Automatic control system of horizontal type coated pipeline

An automatic control system, horizontal technology, applied in the direction of coating, coating liquid on the surface, etc., can solve the problems of non-recyclable, high risk, large moment of inertia, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Such as Figure 1-9 As shown, the horizontal coating pipeline automatic control system includes a feeding system for providing coating raw materials and a coating trolley for horizontally placing pipelines or steel cages; the upper end of the feeding system is provided with a Projection wheel, the coating trolley carries the pipe or reinforcement cage to be coated to move horizontally and straightly along the lower end of the projection wheel, and rotates around its own axis through the pipe or reinforcement cage to be coated to cooperate with the coating projected by the projection wheel Raw materials complete the process of uniform coating.

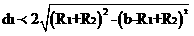

[0067] The upper end of the feeding system is provided with two projecting wheels that rotate relatively. When the two projecting wheels rotate relative to each other, the coating material is driven by the rotating power to sprinkle the coating material. The coating material moves downward from the middle of the two projecting wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com