Method for rolling mill to roll round steel with diameter phi of 120mm and round steel with diameter phi of 130mm by one roller set

A rolling mill and round bar technology, applied in the field of rolling Φ120mm and Φ130mm round bars with a rolling mill sharing a set of rolls, can solve the problems of reducing production efficiency, large capital and space, occupation, etc., to reduce labor intensity and improve production efficiency , The effect of reducing the roll change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The rolling conditions of this embodiment are: use a 220mm×220mm square billet, use a 650mm three-roll rolling mill, there is a turning plate in front of the machine, and the steel is fed from the lower rolling line; feed steel.

[0010] Since there are more passes to be arranged on a set of rolls, the first 6 passes must use conjugate passes.

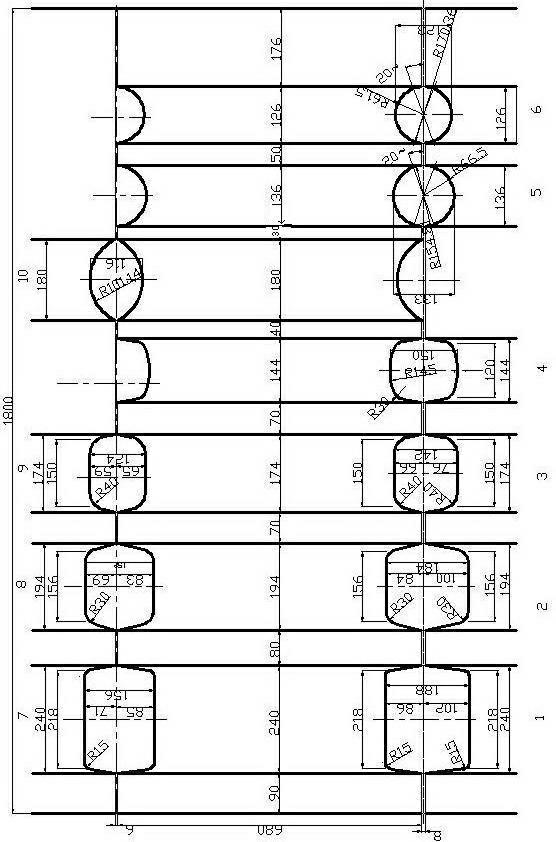

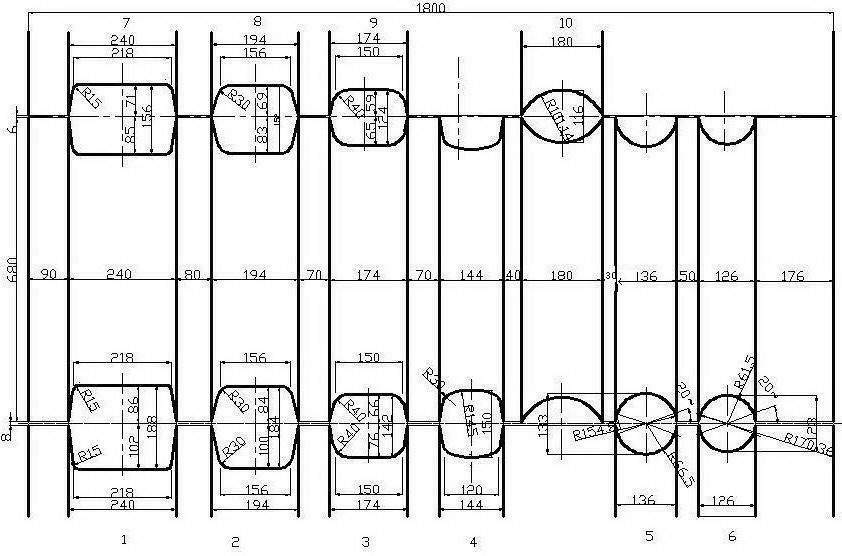

[0011] The rolling passes of Φ120mm and Φ130mm round steel are 9 passes and 7 passes respectively. During rolling, the 1st to 5th holes and the 8th hole are shared ( figure 1 shown).

[0012] After the 10 pass sizes shown in Table 1 are arranged on the roll, it is processed and turned, and the corresponding import and export guide devices are made, the turning plate is made and other production preparations are made.

[0013] Table 1 hole size

[0014] .

[0015] When rolling Φ120mm round steel, the passes of the 1st to 8th holes and the finished pass of Φ120mm are used, a total of 9 rolling passes. The roll gap of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com