Patents

Literature

69 results about "Work injury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

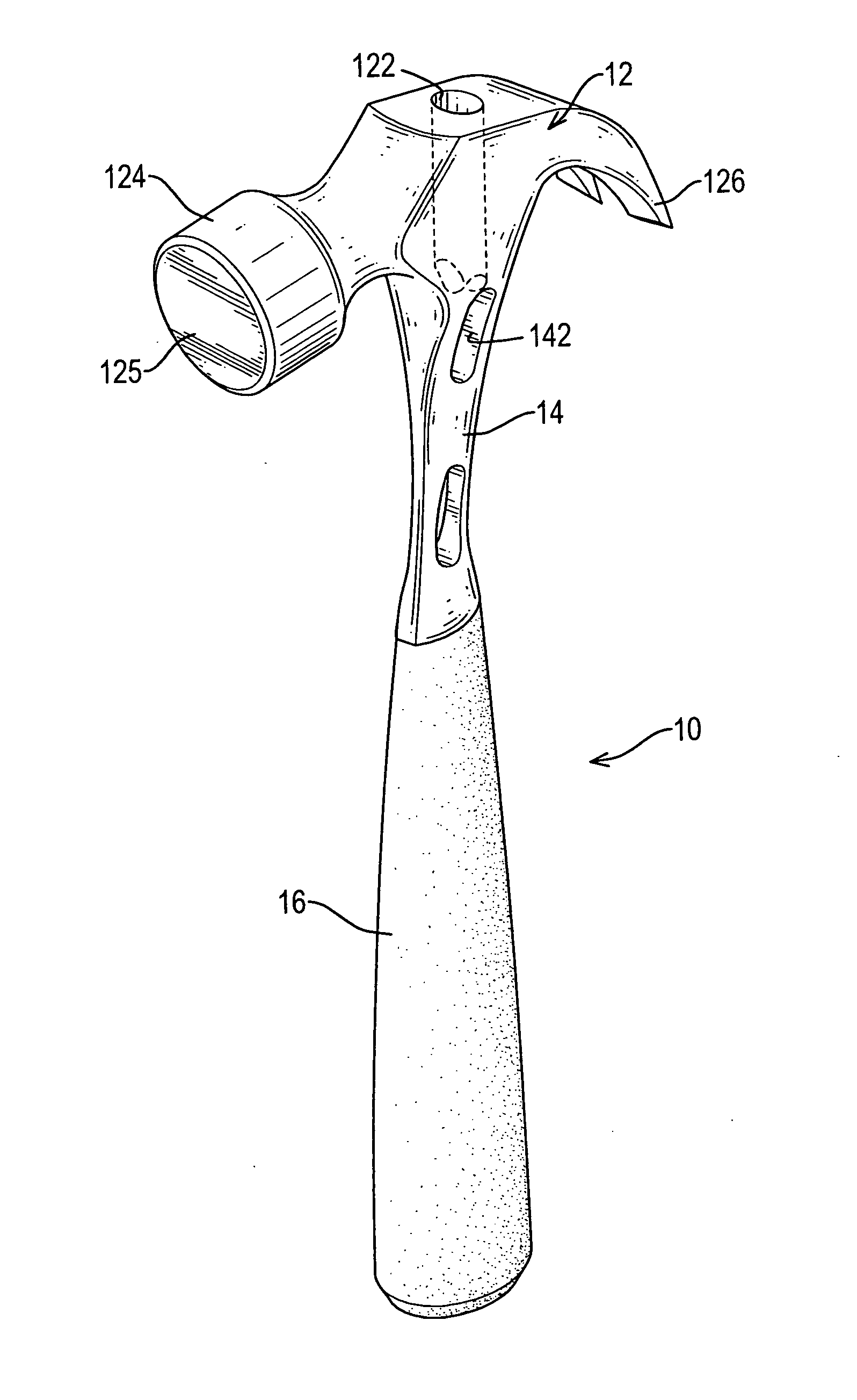

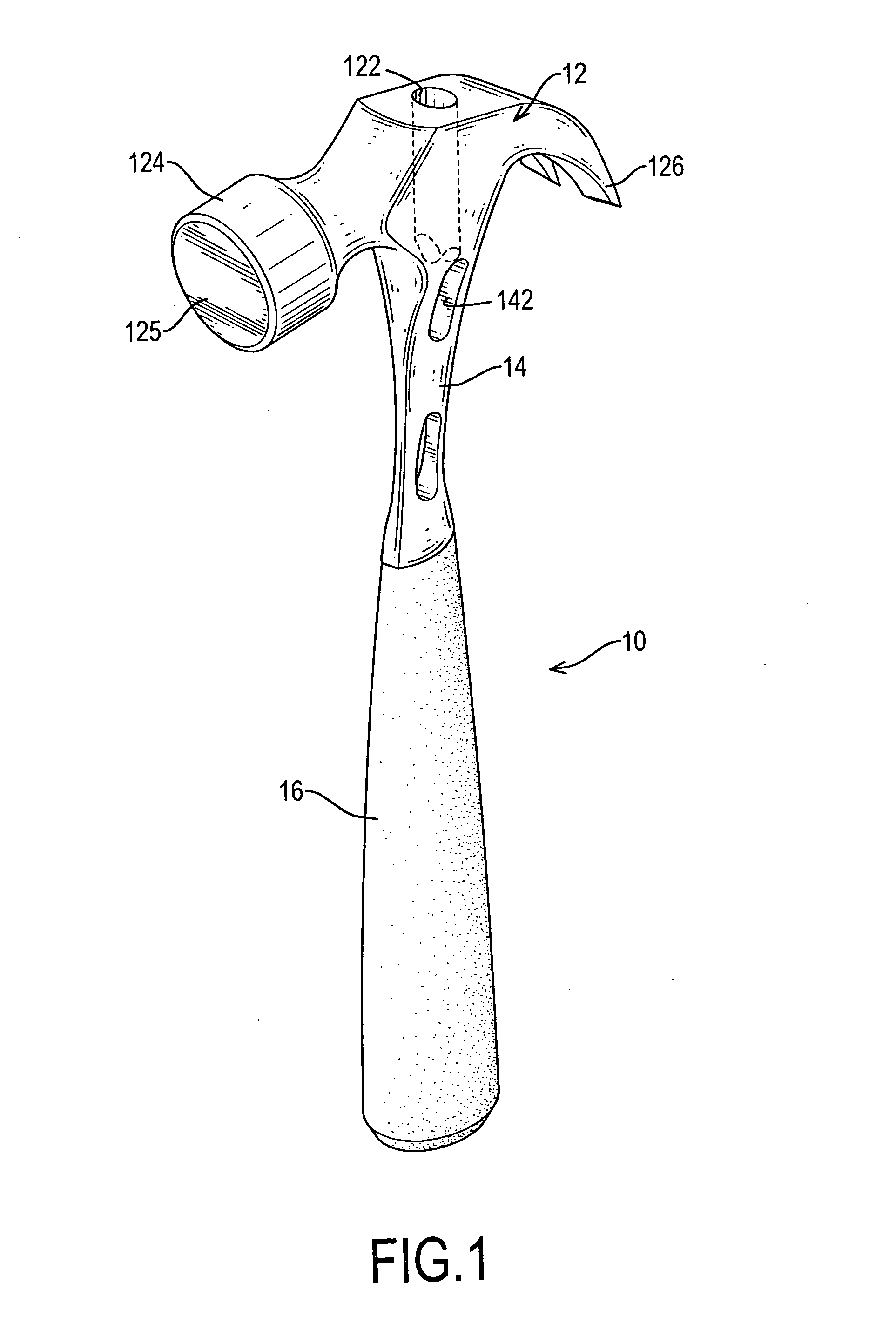

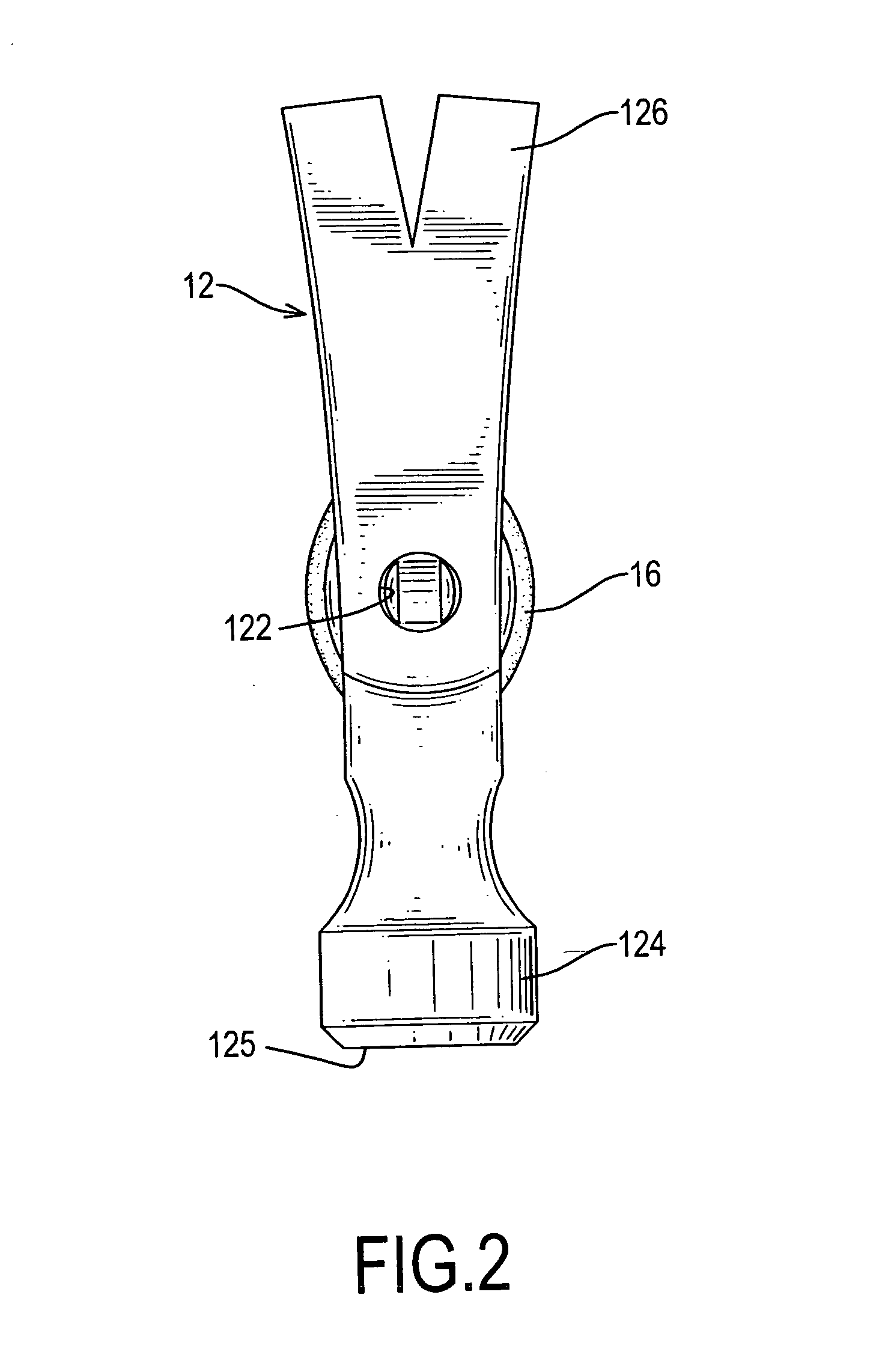

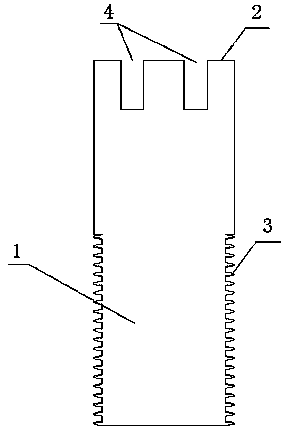

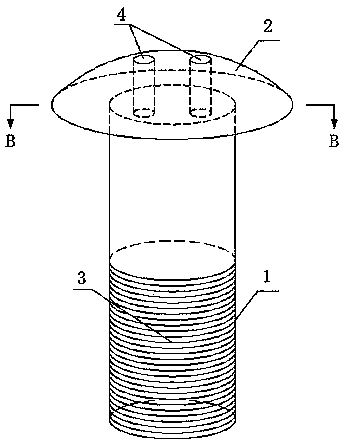

Vibration-damping hammer

A vibration-damping hammer has a head with a neck portion, a handle attached to the neck portion and at least one damping hole defined in the head, particularly in the neck. The at least one damping hole makes the neck sufficiently flexible and mitigates vibration transmission and so eliminates most vibrating energy. Therefore, the hammer has less vibration whereby the comfort enables the user to avoid working injury.

Owner:HUNG YI KUNG

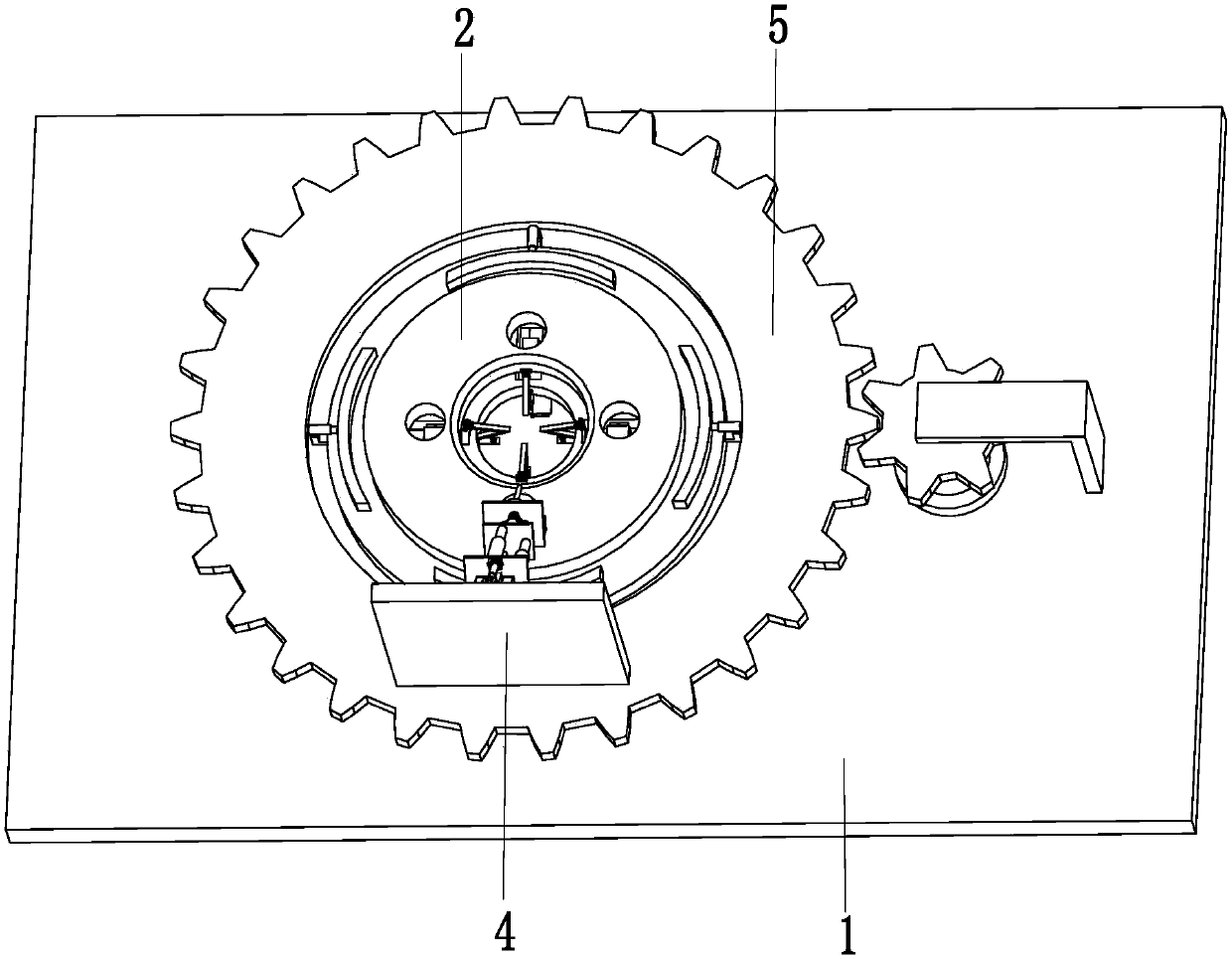

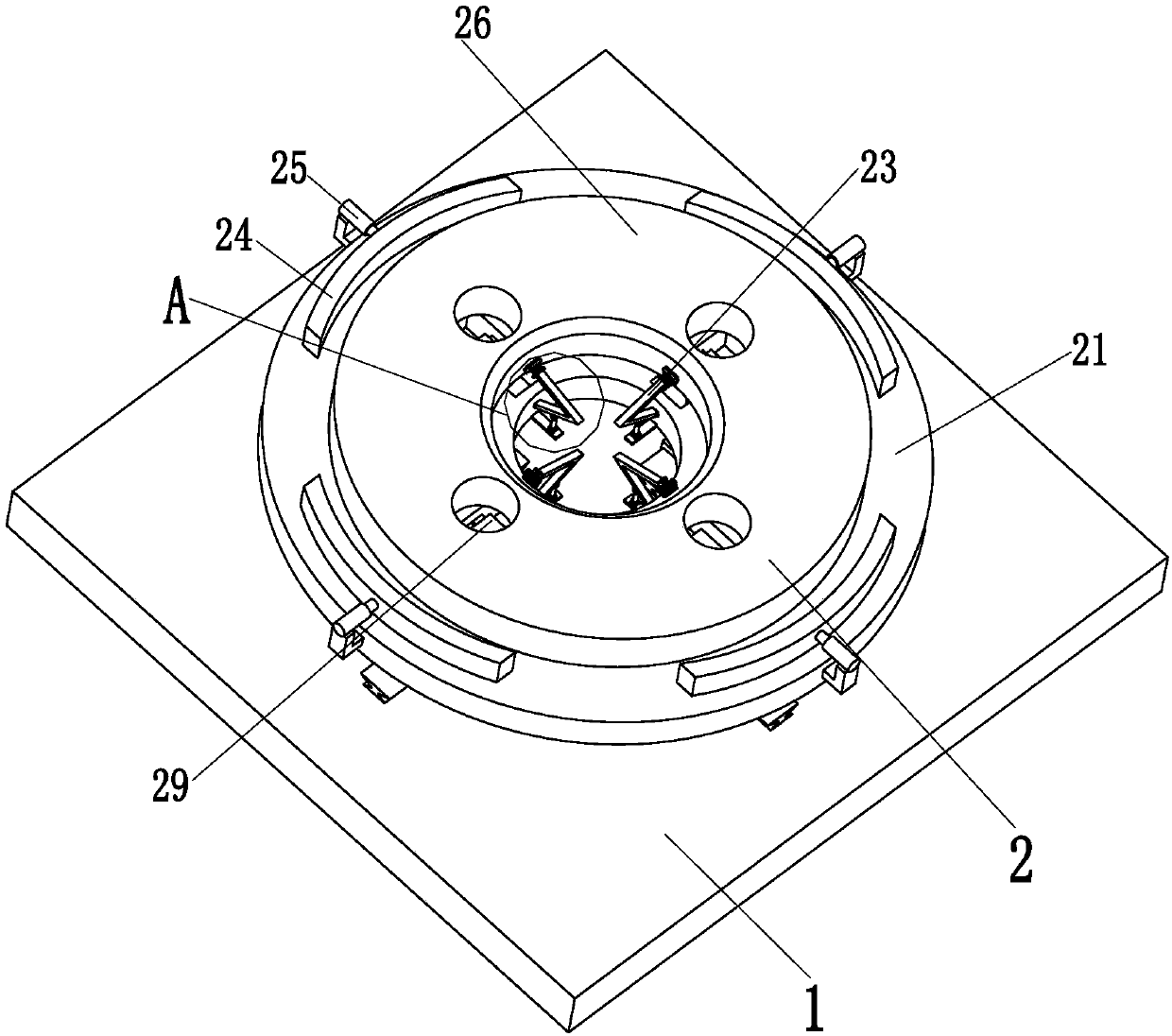

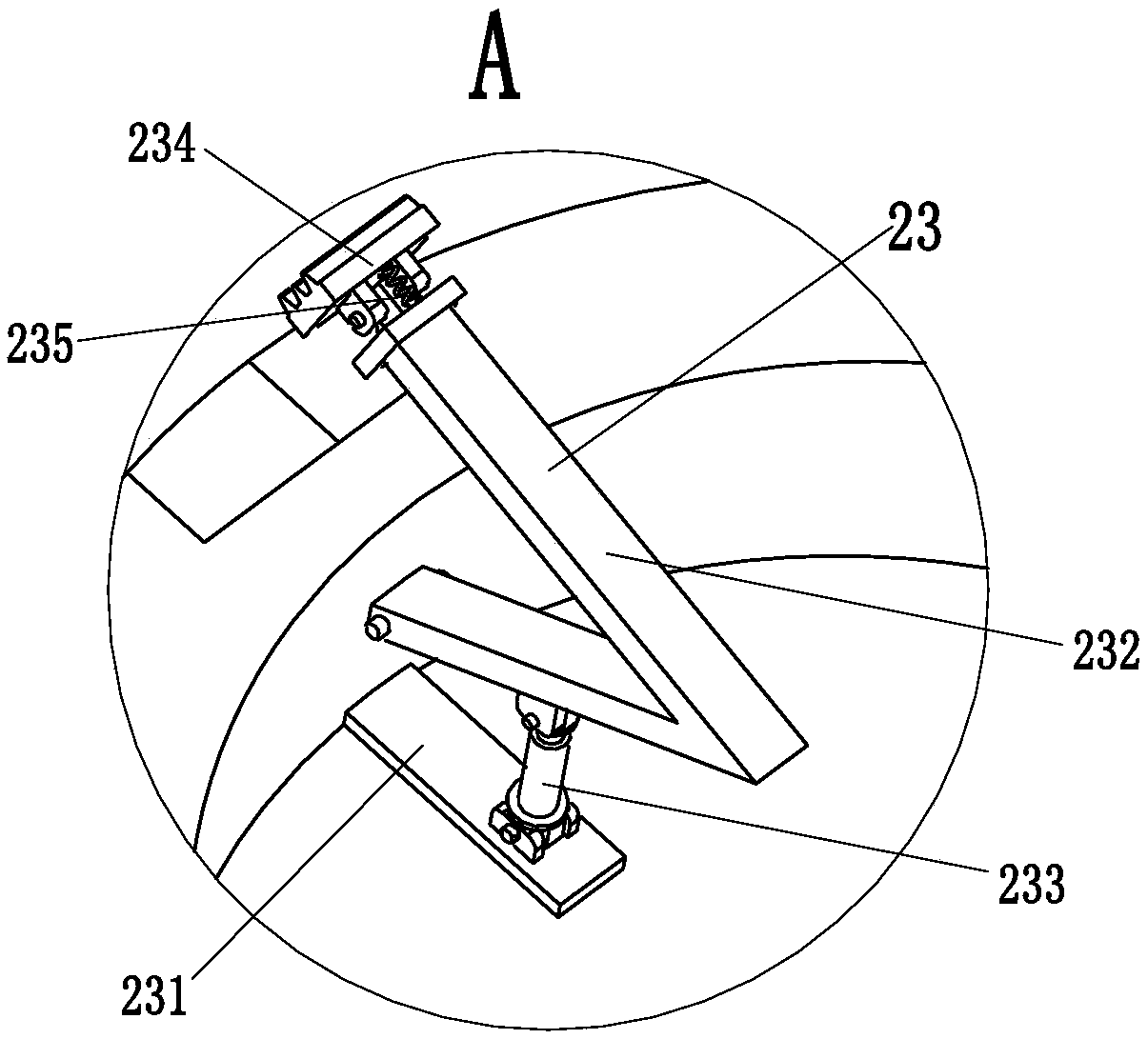

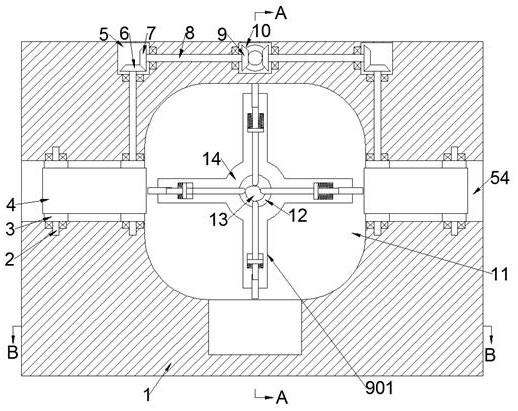

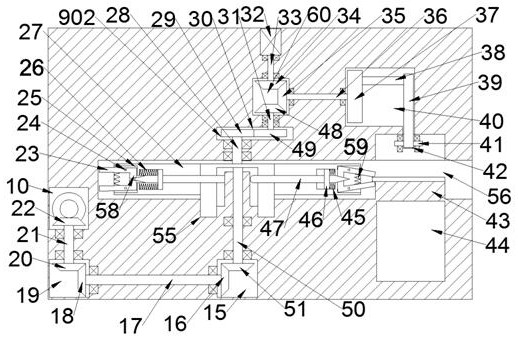

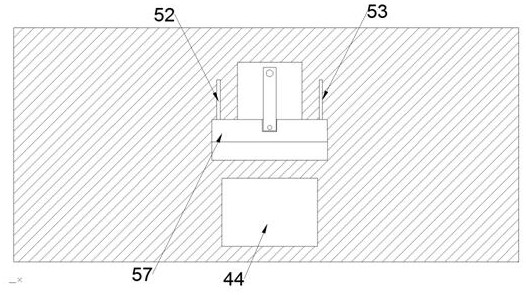

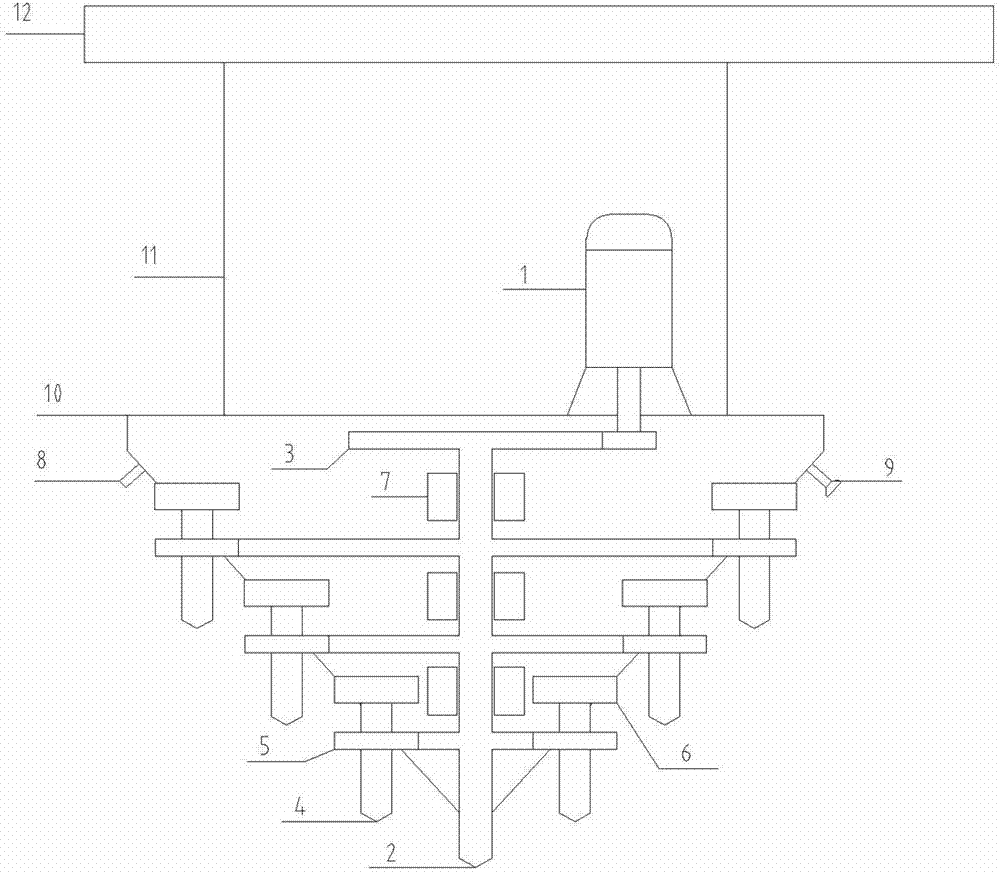

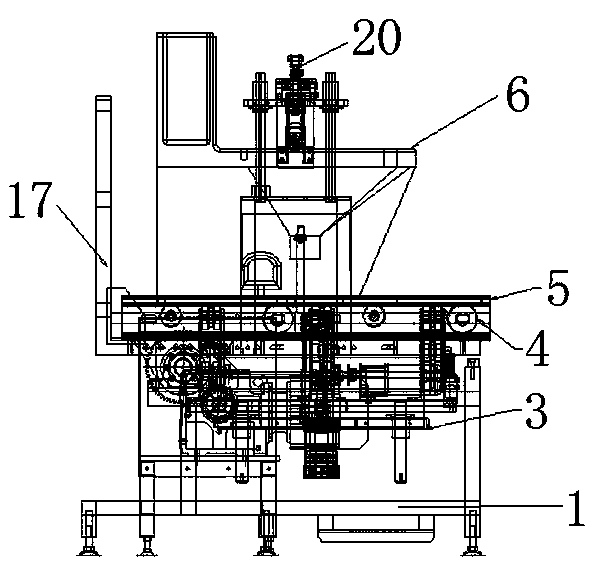

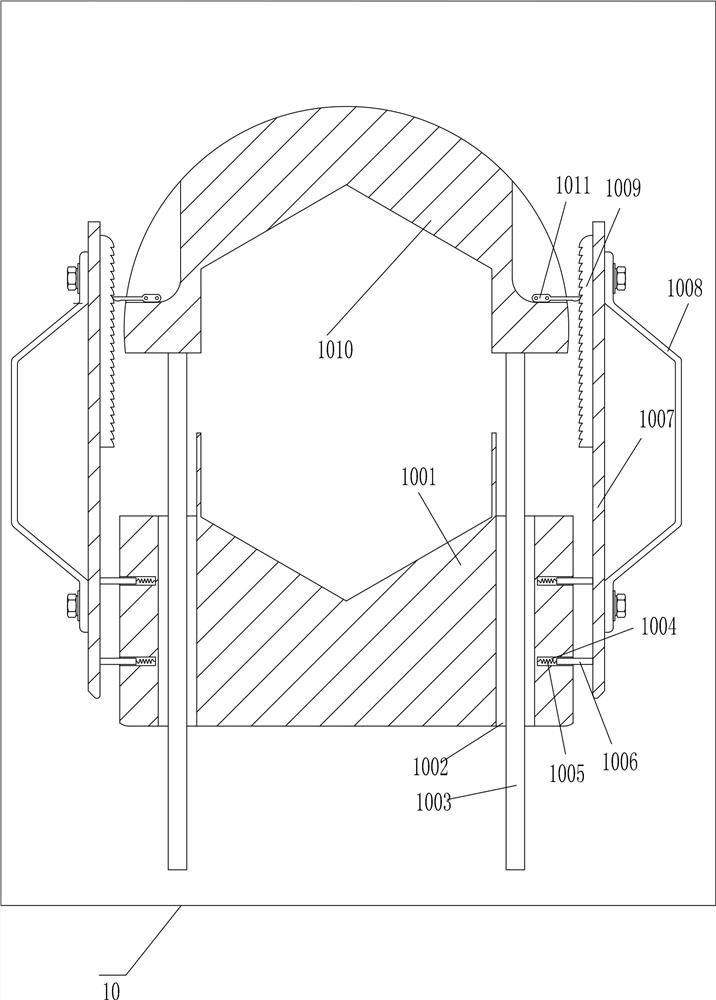

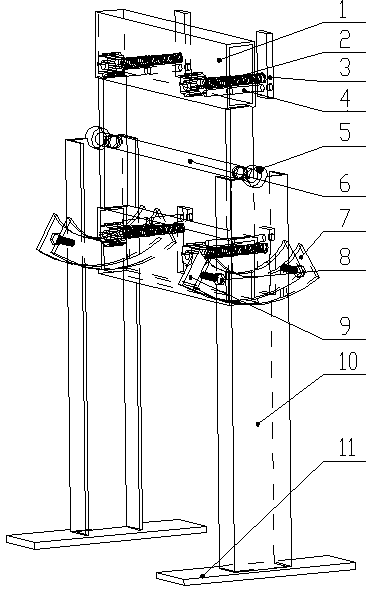

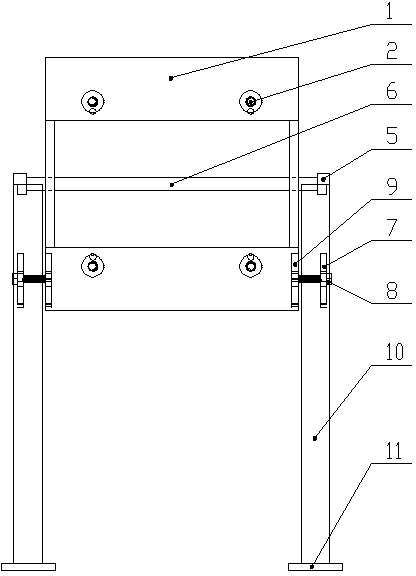

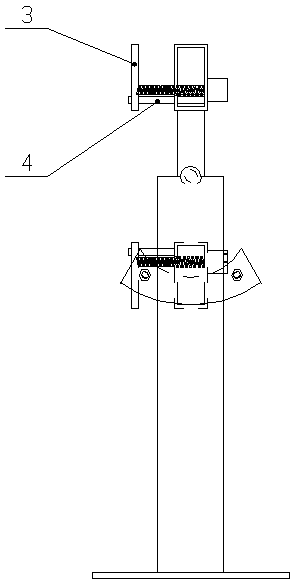

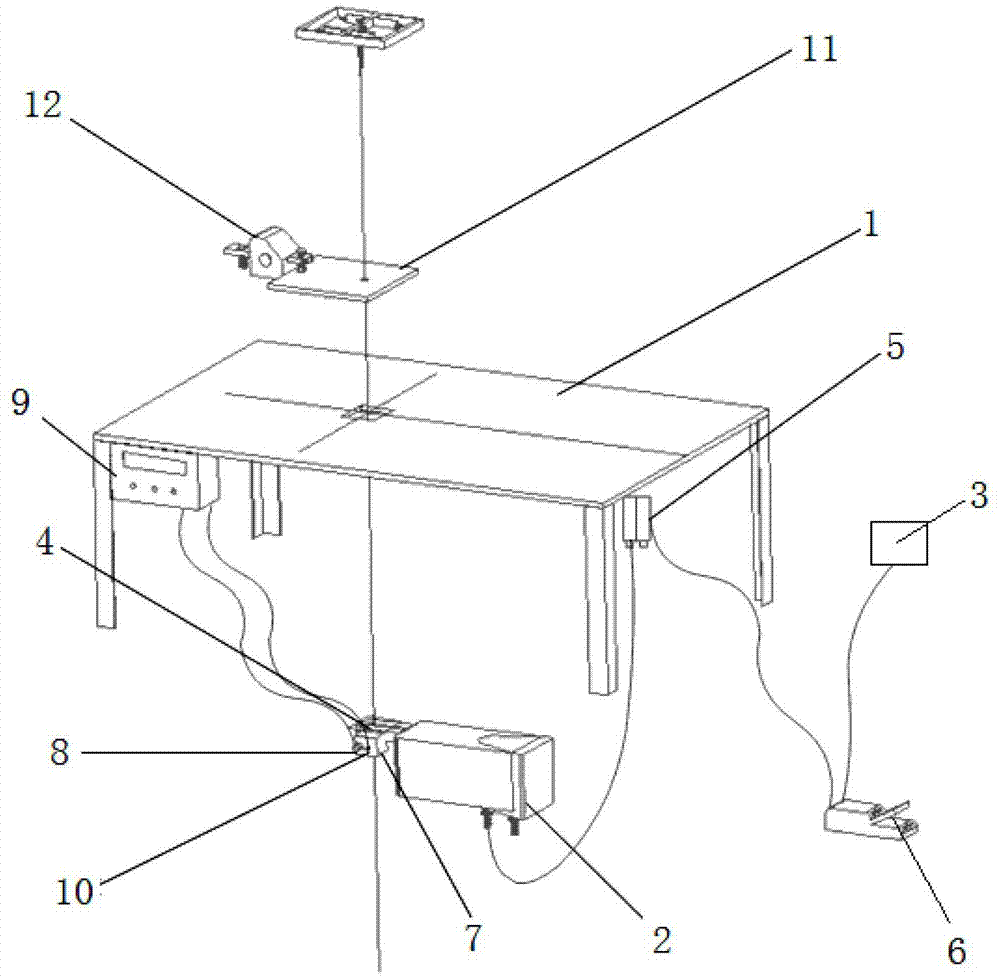

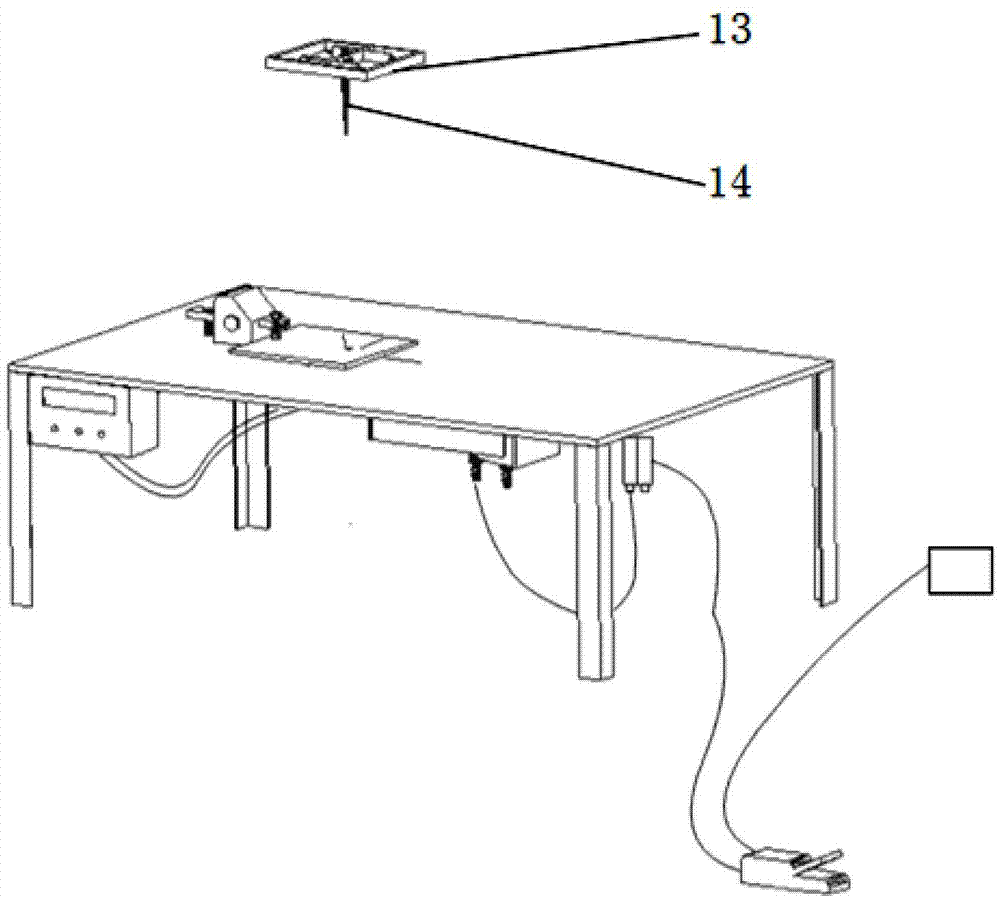

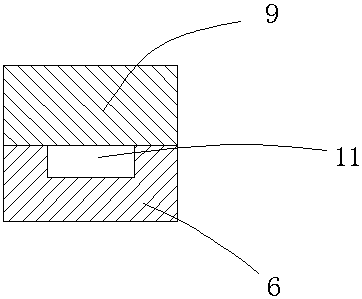

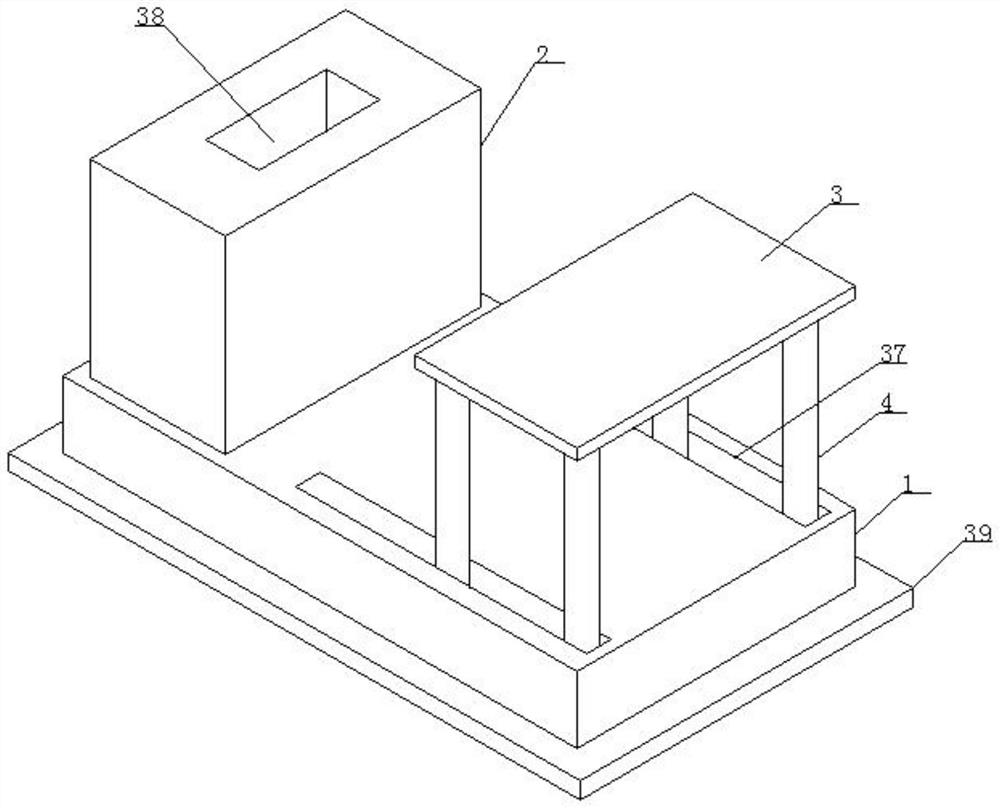

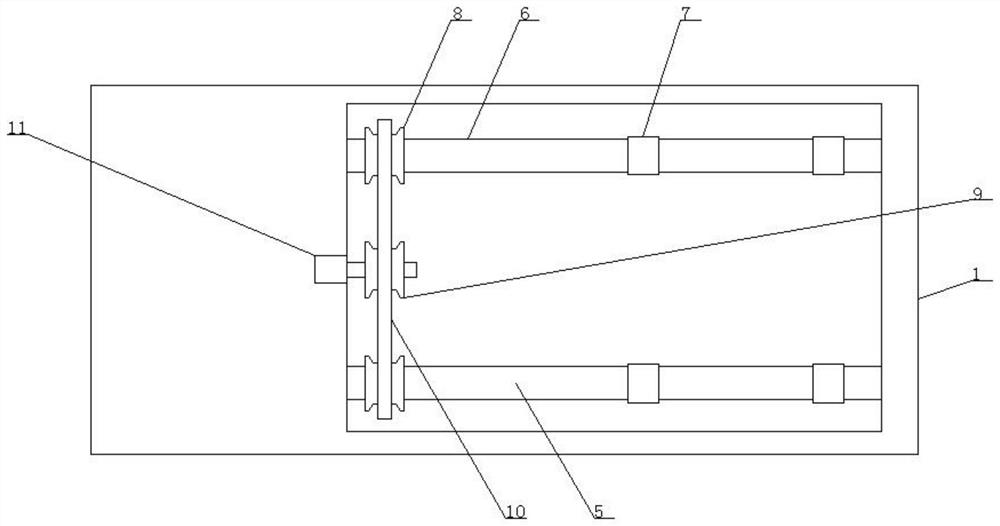

Connecting flange intelligent welding robot for petrochemical equipment mounting projects

InactiveCN107825049AMultiple fixed implementationsImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWork injuryPetrochemical

The invention relates to a connecting flange intelligent welding robot for petrochemical equipment installation engineering, which includes a supporting base plate, a fixing device, a welding device and a rotating device. The fixing device is installed on the middle part of the supporting base plate, and the rotating device is located at the center of the fixing device. On the outside, the rotating device is connected with the support base plate, and the welding device is installed on the rotating device; the welding device includes a welding vertical plate, a welding adjustment push rod, a welding adjustment spring, a welding top plate, a welding push rod, a welding bottom plate, and a welding telescopic rod , welding support plate, welding mechanism and welding telescopic spring. The present invention can solve the existing problems of low work efficiency, large work damage, inability to perform multiple fixings to the flange, weak fixation of the flange, and inability to perform automatic welding actions when welding the flange and the steel pipe; The function of multiple stable fixing of the flange and automatic welding of the flange and the steel pipe.

Owner:吴秋敏

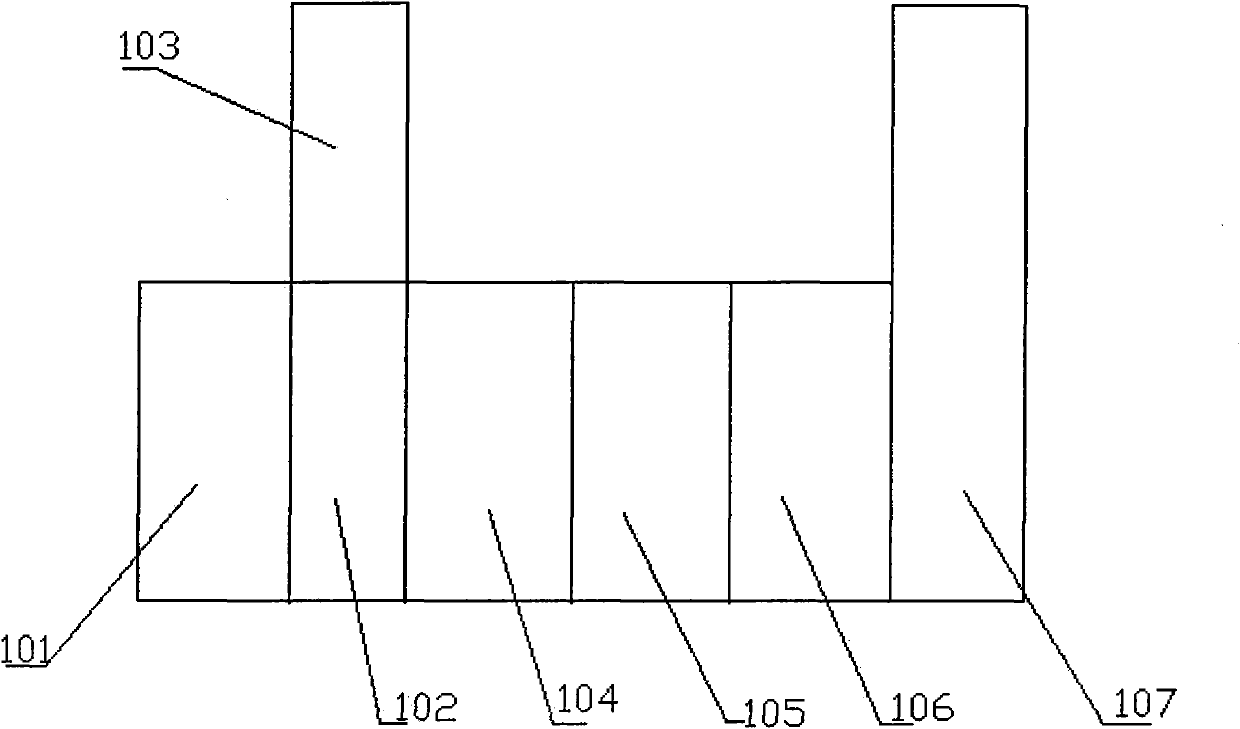

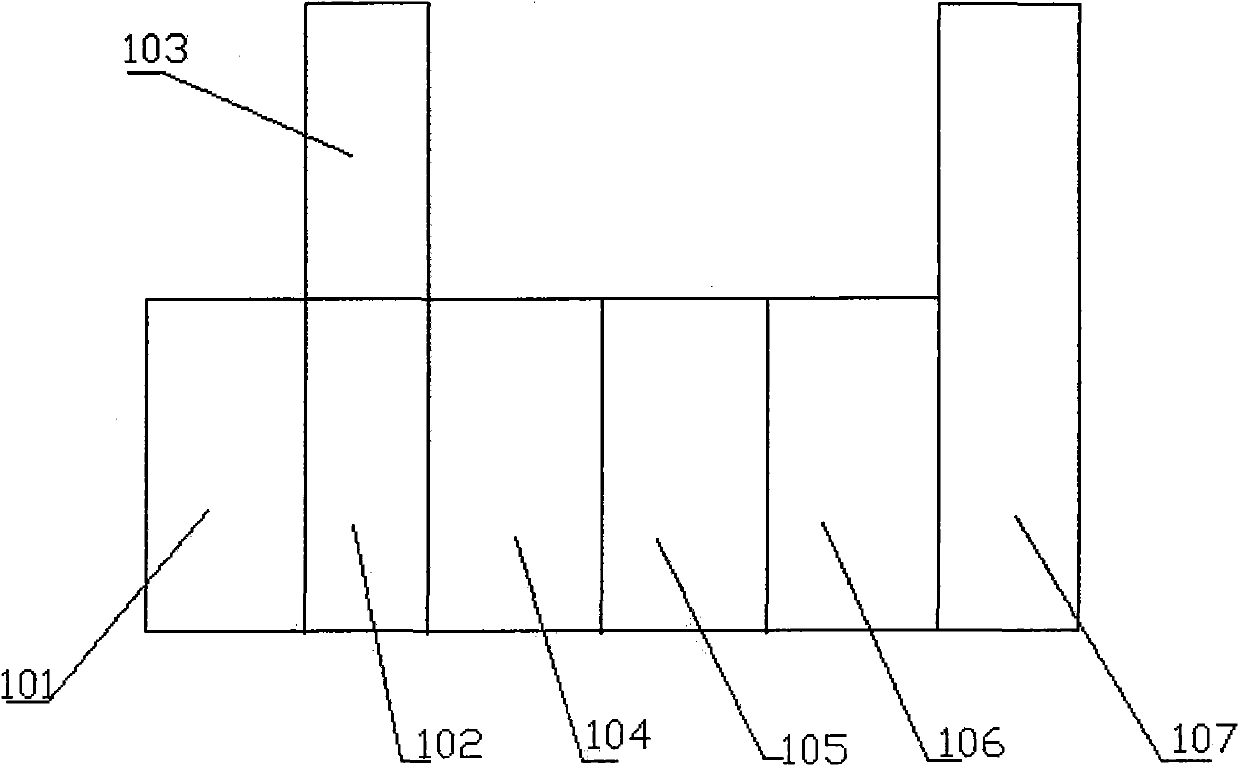

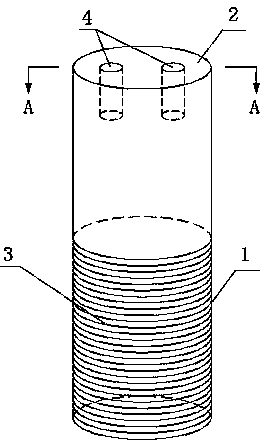

Three-dimensional circular production process for tubular pile

InactiveCN102001133AReduce the use of laborImprove work efficiencyCeramic shaping apparatusWork injuryMechanical engineering

The invention discloses a three-dimensional circular production process for a tubular pile. The process is implemented by the following steps of: lifting a bottom die and placing a steel cage into the die; tensioning the steel cage; feeding; covering the die; centrifuging; performing steam curing; and opening the die and taking the pile, wherein the speed for moving a platform is controlled during the feeding; the thickness of concrete laid on the bottom die of the tubular pile by feeding equipment does not exceed the radius of the bottom die of the tubular pile; the temperature of a steam curing tank is 100 to 180 DEG C; and the steam curing time of the tubular pile die after feeding is 6 to 8 hours. The process has the advantages that: the flow and the spatial layout are rationally arranged by using mechanical automatic equipment; the labor intensity is reduced; meanwhile, the working efficiency is improved and accident work injury is avoided.

Owner:ZHEJIANG KNSN PIPE & PILE

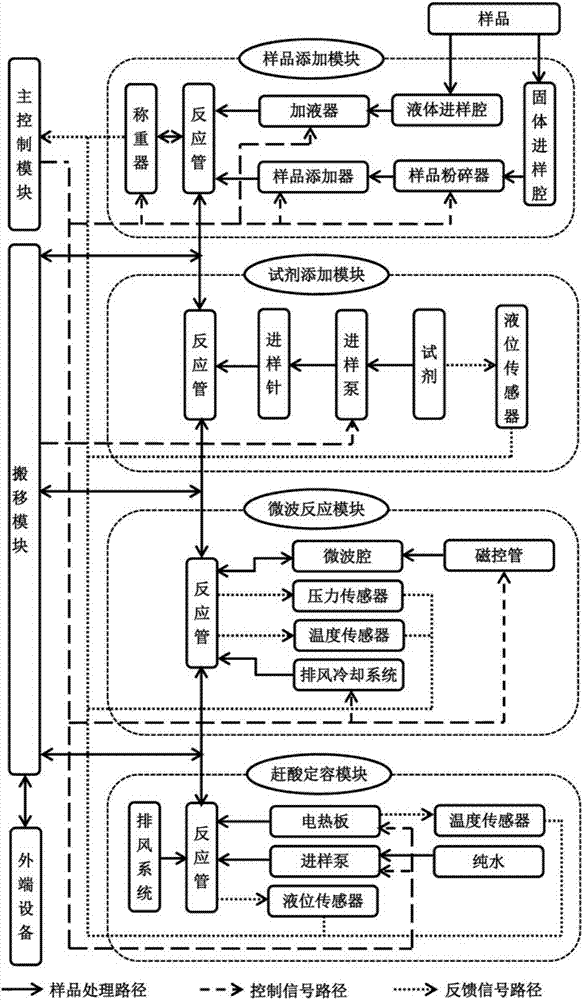

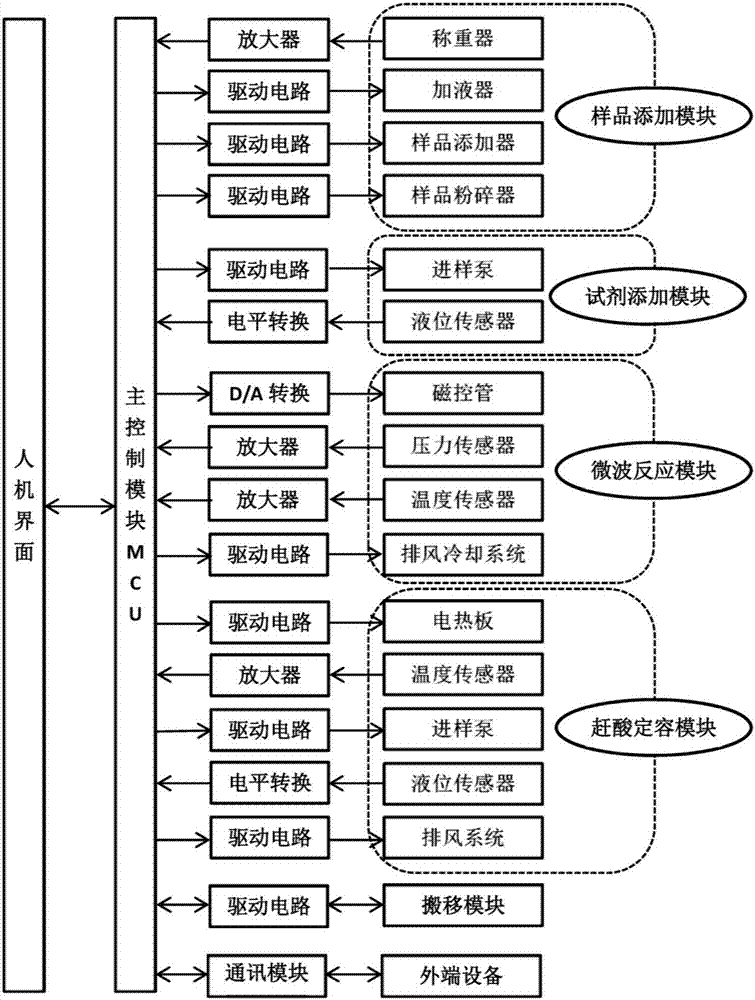

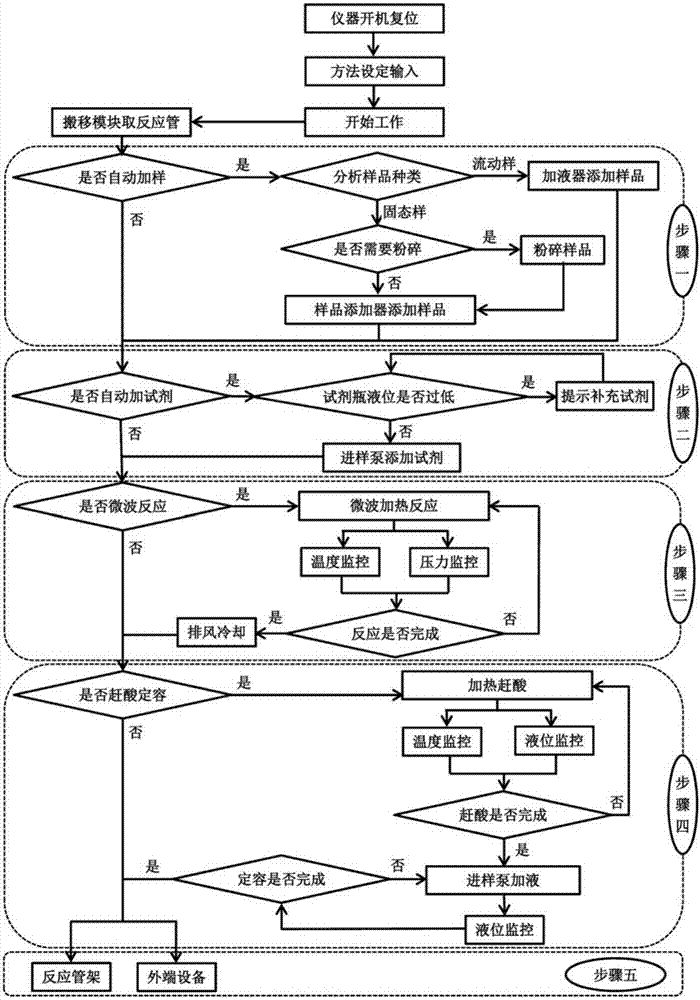

Full-automatic microwave pretreatment device

InactiveCN106872232AAutomate operationEasy to operateWithdrawing sample devicesPreparing sample for investigationDecompositionWork injury

Owner:PREEKEM SCI INSTR

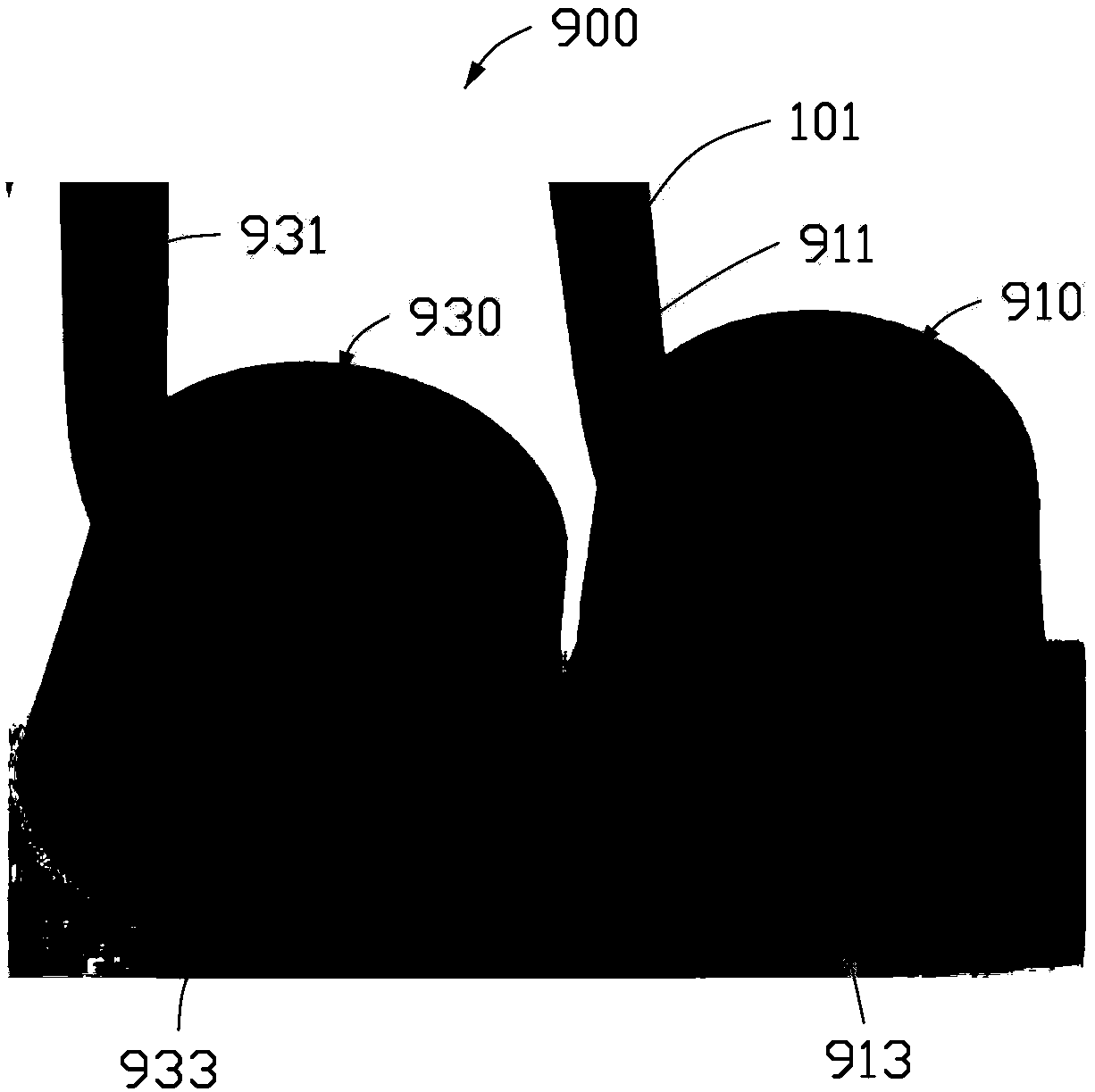

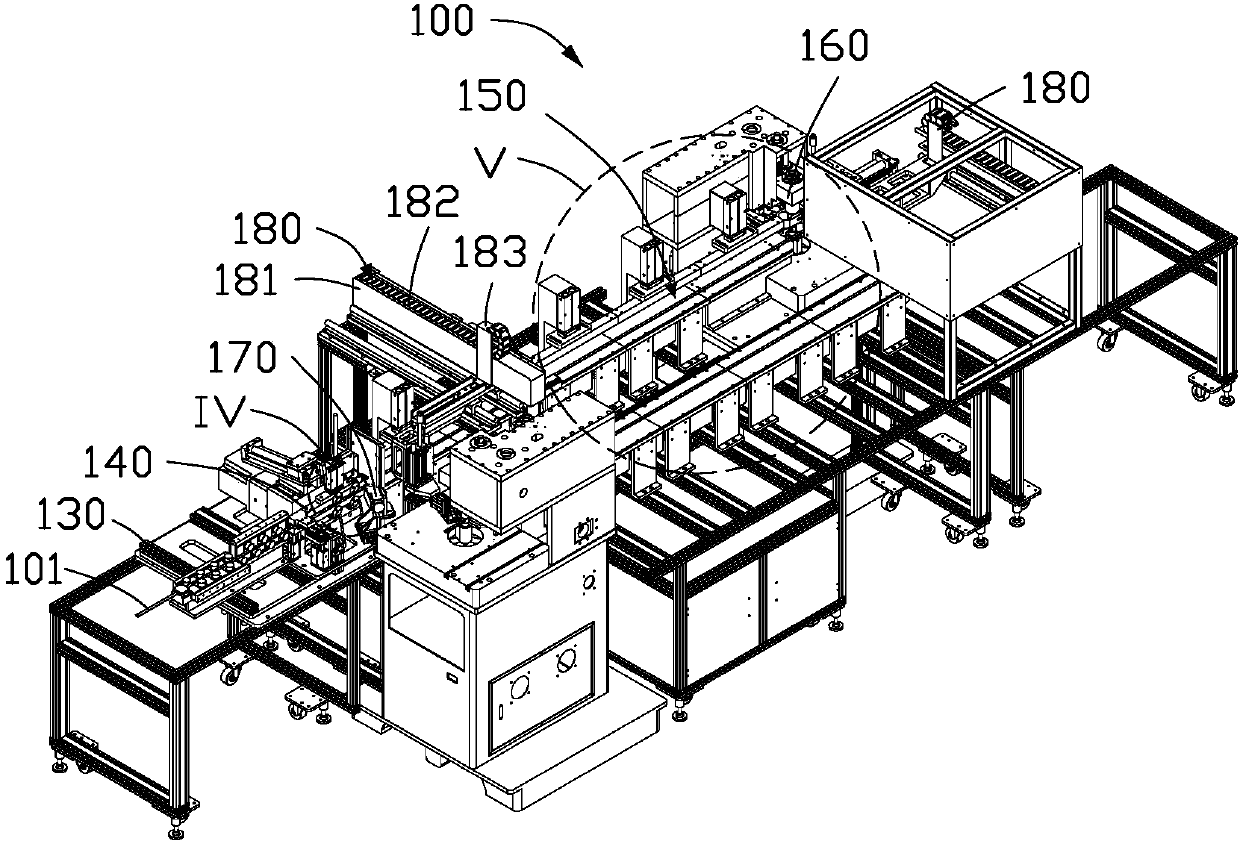

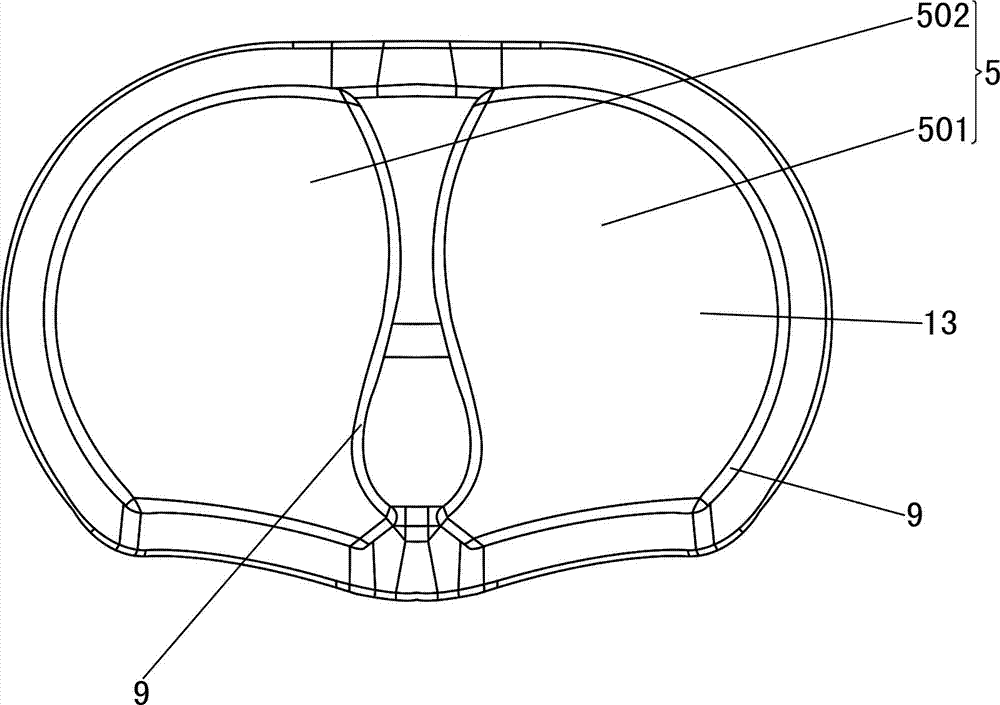

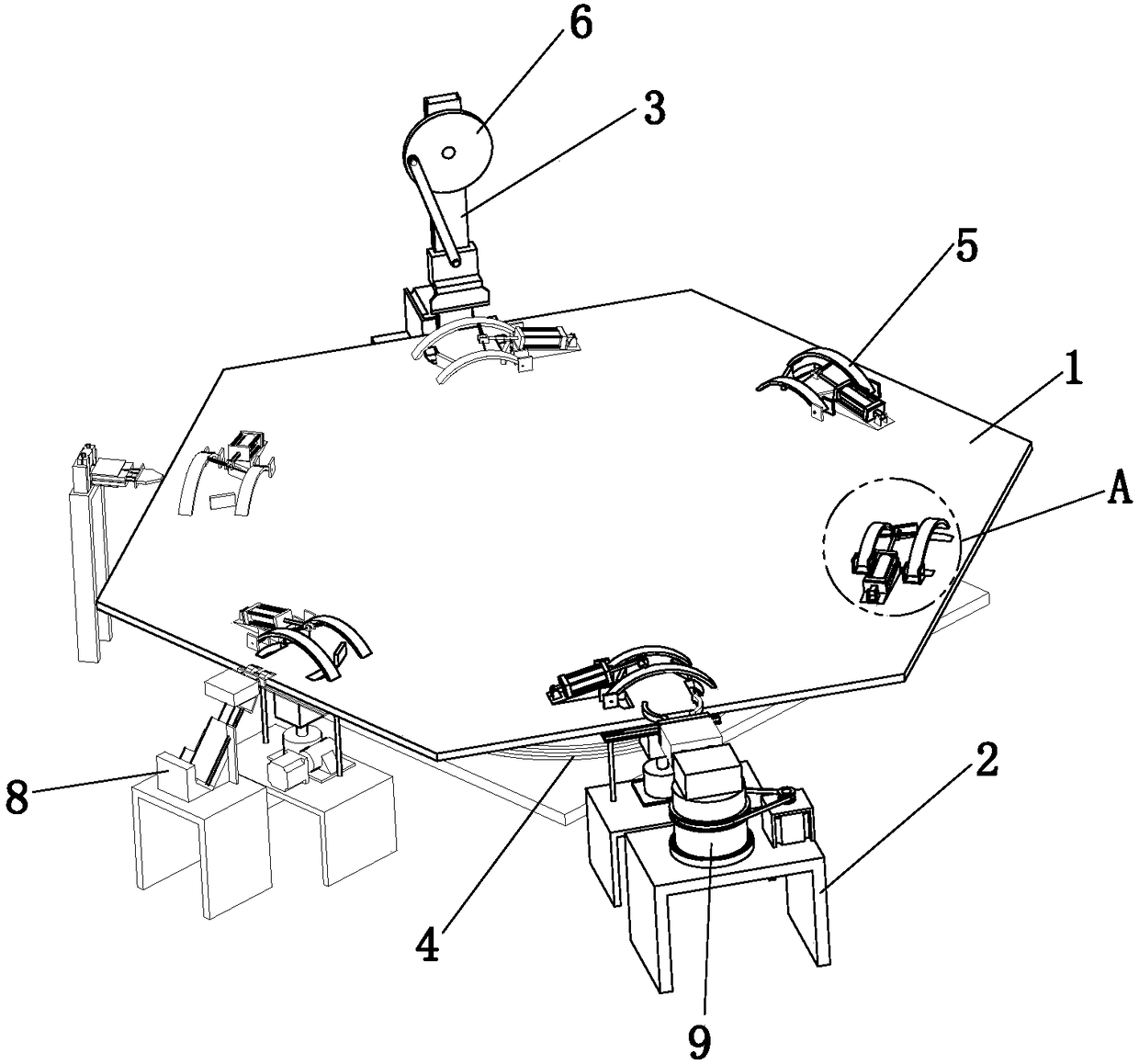

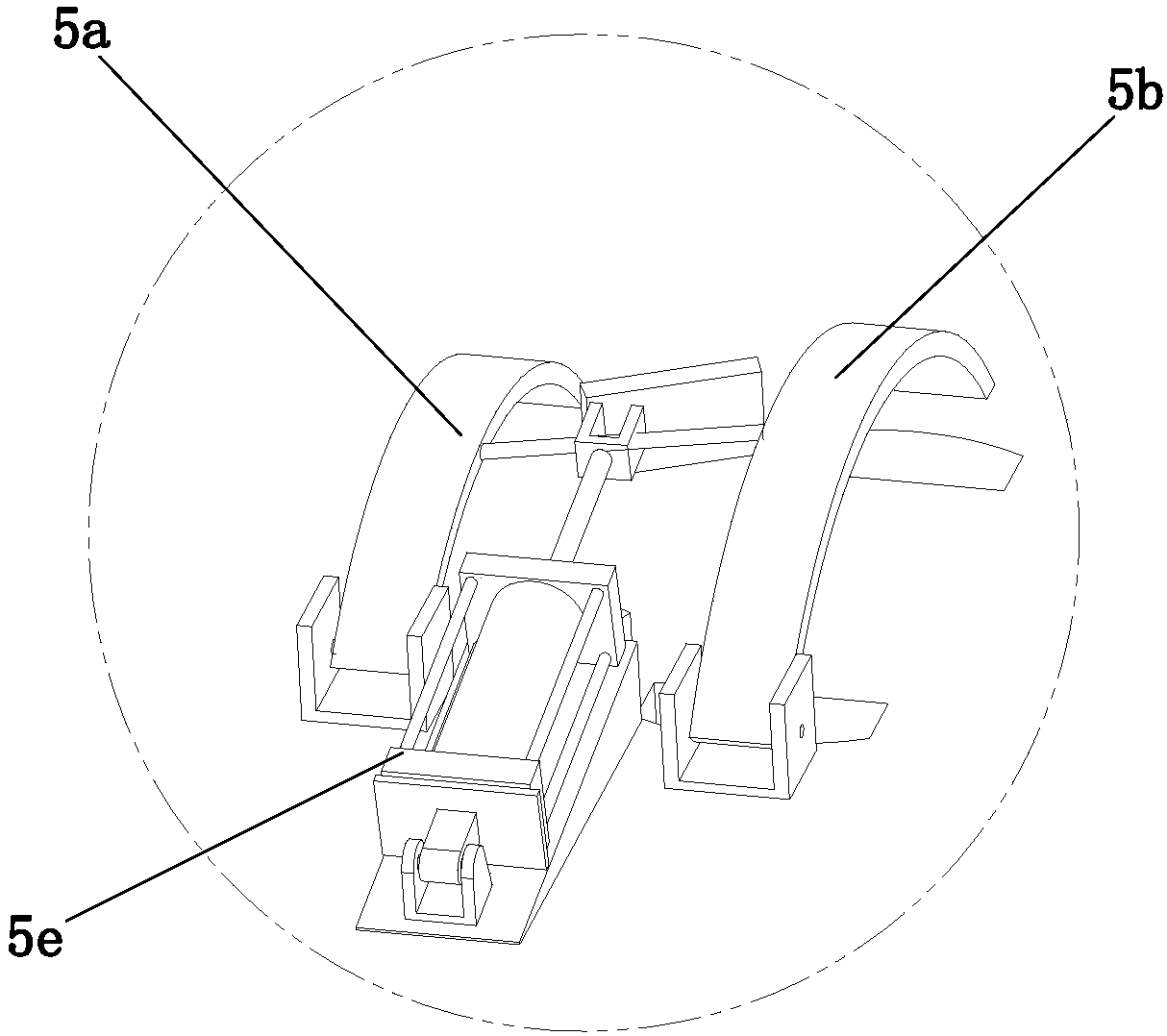

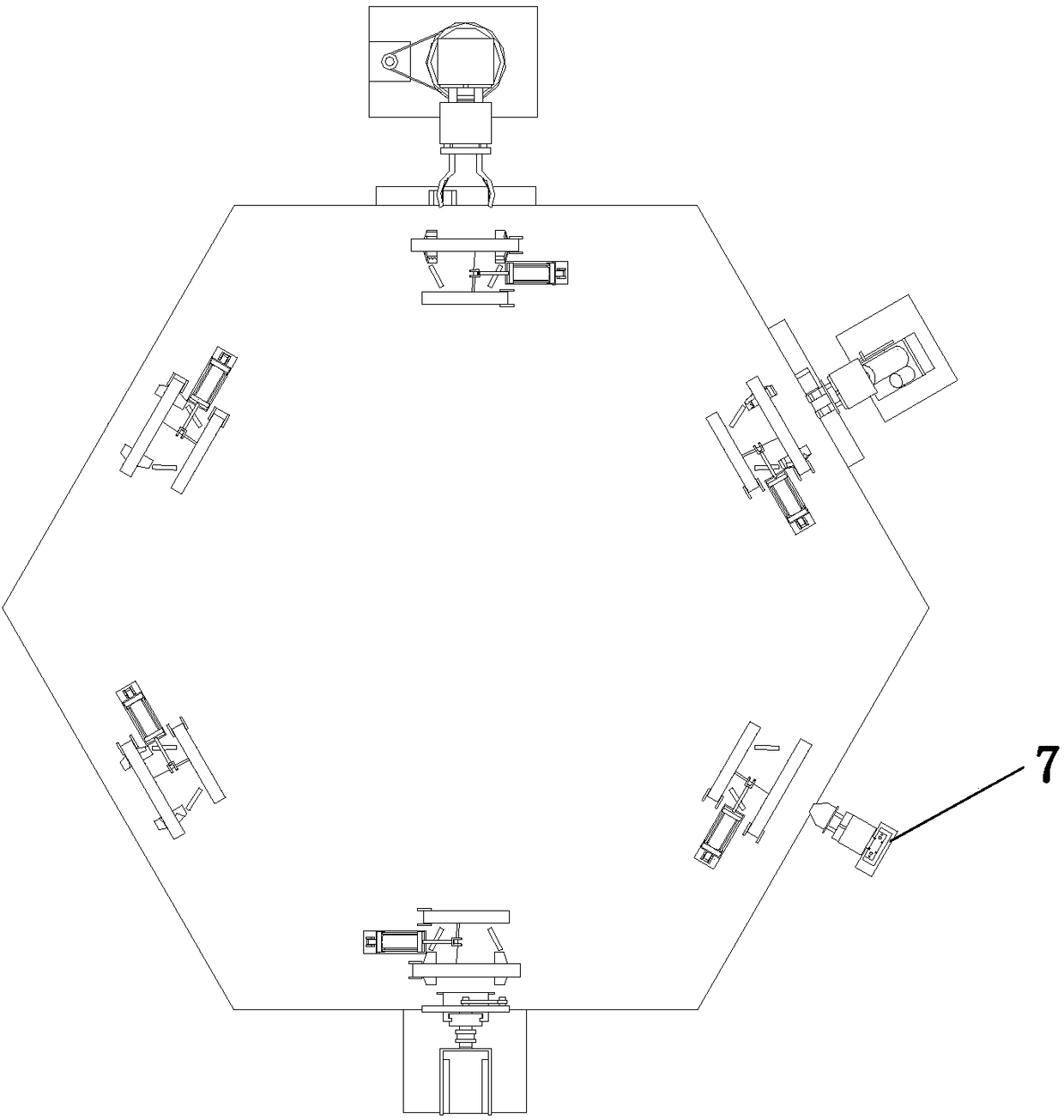

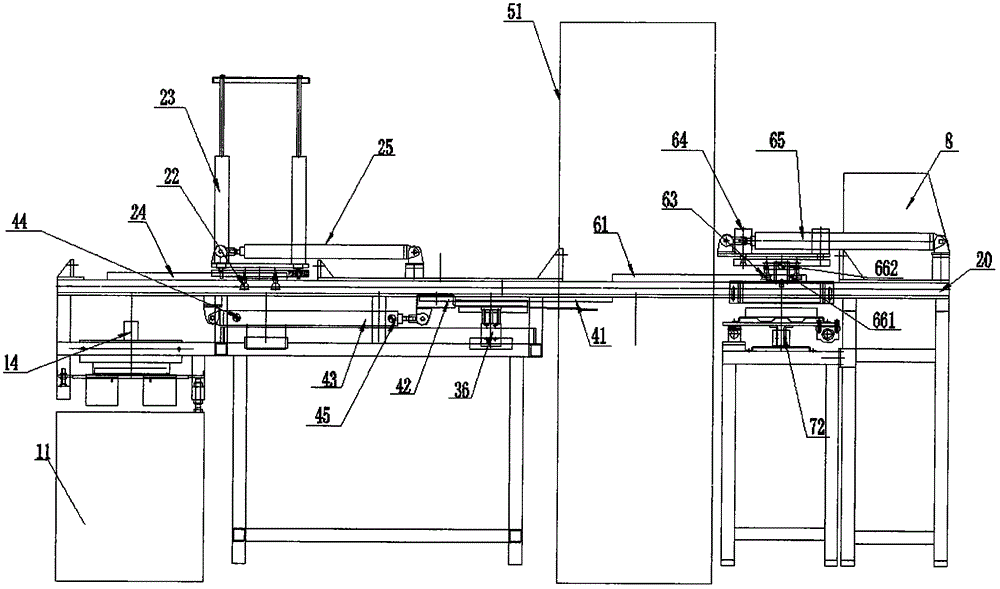

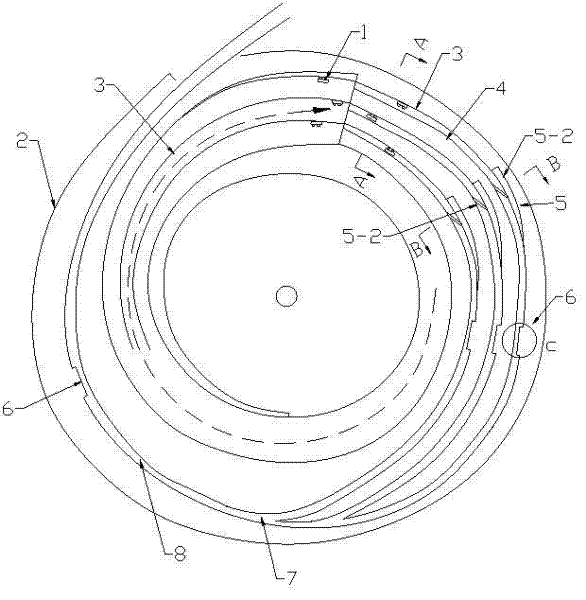

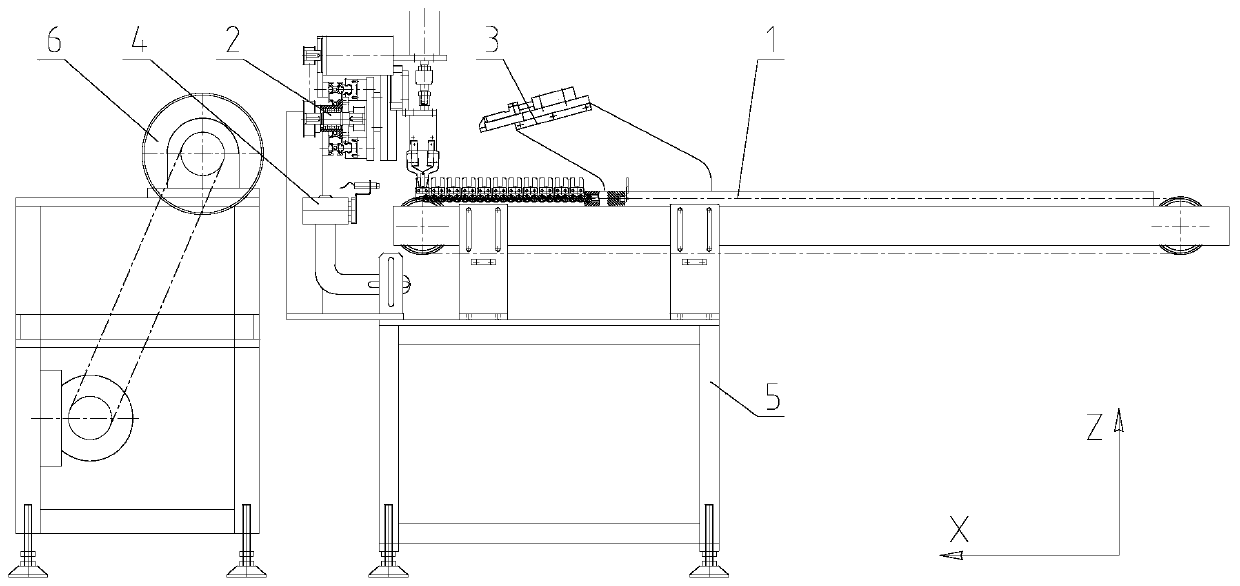

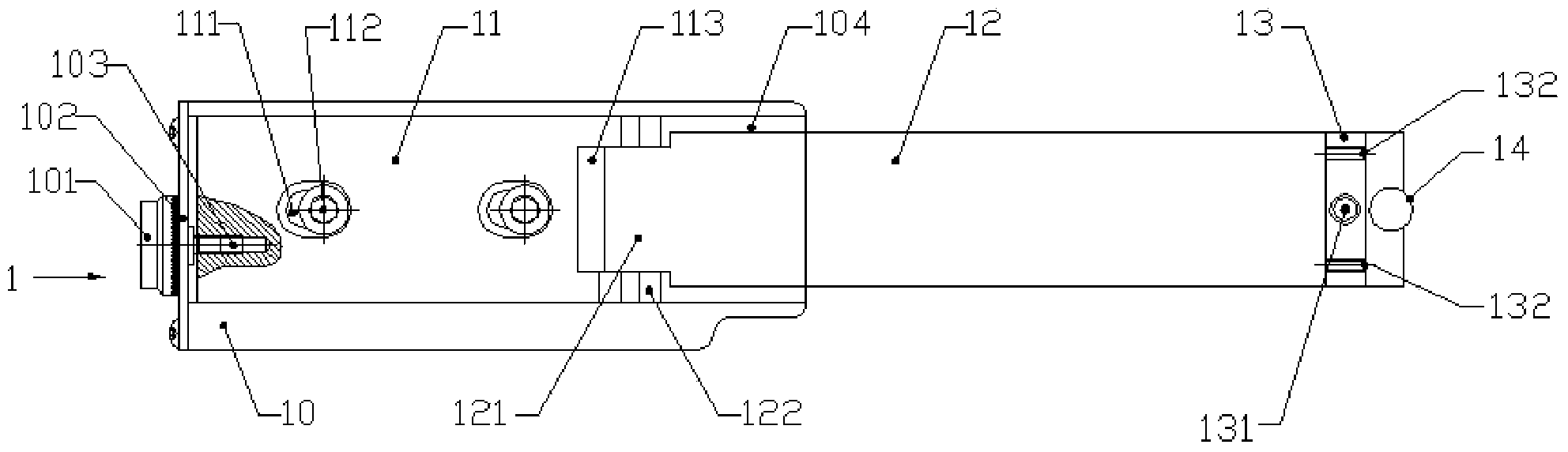

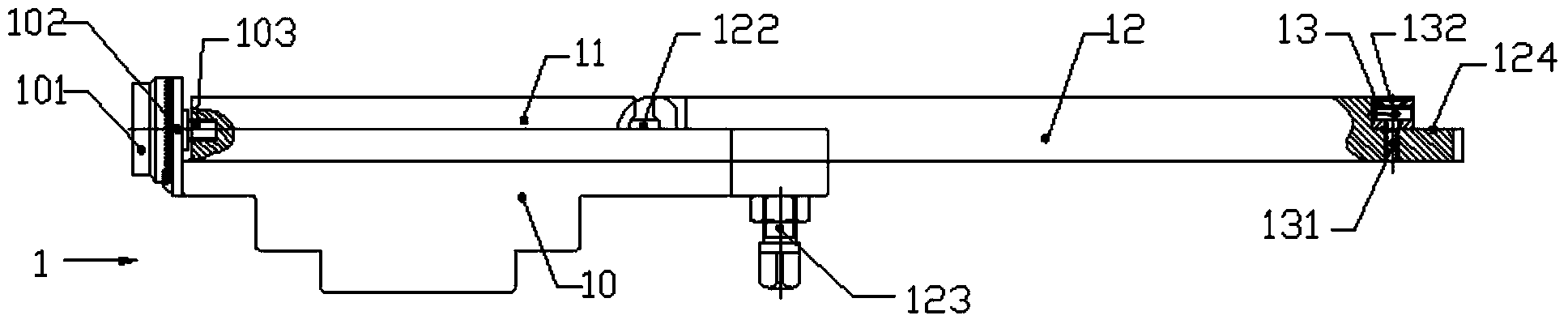

8-shaped winding system and 8-shaped winding method

ActiveCN110060865AReduce manual dependenceReduce work accidentsCoils manufactureWinding machineWind system

The invention provides an 8-shaped winding system and an 8-shaped winding method used by the 8-shaped winding system; the 8-shaped winding system comprises a first winding machine and a second windingmachine; the first winding machine comprises a first feeding device, a first material inputting device, a first winding device, a wire shearing device and a grabbing device; the first winding machineis used for winding a semi-finished product; and the second winding machine comprises a second material inputting device, a second feeding device and a second winding device, wherein the second winding device is used for winding a wire extending out of one end of the semi-finished product into a second set of annular coils to obtain an 8-shaped coil. According to the 8-shaped winding system and the 8-shaped winding method, the dependence of a winding machine on labor is reduced, the production quality is relatively stable, the product precision is high, the production efficiency of the mechanical 8-shaped winding is improved, and the occurrence probability of work injury accidents of a worker is lowered.

Owner:深圳市三通伟业科技有限公司

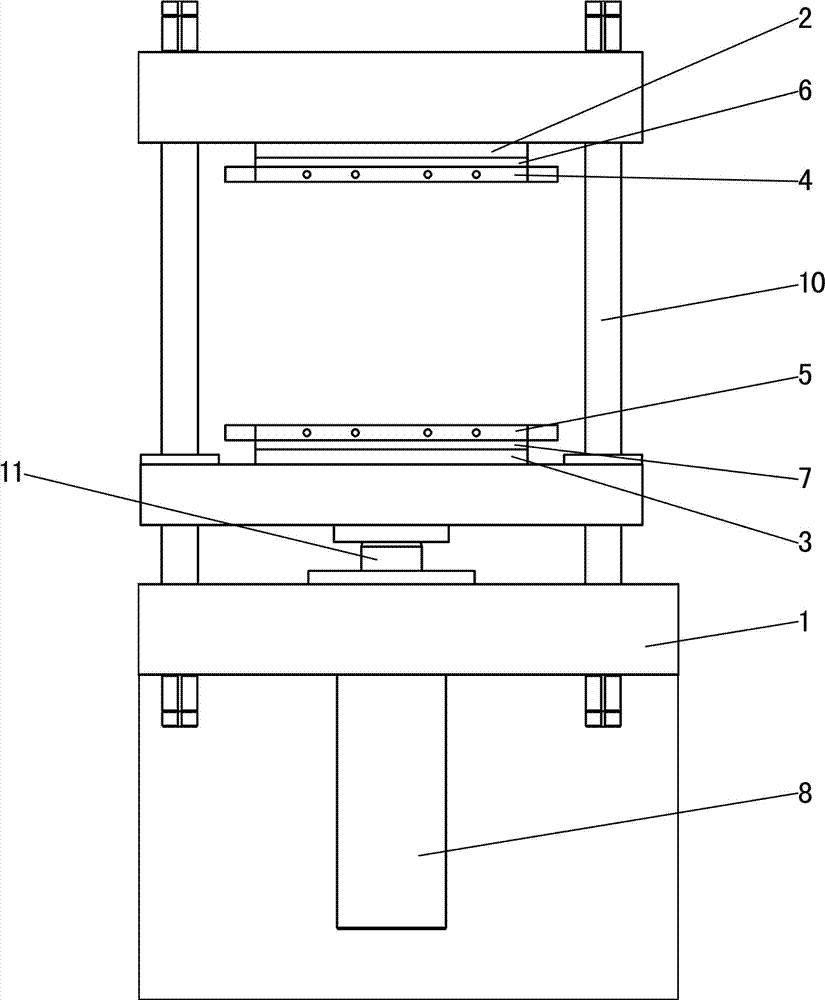

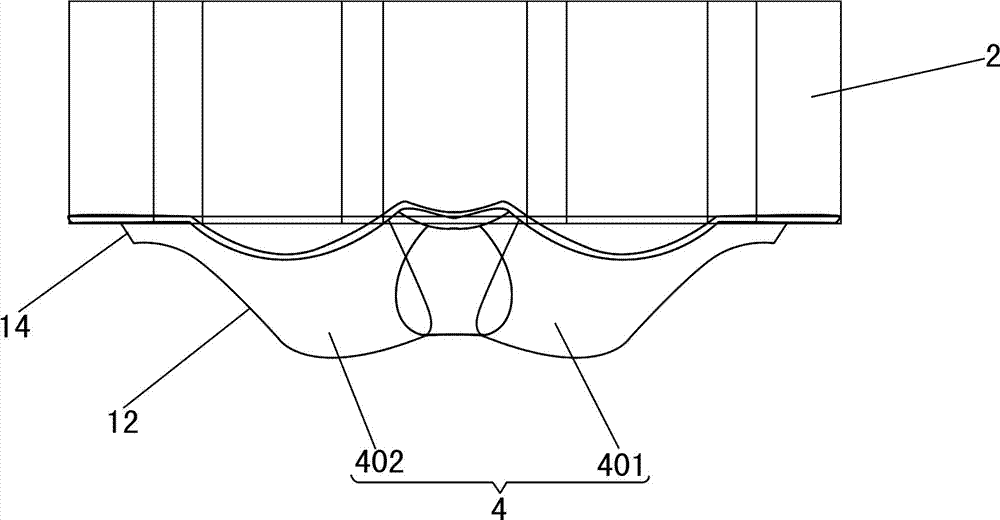

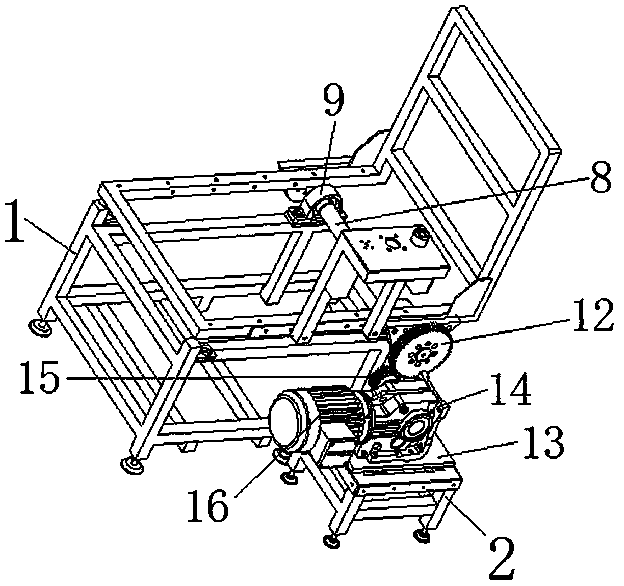

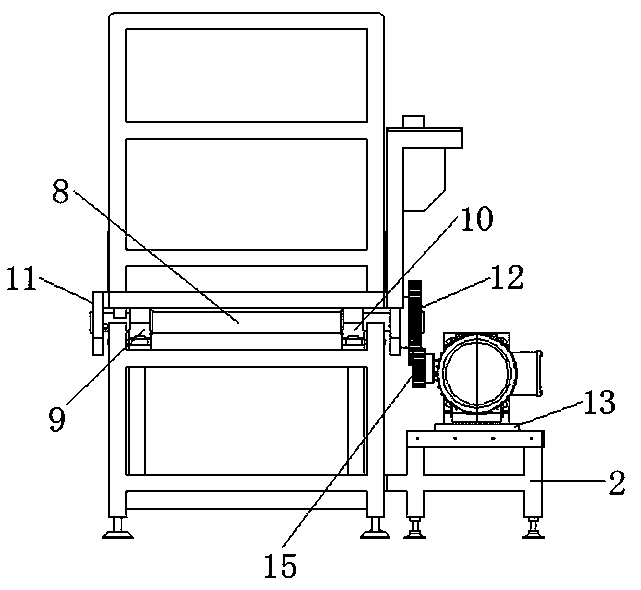

Full-automatic hot press molding and shearing machine for chest cup

ActiveCN102814971AFully automaticRealize fully automatic thermoformingDomestic articlesHydraulic cylinderWork injury

The invention relates to a full-automatic hot press molding and shearing machine for a chest cup. The hot press molding and shearing machine comprises a rack, an upper mould table, a lower mould table, an upper mould, a lower mould, an upper heating device, a lower heating device, a hydraulic cylinder and an annular slicer, wherein the upper mould comprises at least one upper mould unit; the lower mould comprises at least one lower mould unit; the upper mould unit is provided with a first curved surface which protrudes outwards; the lower mould unit is provided with a second curved surface which depresses inwards; the annular slicer is positioned on the second curved surface and is arranged along the edge of the second curved surface; and a cutting edge of the annular slicer faces the first curved surface. Because the annular slicer is arranged along the edge of the second curved surface of the lower mould unit, the edge of the annular slicer faces the first curved surface, and the hydraulic cylinder is subjected to control on two steps of hot press molding and shearing, so that the full-automatic hot press molding and shearing of a chest cup are realized, the edge of the chest cup is smoother and more natural, the production efficiency is improved, the production cost is reduced, and accident work injuries are avoided.

Owner:常建毅 +1

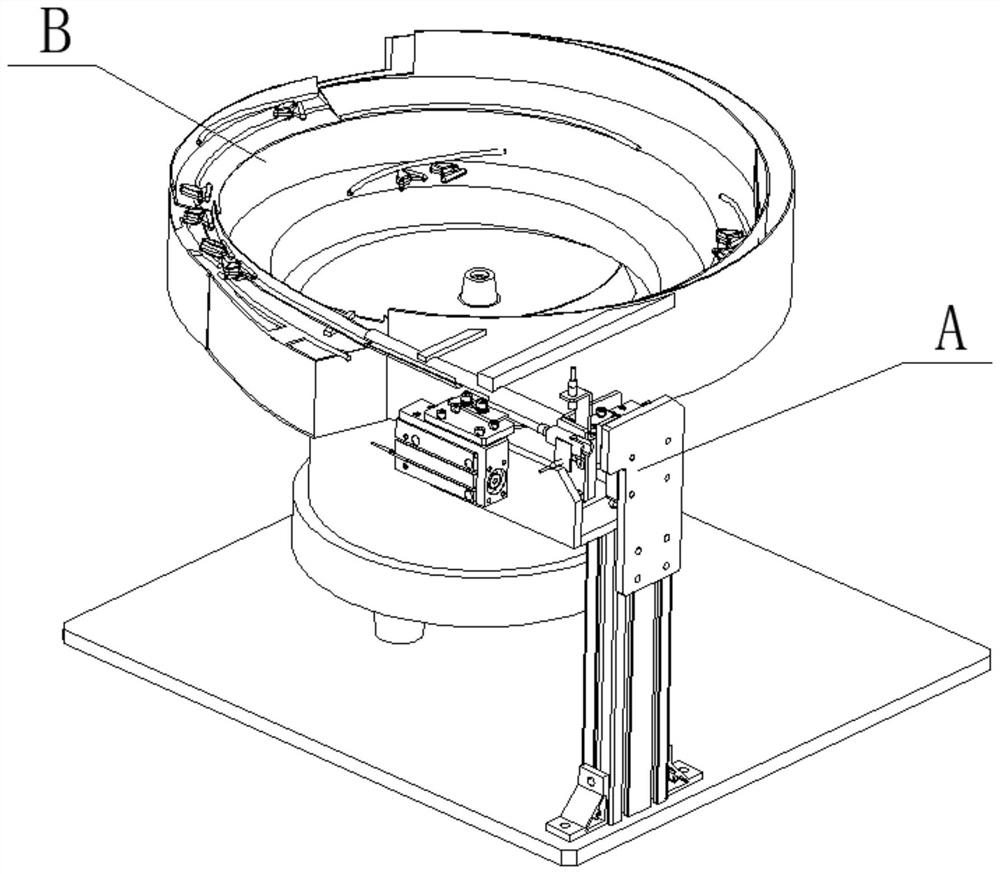

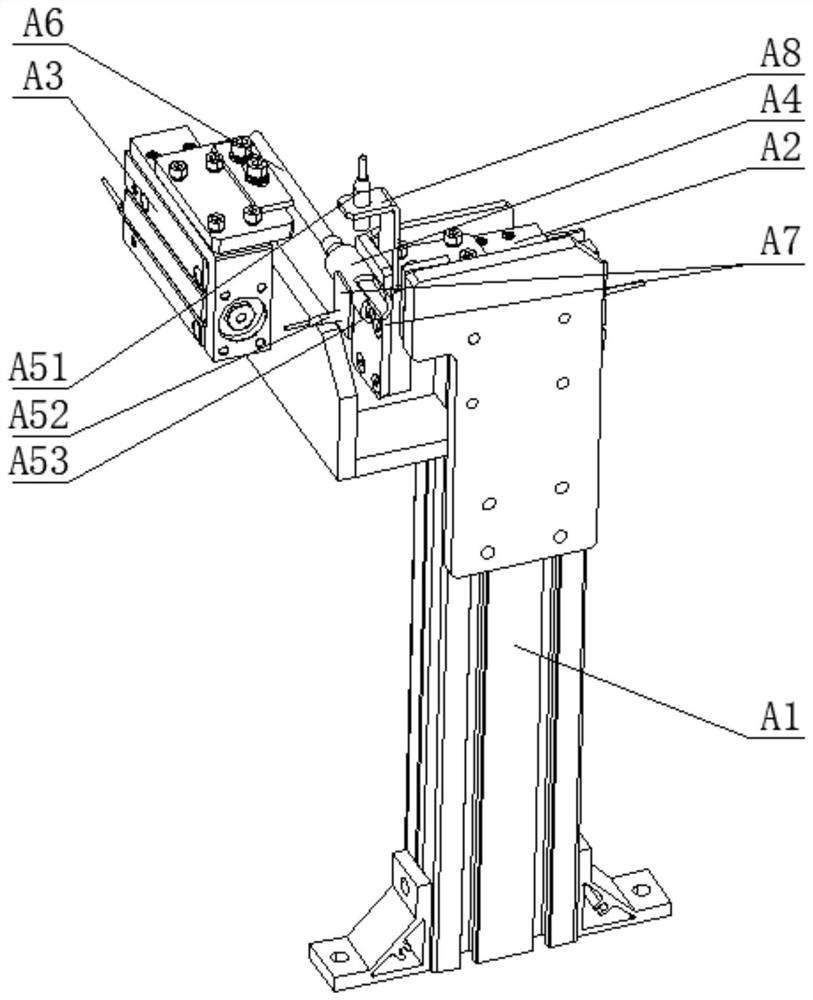

Scallop meat dice taking machine and dice taking process thereof

ActiveCN108094490AThe cutting process is ingeniously designedFew stepsBivalves processingWork injuryEngineering

The invention relates to the technical field of seafood product processing, in particular to a scallop meat dice taking machine. The scallop meat dice taking machine includes a stepping rotary table,a shell-opening meat dice taking device and an incision shell-prying device, the shell-opening meat dice taking device and the incision shell-prying device are both located on the sides of the stepping rotary table, the bottom of the stepping rotary table is equipped with a rotation assembly, the top of the stepping rotary table is equipped with a plurality of limit assemblies that are in equal angle arrangement in order along the rotating direction of the stepping rotary table, the incision shell-prying device includes an incision assembly and a prying assembly for prying the upper shell of ascallop by certain angle, the prying assembly is located between the shell-opening meat dice taking device and the incision assembly, and the incision assembly includes an incision knife and a lifting assembly for driving the movement of the incision knife in the vertical direction. The scallop meat dice taking machine provided by the invention can open the upper shell automatically to facilitatethe next procedure, lowers the labor intensity of workers, and avoids work injury accidents caused by prying of scallops with cutters by workers. The meat dice taking process has few steps, the efficiency is 10 or more times that of manual meat dice taking, no visceral or edge residue is left, and the finished product rate reaches 99%.

Owner:浙江渔福食品有限公司

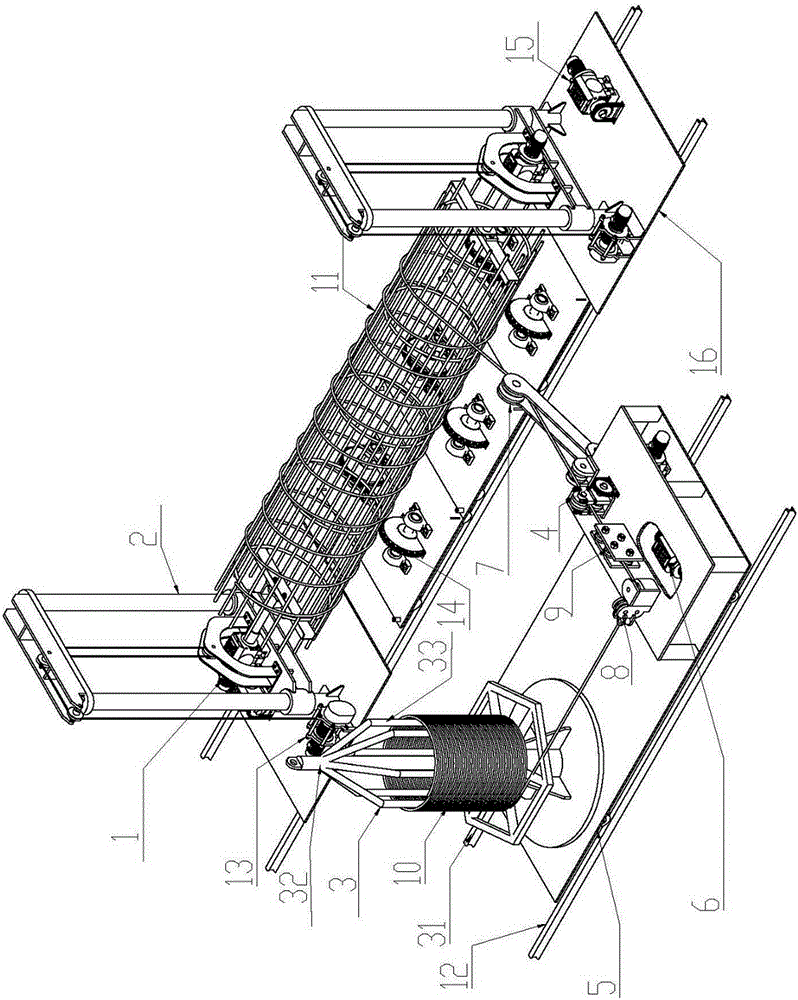

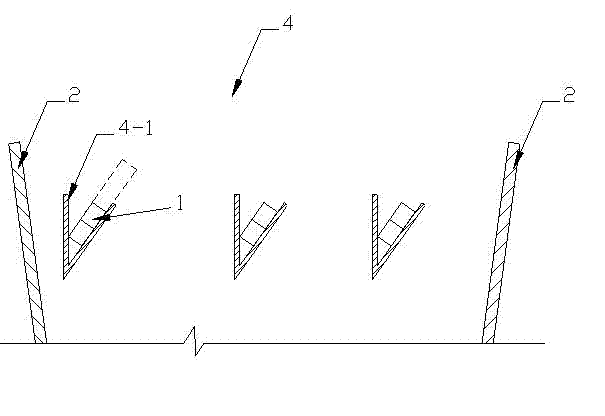

Support chain type cage weaving machine

The invention discloses a support chain type cage weaving machine. The support chain type cage weaving machine comprises a reinforcement cage rotating mechanism, lifting gantries, a reinforcement tray, a reinforcement driving mechanism, a mobile trolley, a mobile trolley driving mechanism, a central lifter, support chains, a gantry trolley walking mechanism and a gantry driving trolley. Automatic weaving and welding of a reinforcement cage are completed by the support chain type cage weaving machine, the labor force is greatly saved, the production efficiency is improved, and the occurrence rate of accident work injury is reduced; meanwhile, through ingenious cooperation of the reinforcement cage rotating mechanism and the support chains, force is more stable and uniform, weaving and welding operation is mechanically completed, the produced reinforcement cage is standard in structure, the welding part has high strength, small errors are caused, a framework is firm, and the production demands of a prefabricated sheet pile can be better met.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

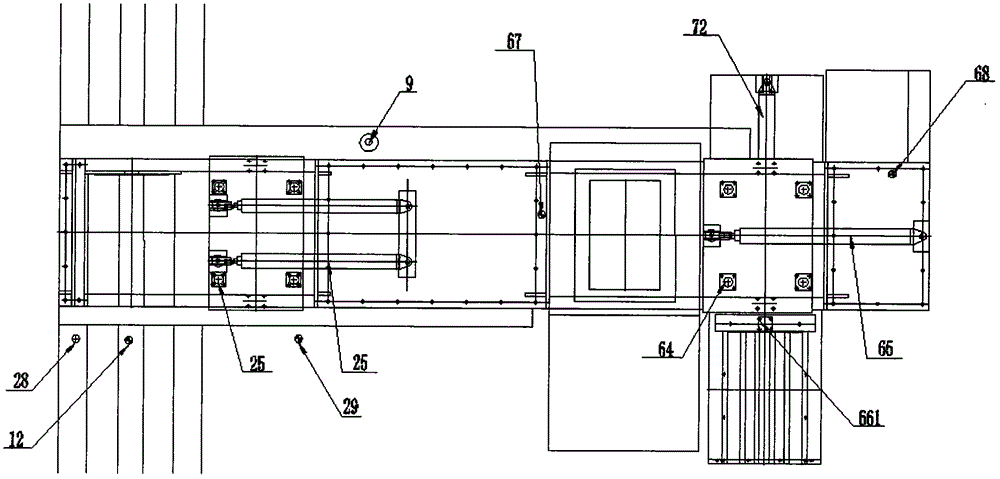

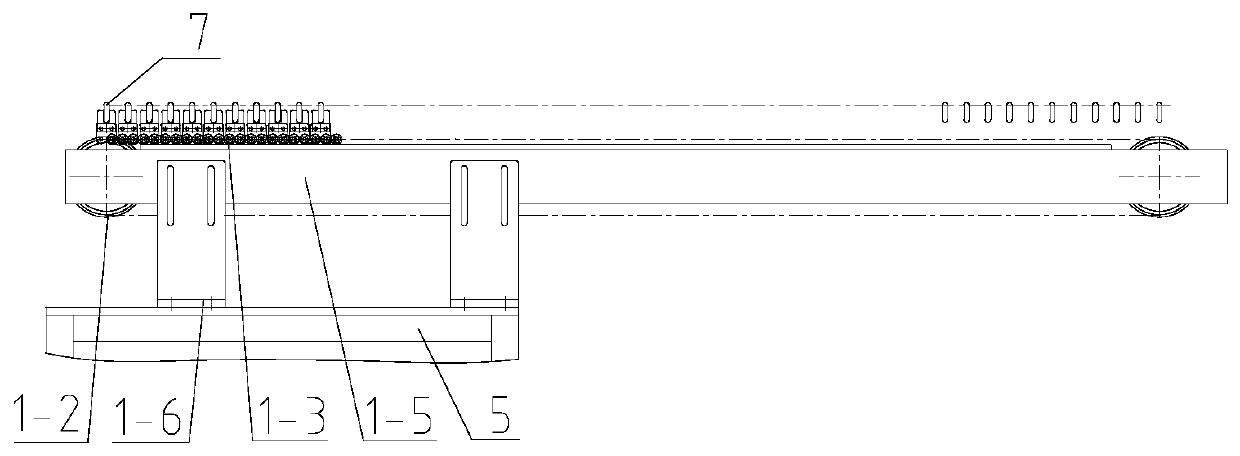

Full-automatic feeder for cylinder tiles

ActiveCN104827552AChanging the game of manual operationsLabor savingAuxillary shaping apparatusPunch pressWork injury

The invention discloses a full-automatic feeder for cylinder tile. The full-automatic feeder comprises a main body support, a frame, a material-gripping mechanism, a feeding mechanism, a material-pushing mechanism, a punch stamping mechanism, a finished product-fetching mechanism, a finished product-conveying mechanism, a PLC control system and a touch screen operation box. The frame is fixedly arranged on the main body support, on which the material-gripping mechanism, the feeding mechanism, the material-pushing mechanism, the punch stamping mechanism and the finished product-fetching mechanism are orderly arranged from left to right. The full-automatic feeder for cylinder tiles has following beneficial effects: the conventional situation of manual operation is completely changed so that labor force is saved, labor intensity is reduced, accident work injuries are prevented and quality of products is improved; by changing the conventional fact that four people are required to closely cooperate with each other for manual operation of each punch, only one person is required to finish operation of equipment disclosed by the invention, thereby greatly increasing production efficiency; per-capita capacity is significantly improved; and production power of a signal feeder can be maintained at 900 pieces / hour.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Automatic metal plate stamping equipment

InactiveCN111922161AAvoid direct contactReduce the chance of work-related injuriesMetal-working feeding devicesPositioning devicesRobot handWork injury

The invention discloses automatic metal plate stamping equipment. The equipment comprises a machine body and a manipulator rotation cavity I formed in the middle of the machine body; a manipulator rotation cavity II with an upward opening is formed in the bottom wall of the manipulator rotation cavity I; feeding and discharging cavities with openings facing the outside of the wall of the machine body are symmetrically formed in the left and right walls of the manipulator rotation cavity I in a communicating manner; and a manipulator device is arranged in the manipulator rotation cavity II andcompletes the functions of clamping and loosening of a manipulator through the structure that a spring and a rocker cooperate with a cam push rod. According to the equipment, the manipulator rotates for 90 degrees for feeding after one-time stamping by the aid of an intermittent wheel, meanwhile, a conveying belt is linked to perform inward feeding and outward waste discharging, clamping and loosening of the manipulator are completed through the structure that the spring and the rocker cooperate with the cam push rod, then a worker is prevented from making direct contact with the stamping device, and the occupational injury probability is reduced.

Owner:浦江县平柜电子科技有限公司

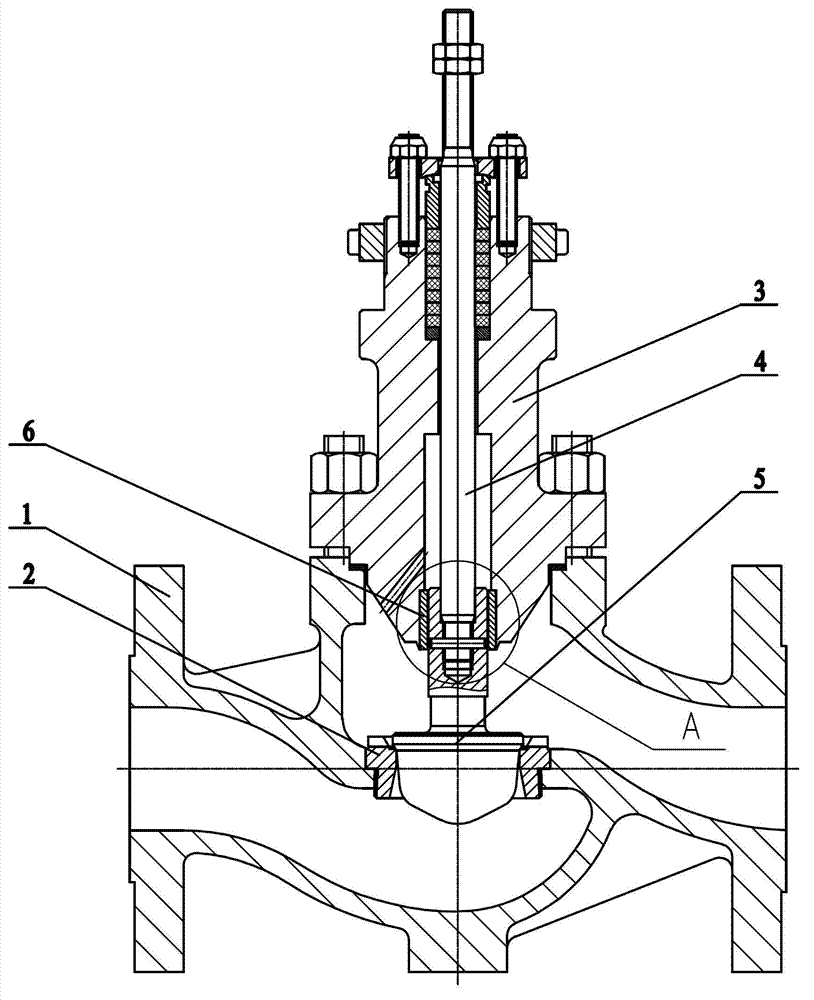

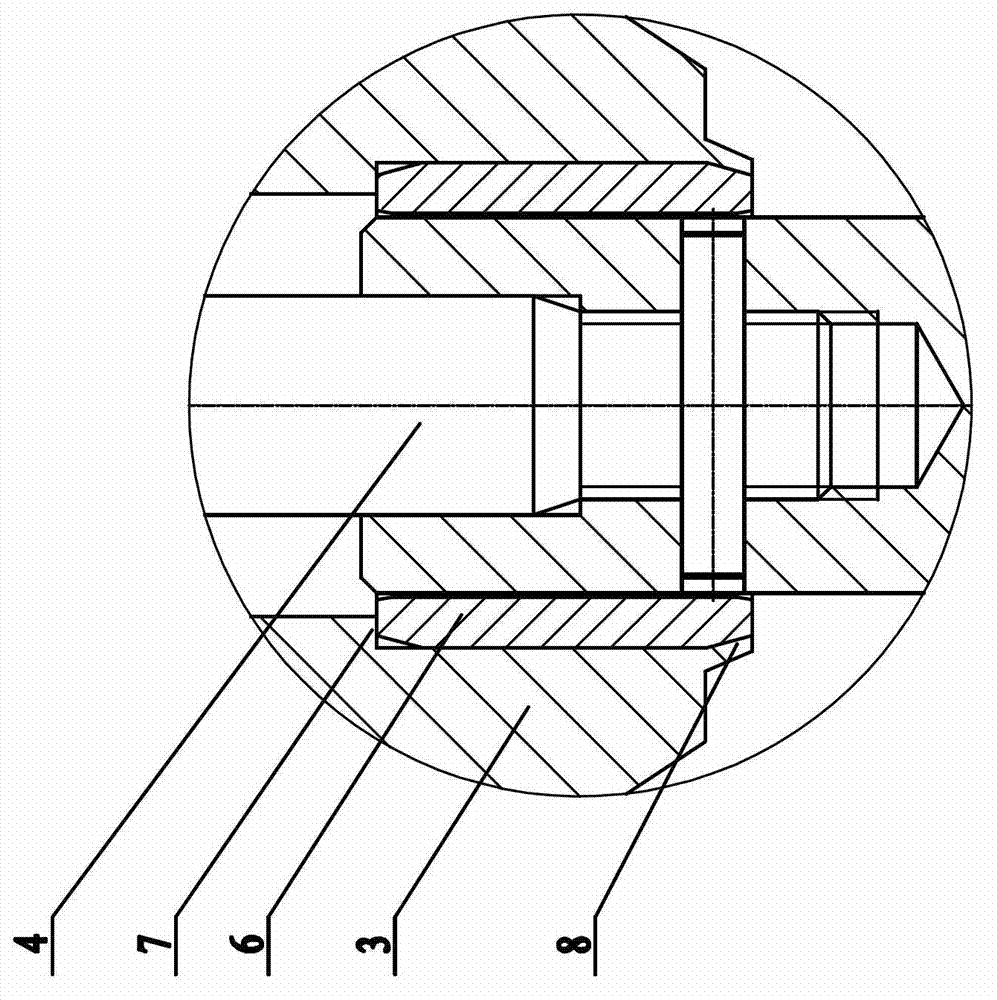

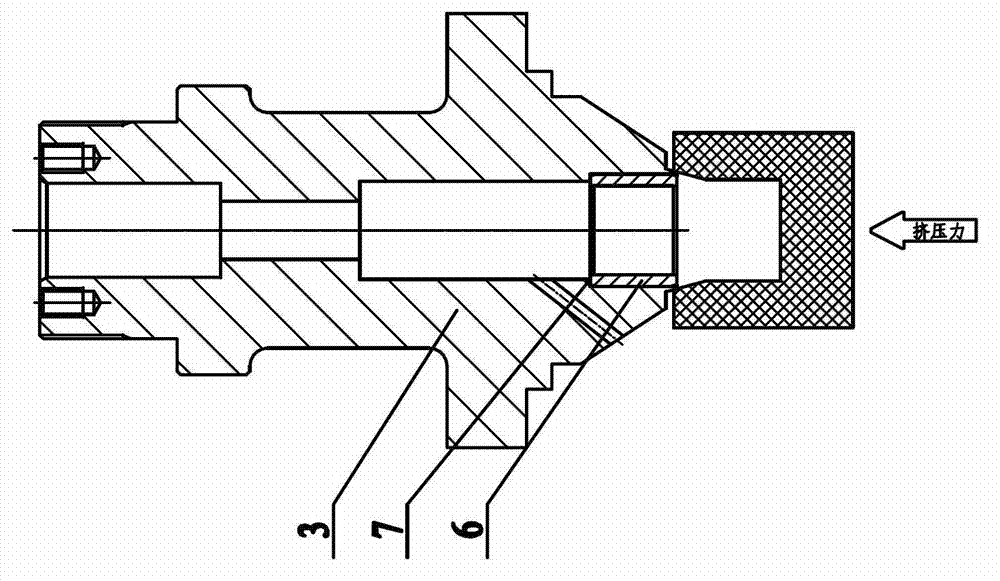

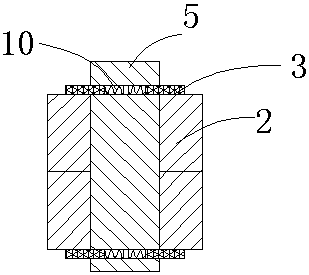

Anti-drop structure for regulating valve bushing

InactiveCN102927297AReduce hazardous processing proceduresReduced dimensional tolerance requirementsLift valveValve housingsWork injuryEconomic benefits

The invention relates to an anti-drop structure for a regulating valve bushing, which comprises a valve body, a valve seat, a valve cover, a valve rod, a valve core and a bushing, wherein the valve seat is fixed in the valve body, the valve cover is fixed on the valve body, the valve rod is spliced in the valve cover in a sliding and sealing manner, the valve core is fixed at the bottom end part of the valve rod, an end face of the bushing pushes against limiting steps, a limiting outer conical surface is arranged at the outer side edge of the other end part of the bushing, and the other end part of the bushing is contacted with a limiting inner conical surface of an extruding flange. With the adoption of the structure, tools such as a drilling bit and a screw tap are not required during the assembly course, as the drilling bit and the screw tap are easy to break when in use to cause work injuries, dangerous processing procedures are reduced, the requirement for the dimensional tolerances of the bushing and a matching surface of the bushing is lowered, the assembly is faster and more reliable, the assembly efficiency is improved, the number of the location steps is increased, the drop of the bushing is effectively prevented, the reliability of a product is improved, the service life of the product is prolonged, and the significant economic benefit is achieved.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Vibrator for feeding punching machine

The invention discloses a vibrator for feeding a punching machine. The vibrator comprises a spiral climbing aggregate bin and a driving device for driving the vibrator to vibrate. The vibrator is characterized by also comprising a plurality of feeding tracks connected with a discharge hole at the highest position of the aggregate bin, wherein the feeding tracks contain a plurality of adjusting structures for arranging and adjusting workpieces, and the plurality of feeding tracks are spirally combined into a feeding passage at the discharge hole. Through the vibrator, manual feeding is substituted, so that work injury of personnel during feeding and taking out materials is prevented; the single machining form is changed into a continuous machining form, so that the electrical energy of the punching machine is reduced by 55 percent; the machining capacity is effectively improved by 12.5 times; and the precision of machining the workpieces is promoted, the quality is stable, and the quality stability CPK reaches 1.33 after machining.

Owner:KUSN CHANGYUN ELECTRONICS IND

Automatic thread forming mechanical arm device

PendingCN110814838AReduce labor intensitySimple structureMetal working apparatusRobot handWork injury

The invention relates to a mechanical arm, in particular to an automatic thread forming mechanical arm device. A chain type material frame, a feeding mechanism, a clamping grabbing mechanism and a base are included. The chain type material frame is arranged on the base and used for storing and conveying workpieces. The feeding mechanism is arranged on the base, located at the end portion of the chain type material frame and used for grabbing and conveying the workpieces on the chain type material frame. The clamping grabbing mechanism is arranged on the base, located on one side of the chain type material frame and the feeding mechanism and used for grabbing the workpieces conveyed by the feeding mechanism to the position of a thread forming machine, and thread forming machining is conducted. The automatic thread forming mechanical arm device is simple and compact in structure, small in size and convenient to operate, control can be accurate, the work efficiency is improved, the laborintensity of operators is lowered, and occupational injuries are avoided.

Owner:辽宁汇智机器人有限公司

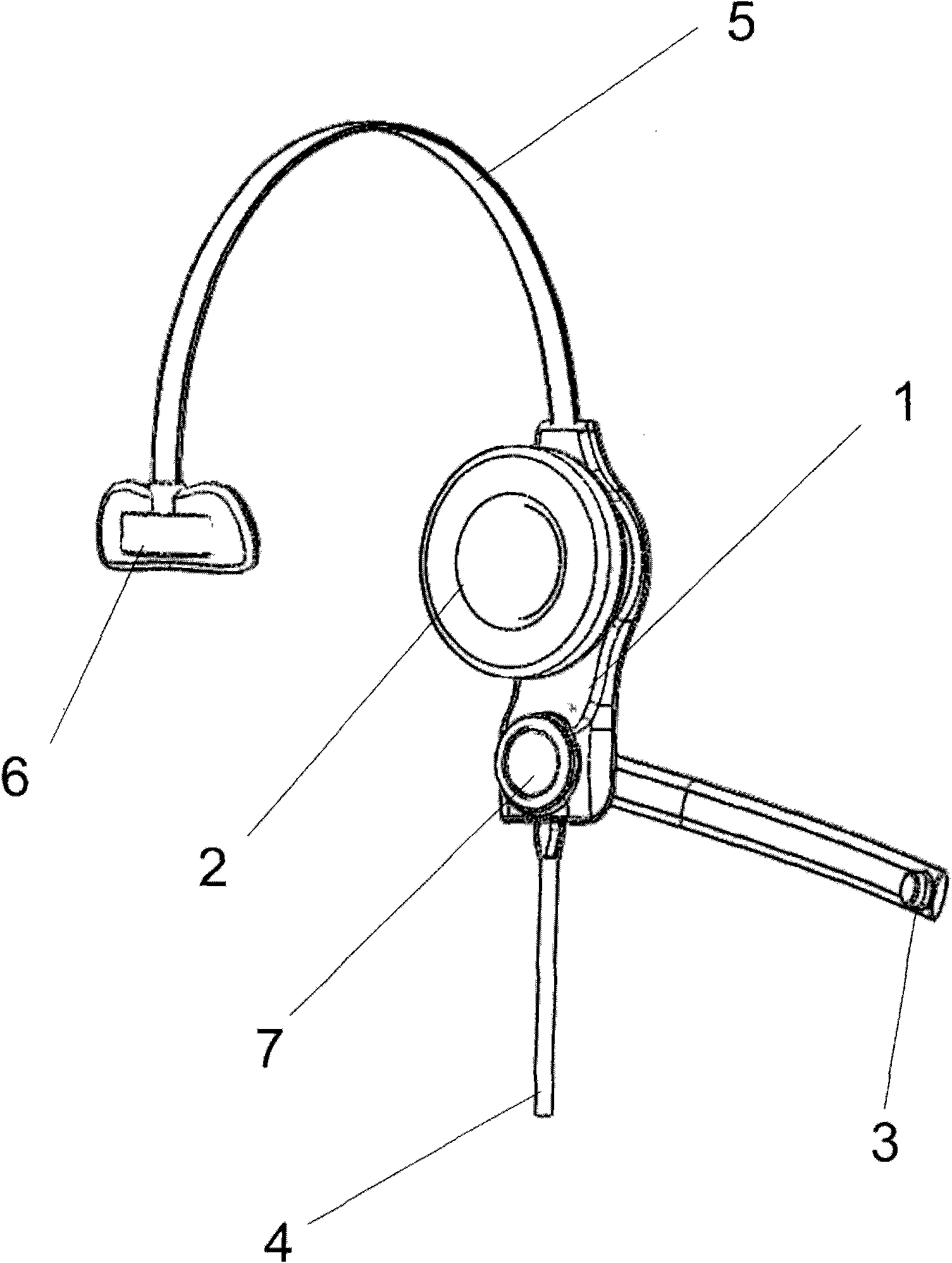

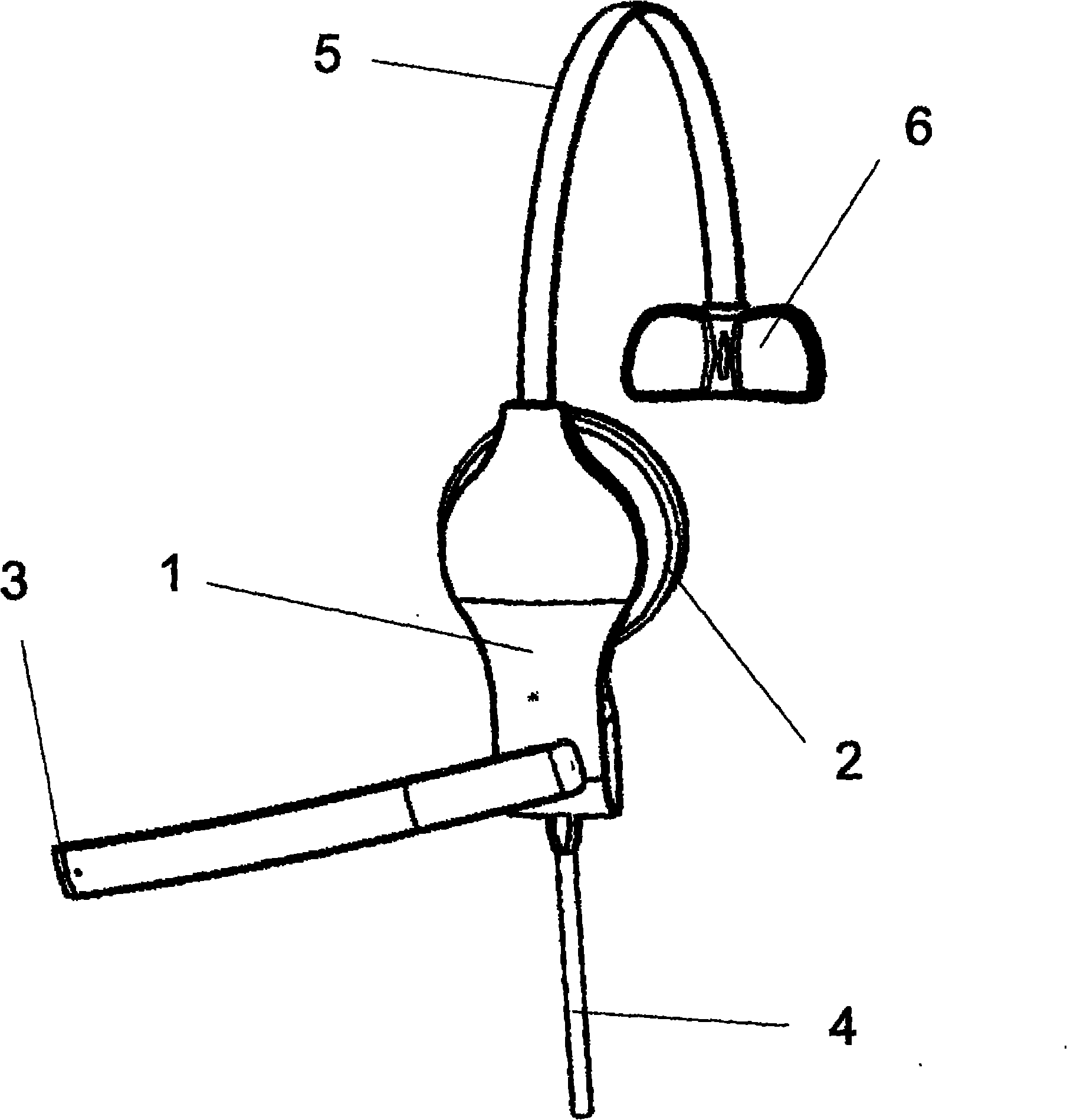

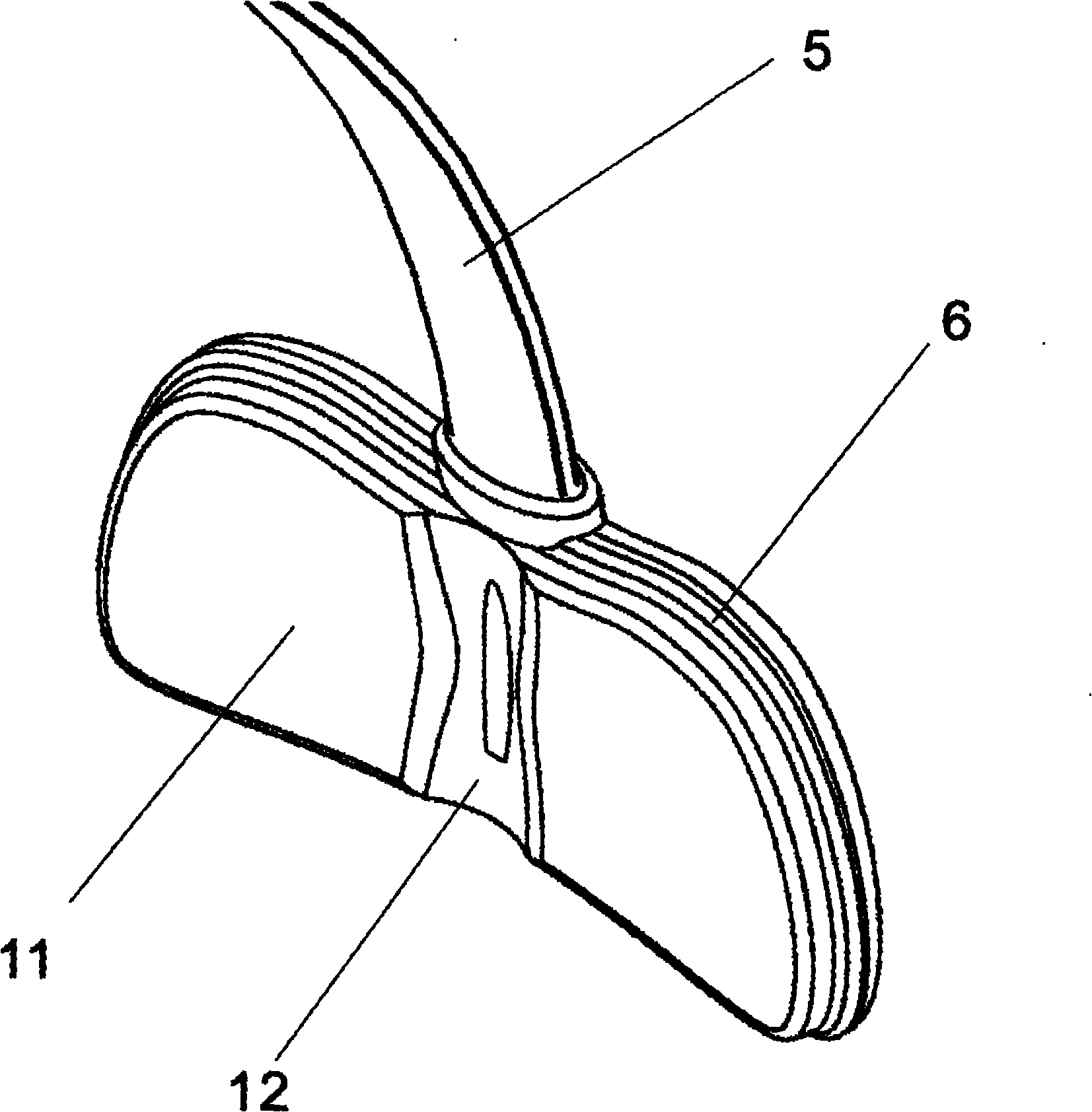

Hearing health care telephone traffic headset

The invention aims at the problems of work injuries of various hearing impairment, swim, and the like and hard hearing or even deafness caused by acoustic fatigue, too large sound or long-time oppression to head vessel by a head-clamp of workers using telephone traffic headsets, in particular workers in a telephone traffic seat center. The invention provides a hearing health care telephone traffic headset with physical therapy and anti-fatigue protection functions specifically for telephone traffic workers. The hearing health care telephone traffic headset is provided with a casing, a spring head bow for being fixedly worn on the head, a pressing piece specifically designed for wearing a single-ear headset for a long time so as to avoid oppressing the head vessel and an additionally arranged removable second pressing piece. The casing is connected with a loudspeaker, a microphone, a device made of tourmaline for radiating far infrared rays and releasing anions, and the second pressing piece can share the pressure of the headset loudspeaker to ears. The invention has a positive effect for preventing work injuries of various hearing impairment, swim, and the like of the telephone traffic workers.

Owner:凌子龙

Drilling machine

InactiveCN104847267AImprove drilling efficiencyComplex structureDrill bitsBorehole drivesWork injurySprayer

The invention provides a drilling machine. A gear bank is meshed with gear teeth on a power outputting shaft of a motor; a secondary drill bit fixing rack is fixedly arranged on a shell rack; a secondary drill bit gear on a secondary drill bit is meshed with a gear on a main drill bit; the gear bank is fixed on the shell rack through a gear bank fixing rack; a steel wire lifting rope is arranged on a ground rack; the ground rack is connected with the shell rack through the steel wire lifting rope; and the shell rack is provided with a pure water sprayer and a mud pumping opening. The drilling machine has the advantages that the drilling machine can be used for drilling holes instead of manual operation, occupational injury can be avoided, the drilling machine is high in drilling efficiency, simple in structure and convenient to implement, investment on labor and materials can be reduced, and the construction time is saved. When the drilling machine runs, the pure water sprayer can spray water to wet ash generated in a drilling process so that the ash is stirred into mud, and the mud can be pumped away from the mud pumping opening.

Owner:赵启荣

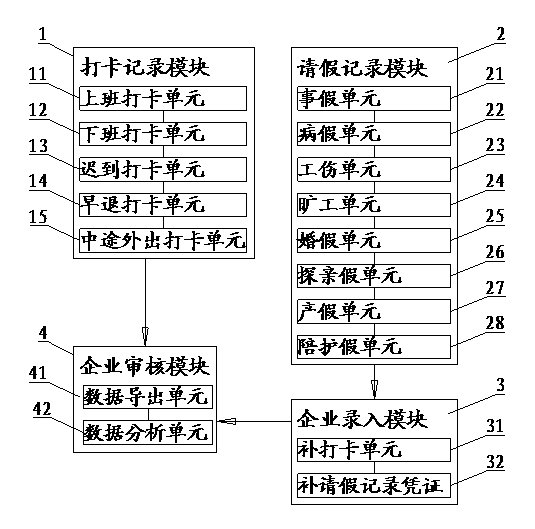

Enterprise attendance recording system

The invention discloses an enterprise attendance recording system. The enterprises attendance recording system comprises a card punching recording module, a leave recording module, an enterprise entering module and an enterprise audit module, wherein the card punching recoding system comprises a clock in unit and a clock out unit; the leave recoding module comprises a casual leave unit, a sick leave unit, a work injury unit and an absenteeism unit; the enterprise entering module comprises a punch card mending module and a leave recording mending evidence; the enterprise audit module comprises a data export unit and a data analysis unit; the card punching mending module, the leave recording module and the enterprise entering module are connected to the enterprise audit module. By the technical scheme, the enterprise attendance recording system provided by the invention realizes full-mechanical recording and automatic comparison analysis, is simple to operate, can effectively improve the implementation efficiency of an attendance appraisal system, reduces labor costs, efficiently avoids misoperation, and is high in record accuracy, long in recording time and easy to store.

Owner:常熟合正企业管理咨询有限公司

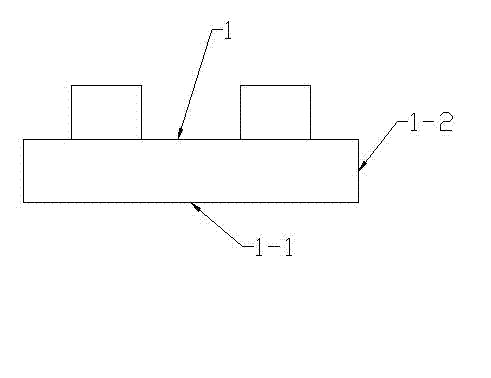

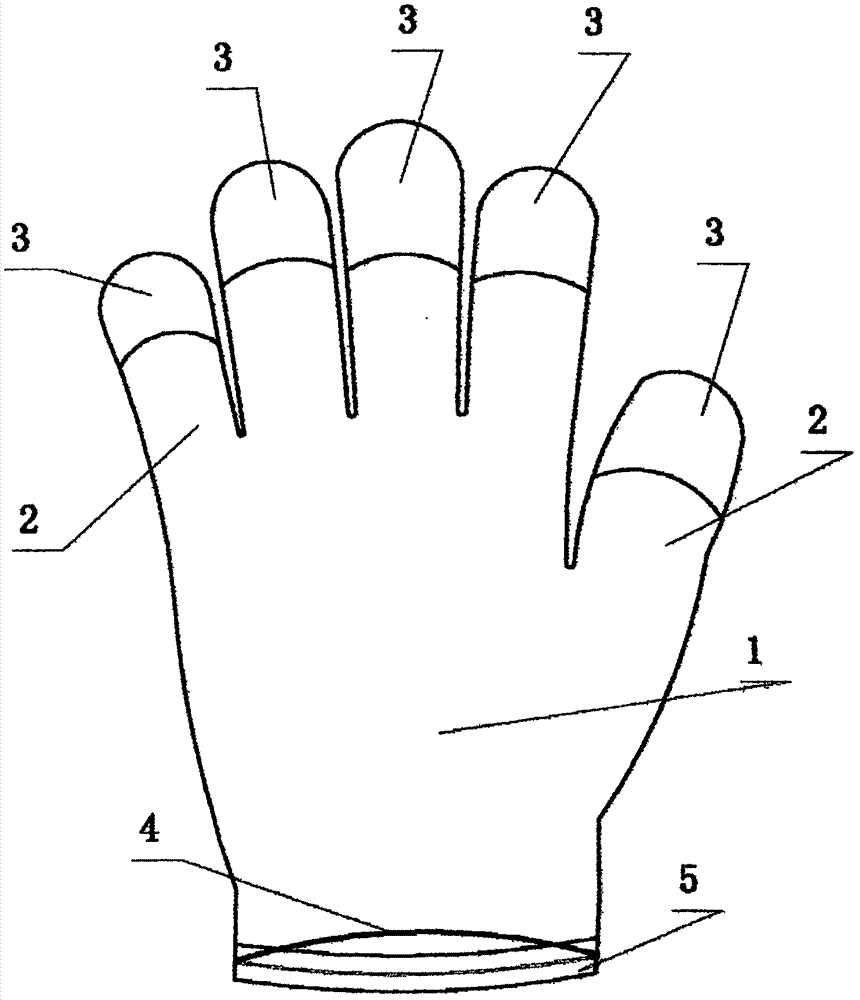

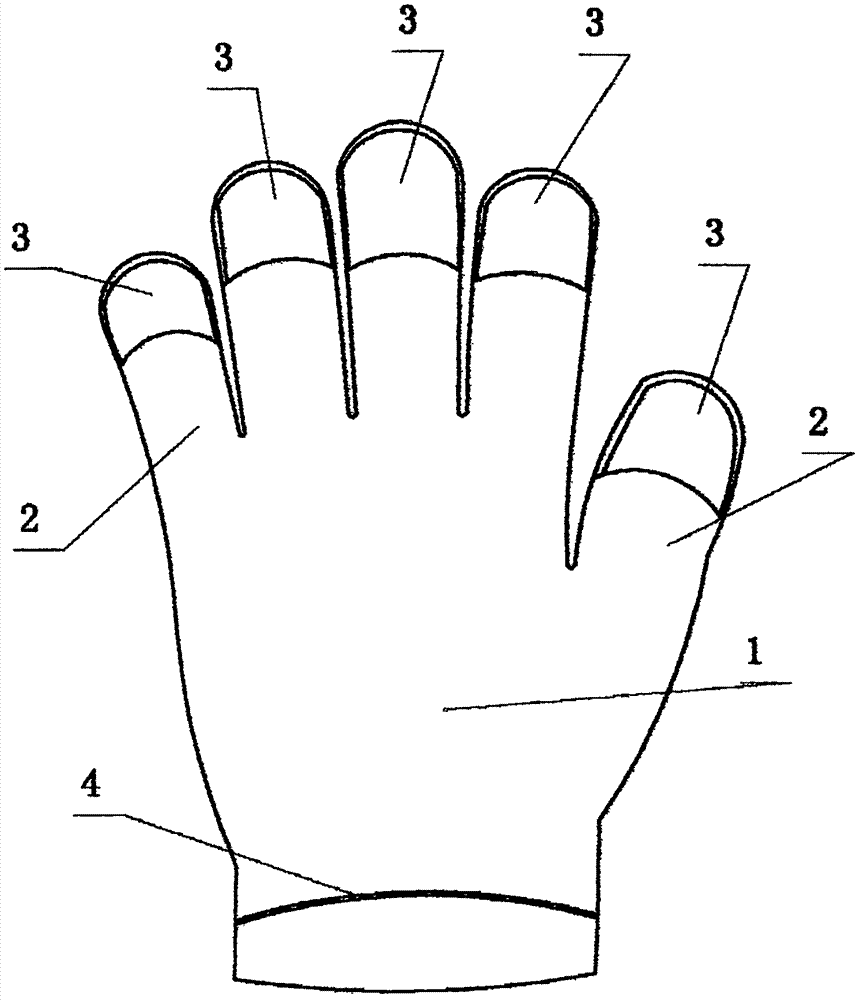

Labor protection glove

PendingCN107173885AAvoid or reduce whiteningAvoid or reduce blisteringGlovesProtective garmentThroatFiber

The invention relates to a labor protection glove, belonging to gloves in the labor protection field. Although operators are forbidden to wear gloves by operating manuals of equipment with rotating parts and each safety management requirement, the operators rely on luck to wear gloves to operate the equipment against the rule so as to avoid the direct contact between the hands and workpieces, however, once fibers of the gloves are hung to the rotating parts, the occupational injury and even death are very possibly caused. The events have never stopped in the production field. The labor protection glove (as shown in the description) is structurally characterized in that finger pulp protection parts (2) are connected to the upper end of a palm protection surface (1), figure accommodating cavities (3) are formed in the front ends of the finger pulp protection parts, a throat belt (4) (a rubber band is adopted, and one single side of the rubber band is prefabricated in a throat belt channel (5)) is located on the lower part of the palm protection surface, and the throat belt and the palm protection surface form a waist accommodating channel. Therefore, the labor protection glove has the beneficial effects that when a winding event occurs, the throat belt on the glove can extend to be separated, so that the glove is easily separated from the hand, and the operator is protected; and meanwhile, the material use amount ofthe gloveis reduced.

Owner:杨俊琪

Bolt with end paired holes and matched wrench thereof

Owner:LANZHOU UNIVERSITY

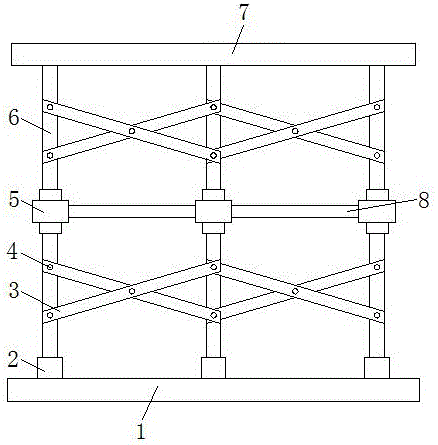

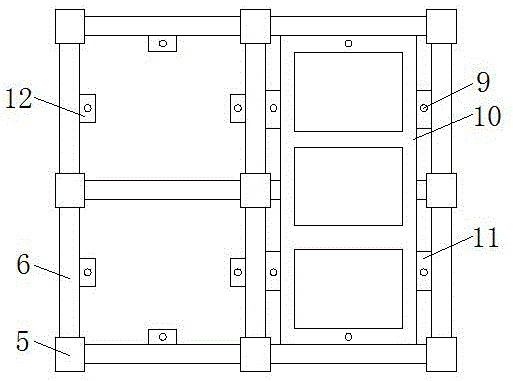

Cargo placement frame for ship shipping

InactiveCN106724160AFlexible and convenient placementEasy to placeDismountable cabinetsWork injuryEngineering

The invention discloses a cargo placement frame for ship shipping. The cargo placement frame comprises a supporting plate. Connecting bases distributed at equal intervals are fixedly connected to the upper surface of the supporting plate. A groove is formed in the upper surface of each connecting base. A supporting rod is arranged on the upper surface of each connecting base. The bottom end of each supporting rod extends into the corresponding groove to be connected with the corresponding connecting base in a clamped mode. A four-way pipe is arranged on the top of each supporting rod. The top end of each supporting rod extends into a through hole in the lower surface of the corresponding four-way pipe to be connected with the four-way pipe in a clamped mode, a top plate is fixedly connected to the portions, located on the upper sides of the four-way pipes, of the tops of the supporting rods, and a connecting rod is arranged between every two adjacent four-way pipes. When cargos are placed, the cargos can be placed on the outer side, then, a fixing plate is used for pushing the cargos to the inner side of the placement frame, manpower and material resources can be saved, workloads of workers can be lowered, the phenomenon that the cargoes are damaged due to the fact that the cargos fall down during transportation can be avoided, work injuries are avoided, and use is safer.

Owner:侯如升

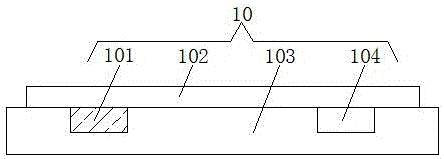

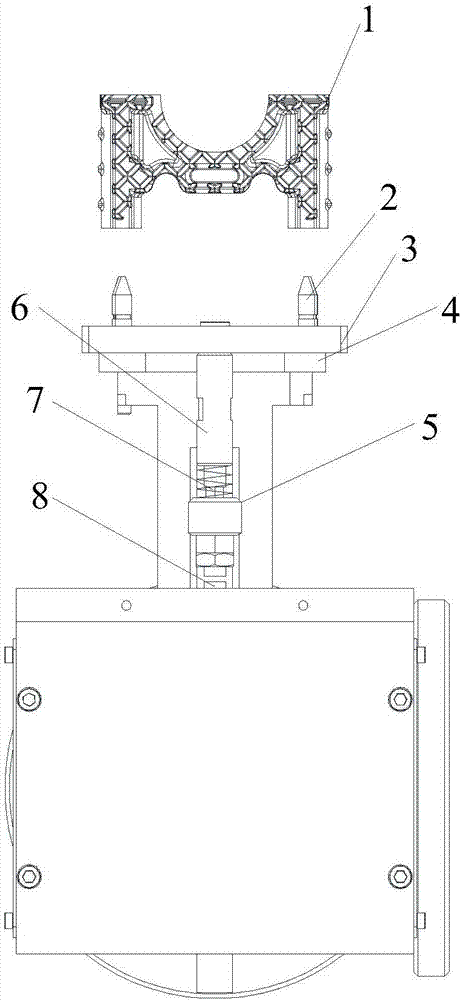

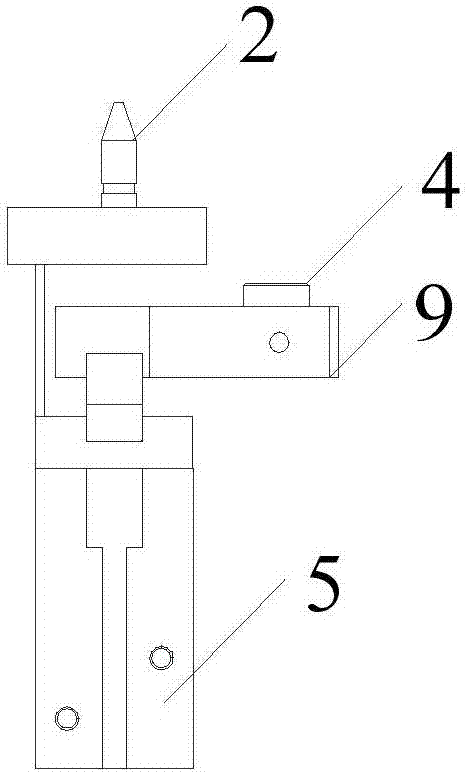

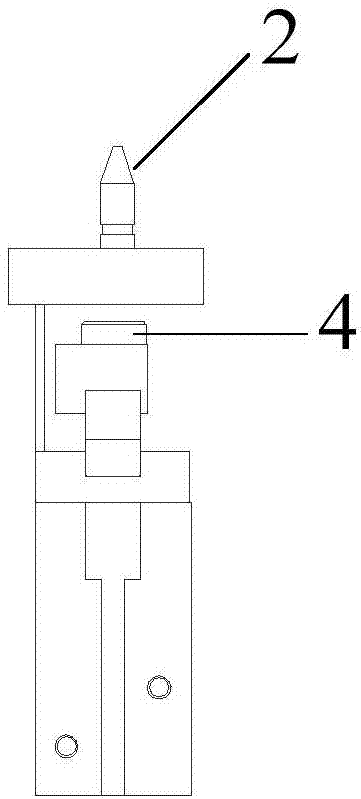

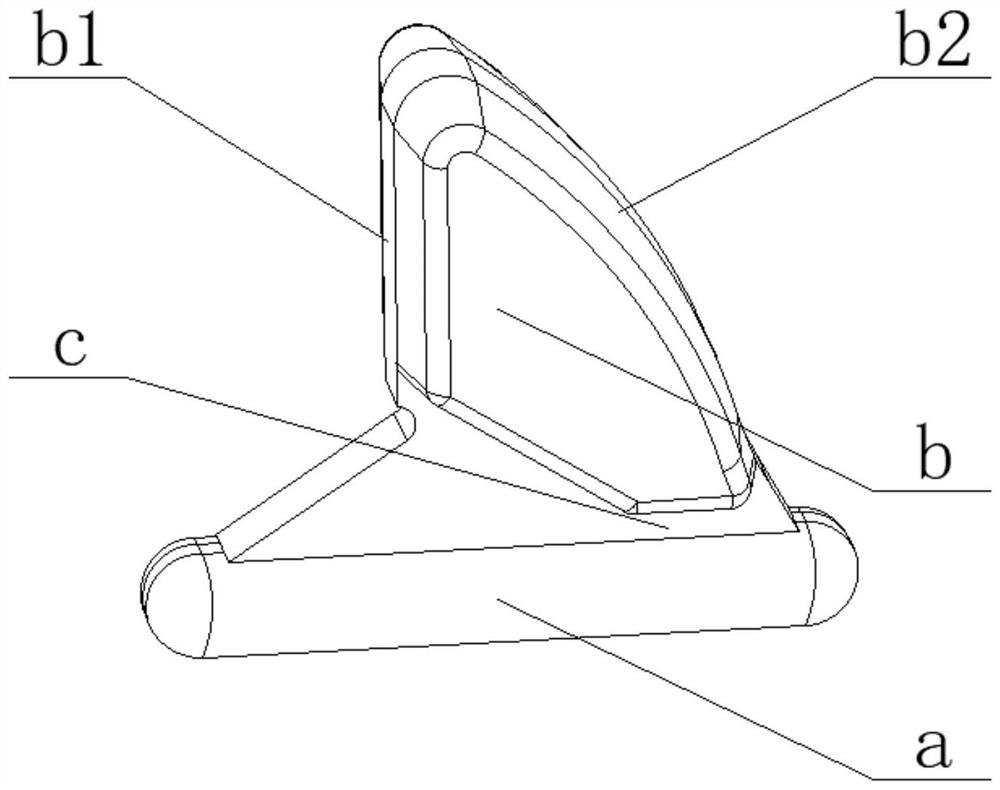

Permanent-magnet embedded part gripper device

The invention discloses a permanent-magnet embedded part gripper device. A location pin is arranged on a location pin installation plate, the location pin installation plate is loaded on a pedestal through a sensing rod, the bottom end of the sensing rod is arranged in a guide hole of the pedestal through a spring, a rotary air cylinder is arranged on the pedestal, a magnet installation plate is fixed to a rotating shaft of the rotary air cylinder, a permanent magnet is arranged on the magnet installation plate, and the permanent magnet is arranged under the location pin installation plate. The rotating shaft of the rotary air cylinder can drive the magnet installation plate to rotate, the permanent magnet is accordingly rotated to directly face the location pin, an embedded part can be attracted by magnetic force of the permanent magnet, then a robot gripper drives the whole gripper device to place the embedded part into a mold, then the rotating shaft of the rotary air cylinder is rotated again to drive the permanent magnet be away from the embedded part position, magnetic force on the embedded part disappears, the embedded part is left in a mold, and automatic embedment of the embedded part is achieved. The permanent-magnet embedded part gripper device has higher automatic degree, greatly improves efficiency and avoids work injury accidents.

Owner:SUZHOU SANJI FOUNDRY EQUIP

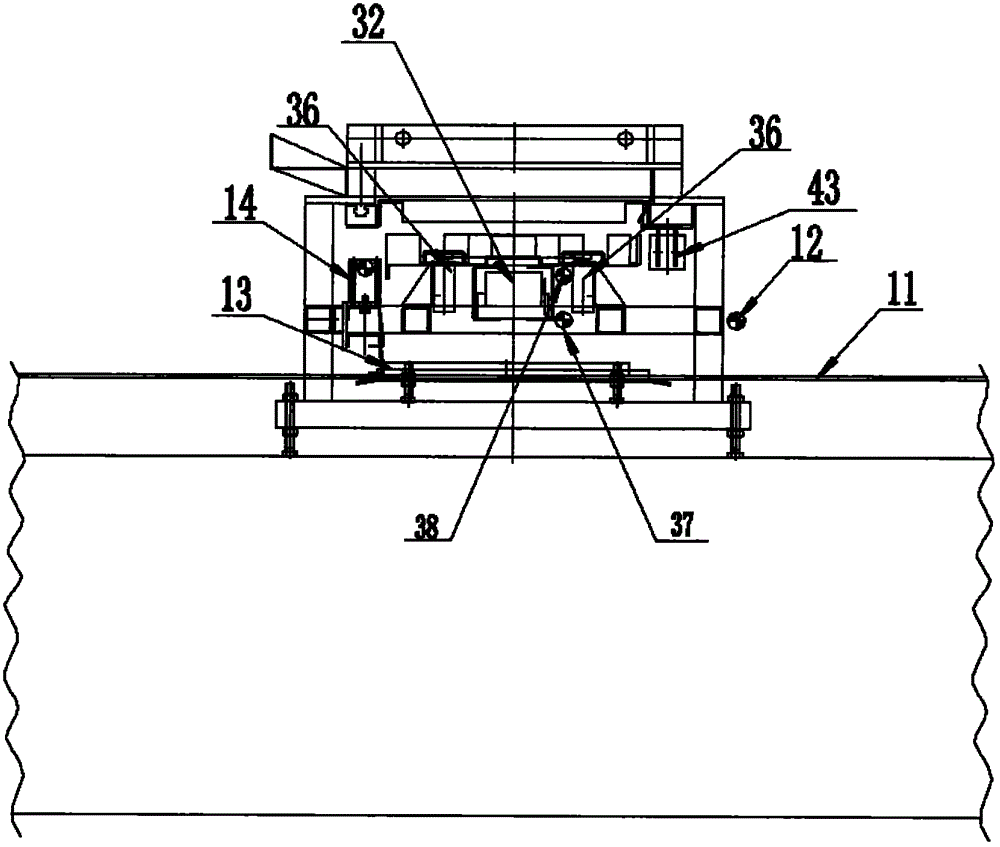

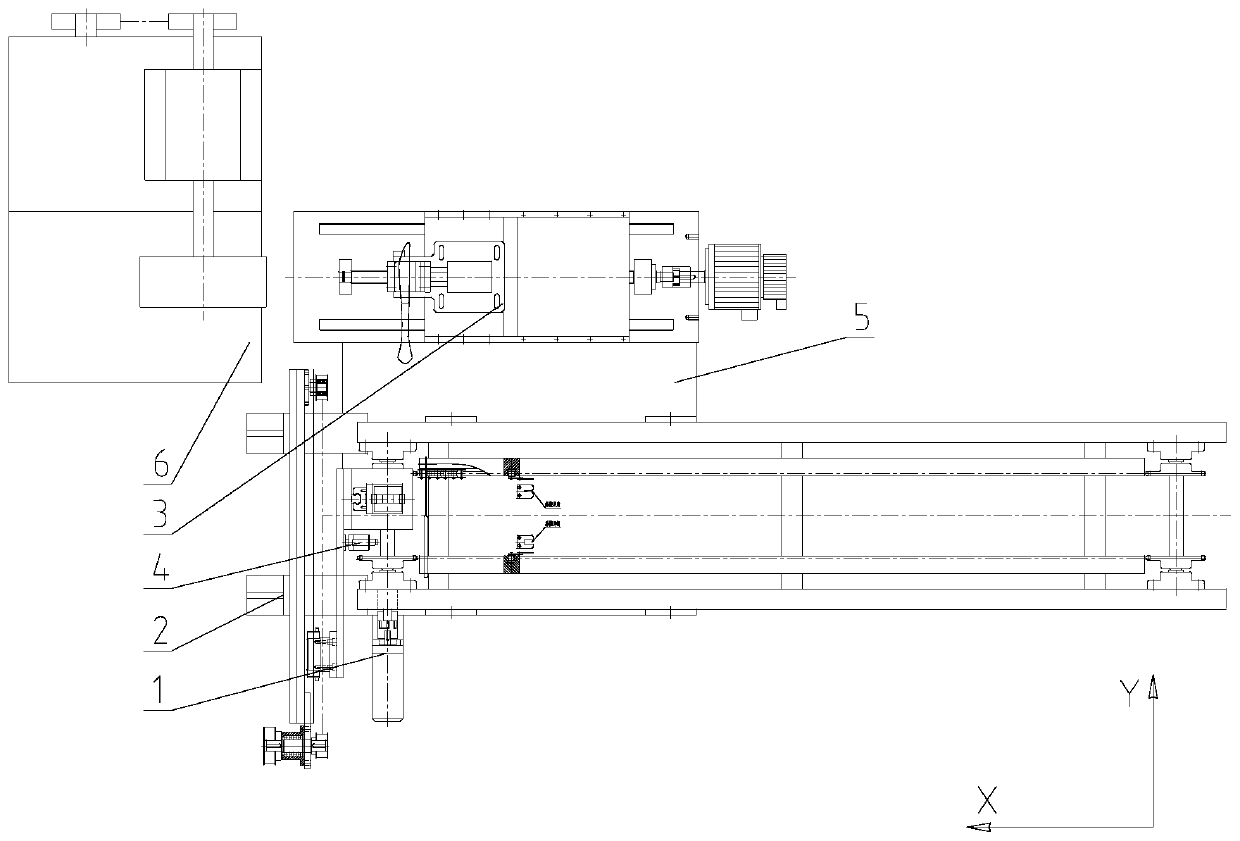

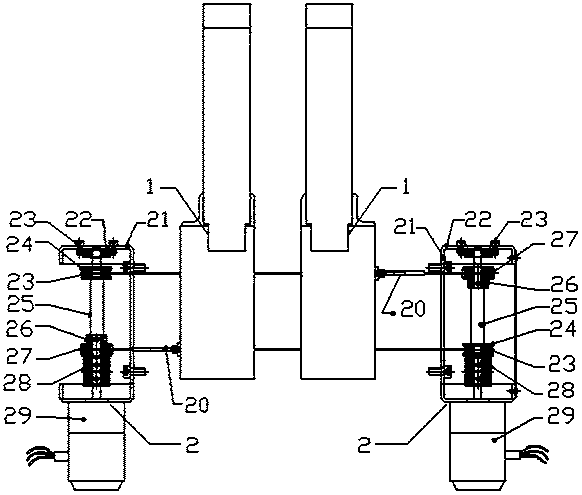

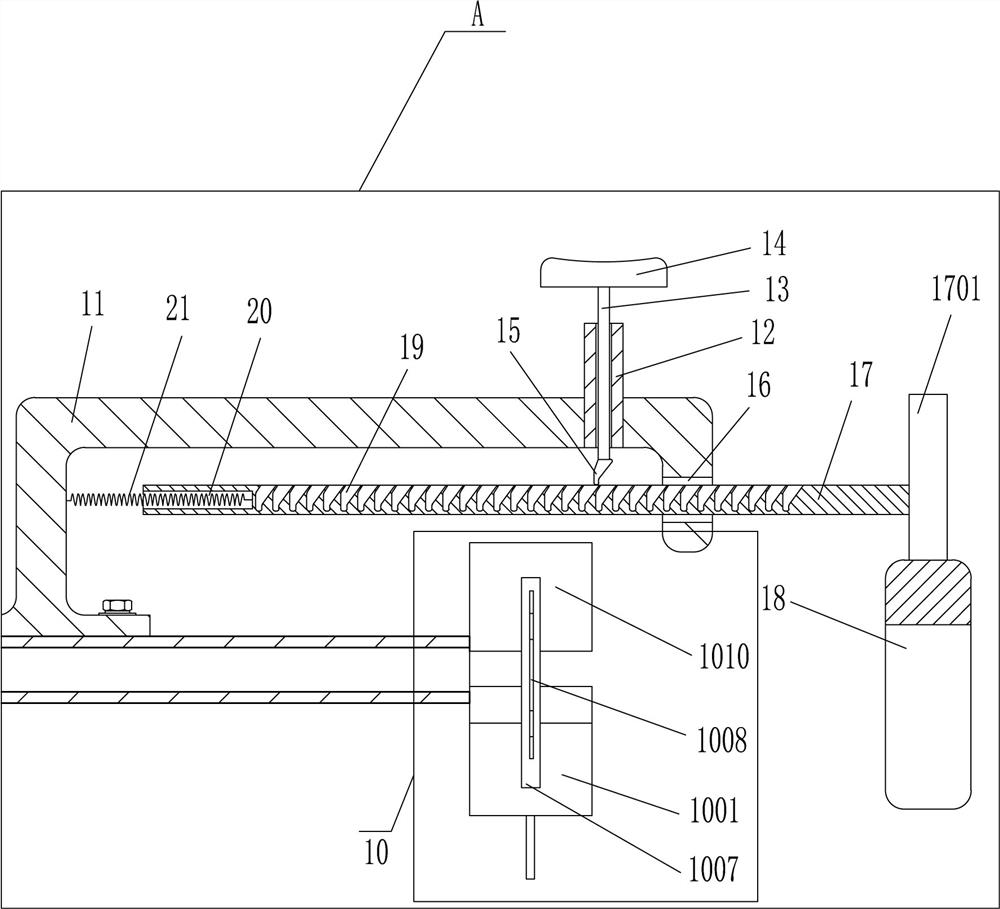

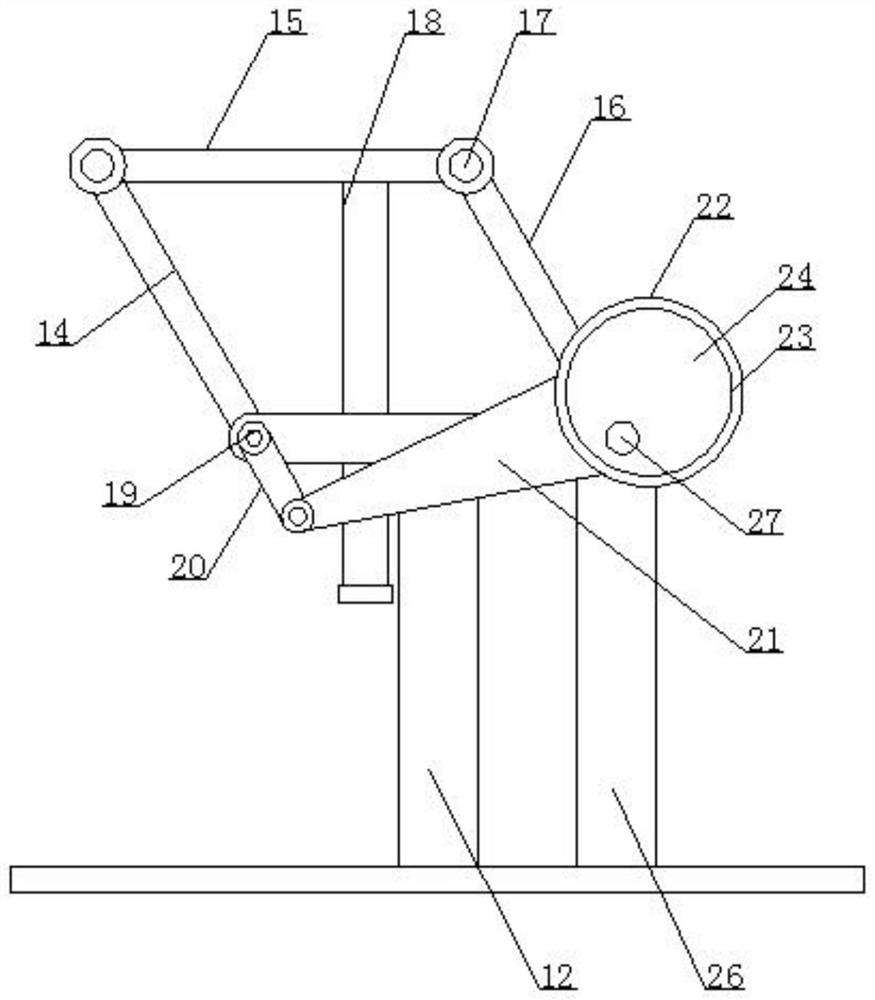

Automatic stop finger mechanism of bending machine

ActiveCN103949555ARealize semi-automatic controlAvoid the Risk of Work InjuryMetal-working feeding devicesPositioning devicesDrive wheelWork injury

The invention discloses an automatic stop finger mechanism of a bending machine, which comprises stop finger drive devices arranged on the left side and the right side of the bending machine, wherein a pair of stop fingers is arranged side by side between the stop finger drive devices on the left side and the right side; drive shafts are axially equipped with driving wheels and driven wheels; the driving wheels are fixed with the drive shafts; drive belts are arranged between the driving wheels and the driven wheels on the drive shafts on the left side and the right side; the two drive belts are fixed with the two stop fingers respectively and drive the two stop fingers to move between the left side and the right side respectively; stop finger fore-and-aft fine adjustment devices for adjusting fore-and-aft positions of stop finger bases in slide grooves are arranged on stop finger slide blocks; the front end of each stop finger base is connected with a front stop finger via a floating pin shaft; and horizontal adjustment device for adjusting horizontal positions of the front stop fingers are arranged on the stop finger slide blocks.The mechanism achieves semi-automatic control of a stop finger Z-axis mechanism, and allows the stop fingers to have an overall precise fine adjustment function, so that a risk of work injuries are avoided to the full extent, the cost is controlled at the same time, and the locating accuracy is ensured.

Owner:诸暨市英帕斯机械有限公司

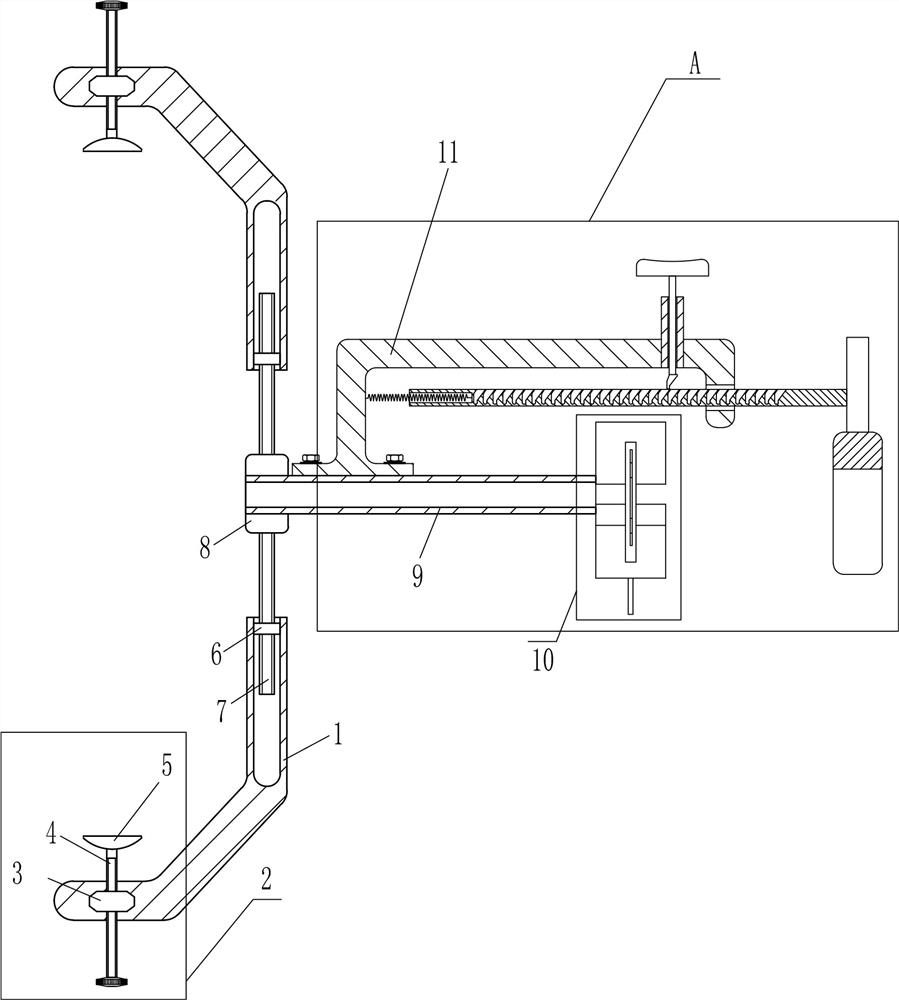

Automatic jaw conveying equipment

PendingCN113401593AAvoid misuseImprove reliabilityControl devices for conveyorsJigging conveyorsWork injuryEngineering

The invention discloses automatic jaw conveying equipment. The automatic jaw conveying equipment comprises a material supply vibration disc and a pushing device arranged at one side of the material supply vibration disc, wherein the material supply vibration disc is connected with the pushing device, the pushing device comprises a rack, a transverse moving air cylinder and a pushing air cylinder are arranged on the rack, and a pushing guide pipe is arranged on the transverse moving air cylinder; locating induction sensors are arranged in the vertical direction and the horizontal direction of the pushing guide pipe, a pushing rod is arranged on the pushing air cylinder, the pushing rod carries out straight pushing action in the horizontal direction along with the pushing air cylinder, and the pushing guide pipe carries out transverse movement action in the horizontal direction along with the transverse movement air cylinder; and the pushing guide pipe and the pushing rod are located on the same axis after the pushing guide pipe carries out the transverse movement action. According to the automatic jaw conveying equipment, the purpose of replacing workers with machines is realized, the production cost can be reduced, the standardization of workpiece machining and the conveying stability are improved, and the probability of occupational injuries can be greatly reduced.

Owner:杭州临安太阳工具有限公司

Water pouring mechanism for closestool

ActiveCN109626006APrecise positioningReduce breakage rateBottle emptyingLoading/unloadingWork injuryDrive shaft

The invention provides a water pouring mechanism for a closestool. The water pouring mechanism comprises a rack, a motor installing base, a jacking mechanism, a horizontal moving mechanism, a tool plate, the closestool, a buffer fixing block, multiple bearing pedestals, a first transmission shaft, a shaft end cover, a driven gear, a motor installing plate, a locking base, a driving gear, a motor,a chain wheel and a closestool follow-up fixing mechanism. According to the water pouring mechanism, the automatic water pouring function of the closestool is achieved, due to the design of the bufferfixing block, the function of buffering operation of a first telescoping air cylinder and a second telescoping air cylinder can be achieved, the first telescoping air cylinder and the second telescoping air cylinder drive the closestool together, in the turning over and water pouring process, collision is avoided, cracking is avoided, falling of the closestool is avoided, noise generated by falling or colliding of the closestool is avoided, the situation that the closestool slips and falls off, and accident work injuries occur can be avoided, a good production environment can be created for production workers, in the whole water pouring process, manual participation to operation is not needed, and therefore the water pouring efficiency of the closestool is improved greatly.

Owner:GUANGDONG HUI LIXING SEIKO TECH

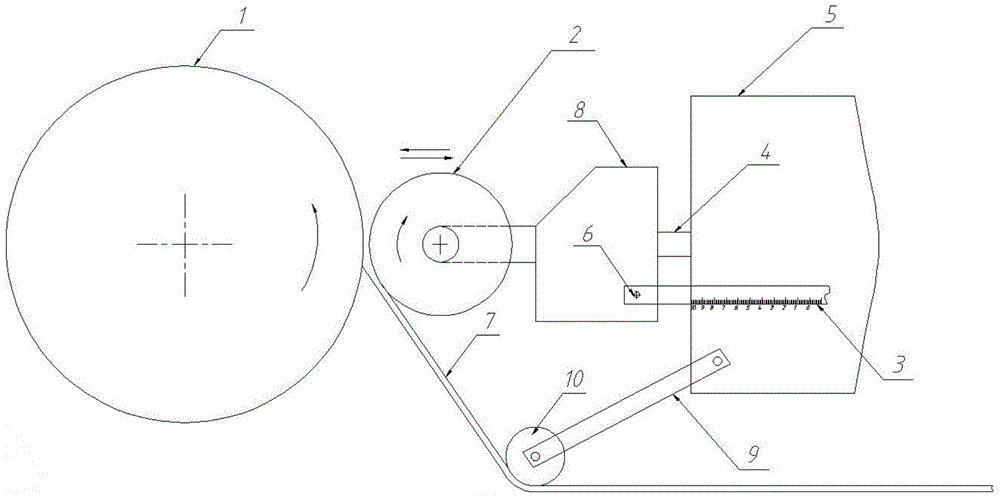

Rubber roll winding machine with measuring device

The invention discloses a rubber roll winding machine with a measuring device. The rubber roll winding machine comprises a machine body, a telescopic rod, a support, a pressing wheel, a suspension arm and a guide wheel, wherein the pressing wheel is fixed on the support, and the support is arranged on one side of the machine body through the telescopic rod; the suspension arm is arranged at the lower part of the machine body, the suspension arm and the support are positioned on the same side of the machine body, and the guide wheel is arranged at the end, far away from the machine body, of the suspension arm; a dividing ruler is also arranged on the support, and is parallel to the telescopic rod. The rubber roll winding machine is simple in structure, reasonable in design and easy to manufacture; by applying the measuring device of the rubber roll winding machine, an operator can read out the measuring result at any time, so that the encapsulated thickness is quickly and accurately obtained, and unnecessary material waste is avoided; the operation safety is guaranteed, and unnecessary accident work injuries are avoided.

Owner:宜兴市鑫源辊业有限公司

Auxiliary disassembler for mold oil pipe joint

The invention relates to a dismounting machine, in particular to a mold oil pipe joint auxiliary dismounting machine. The mold oil pipe joint auxiliary dismounting machine conveniently dismounts oil pipe joints without deforming oil pipes and causing occupational injury. According to the technical scheme, the mold oil pipe joint auxiliary dismounting machine comprises bent frames, second nuts, second screw rods, a first fixed plate, an arc sleeve, clamping devices and the like; the second screw rods are arranged on the upper and lower sides of the first fixed plate; the second screw rods are connected with the second nuts through threads; the bent frames are symmetrically arranged on the second nuts on the upper and lower sides; and the arc sleeve is arranged on the front side of the firstfixed plate. Molds are clamped through the bent frames and fixing devices, and nuts on the left sides of oil pipe joints are fixed through the clamping devices to perform dismounting, so that the operation process is simple, and the dismounting is convenient by people; and through downward beating of a baffle plate, a second guide rod is pushed to move to the right side, so that oil pipes are pushed to move to the right side for disengagement.

Owner:威海高新园区运营管理有限公司

Rotary clamp equipment for manipulator

InactiveCN104924005AImprove quality and efficiencyImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWork injuryFixed frame

The invention relates to rotary clamp equipment for a manipulator. The rotary clamp equipment comprises a fixing frame component, a rack, locking fixing plates, adjustment plates, locking bolts and foundations, wherein the locking fixing plates are weld on the rack; the locking bolts are mounted on the locking fixing plates in a threaded connection manner; the foundations are welded below the rack; the fixing frame component is mounted on the rack via bearings in a rotary manner; gripper jaws can clamp a workpiece by adjusting clamp bolts; the fixing frame component is rotated to an appropriate angle and then the locking bolts are locked ; and the equipment can be matched with the manipulator for operation at any angle. The rotary clamp equipment for the manipulator reduces labor intensity of a worker, improves product quality, and lowers labor cost as work to be accomplished by three persons originally can be accomplished only by one person at present; more appropriate gripper jaws can be replaced according to different workpiece shapes at the same time; the locking angle is adjusted by self weight and inertia of the workpiece; no electric energy is consumed; and the equipment is energy-saving, environmentally-friendly, safe and reliable and reduces work injuries.

Owner:天津鑫泰博弈科技有限公司

Preparation method of efficient multi-planar cylindrical steel forging

The invention relates to a preparation method of an efficient multi-planar cylindrical steel forging and belongs to the technical field of smelting and casting production of metal steel balls. According to the efficient multi-planar cylindrical steel forging, pig iron, waste steel and alloys are selected as raw materials, melted by an intermediate frequency furnace and smelted to form high-quality molten steel, a cylindrical steel forging box type steel mold is used for casting production, a product is naturally cooled, quenched by an electric heating furnace, subjected to finish forging forming and trimming, and the efficient multi-planar cylindrical steel forging is obtained. According to the efficient multi-planar cylindrical steel forging, the cylindrical steel forging box type steel mold is used for casting production, and singleness of cast products is improved; the safety of the cylindrical steel forging box type steel mold is high, molten iron is cast through a casting riser, the condition that the molten iron is splashed easily and injures people is prevented, the work injury accident is reduced, and safety production management is facilitated; by comparison with ordinary casting, the injury accident due to molten iron splashing is fundamentally prevented; the steel forging is remarkably superior to a steel ball in grinding when used for ore grinding in a mine and a machining enterprise, and the grinding cost of the mine and the machining enterprise is greatly saved.

Owner:YONGREN COUNTY JINFENG SMELTING & CASTING CO LTD

Injection molding element large-flow-pass high-precision hot-melting shearing jig

The invention discloses an injection molding element large-flow-pass high-precision hot-melting shearing jig which comprises a base. The injection molding element large-flow-pass high-precision hot-melting shearing jig is characterized by also comprising air heat scissors, a flow rate regulating valve and an air source; an opening which is used for running through a water port of an injection molding element is formed on the base; the air heat scissors are arranged below the base; a moving cutter at the front end of the air heat scissors is positioned below the opening; the air heat scissors are connected with the air source through an air channel; and the flow rate regulating valve which is used for regulating the shearing speed of the moving cutter of the air heat scissors is arranged between the air heat scissors and the air source. According to the invention, the problems that in the prior art, the water port of the injection molding element is shorn by shearing scissors, the shearing speed is slow, the precision is low, the cost is high, the labor intensity of the operators is high, and accident work injury is easy to be generated are solved, and the injection molding element large-flow-pass high-precision hot-melting shearing jig which can relieve the labor intensity of operators, and improve the shearing precision and speed is provided.

Owner:FUJIFILM IMAGING SYST SUZHOU

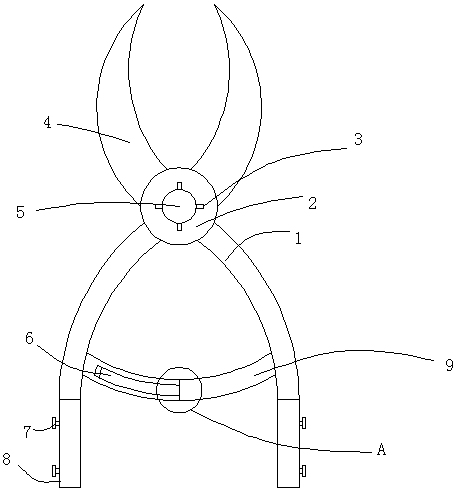

Branch trimming device for plant protection

InactiveCN109287306ASolve the problem of work-related injuriesEasy to replaceSecateursWork injuryEngineering

The invention discloses a branch trimming device for plant protection. Aiming at solving the existing work injury problem, the branch trimming device comprises symmetrical working rods, a connecting column is fixedly welded to one end of each working rod, a connecting shaft is rotatably connected to the middles of the two connecting columns, the two ends of the connecting shaft are fixedly connected with symmetrical springs, connecting blocks are fixedly connected to the outer ends of the springs, a scissor frame is fixedly connected to the end, away from the corresponding working rod, of eachconnecting column through a bolt, and a connecting rod is fixedly welded to the end, away from the corresponding scissor frame, of each working rod. The branch trimming device is simple in structureand convenient to use, and the trimming task can be well completed; meanwhile, through the connecting shaft, the inner springs and the connecting blocks, the scissor frames can be conveniently replaced, the replacement of the whole scissor device can be reduced accordingly, the cost is reduced, a user is prevented from injuries at the same time, an external device is conveniently connected, different trimming environments are adapted to, and the efficiency is improved.

Owner:郑州浩普信息技术有限公司

Automatic feeding device capable of reducing occupational injury rate for celadon blank mud manufacturing and rolling

PendingCN114505948AAvoid OverloadingReduce labor intensityClay processing apparatusCeramic materials productionWork injuryMachine

The automatic feeding device comprises a base and a grinding machine located at the top end of the base, a workbench is arranged at the position, located on one side of the grinding machine, above the base, and a plurality of evenly-distributed supporting columns are arranged at the bottom end of the workbench; the bottom ends of the supporting columns extend into the base, a first lead screw and a second lead screw are symmetrically arranged in the base, and the first lead screw and the second lead screw are each provided with a movable block connected with the corresponding supporting column. The device has the beneficial effects that the effect of accurate quantity control is achieved, the capacity of the barrel can be quantitatively adjusted, the grinding machine can be utilized to the maximum extent, the grinding efficiency is improved, overload operation of the grinding machine is prevented, and the service life of the device is prolonged; a large amount of manual labor cost is saved, the labor intensity of workers is reduced, workers do not make contact with machines during machine work, the probability that the machines hurt people is reduced, and therefore the occupational injury rate is reduced.

Owner:李华生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com