Vertical double-position wiping machine

A squeeze dryer, vertical technology, applied in the field of vertical squeeze dryer, can solve the problems of easy to scratch the surface of the strip, easy to scratch the roller, difficult to change the roller, etc., to shorten the roller changing time, easy to change the roller. , The effect of convenient roller change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

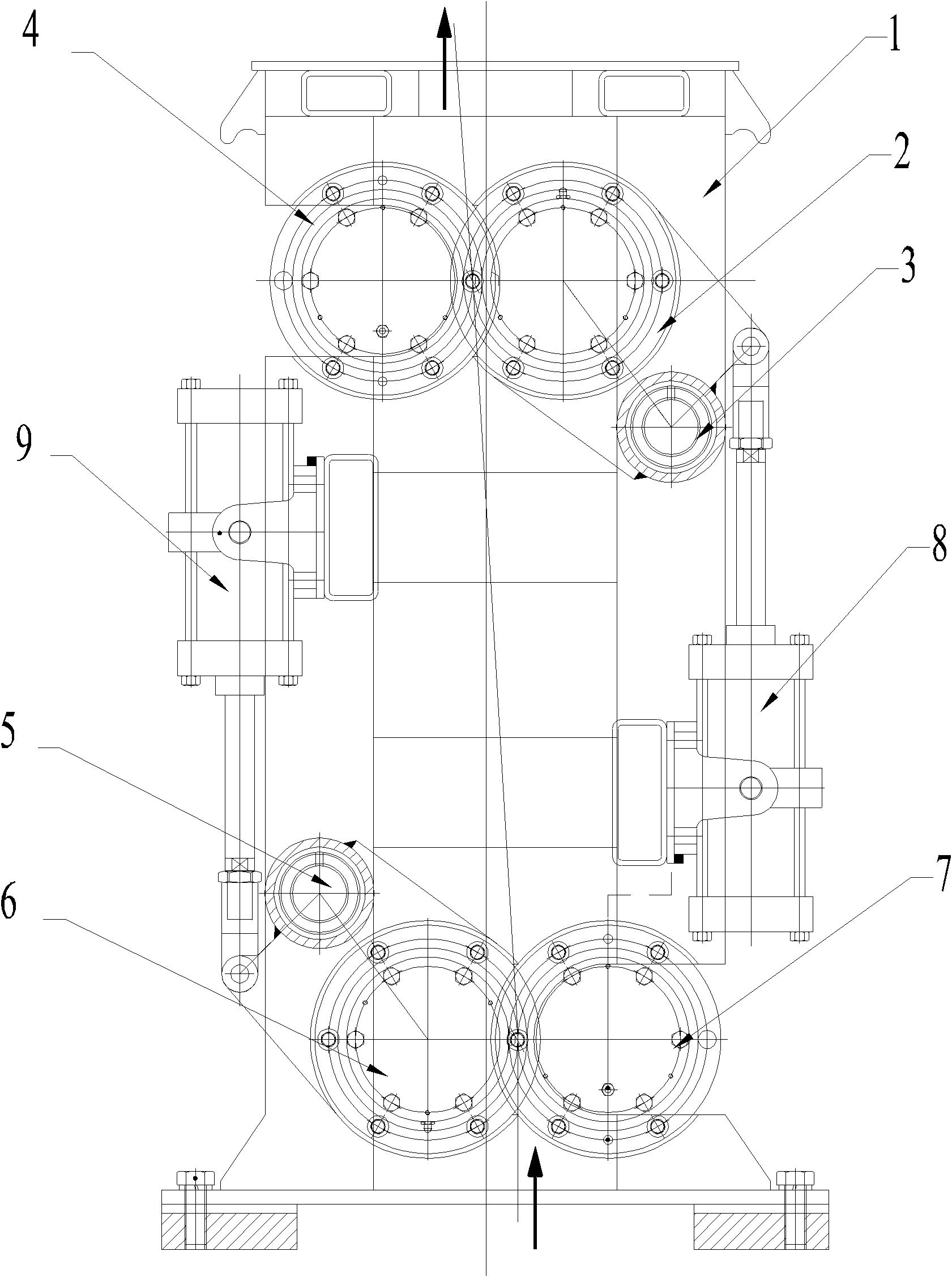

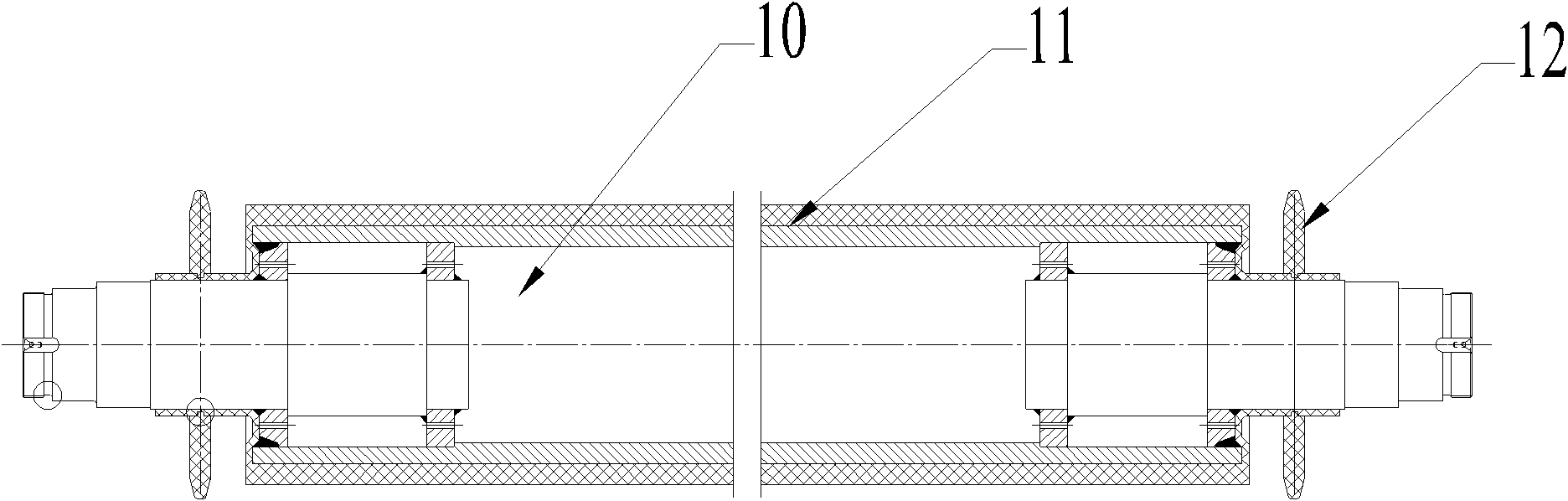

[0011] Such as figure 1 and figure 2 As shown, the present invention is that its frame 1 is provided with two pairs of upper and lower squeeze rollers, and the upper squeeze roller is composed of an upper swing roller 2 and an upper fixed roller 4, and the upper fixed roller 4 is fixed on the frame 1 by a flange. On the top, the flange has an outward gap, the upper swing roller 2 is connected to the upper swing arm 3 through the flange, the upper swing arm 3 is connected to the frame 1 through a rotating shaft, and the upper swing arm 3 is driven by the first cylinder 8 It can rotate along the rotating shaft; the lower working roll is composed of the lower swing roll 6 and the lower fixed roll 7, the lower fixed roll 7 is fixed on the frame 1 by a flange, and the flange has a gap facing outward, and the lower swing roll 6 passes through The flange is connected on the lower swing arm 5, the lower swing arm 5 is connected with the frame 1 through a rotating shaft, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com