Method for enhancing clamping accuracy during rough machining of crankshaft and turning tool applying same

A technology of crankshafts and sets of cars, which is applied in the field of crankshaft machining, can solve problems such as unfavorable equipment maintenance, hidden dangers of processing quality, and fixture wear, and achieve the effects of increasing processing beats, controlling processing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

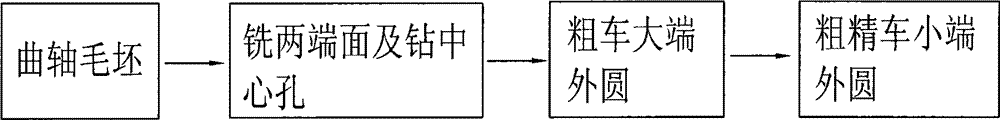

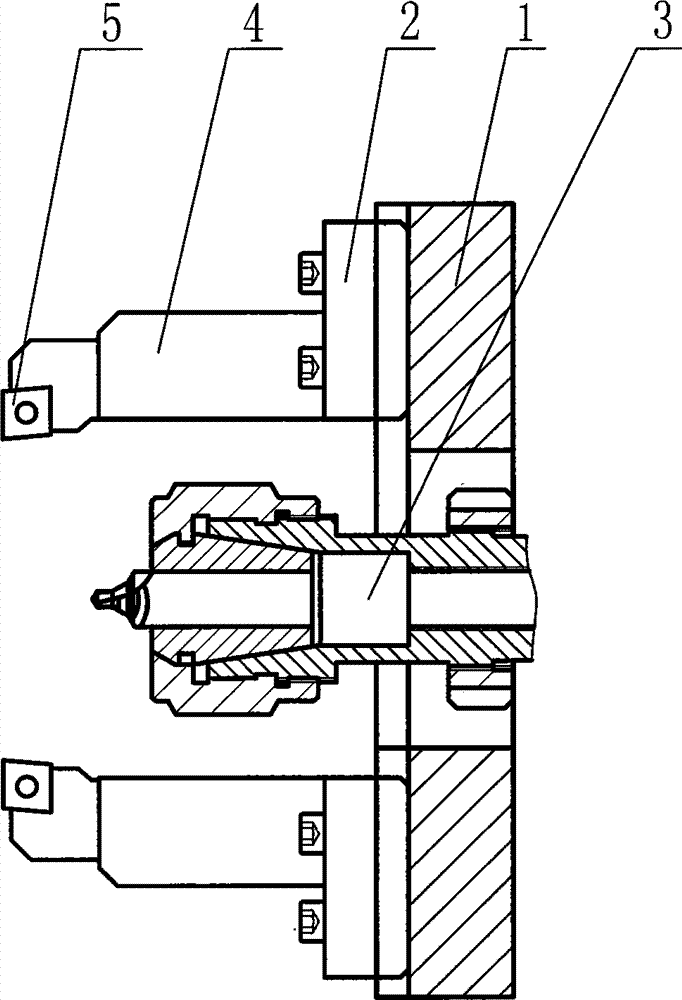

[0012] Such as figure 1 As shown, the present invention discloses a method for improving the clamping accuracy of rough machining of crankshafts, which is characterized in that: on the original process of milling both ends and drilling the center hole, the outer circle process of the big end of the car is added, and the outer circle of the big end of the car is provided. The specific method for the turning tool of the circular process is that after the machine tool is started, the crankshaft blank does not move, and the milling cutter head first feeds and mills the two ends of the crankshaft blank to control the total length, and then the milling cutter head withdraws, and the center drills at the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com