Press-fit production line for manufacturing of parts in electric power steering system

A technology of electric power steering and production line, which is applied in the field of pressing production line, can solve the problems of occupying workshop space, high production cost, manual operation, etc., and achieve the effect of saving workshop space, saving manpower, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

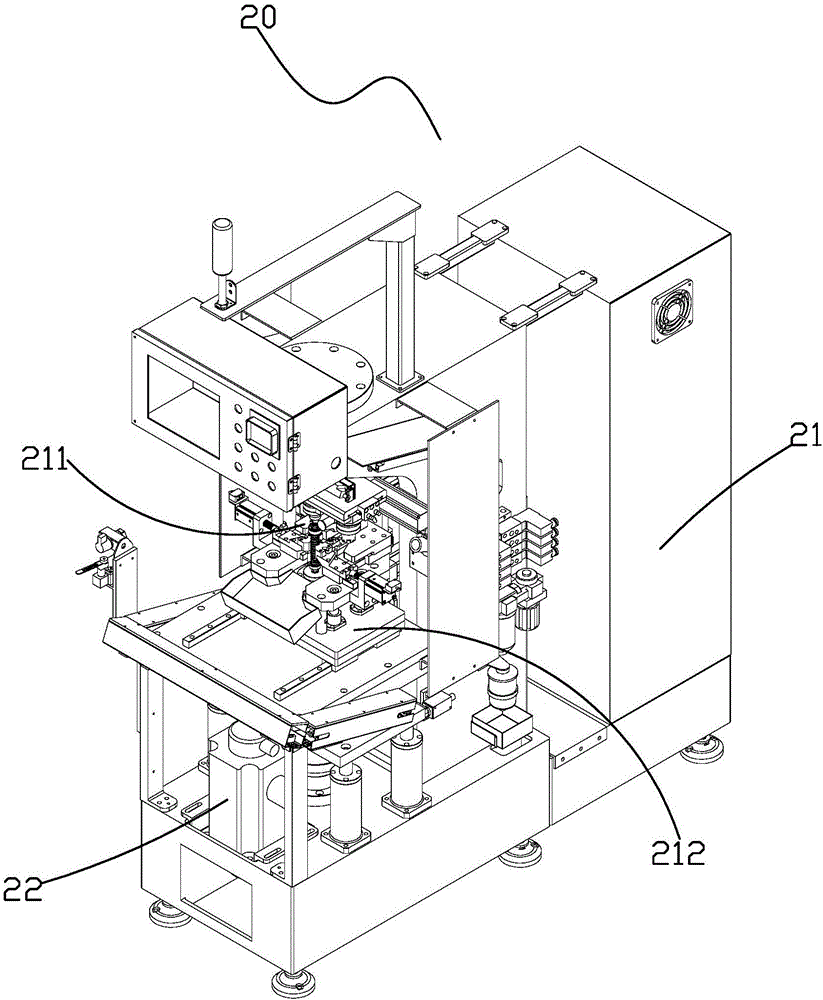

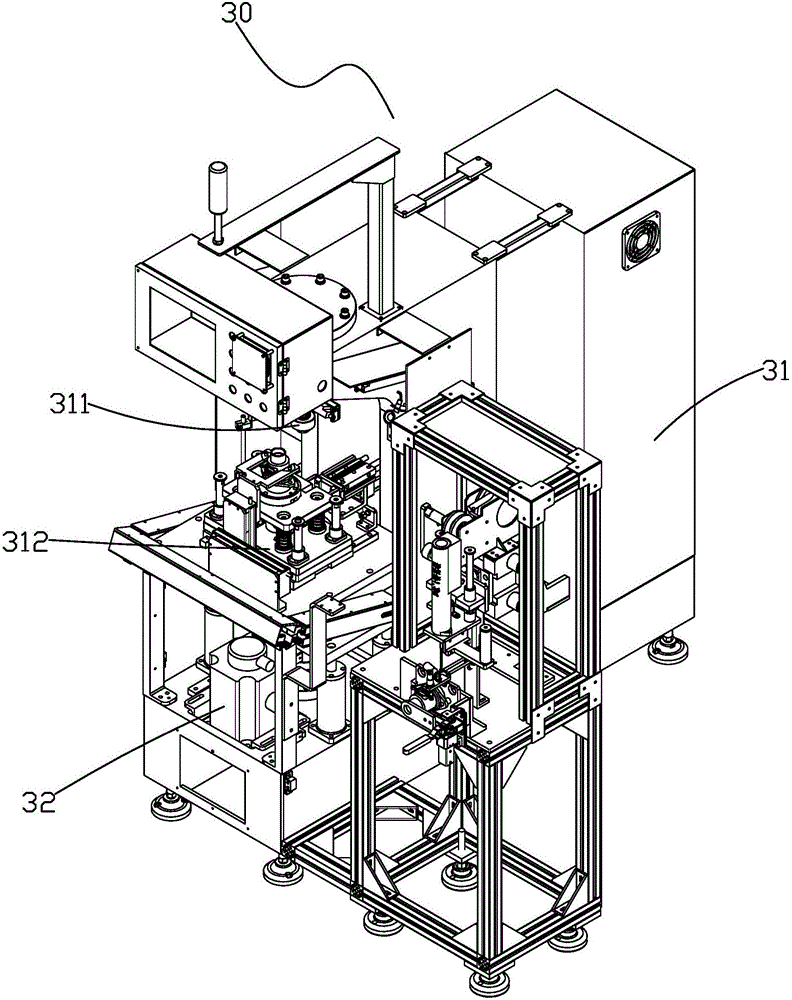

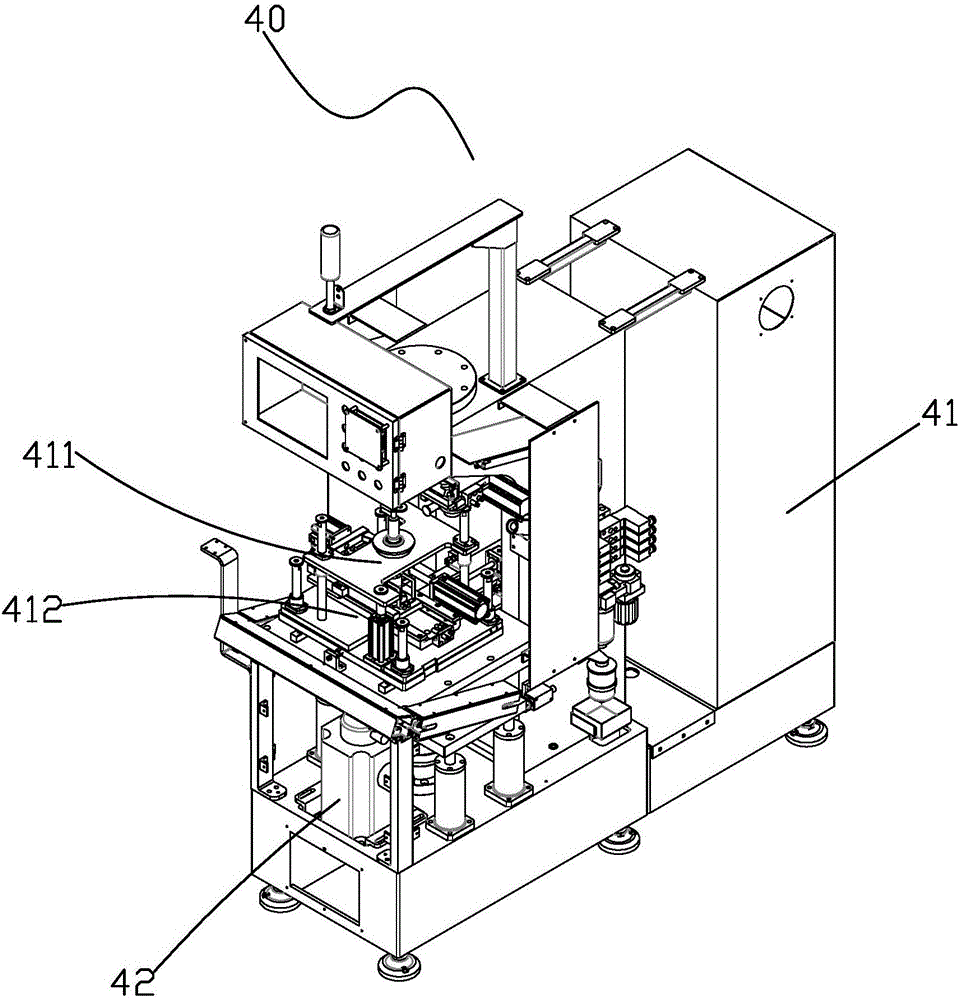

[0026] refer to figure 1 to Figure 8 ( Figure 8 The direction of the middle arrow indicates the moving direction of the workpiece or the conveying direction of the workpiece conveyor belt 10), a pressing production line for making electric power steering system parts, including a workpiece conveyor belt 10 for conveying processed workpieces, One side of the workpiece conveyor belt 10 is sequentially provided with a worm bearing press-in machine 20 for pressing the worm bearing, an oil seal assembly press-in machine 30 for pressing the oil seal assembly, The torsion bar pressing machine 40 for pressing the torsion bar, the yoke pressing machine 50 for pressing the magnetic yoke, the bottom cover pressing machine 60 for pressing the bottom cover, and the second pressing machine for pressing the needle roller bearing A needle bearing pressing machine 70 and a second needle bearing pressing machine 80 for pressing the needle bearings.

[0027] Since the pressing production line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com