Bearing processing lifting feed device

A feeding device and bearing processing technology, which is applied in metal processing and other directions, can solve the problems of increasing production costs and increasing production cycles, and achieve the effects of reducing production costs, shortening production cycles, and reducing the use of labor in enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

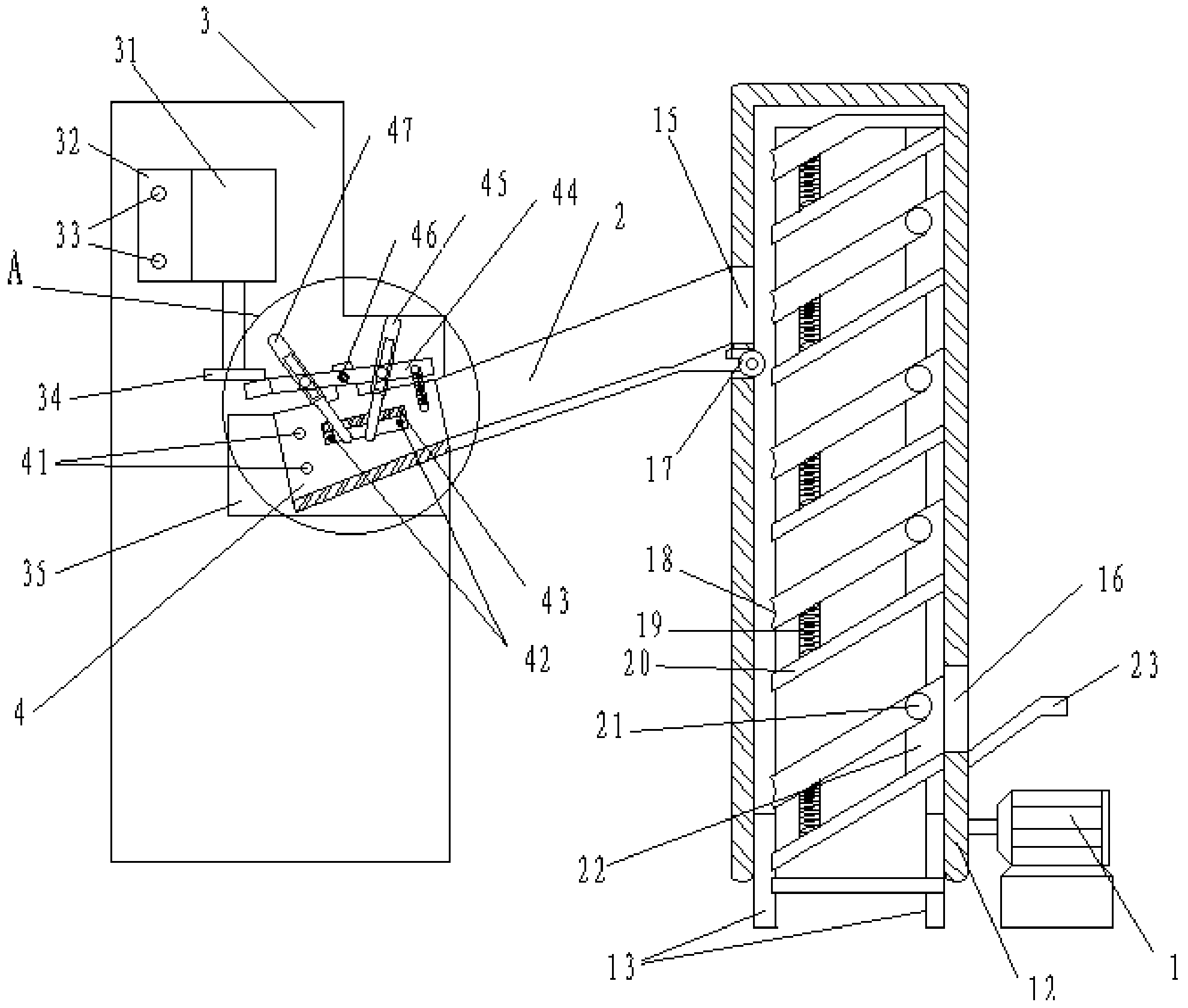

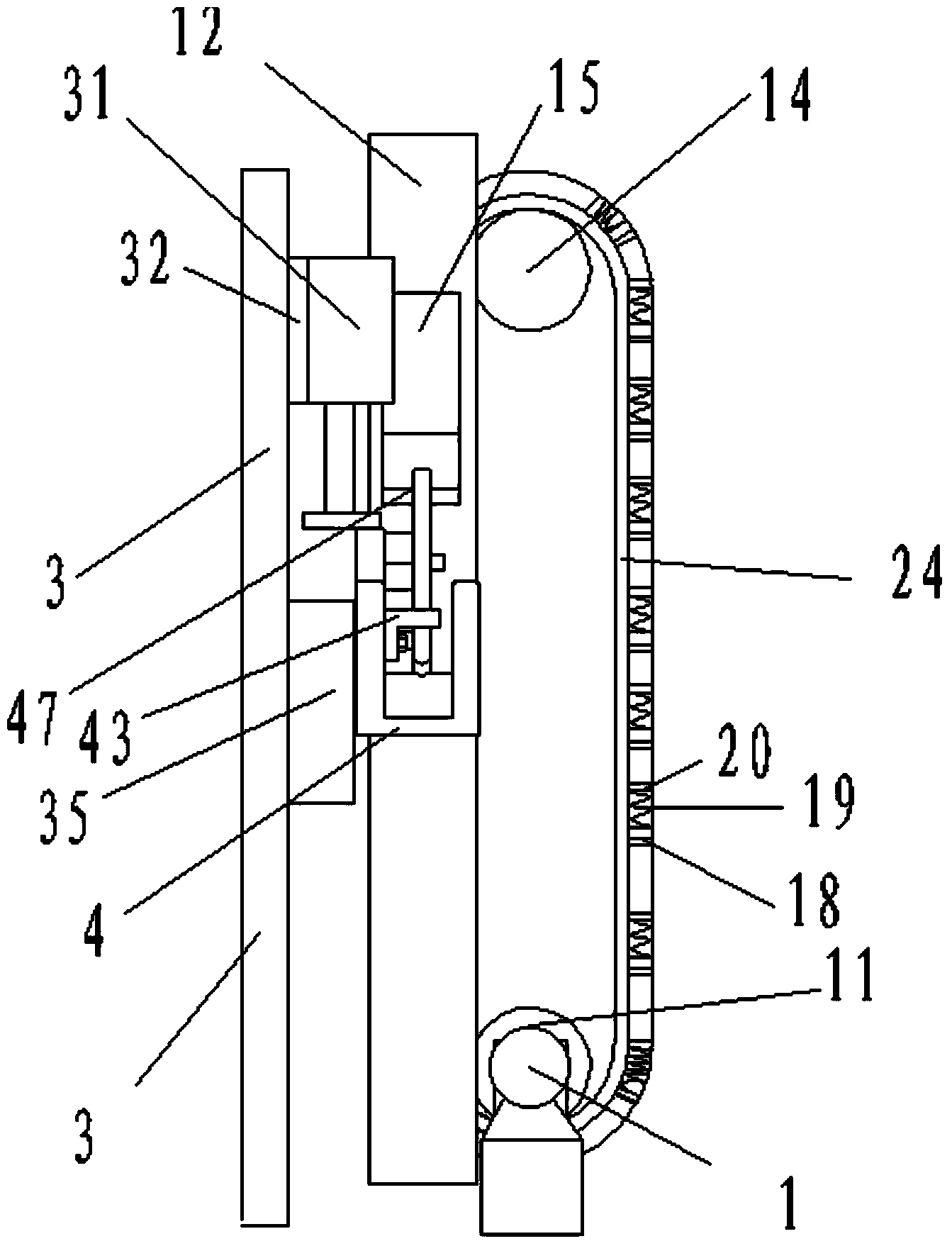

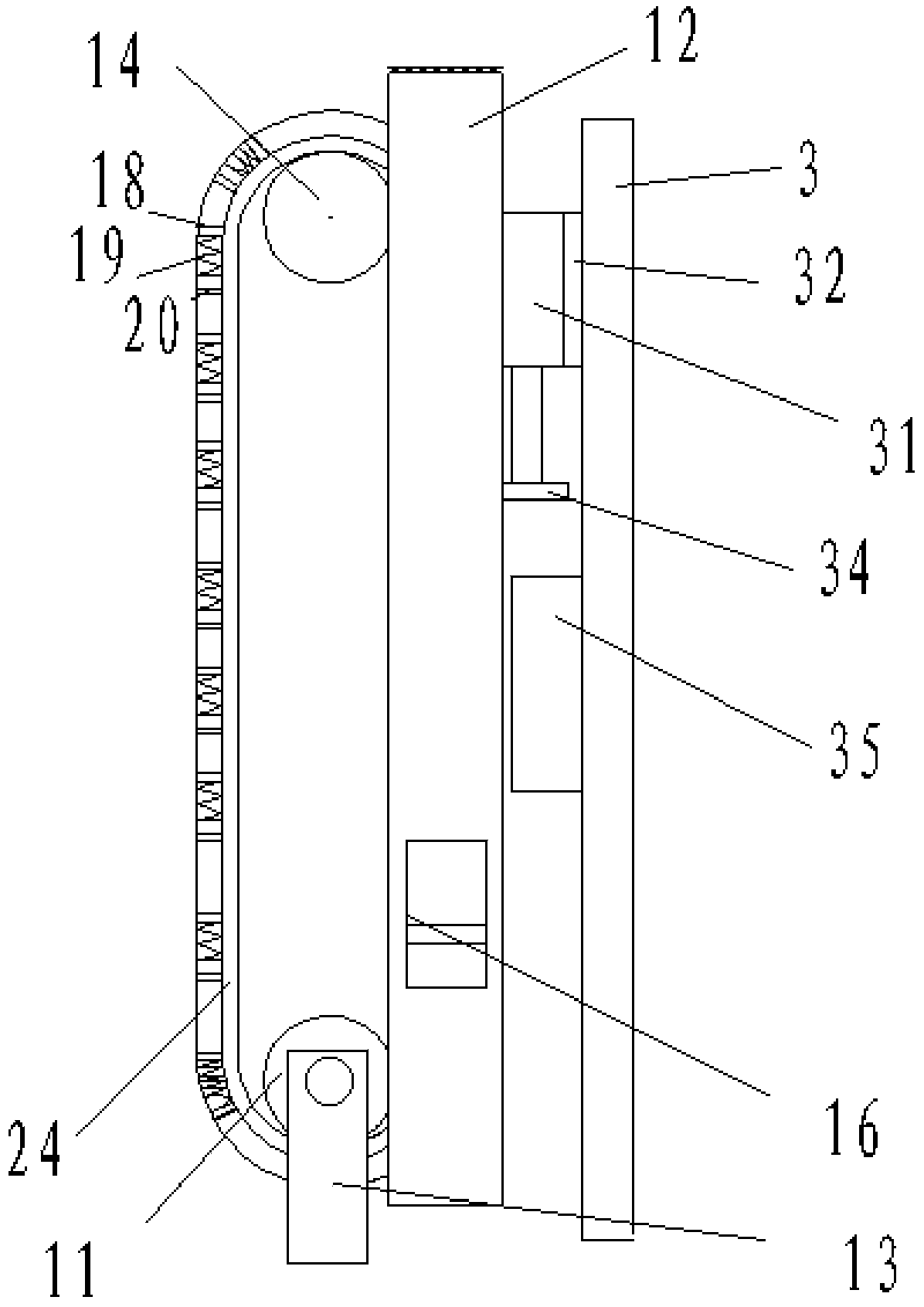

[0018] refer to figure 1 , figure 2 , image 3 with Figure 4 , a bearing processing lifting feeding device of the present invention includes a motor 1, a support frame 12, a support seat 13, a driving wheel 11, a driven wheel 14, an endless belt 24, a conveying track 2, a roller 17, a support plate 3, a piston cylinder 31, Pressure plate 34, feeding mechanism 4, described motor 1 is fixedly connected with driving wheel 11, described endless belt 24 interior is provided with driving wheel 11 and driven wheel 14, and described support base 13 and driving wheel 11 are movably connected, and described Support frame 12 is provided with feeding rail 2, and feeding rail 2 is provided with roller 17, and roller 17 is movably connected with feeding rail 2, and roller 17 is fixedly connected with supporting frame 12, and described support plate 3 is provided with piston cylinder 31, and piston cylinder 31 A pressure plate 34 is provided, the support plate 3 is provided with a feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com