X-ray detection method and full-automatic detection equipment for engineering tires

A technology of detection equipment and detection method, which is applied in the field of X-ray detection of tires, can solve the problems of cumbersome and complicated operations, large space occupation, and large installed capacity, and achieve the effects of simplifying operating procedures, saving space, and improving imaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

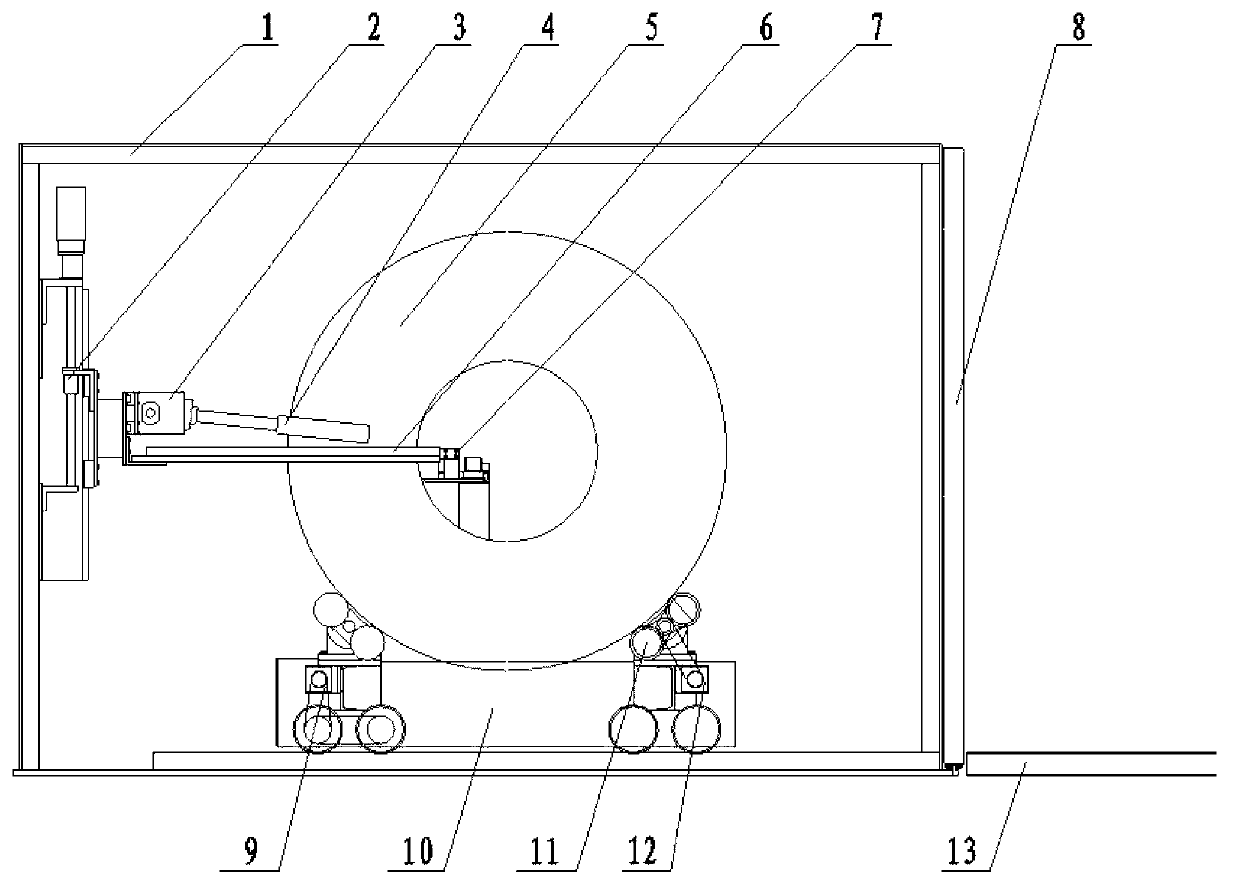

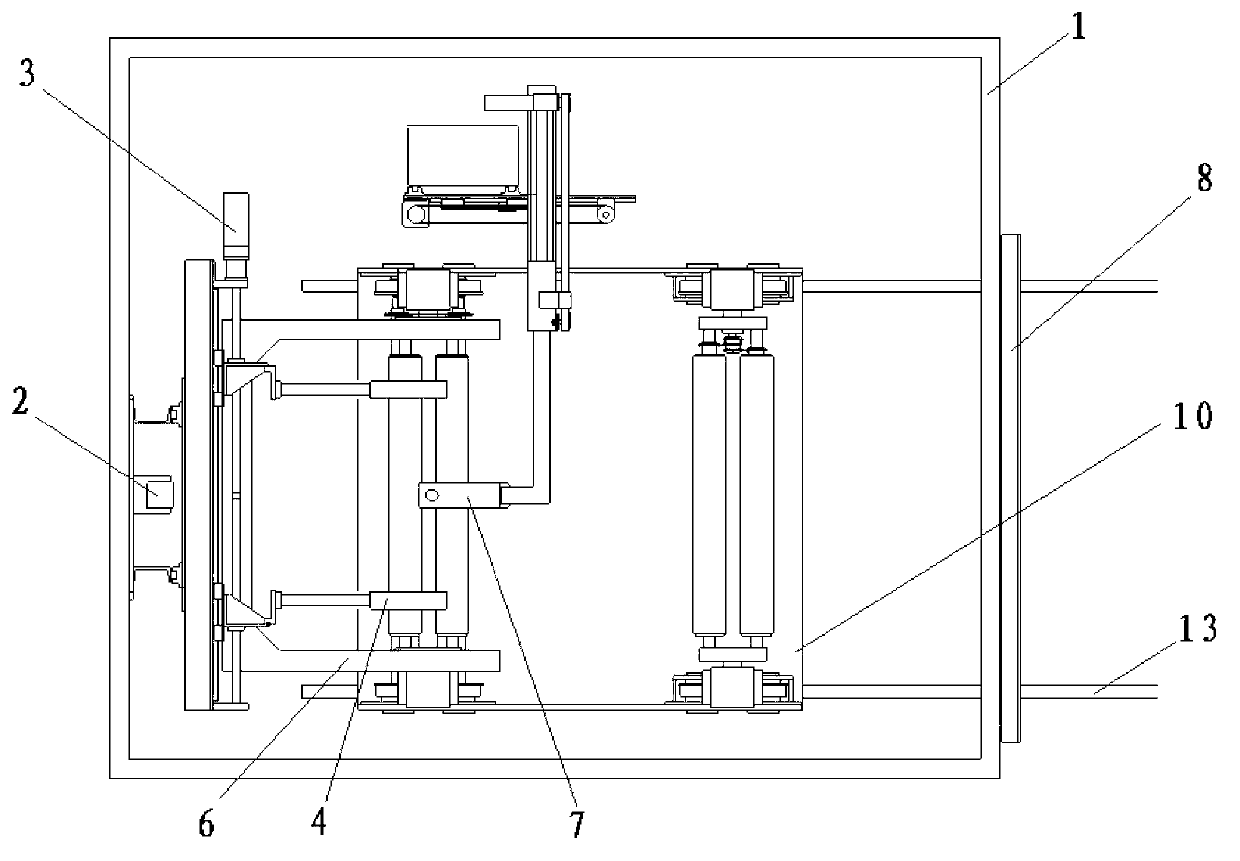

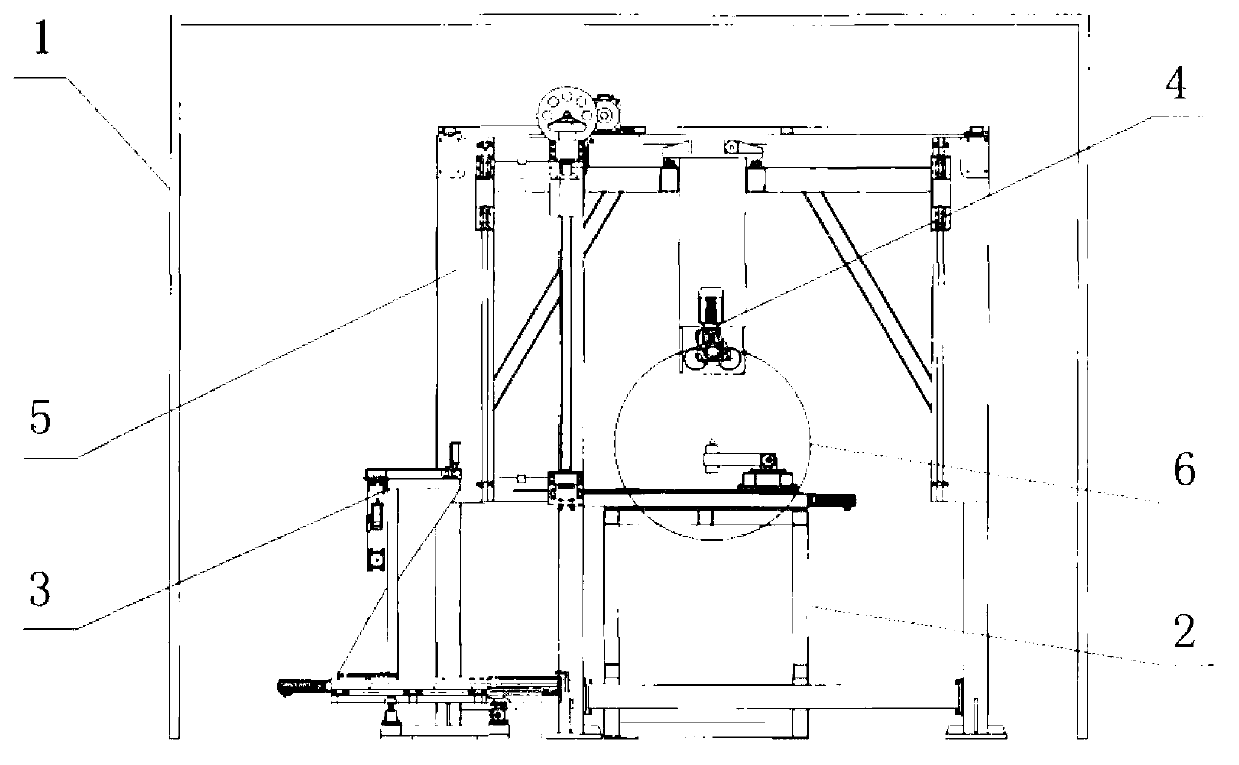

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention includes an X-ray protection room 1, a ray tube 7, an imaging sensor 6, and the imaging sensor 6 is connected to a data processing system through a data line; A tire-turning mechanism and a running mechanism are set; the tire-turning mechanism is used to rotate tires, and the running mechanism is used to drive the carrier to move back and forth; the centering mechanism 3 is provided with a tire pushing arm 4, and the tire wall 4 is used to Make sure the tires maintain the correct axial position.

[0020] The tire-changing mechanism includes a driving tire-changing roller group and a driven tire-changing roller group, and the driving tire-changing roller group includes a tire-changing motor 12 and a plurality of tire-changing rollers 11, and the tire-changing motor 12 drives the driving wheel, so The driving wheel driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com