Lower transmission sealing box used for producing float glass and roller-changing method thereof

A float glass, transmission sealing technology, applied in glass production and other directions, can solve the problems of equipment roller stuck, roller sticking tin is difficult to remove, poor sealing of the tin bath outlet, etc., to shorten the roller change time, improve production efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

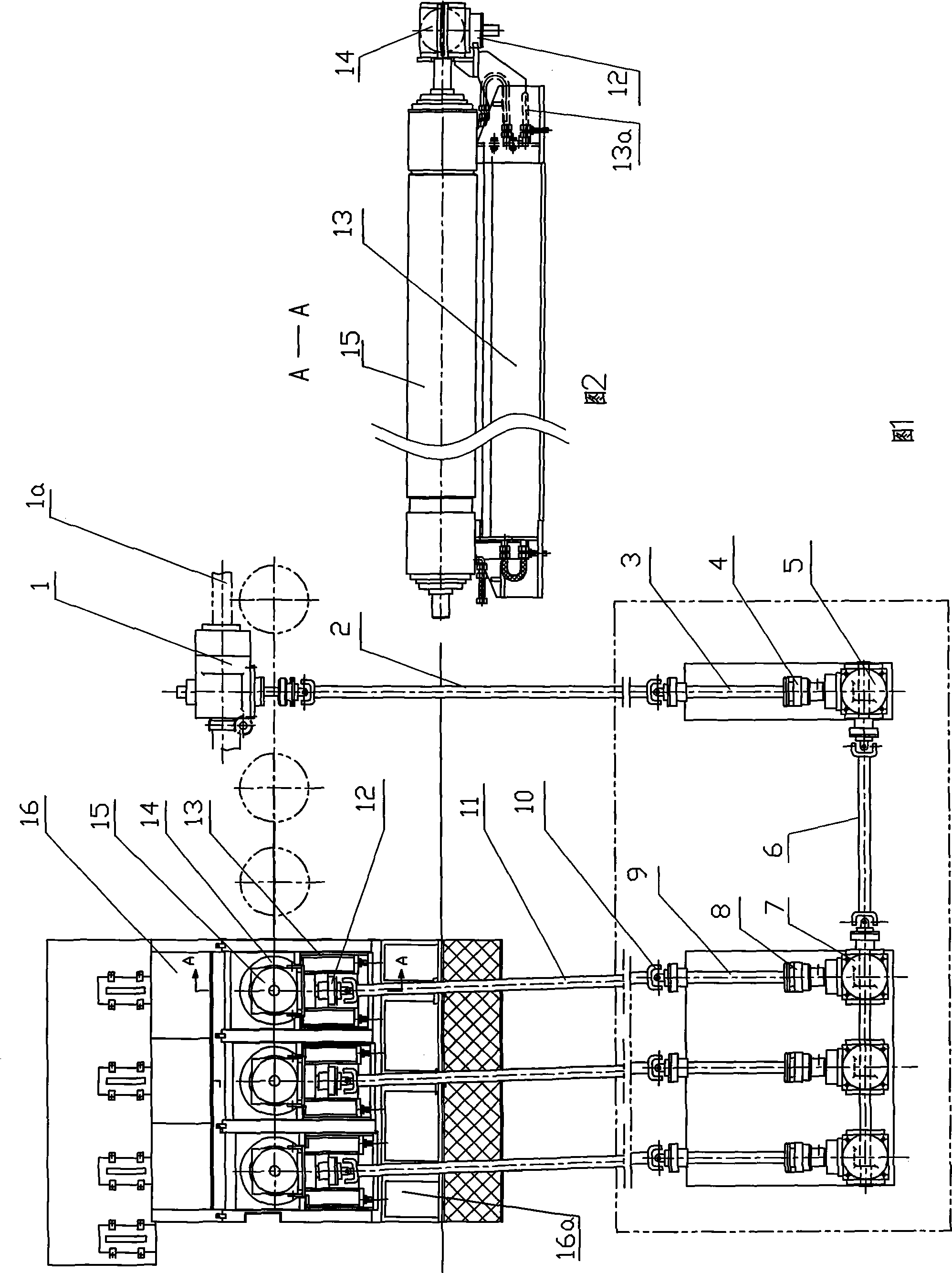

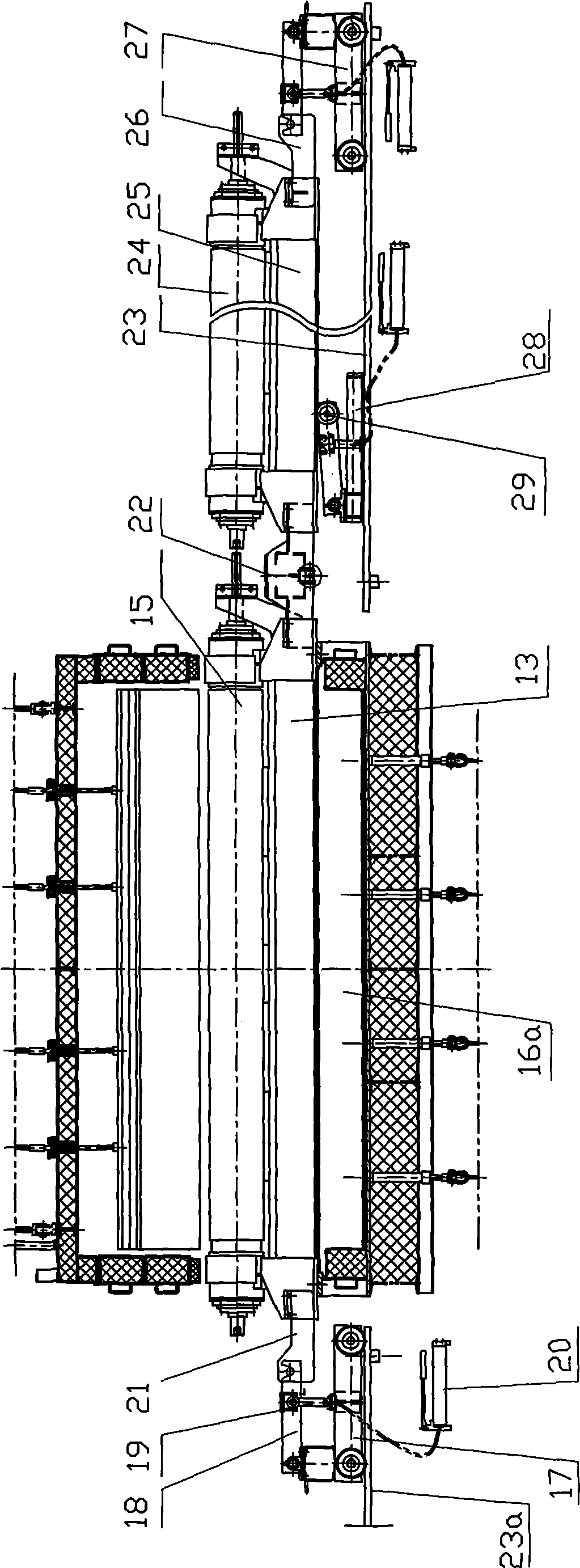

[0022] As shown in Figure 1, the lower float glass transmission sealing box device of the present invention mainly relates to the upper box body 16, the transition roller units 13, 14, 15, the lower box body 16a, and the pit of the float glass melting furnace. The lower drive system. The upper box, lower box and side walls of the melting furnace are used to seal the glass ribbon in the box; the transition roller unit is used to convey the passing glass ribbon; the lower transmission system provides the conveying power.

[0023] The float glass lower transmission sealing box device of the present invention is specifically composed as follows: a gear box 1 is connected to the transmission shaft 1a of the annealing furnace roller table, and the inside contains two orthogonal bevel gears, one of which is connected to the drive shaft 1a. The transmission shaft 1a is connected, the other bevel gear is connected through a universal joint, a transmission shaft 2 and a transmission shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com