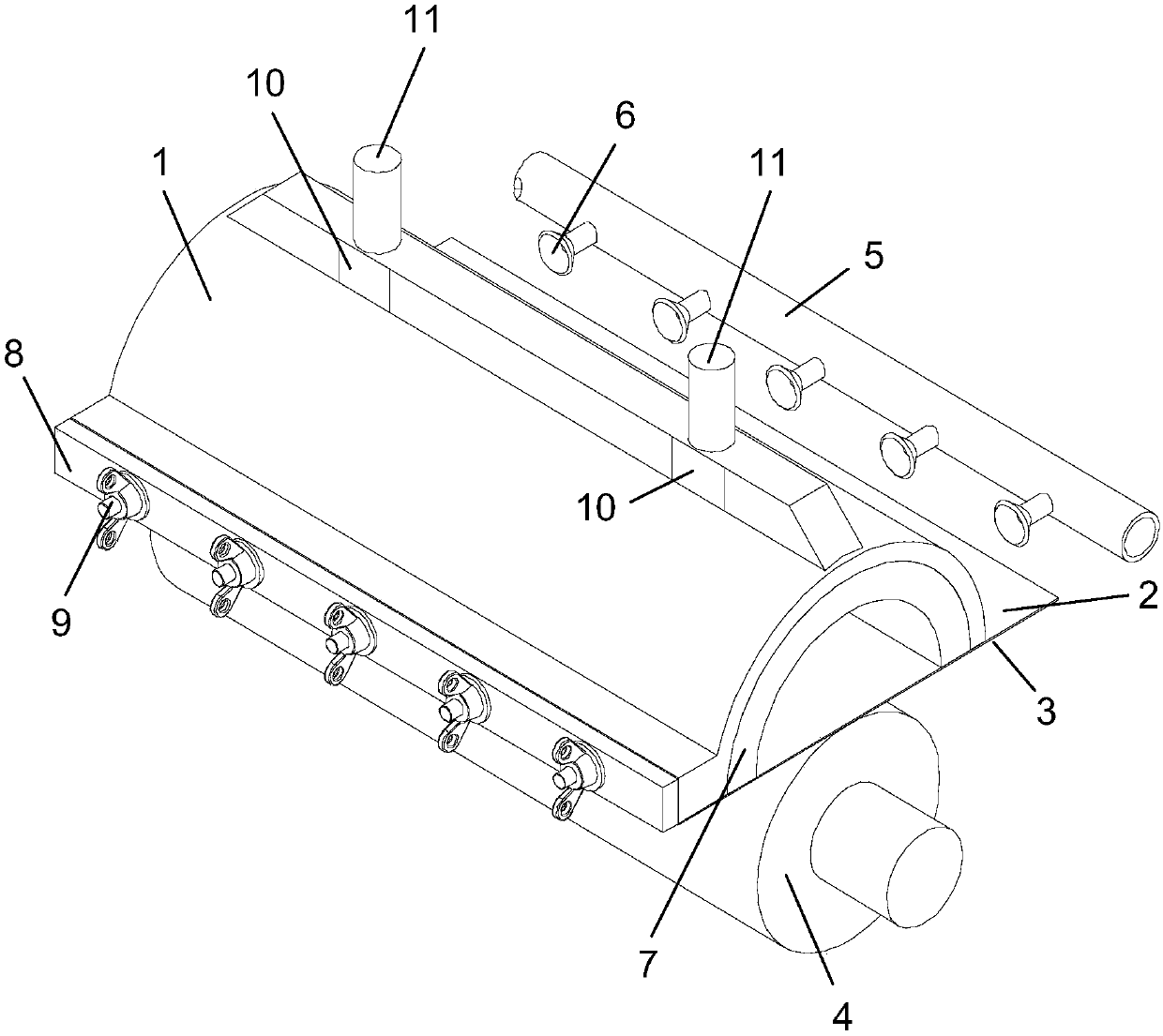

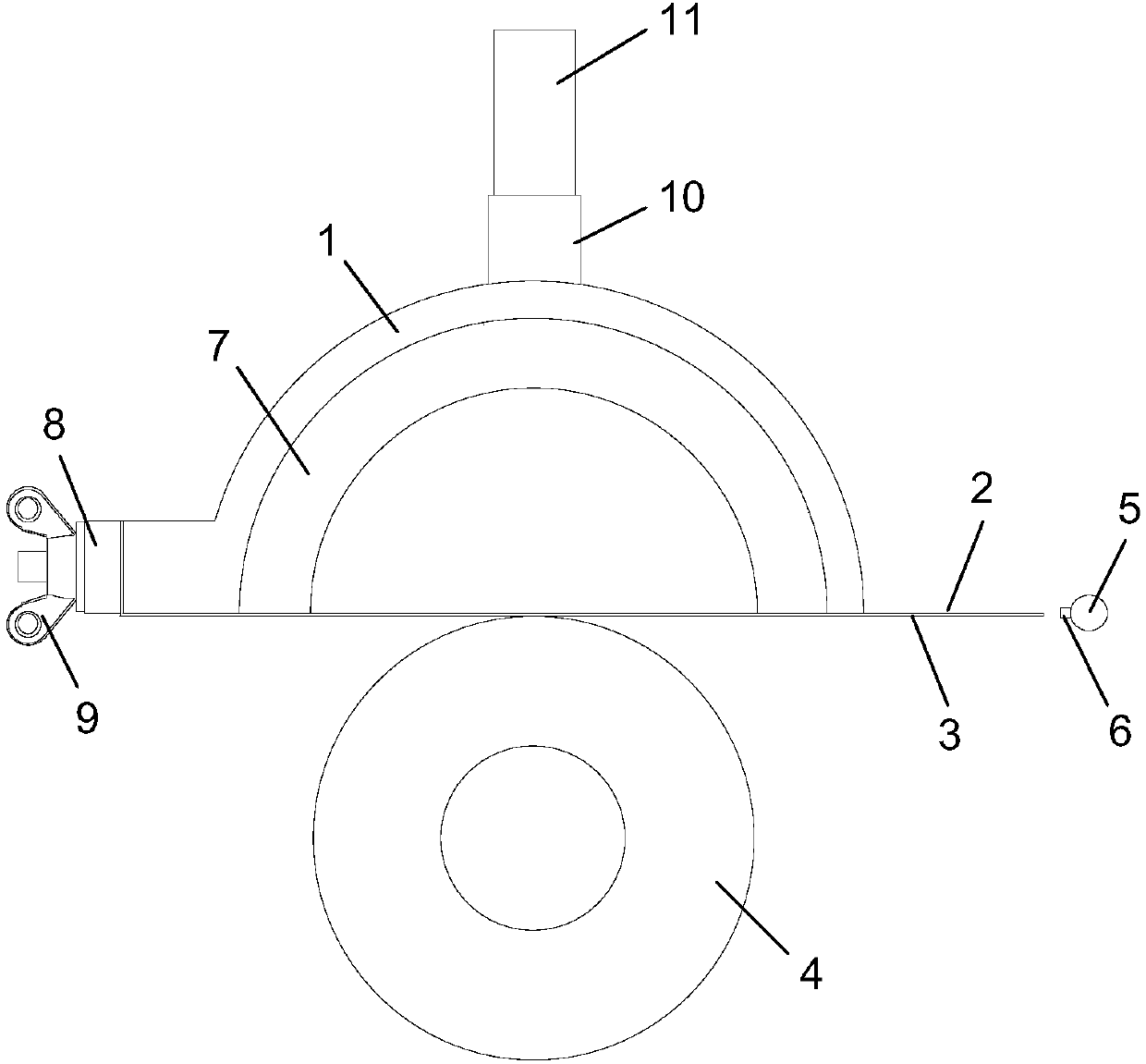

Double-rotating-shaft cantilever type skew rolling mill

ActiveCN110153339ASmall fluctuationShort to the axis of the roller systemSkewed roll standMetal rolling stand detailsGear wheelEngineering

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a double-rotating-shaft cantilever type skew rolling mill. The skew rolling mill is mainly composed of a base, a cantilever type roller system, a gear synchronizing mechanism, a radial reduction mechanism, machine frames, a material guiding unit and inclination angle adjusting mechanisms, wherein the cantilever type roller system is tensioned by bolts on the backs of the machine frames of the rolling mill, and the roller system inclination angle adjustment is realized through the inclination angle adjusting mechanism below bearing seats; the two machine frames which are supported by double rotating shafts of the rolling mill base; synchronous alignment and reduction are realized on the two machine frames through the gear synchronizing mechanism, and the center line of the vertical direction of the rolling mill is ensured to be fixed; the radial reduction mechanism is arranged above the machine frames, and the roller distance adjustment of two rollers is realized by rotating reduction nuts; and the inclination angle adjusting mechanisms are arranged at the corners of the machine frames so that the space can be saved, moreover, the action line is long, and the high-precision adjustment of the inclination angle of the roller system can be realized. The double-rotating-shaftcantilever type skew rolling mill is ingenious in design, has the advantages of convenience in roller replacement, fixation of the vertical center line of the rolling mill, convenience in installationand adjustment and the like, and is suitable for the production of large-scale small-diameter steel balls.

Owner:UNIV OF SCI & TECH BEIJING

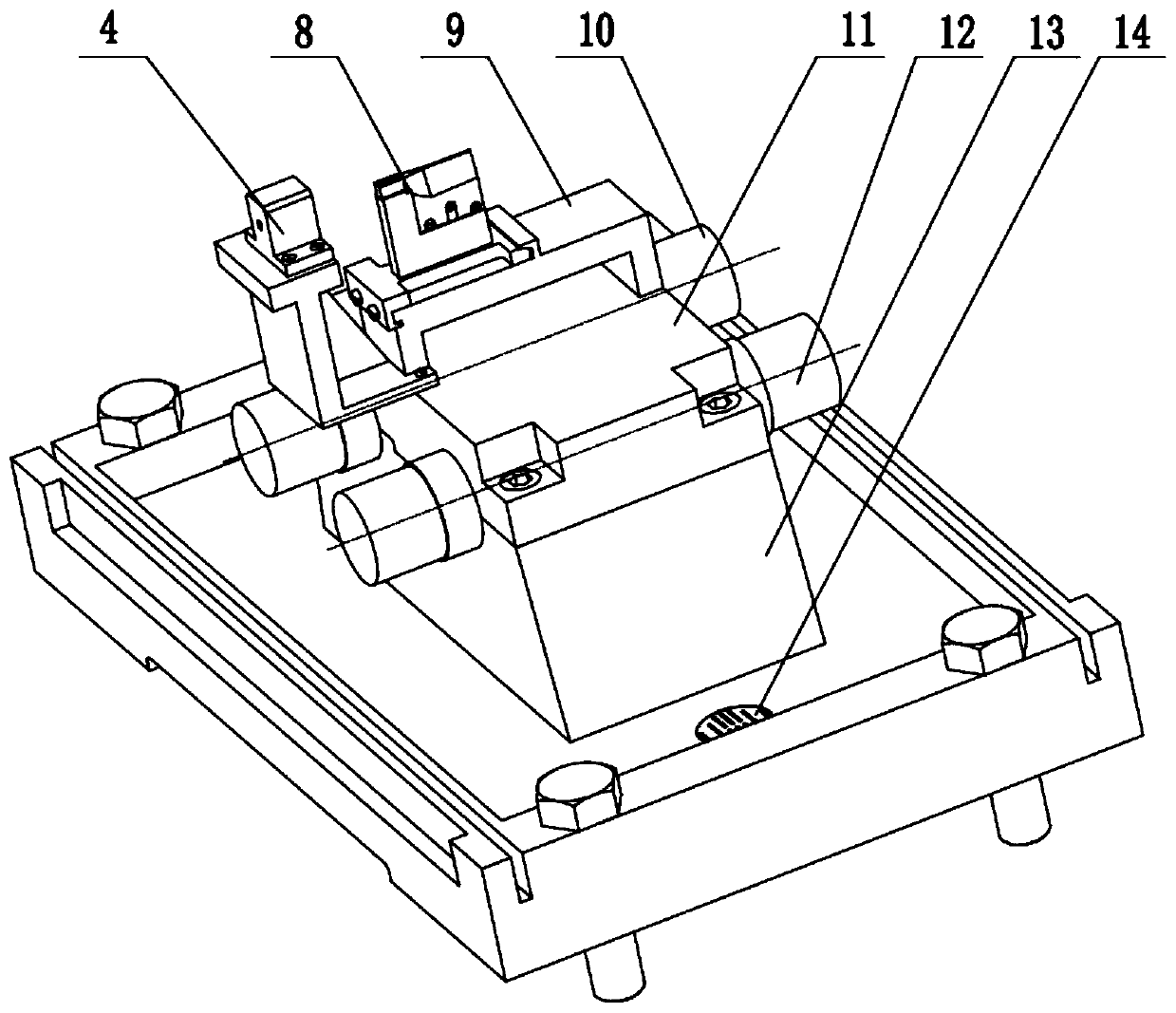

Roll change templates of straightening machine and roll change positioning method

ActiveCN103056641ASimplify the roll change preparation processReduced roll change timeMetal working apparatusStructural engineeringMachine

The invention relates to roll change templates of straightening machine and a roll change positioning method. The two roll change templates are strip-shaped; the top surfaces of the roll change templates are parallel to the bottom surfaces of the roll change templates; the two roll change templates are arranged between an upper straightening roll bearing seat and a lower straightening roll bearing seat on the two sides of the straightening machine respectively; the upper straightening roll bearing seat is pressed on the lower straightening roll bearing seat through the roll change templates; and the sum of the central height of the upper straightening roll bearing seat, the central height of the lower straightening roll bearing seat and the thicknesses of the roll change templates is equal to the central distance between an upper straightening roll and a lower straightening roll. Even if the roll diameters of the straightening rolls and support rolls are changed by different combinations, the thicknesses of the roll change templates are still not changed, so that the influence on the central distance between the upper straightening roll and the lower straightening roll due to the combined change of the roll diameters of the straightening rolls and the support rolls is avoided, the roll change preparation process of the roll type straightening machine is simplified, the roll change time is shortened, the tooth contact risk in the roll change process is lowered, and the working efficiency is improved.

Owner:CISDI ENG CO LTD

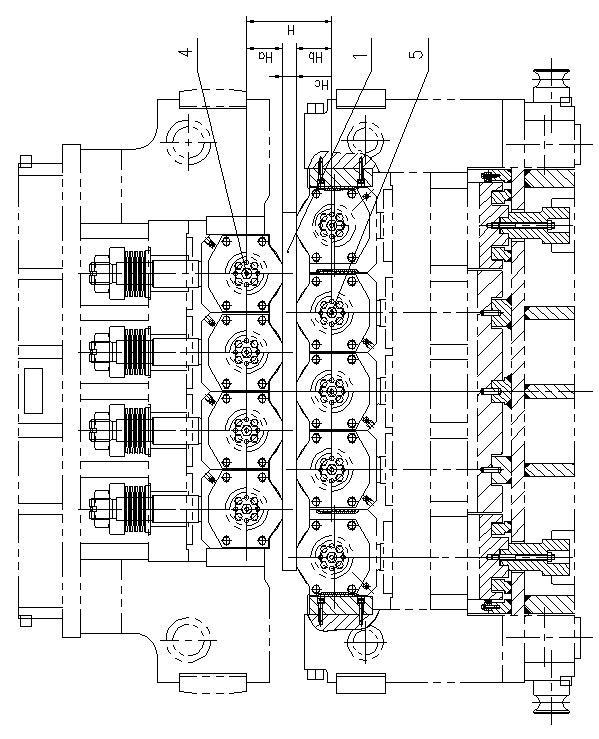

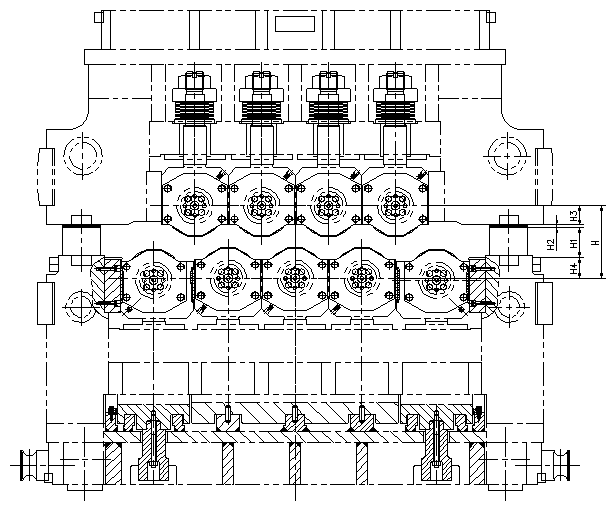

Multi-roll straightening machine

ActiveCN102553975BEnables individual vertical adjustmentGuaranteed straightnessThick plateEngineering

The invention discloses a multi-roll straightening machine, which comprises a main transmission mechanism, a universal connecting shaft, a connecting shaft holding mechanism, a stand, an upper roll device, a lower roll device, a pressing mechanism, a bending roll and balance mechanism and a roll change device, wherein the stand is provided with an upper movable cross beam; the upper roll device is supported by the upper movable cross beam; the upper roll device is connected with the upper movable cross beam through a plurality of clamping devices; the lower roll device comprises a lower row straightening roll, a lower roll device pedestal and side rolls; the side rolls are arranged on the two sides of the lower row straightening roll; the lower roll device is supported through the lower roll device pedestal; the side part of the lower roll device pedestal is provided with a side roll lifting device; and the side roll lifting device is pressed against the side rolls oppositely. The multi-roll straightening machine is applied to the field of straightening of medium and thick plates, has a compact structure, high rigidity and high roll change speed, can realize reversible reciprocating straightening, has good plate shape correction and can particularly meet the requirement of straightness of high-strength steel plates of thin specification.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

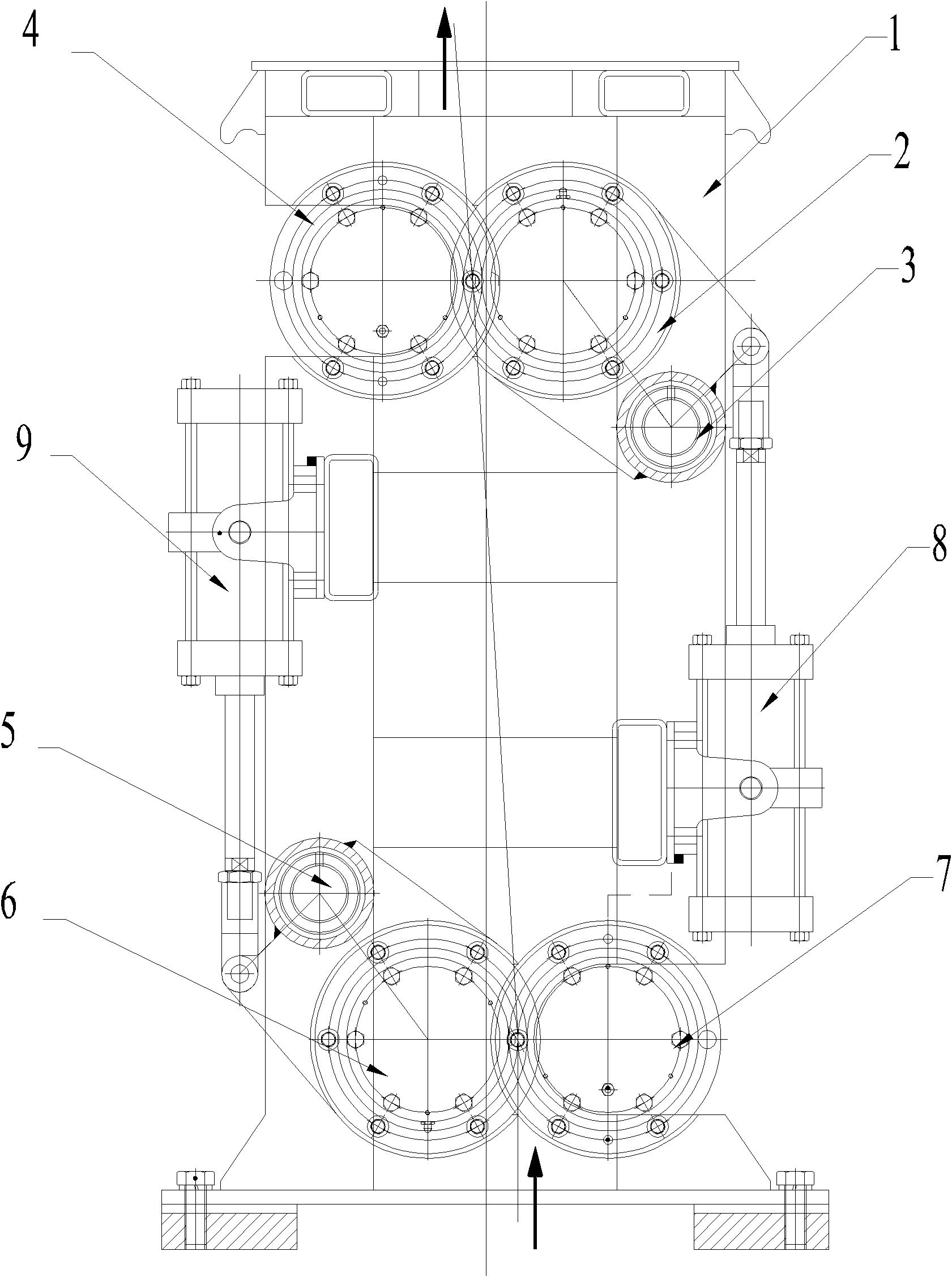

Device and working method for automatically changing the work rolls, the back-up rolls and the intermediate rolls of a single-stand or multiple-stand strip mill

InactiveUS7381301B2Reduce downtimeIncrease productionMetal rolling stand detailsHarvestersWork rollStrip mill

A roll changing carriage can be displaced transversely with respect to the strip rolling stand and a removal crossbar is provided for the removal of the set of backup rolls. In order to shorten the roll changing times and to automate the changing of the rolls, the removal crossbar can be positioned on the roll changing carriage and is provided with wheels on which the removal crossbar can be moved out of the roll changing carriage on guide rails running parallel to the rolls into the strip rolling stand on the intermediate roll rails, and can be pulled out of the strip rolling stand together with the set of backup rolls.

Owner:SMS DEMAG AG

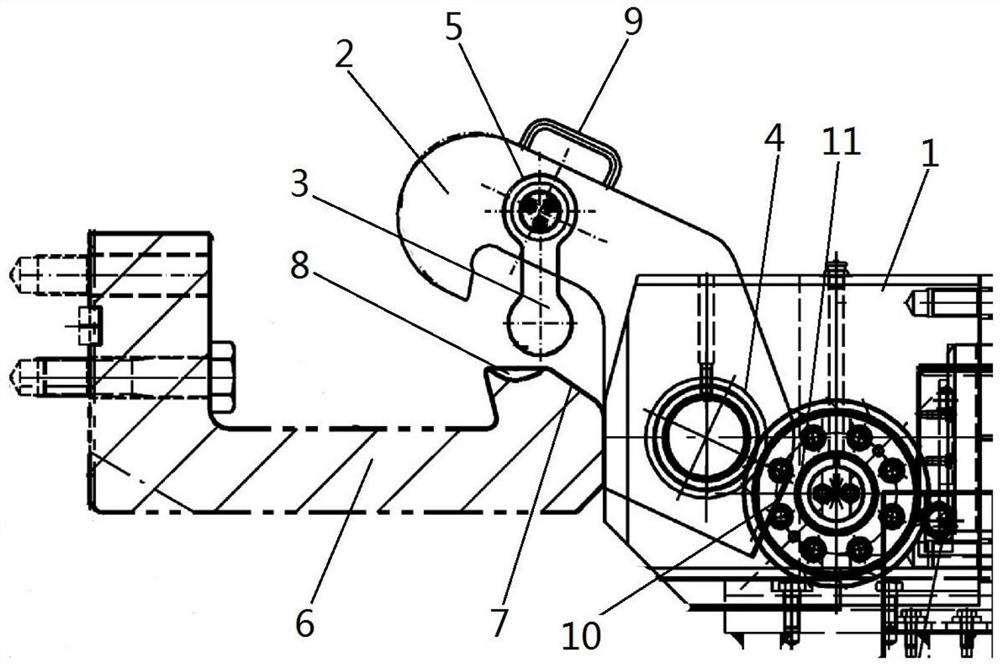

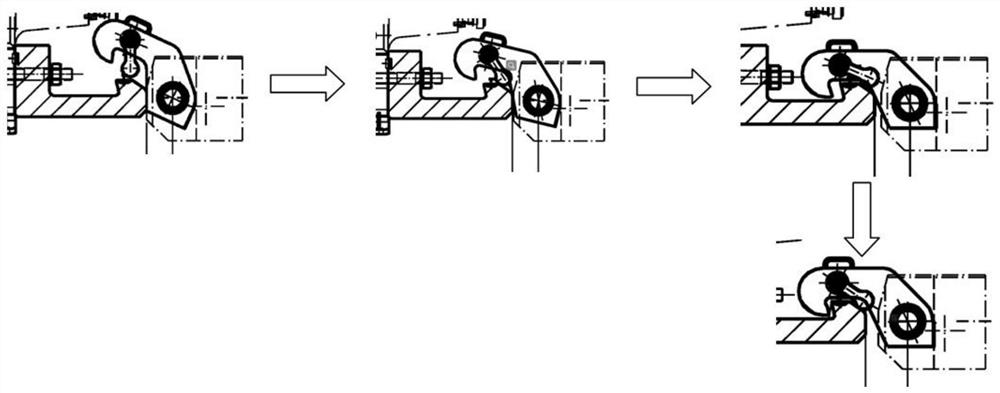

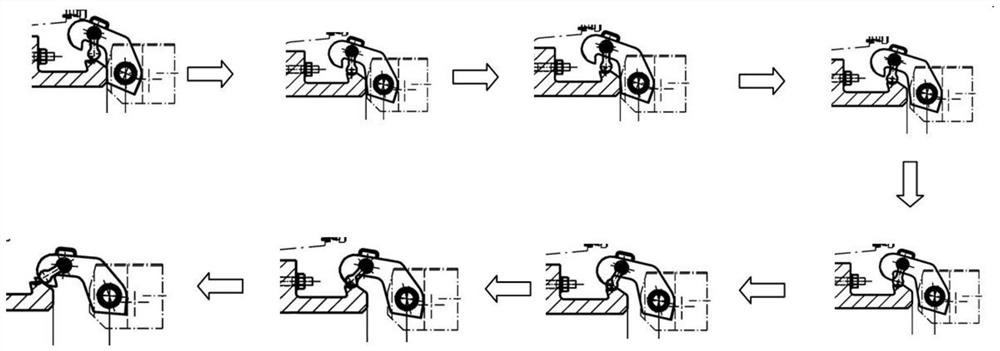

Automatic unhooking and hooking device for roll change of horizontal mill and unhooking and hooking method

ActiveCN111842501ASimple configurationReduce manual operationsMetal rolling stand detailsMetal rolling arrangementsCarriageManual handling

The invention discloses an automatic unhooking and hooking device for roll change of a horizontal mill. The automatic unhooking and hooking device comprises a roll change carriage, a carriage hook head, a positioning oscillating bar and a roll hook head, wherein the roll hook head is arranged on one end of a roll of the mill, one end of the carriage hook head is hinged with the front end of the roll change carriage, the other end of the carriage hook head is bent downwards and is provided with a carriage hook head part with a downward opening, a limiting mechanism which is used for limiting the carriage hook head part to rotate downwards to be lower than a horizontal plane is arranged between one end of the carriage hook head and the roll change carriage, the upper end of the positioning oscillating bar is hinged with the middle of one end, which is bent downwards, of the carriage hook head, a roll hook head part with an upward opening is arranged on the roll hook head, and a limitinginclined plane and a positioning groove are formed in the roll hook head part. According to the automatic unhooking and hooking device, the automatic hooking and unhooking can be realized, compared with a manual operating mode of the carriage hook head of an existing horizontal mill during roll change, the manual operation is reduced, human input is released, potential safety hazards are eliminated, and the roll change time is shortened. The invention further discloses an automatic unhooking and hooking method for roll change of the horizontal mill.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Detachable roller special for composite plate rolling

InactiveCN108326046AReduce replacement costsQuick swapRollsMetal rolling arrangementsEngineeringComposite plate

The invention relates to the technical field of composite plate rolling, in particular to a detachable roller special for composite plate rolling. The detachable roller comprises a core shaft, rollersleeve pieces, fastening screws, nuts and the like. The three or more completely-identical roller sleeve pieces are mounted outside the core shaft, and the roller sleeve pieces can be independently demounted. The roller sleeve pieces are divided into flat roller sleeve pieces and corrugated roller sleeve pieces, and the corrugated cross section on each corrugated roller sleeve piece is designed into a sine function curve or other function curves. The positions of the roller sleeve pieces can be aligned in the axial direction of the roller so as to meet mounting of the roller sleeve pieces of different widths. The connected parts of the corrugated roller sleeve pieces are trough positions, and the influence of the connecting parts on the rolling surface of a composite plate is reduced. Thedetachable roller is simple in mounting during use, the roller replacement time is saved, the rolling pass is reduced, and the production efficiency of composite plate rolling is improved.

Owner:TAIYUAN UNIV OF TECH

Vertical double-position wiping machine

InactiveCN102172648AAvoid scratchesScratching the strip effectively solves the problem of preventing the strip from being easily scratchedMetal rolling stand detailsWork treatment devicesProduction lineEngineering

The invention provides a vertical double-position wiping machine, aiming at overcoming the defects that the roller replacing time is long, the roller is easy to scratch and the wiping effect of a horizontal wiping machine is poor. The invention adopts the technical scheme that the wiping machine comprises a rack (1), the rack (1) is provided with a pair of upper wiping rollers and a pair of lower wiping rollers, the upper wiping roller is composed of an upper swing roller (2) and an upper fixed roller (4), the lower wiping roller is composed of a lower swing roller (6) and the lower fixed roller (7), one pair of wiping rollers or two pairs of wiping rollers are caused to operate according to the technological need of a production line to the wiping effect, thus a satisfied wiping effect is achieved and the application is flexible; when the rollers are abraded, one pair of the rollers operate while the other pair of the rollers are replaced, thus one pair of the rollers operate and the pair of the rollers are spare; and the strike direction of plate and strip is not contacted with the surface of the wiping rollers while the wiping rollers are not in operation, thus the plate and strip can not be scratched when the rollers are replaced and the problem that the plate and strip are easy to scratch is effectively solved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

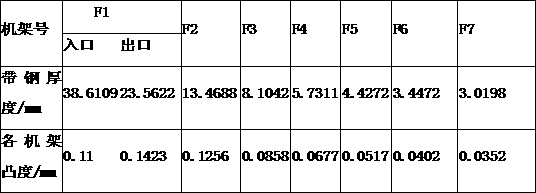

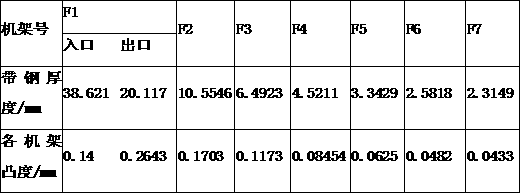

Method for solving wave shapes among racks through proportional convexity variation coefficients

ActiveCN111229838AWaves will not appearGuaranteed straightnessProfile control deviceWave shapeStructural engineering

The invention relates to a method for solving wave shapes among racks through proportional convexity variation coefficients. The method comprises the following steps of determining the ratio convexityvariation coefficient of each rack, determining the target convexity of a product, configuring the convexity of a middle blank, calculating the convexity value of each rack and the like. According tothe method for solving the wave shapes among the racks through the ratio convexity variation coefficients, it can be guaranteed that the head convexity of strip steel reaches the target value completely, that is to say, it is guaranteed that the outlet convexity of each rack is within the equipment capability range, and the precondition is established for the purpose of enabling the full-length convexity to reach the target value. In addition, it can be guaranteed that no wave shape exists among the racks and at an outlet of a finish-rolling group, especially the flatness of the strip steel between the finish-rolling rear-section racks such as F5, F6 racks and F6, F7 racks. Thus, the strip-threading stability in the thin-specification strip steel rolling process is guaranteed, the rollingplan is finally prolonged by at least 15% or above, the roll changing time is reduced, and the roller consumption is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

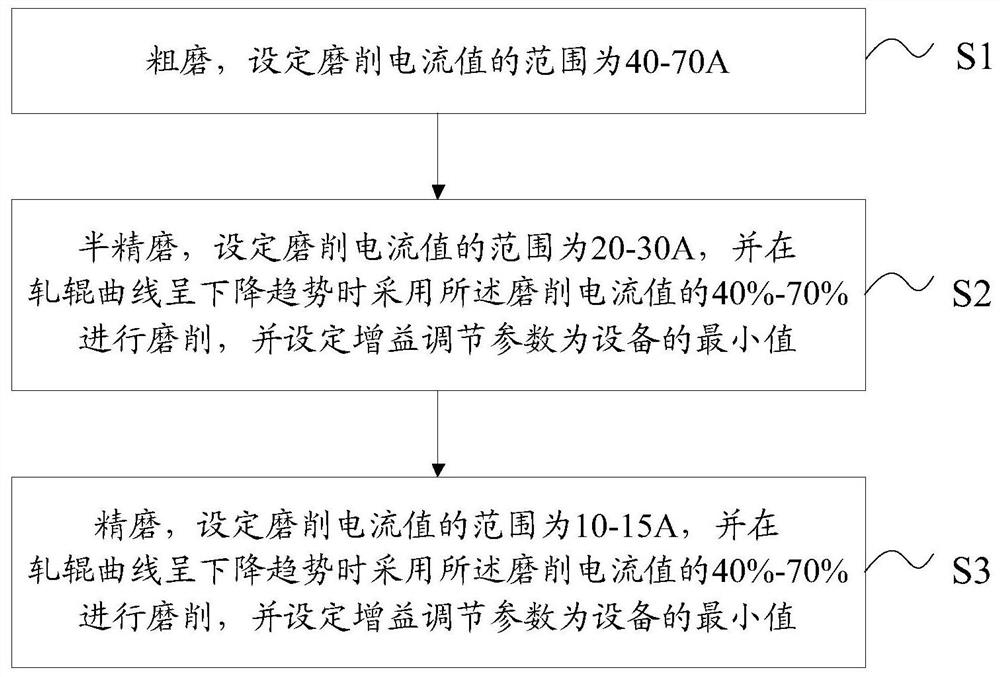

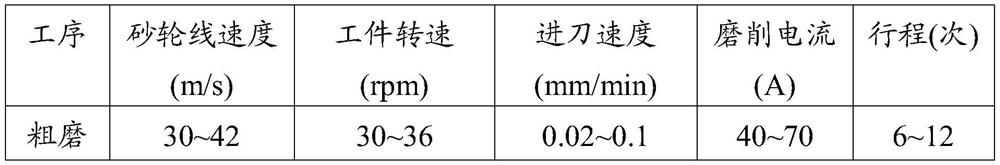

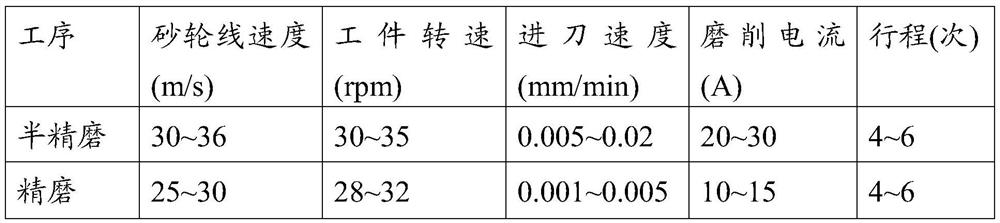

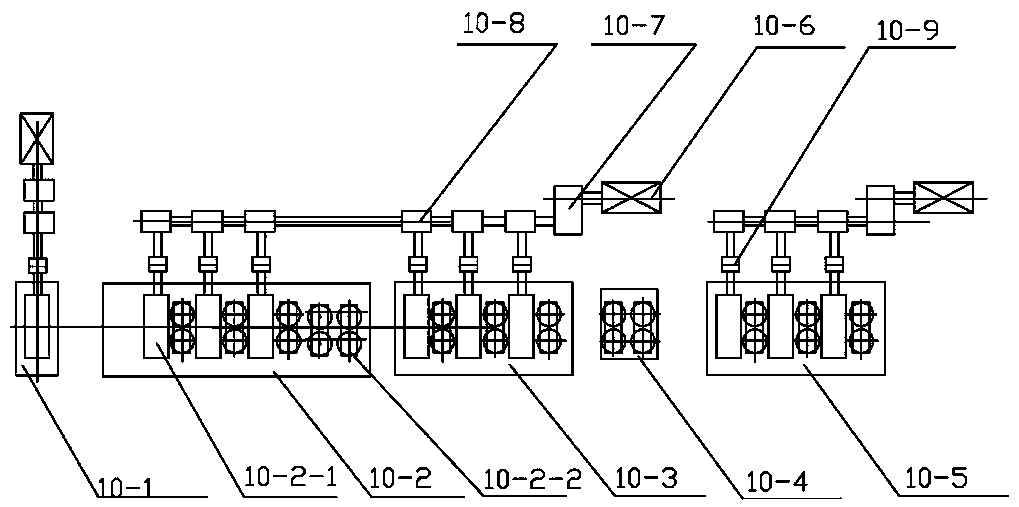

A kind of grinding method of cvc roll

The invention discloses a grinding method of a CVC roller. The grinding method of the CVC roller comprises the following steps of rough grinding, semi-finish grinding and fine grinding, wherein the rough grinding is carried out, wherein the range of a grinding current value is set to be 40-70 A; finish grinding is carried out, wherein the range of the grinding current value is set to be 20-30 A, moreover, 40%-70% of the grinding current value is adopted when a roller curve is in a descending tendency for grinding, and a gain adjusting parameter is set as the minimum value of equipment; and thefine grinding is carried out, the range of the grinding current value is set to be 10-15 A, moreover, 40%-70% of the grinding current value is adopted when the roller curve is in the descending tendency for the grinding, and the gain adjusting parameter is set as the minimum value of the equipment. According to the method, the grinding method of the CVC roller is provided, by using different methods of grinding current in different areas, the situation that the stress of each grinding area is uneven is effectively counteracted, the stress state of grinding stress is improved, and the generation of grinding lines is restrained; and meanwhile, the grinding efficiency is effectively improved by the method, the production amount of waste materials produced by a plate belt is reduced, the roller changing time is shortened, and the economic benefits of enterprises are improved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Metal welded pipe forming device with common roller and production method thereof

Disclosed is a metal welded pipe forming device with a common roller and a production method thereof. The metal welded pipe forming device comprises a first small roller set, a second small roller setand a third small roller set. A pipe blank is conveyed by a clamping-conveying roller, a belt-drive fine-forming roller and a sizing roller in a metal welded pipe production line. Combined roller bending technology is adopted, a set of small rollers are used for replacing a set of existing large-diameter horizontal rollers and vertical rollers at the rough-forming stage, vertical rollers are notneeded, when specifications of welded pipes are changed, only the positions of the small rollers need to be adjusted, thus equipment investment is lowered substantially, and production efficiency is improved greatly.

Owner:杨元恒

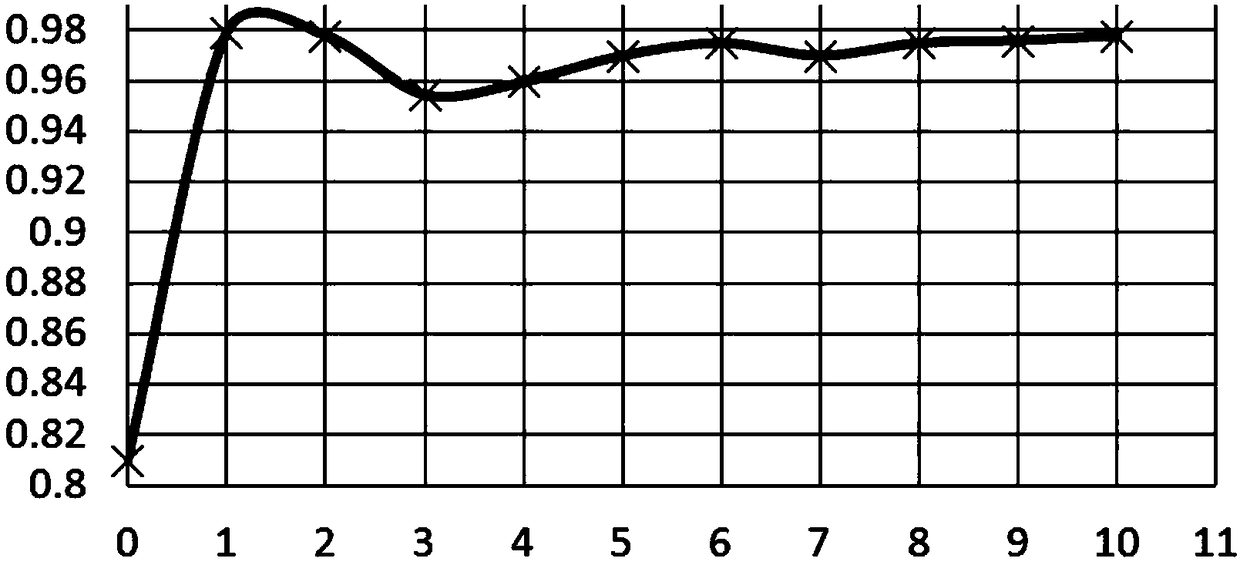

Ten-gate holeless rod continuous rolling process

InactiveCN108296283AImprove the annual operating rateImprove productivityTemperature control deviceRollsReduction rateStrip mill

The invention discloses a ten-gate holeless rod continuous rolling process, and belongs to a metal rolling process. The ten-gate holeless rod continuous rolling process is characterized in that hole rollers in previous ten gates of rod continuous rolling are replaced by flat rollers; hole rolling of rods in the previous ten gates is replaced by holeless rolling; holeless rolling in the previous ten gates is adopted to roll the rods; the rolling parameters are as follows: the rolling height-width ratio is 0.90-1.8; the reduction rate in each gate is 20%-60%; the rolling temperature is 950 DEG C-1100 DEG C; the height*width range of blanks is 150 mm*150 mm-165 mm*165 mm; the absolute broadsiding coefficient range is 0.18-0.45; holeless rolling of the rods in the previous ten gates is realized; the production cost is reduced; the product quality and the utilization rate of a rolling mill are improved; and the application range of the blanks is widened.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Machining device for improving roller surface clearness and machining method thereof

InactiveCN107756158AReduce roll changeReduced roll change timeGrinding carriagesRevolution surface grinding machinesUltrasound attenuationPulp and paper industry

The invention discloses a machining device for improving the roller surface clearness and a machining method thereof. The machining device is connected to a machine body of a grinding machine, and comprises a shell body, a compression mechanism, a hydraulic mechanism and a surface treatment mechanism; the hydraulic mechanism is arranged above the shell body, the shell body is connected to the machine body of the grinding machine through the hydraulic mechanism, and one end of the surface treatment mechanism is connected to one side edge of the shell body through the compression mechanism and is arranged below the shell body; and the surface treatment mechanism comprises a steel plate and abrasive paper, the upper surface of the steel plate is in contact with the shell body, the abrasive paper is connected to the lower surface of the steel plate, the abrasive paper and the steel plate form a whole, and the lower surface of the abrasive paper is used for machining the roller surface clearness. By means of the machining device and the machining method, generation of powder in the roller rolling process can be reduced, strip steel surface spot defect generation caused by reduction of the roller surface clearness is reduced, meanwhile, the roller roughness attenuation is reduced, and the roller abrasive resistance is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com