Metal welded pipe forming device with common roller and production method thereof

A forming device and welded pipe technology, which is applied in the field of metal welded pipe equipment, can solve the problems of high cost, large number of rollers, and affecting production output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

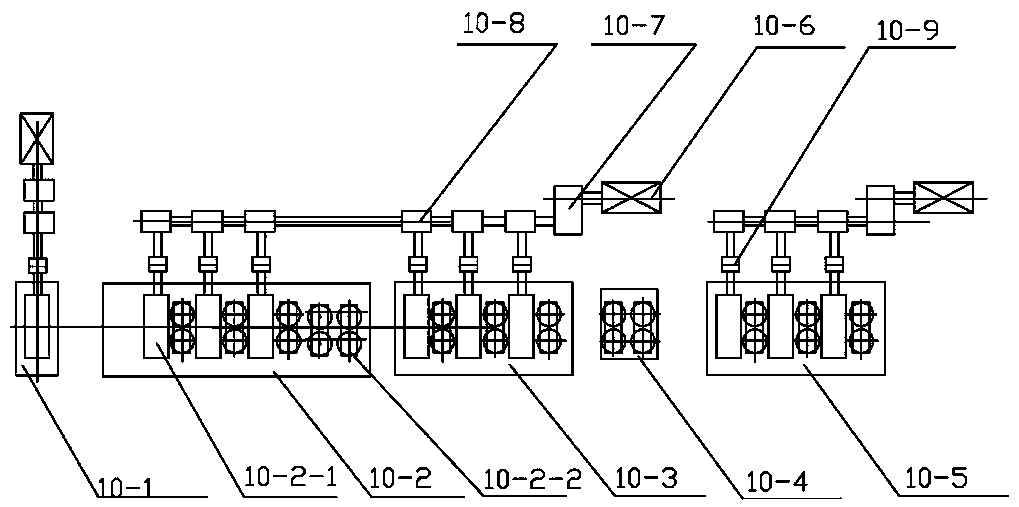

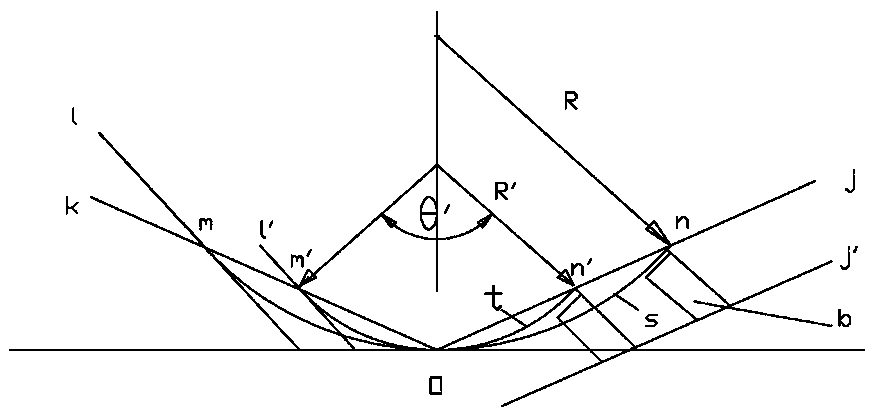

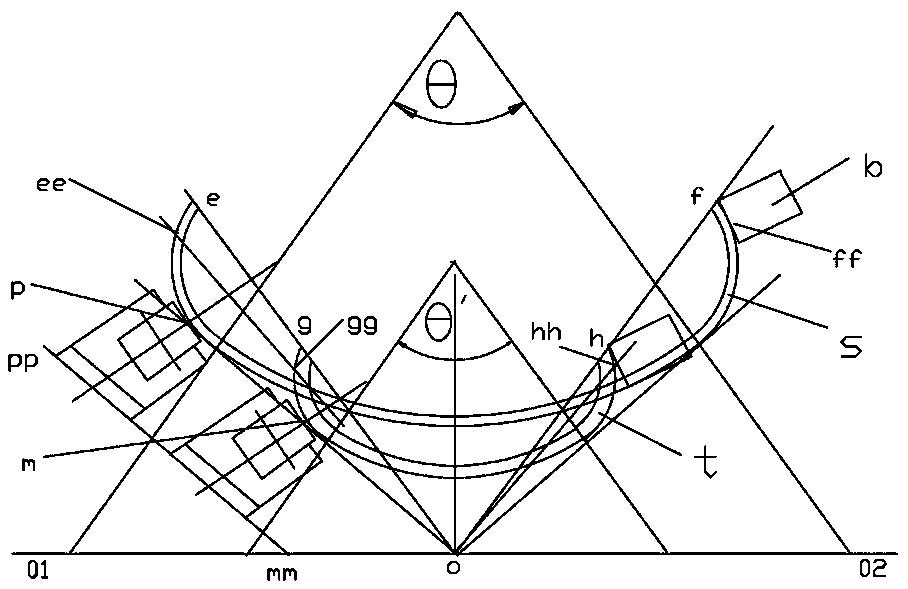

[0054] see Figure 5 ~ Figure 16 As shown, a metal welded pipe forming device with a common roller, the metal welded pipe forming device is located between the uncoiler in the metal welded pipe unit and the finishing section in the forming machine, the metal welded pipe forming device includes a rolling deformation The first small roll group for tube blanks with an angle θi≤180° and for rolling deformation angles at 240°≥θ i The second small roll group for tube blanks in the >180° interval and the rolling deformation angle θ i For the third small roll group of >240° tube blank, the first small roll group adopts the arrangement structure of three inner small rolls and three outer small rolls, and the second small roll group adopts three inner small rolls and three outer small rolls. The arrangement structure of three outer small rollers, the third small roller group adopts the arrangement structure of five inner small rollers and five outer small rollers, and the tube blank pa...

Embodiment 2

[0059] see Figure 5 ~ Figure 16 As shown, a metal welded pipe forming device with a common roller of the present invention is used for the rough forming section in the metal welded pipe production line, and it is suitable for rolling metal welded pipes with a diameter of φ610mm~φ1120mm. For this purpose, a φ1120 unit is designed, and the unit It can produce welded pipes with diameters of φ610mm, φ660mm, φ711mm, φ762mm, φ864mm, φ965mm, φ1016mm and φ1120mm. This embodiment takes the finished metal welded pipes with specifications of φ610mm×6.0mm and φ1120mm×12mm as examples to elaborate the setting, calculation, equipment adjustment and production method of various technical parameters of the φ1120 unit.

[0060] (1) Use the circular forming method for pass design.

[0061] (2) The rough forming section adopts the common combination roll pass design.

[0062] The specifications of the finished welded pipe are:

[0063] Minimum diameter φ610×6.0mm;

[0064] Maximum diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com