Three-dimensional circular production process for tubular pile

A technology of production technology and three-dimensional circulation, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as low degree of automation, work-related accidents, and low work efficiency, and achieve the goals of reducing labor usage, rational setting, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0022] A pipe pile three-dimensional circulation production process is realized through the following steps:

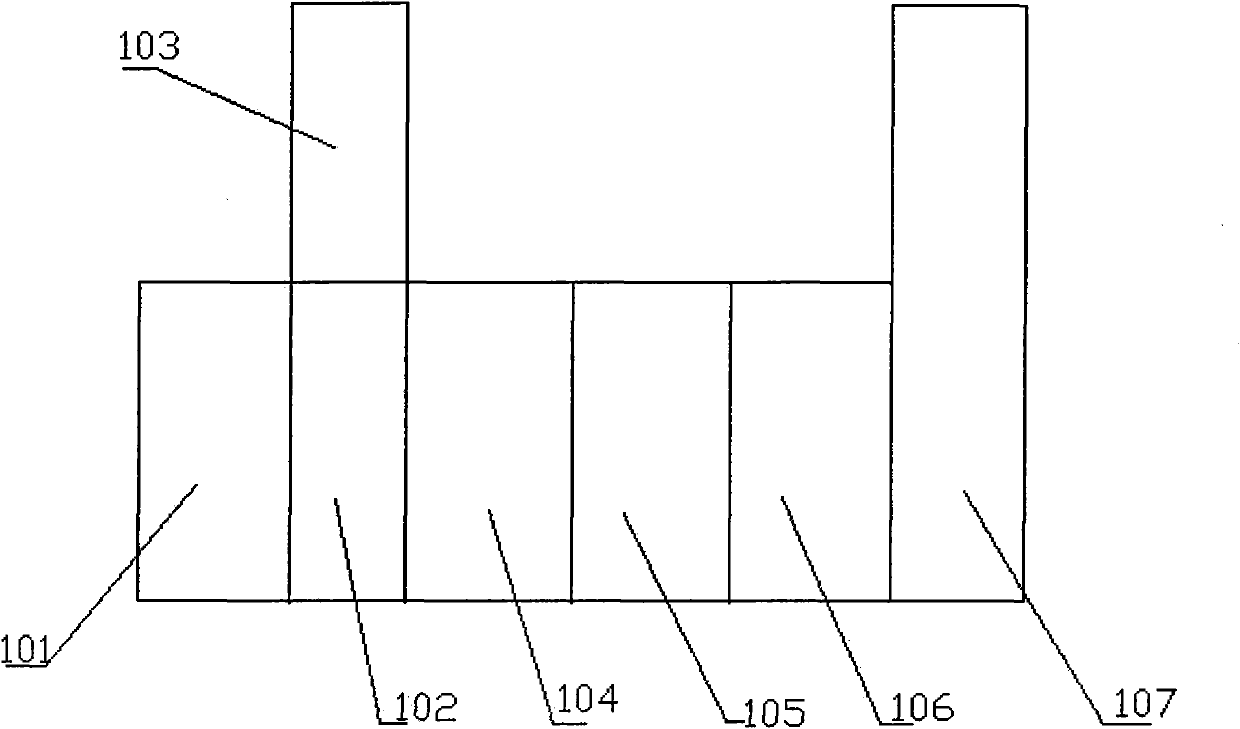

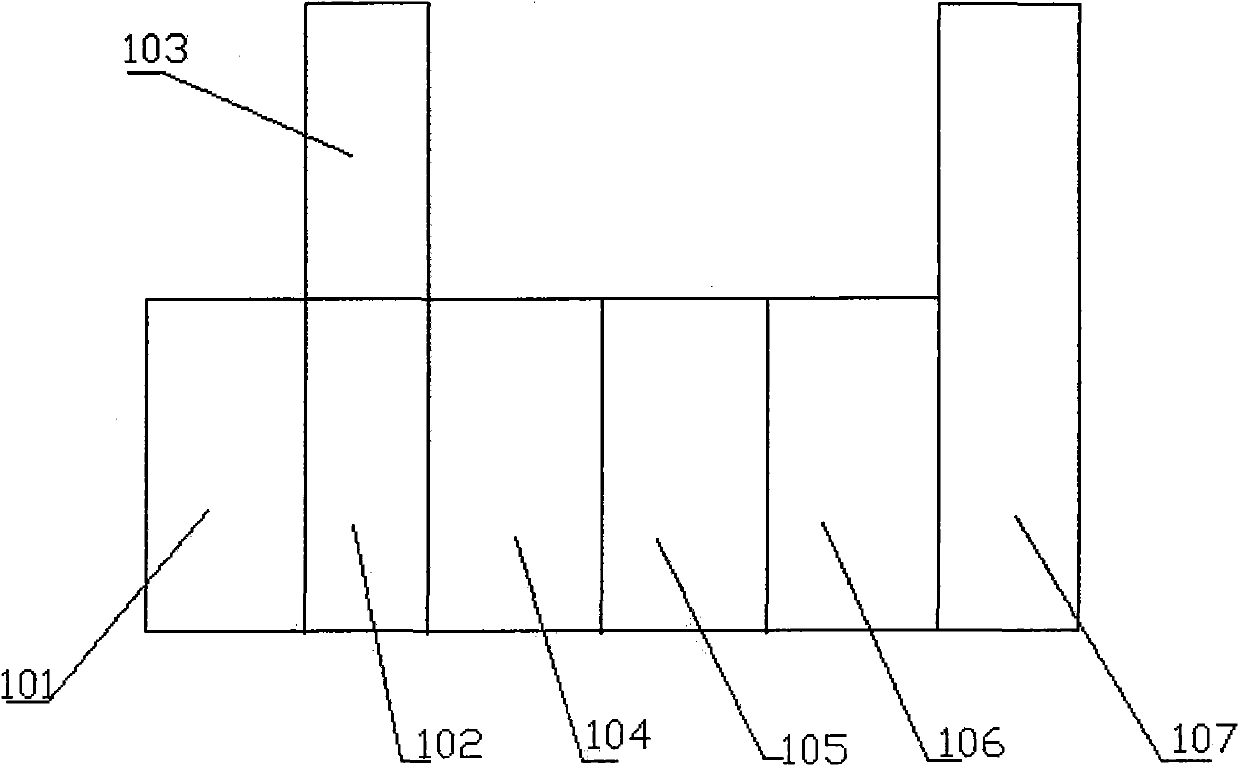

[0023] Firstly, the pipe pile lower mold in the circulation process is placed in the pipe pile 101-lower mold storage area, and then the solidified concrete part in the pipe pile lower mold is cleaned. Put the welded steel cage into the lower mold of the pipe pile, and then use the crane to hoist it to the mobile platform in the 107-feed area, and use the tensioning device to prestress the steel cage. Move the mobile platform at a constant speed, and open the concrete feeding equipment at the same time. At this time, the concrete is evenly spread in the lower mold of the pipe pile. After feeding, the mobile platform moves back to its original position. Use the crane to hoist the upper mold placed in the upper mold storage area to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com