Square battery separated feeding system

A square battery and spacing technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and dry solid materials, etc., can solve the problems of increasing equipment investment costs and large workshop space, so as to improve equipment production efficiency and reduce equipment investment costs , The effect of saving plant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the technical solution of the present invention will be described in detail through specific examples.

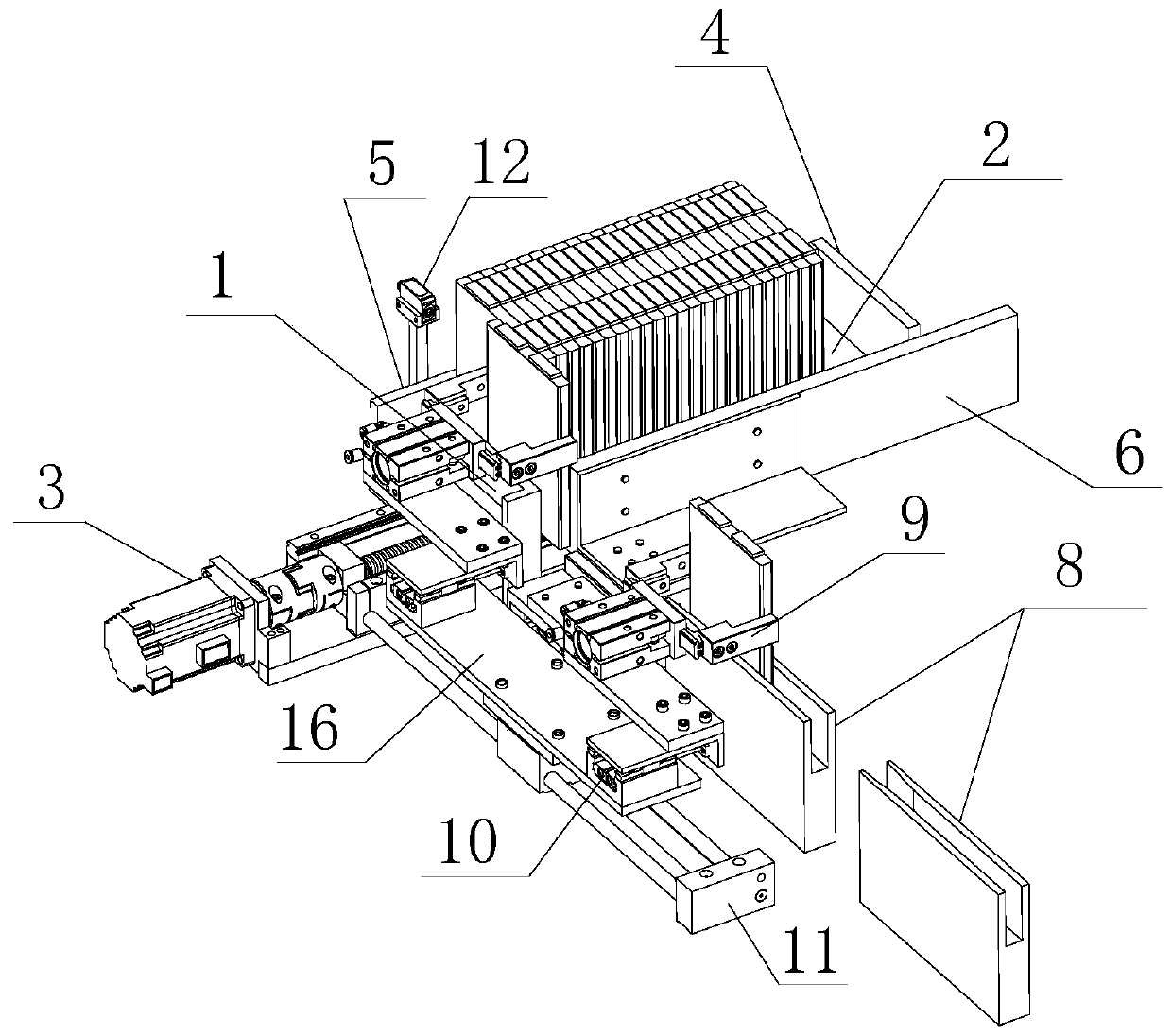

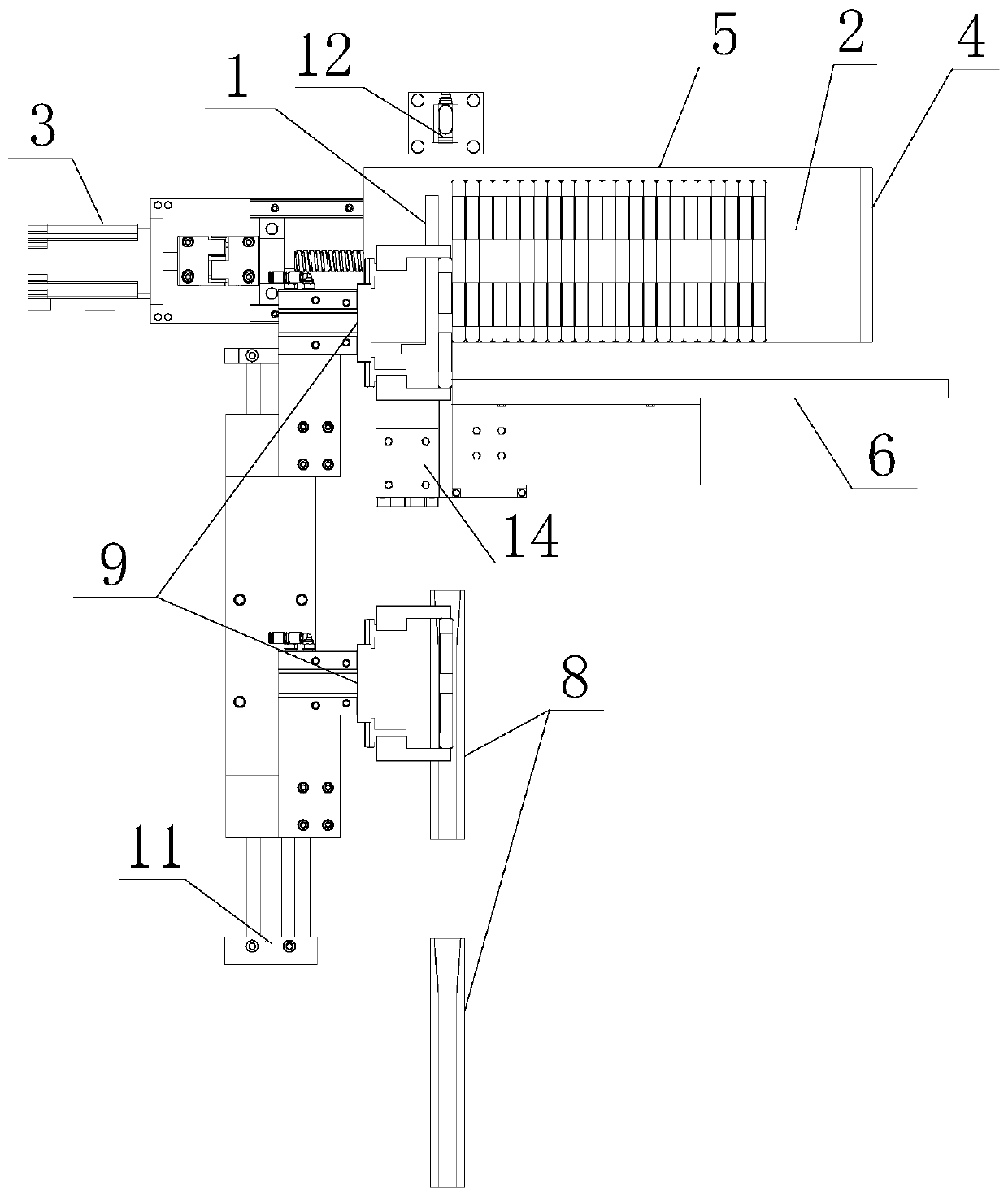

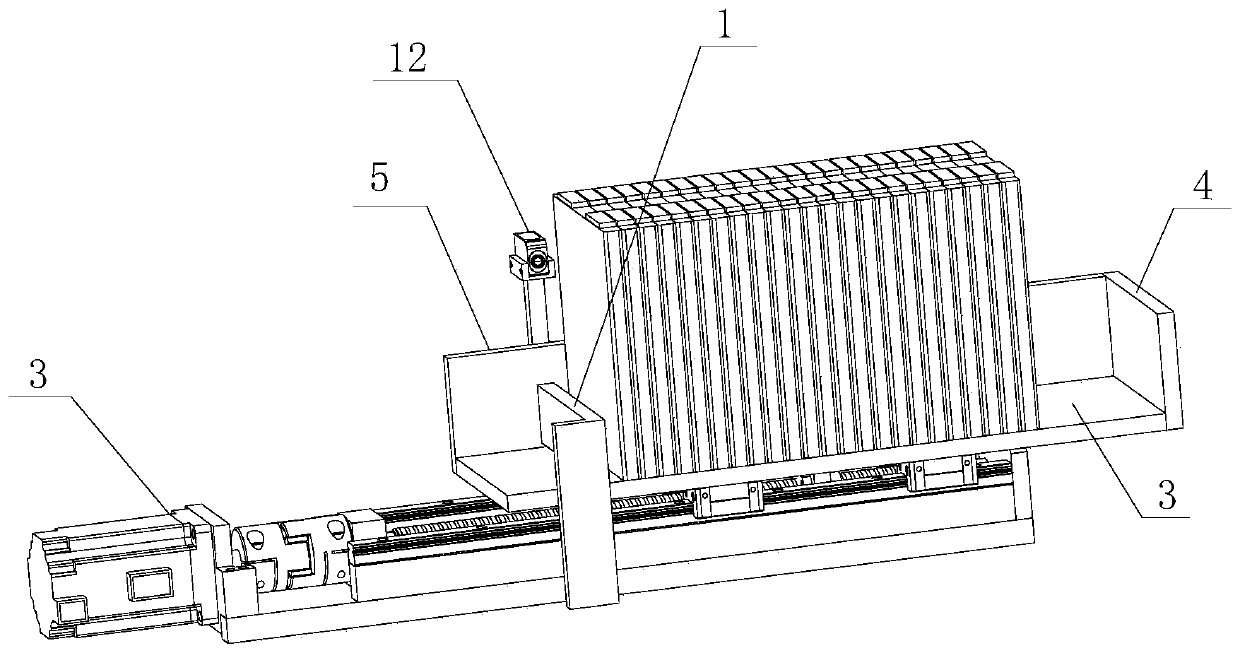

[0023] Such as Figure 1-5 as shown, figure 1 It is a schematic structural diagram of a square battery spacing feeding system proposed by the present invention; figure 2 It is a top view of a square battery spacing feeding system proposed by the present invention; image 3 It is a structural schematic diagram of the conveying device in a square battery spacing feeding system proposed by the present invention; Figure 4 It is a schematic structural diagram of the regularizing device in a square battery spacing feeding system proposed by the present invention; Figure 5 It is a structural schematic diagram of the grabbing device in a rectangular battery spacing feeding system proposed by the present invention.

[0024] refer to Figure 1-3 , a square battery spacing feeding system proposed by the present invention includes: a conveying device, a regularizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com