Float glass encapsulation box and roller replacing method thereof

A float glass and sealed box technology, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of difficult replacement of transition rollers, shorten the roller changing time, simplify the transmission system, and solve the problem of online roller changing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

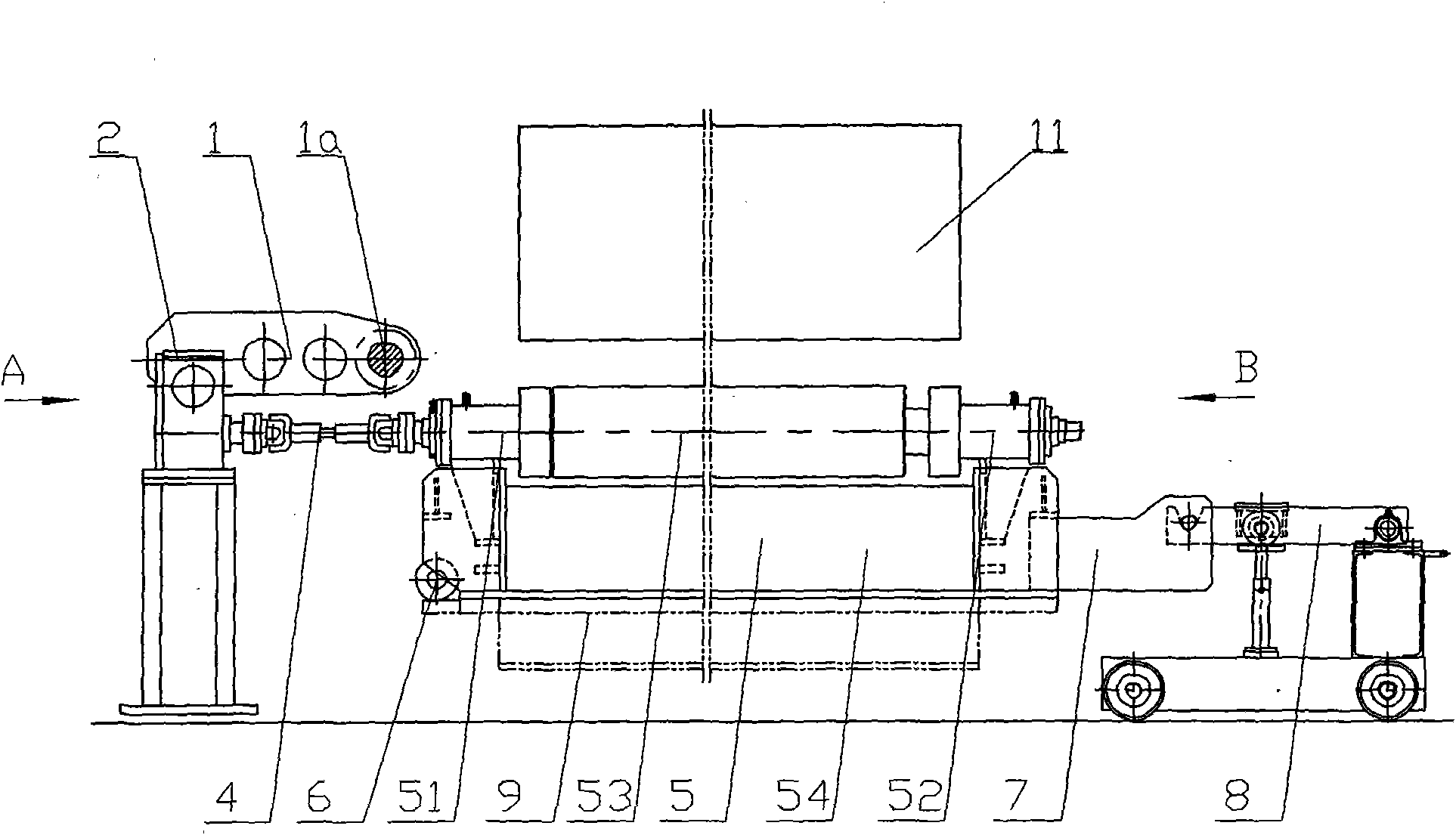

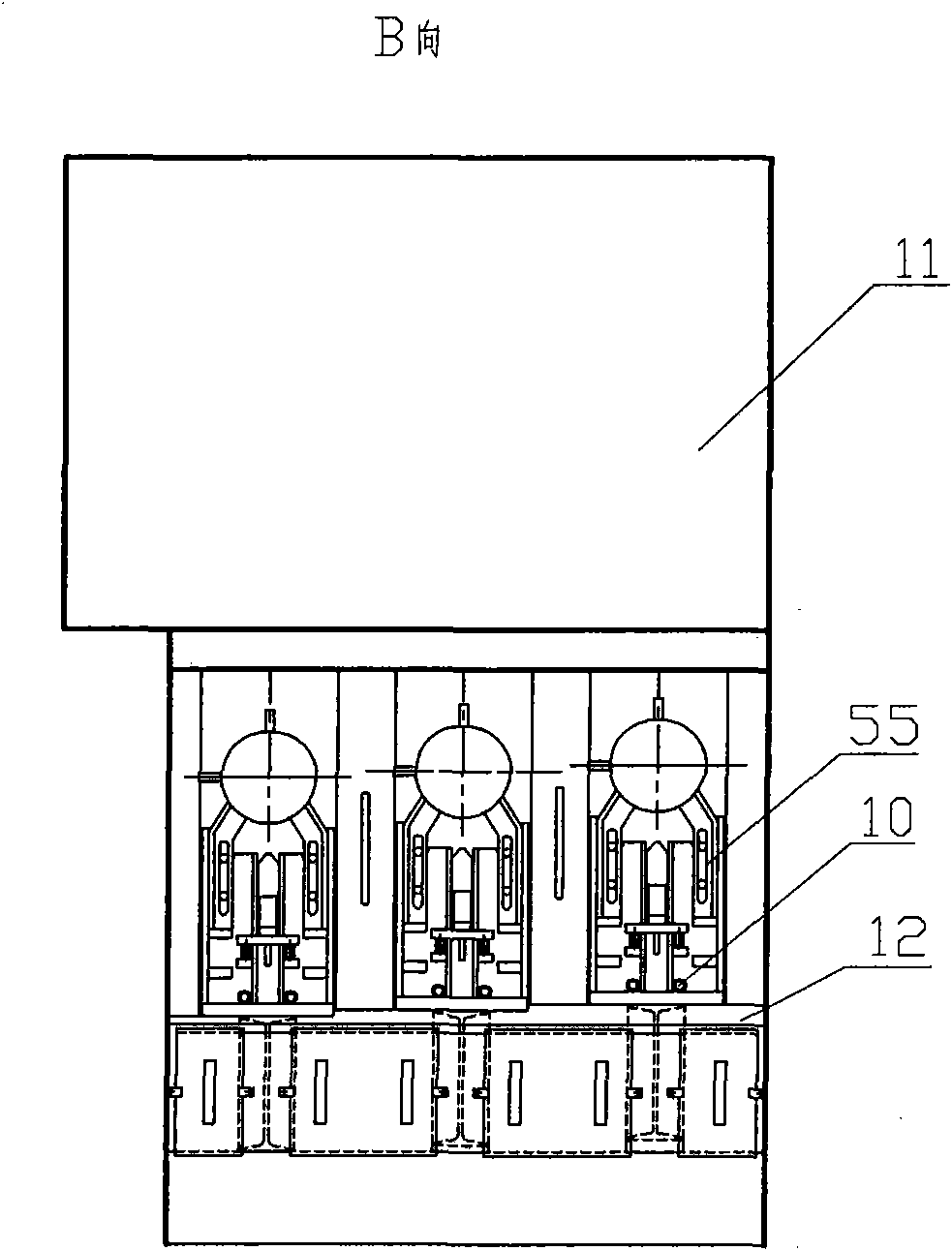

[0022] Such as figure 1 , figure 2 , image 3 As shown, the float glass sealing box is mainly composed of an upper box body 11, three groups of roller changing units 5 arranged in parallel, a transmission system, and a platform 12 supporting three groups of roller changing units 5.

[0023] The following are described separately according to their composition:

[0024] 1. Upper box body 11: set above the roll changing unit 5.

[0025] 2. Roller changing unit 5: the transition roller 53, the bearings 51, 52 at both ends and the car body 54 form the roller changing unit 5, the roller changing unit 5 cooperates with the track 9 of the sealing box, and the bearings 51, 52 and the car body 53 The two ends are bolted, and the bolted joints of the bearings 51, 52 and the car body 54 are provided with slots 55, and the bearings 51, 52 and the transition rollers can adjust the lifting height relative to the car body 54.

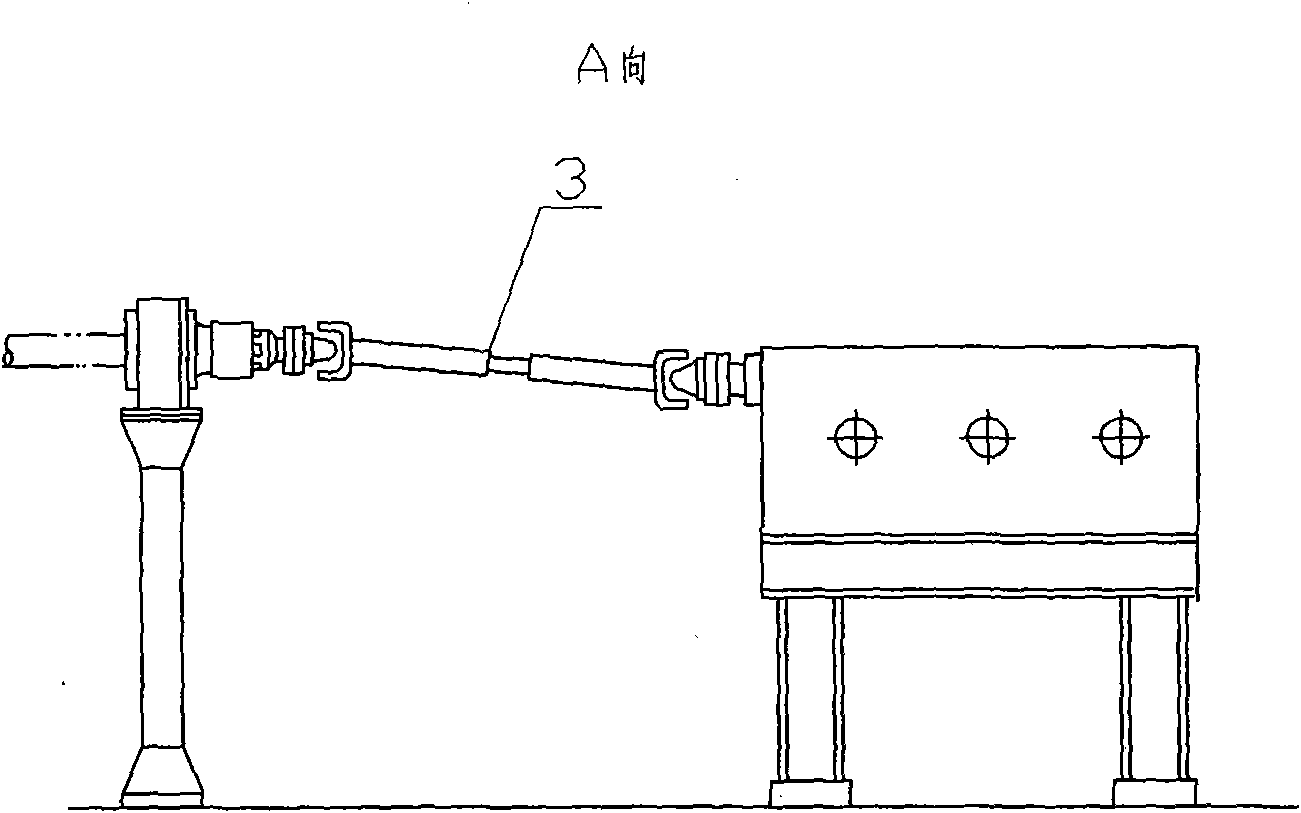

[0026] 3. Transmission system: The gear box 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com