Rotary clamp equipment for manipulator

A technology of clamping equipment and manipulators, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., to achieve the effect of improving welding quality and work efficiency, improving work efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

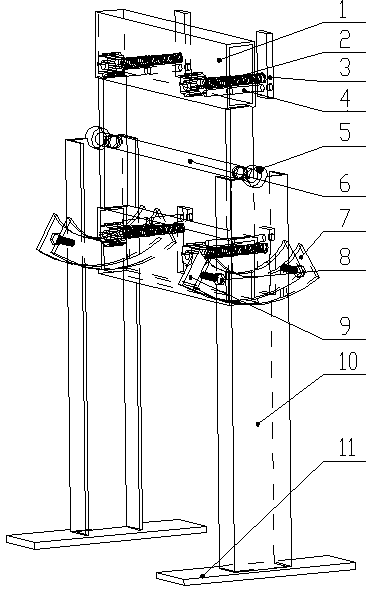

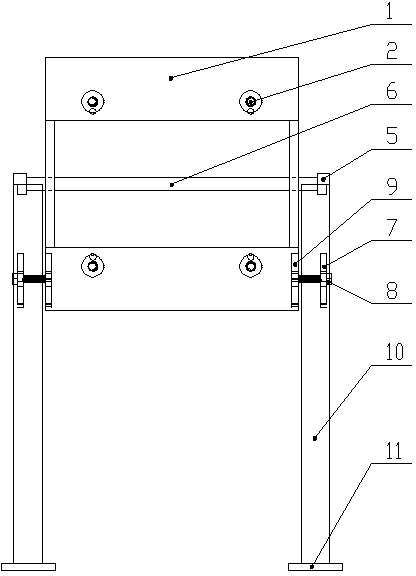

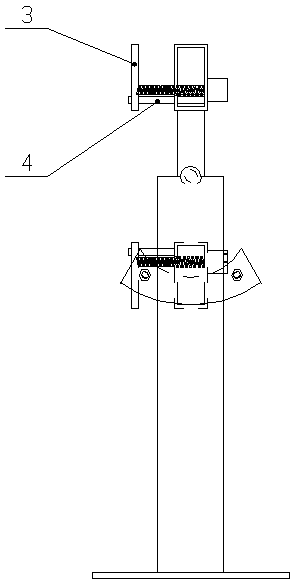

[0015] A rotary clamping device for a manipulator includes a fixed frame assembly, a frame 10, a locking fixed plate 7, a locking bolt 8, and an anchor 11, wherein the fixed frame assembly includes a fixed frame 1, a clamping bolt 2, and a clamping claw 3 , guide rod 4, shaft 6, bearing 5 and adjustment plate 9, the fixed frame 1 is a rectangle welded by square tubes, a shaft 6 is fixed in the middle, bearings 5 are installed at both ends of the shaft 6, and the upper and lower parts of the fixed frame 1 Clamping bolts 2 and guide rods 4 are symmetrically arranged on the square tube, and the clamping claw 3 can move along the guide rod 4 driven by the clamping bolts 2 . The locking fixing plate 7 is welded on the frame 10, the locking bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com