Patents

Literature

44results about How to "Save workshop space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

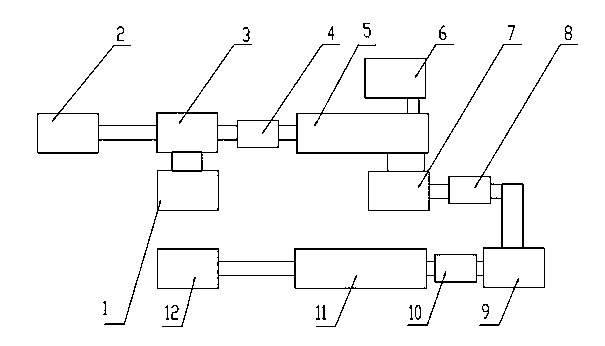

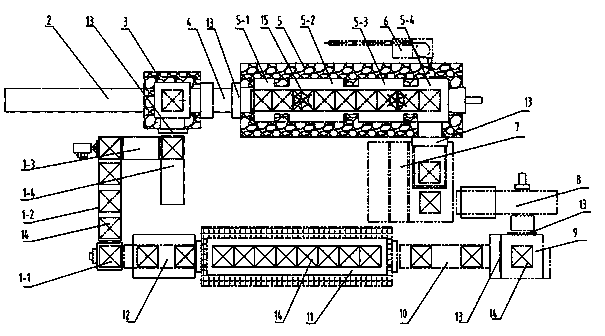

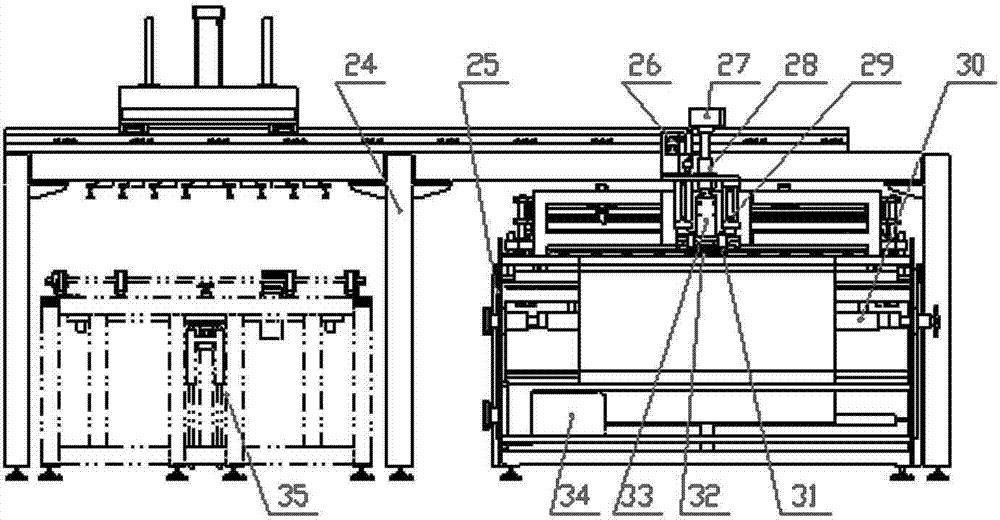

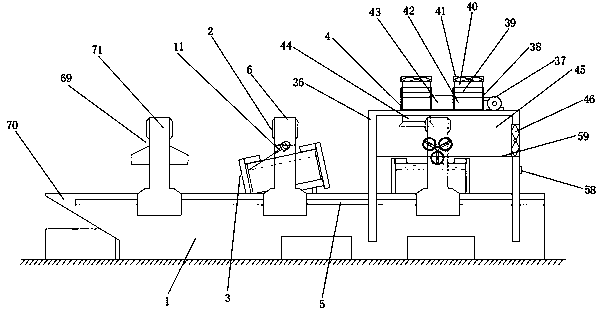

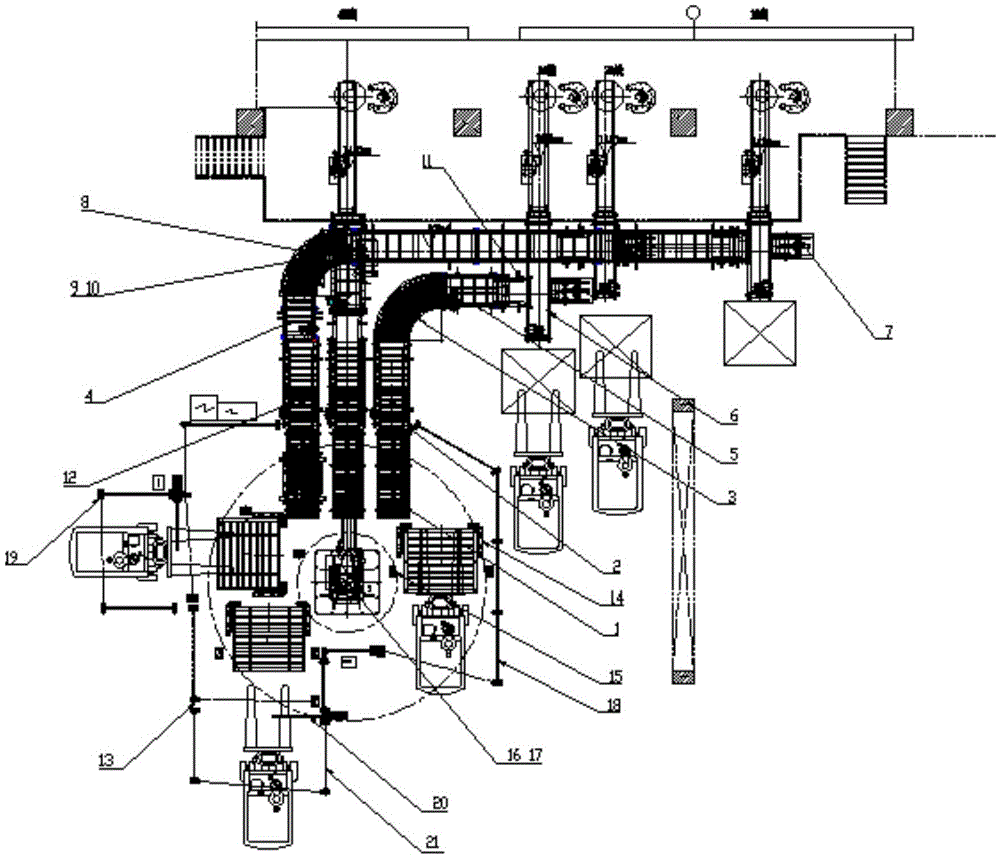

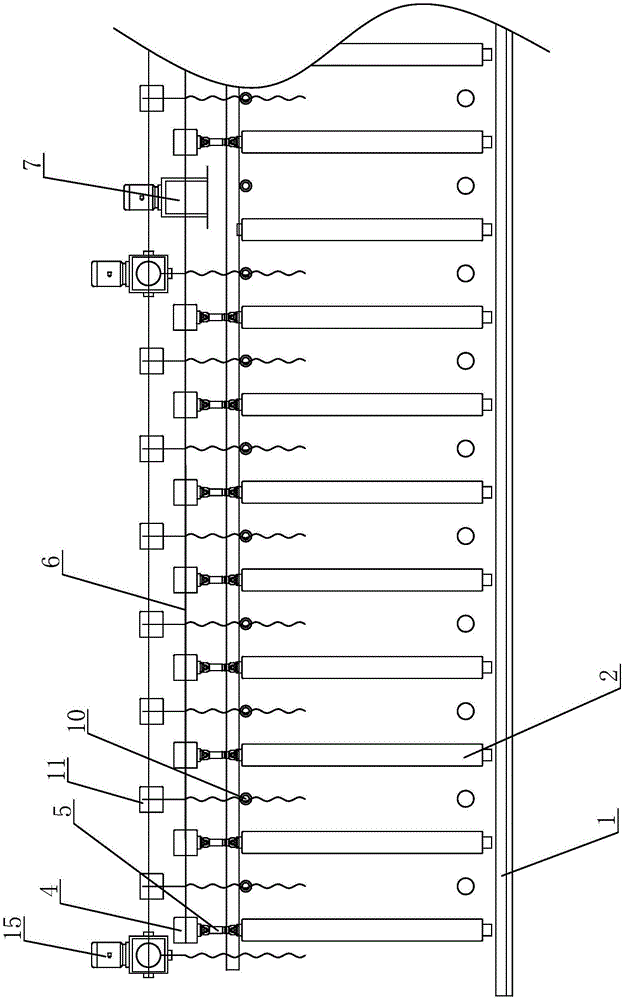

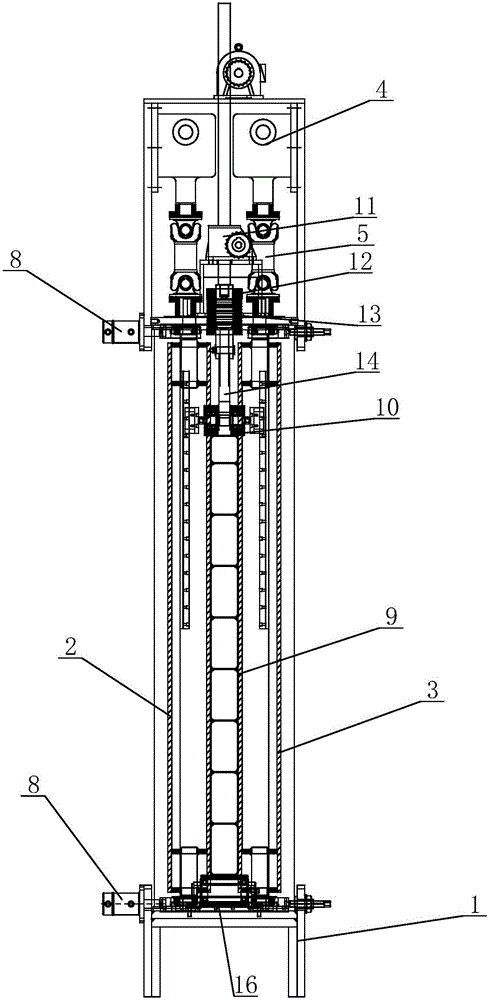

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

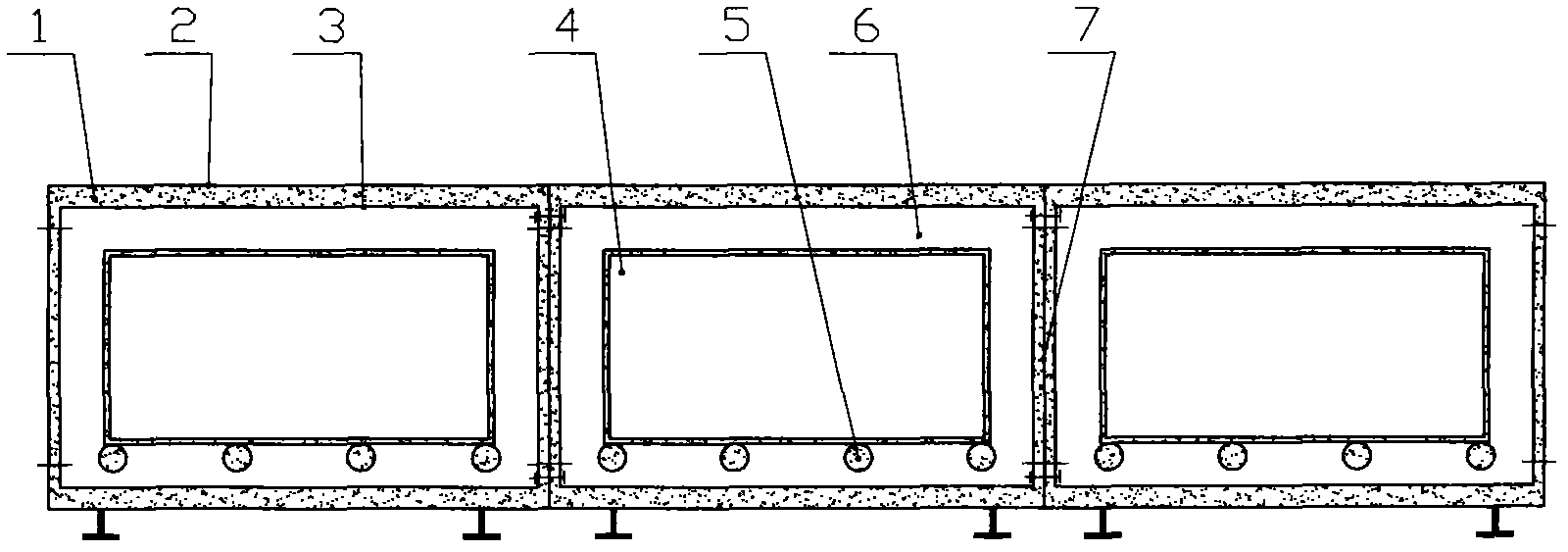

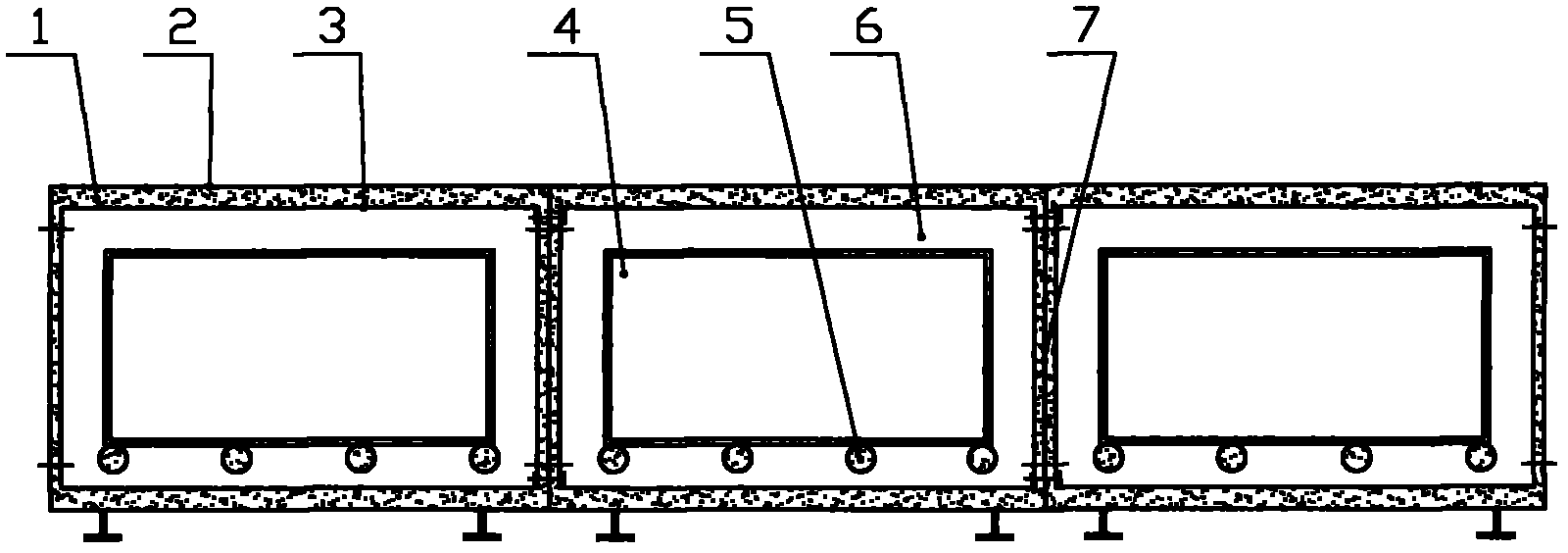

Tunnel vacuum drying equipment

InactiveCN102589265AAvoid getting lostConvenient process managementDrying using combination processesFinal product manufactureTemperature controlThermal insulation

The invention discloses tunnel vacuum drying equipment, which comprises a shell, wherein a liner is fixedly connected in the shell; a thermal insulation material is filled between the liner and the shell; two ends of the shell and the liner are connected with isolating doors; an air inlet / outlet is formed and a steam heating device and a condensate water cooling device are arranged on an inner cavity; a temperature control device is arranged on the inner cavity; rollers are connected in the inner cavity; vacuum box bodies are connected on the rollers and are provided with sealing doors; pipelines are fixedly connected on the vacuum box bodies; valves are arranged on the pipelines; and two or more pieces of tunnel vacuum drying equipment are matched. Materials to be dried can be strictly controlled according to process flows and are subjected to monitoring management and production in a centralized mode in batches by stages, and the quality of products can be guaranteed; meanwhile, manual labor and workshop space are saved, fund and energy are saved, and the equipment is environment-friendly.

Owner:山东润工自动化设备有限公司

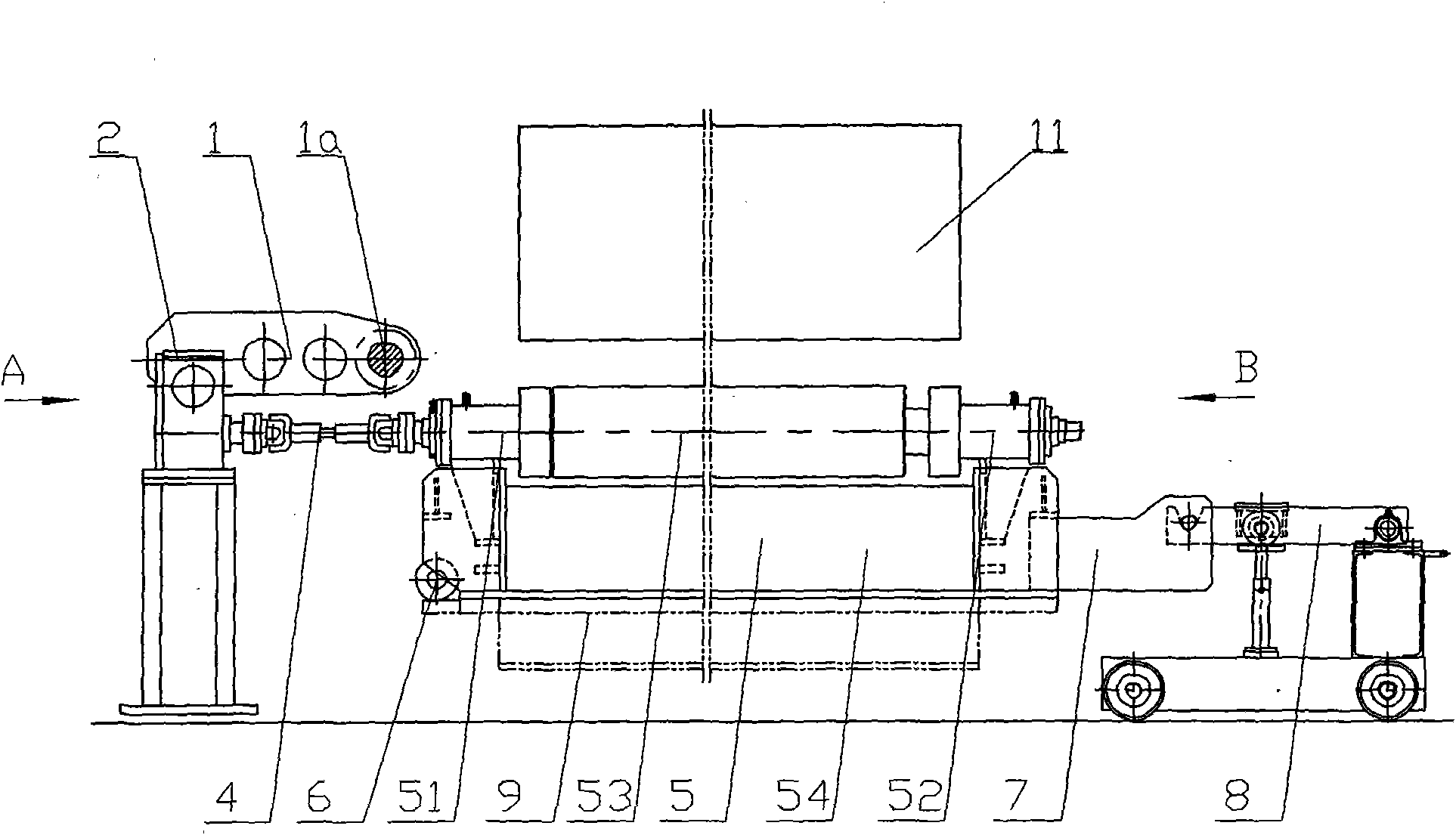

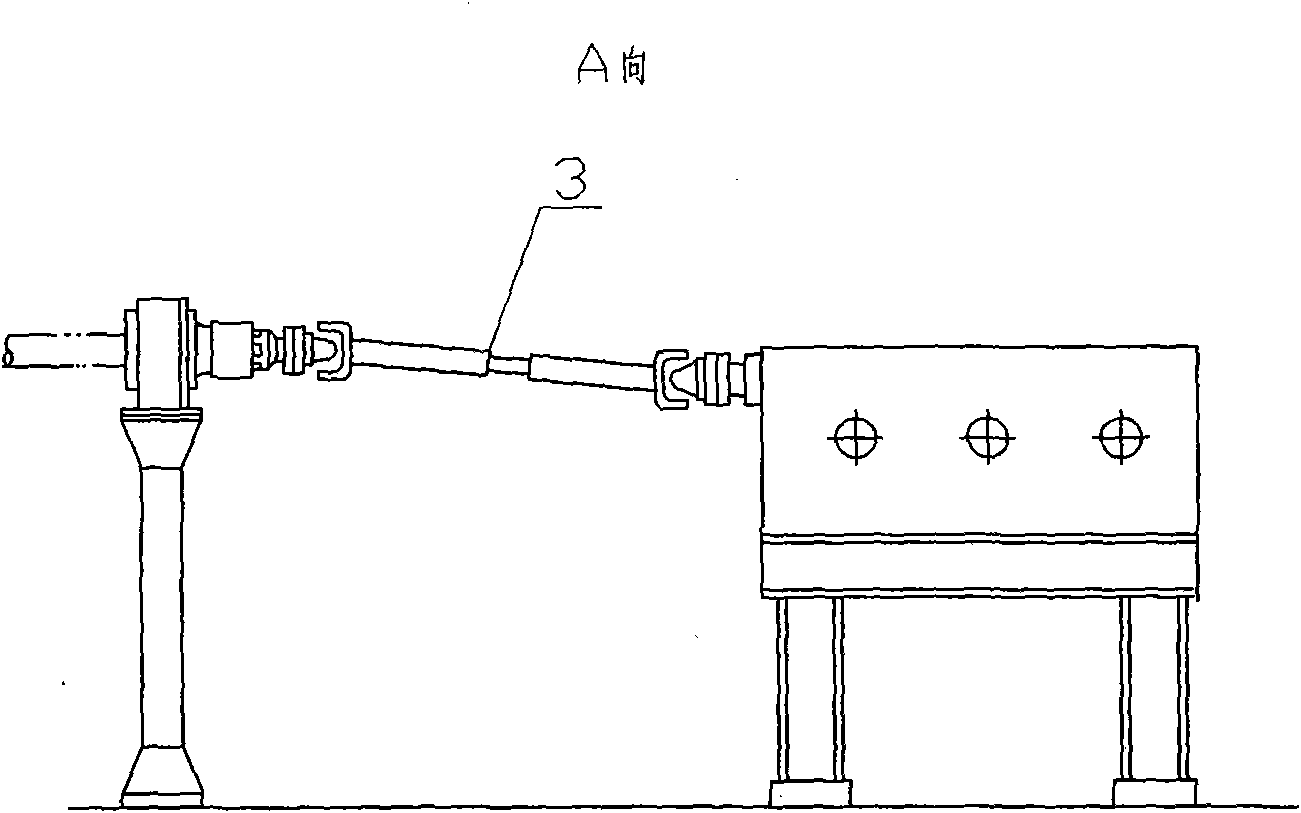

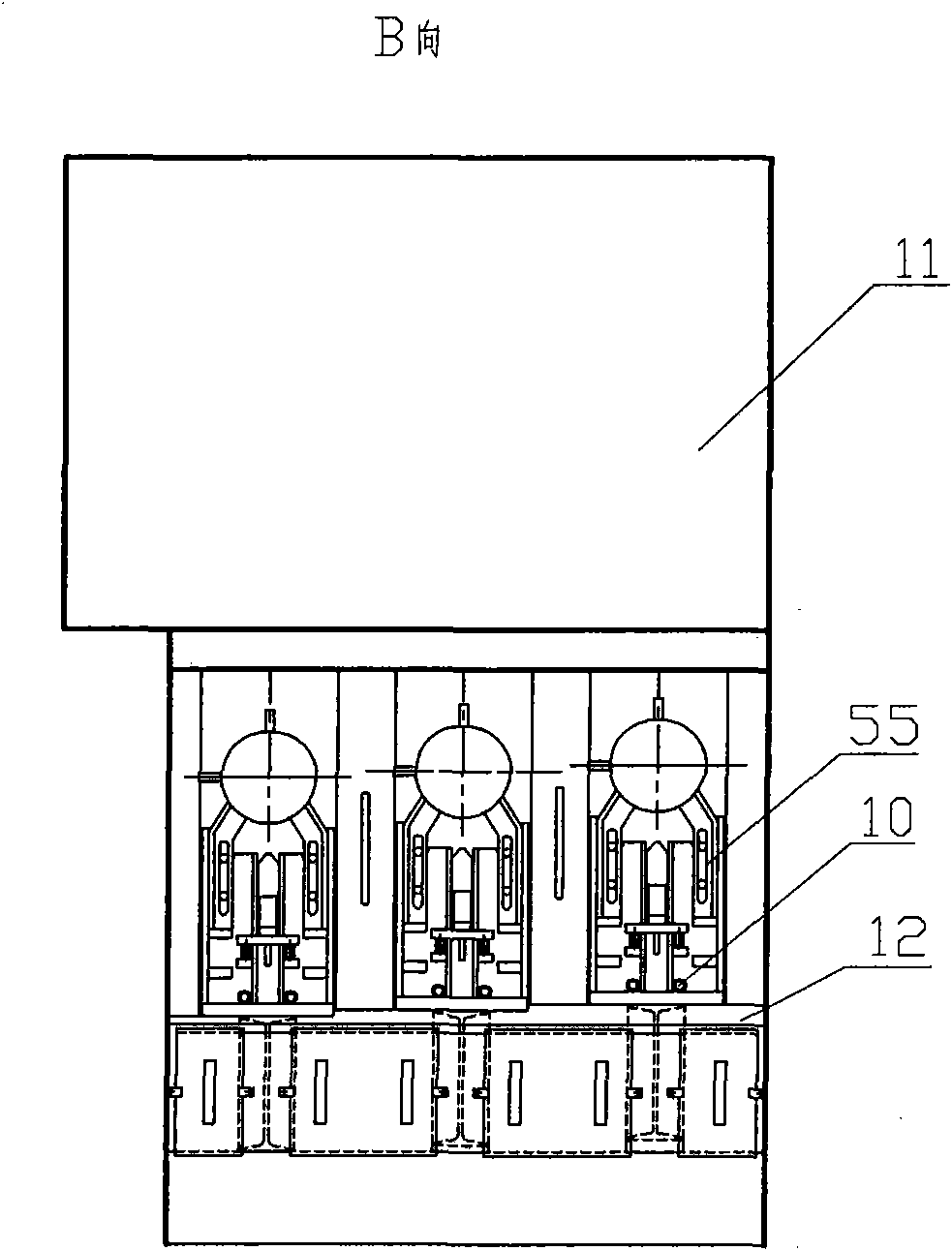

Float glass encapsulation box and roller replacing method thereof

ActiveCN102167496ASimplify the drivetrainSave workshop spaceGlass transportation apparatusDrive shaftEngineering

Owner:BENGBU TRIUMPH ENG TECH CO LTD +2

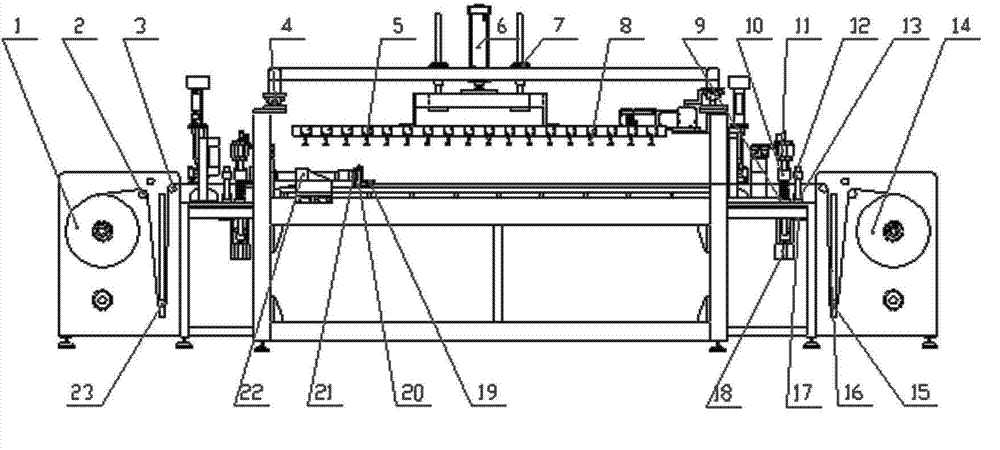

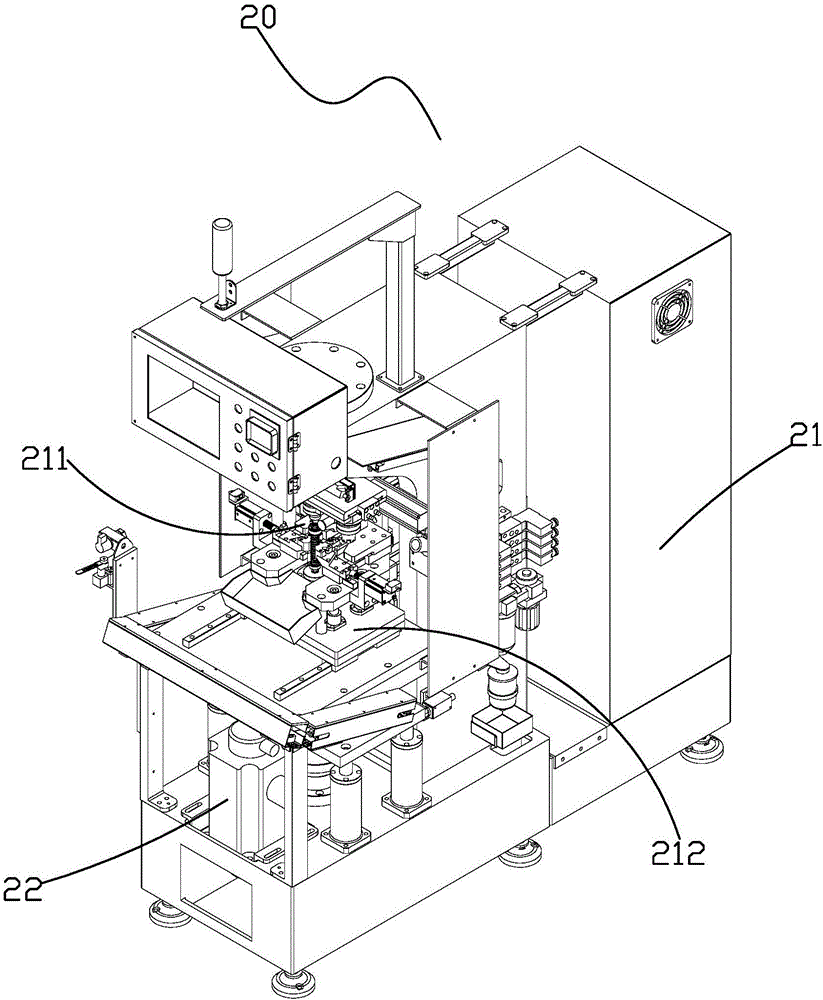

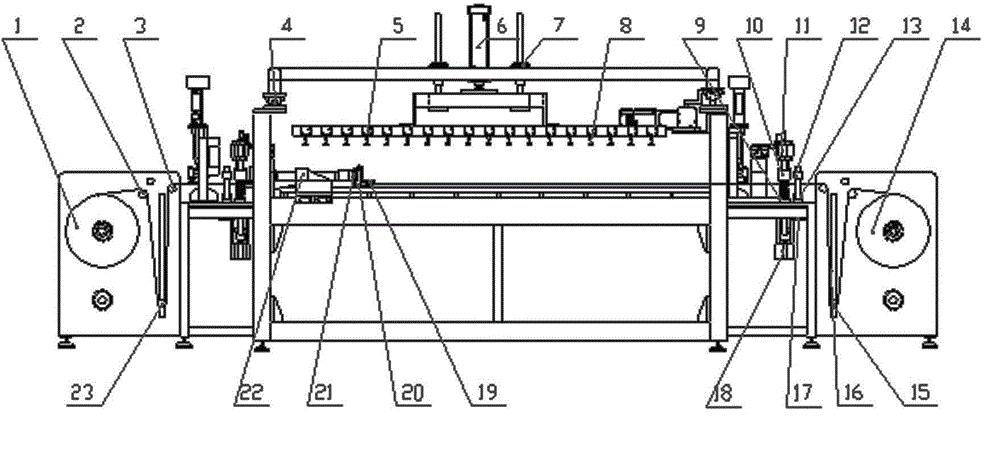

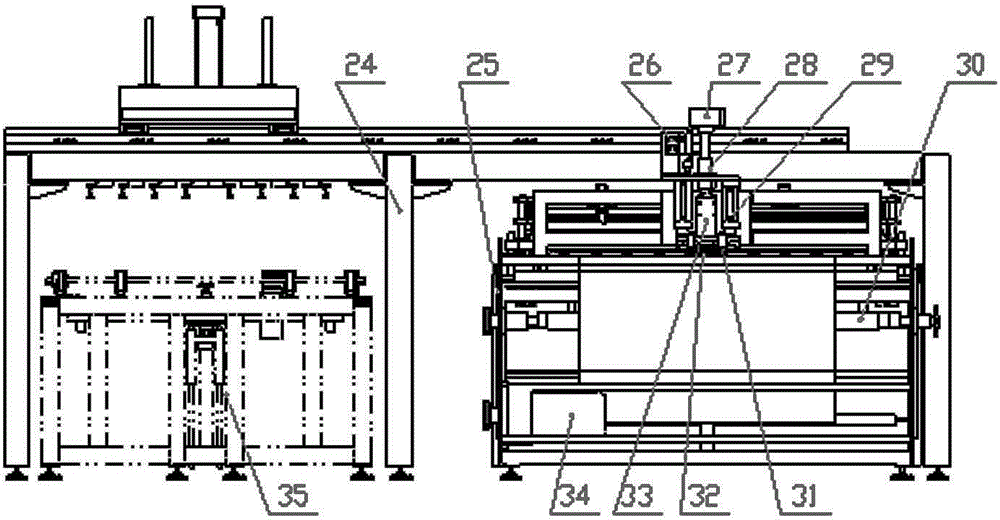

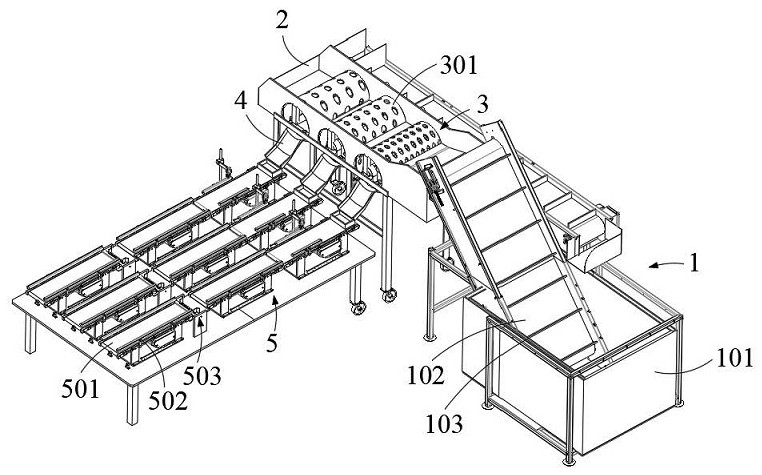

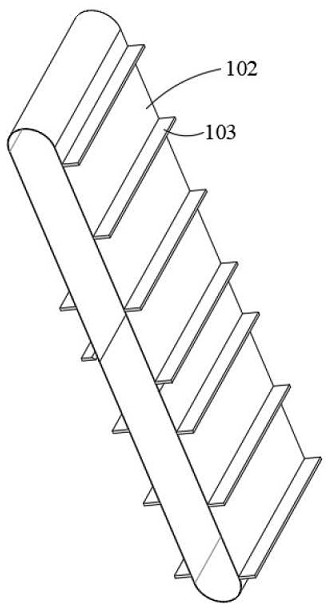

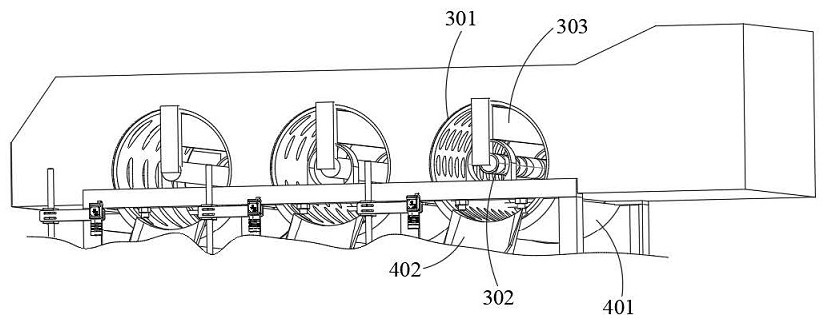

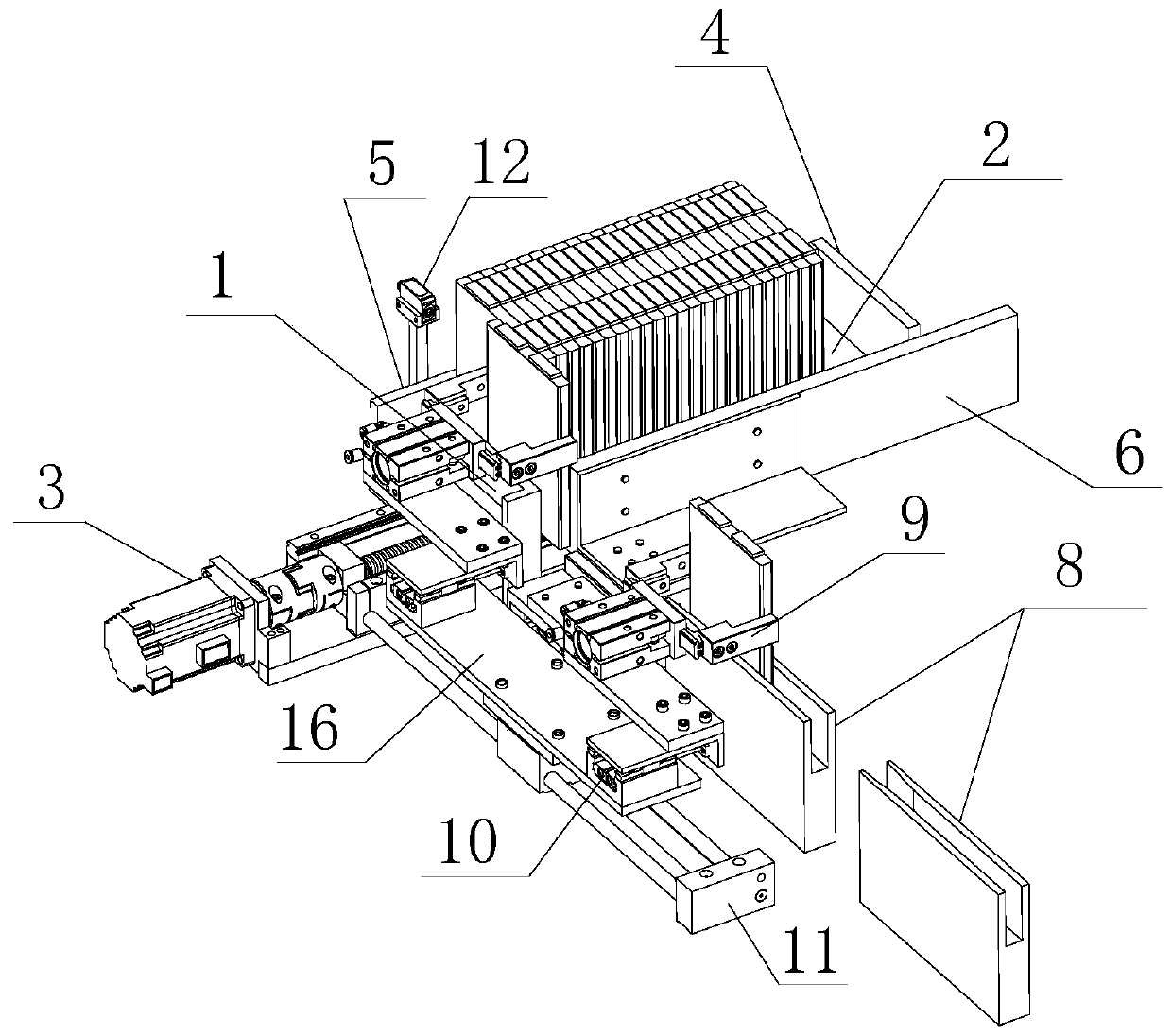

SLD (Super Luminescent Diode) automatic cutting and paving machine

ActiveCN102848413ACompact structureImprove the precision of fixed lengthMetal working apparatusEngineeringEthylene-vinyl acetate

The invention discloses an SLD (Super Luminescent Diode) automatic cutting and paving machine comprising an EVA (Ethylene Vinyl Acetate Copolymer) and TPT (Topotecan Hydrochloride) automatic cutting system and an automatic paving system located on the EVA and TPT automatic cutting system, wherein discharging devices and two punching devices and two cutting devices respectively connected with the two discharging devices are respectively arranged on the two ends of the EVA and TPT automatic cutting system, a material clamping and conveying device is arranged at the middle part of the EVA and TPT automatic cutting system, and the automatic paving system comprises a material paving device. Compared with the prior art, the machine has the advantages that the cutting and paving operations of solar cell panel EVA, TPT are integrated, so that the structure is compact and the operation is smooth and continuous, the locating and length fixing precisions in the cutting and punching operation are higher, the production benefit and the product quality are improved, and the manpower, physical resources and factory building space are saved.

Owner:秦皇岛硕谷光伏科技有限公司

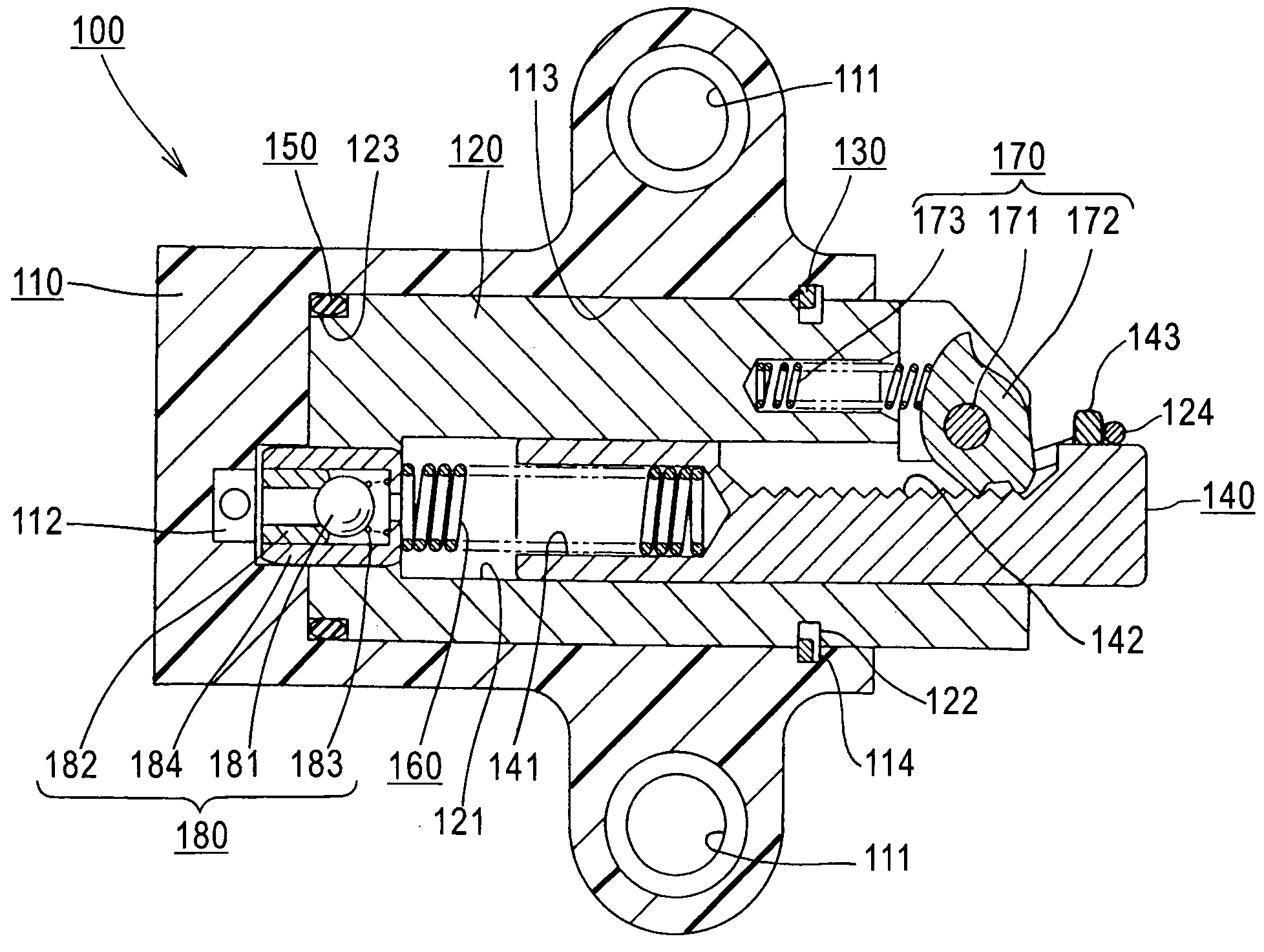

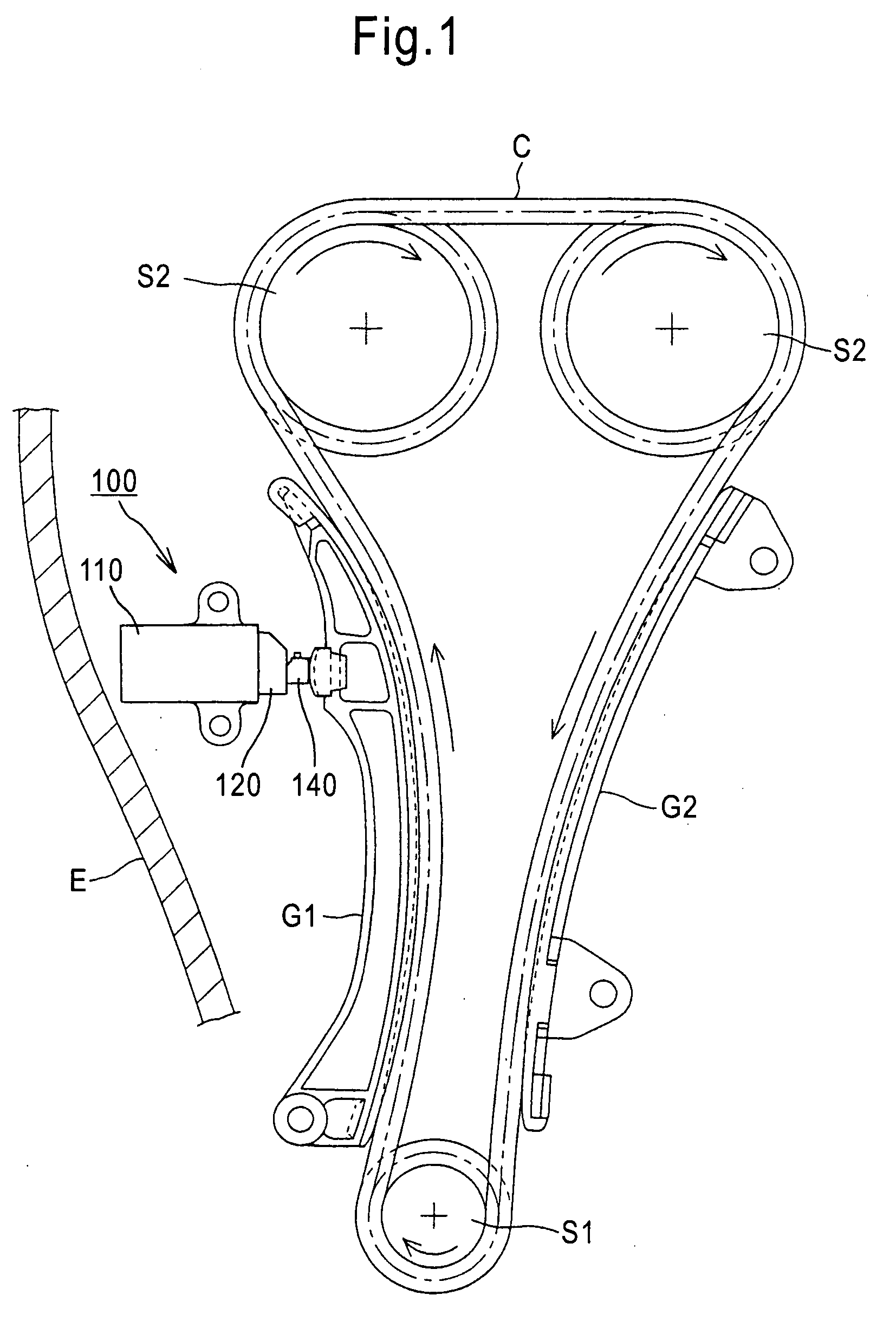

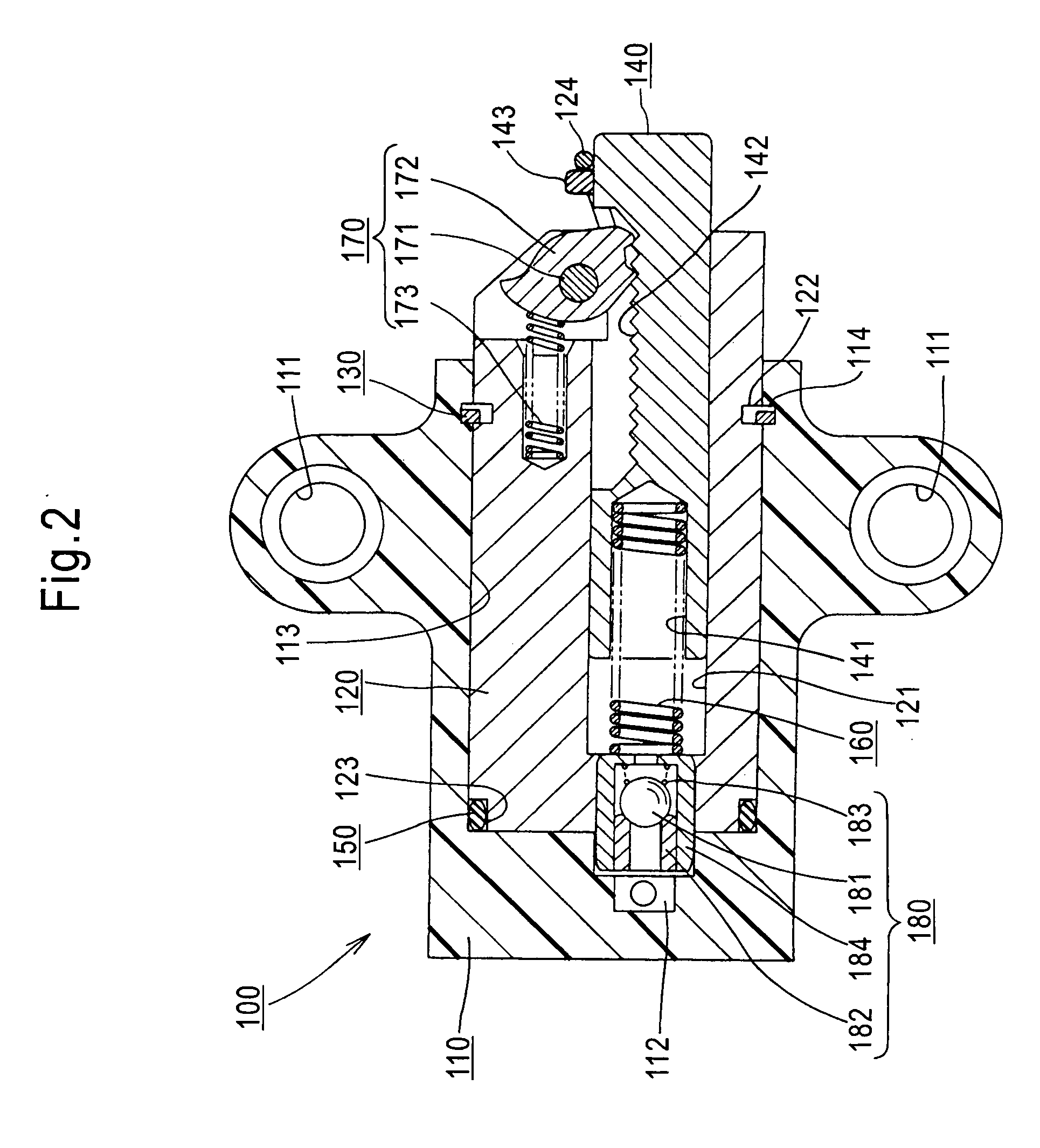

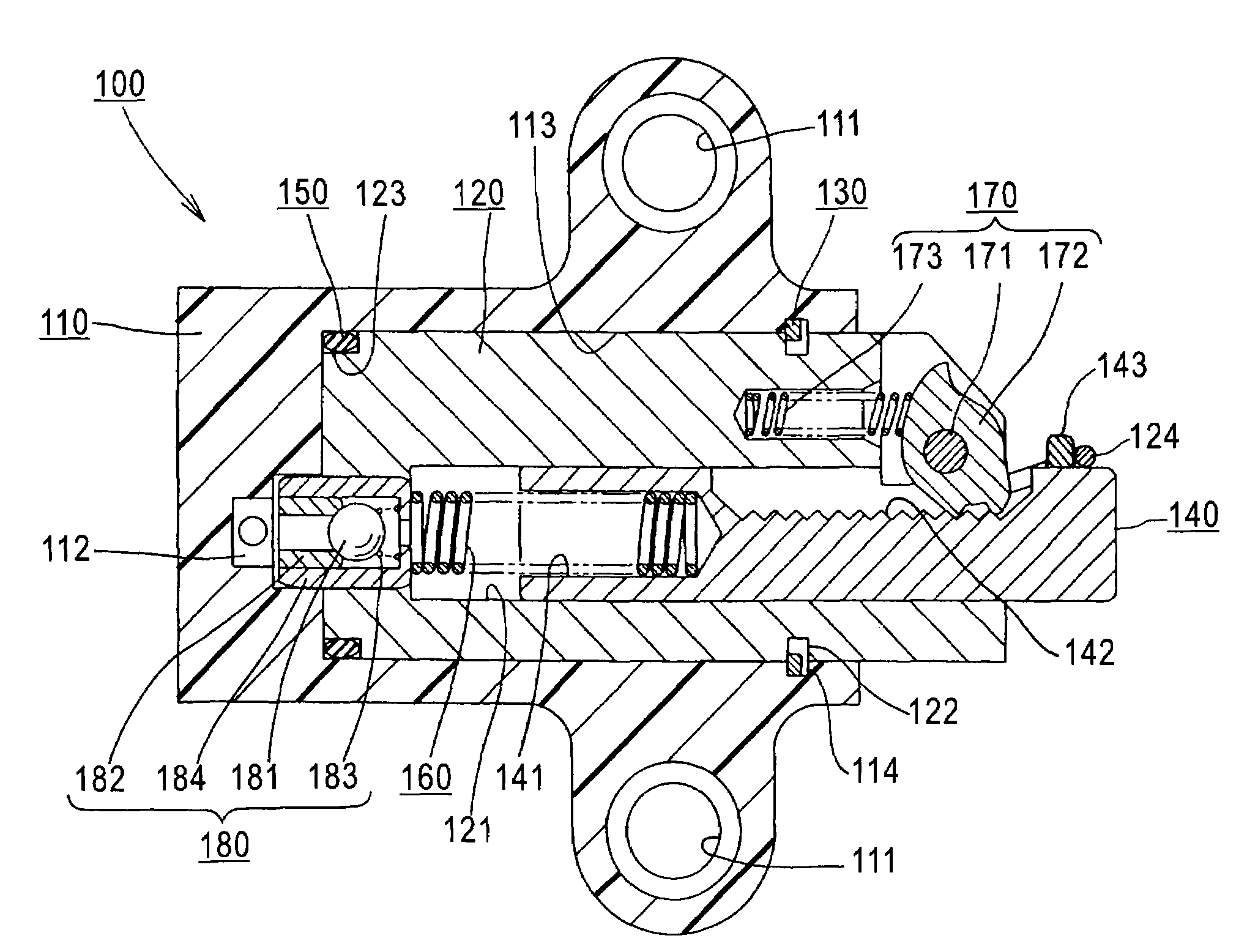

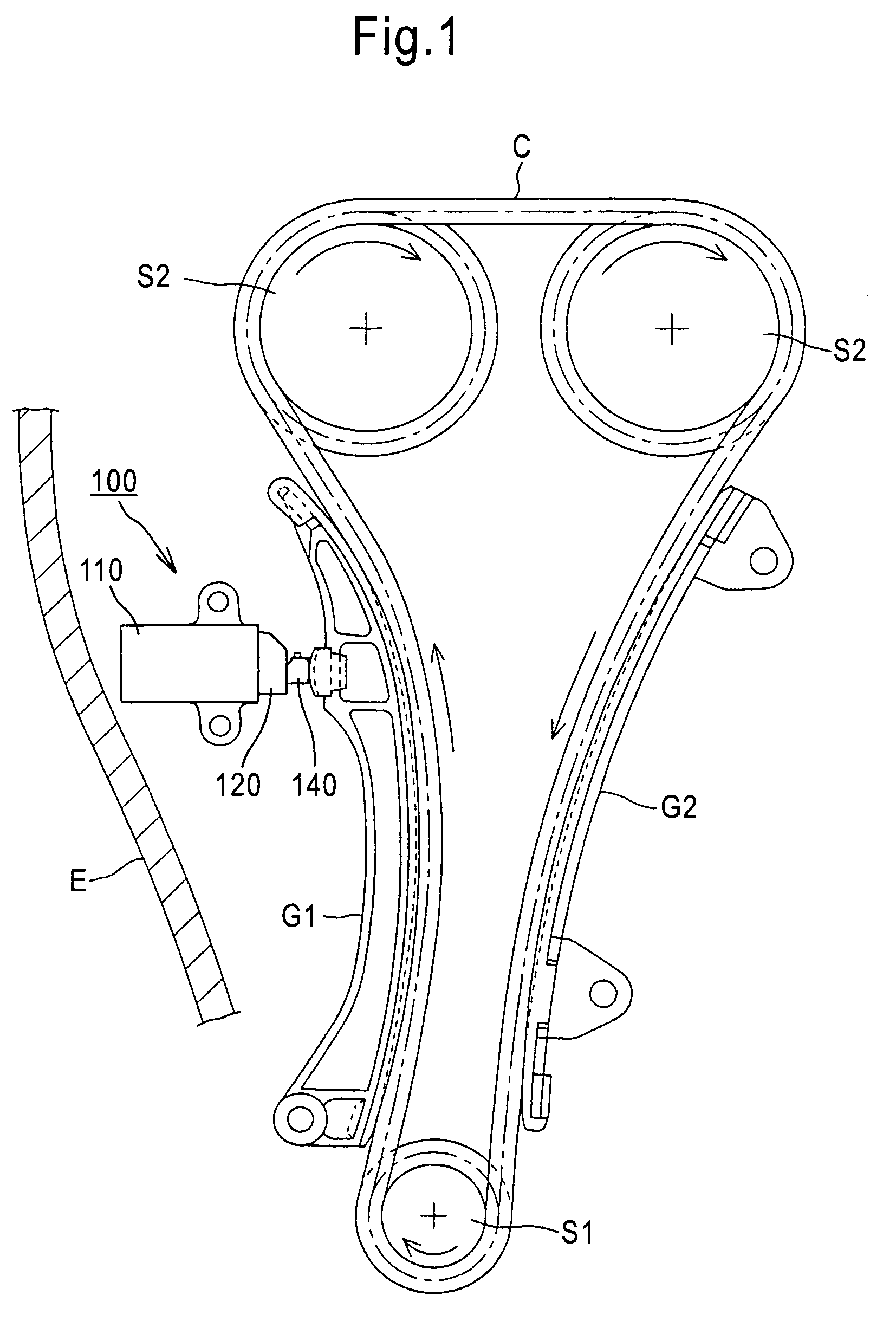

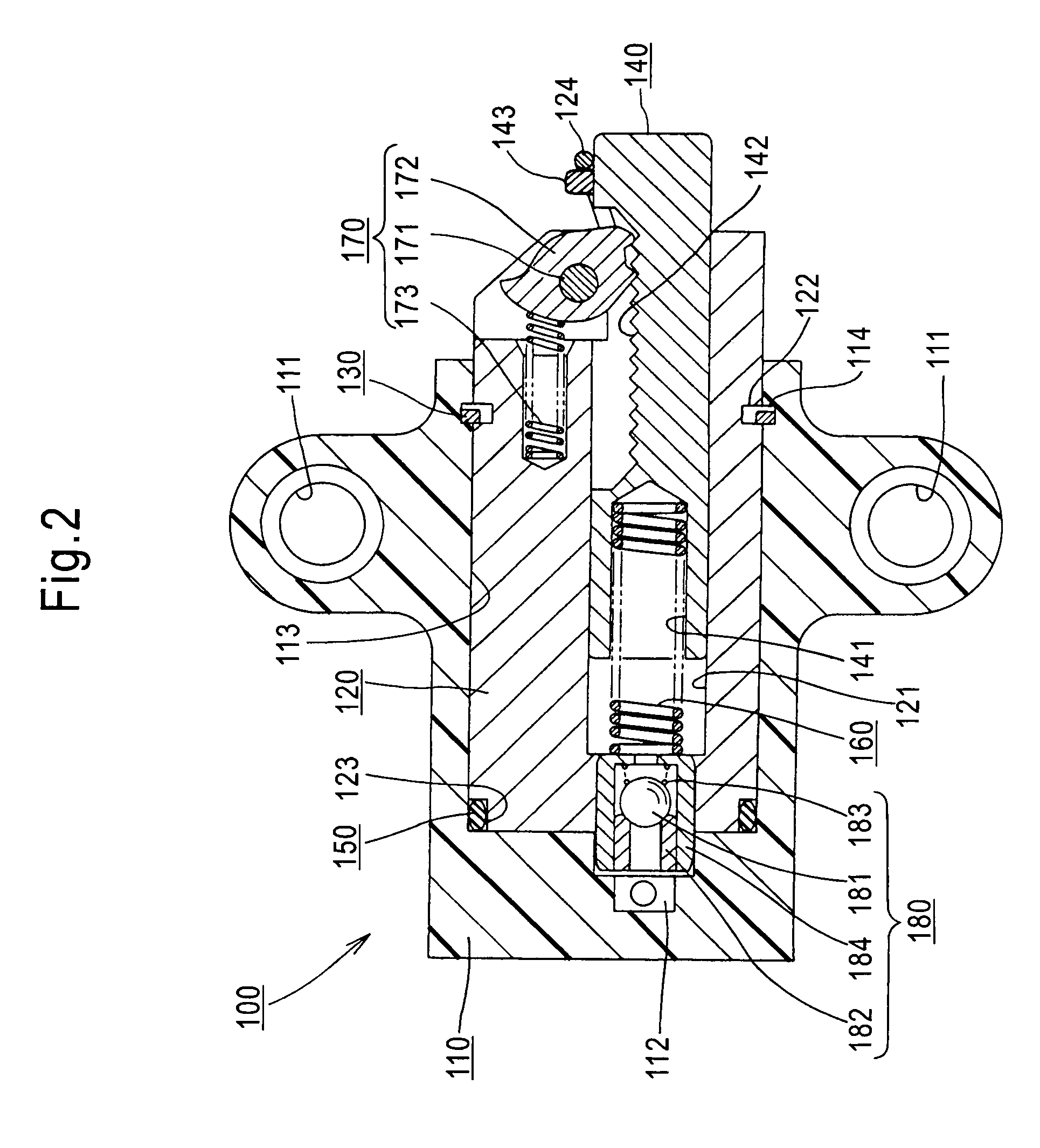

Hydraulic tensioner

In a hydraulic tensioner, a check valve provided on the rear end of a circular, cylindrical inner tensioner body, fits into a recess formed in the bottom of a hole in an outer body which receives the inner body. The check valve is radially offset from the center line of the inner body, and its engagement with the recess secures the inner body against rotation relative to the outer body.

Owner:TSUBAKIMOTO CHAIN CO

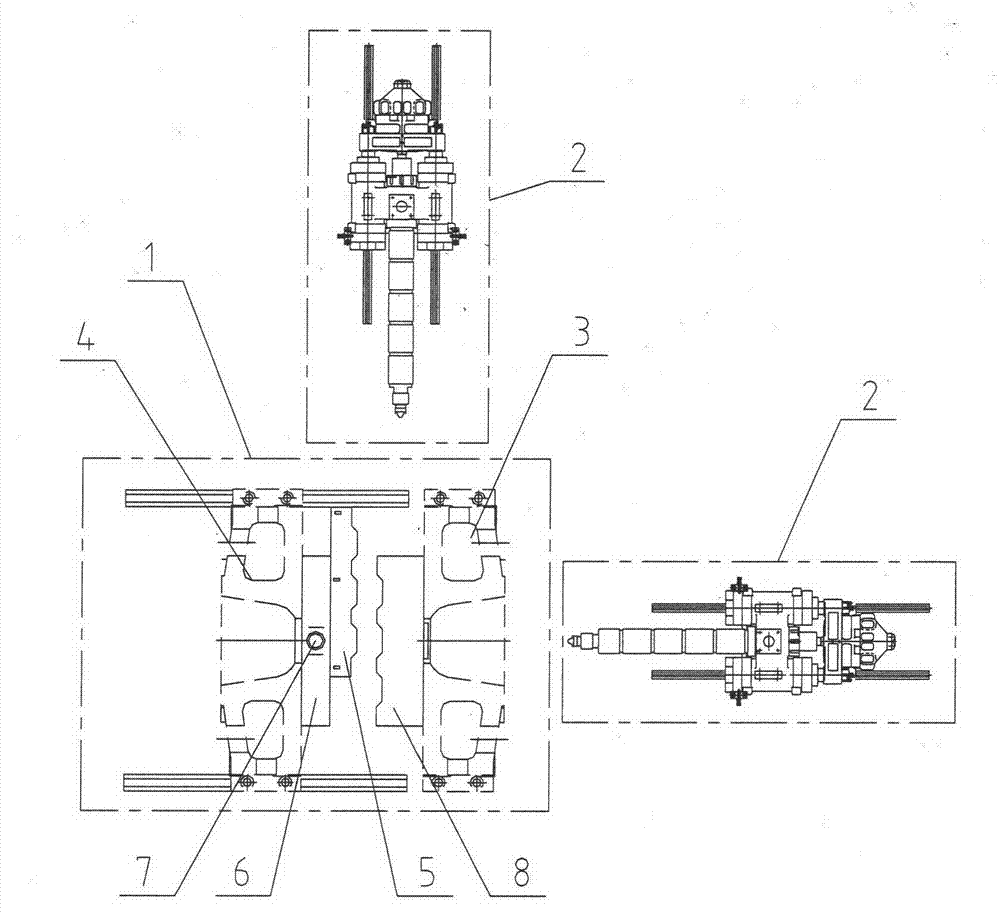

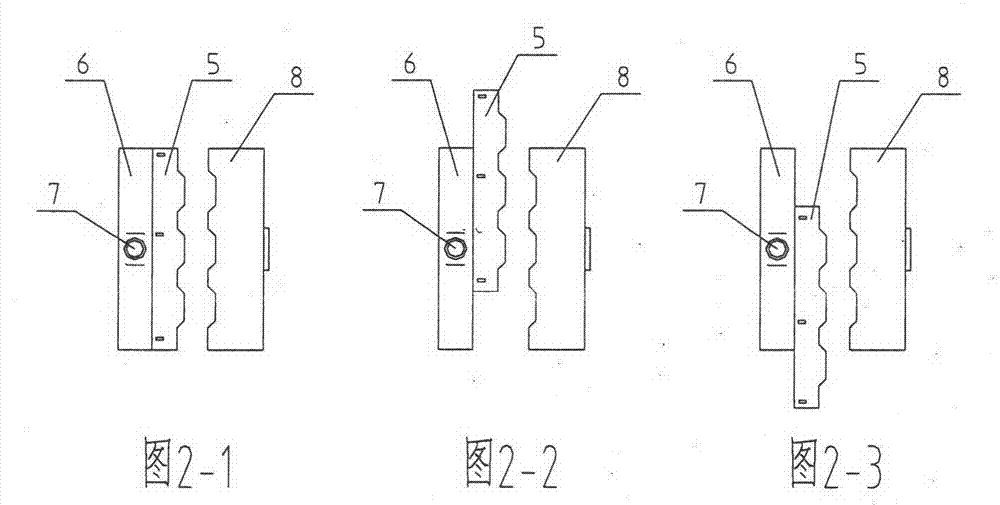

In-mold multi-station injection molding machine

The invention relates to an in-mold multi-station injection molding machine comprising a mold locking mechanism, an injection stage mechanism, and related driving and controlling mechanisms. A fixed plate and a moving plate are arranged on the mold locking mechanism. The fixed plate matches and is fixed with a fixed mold, and the moving plate matches and is fixed with a moving mold. A sub mold is arranged on the moving mold. The sub mold can perform relative movement on the moving mold through a sliding or rolling mechanism or other motion pair mechanisms. The relative movement of the sub mold is driven by a sub mold driving mechanism. The sub mold driving mechanism drives the sub mold, such that different station requirements are satisfied. Therefore, production processes such as in-mold assembling and multi-color multi-material injection are realized. According to the invention, some processes requiring secondary processing, especially movable parts, are executed in the mold. When a plastic product leaves the mold cavity, the product is already a finished product. Therefore, product assembling quality stability and fit compactness are improved, labor and material resources are saved, and factory spaces are saved.

Owner:BORCH MACHINERY

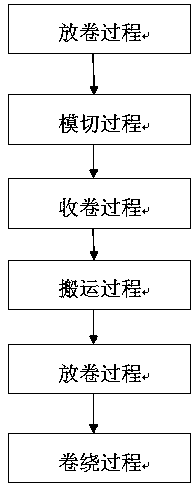

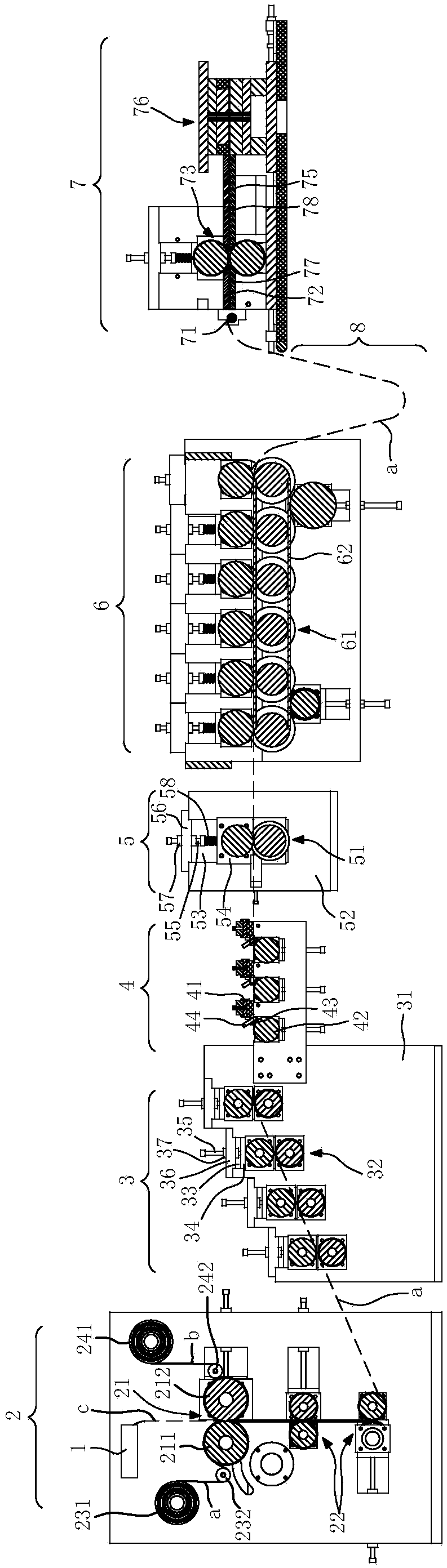

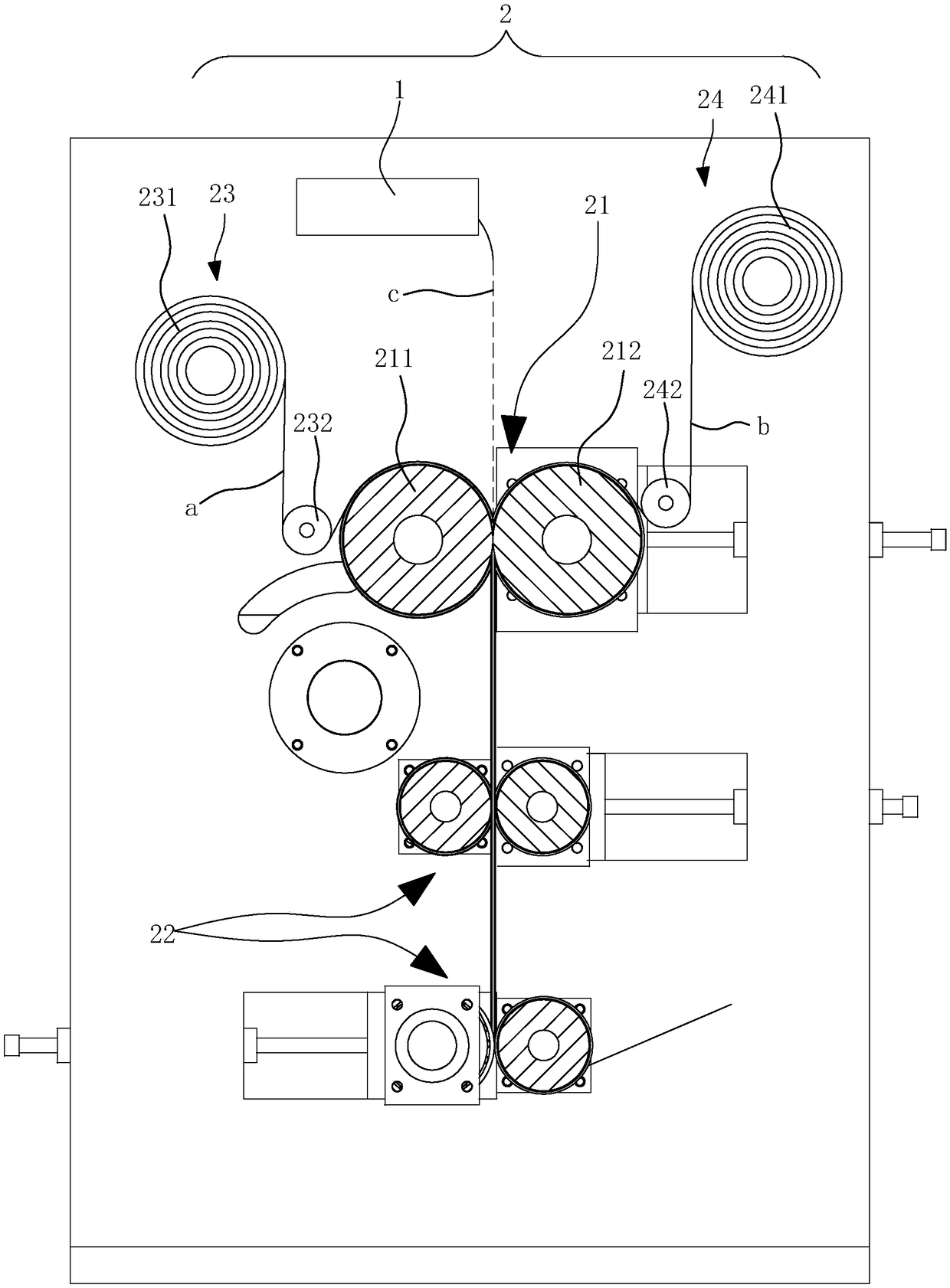

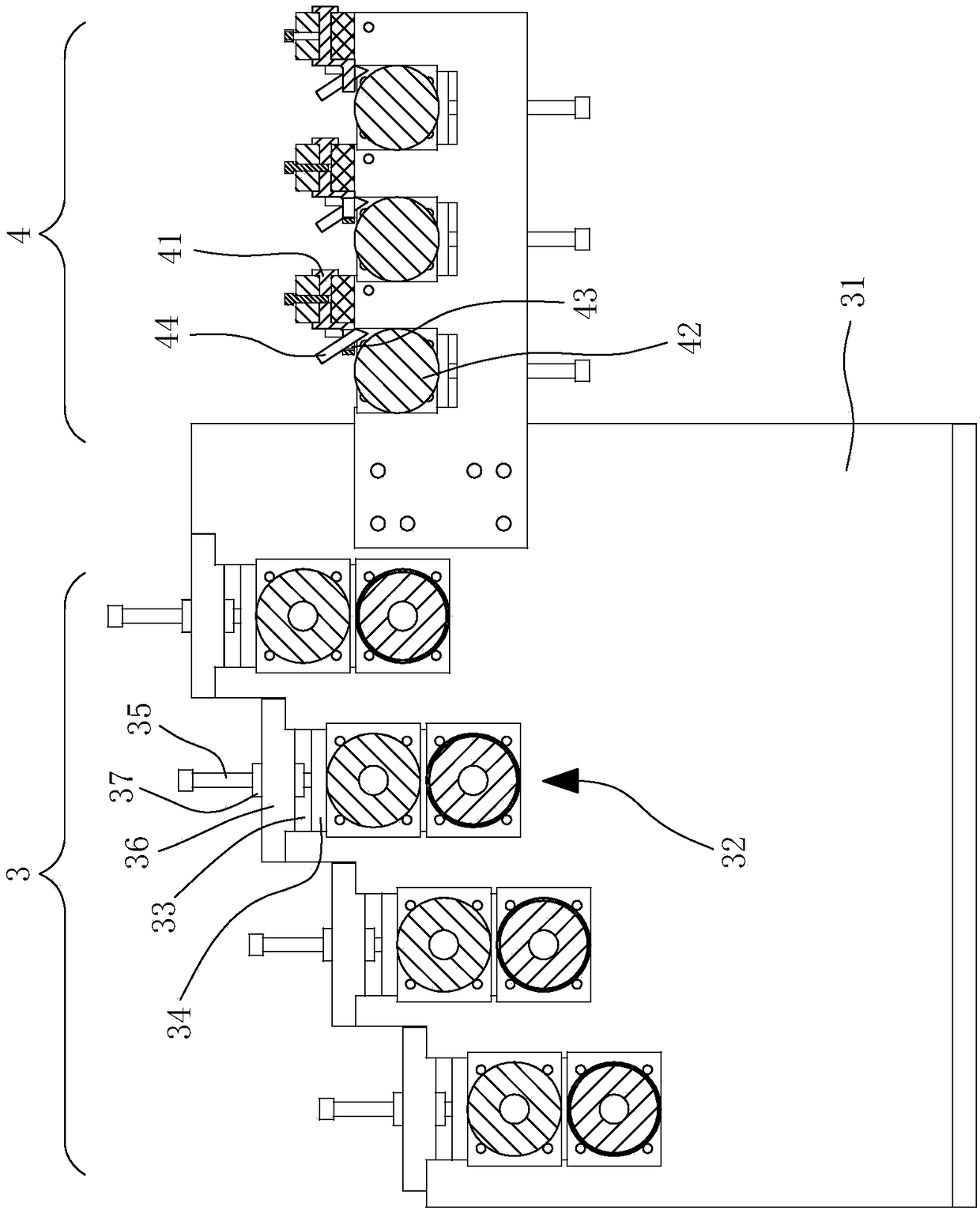

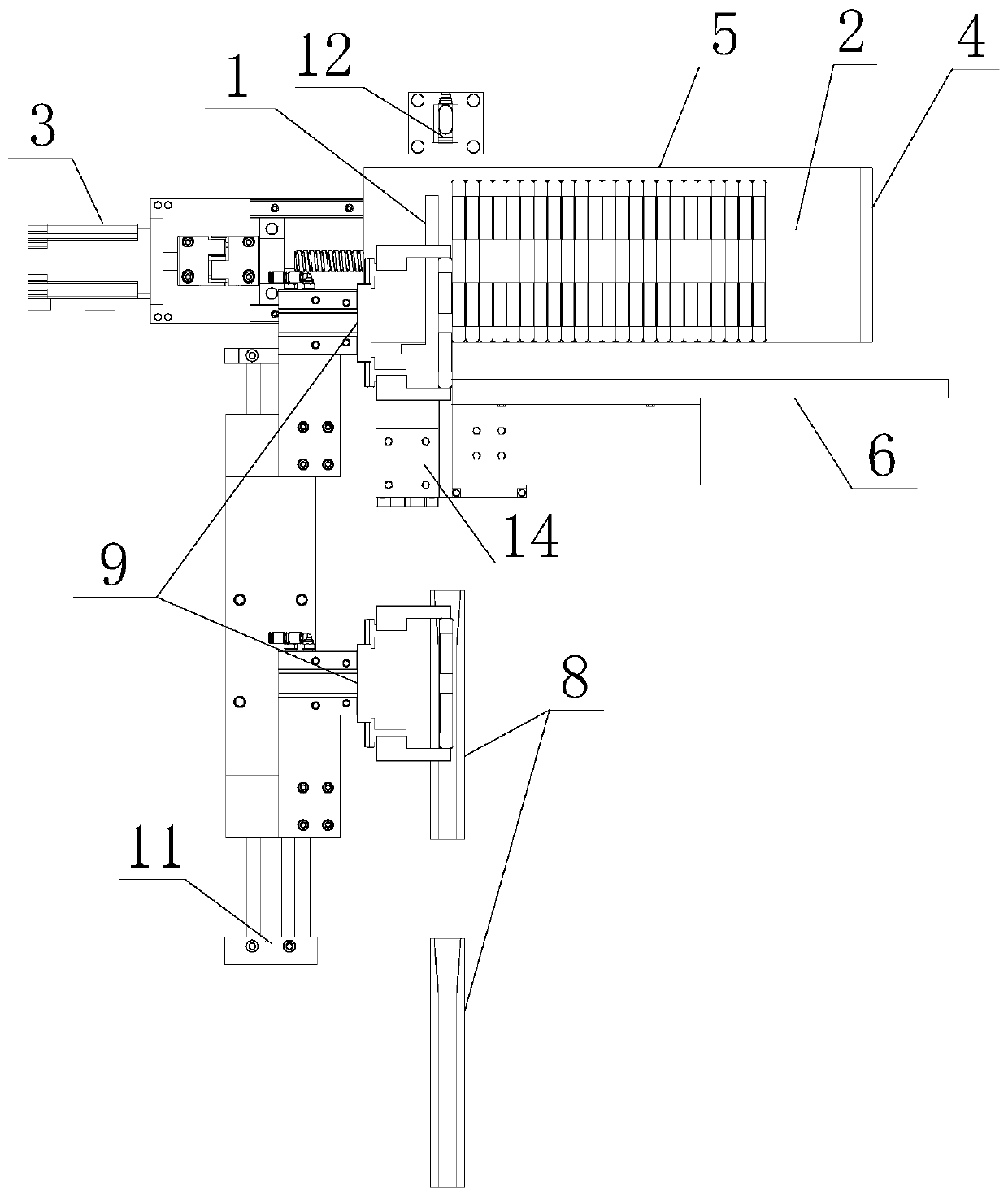

Battery cell winding method and winding equipment

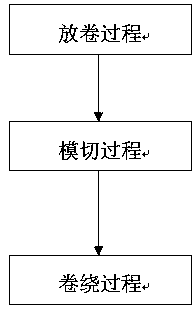

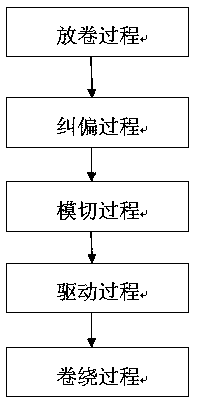

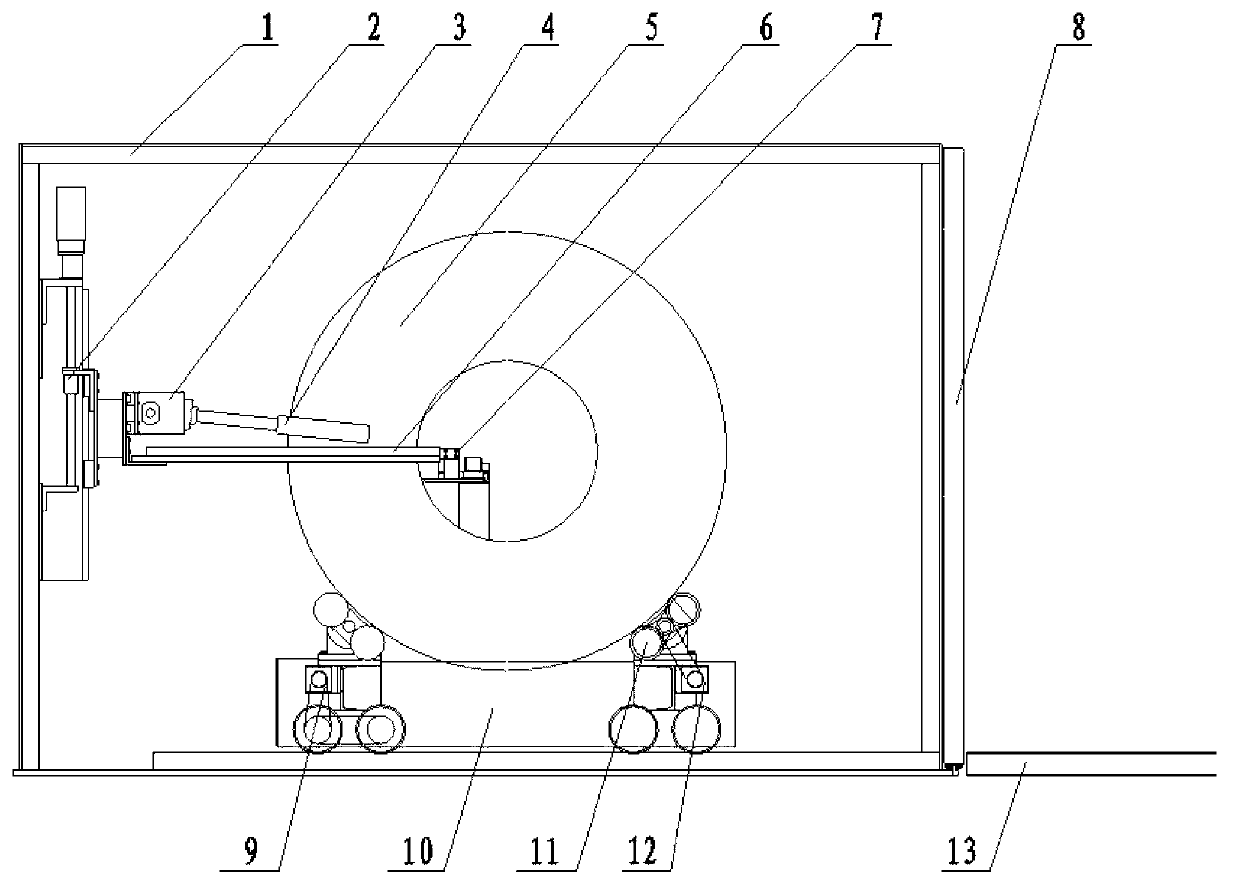

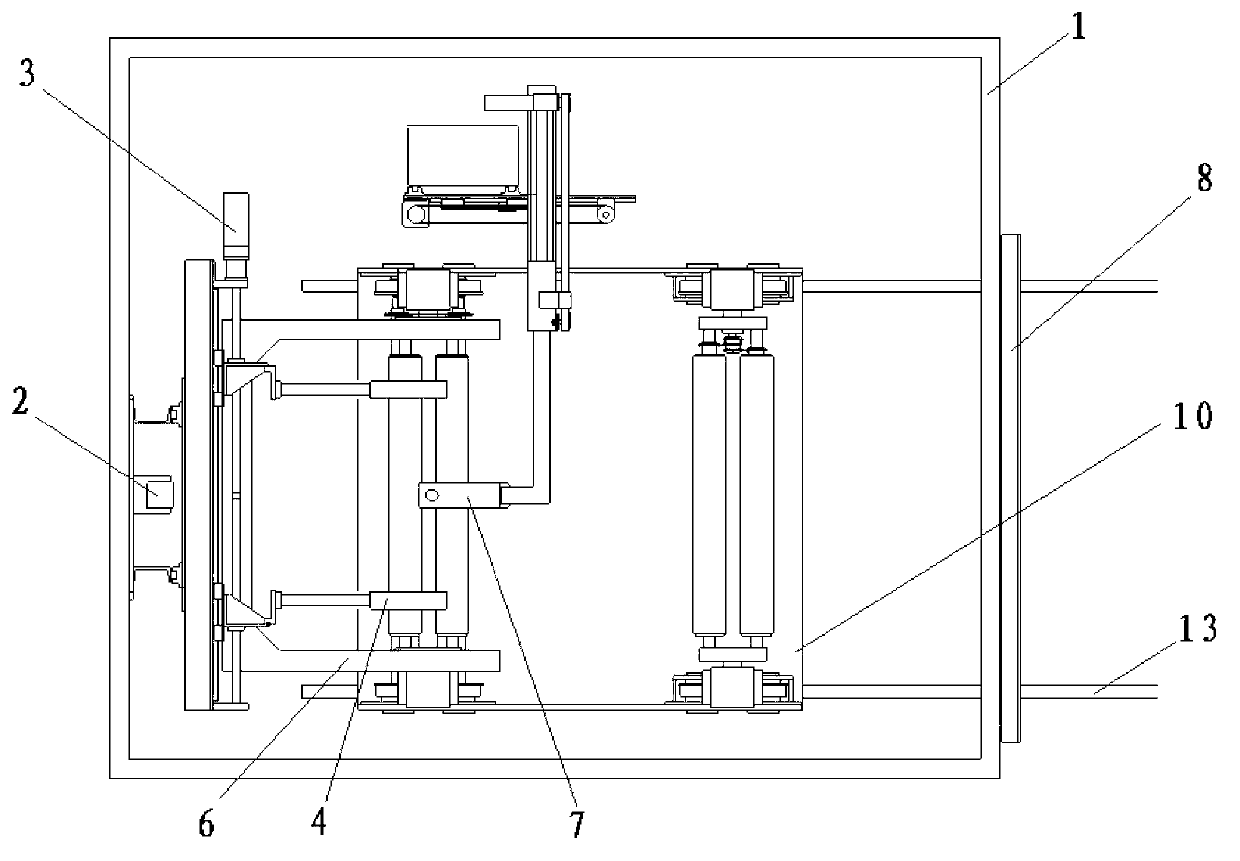

PendingCN107946663AWinding Process ImprovementSave labor costFinal product manufactureSecondary cellsEngineeringConductor Coil

The invention provides a battery cell winding method, and belongs to the field of automatic equipment. The battery cell winding method comprises the following steps of unwinding process, in which a pole plate in a roll is unwound; die cutting process, in which the unwound pole plate is cut by a die; and winding process, in which the die-cut pole plate is wound to form a battery cell. Moreover, theinvention also discloses winding equipment. The existing battery cell winding process flow is improved, two steps of die cutting and winding are combined into one step, the pole plate is directly transferred to the winding process after unwinding in one time and after die-cutting process is completed, die cutting and winding are simultaneously performed, labor cost and time are reduced, and the production efficiency is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

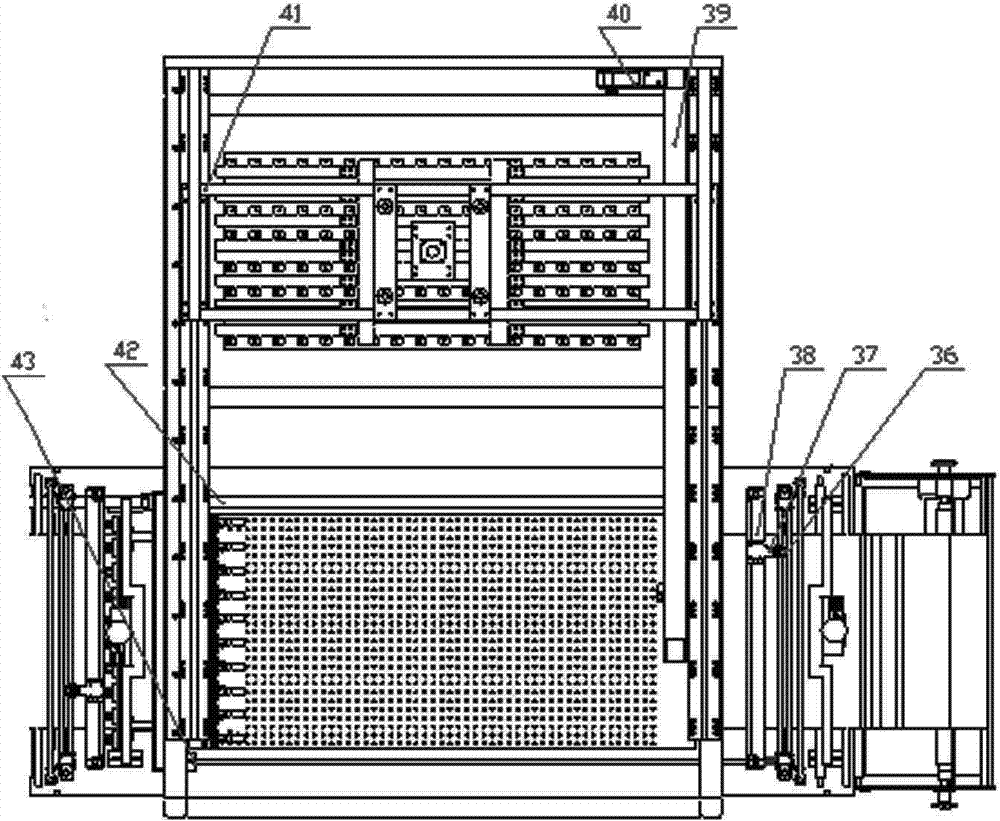

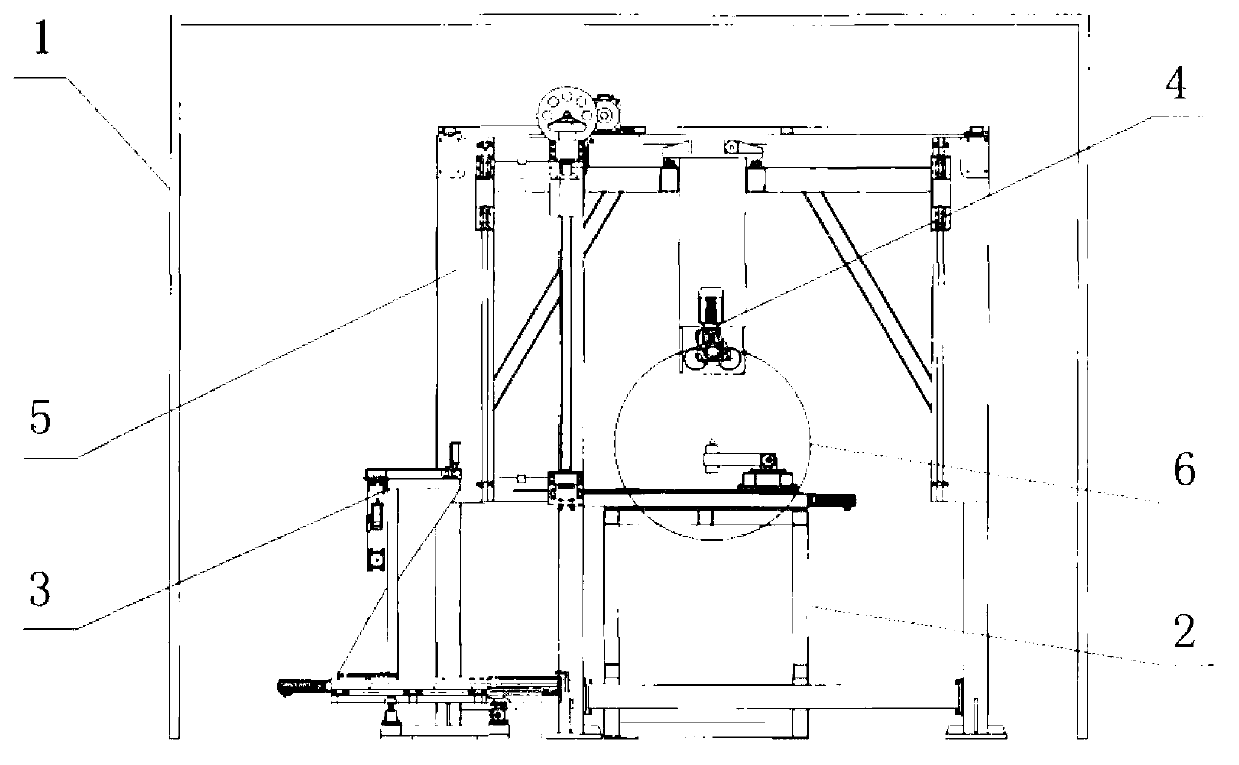

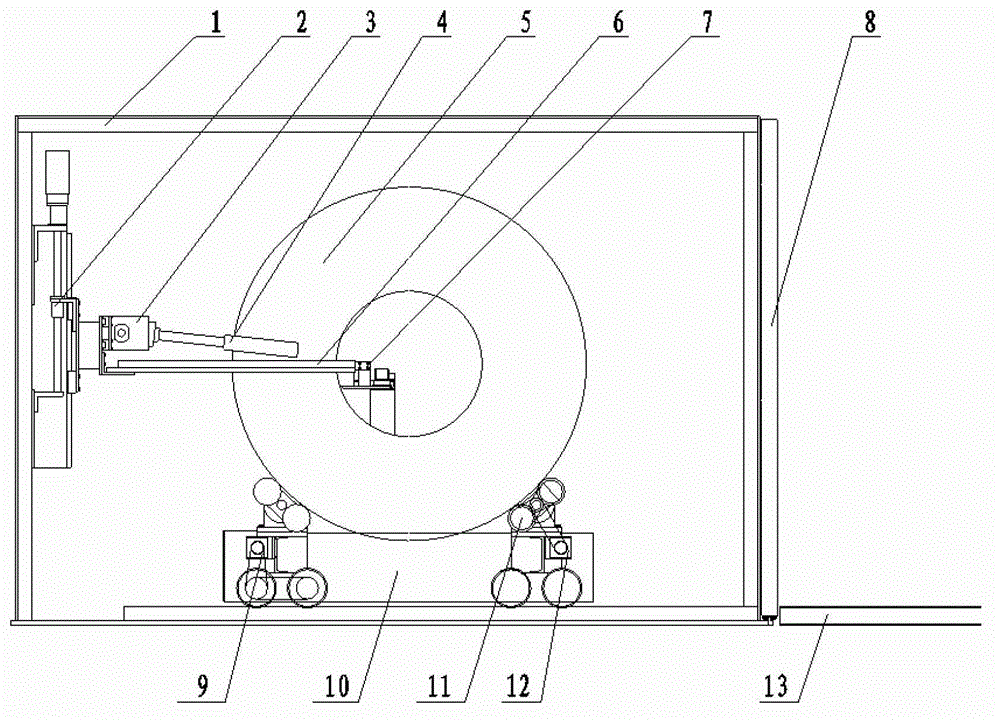

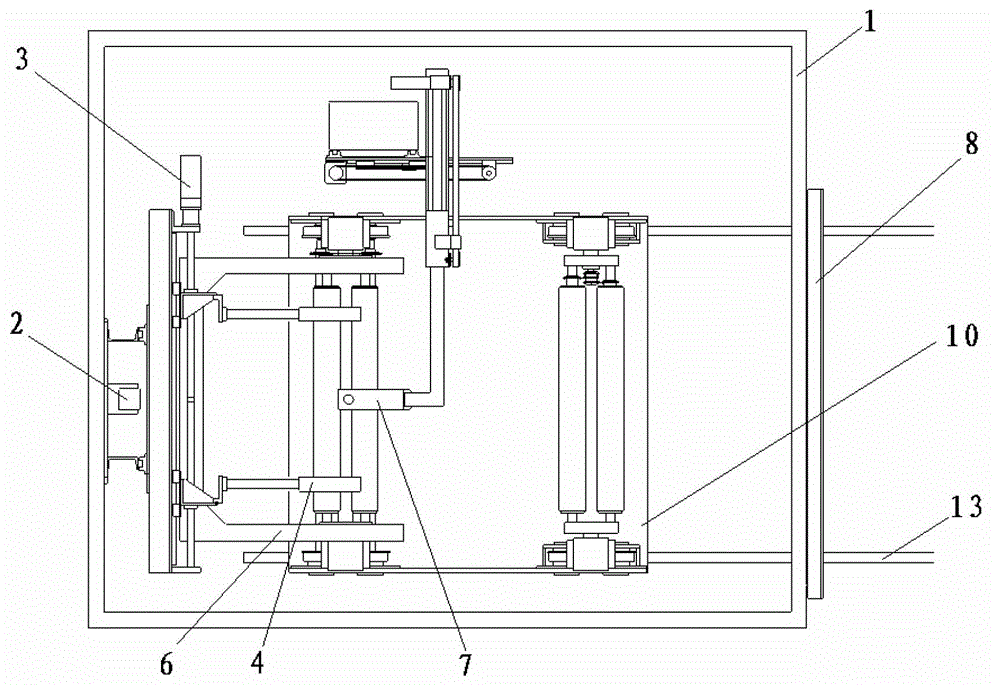

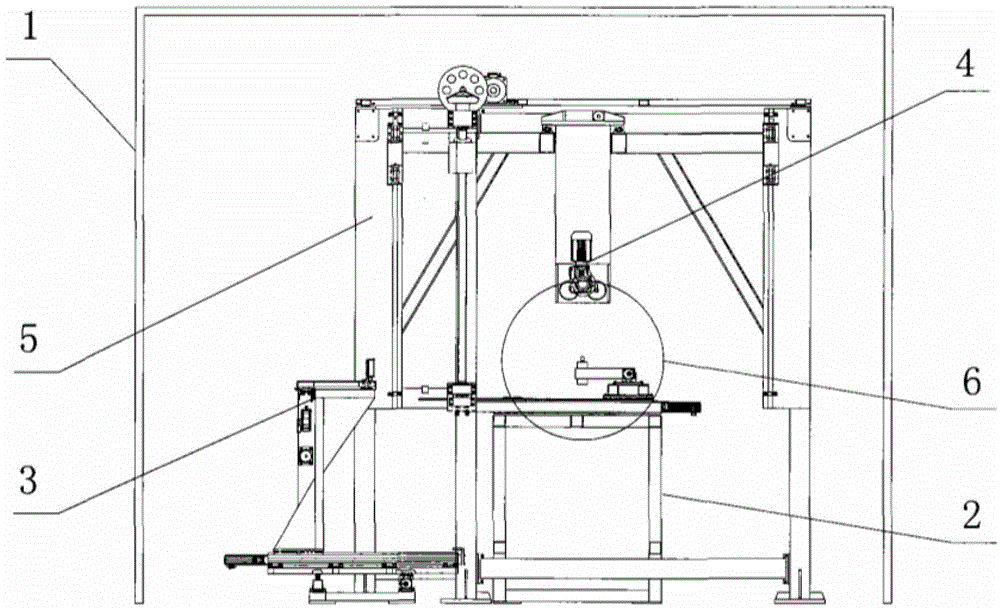

X-ray detection method and full-automatic detection equipment for engineering tires

ActiveCN103105404ASmooth rotationRadial stabilityMaterial analysis by transmitting radiationAutomatic test equipmentX-ray

The invention discloses an X-ray detection method and full-automatic detection equipment for engineering tires. The method comprises the step of detecting the interior of a tire to be detected in an X-ray protection chamber by virtue of a ray tube and an imaging sensor, and specifically comprises the following steps of: mounting the tire on a carrier vehicle on rails outside the ray protection chamber, and moving the vehicle to a preset position in the protection chamber and closing a protection door when the tire is mounted on the vehicle, wherein the tire bearing part of the vehicle is a tire rotating mechanism consisting of multiple rollers; and starting a tire centering mechanism and the tire rotating mechanism, rotating the tire on the rollers of the tire rotating mechanism, adjusting the tire to an accurate detection position through the centering mechanism, starting the imaging sensor and the X-ray tube to preset positions for detection, and displaying and storing detected images in a computer. The method has the advantages that the size of the X-ray protection chamber is reduced, and the construction cost is reduced; the tire rotates stably, and thus the imaging precision is improved; radial run-out caused by concave and convex parts of the excircle of the tire is prevented; and moreover, radiation during manual operation is eliminated.

Owner:辽宁仪表研究所有限责任公司

Full-automatic rolling composite molding machine for plastic sheet double-sided composite materials

InactiveCN109466066ASave the cost of plant space and equipmentReduce manufacturing costMetal working apparatusWebs handlingPlastic filmEngineering

The invention discloses a full-automatic rolling composite molding machine for plastic sheet double-sided composite materials, and the machine includes a discharge port connected to an extruder, a compound molding unit, a cooling unit, a cutting unit, a belt traction unit and a numerical control punching unit, the discharging port is arranged above the composite molding unit, the cooling unit, thecutting unit, the belt traction unit and the numerical control punching unit are arranged at the rear of the composite molding unit in sequence, the composite molding unit cutting unit is composed ofa pair of mold rollers, a pair of primary cooling rollers and unwinding devices, the pair of mold rollers are left and right aligned, the discharge port is arranged above the pair of mold rollers, each forming roller of the pair of mold rollers is correspondingly provided with a set of unwinding device, the unwinding device releases the coil to the forming roller, and a free falling space for products is reserved between the belt traction unit and the numerical control punching unit.

Owner:何浩然

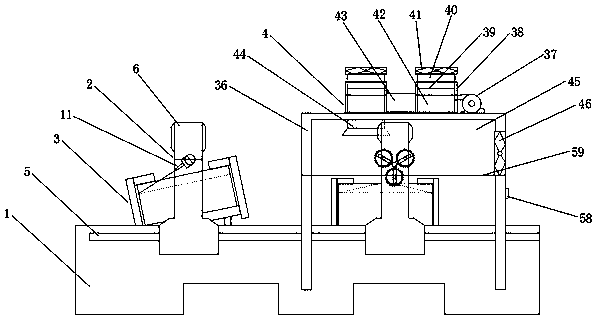

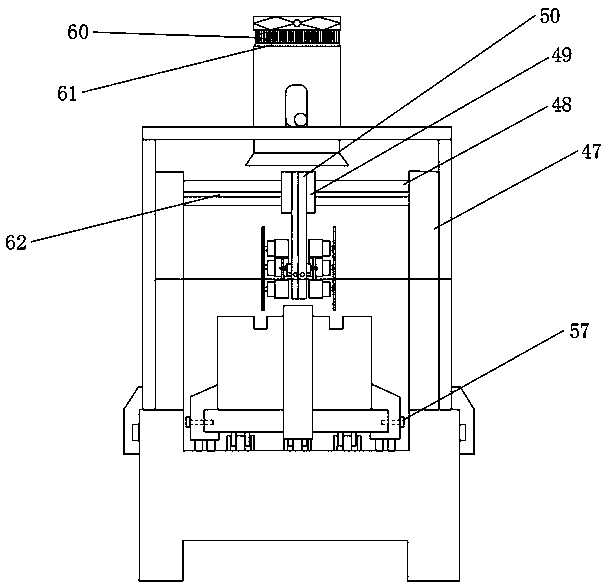

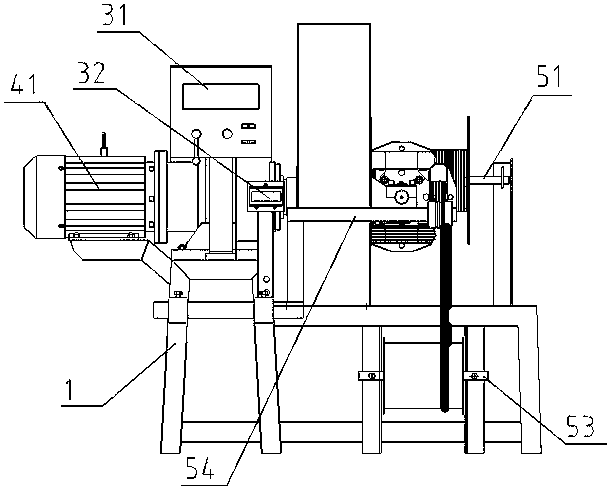

Manpower saving combined anode carbon block slotting equipment

InactiveCN108789857ASmall sizeSave workshop spaceWorking accessoriesStone-like material working toolsElectric machineryWater jet

The invention provides manpower saving combined anode carbon block slotting equipment. The manpower saving combined anode carbon block slotting equipment comprises a machine base, a water cutting device, an automatic fixing device, a mechanical cutting device, an automatic feeding device and a control system. The water cutting device, the mechanical cutting device and the automatic feeding deviceare transversely erected on the machine base in a sliding manner. The automatic fixing device is in sliding connection into the machine base. The water cutting device is provided with water jet cutterspraying ports and a numerical control operation platform. The mechanical cutting device is provided with a sound isolation hood, and the sound isolation hood is divided into a cooling section and acutting section. The cooling section is provided with a cooling device established on the basis of semiconductor refrigeration sheets. The cutting section is provided with a cutter changing motor, a cutter rest and cutting blades. The automatic fixing device is provided with a bent track and is divided into a transverse fixing device body and an axial fixing device body, and both-way automatic clamping is conducted. The automatic feeding device is arranged at the end portion of the machine base. The manpower saving combined anode carbon block slotting equipment is ingenious in design, excellent in effect and capable of saving manpower, lowering noise and mechanical loads and optimizing the producing and manufacturing technology.

Owner:李春洪

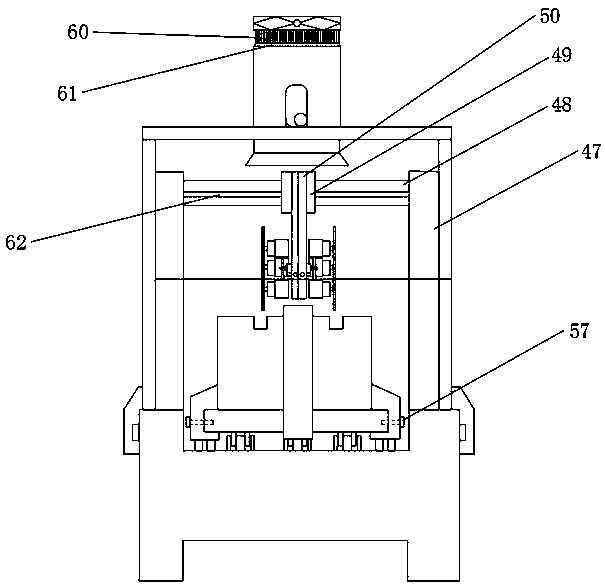

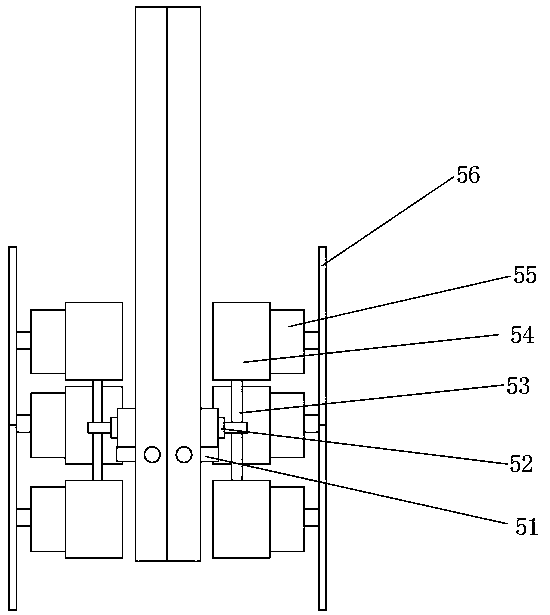

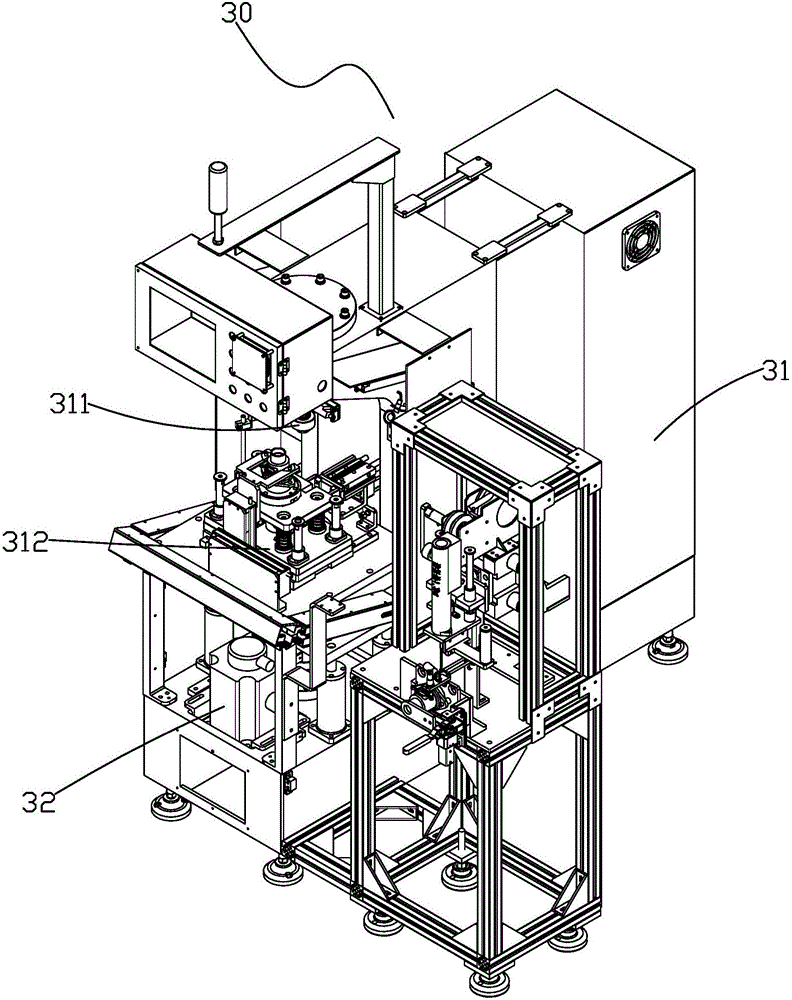

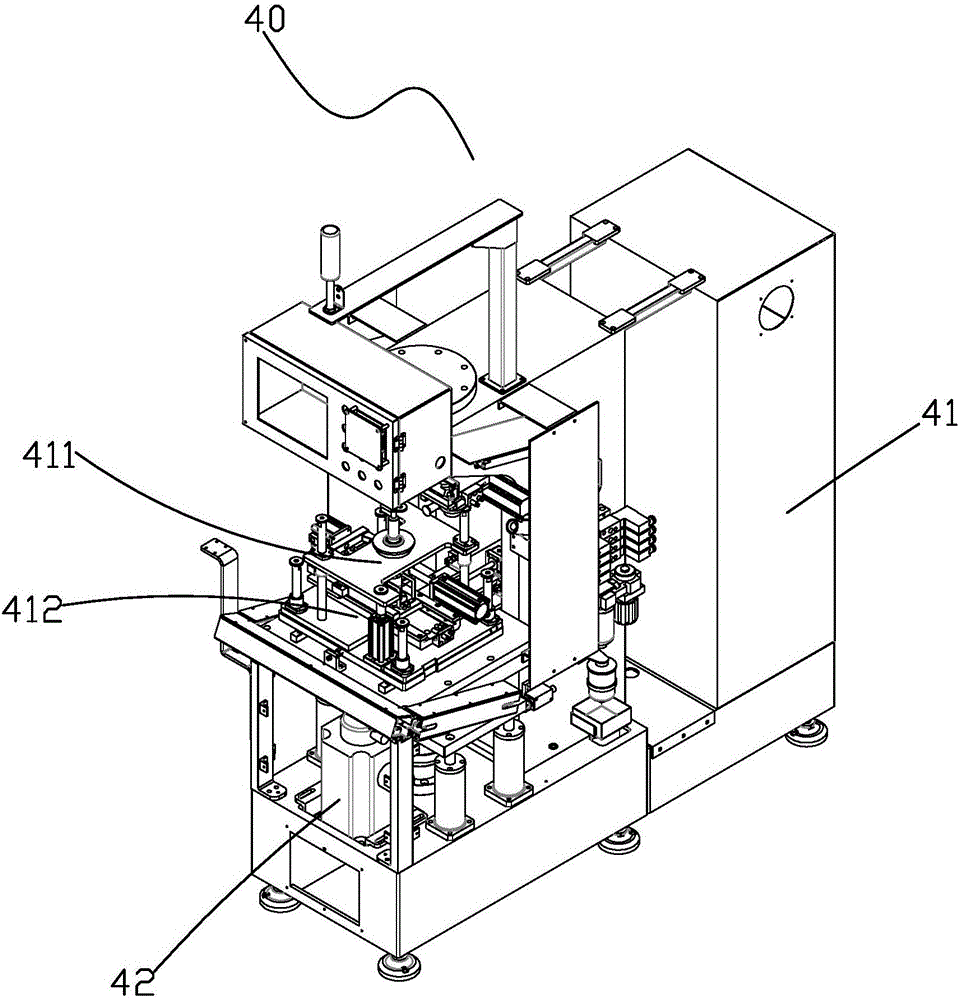

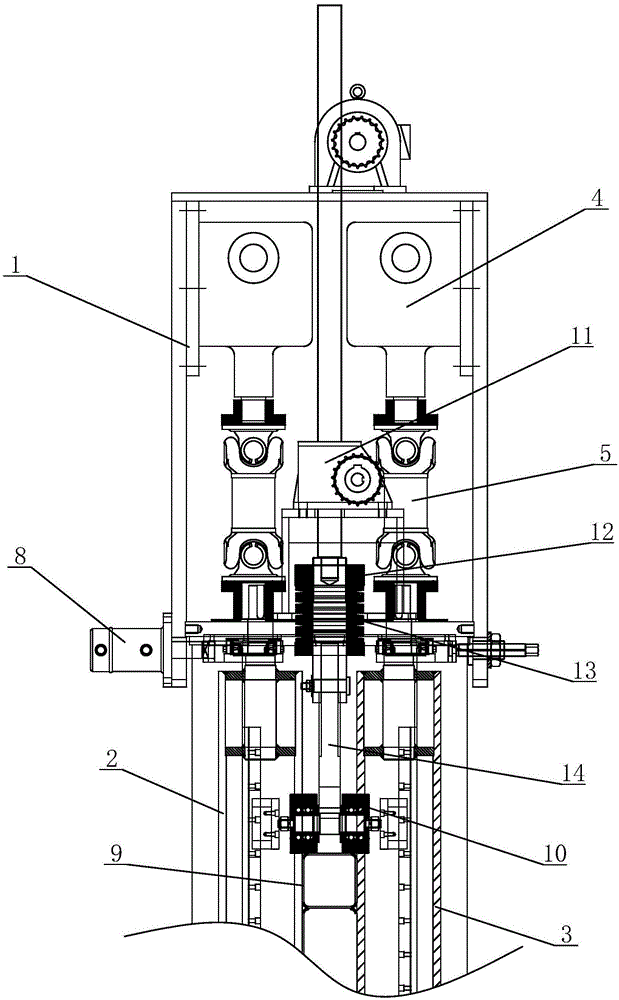

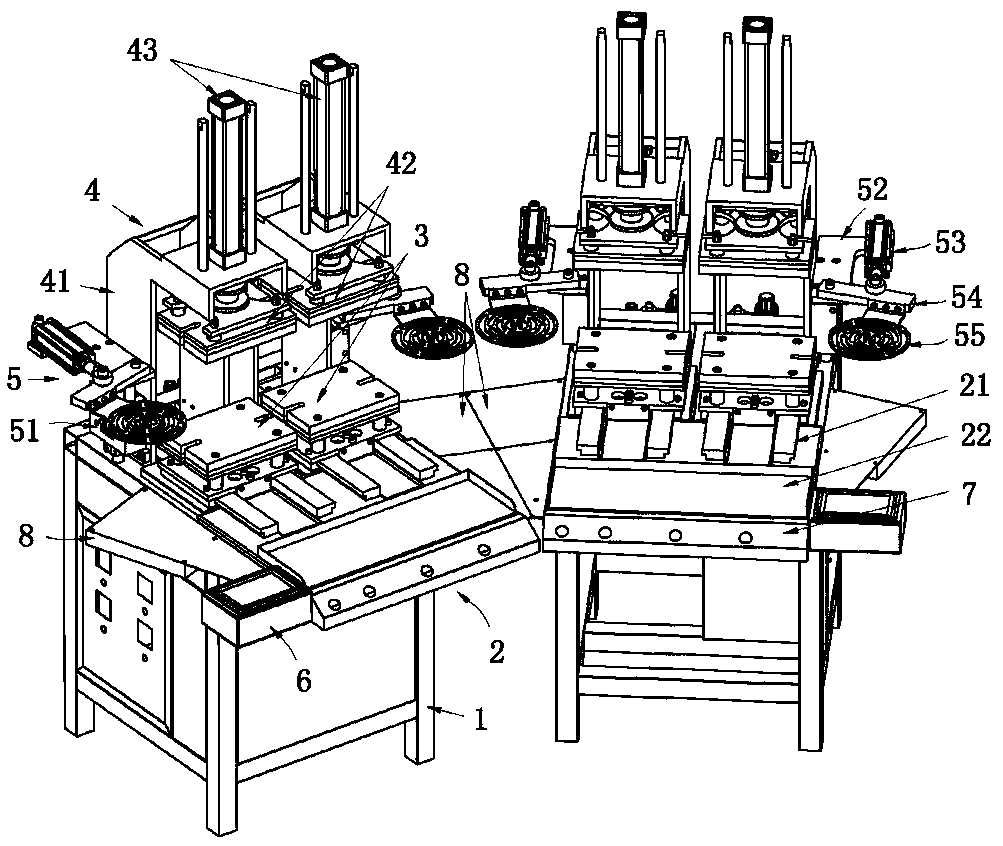

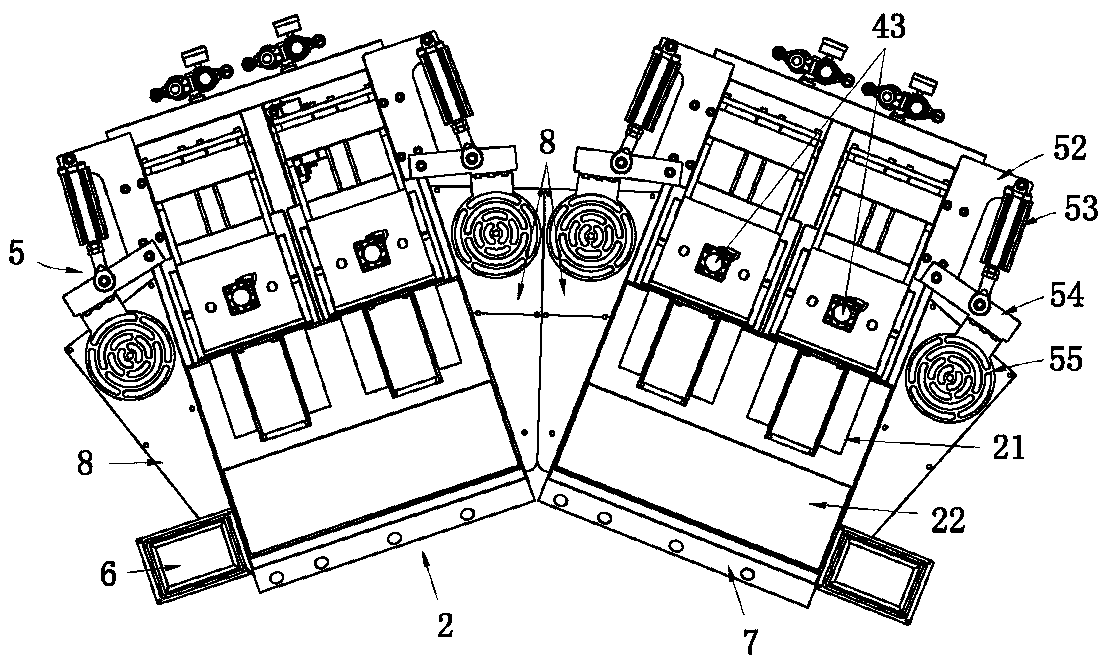

Press-fit production line for manufacturing of parts in electric power steering system

The invention discloses a press-fit production line for manufacturing of parts in an electric power steering system. The press-fit production line comprises a workpiece conveying belt used for conveying machined workpieces, wherein a worm bearing press-in machine, an oil seal component press-in machine, a torsion bar press-in machine, a magnetic yoke press-in machine, a bottom cover press-in machine, a first needle bearing press-in machine and a second needle bearing machine are sequentially arranged on one side of the workpiece conveying belt along the conveying direction of the workpiece conveying belt. Therefore, when the press-fit production line disclosed by the invention is arranged in one workshop, all the parts required by the electric power steering system can be produced simultaneously and need not be separately produced in a plurality of workshops, thereby saving the workshop space; and meanwhile, the press-fit production line can be operated by adopting a small amount of manpower, that is, a plurality of operating workers are not needed, thereby reducing the manpower and the production cost.

Owner:ZHONGSHAN CLG AUTOMATION EQUIP

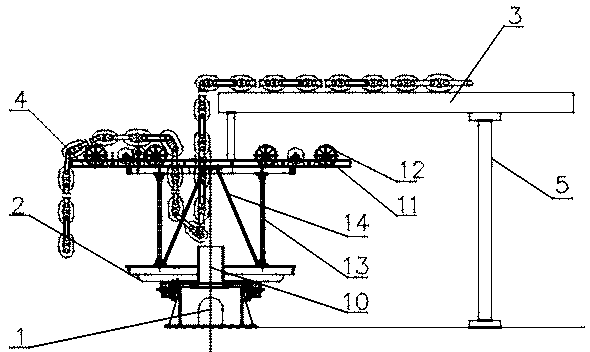

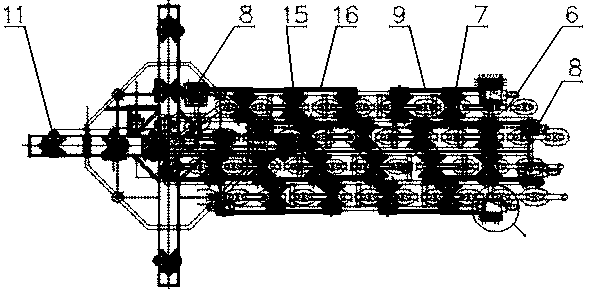

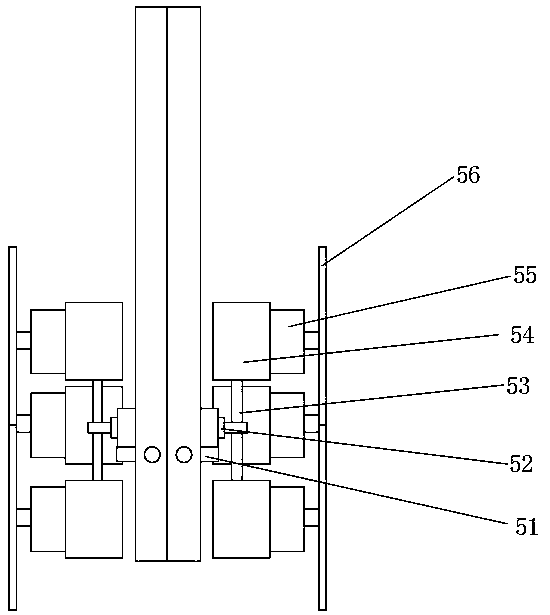

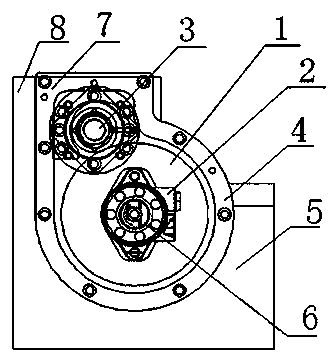

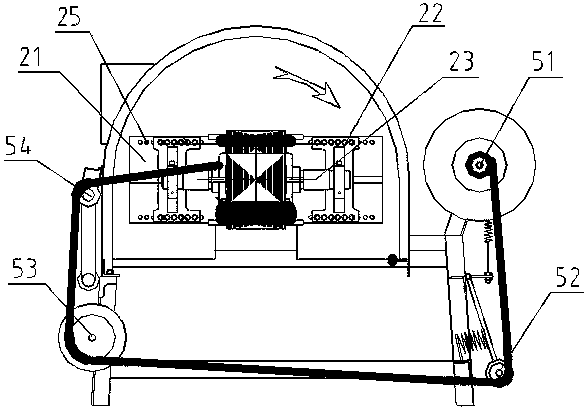

Infinite length anchor-chain link manufacturing equipment

InactiveCN107803457AReduce the ring processSave workshop spaceMetal chainsElectric machineryChain link

Disclosed is infinite length anchor-chain link manufacturing equipment. The infinite length anchor-chain link manufacturing equipment is characterized in that the manufacturing equipment comprises a turntable base, a turntable mechanism assembly, a chain conveying rack and station outlets; the turntable mechanism assembly is arranged on the turntable base and is further provided with the four station outlets, and the chain conveying rack is arranged on the station outlets; chain conveying rack supporting legs are arranged under the chain conveying rack, and the chain conveying rack comprises chain conveying channels, a plurality of rollers, motors and transmission connecting pieces; the chain conveying rack is composed of the four chain conveying channels, and the multiple rollers are evenly arranged in the chain conveying channels; the rollers are connected through the transmission connecting pieces and the motors; a plurality of station supporting legs are evenly arranged between theturntable mechanism assembly and the station outlets, and reinforcing ribs are arranged between the station supporting legs and the station outlets; and a plurality of station rollers are evenly arranged on the station outlets. By means of the infinite length anchor-chain link manufacturing equipment, the problem of accumulation in large-sized anchor chain processing is effectively solved, spaceis saved, and working efficiency is improved; and moreover, improvement can be made based on original equipment, and cost is reduced.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN

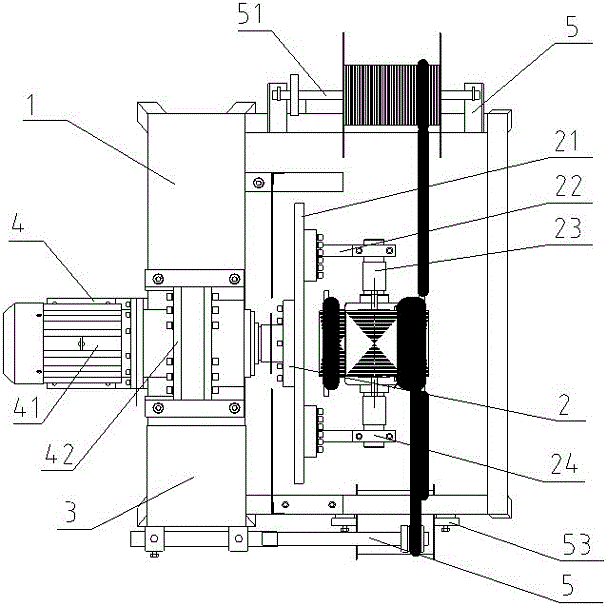

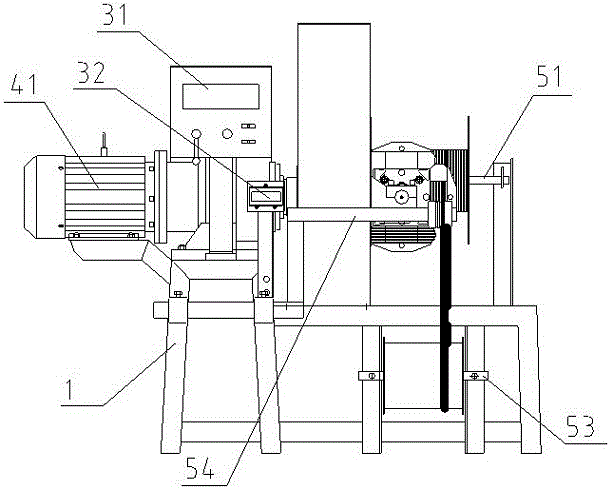

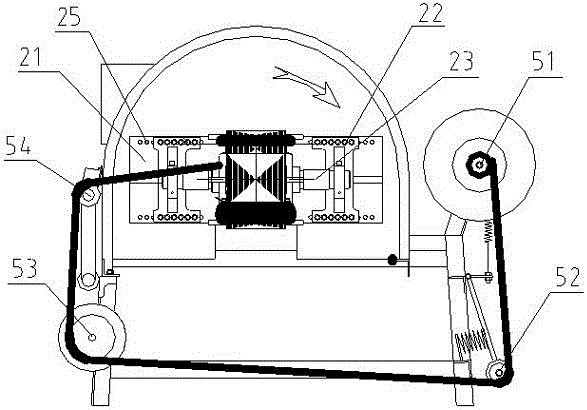

Dual-display winding machine of shaping rotor

InactiveCN105680643ASmooth outEasy to installManufacturing dynamo-electric machinesWinding machineDrive shaft

The invention provides a dual-display winding machine of a shaping rotor. The dual-display winding machine comprises a workbench, a rotor fixture, a driving device and a coil fixture, wherein the driving device is arranged on the workbench, the rotor fixture comprises a rotation plate, supports and a rotor shaft, the rotation plate is arranged on a driving shaft of the driving device and rotates with the rotation of the driving shaft, the supports are arranged on the rotation plate and is used for fixing the rotor shaft, installation plates are arranged on the supports, the rotor shaft can be assembled on the rotor fixture by the two installation plates, the coil fixture is arranged in correspondence to the rotor fixture, the rotation direction of a coil assembled on the coil fixture is consistent with the rotation direction of the rotor fixture, the rotor fixture can be driven to rotate on a vertical surface, a plurality of support installation holes are formed in the rotation plate, the installation positions of the two supports can be adjusted, and the rotor shaft is movably arranged on the supports and can be convenient to disassemble. The dual-display winding machine has the advantages of reasonable structural design and a good processing effect, and is simple to install.

Owner:GUANGXI LUZHOU MACHINERY MFG

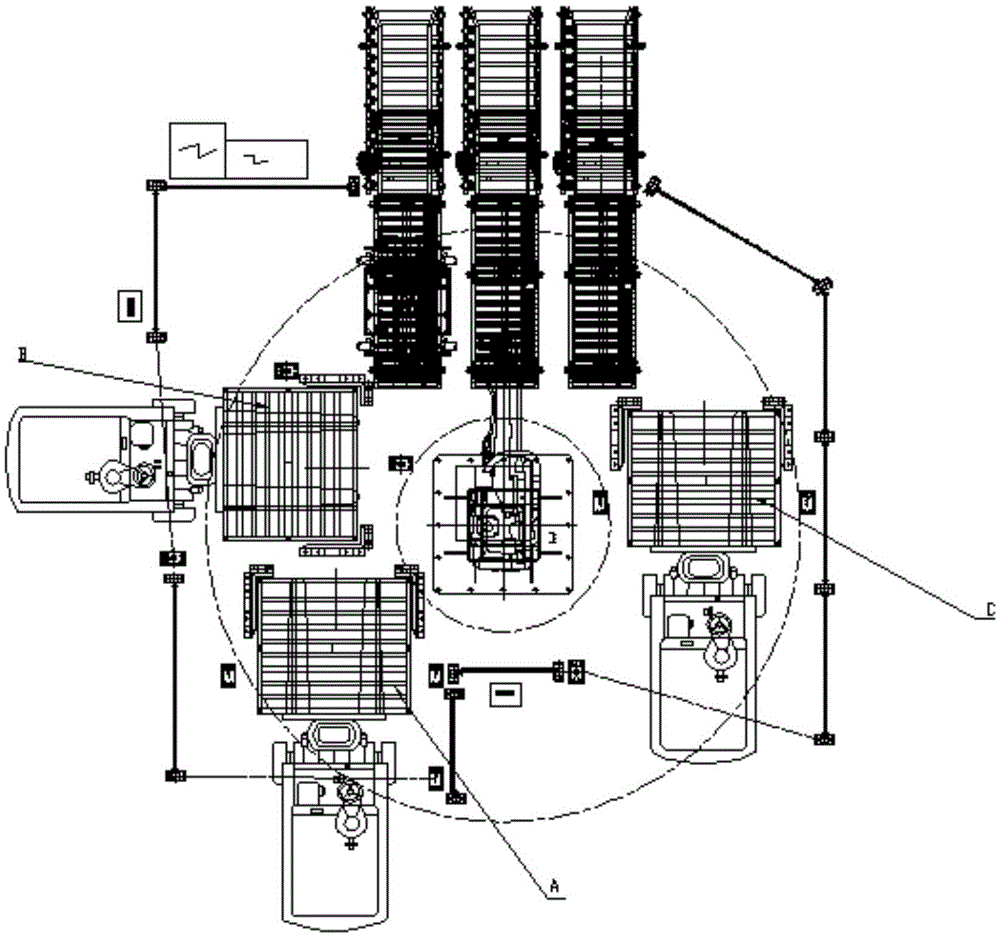

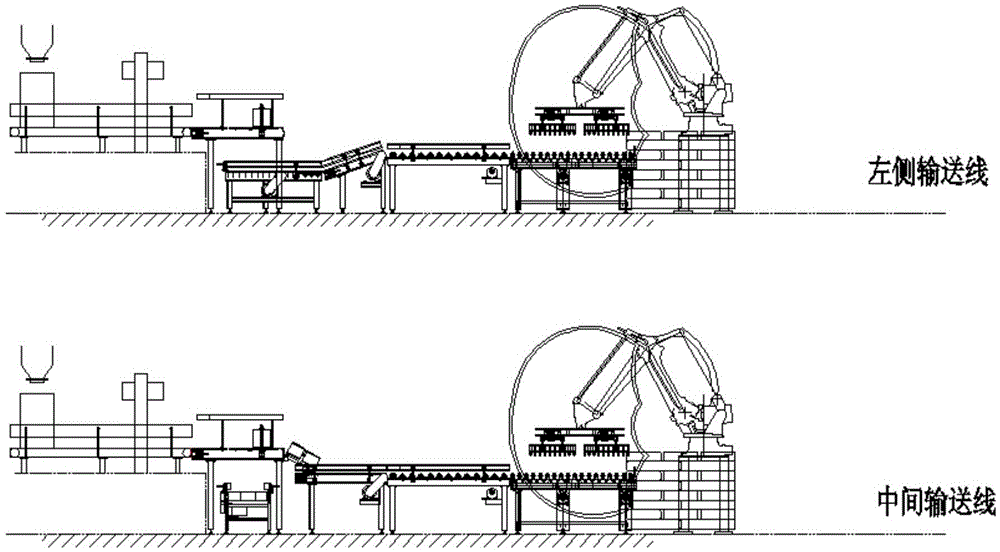

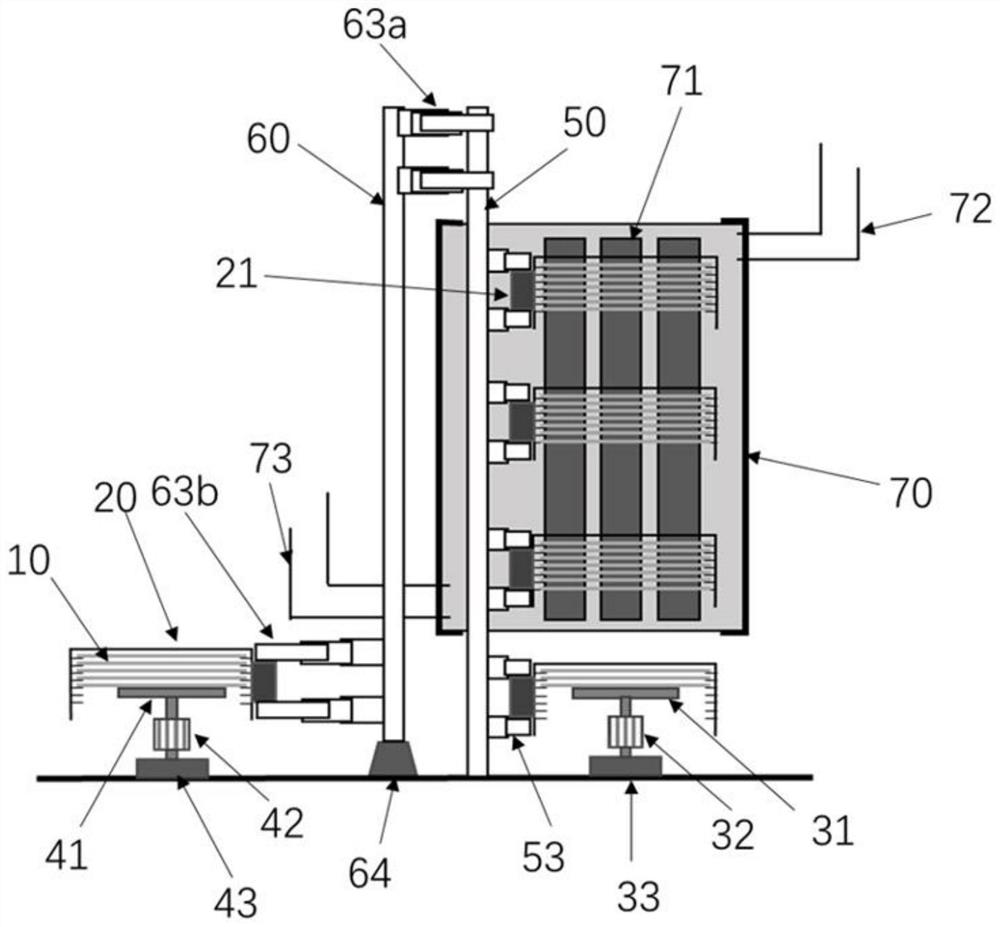

A palletizing device with three stacking positions without a pallet warehouse on a palletizing conveyor line

ActiveCN104261078BWide variety of productsSave workshop spaceStacking articlesDe-stacking articlesProduction lineManufacturing engineering

Disclosed is a three-palletizing-position tray-free warehouse palletizing device for a palletizing conveyor line. A palletizing robot (17) is arranged corresponding to three production lines A, B and C and three palletizing positions, the three palletizing positions respectively correspond to the three production lines A, B and C, the three production lines A, B and C deliver material bags to positions of three dual standby claws (1) in front of the palletizing robot (17) through conveyor units respectively, and the palletizing robot (17) sequentially claws different materials and places the materials on trays according to the conveyor speed of the conveyor line. The three-palletizing-position tray-free warehouse palletizing device for the palletizing conveyor line takes full and reasonable use of field space resources of a factory, is based on an existing production line, and uses the dual claw mechanisms capable of simultaneously clawing two bags of materials in the process, thereby greatly improving the production efficiency as well as reducing production costs and labor costs and completely achieving unmanned palletizing.

Owner:青岛宝佳智能装备股份有限公司

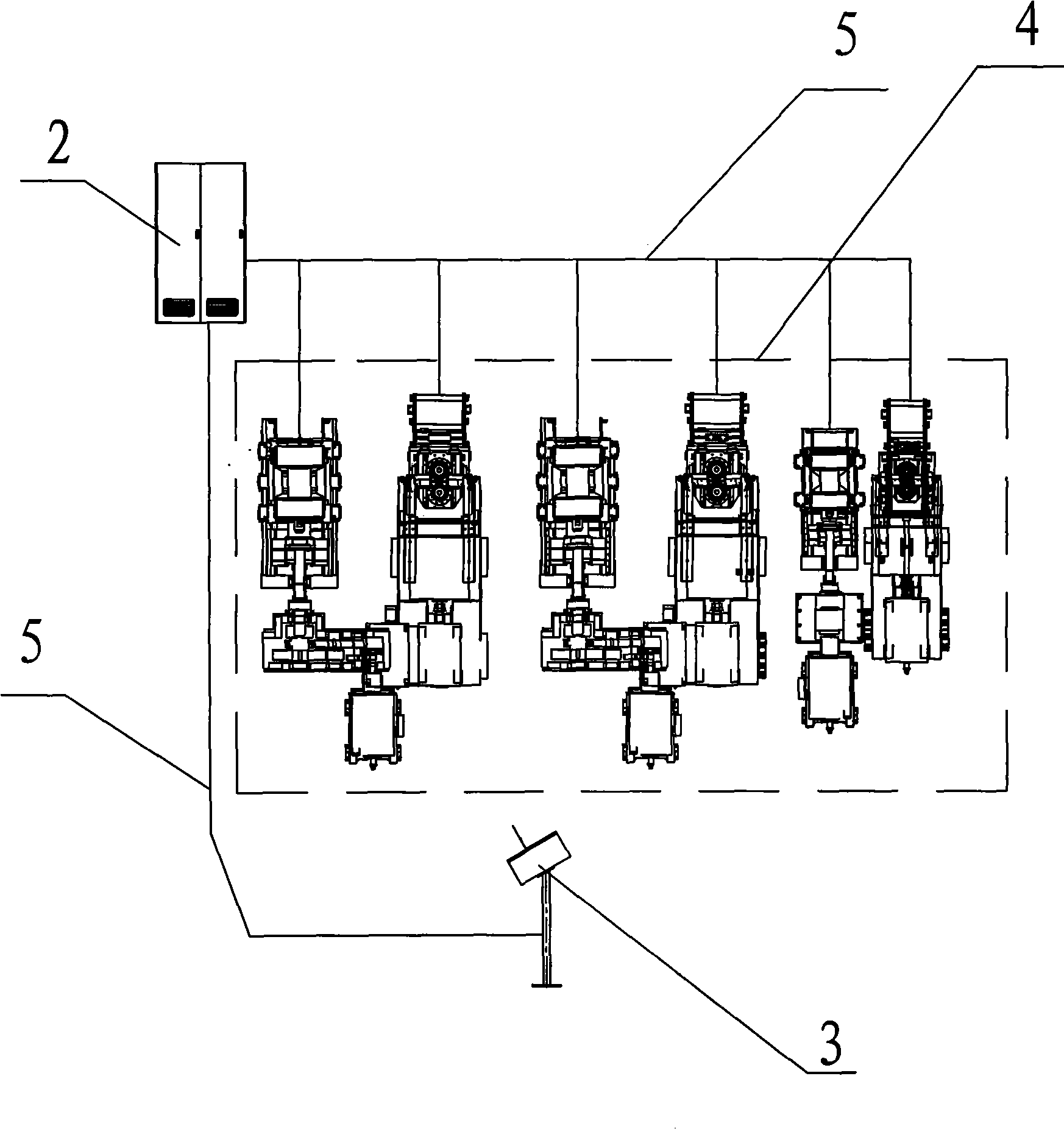

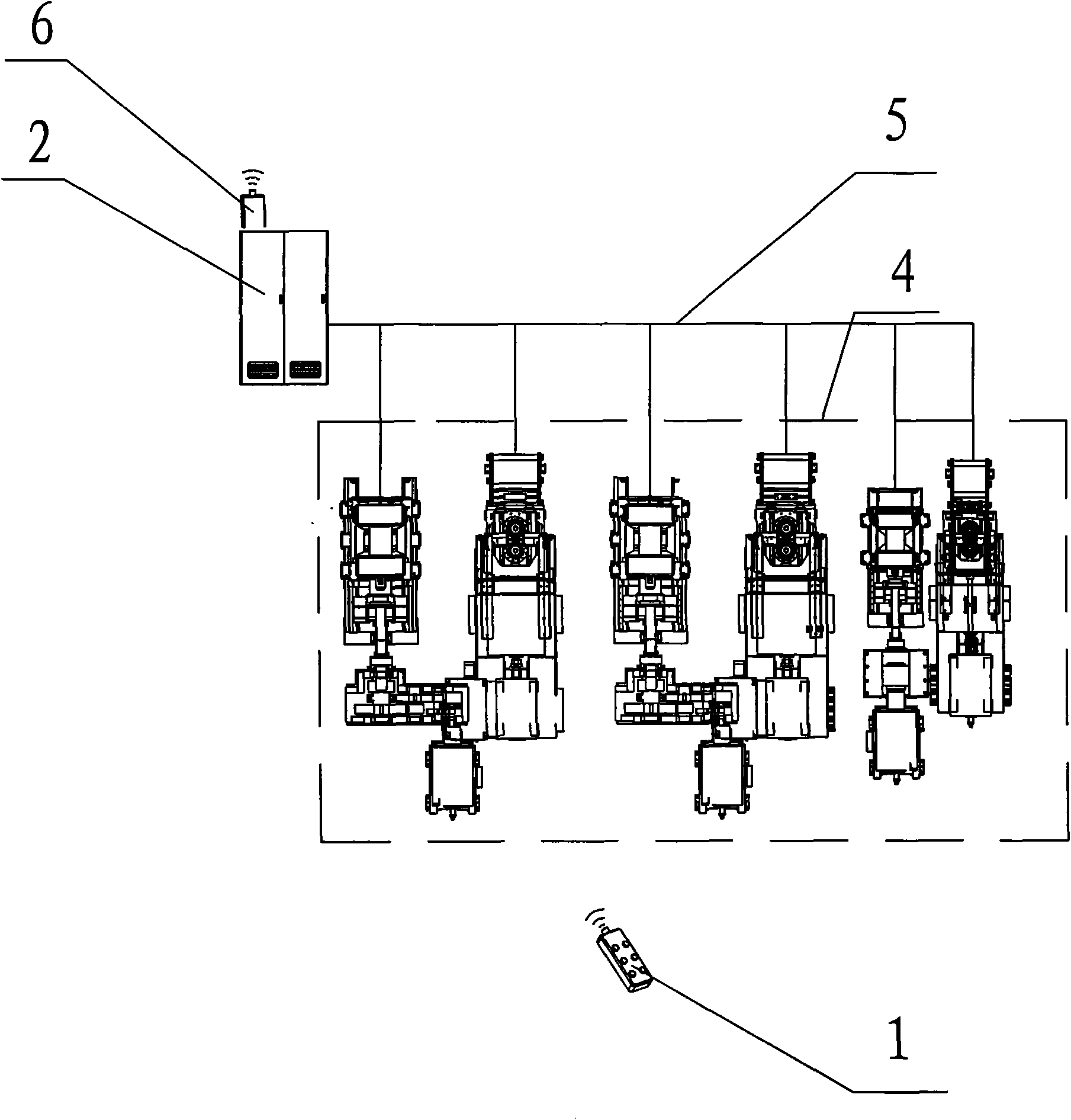

Control system of continuous rolling mill

InactiveCN101539774AReduce equipment investmentSave workshop spaceTransmission systemsRoll mill control devicesEmbedded systemEngineering

The invention discloses a control system of a continuous rolling mill, which comprises an I / O tank (2), a continuous rolling mill unit (4) and a data line (5); the system also comprises a remote control terminal (1) and a receiving / transmitting device (6); the remote control terminal (1) transmits signals to the receiving / transmitting device (6) by a wireless transmission line; the receiving / transmitting device (6) processes and converts the signals and then transmits the signals to the I / O tank (2); and the I / O tank (2) transmits the control signals to each function block of the continuous rolling mill unit (4), thus realizing the remote control on site. As wireless transmission is adopted, the on-site operation desk and the cables between the operation desk and the I / O tank (2) in the traditional operation system are removed, the equipment investment is reduced and the workshop area is saved.

Owner:CISDI ENG CO LTD

Hydraulic tensioner

In a hydraulic tensioner, a check valve provided on the rear end of a circular, cylindrical inner tensioner body, fits into a recess formed in the bottom of a hole in an outer body which receives the inner body. The check valve is radially offset from the center line of the inner body, and its engagement with the recess secures the inner body against rotation relative to the outer body.

Owner:TSUBAKIMOTO CHAIN CO

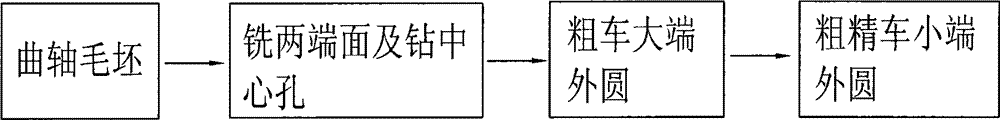

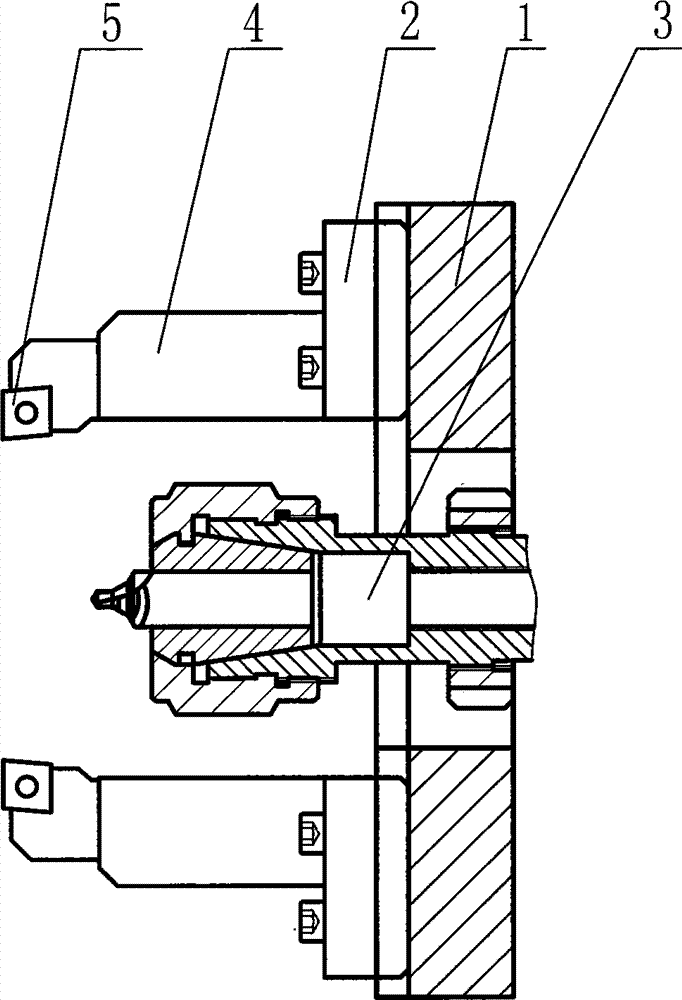

Method for enhancing clamping accuracy during rough machining of crankshaft and turning tool applying same

InactiveCN104289878ALow costSimple structureTransportation and packagingTrepanning drillsOperabilityMachining

The invention discloses a method for enhancing clamping accuracy during rough machining of a crankshaft and a turning tool applying the method. According to the method, on the basis of the original process comprising the steps that two end faces are milled, and a central hole is drilled, the process of turning a big-end outer circle is added, in addition, the turning tool for turning the big-end outer circle is provided, and finally rough turning and finish turning are performed on a small-end outer circle through a process. The turning tool comprises a base, supports and a center drill. The supports are arranged in the front of the base. The center of the base is provided with the center drill. The turning tool further comprises tool handles and blades. The tool handles are fixed to the supports and provided with the blades. According to the method, the machining quality can be guaranteed, no new machining procedure is added, and meanwhile no machining tact is added. The turning tool is simple in structure and low in cost; the clamping quality of subsequent procedures can be guaranteed, neither new equipment nor new worker needs to be additionally arranged, the place in a workshop is saved, the machining cost is controlled, and operability is extremely high.

Owner:ZHEJIANG SUN STOCK

Automatic control system of horizontal type coated pipeline

ActiveCN103111399AImprove securityLower the center of gravityLiquid surface applicatorsCoatingsProduction lineAutomatic control

The invention relates to a coating production technology and particularly relates to an automatic control system of a horizontal type coated pipeline. The automatic control system is characterized by comprising a material supplying system for providing a coating raw material and a coating trolley for horizontally placing a pipeline or a steel bar cage, wherein the upper end of the material supplying system is provided with a casting wheel for coating work; the coating trolley carries the pipeline or the steel bar cage to be coated to do horizontal straight-line movement along the lower end of the casting wheel; and a process of uniformly coating is finished by taking the pipeline or the steel bar cage to be coated as a self axis as a center to be rotatably matched with the coating raw materials sprayed out by the casting wheel. According to the automatic control system disclosed by the invention, a horizontal coating manner is adopted so that the safety is greatly improved, the size limitation on the coated pipeline does not exist and the energy consumption of a coating production line is greatly reduced; the automatic control system is good for recycling the coating raw materials and reducing air pollution; and a workshop space of the coating production line is greatly reduced and the production efficiency is greatly improved.

Owner:四川伟力得能源股份有限公司

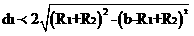

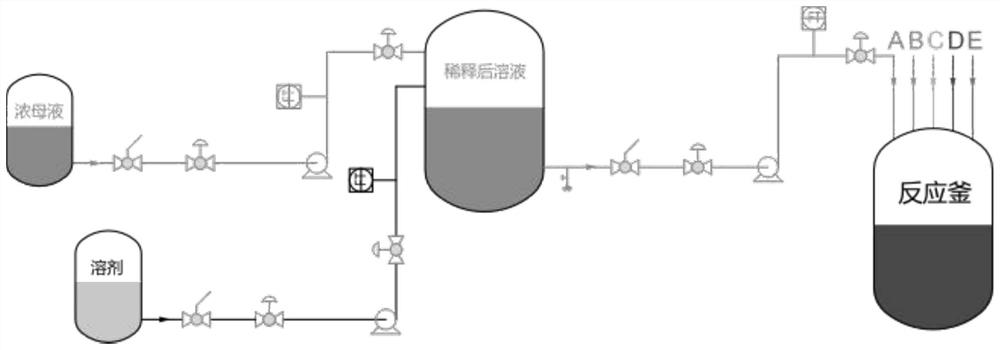

Accurate online dilution system and dilution method thereof

PendingCN113663547AReduce investmentSave workshop spaceFlow mixersMixing methodsSolventProcess engineering

,The invention discloses an accurate online dilution system and a dilution method thereof, the lower part of a concentrated mother liquor tank is connected with the inlet end of a pipeline mixer through a first pipeline, the outlet end of the pipeline mixer is respectively connected with a third pipeline and a fourth pipeline, the other end of the third pipeline is connected with the top of the concentrated mother liquor tank, and the other end of the fourth pipeline is connected with a reaction kettle, the lower portion of the solvent tank is connected with the inlet end of the pipeline mixer through a second pipeline, a second pump and a plurality of valves are installed on the first pipeline, valves are installed on the third pipeline and the fourth pipeline, and a third instrument set is installed at the joint of the third pipeline and the fourth pipeline and the outlet end of the pipeline mixer. In the whole automatic dilution process, a user only needs to provide target temperature, target concentration and target flow, the concentration of mother liquor does not need to be detected, the concentration of the diluted solution does not need to be detected, it can be guaranteed that the concentration value and the flow after dilution are within the target range of the user, and the whole process is automatically completed by the system and does not need manual control.

Owner:陆越自动化科技(上海)有限公司

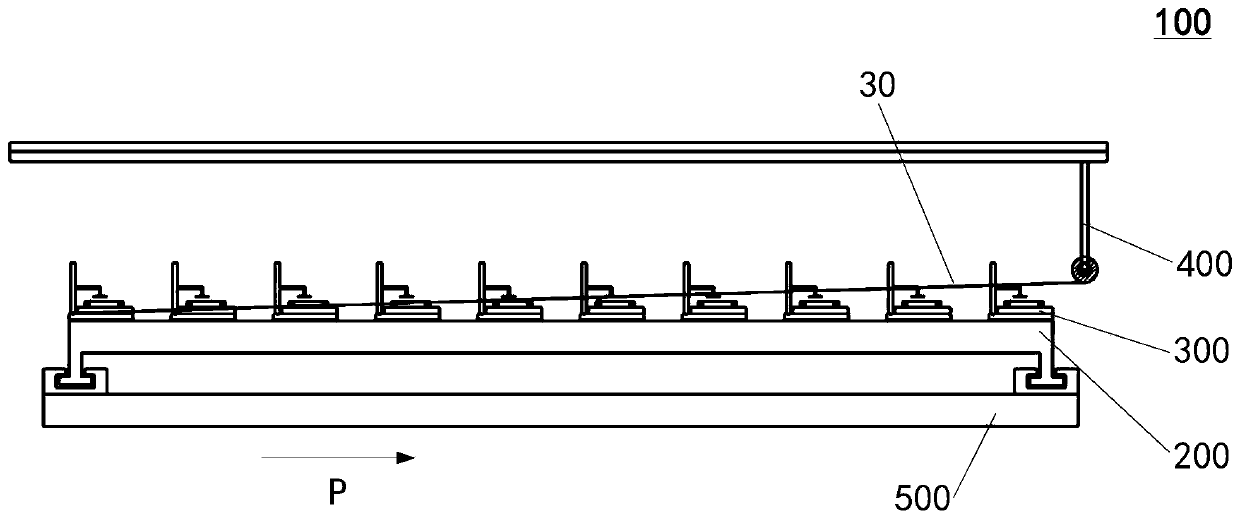

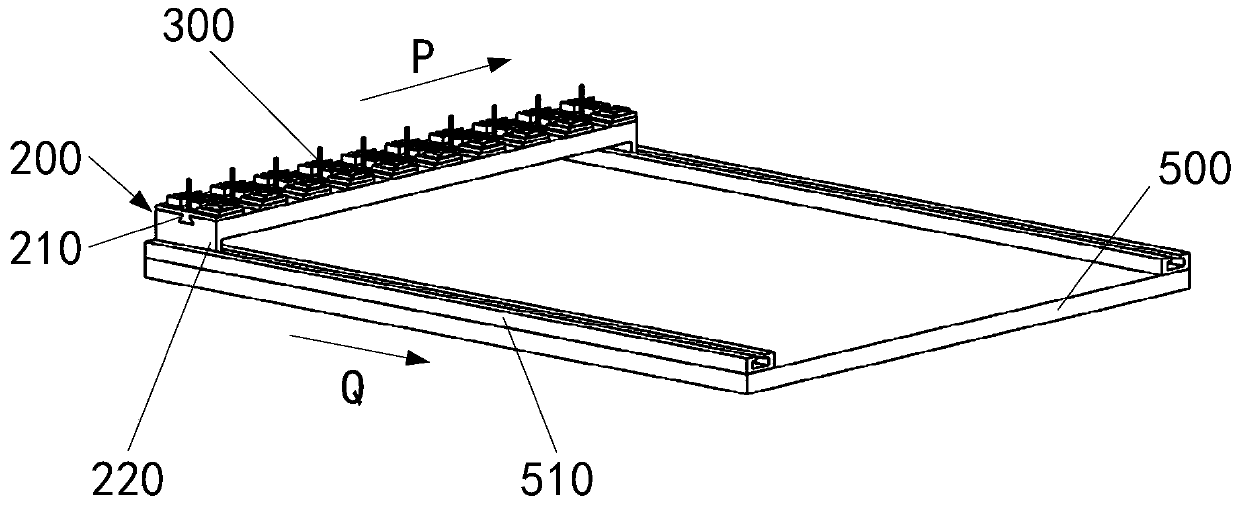

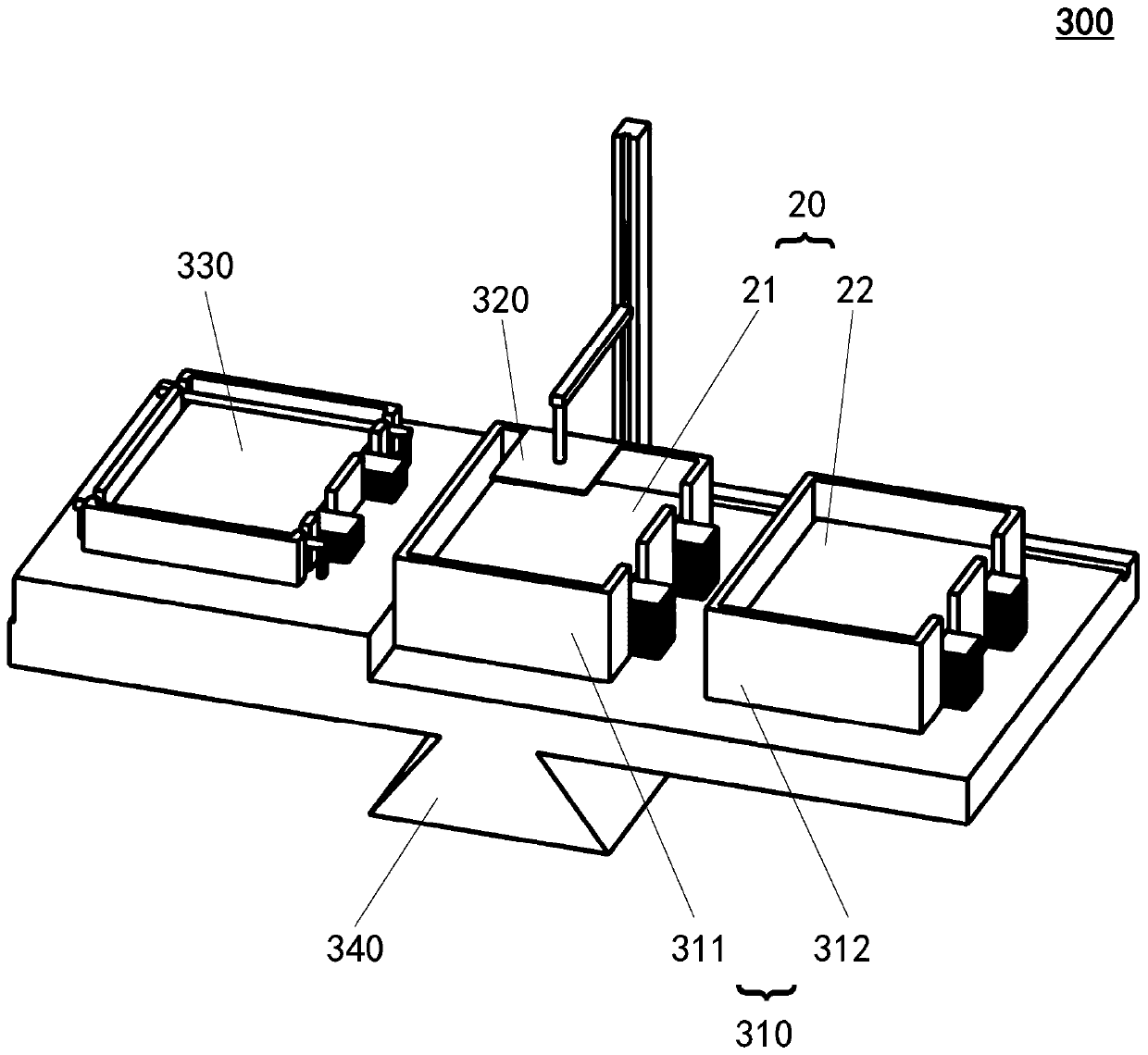

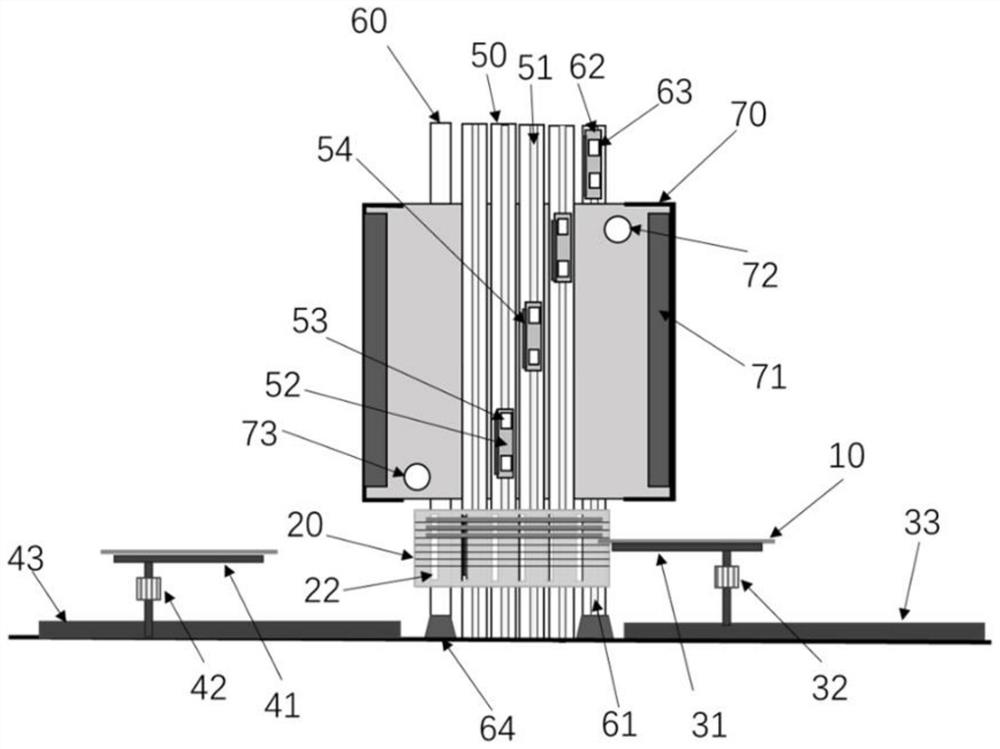

Laminating device

PendingCN111477939AImprove efficiencySave workshop spaceAssembling battery machinesFinal product manufactureEngineeringPole piece

The invention provides a lamination device. The lamination device comprises: a lamination platform extending along a first direction; at least one pole piece clamping platform, wherein the at least one pole piece clamping platform is arranged on the lamination platform, is arranged along the first direction and is used for clamping a pole piece; and a diaphragm moving mechanism, wherein the diaphragm moving mechanism is arranged at one end of the lamination platform, can load a diaphragm and drives the diaphragm to move from one end of the lamination platform to the other end of the laminationplatform, so that the diaphragm covers the at least one pole piece clamping platform. And the diaphragm moving mechanism drives the diaphragm to move once to cover all the pole pieces on the lamination platform, so that the lamination efficiency is improved. In addition, the lamination device can further comprise a base. And a second guide rail is arranged on the base. The lamination platform isslidably connected to the second guide rail. And a target station is arranged on the second guide rail. And the at least one pole piece clamping platform can integrally move to the target station along with the lamination platform, so that the required workshop space is reduced.

Owner:湖南领湃达志科技股份有限公司 +4

Combined anode carbon block slotting equipment

InactiveCN108789877ASmall sizeSave workshop spaceWorking accessoriesAbrasive blasting machinesWater jet cutterEngineering

The invention provides combined anode carbon block slotting equipment. The combined anode carbon block slotting equipment comprises a machine base, a water cutting device, an automatic fixing device,a mechanical cutting device and a control system. The water cutting device and the mechanical cutting device are transversely erected on the machine base in a sliding manner. The automatic fixing device is in sliding connection into the machine base and can penetrate the water cutting device and the mechanical cutting device. The water cutting device is provided with water jet cutter spraying ports and a numerical control operation platform. The mechanical cutting device is provided with a sound isolation hood, and the sound isolation hood is divided into a cooling section and a cutting section. The cooling section is provided with a cooling device established on the basis of semiconductor refrigeration sheets. The cutting section is provided with a cutter changing motor, a cutter rest andcutting blades. The automatic fixing device is provided with a bent track and is divided into a transverse fixing device body and an axial fixing device body, and both-way automatic clamping is conducted. According to the combined anode carbon block slotting equipment, water cutting and mechanical cutting are ingeniously combined to be applied to anode carbon block exhaust groove slotting equipment, noise is lowered, the equipment load is relieved, and the producing and manufacturing technology is optimized.

Owner:李春洪

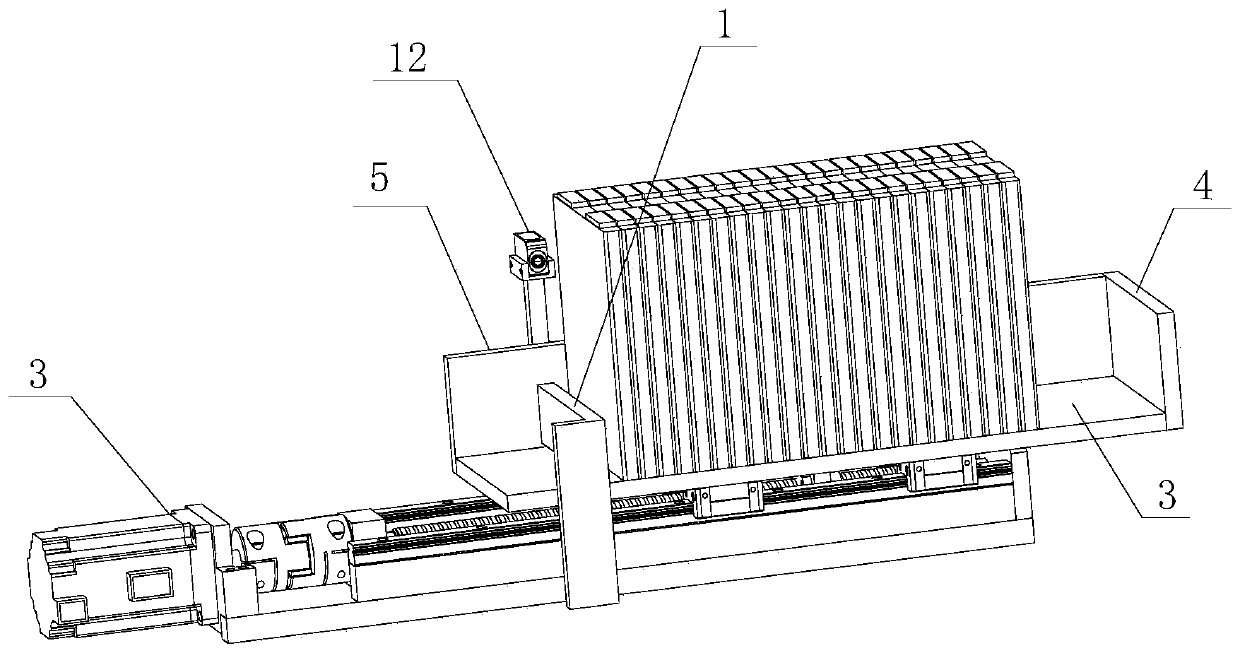

Integrated profile steel storage device

InactiveCN106217338AHigh degree of automationSave human effortOther manufacturing equipments/toolsWork tools storageSmall footprintEngineering

The invention discloses an integrated profile steel storage device. The integrated profile steel storage device comprises a feeding end and a discharging end. Multiple sets of roller clamping devices are arranged between the feeding end and the discharging end at intervals. Each roller clamping device comprises a rack. A first vertical clamping and conveying roller and a second vertical clamping and conveying roller are rotationally arranged on the rack in a spaced manner. Both the first vertical clamping and conveying roller and the second vertical clamping and conveying roller are connected with rotary drive assemblies. The two ends of the first vertical clamping and conveying roller are both provided with pressing drives for driving corresponding profile steel clamped by the two vertical clamping and conveying rollers. The portions, between the adjacent two sets of roller clamping devices, of the top of the rack are each provided with a pressing device for pressing the profile steel. The portion, between the first vertical clamping and conveying roller and the second vertical clamping and conveying roller, of the bottom of the rack is provided with a profile steel conveying supporting roller. The integrated profile steel storage device is high in degree of automation, capable of saving manpower, safe and reliable in operation, capable of improving work efficiency, small in occupied area and capable of saving the valuable workshop space.

Owner:WUXI GUANGCAI MACHINERY MFG

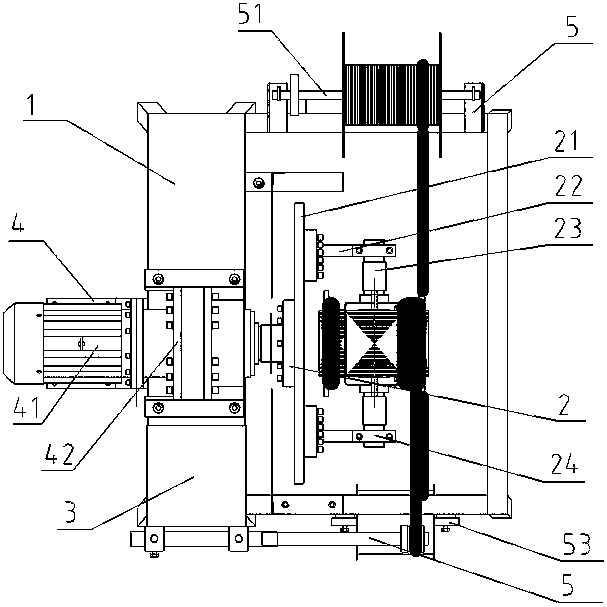

Numerically controlled type hydraulic transmission system

InactiveCN103894866ARealize Programmable ControlMeet processing requirementsFeeding apparatusGear wheelEngineering

A numerically controlled type hydraulic transmission system comprises a big gear, a high-sensitivity hydraulic motor, a servo encoder, a small gear, a lead screw, a spiral sliding block and an installation base, wherein the high-sensitivity hydraulic motor is connected with the lead screw through the big gear and the small gear, the high-sensitivity hydraulic motor drives the big gear to rotate, the small gear and the lead screw rotate along with the big gear, the lead screw is provided with the spiral sliding block which moves back and forth along the lead screw, the spiral sliding block is connected with a cutting tool, and the lead screw is movably connected to the installation base. The numerically controlled type hydraulic transmission system is characterized in that a dust guard is arranged on the outer edge of the lead screw and protects the transmission lead screw, and the servo encoder is installed at the tail portion of the lead screw and the installation base. The numerically controlled type hydraulic transmission system achieves programmable control and can change programs within the short time to meet the machining requirement of various products. The transmission torque is improved, the size of equipment is not increased, the valuable space of a factory building is saved for clients, and rapid and accurate stopping can be achieved when the equipment moves at a high speed.

Owner:范朝民

sld automatic cutting and laying machine

The invention discloses an SLD (Super Luminescent Diode) automatic cutting and paving machine comprising an EVA (Ethylene Vinyl Acetate Copolymer) and TPT (Topotecan Hydrochloride) automatic cutting system and an automatic paving system located on the EVA and TPT automatic cutting system, wherein discharging devices and two punching devices and two cutting devices respectively connected with the two discharging devices are respectively arranged on the two ends of the EVA and TPT automatic cutting system, a material clamping and conveying device is arranged at the middle part of the EVA and TPT automatic cutting system, and the automatic paving system comprises a material paving device. Compared with the prior art, the machine has the advantages that the cutting and paving operations of solar cell panel EVA, TPT are integrated, so that the structure is compact and the operation is smooth and continuous, the locating and length fixing precisions in the cutting and punching operation are higher, the production benefit and the product quality are improved, and the manpower, physical resources and factory building space are saved.

Owner:秦皇岛硕谷光伏科技有限公司

Intelligent textile stacking and conveying system

ActiveCN114273230ARealize spatial distributionSave workshop spaceSievingConveyorsManufacturing engineeringTextile

The invention belongs to the technical field of textile stacking and conveying systems, and particularly relates to an intelligent textile stacking and conveying system which comprises a feeding conveying device, a screening bin, at least two screening mechanisms, at least two guide plates and at least two discharging conveying devices. Wherein all the material screening mechanisms screen materials in the material screening bins, namely, all the material screening mechanisms screen out the materials with the corresponding particle sizes and convey the materials to the corresponding guide plates, and the materials slide into material boxes on the corresponding discharging conveying devices along the corresponding guide plates; each blanking conveying device conveys the material box filled with the material with the corresponding particle size in the conveying direction; the feeding conveying device and the discharging conveying device are arranged below the screening bin, spatial distribution can be achieved, the workshop space is saved, the feeding conveying device, the screening mechanism and the discharging conveying device are integrally arranged, conveying, screening and boxing of materials can be achieved, and the working efficiency is improved.

Owner:常州天虹纺织有限公司

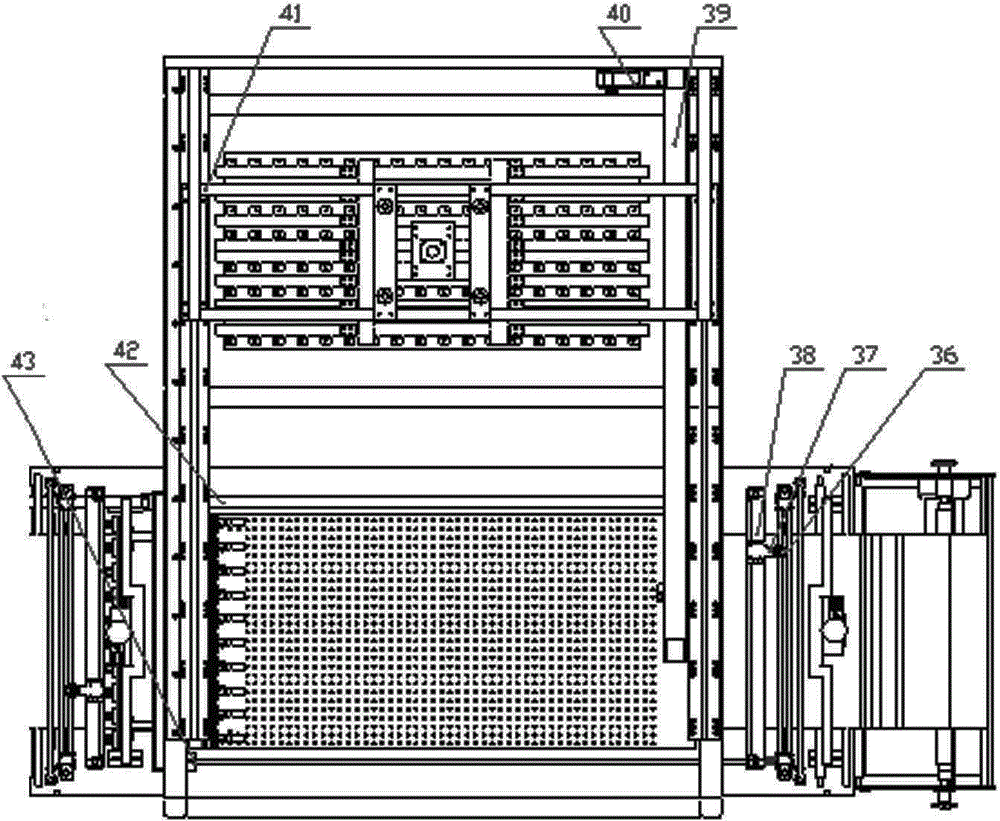

Feeding and discharging buffer mechanism with environment control function

ActiveCN111799201AReduce transmissionSave workshop spaceFinal product manufactureSemiconductor/solid-state device manufacturingEnvironmental engineeringControl room

The invention discloses a feeding and discharging buffer mechanism with an environment control function. The mechanism comprises an environment control chamber, a feeding lifting mechanism, a discharging lifting mechanism, a feeding wafer inserting device, a discharging wafer taking device and a wafer storage box. An environment control unit is arranged in the environment control chamber; the feeding lifting mechanism comprises a feeding movement sliding rail, a feeding movement module and a feeding clamp. The discharging lifting mechanism comprises a discharging movement sliding rail, a discharging movement module and a discharging clamp, the feeding clamp and the discharging clamp drive the wafer storage box to move up and down, the feeding wafer inserting device and the discharging wafer taking device can move horizontally, and silicon wafers are inserted into the wafer storage box or taken out of the wafer storage box. According to the invention, extra equipment cost and workshop space are saved, the transmission of the silicon wafers among different equipment is reduced, and the production yield is improved. Different environmental control units are arranged to meet differentprocess requirements of pretreatment or post-treatment of the silicon wafers in different steps.

Owner:SUZHOU SUNWELL NEW ENERGY CO LTD

Square battery separated feeding system

ActiveCN110542305ASave workshop spaceRealize battery separation and transfer workFinal product manufactureDrying solid materialsEngineeringReciprocating motion

The invention discloses a square battery separated feeding system which includes a conveying device, a regularization device, a conveying line and a grasping device. The conveying device includes a limiting plate, a conveying platform located on one side of the limiting plate and a first driving mechanism used for driving the conveying platform to do horizontal reciprocated motion towards the limiting plate, and the conveying platform is provided with a first baffle and a second baffle; the regularization device includes a push plate arranged in a manner of being opposite to the second baffleand a second driving mechanism used for driving the push plate to do horizontal reciprocated movement towards the second baffle, and a material running channel is formed between the push plate and theplane where the limiting plate is located; the conveying line is located at one end of the material running channel; and the grasping device includes a pneumatic mechanical claw, a third driving mechanism for driving the pneumatic mechanical claw to do reciprocated motion towards the conveying platform and a fourth driving mechanism for driving the pneumatic mechanical claw to do reciprocated motion in the direction of a connecting line of the material walking channel and the conveying line. The square battery separated feeding system greatly saves the plant space to a large extent and realizes separation and transfer work of batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Multi-head semi-automatic setting machine

ActiveCN105459387BIngenious designReasonable structure configurationDomestic articlesElectronic control systemWork injury

The invention discloses a semi-automatic multi-head setting machine. The semi-automatic multi-head setting machine comprises a rack, a feed and discharge workbench, a lower die, an upper die mechanism, a picking and placing device and an electronic control system. The feed and discharge workbench is arranged on the rack. The lower die is arranged on the feed and discharge workbench. The upper die mechanism is arranged on the rack and located above the feed and discharge workbench. The picking and placing device is arranged on the feed and discharge workbench and used for conducting picking and placing action on the lower die. The electronic control system controls the feed and discharge workbench and the upper die mechanism to achieve setting of forming sheet materials and controls the picking and placing device to achieve the picking and placing process. The semi-automatic multi-head setting machine is ingenious in design, reasonable in control principle, structure configuration and operating mode and high in automation degree. The problems that leaf tearing operation of workers in prior processing is long in time, high in labor intensity and low in work efficiency are solved. Meanwhile, work injury accidents are avoided completely. When the semi-automatic multi-head setting machine works in the semi-automatic working mode, the forming sheet materials and products are picked and placed manually. The semi-automatic multi-head setting machine is used for production of the specific products, so that the purpose that the rejection rate of the specific products is lowered is achieved, and the application range is wide.

Owner:东莞东业工艺制品有限公司

A shaping rotor double display winding machine

InactiveCN105680643BSmooth outEasy to installManufacturing dynamo-electric machinesWinding machineVertical plane

The invention provides a shaping rotor double-display winding machine, which includes a working frame, a rotor fixture, a driving device and a coil fixture; the driving device is installed on the working frame; the rotor fixture includes a rotating plate, a bracket, and a rotor shaft The rotating plate is installed on the driving shaft of the driving equipment and rotates following the rotation of the driving shaft; the bracket is arranged on the rotating plate to fix the rotor shaft; the bracket is provided with a mounting plate, and the rotor shaft It can be assembled on the rotor fixture through the two mounting plates; the coil fixture is set corresponding to the rotor fixture, and the coil assembled on the coil fixture is in the same rotation direction as the rotor fixture, which can drive the rotor fixture to rotate on the vertical plane. A plurality of bracket mounting holes are arranged on the rotating plate, and the installation positions of the two brackets can be adjusted; the rotor shaft is movably mounted on the bracket and can be easily disassembled. The invention has reasonable structural design, simple installation and good processing effect.

Owner:GUANGXI LUZHOU MACHINERY MFG

A fully automatic detection equipment for X-ray detection of engineering tires

ActiveCN103105404BSmooth rotationRadial stabilityMaterial analysis by transmitting radiationX-rayTest equipment

The invention discloses an X-ray detection method and full-automatic detection equipment for engineering tires. The method comprises the step of detecting the interior of a tire to be detected in an X-ray protection chamber by virtue of a ray tube and an imaging sensor, and specifically comprises the following steps of: mounting the tire on a carrier vehicle on rails outside the ray protection chamber, and moving the vehicle to a preset position in the protection chamber and closing a protection door when the tire is mounted on the vehicle, wherein the tire bearing part of the vehicle is a tire rotating mechanism consisting of multiple rollers; and starting a tire centering mechanism and the tire rotating mechanism, rotating the tire on the rollers of the tire rotating mechanism, adjusting the tire to an accurate detection position through the centering mechanism, starting the imaging sensor and the X-ray tube to preset positions for detection, and displaying and storing detected images in a computer. The method has the advantages that the size of the X-ray protection chamber is reduced, and the construction cost is reduced; the tire rotates stably, and thus the imaging precision is improved; radial run-out caused by concave and convex parts of the excircle of the tire is prevented; and moreover, radiation during manual operation is eliminated.

Owner:辽宁仪表研究所有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com