Patents

Literature

105results about How to "Avoid Work Injury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

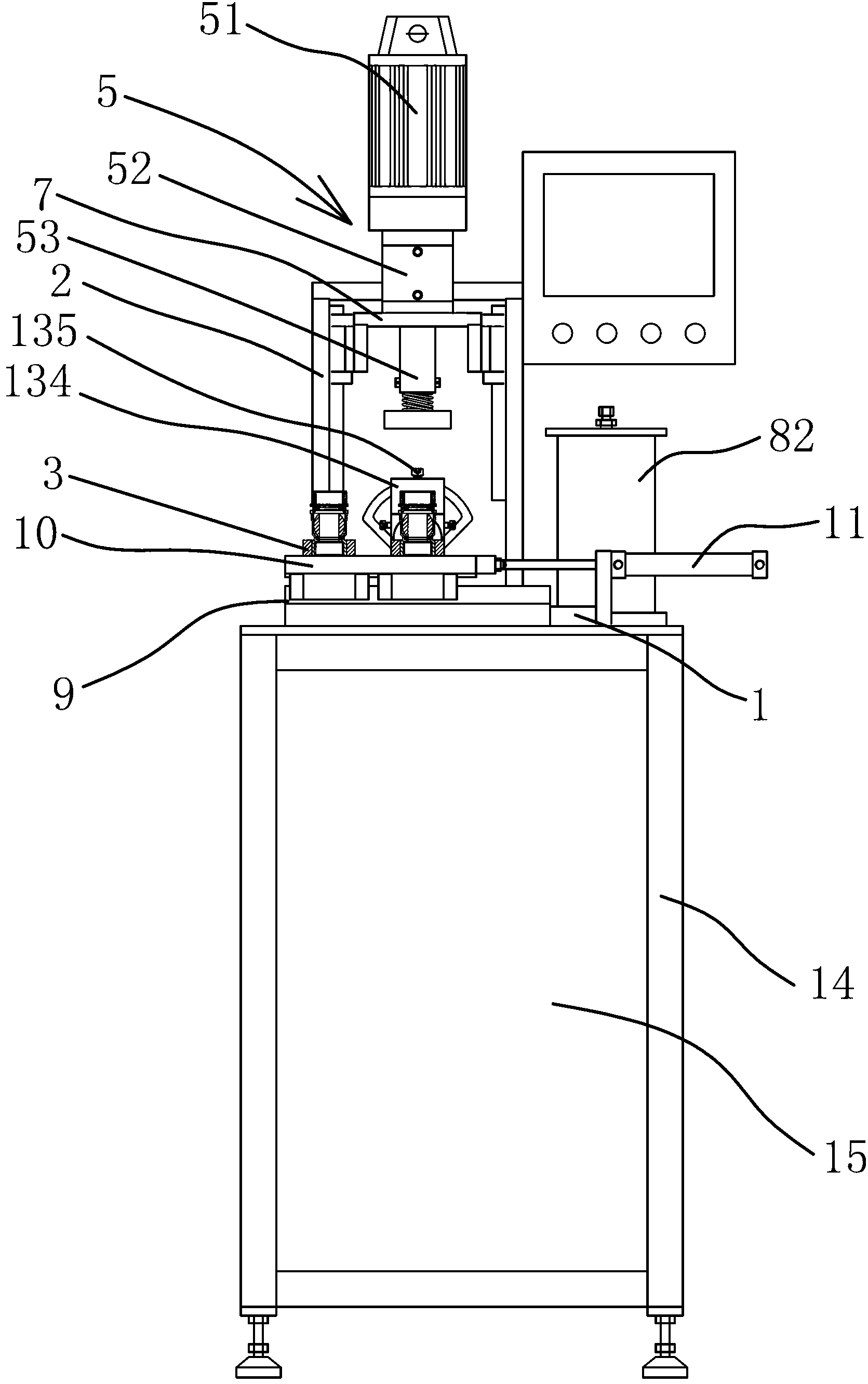

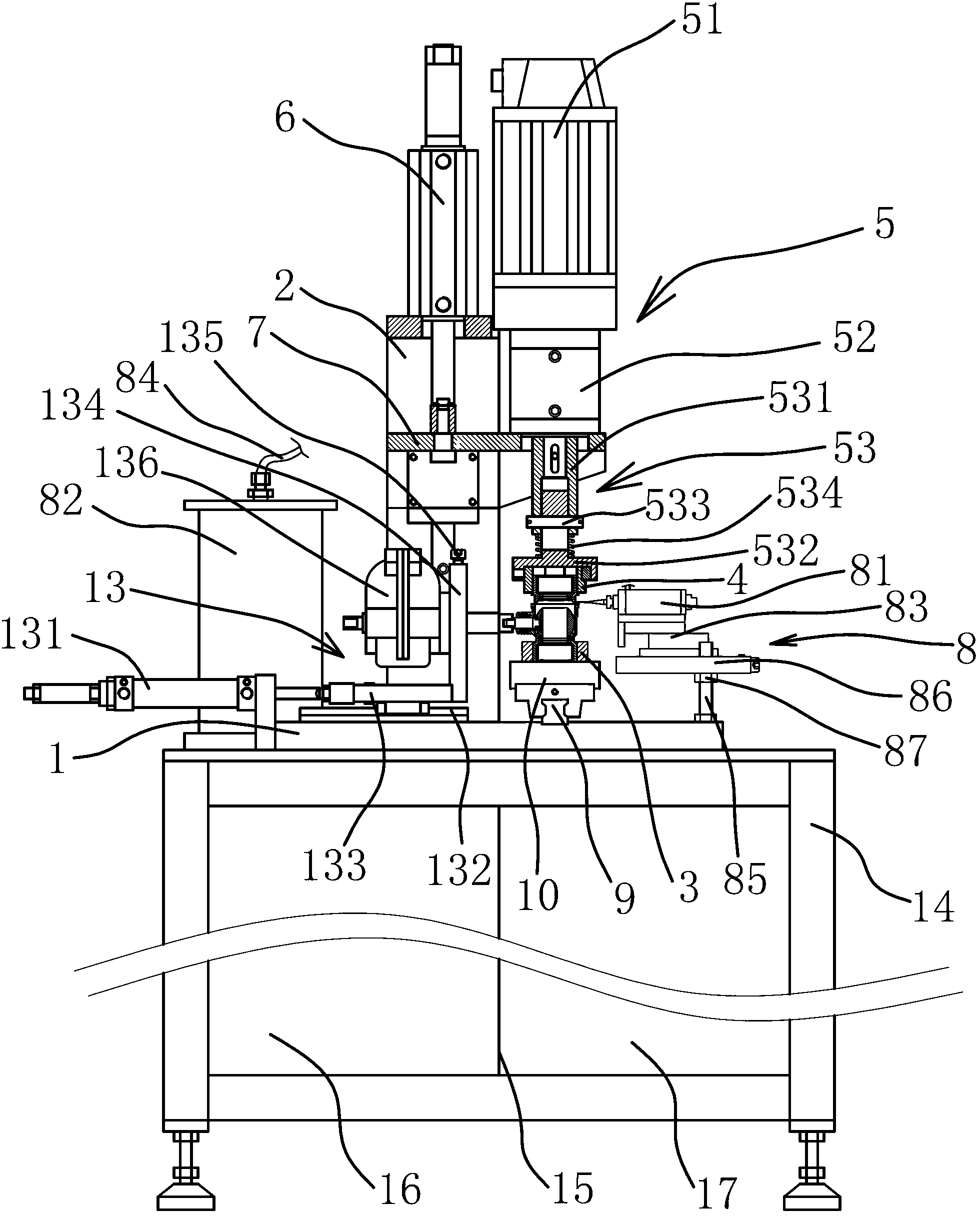

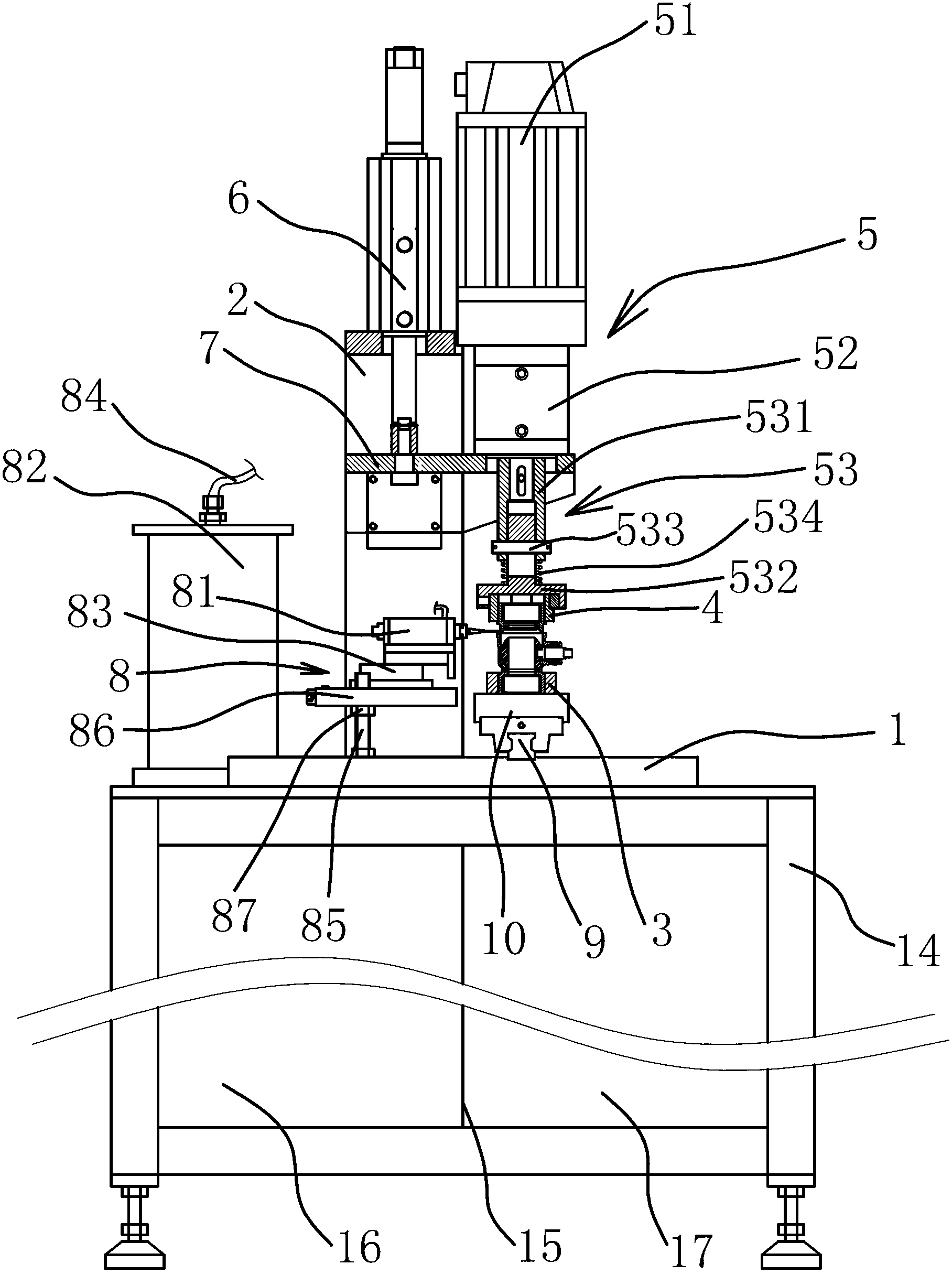

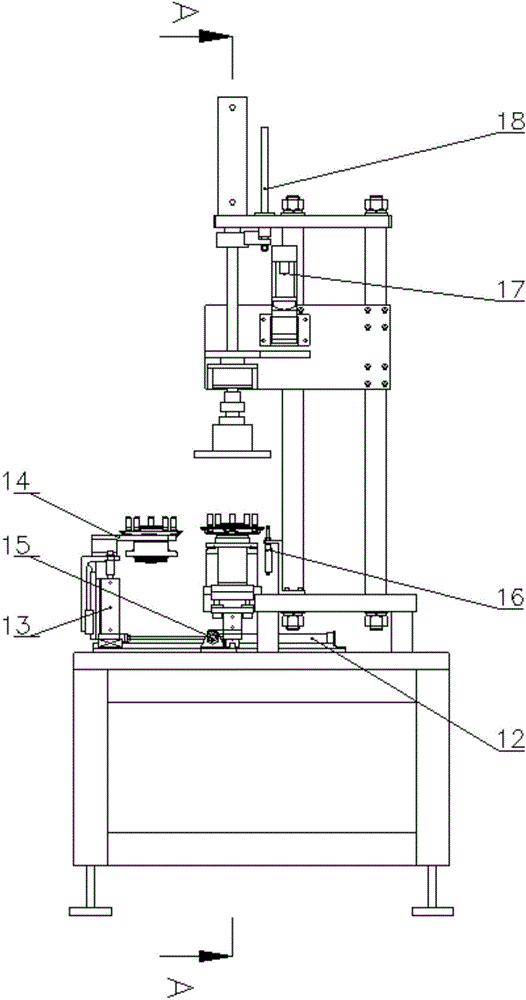

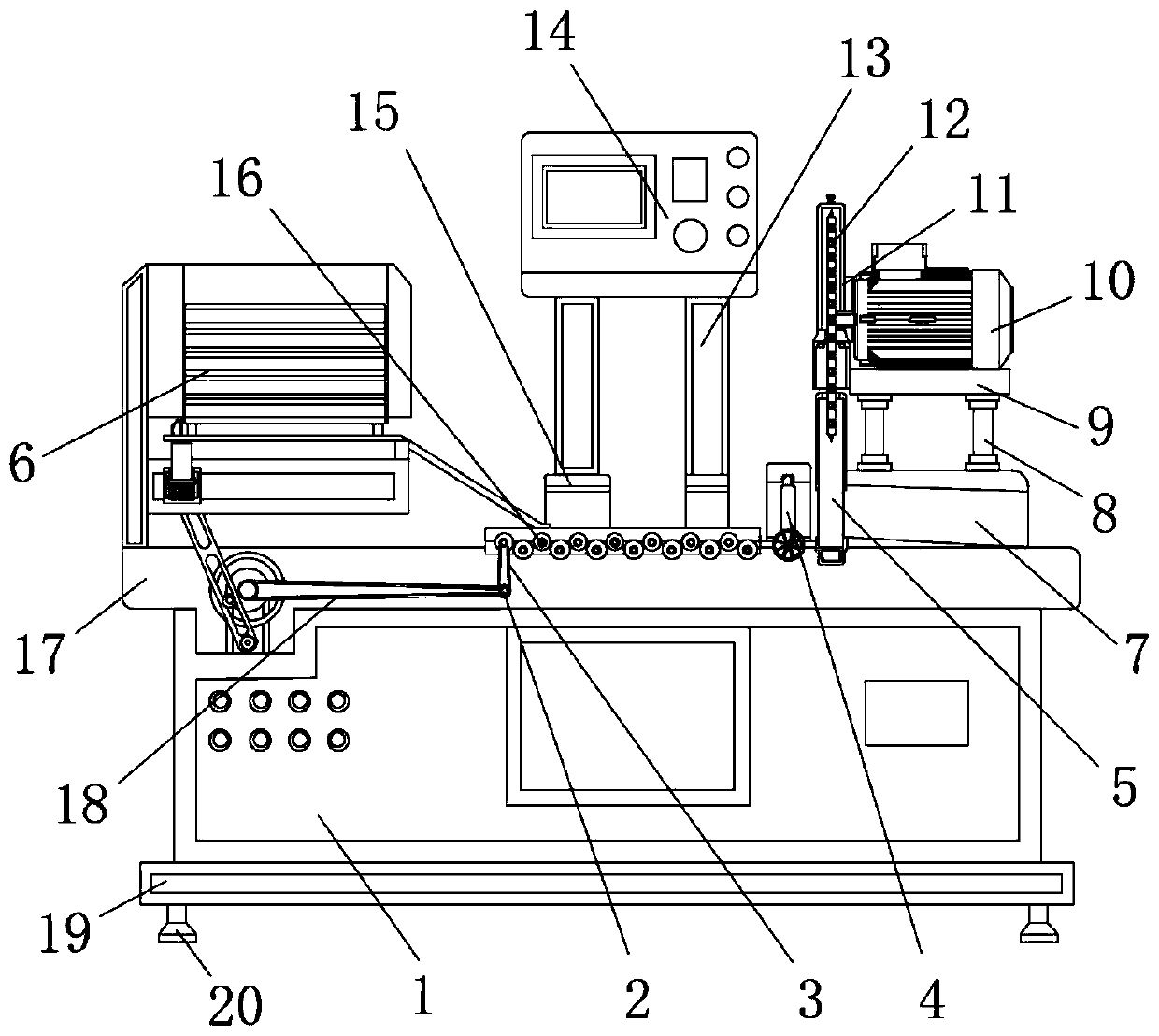

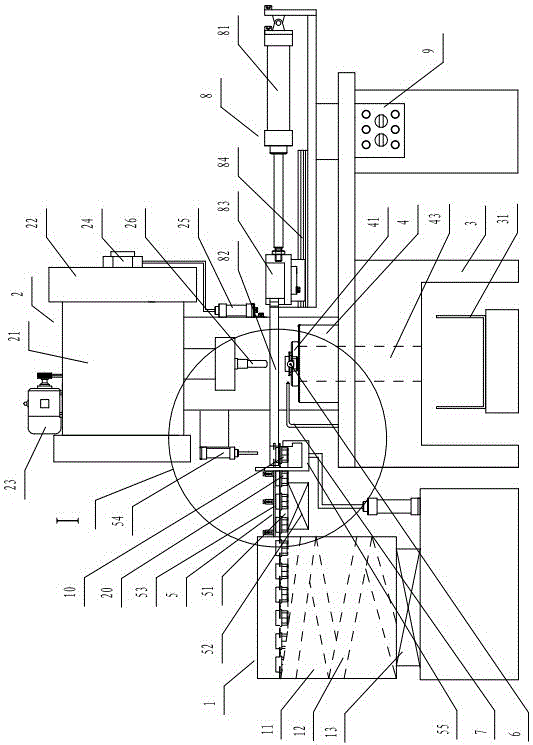

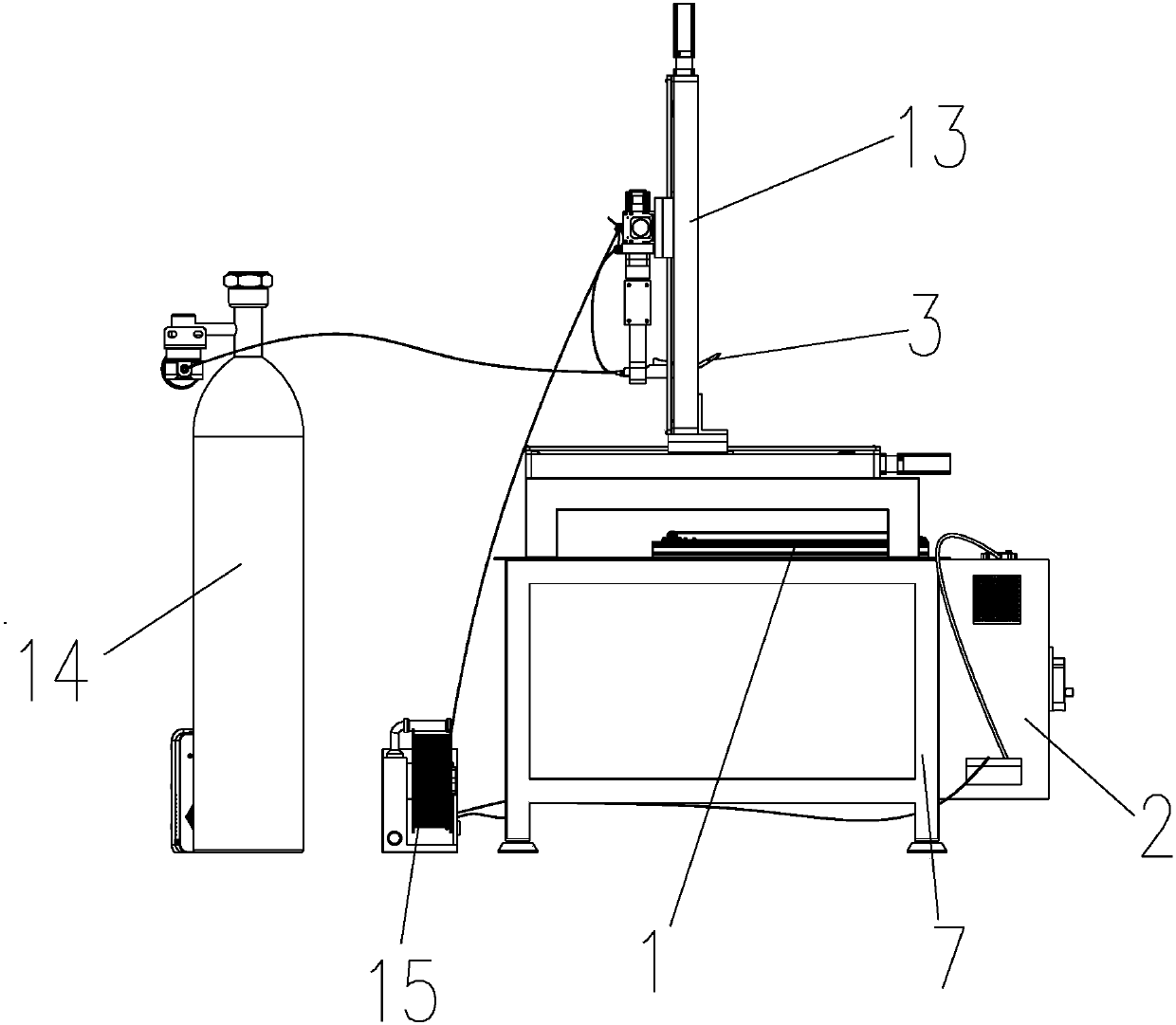

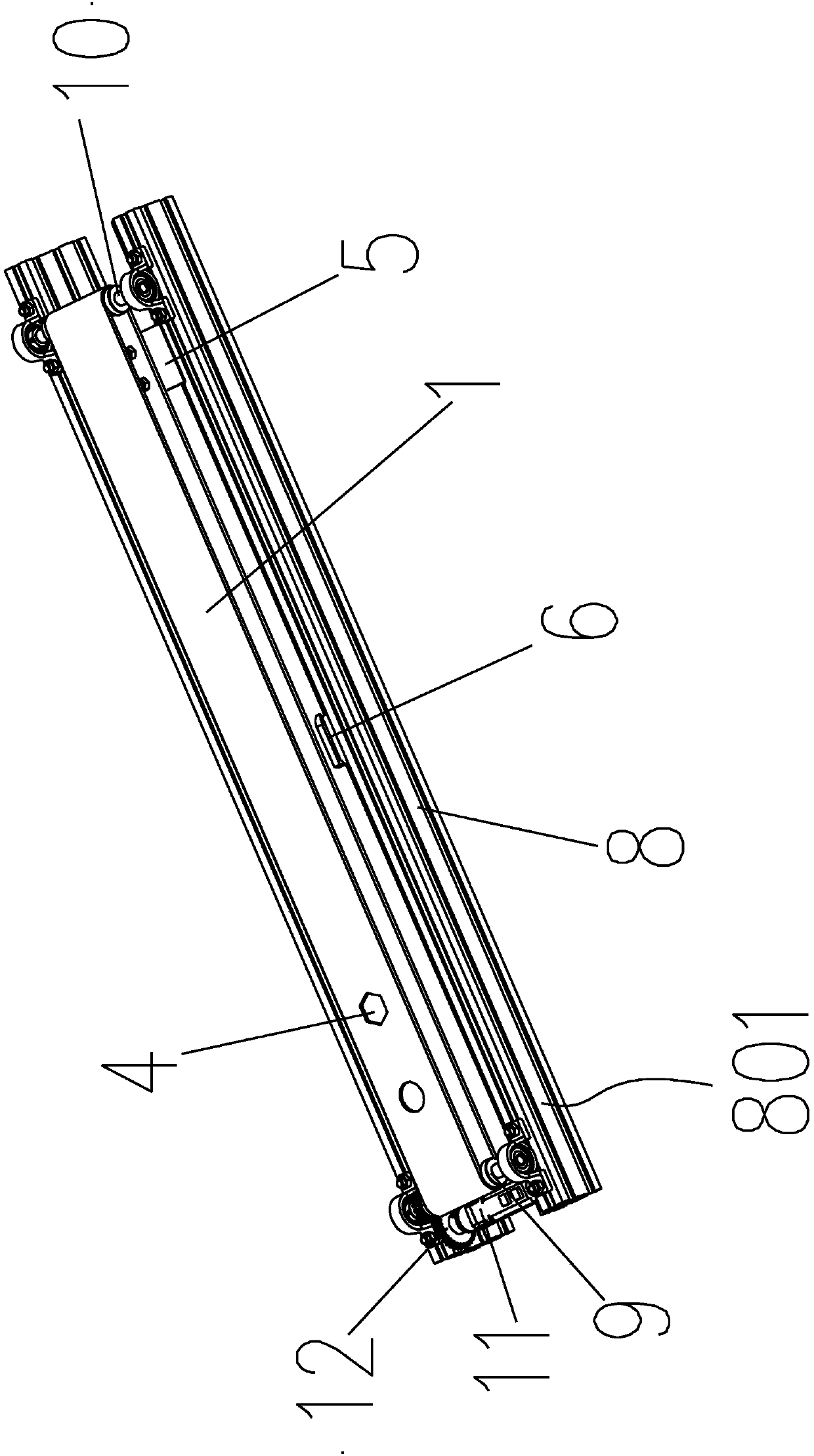

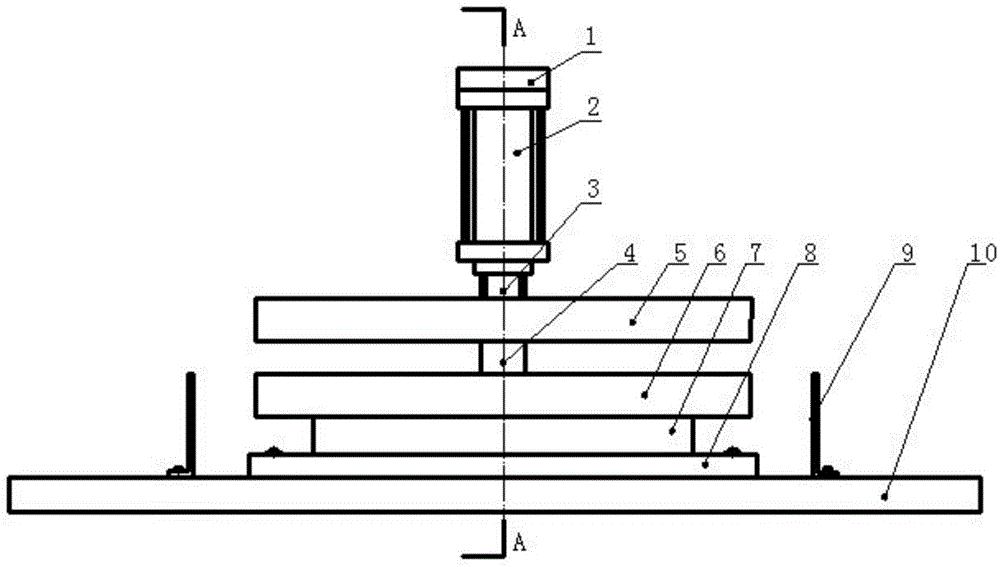

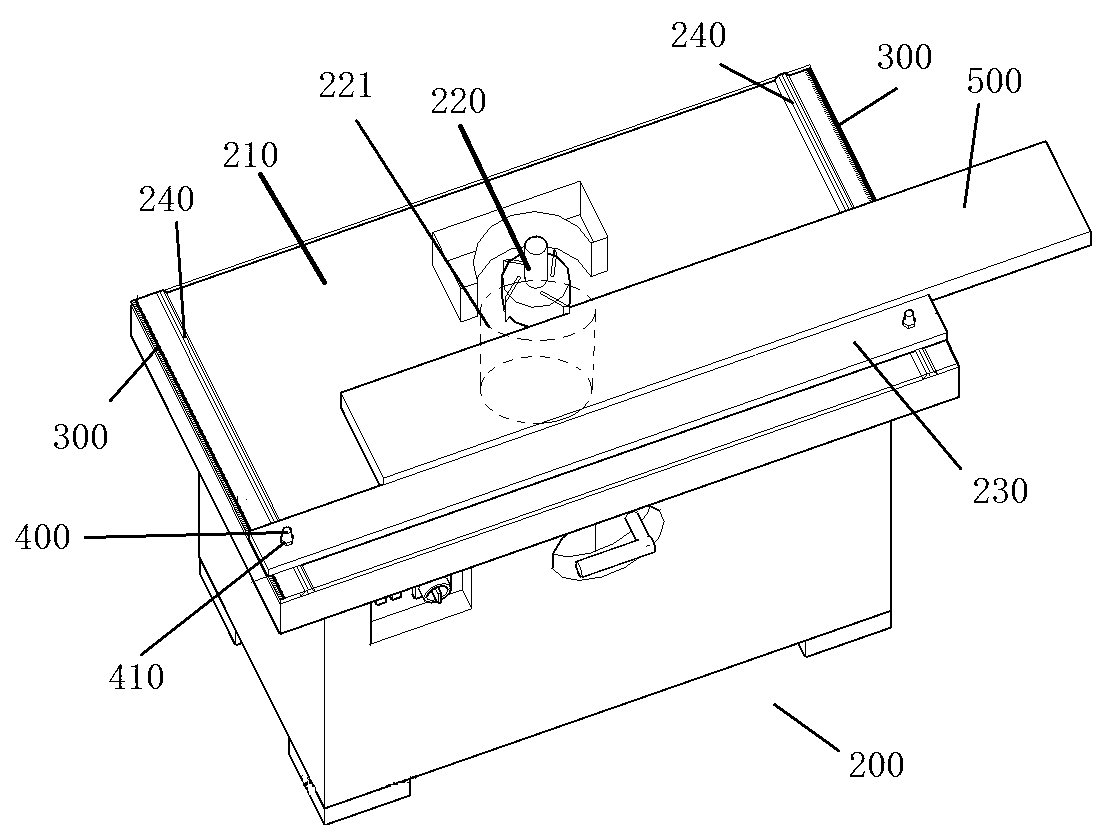

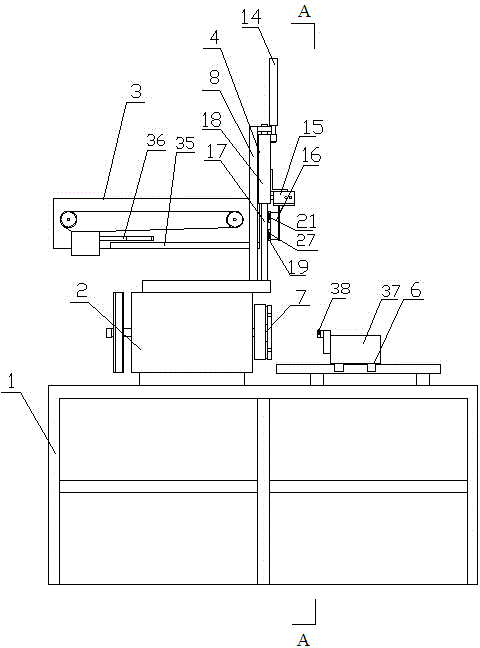

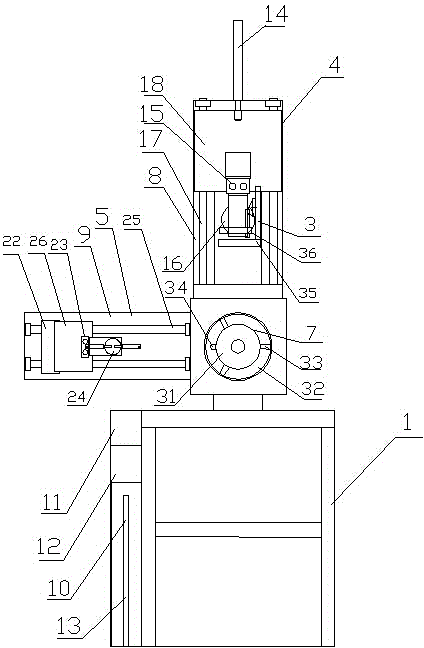

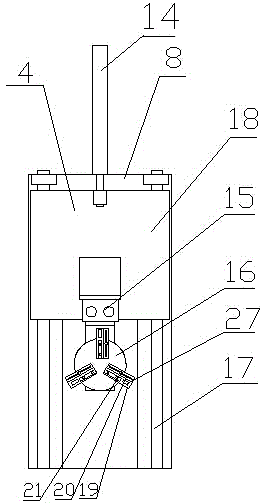

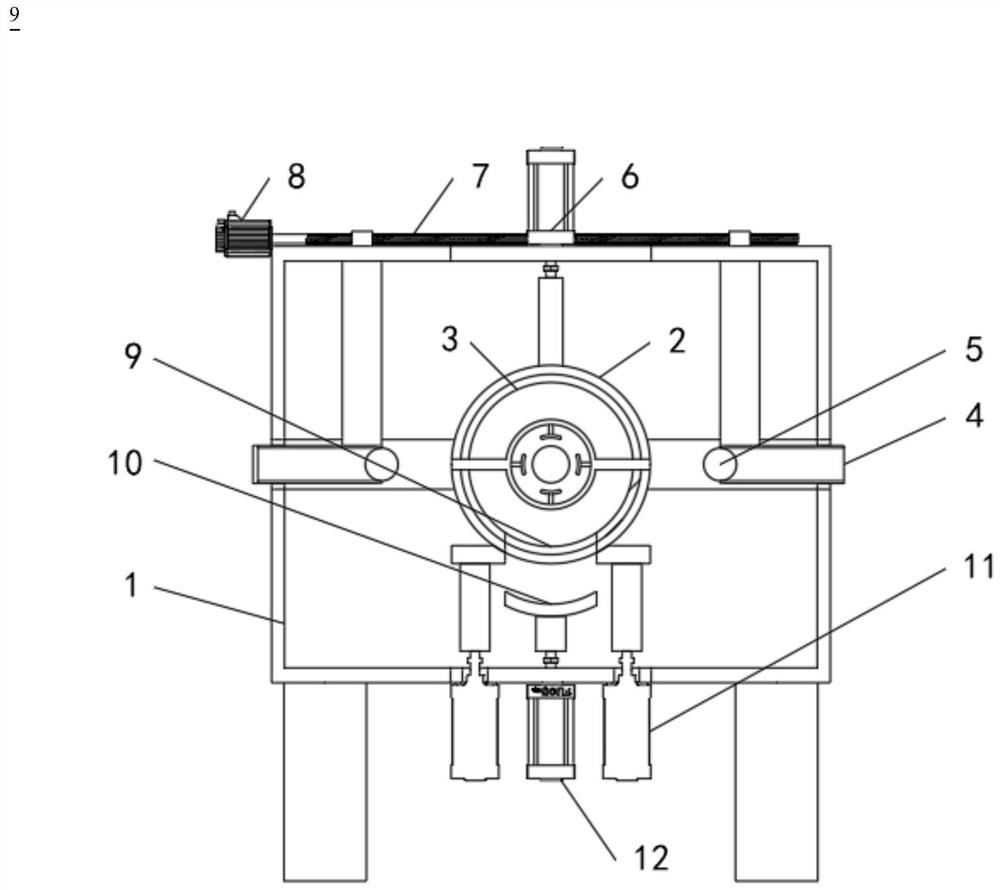

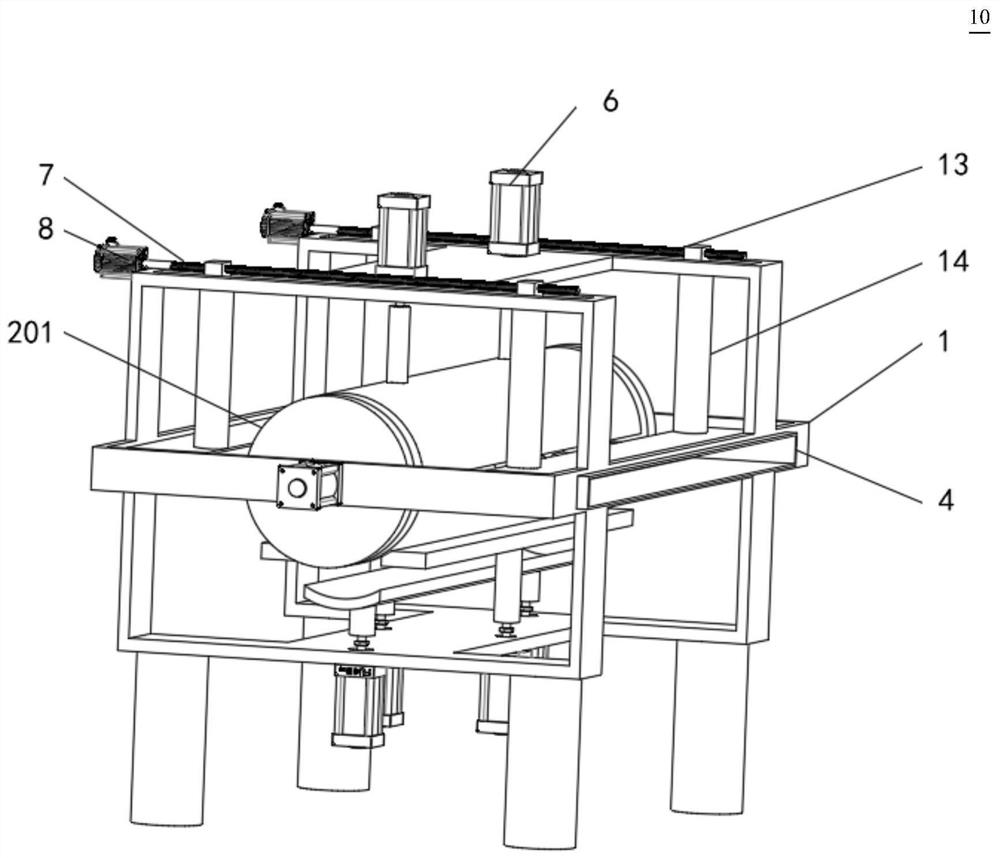

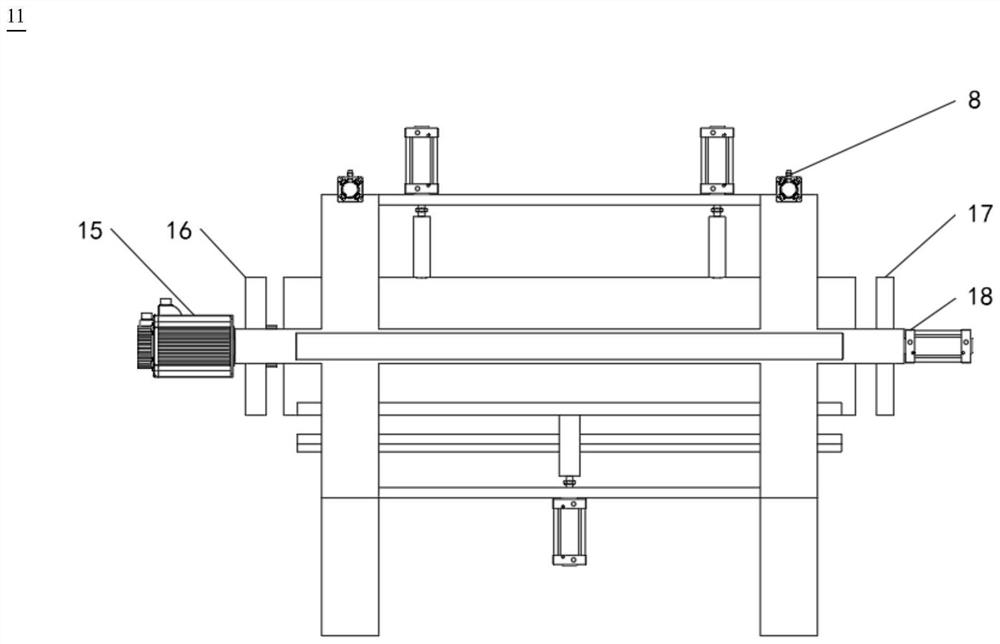

Valve body and bonnet connection torsion dispensing assembly machine

InactiveCN103231241AUniform coatingImprove the firmness of the connectionLiquid surface applicatorsAssembly machinesEngineeringPiston rod

The invention provides a valve body and bonnet connection torsion dispensing assembly machine, belongs to the technical field of valve production devices and solves problems that the existing valve body and bonnet connection assembly machine cannot achieve automatic gluing. The valve body and bonnet connection torsion dispensing assembly machine comprises a worktable and a support fixed on the worktable, wherein a lower die body is arranged on the worktable, an upper die body is arranged right above the lower die body and is fixed on the lower portion of a torsion control mechanism used for controlling rotating of the upper die body, a lifting cylinder is fixedly connected onto the support, a lifting sliding table is fixedly connected at the end of a piston rod of the lifting cylinder, the torsion control mechanism is fixed on the lifting sliding table, and a dispensing mechanism is arranged on the side portion of the lower die body. The valve body and bonnet connection torsion dispensing assembly machine has the advantages of having double functions of valve bonnet screwing and gluing, being high in automation and work efficiency and the like.

Owner:ZHEJIANG VALOGIN TECH

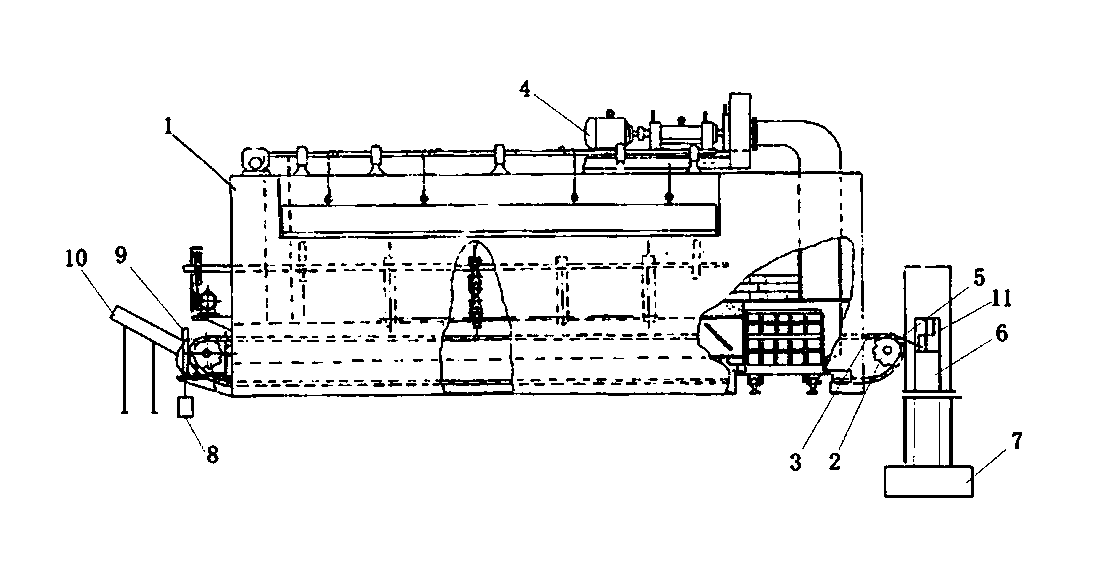

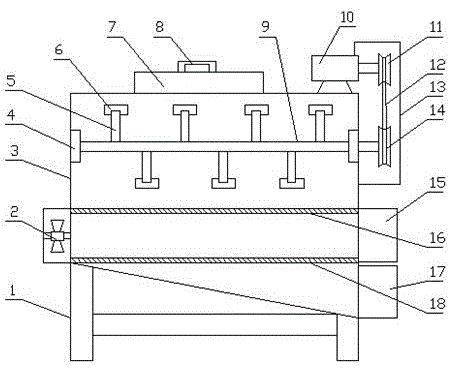

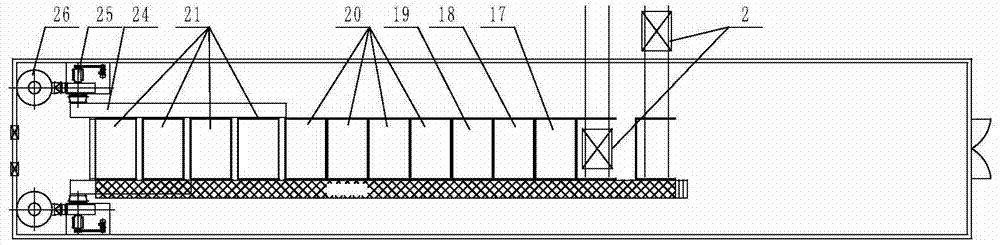

Full-automatic aluminum rod heating furnace

ActiveCN103375988ARealize fully automatic inputIncrease productivityFurnace typesSprocketEngineering

The invention discloses a full-automatic aluminum rod heating furnace. A heat insulating layer is arranged on the outer side of a hearth in a furnace body, an inlet of the hearth is correspondingly connected with a feeding mechanism, chain wheels are arranged on chain wheel frames at two ends of the furnace body, chains sleeved on the chain wheels penetrate in the hearth, a driving device drives the chain wheels to rotate, an air outlet of an induced draft fan is communicated with the interior of the hearth, a smoke-discharging chimney communicated with the outside is arranged on the hearth, the high end of a connecting plate is in aligned connection with an outlet of the hearth, the low end of the connecting plate is connected with the high end of a feeding passage, the low end of the feeding passage is connected with a discharging chute which is correspondingly connected with a feeding port of an aluminum extruder exactly, and the controller controls the feeding mechanism and the driving device to act. By the full-automatic aluminum rod heating furnace, aluminum rods are full-automatically fed into the hearth to be heated and then conveyed into the aluminum extruder for aluminum extruding, and no manual operation is needed in the whole process, so that production efficiency is improved, manpower is saved, and work injuries are reduced.

Owner:昆山市源丰铝业有限公司

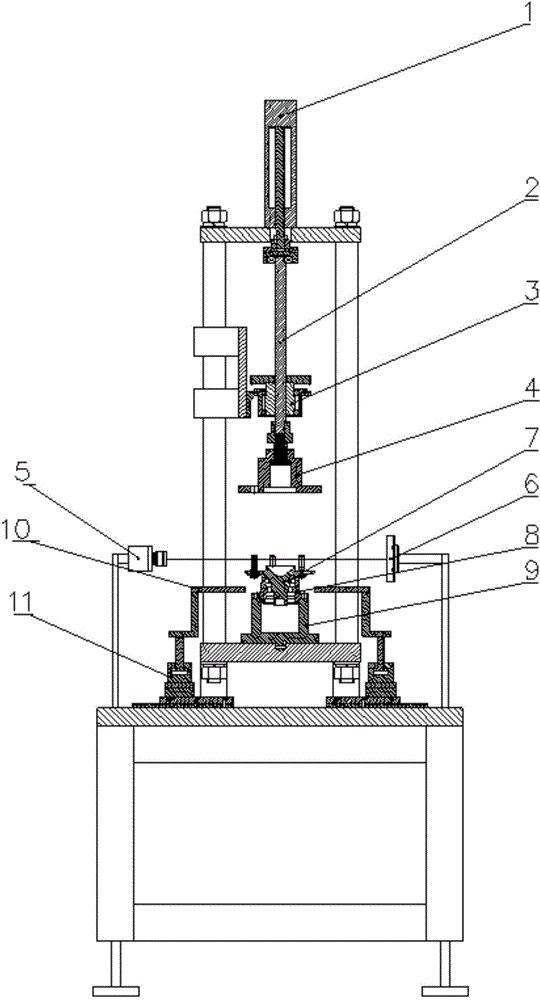

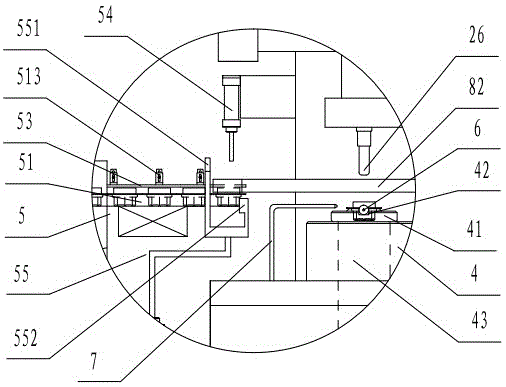

End face run-out and bolt detection integrated machine for third generation hub unit

ActiveCN105716650AAvoid secondary damageAvoid Work InjuryMechanical measuring arrangementsOutput deviceEngineering

The invention discloses an end face run-out and bolt detection integrated machine for a third generation hub unit. A measuring table on a workbench can position and support a bearing to be detected; a light source and an image acquisition device symmetrically distributed on two sides of the measuring table image the bearing; a bearing outer ring flange positioning device can fix and position a bearing outer ring flange; the lower end of a measuring panel capable of lifting and being rotationally positioned above the measuring table can just press against the upper end face of a bearing inner ring flange, and the measuring panel is also provided with a bolt hole for inserting an upper bolt of the bearing inner ring flange; a longitudinal driving device and a rotary driving device can separately drive the measuring panel to longitudinally lift and intermittently rotate to the set angle, and a contact at the upper end of a measuring pen can just press against the lower end surface of the measuring panel; and a controller controls the bearing outer ring flange positioning device, the longitudinal driving device and the rotary driving device to act, and controls a measuring result output device to output the detection result. The integrated machine can detect two indexes at one time, and is quick in detection and exact in detection value.

Owner:江苏康斯特智能装备有限公司

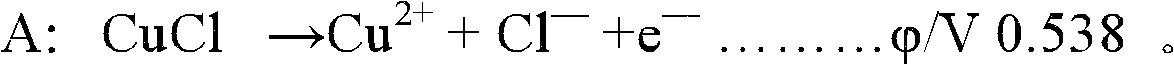

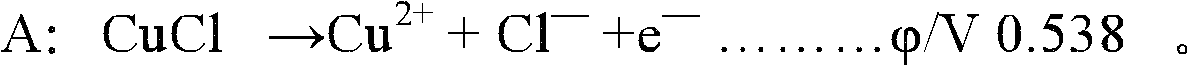

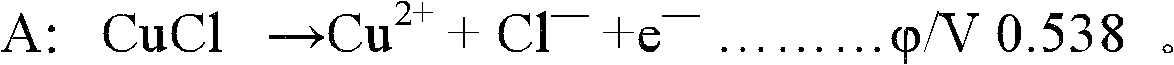

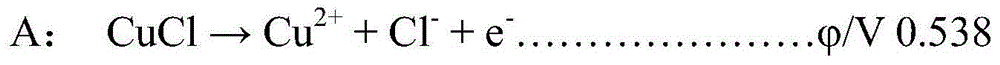

Acidic etching solution not generating chlorine and catalyst of acidic etching solution

InactiveCN102154646AAvoid Chlorine SpillsAvoid work injuries and industrial accidentsOrganic-compounds/hydrides/coordination-complexes catalystsIonCopper chloride

The invention relates to acidic etching solution not generating chlorine and a catalyst of the acidic etching solution. The solution comprises mother solution, son solution and catalyst, wherein the mother solution consists of copper chloride solution, chloride ions and an acid group, the content of copper in the copper chloride solution is between 80 and 180 g / L, the content of the acid group is between 0.3 and 5.0 N, the sources of the chloride ions are hydrochloric acid or salt of various kinds of hydrochloric acid, and the content of the chloride ions is between 160 and 330 g / L; the son solution consists of chloride ions and an acid group, the content of the acid group is between 0.3 and 6.0 N, the sources of the chloride ions are hydrochloric acid or salt of various kinds of hydrochloric acid, and the content of the chloride ions is between 160 and 330 g / L; and the catalyst has the complexing action on monovalent copper ions and bivalent copper ions in the acidic etching solution, or can be used for the generation of stable coordination compounds, can be used for regulating oxidation-reduction potentials in a reaction A without the generation of chlorine.

Owner:侯延辉 +1

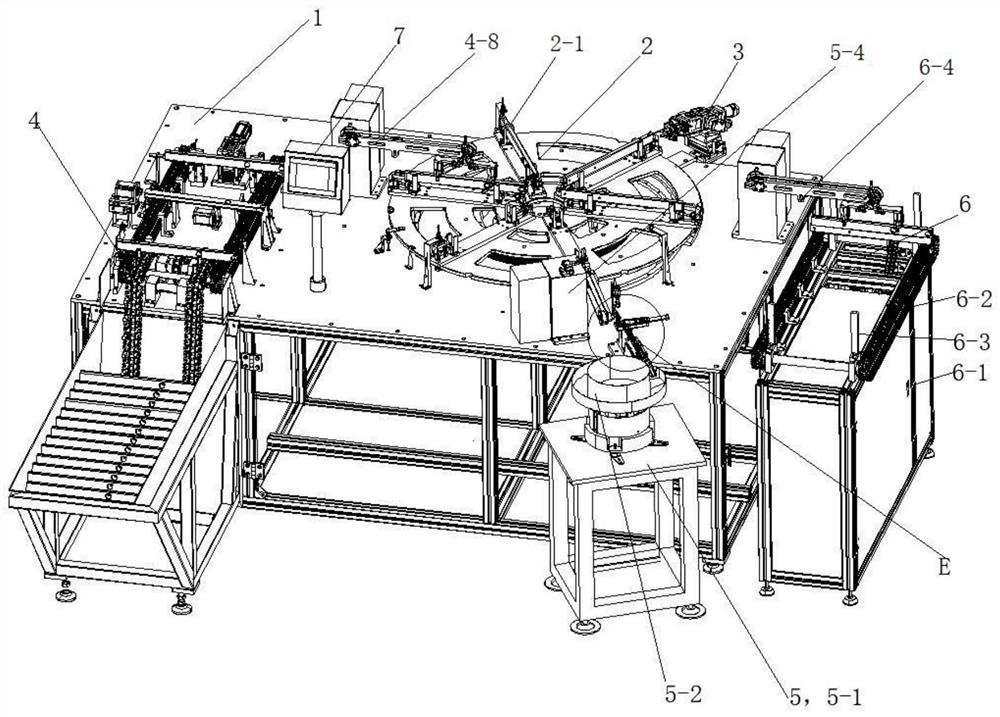

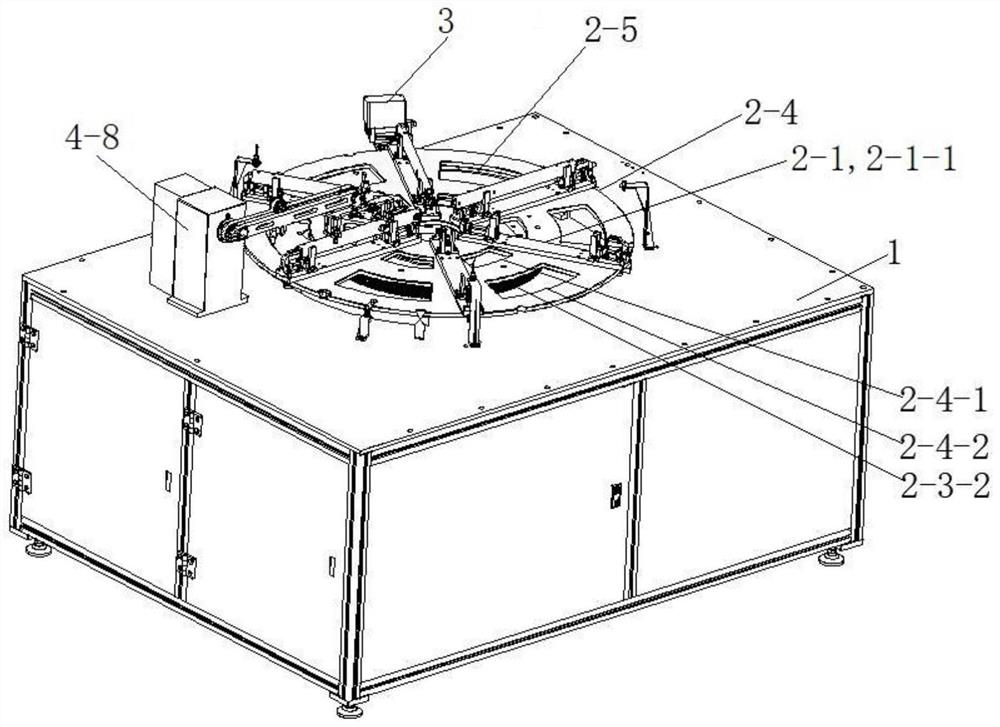

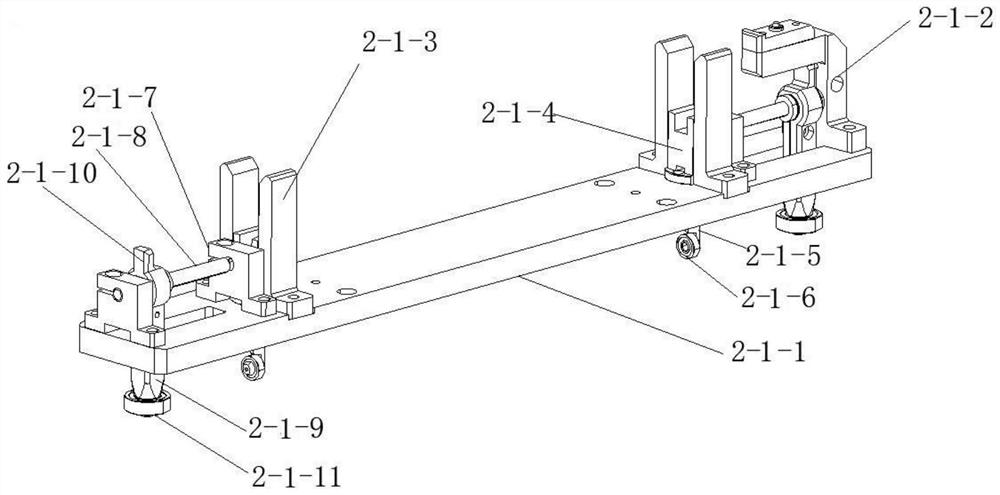

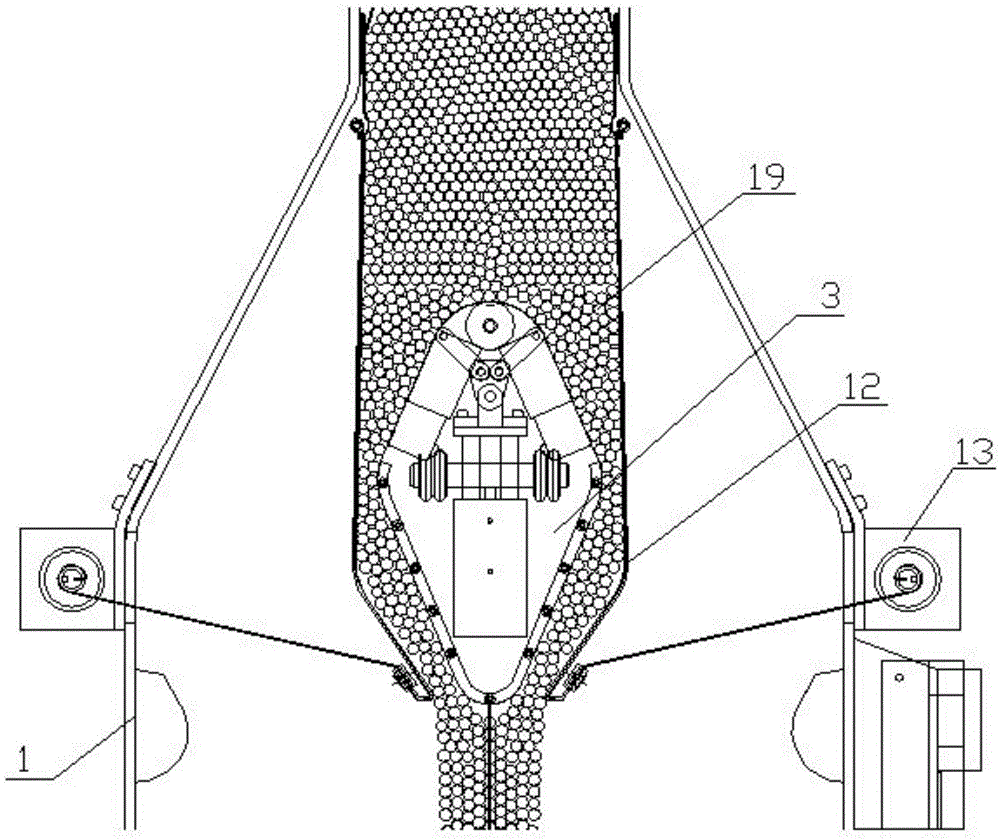

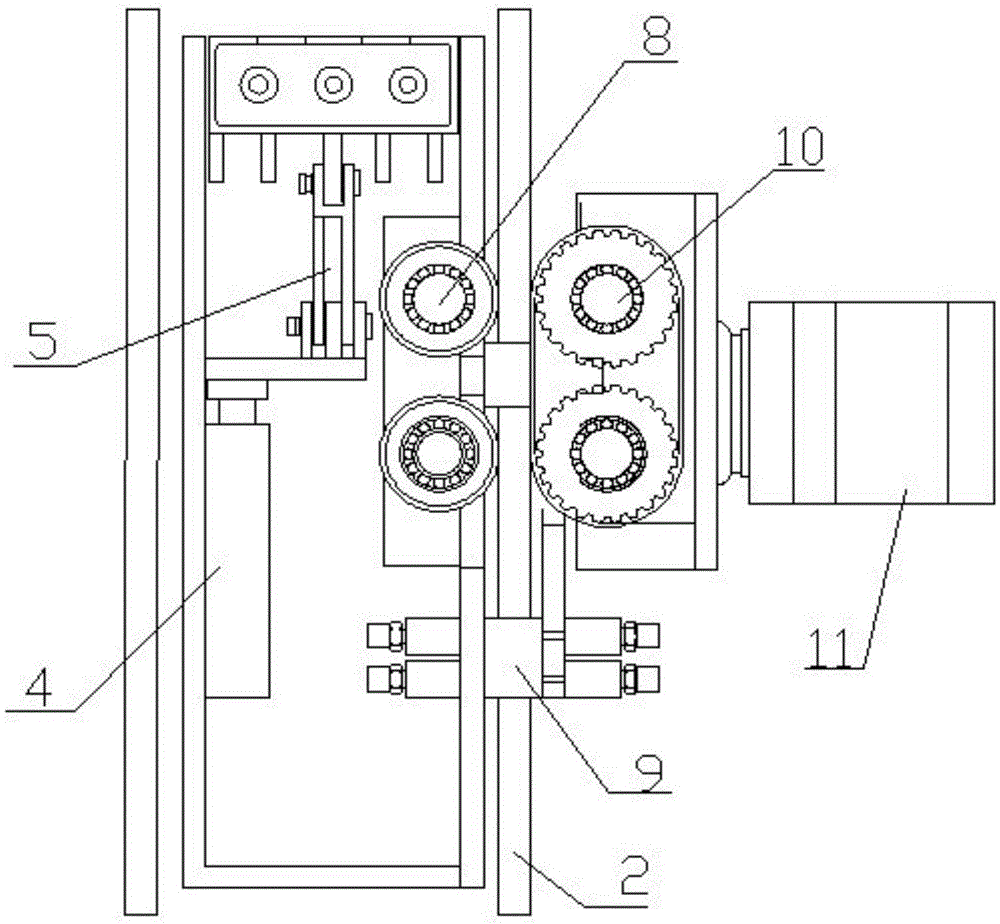

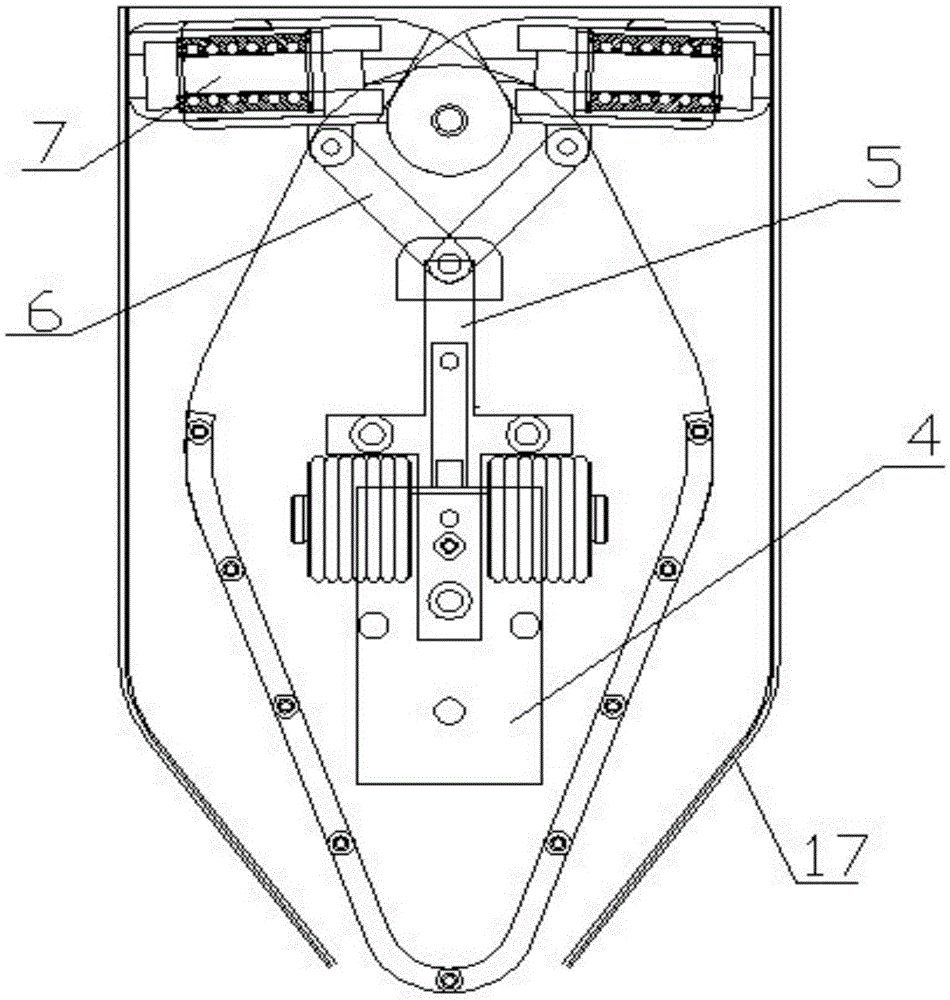

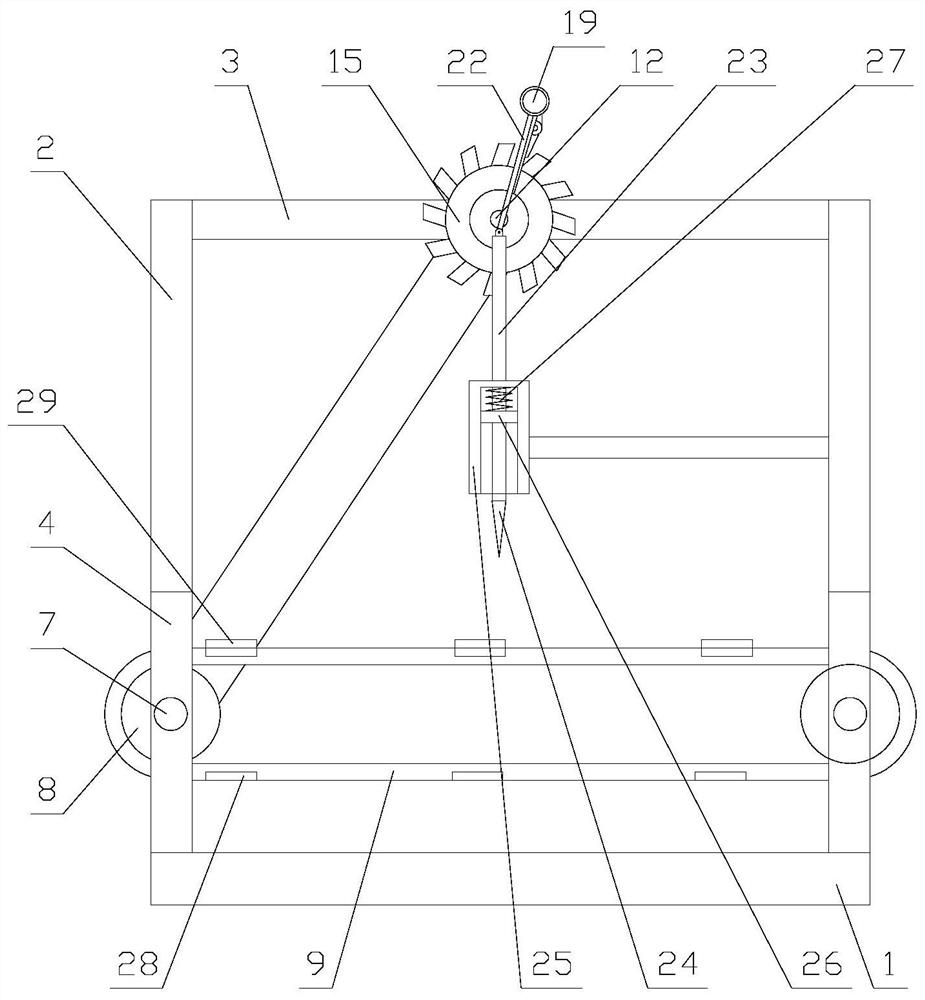

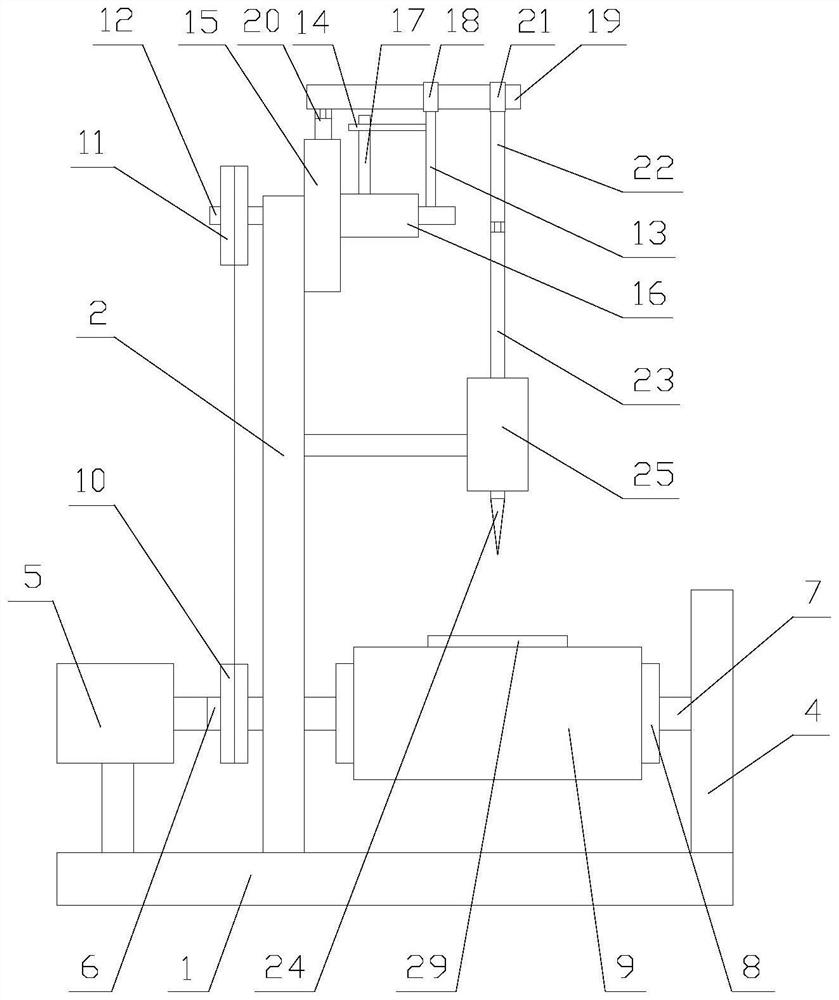

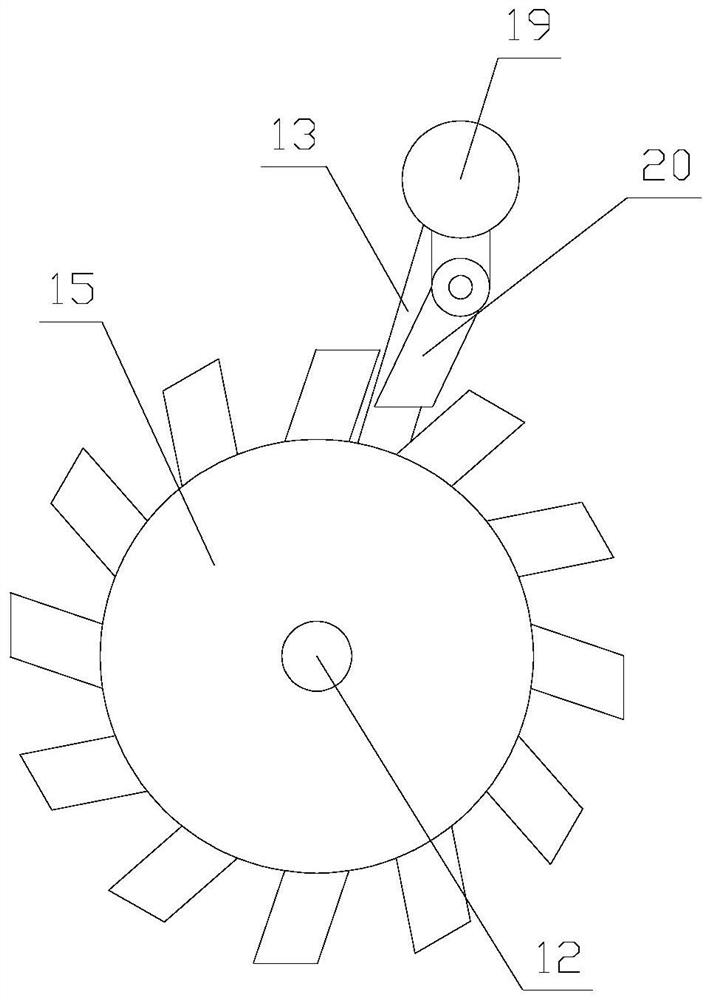

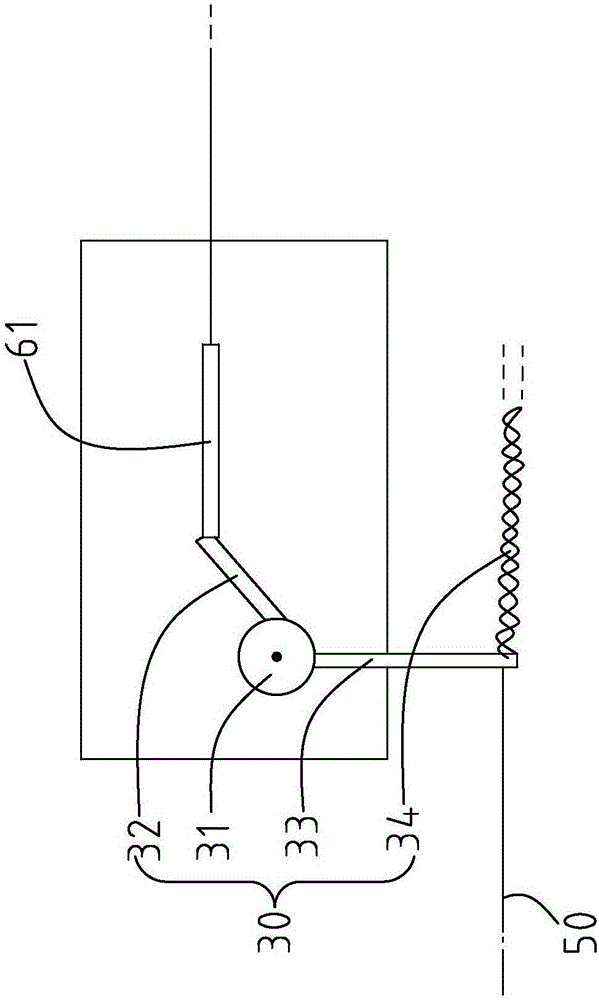

Automatic welding machine for square pipes and gaskets

PendingCN111958141AReduce human inputImprove welding accuracy andWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintManufacturing engineering

The invention discloses an automatic welding machine for square pipes and gaskets. The welding machine comprises an operating table, a rotary worktable fixedly installed on the operating table, and anautomatic gasket feeding device, an automatic square pipe feeding device, a welding device and an automatic discharging device which are arranged around the rotary worktable sequentially. A welding assembly mechanism is arranged on the rotary worktable; the rotary worktable drives the welding assembly mechanism to circulate and operate among the automatic gasket feeding device, the automatic square pipe feeding device, the welding device and the automatic discharging device; and the welding assembly mechanism receives gaskets at the automatic gasket feeding device and square pipes at the automatic square pipe feeding device, and assembly of the gaskets and the square pipes is completed before movement to the welding device. According to the automatic welding machine, automatic feeding, automatic assembly and welding of the square pipes and the gaskets can be achieved, welded parts are conveyed to a discharging area, manual operation is not needed in the whole process, manpower input is reduced, the welding accuracy and the production safety are improved, the floor area is small, and the production cost is greatly reduced.

Owner:常州三拓焊接设备有限公司

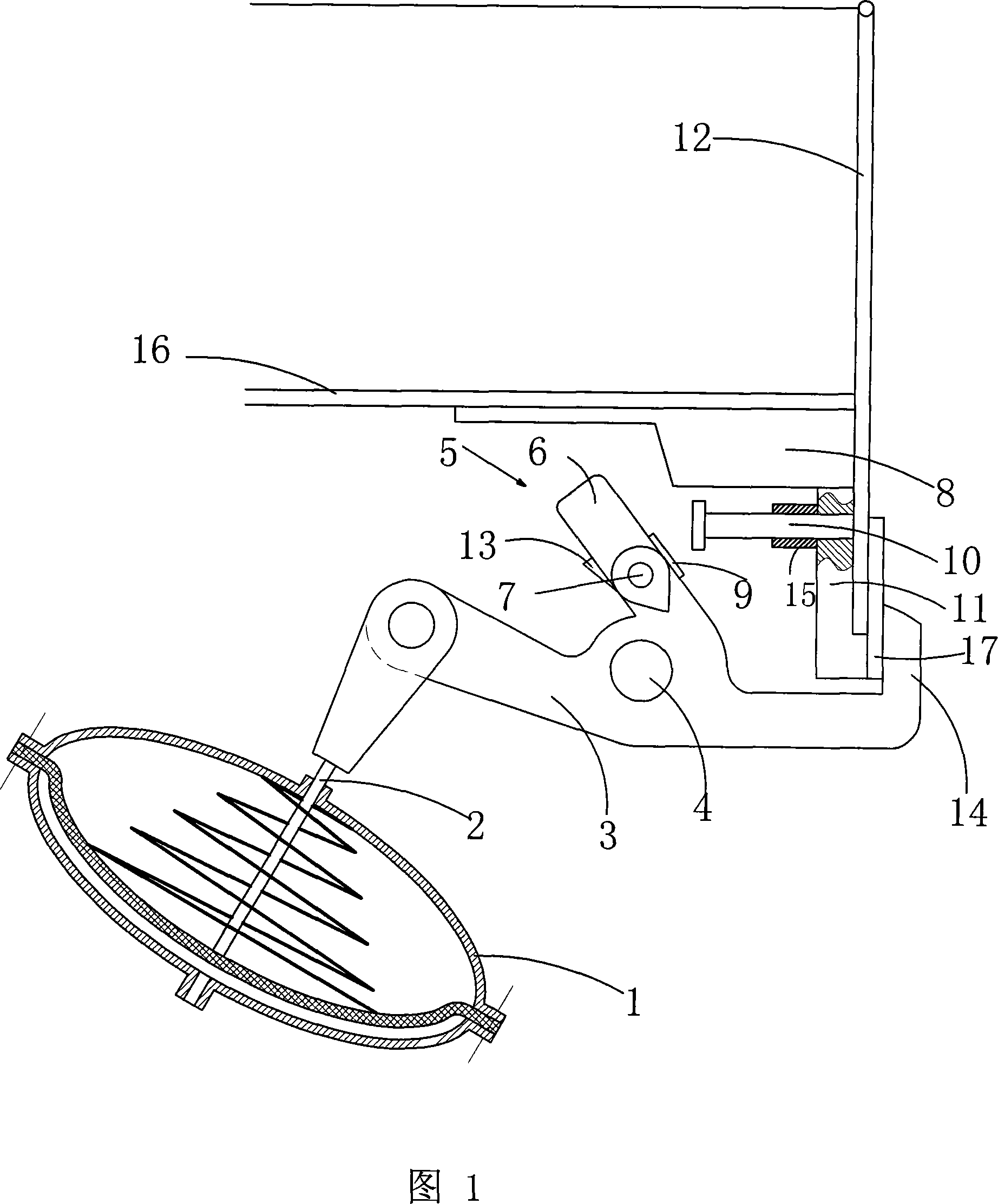

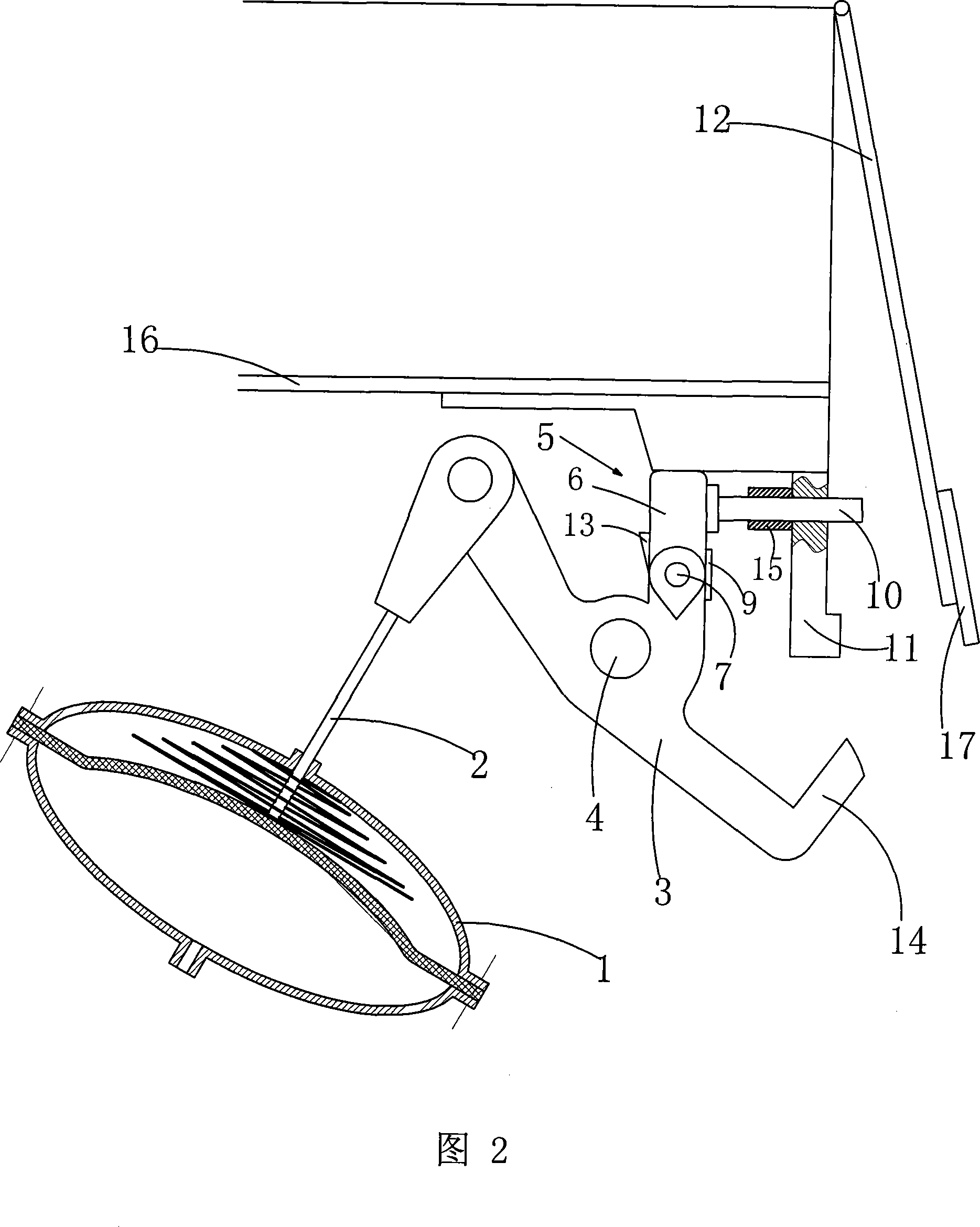

Laterial carriage plate opening and closing device for dumper truck

InactiveCN101088832AImprove unloading work efficiencyAvoid Work InjuryVehicle with tipping movementLoading-carrying vehicle superstructuresPush pullTruck

The lateral carriage plate opening and closing device for dumper truck is one pneumatic braking chamber assembly mounted on the truck chassis. The pneumatic braking chamber assembly has one push-pull rod, one swing link hinged to the push-pull rod and mounted through a middle rotation shaft onto the truck chassis, and one swing link locator, one top block, one top board fixed on to the underbed of the carriage, one release pin acting on the lateral carriage plate, one limiting board on the swing link, one spring inside the top block, and one lateral carriage plate locating hook in the outer end of the swing link. The lateral carriage plate opening and closing device for dumper truck has high truck unloading efficiency and high safety.

Owner:赵彬

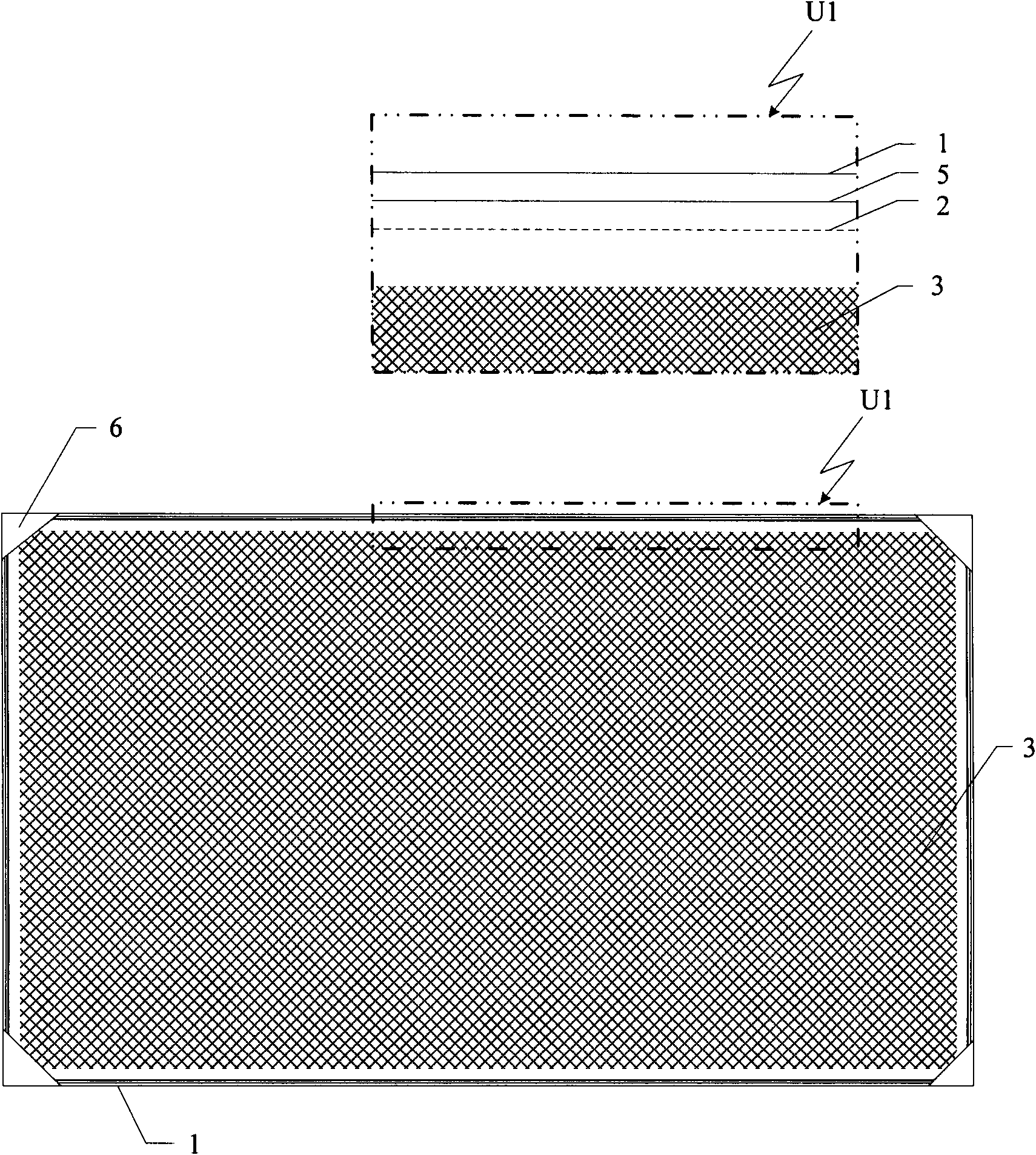

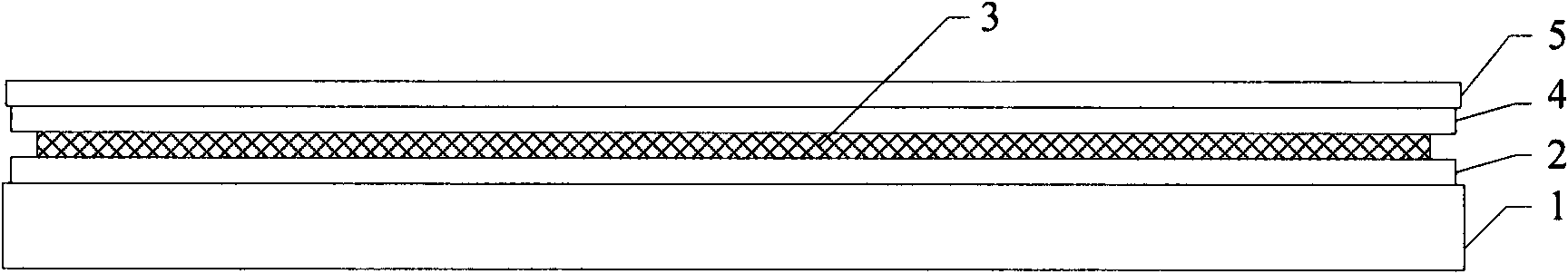

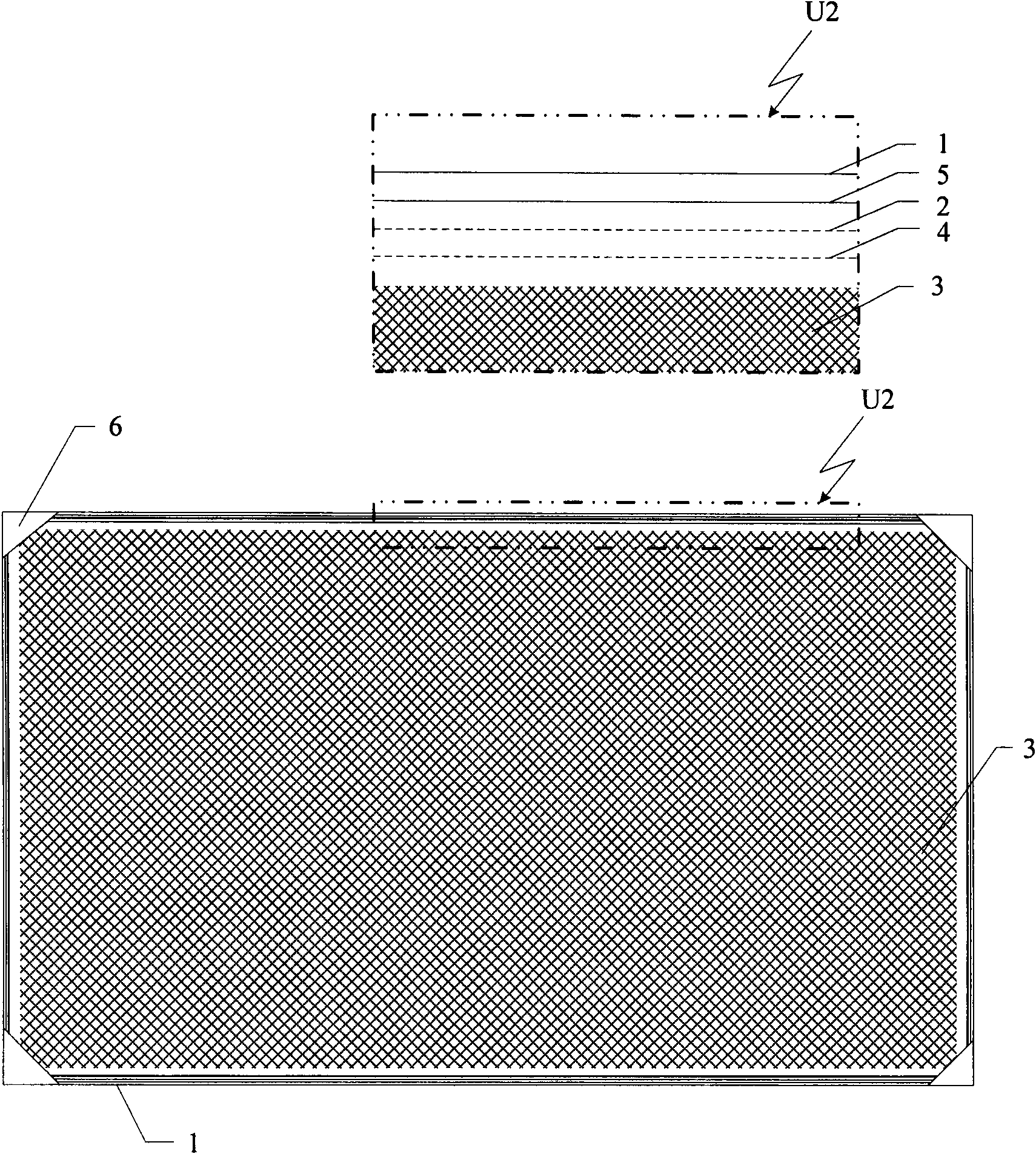

Solar battery component and precise superposing method

ActiveCN101656277AReduce dosageAvoid accidental injuryFinal product manufacturePhotovoltaic energy generationMaterial consumptionEngineering

The invention discloses a solar battery component and a precise superposing method. The method comprises the step of superposing glass, a first layer of glue film, a solar battery string, a second layer of glue film and a back plate layer, wherein the distance between each side edge of the first layer of glue film and the second layer of glue film and the corresponding side edge of the glass cannot enable glue to overflow in lamination, and each side edge of the back plate is shorted than the corresponding side edge of the glass and completely covers the first layer of glue film and the secondlayer of glue film. The solar battery component and the precise superposing method prevent the glue from overflowing, thereby avoiding edge cutting treating procedure, washing procedure and the like,ensuring the product quality, reducing the process difficulty, saving the labor cost and improving the production efficiency. Meanwhile, the invention saves the use quantity of the first layer of glue film, the second layer of glue film and the back plate and reduces material consumption, thereby largely saving the production cost.

Owner:WUXI SUNTECH POWER CO LTD

Rotor treatment device for building stirring motor production

InactiveCN107344306AEasy to installEasy to handleGrinding carriagesRevolution surface grinding machinesTherapeutic effectEngineering

The invention discloses a rotor processing device for building stirring motor production, which comprises a device body, a base is arranged on the device body, and a supporting column is arranged above the base, and the supporting column consists of three parts: A column, B column and C column from left to right , the top of the support column is provided with a support beam, the device body is provided with a slider, the device body is provided with a screw A, the right end of the slider is provided with a fixing part, the right end of the fixing part is provided with a support rod, the device body is provided with a screw B, and the bottom of the screw B A mounting plate is set, a motor is set above the mounting plate, and a grinding wheel is set at the end of the output shaft on the right side; the structure of the invention is simple, the overall structure is stable, and the installation of the rotor is made more firm by the function of the device body during operation, and the handling is convenient , to ensure the treatment effect, and the safety of the device body is high when used, avoiding slipping, avoiding work-related injuries, improving safety performance, very convenient to use, and strong practicability.

Owner:陈春女

Thin-wall stainless steel pipe cutting machine capable of preventing scrap iron from splashing

PendingCN111468779APrevent splashAvoid damageTube shearing machinesPositioning apparatusSlide plateScrap

The invention discloses a thin-wall stainless steel pipe cutting machine capable of preventing scrap iron from splashing. The thin-wall stainless steel pipe cutting machine comprises a pipe cutting machine body, wherein the bottom end of the pipe cutting machine body is fixedly connected with a base, and the bottom end of the base is fixedly connected with supporting legs; the top end of the pipecutting machine body is fixedly connected with a supporting table, and a transmission mechanism is fixedly arranged on the left side of the top end of the supporting table; and a first roller is arranged on the transmission mechanism, and the surface of the first roller is connected with a fixed rotating wheel through a second connecting belt. According to the thin-wall stainless steel pipe cutting machine, a protection mechanism is arranged, a first protection plate and a second protection plate are arranged on the protection mechanism, the first protection plate and the second protection plate are matched with each other so as to wrap a cutting piece, and the scrap iron and sparks can be effectively prevented from splashing during cutting; and meanwhile, the scrap iron can be collected and stored through a closed space formed by combining the first protection plate and the second protection plate, and a push block pushes the stainless steel pipe body to move in the moving process, sothat the stainless steel pipe body slides to the surface of a sliding cylinder along a sliding plate.

Owner:张家港市越泰精密机械有限公司

Stirring device for textile fiber

ActiveCN105642148AAvoid CatonEasy to separateTransportation and packagingRotary stirring mixersTextile fiberEngineering

The invention relates to the field of textile, in particular to a stirring device for textile fiber. The stirring device for textile fiber can rapidly and continuously stir fiber, separate the fiber which is uniformly stirred from the fiber which is not uniformly stirred, and prevent fiber blocks or fiber agglomerates from flowing in a textile process to cause blocking and stopping of a textile machine. The stirring device structurally comprises a base, wherein the upper surface of the base is provided with a barrel; the undersurface of the barrel is an inclined plane; the upper surface of the barrel is provided with a feeding door, one side of the feeding door is provided with a motor; one side of the motor is connected with a first belt pulley in a sleeving manner, the first belt pulley is connected with a second belt pulley through a triangular belt, and the second belt pulley is connected with one end of a stirring shaft in a sleeving manner; the barrel is internally partitioned into a stirring cavity, a material disturbing cavity, and a material sinking cavity by a first filter screen and a second filter screen, and the undersurface of the material sinking cavity is an inclined plane; the stirring device for the textile fiber is convenient and efficient in usage, low in cost, and suitable for fiber stirring.

Owner:WUJIANG CHENGYU TEXTILE CO LTD

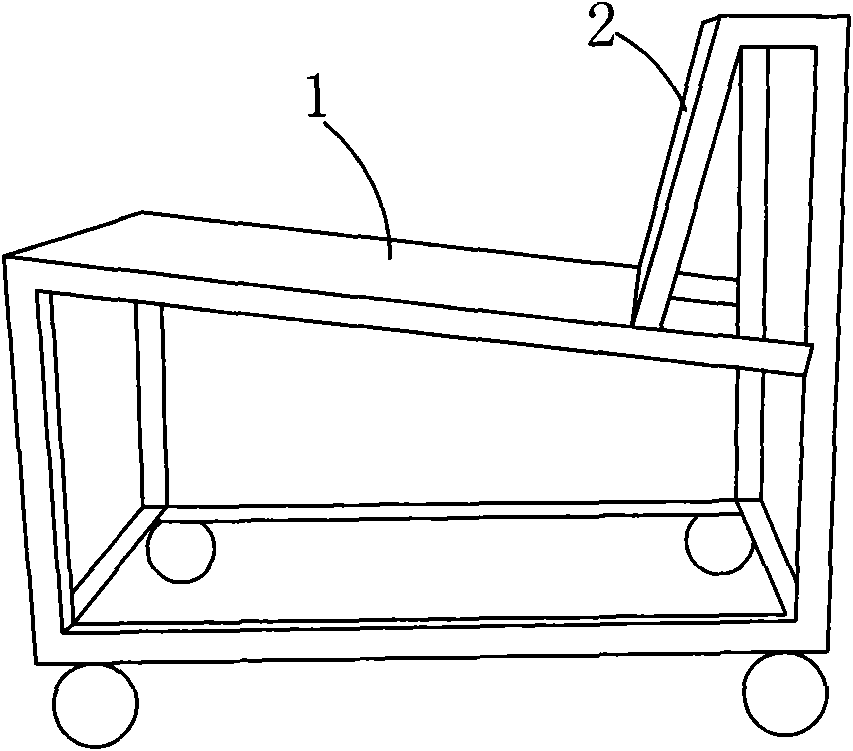

Efficient conveying device for building equipment

InactiveCN106043386ASimple structureEasy to useSupporting partsHand carts with multiple axesEngineeringIdler-wheel

Owner:周末

Automatic feeding and grabbing device for automatic trimming machine

ActiveCN104959443ARealize automatic dischargeRealize automatic pinchingMetal-working feeding devicesShaping safety devicesPunch pressEngineering

An automatic feeding and grabbing device for an automatic trimming machine comprises a punch and a die frame. A feeding vibration disc and a material guiding mechanism connected with the feeding vibration disc are arranged in front of the die frame. A grabbing mechanical arm and a program controller are arranged behind the die frame. Automatic blank discharging can be achieved through the control of the program controller, a vibrating mechanism and a guiding mechanism. Precise and automatic blank clamping and conveying can be achieved through the cooperation of the mechanical arm and a material guiding frame of the guiding mechanism. Automatic punching and burr removing can be achieved in the manner that an air cylinder is additionally arranged on the punch. Removed burrs are automatically purged and removed through an automatic purging device. Equipment damage or worker occupational injuries caused by mistaken punching can be avoided through an induction head. By means of automatic operation, the operation efficiency is improved, labor is reduced, and potential safety hazards are also reduced.

Owner:NINGBO JIEKELONG PRECISION MFG

Acidic etching liquid

ActiveCN103602986APrevent overflowNot easy to driftOrganic-compounds/hydrides/coordination-complexes catalystsOxidation-Reduction AgentRedox

The invention discloses application of a compound used as a catalyst in preparing an acidic etching liquid which does not generate chlorine. The compound has a complexation effect on monovalent or bivalent copper ions in the acidic etching liquid or can generate a stable complex. According to the Nernst equation, the redox potential of the monovalent copper ions converted to the bivalent copper ions after complexation or coordination is reduced till the redox potential is less than the reduction potential of oxygen in aqueous liquor, so that balance of a reaction A can be further smoothly carried out toward a direction of generating the bivalent copper ions even in an acidic high chlorine environment, wherein the reaction A is as shown in the specification.

Owner:珠海市智宝化工有限公司

Automatic cigarette catching device of cigarette storage device

ActiveCN105639721AAvoid Work InjuryRealize lifting movementCigarette manufactureDrive wheelEngineering

The invention discloses an automatic cigarette catching device of a cigarette storage device. The automatic cigarette catching device comprises two side plate machine frames oppositely arranged. Two organic glass panels are oppositely arranged in the direction perpendicular to the side plate machine frames. A guide rail groove is formed in the middle of each organic glass panel from bottom to top. A movable splitter is arranged between the two organic glass panels and comprises a mini-type cylinder. One end of a cylinder connection rod arranged on the mini-type cylinder is connected with two connection supporting rods in a rotating mode. The two connection supporting rods are connected with two supporting plate assemblies rotating around the same axis respectively. A set of driven wheels are arranged on the movable splitter and supported by the inner sides of the organic glass panels. Driven wheels are connected with driving wheels supported by the outer sides of the organic glass panels through a connection frame. The automatic cigarette catching device is simple in structure, the automatic cigarette catching action can be achieved, it is avoided that cigarettes are prone to falling when caught manually through supporting plates or occupational injuries possibly happen in the manual cigarette catching process.

Owner:ANHUI YITONG MACHINERY

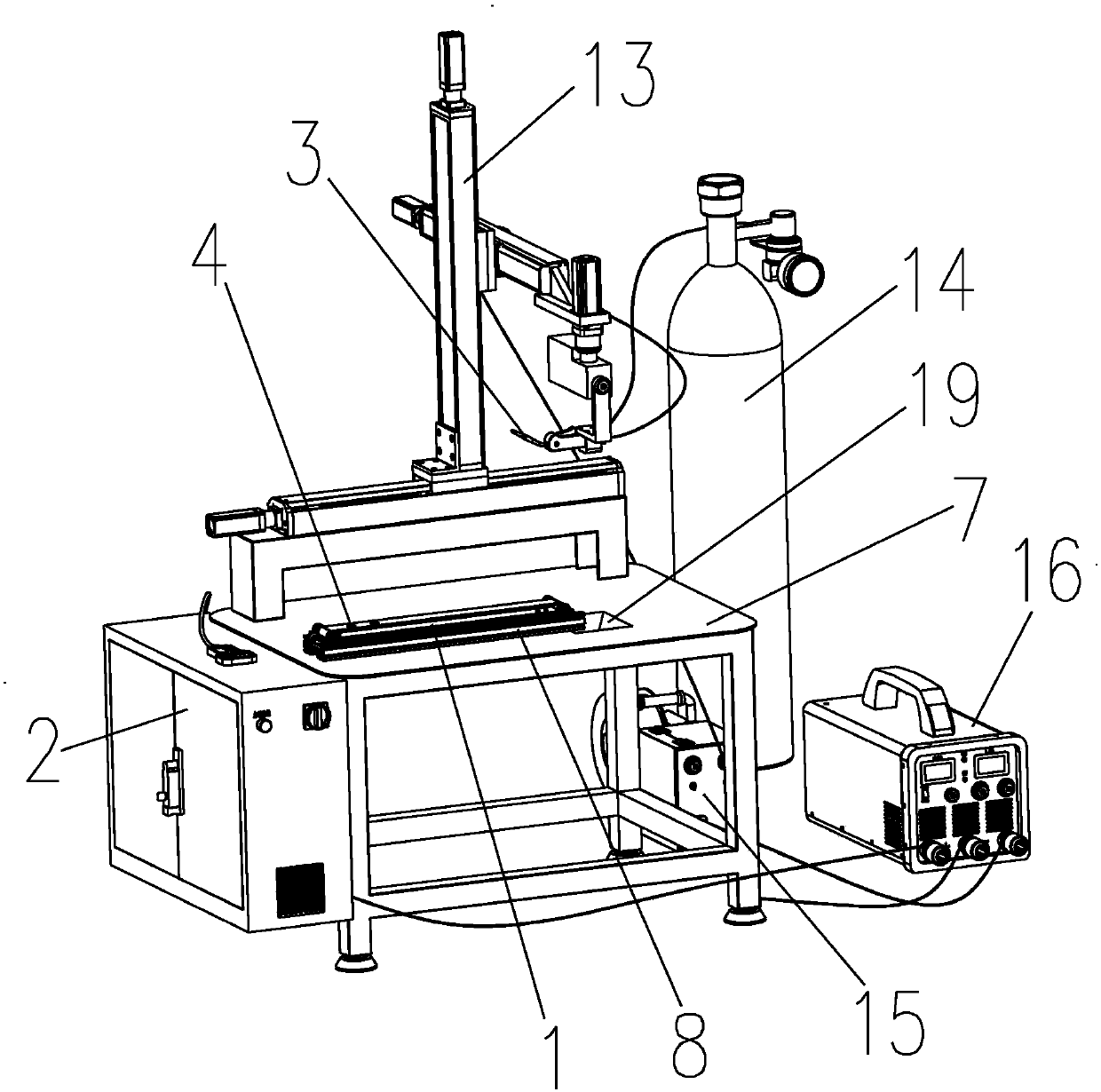

Automatic welding device

The invention belongs to the technical field of welding, and particularly relates to an automatic welding device. The automatic welding device comprises a belt conveying mechanism, a servo driver anda welding mechanism assembly, and the welding mechanism assembly comprises a welding gun; a plurality of welding workpiece storing model holes are arrayed on a belt of the belt conveying mechanism, and a light shading plate is fixed to one side of the belt of the belt conveying mechanism; and a light control switch is arranged on one side of the belt conveying mechanism and used for sending a welding signal to the servo driver, and the servo driver is used for controlling the belt conveying mechanism to stop conveying and controlling the welding gun to conduct welding. The automatic welding device has the beneficial effects that automatic feeding and automatic positioning of to-be-welded workpieces can be realized, positioning is accurate, suspension and position adjusting are not required, welding is continued, integration of the automation welding device and a welding conveying production line is achieved, and resource waste is avoided; and the situation that the to-be-welded workpieces are loaded on a welding station by manual operation is not required, work injury is avoided, workers are kept away from welding radiation, and health of the workers is facilitated.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

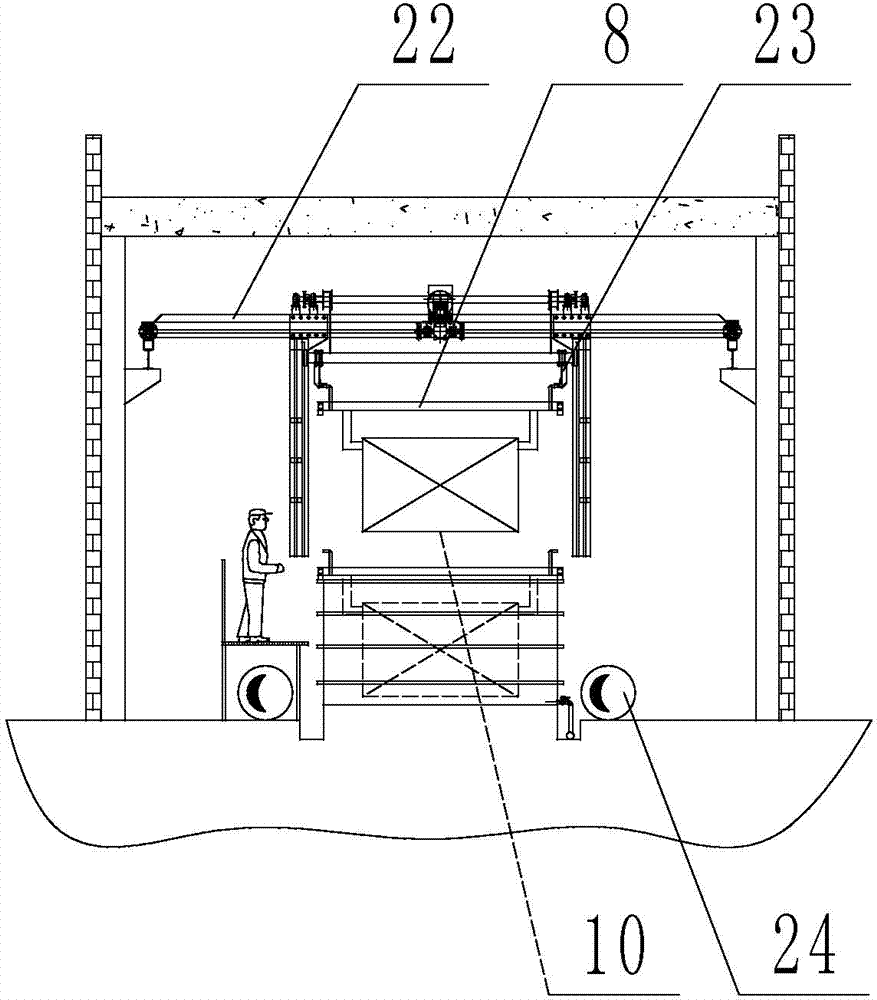

Stereo circular production technology for pipe pile

ActiveCN107127880AImprove reuse efficiencyAvoid collision riskShaping reinforcementsFeeding arrangmentsEngineeringStructural engineering

The invention relates to a stereo circular production technology for a pipe pile. Longitudinal reversed L-shaped layout is adopted by a workshop; a feeding device area, a centrifuge area, an upper mold storage bracket, a steam curing tank, a disassembling mold area, a pipe pile transporting area and a reinforcement cage processing area are paved on the workshop ground; channels are arranged on the two sides of the workshop along the longitudinal direction; a feeding device is arranged on a horizontal bent part of L-shaped head part; a low-position crane I, a low-position crane II and a low-position crane III which run on a same longitudinal rail are arranged on the middle part of a pipe pile workshop wall; a high-position crane IV which runs on the longitudinal rail is arranged at the top of the pipe pile workshop wall. According to the stereo circular production technology provided by the invention, the four cranes move in respective areas, so that the collision risk prevention is realized while the cranes and the mold can efficiently operate in order, the reuse efficiency of the mold is increased and the production efficiency of the pipe pile is increased.

Owner:ZHEJIANG KNSN PIPE & PILE

Safety device of punch

InactiveCN103203421AIncrease production speedAvoid Work InjuryShaping safety devicesProduction rateEngineering

The invention discloses a safety device of a punch. The safety device of the punch comprises a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a first deflector rod and a second deflector rod, wherein one ends of the first connecting rod and the second connecting rod are respectively hinged with a punch hammer of the punch; turnings of the L-shaped third connecting rod and the L-shaped fourth connecting rod are hinged with the body of the punch; the other ends of the first connecting rod and the second connecting rod are respectively and movably hinged with one ends of the third connecting rod and the fourth connecting rod; the other ends of the third connecting rod and the fourth connecting rod are respectively and fixedly connected with one ends of the first deflector rod and the second deflector rod; the other ends of the first deflector rod and the second deflector rod are located at one side of an operating floor of the punch, which is near an operator; and arms of the operator stop at both mutually deviating sides of the other ends of the first deflector rod and the second deflector rod. According to the safety device of the punch disclosed by the invention, through arranging a connecting rod mechanism driven by the punch hammer on the punch, when the punch hammer falls, the first deflector rod and the second deflector rod of the connecting rod mechanism automatically push aside the arms of the operator to enable the arms of the operator to automatically be away from the lower side of the punch hammer, and thus, even if the operator forgets to leave the arms from the lower side of the punch hammer by misoperation, the first deflector rod and the second deflector rod can automatically push aside the arms of the operator so as to avoid work injury occurring, and therefore, the increase of the production rate is facilitated.

Owner:KUNSHAN ANIL PRECISE METAL

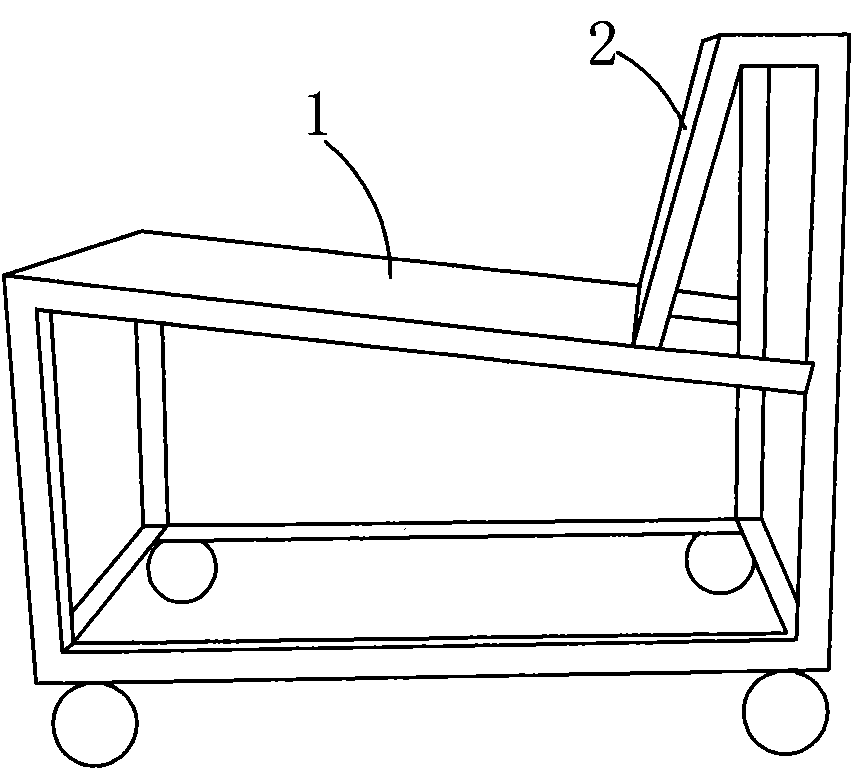

L-shaped trolley

Owner:竞陆电子(昆山)有限公司

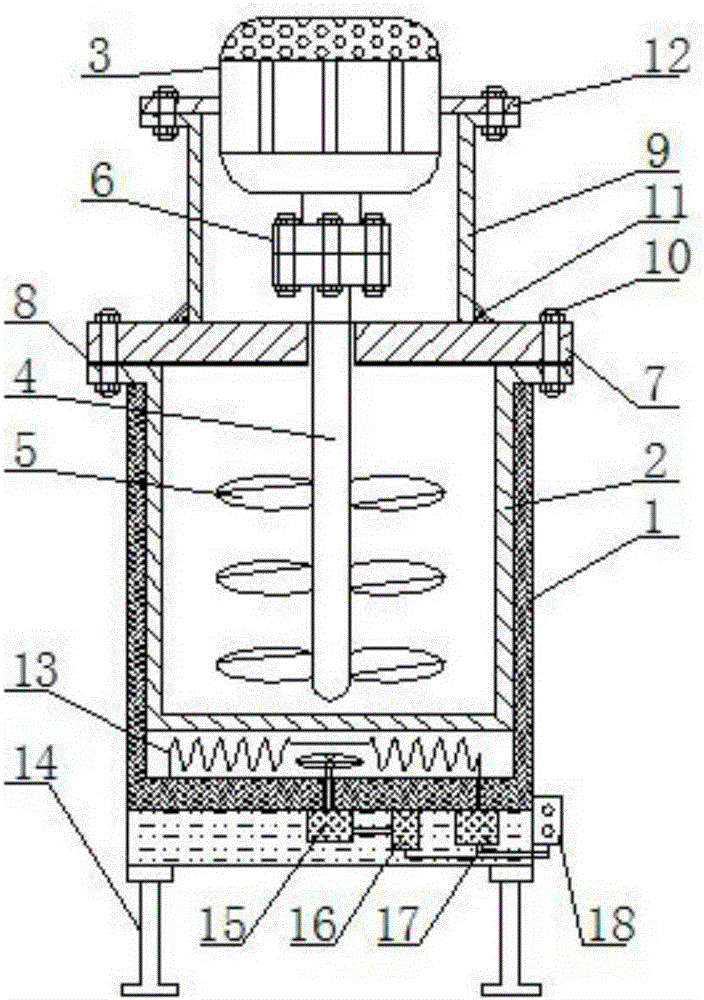

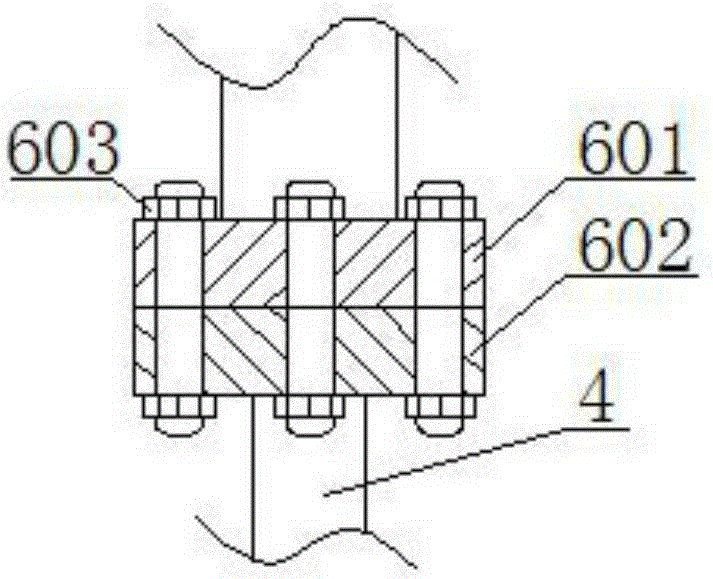

Material mixer for production of chemical raw material

InactiveCN106474979AEasy to cleanWell mixedRotary stirring mixersMixer accessoriesTemperature controlCoupling

The invention relates to a material mixer for production of a chemical raw material. The material mixer comprises an outer shell, an inner shell and a stirrer, wherein the outer shell sleeves the inner shell; the upper end of the upper shell is detachably connected with a cover plate through a bolt fastening structure; the stirrer is connected with a stirring shaft via a shaft coupling; stirring vanes are uniformly distributed on the body of the stirring shaft; the lower end of the inner shell is provided with a heating resistance wire net; a temperature sensing device is arranged below the heating resistance wire net; and a temperature control box is fixedly arranged below the right part of the outer shell. Through arrangement of the outer shell and the inner shell in a sleeving manner, the inner shell can be conveniently taken out for cleaning after use; three layers of the stirring vanes are arranged on the stirring shaft, so materials are fully mixed; a heating device is arranged below the inner shell, so the materials can be heated according to operation conditions, and mixing and fermentation are promoted; through arrangement of the shaft coupling, stability of the stirring shaft in operation is improved, and the stirring vanes are prevented from bumping with the inner shell, which enable potential dangers to be avoided; and The material mixer is simple in structure, high in practicality and suitable for promotion and application.

Owner:YANCHENG OUHUA CHEM IND

Automatic punching device for metal products

The invention relates to an automatic punching device for metal products. The automatic punching device for the metal products comprises a base, a supporting rod, a transverse rod, a fixing rod, a conveying mechanism and a punching mechanism, wherein the conveying mechanism is arranged between the fixing rod and the supporting rod; the punching mechanism is arranged on the supporting rod; and thepunching mechanism is located above the conveying mechanism. According to the automatic punching device for the metal products, workpieces are conveyed through the conveying mechanism and are punchedthrough the punching mechanism, and; compared with an existing punching device, the device has the advantages that conveying and punching of the workpieces are achieved through one output end, so thatenergy is saved; pure mechanical linkage is adopted for the conveying mechanism and the punching mechanism, and the use of sensors and other electronic elements is avoided, so that the temperature type and the service life of the device are improved; and compared with an existing punching mechanism, the punching mechanism has the advantages that under the action of a clamping rod, a ratchet wheeland a spring, the device is kept in a fixed state, movement of a drill bit is avoided, damage to the workpieces is avoided, an operator is protected, and industrial injuries are avoided when the device is suddenly powered off.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

Multi-tube side-by-side crimping machine

InactiveCN105679467AFast crimping speedIncrease productivityCable/conductor manufacturePulp and paper industryAtmospheric pressure

The invention relates to a multi-tube side-by-side crimping machine, which comprises an engine base, air cylinders, an upper mold and a lower mold, wherein the air cylinders are suspended and fixedly arranged on the engine base through a bracket in a front-back symmetrical manner; the upper mold is fixedly arranged at the lower ends of plungers of the two air cylinders; the lower mode, corresponding to the upper mold, is fixedly arranged on the engine base; and mold cavities are formed in the opposite surfaces of the upper mold and the lower mold and are formed by evenly arranging arc grooves with the same diameter. In a transmission rod manner, with a pneumatic pump as power, the crimping machine can perfectly crimp iron protecting tubes on a wiring harness by the molds, and simultaneously can crimp a plurality of protecting tubes, so that the multi-tube side-by-side crimping machine is high in crimping speed and high in production efficiency, saves manpower and ensures the personal safety.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

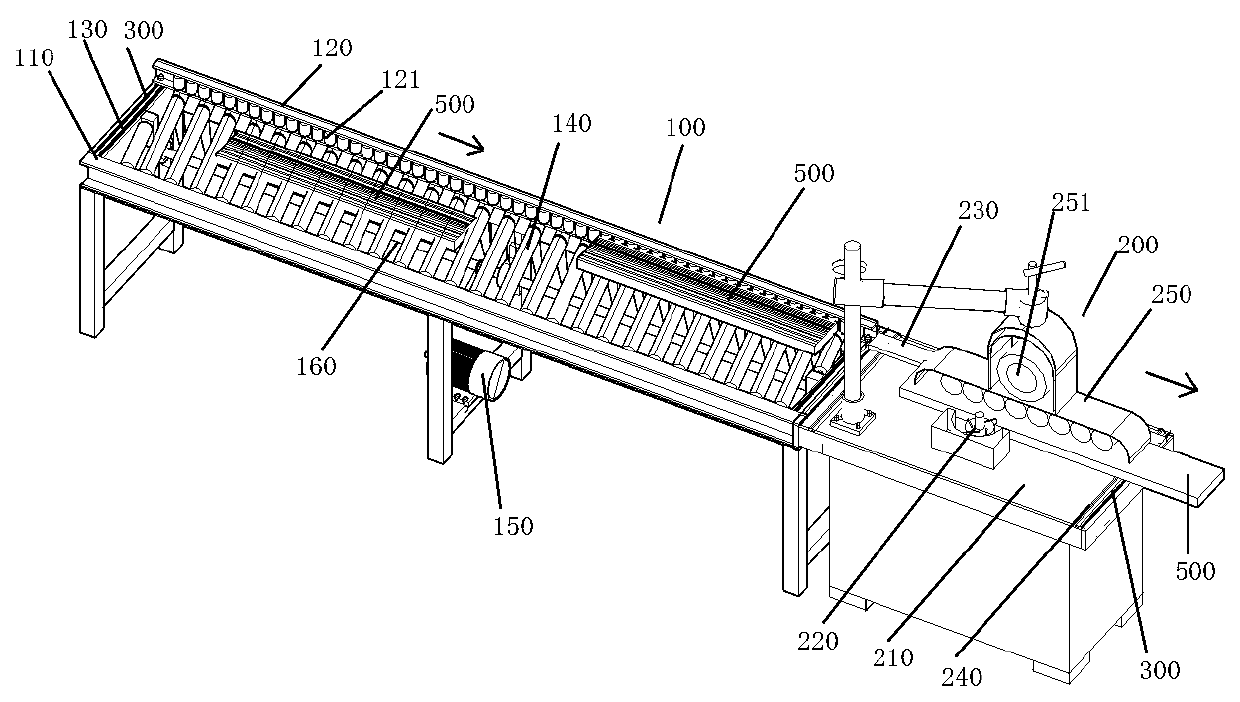

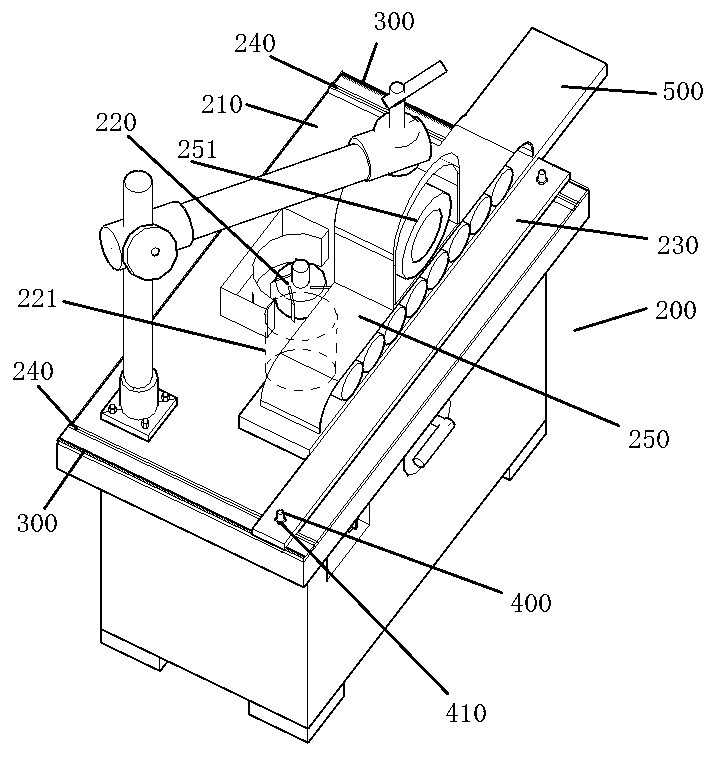

Wood plate processing assembly line device and working method thereof

The invention relates to a wood plate processing assembly line device. The wood plate processing assembly line device is provided with a wood plate conveying mechanism and a wood plate processing mechanism in the wood plate conveying direction; the wood plate processing mechanism comprises a machine table, a tool used for processing wood plates is arranged on one side of the machine table, a firstguiding backer base used for conducting backer guiding on the wood plates and adjusting the wood plate processing size is arranged on the other side of the machine table, and a first installing groove used for adjusting the distance between the first guiding backer base and the tool is formed in the upper end face of the machine table; and the wood plate conveying mechanism comprises a rack, a second guiding base is arranged on the rack, a second installing groove used for adjusting the installing position of the second guiding base is formed in the upper end face of the rack, and oblique guiding wheels used for enabling the wood plates to be closely attached to the second guiding base and conveyed forwards are arranged on the rack. The invention further relates to a working method of thewood plate processing assembly line device. According to the wood plate processing assembly line device, the structure is simple, operation is easy and convenient, and the wood plates can be precisely processed.

Owner:江慧

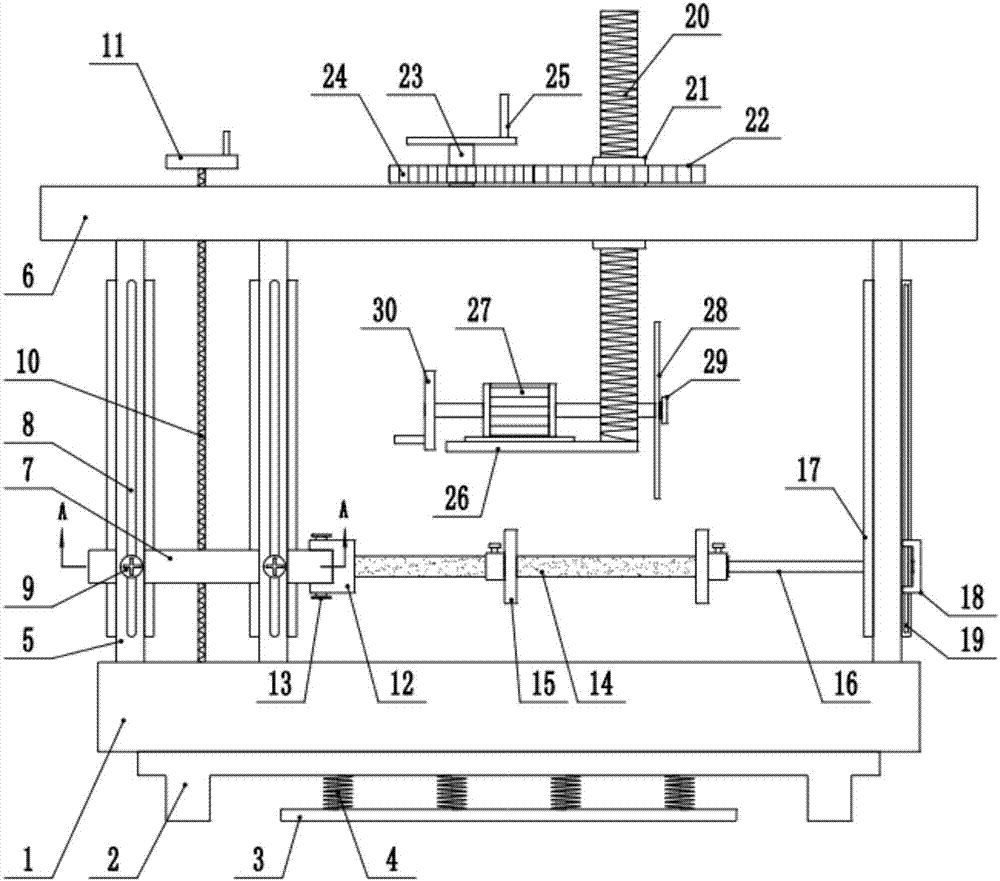

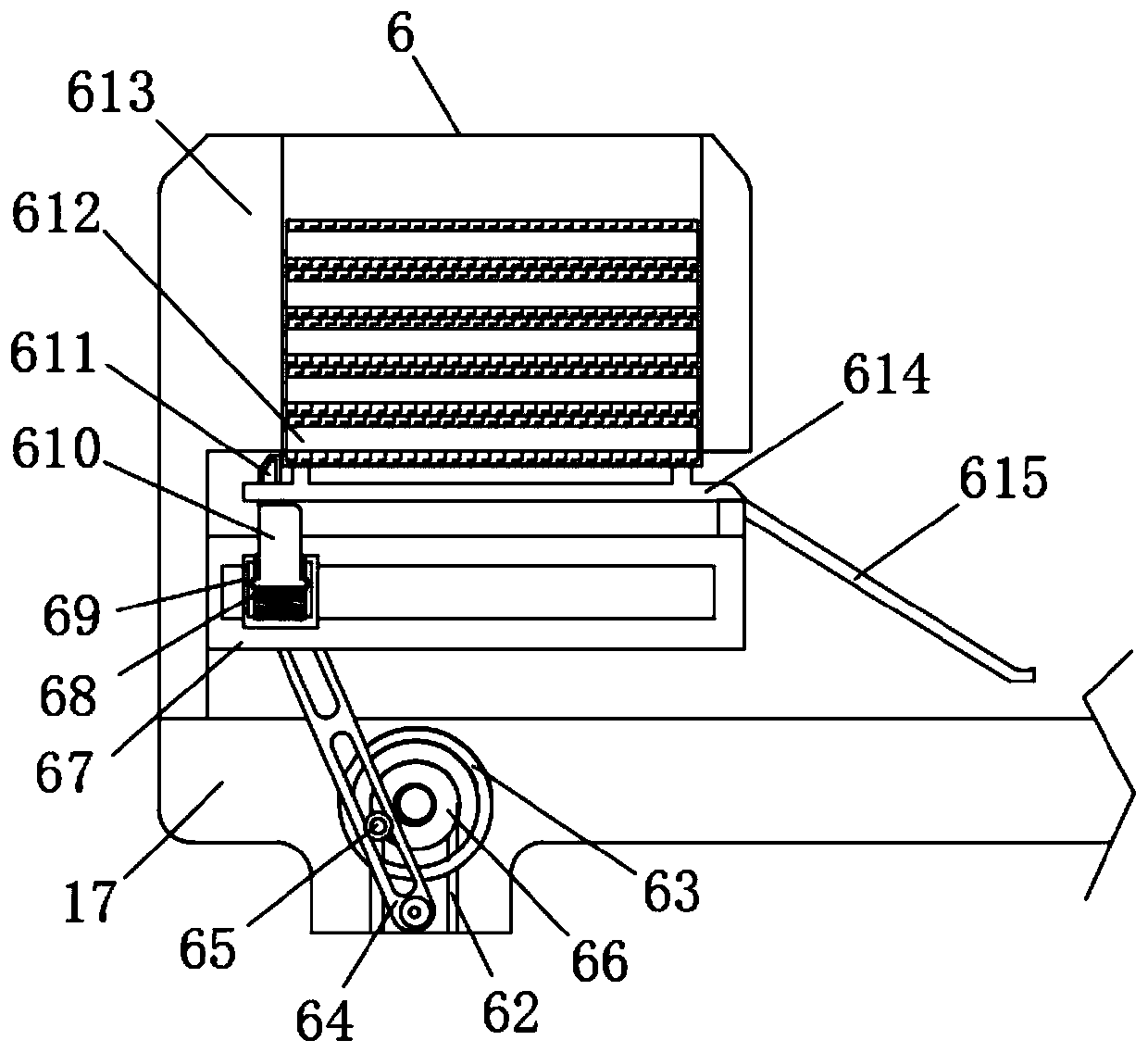

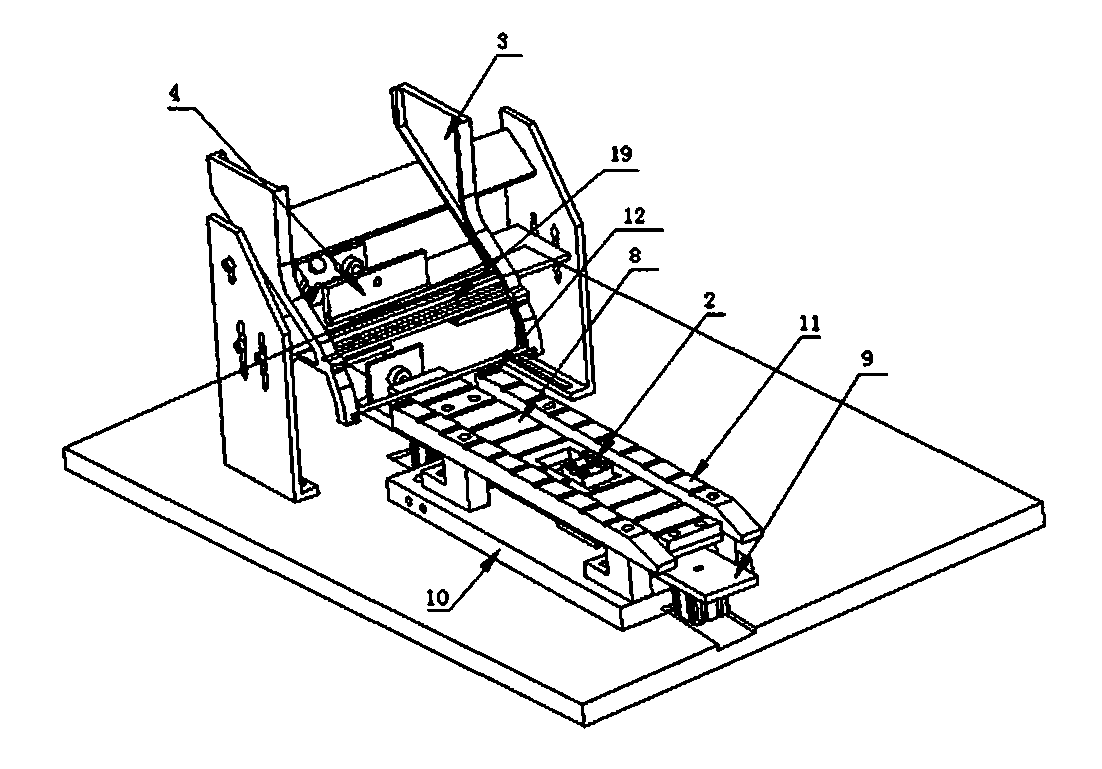

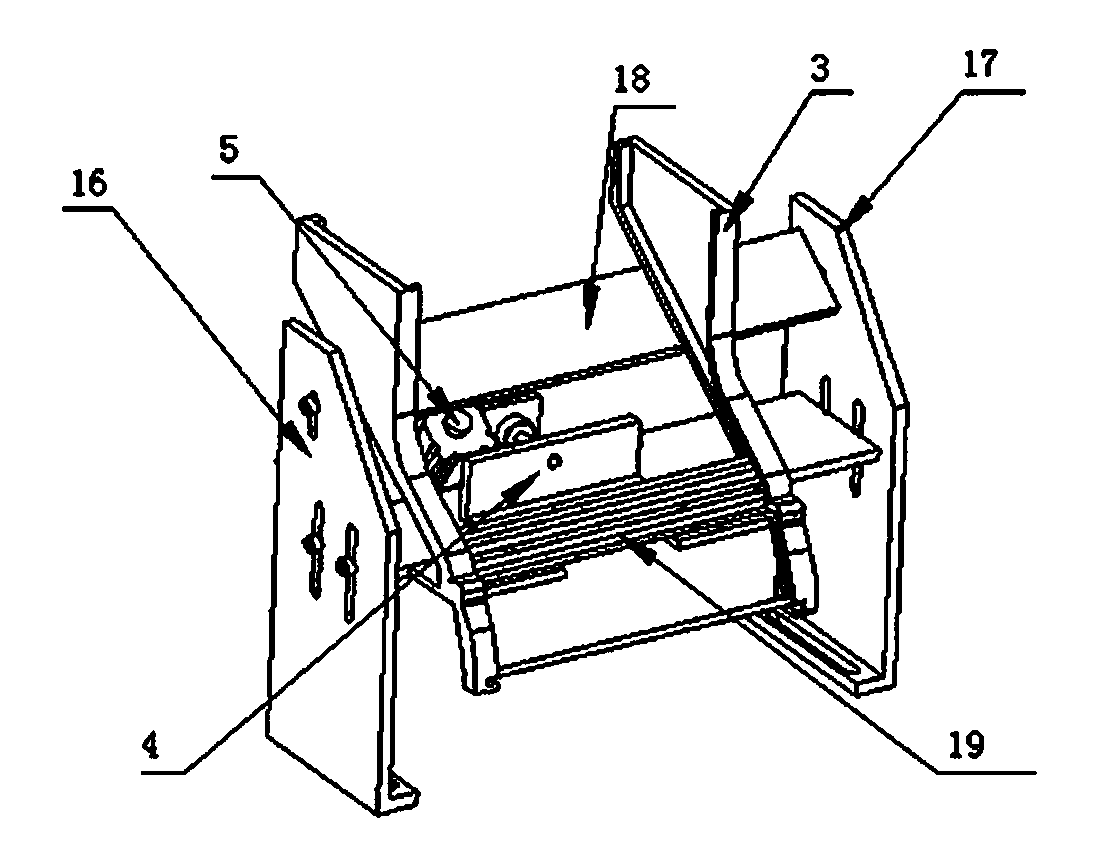

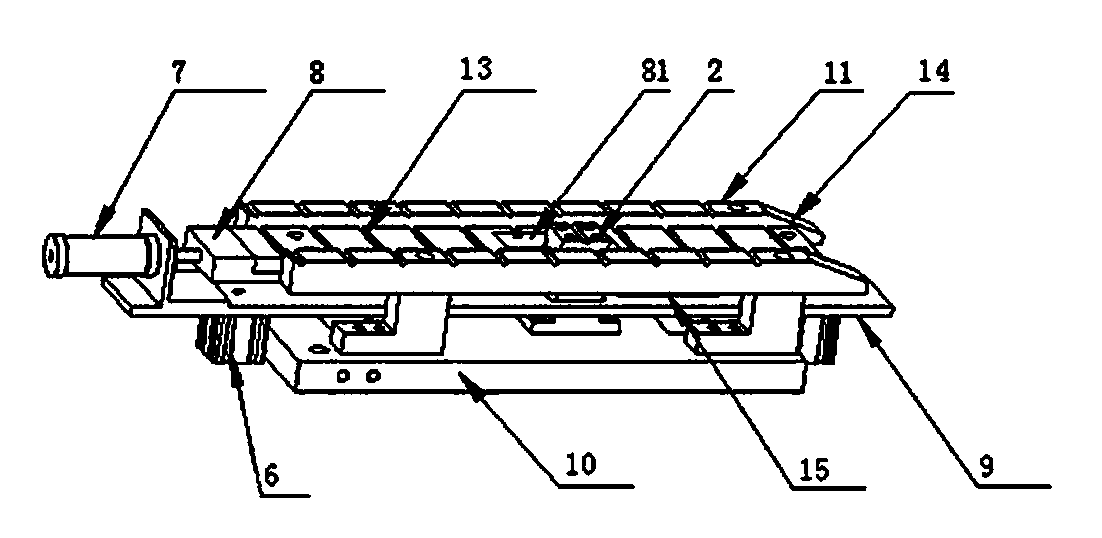

Fully-automatic typewriter

ActiveCN103522778AReduce labor intensityReduce defective rateStampingFully automaticMaterials science

The invention discloses a fully-automatic typewriter which comprises a material discharging device, a conveying device, a typing mold and a controller. The typing mold comprises an upper mold body and a lower mold body, the lower mold body stops moving, the upper mold body can move to be positioned over the lower mold body, the lower mold body is provided with a workpiece positioning device, and the lower end of the upper mold body is provided with a plunger chip. The material discharging device can sequence workpieces and output the workpieces to the conveying device sequentially. The conveying device can convey the workpieces sequentially to a positioning device of the lower mold body of the typing mold to stay for a set time period and output the workpieces from the typing mold. The controller controls the material discharging device, the conveying device and the typing mold to operate. The fully-automatic typewriter achieves fully-automatic steel blade typing, workers only need to feed and inspect, labor intensity is low, the machining speed is high, the machining quality is high, the rejected rate is low, occupational injuries are avoided, production efficiency is improved, and production cost is reduced.

Owner:美事满工具(海安)有限公司

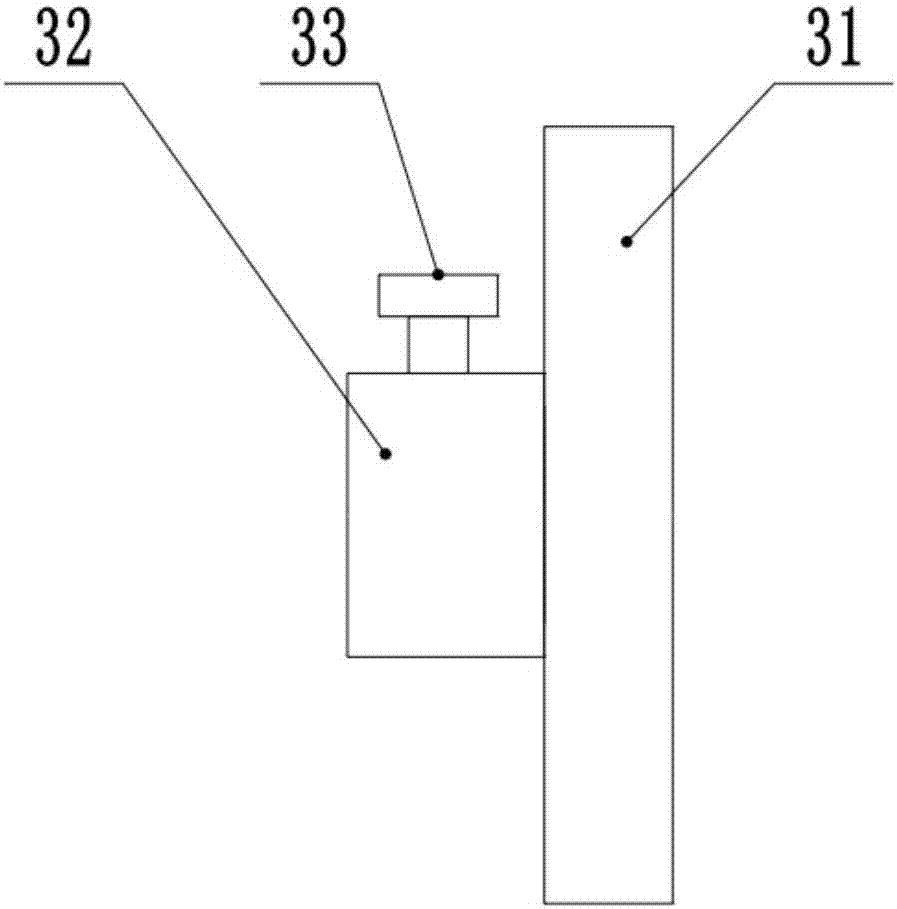

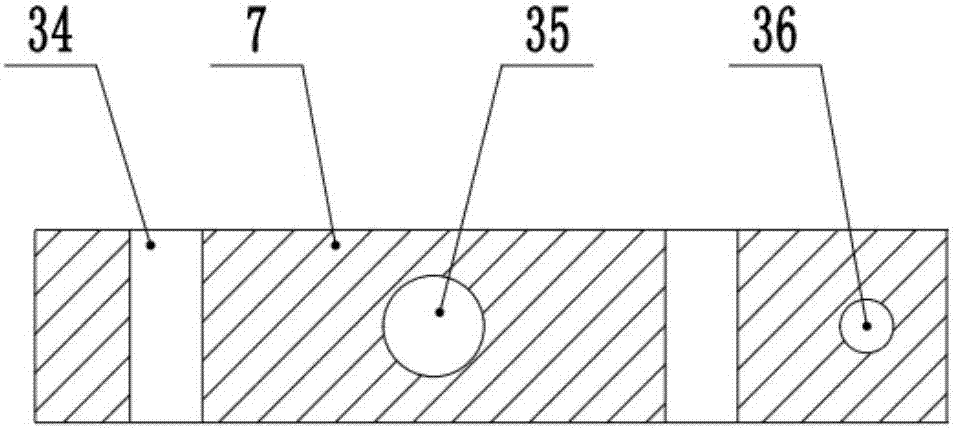

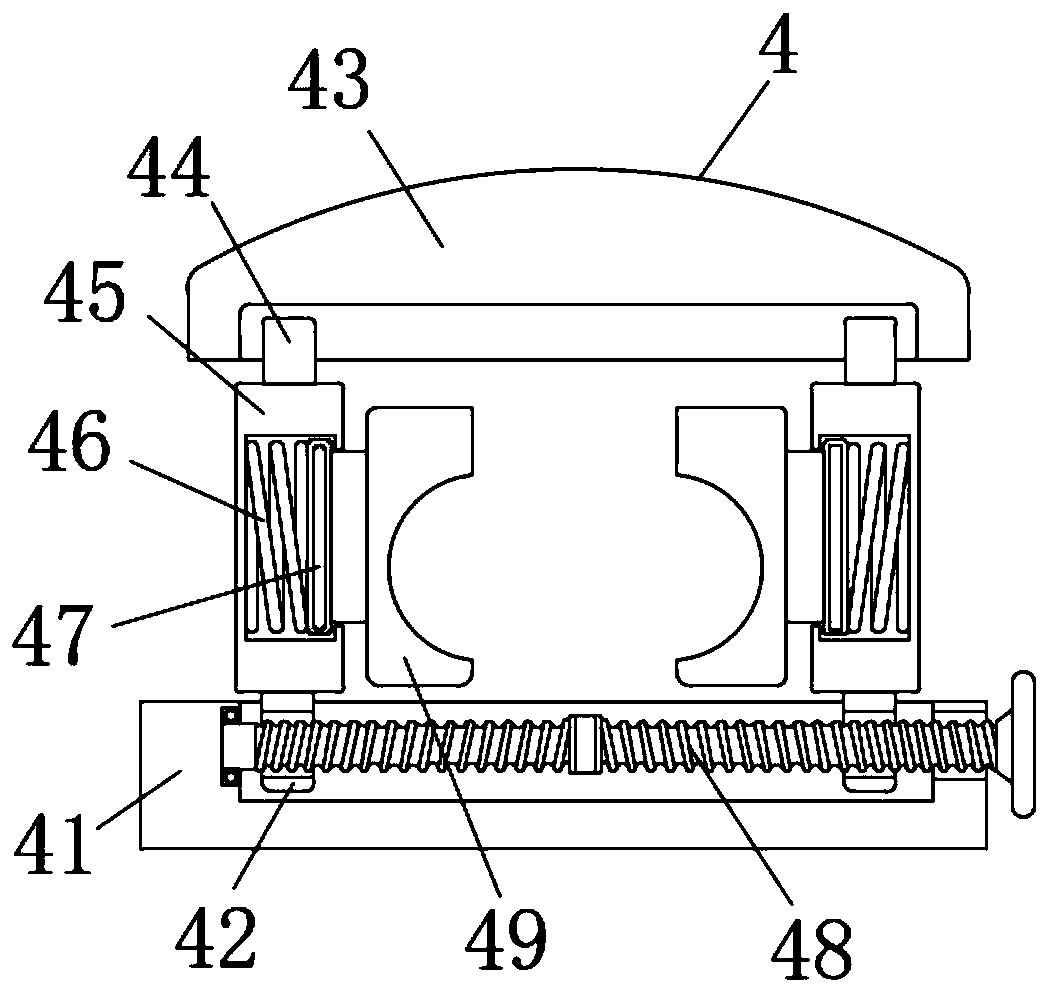

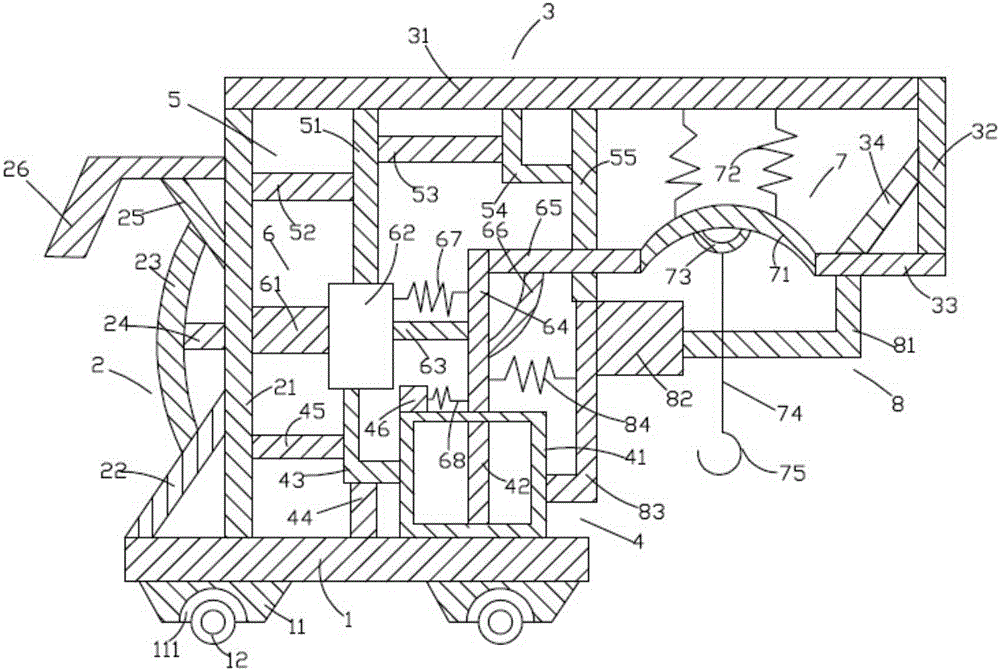

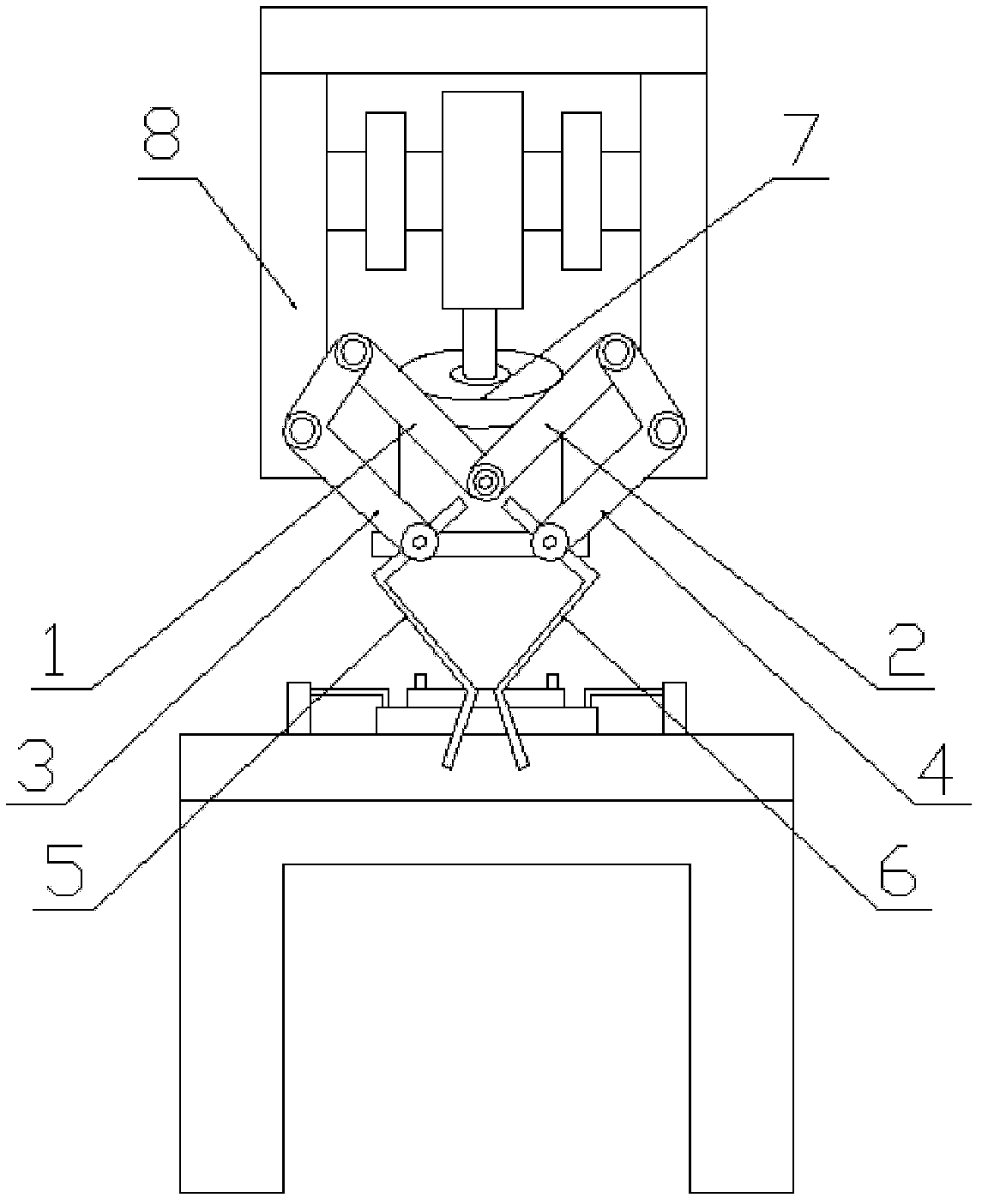

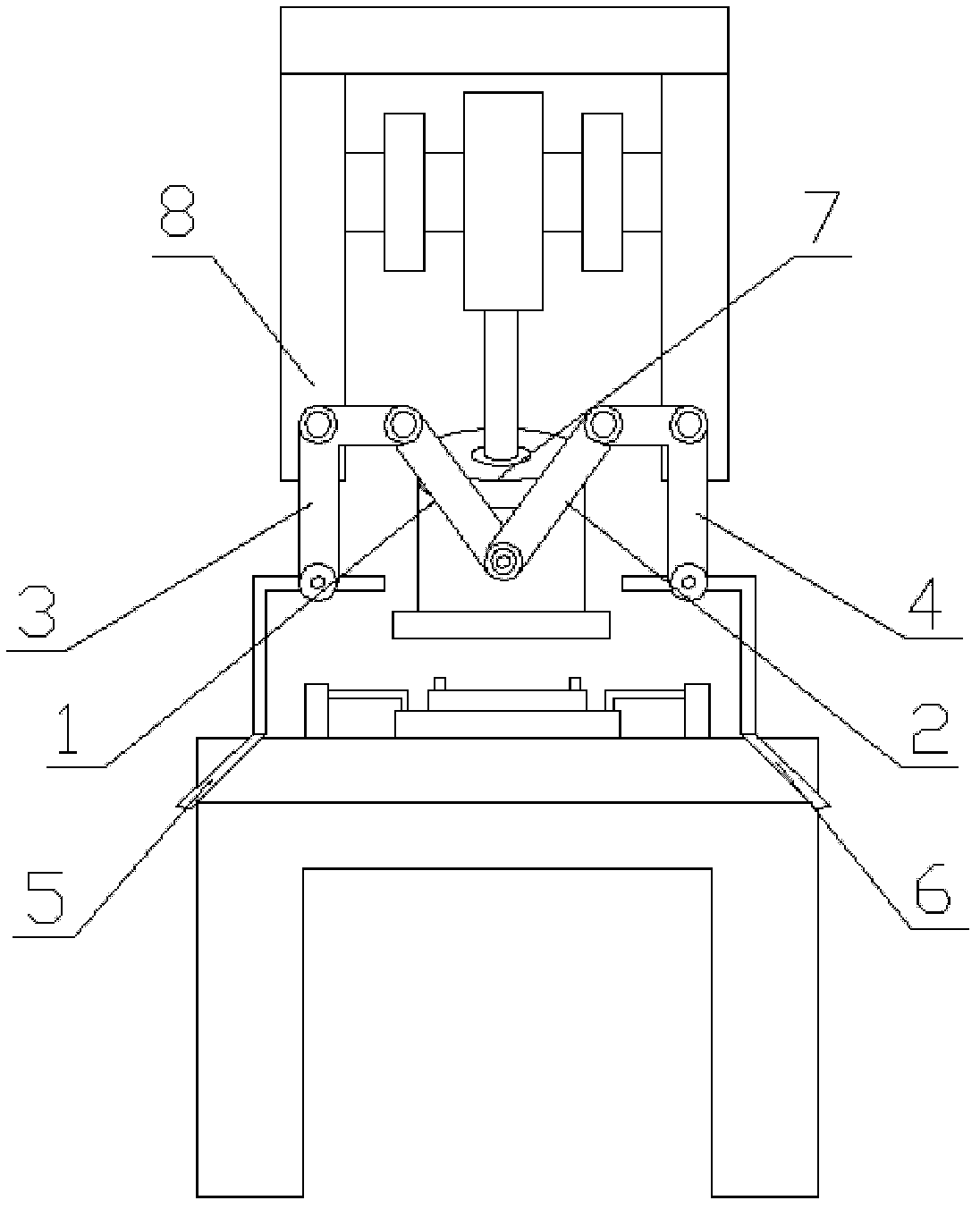

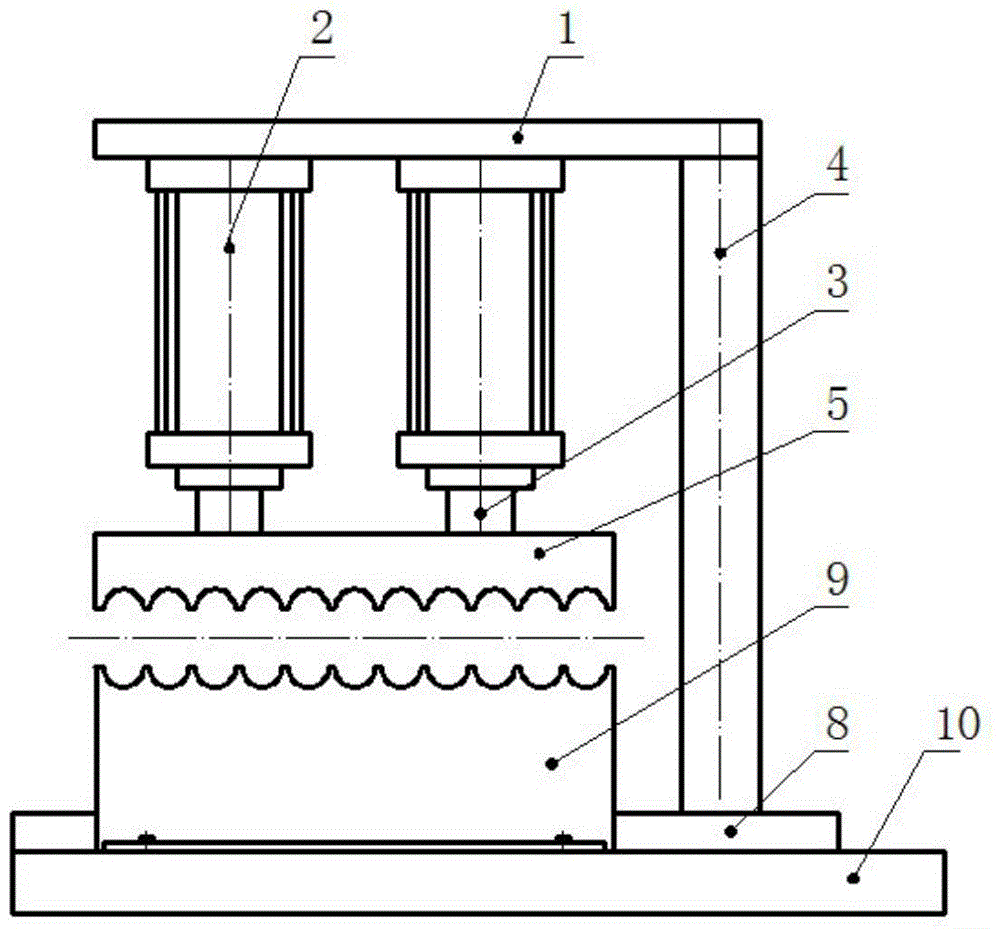

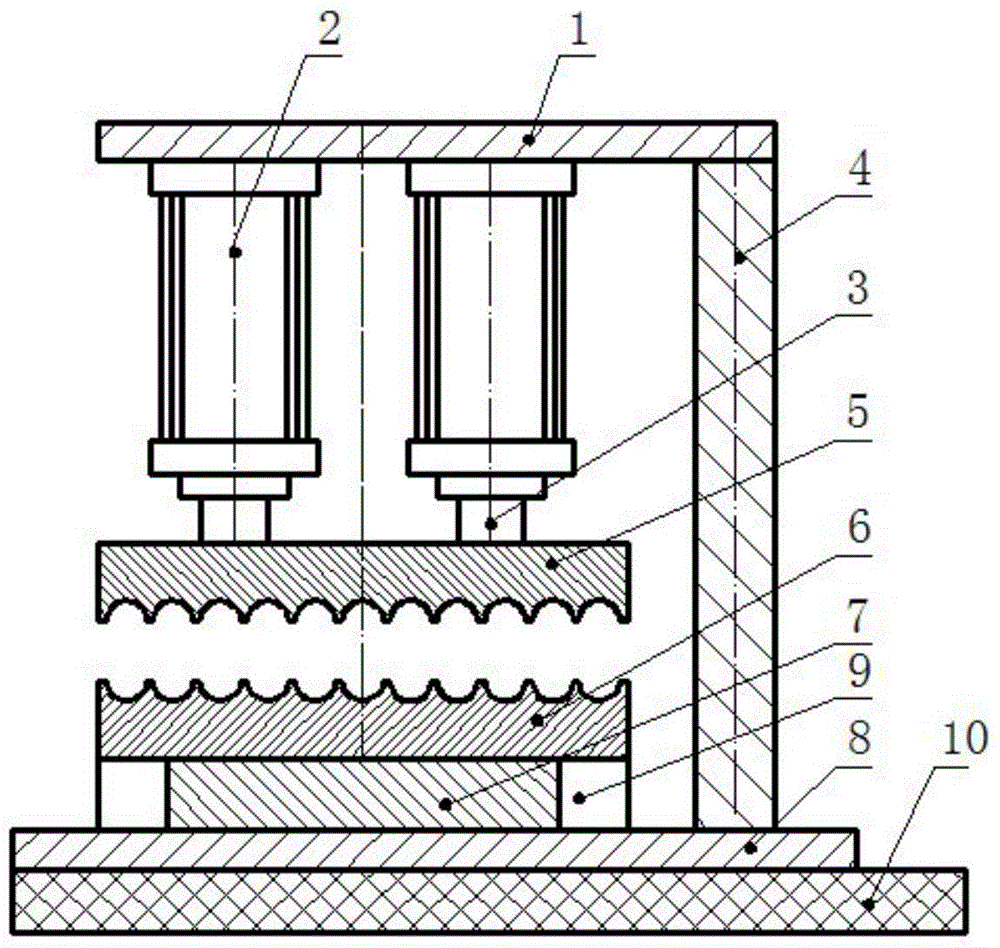

Mechanism for continuously press-fitting magnetic yokes of electromagnets on bottom plates

The invention discloses a mechanism for continuously press-fitting magnetic yokes of electromagnets on bottom plates. The mechanism comprises a hydraulic machine tool (1), wherein a base (2) and a punch (3) are arranged on the hydraulic machine tool (1), and the punch (3) is vertically arranged on the hydraulic machine tool (1); the mechanism further comprises a rotating table (4) and positioning seats (7); the rotating table (4) is vertically located between the lower end of the punch (3) and the upper surface of the base (2), mounting holes (8) are circumferentially formed in the rotating table (4) and penetrate through the upper surface and the lower surface of the rotating table (4), and a power device for driving the rotating table (4) to rotate so as to send the multiple positioning seats (7) to the position under the punch (3) one by one is arranged on the hydraulic machine tool (1). With the adoption of the mechanism for continuously press-fitting the magnetic yokes of the electromagnets on the bottom plates, operation of workers is safe, and the press-fitting efficiency is high.

Owner:宁波市鄞州通力液压电器厂

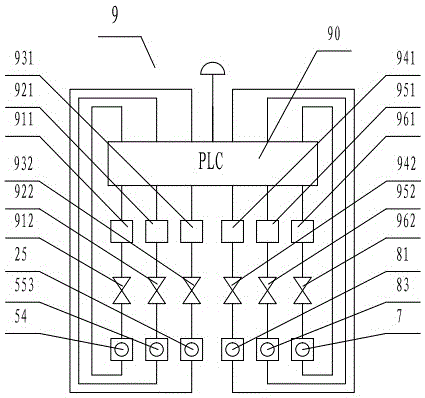

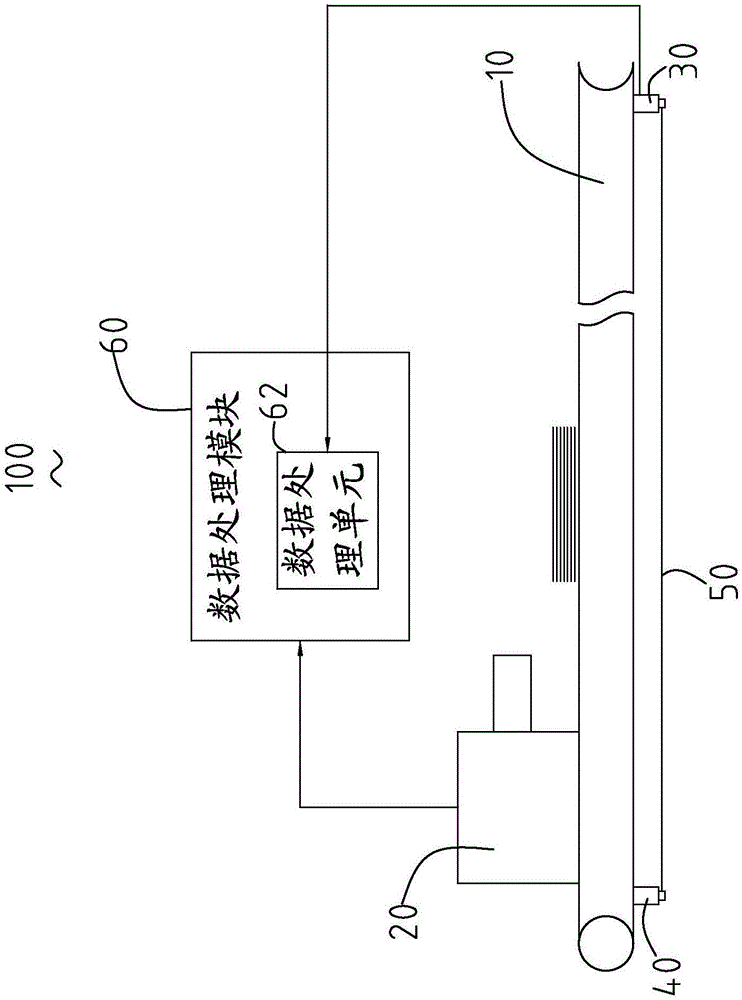

Control system of fabric spreading device

ActiveCN106743969AAvoid walking back and forthAvoid Work InjuryUnfolding thin materialsArticle deliveryControl systemComputer module

The invention relates to a control system of a fabric spreading device. The control system comprises a fabric spreading machine, a limit switch, an inhaul cable and a data processing module, wherein the limit switch comprises a wheel disc, a switch blade, a pull rod and an elastic part; the pull rod and the switch blade are arranged in the radial direction of the wheel disc in a deviated manner; the pull force direction of the inhaul cable is opposite to the restoring force direction of the elastic part; the data processing module comprises a contact and a data processing unit, the on and off of the contact are controlled by the switch blade, and the data processing unit receives the triggering signal of the contact; the data processing unit controls the fabric spreading machine to switch on and switch off according the triggering signal of the contact. The control system has the advantages that by the control system, an operator can pull the inhaul cable to switch on and switch off the fabric spreading machine, the operator does not need to walk back and forth beside a fabric spreading table of 30-50 meters, and time and manpower waste can be avoided.

Owner:BULLMER ELECTROMECHANICAL TECH

Automatic ring cutting machine

InactiveCN104551019ASimple structureHigh degree of automationAutomatic conveying/guiding stockFeeding apparatusPiston ringEngineering

The invention discloses an automatic ring cutting machine, and relates to the field of machinery, in particular to the technical field of manufacture of piston ring cutting devices. The automatic ring cutting machine comprises a frame, a power mechanism, a conveying mechanism, a feeding arm, a discharging arm and a cutter assembly, the power mechanism, the cutter assembly and the conveying mechanism are respectively fixed on the frame, an output end of the power mechanism is fixedly connected with a pneumatic fixture, the cutter assembly corresponds to the pneumatic fixture, the conveying mechanism is arranged above the power mechanism, a vertical mounting plate is arranged above the power mechanism, the feeding arm is slidably fixed on the vertical mounting plate and vertically slides, a horizontal mounting plate is fixedly connected on the side face of the frame, and the discharging arm is slidably fixed on the horizontal mounting plate and horizontally slides. The ring cutting machine is simple in structure and high in automation degree, efficiency and product quality.

Owner:仪征市新城镇三将内燃机配件二厂

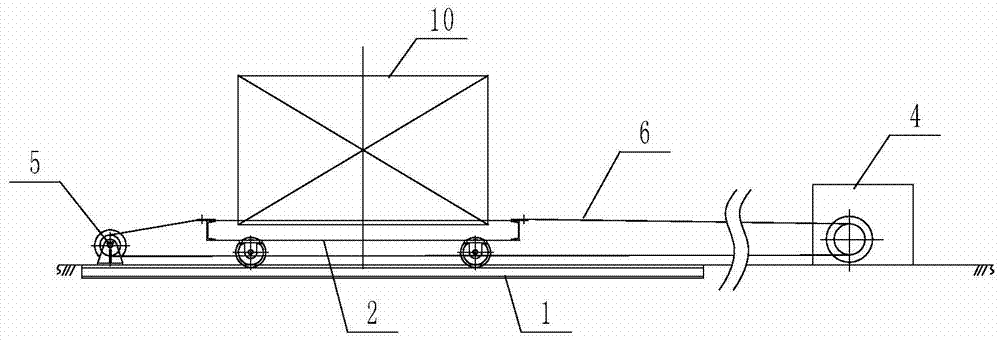

Steel wire roll cleaning device

The invention relates to a steel wire roll cleaning device, which includes a hot water washing pool, a phosphorization pool, a boronation pool, a plurality of rinsing pools and a plurality of pickling pools that are arranged in a workshop in order. A cross vehicle is disposed in the workshop, both ends of the cross vehicle are equipped with hooks, and the side of the hot water washing pool is provided with loading and unloading equipment. The loading and unloading equipment includes two tracks arranged on the ground and a loading trolley and an unloading trolley that are respectively arranged on the two tracks and a driving unit driving the loading trolley and the unloading trolley to move along the tracks, one ends of the tracks are equipped with a rack, two hanging rods are laid on the rack, the lower parts of the hanging rods are equipped with L-shaped hooks, when a steel wire roll is located on the loading trolley or the unloading trolley, the height positions of the hooks are in the horizontal mapping range of the steel wire roll's centre hole, and the upper parts of the hanging rods are equipped with cross rods cooperating with the hooks of the cross vehicle. The steel wire roll cleaning device provided by the invention not only can realize mechanized loading, unloading and material shifting, but also can remove the volatile acid fluid in the pickling pools by suction, and improves the working environment of the workshop.

Owner:ZHANGJIAGANG HENGCHANG WELDING MATERIALS

Steel pipe polishing and derusting device for bridge construction

ActiveCN113829215AEfficient positioningEfficient grippingGrinding drivesGrinding machinesElectric machinePolishing

The invention discloses a steel pipe polishing and derusting device for bridge construction. The steel pipe polishing and derusting device comprises a positioning and polishing structure and a sealing structure, the positioning and polishing structure comprises a working frame, a limiting frame, a polishing barrel, a rotating motor, a clamping plate, a telescopic plate, an extrusion air cylinder, a clamping air cylinder and a limiting plate, the rotating motor is installed at the center of one side of the outer wall of the working frame through a bolt, and the center of one side of the outer wall of the clamping plate is fixedly arranged at the output end of the rotating motor. According to the steel pipe polishing and derusting device for bridge construction, efficient positioning and clamping of steel pipes with different pipe diameters can be achieved through the positioning and polishing structure and the sealing structure, in the polishing process, slipping and thread slipping are avoided, eccentric polishing is avoided in the polishing process, and finally the structural strength of steel pipes is not reduced; and in addition, in the polishing and anti-rust paint spraying process, a sealing shell is combined, dust and anti-rust paint generated during rust removal cannot leak into the working environment, so that the working environment of workers is guaranteed, industrial injuries are avoided, and the practicability of the steel pipe polishing and derusting device is improved.

Owner:青海格茫公路管理有限公司

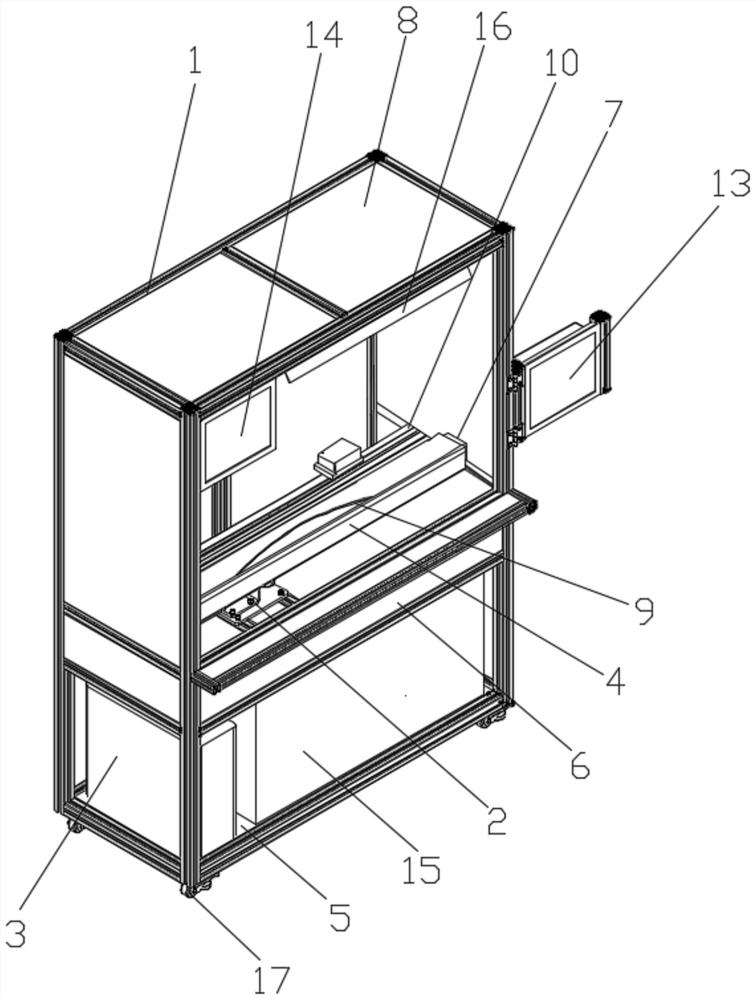

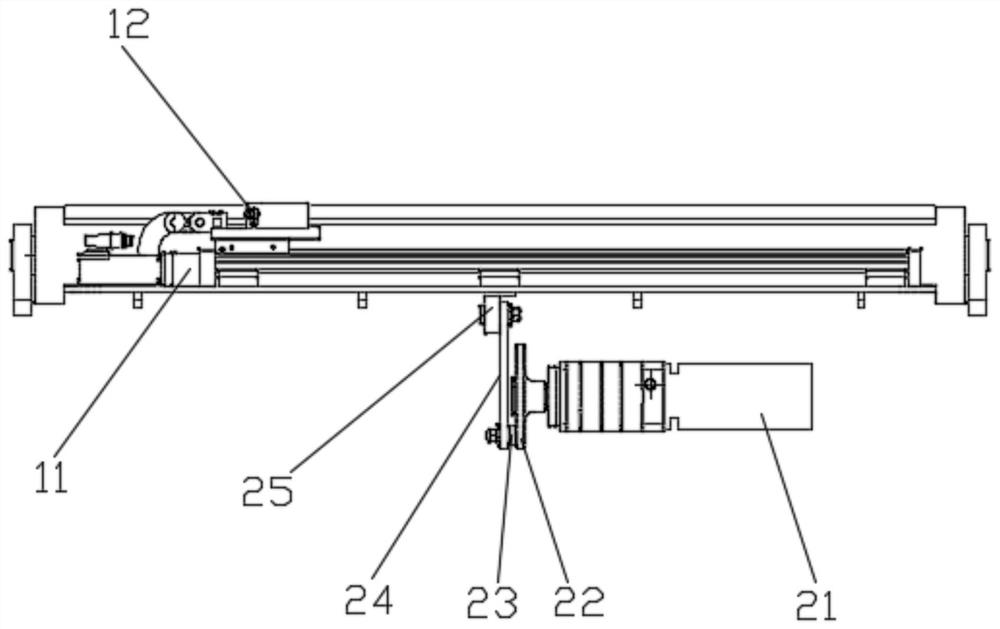

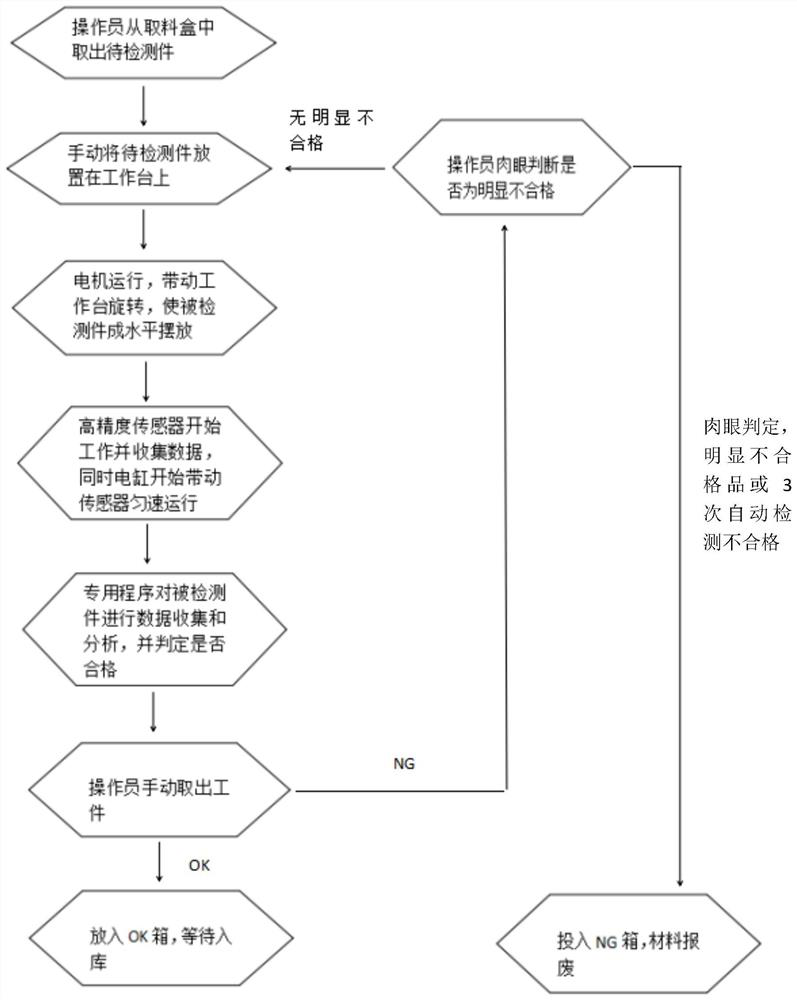

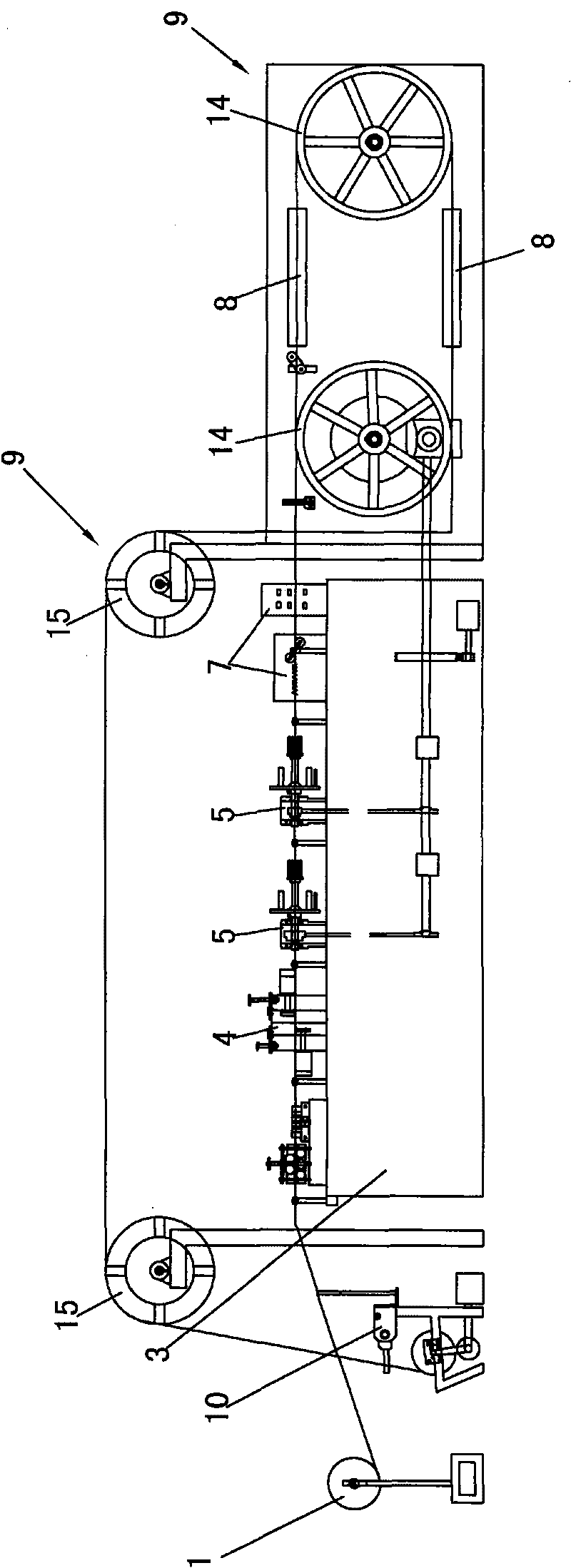

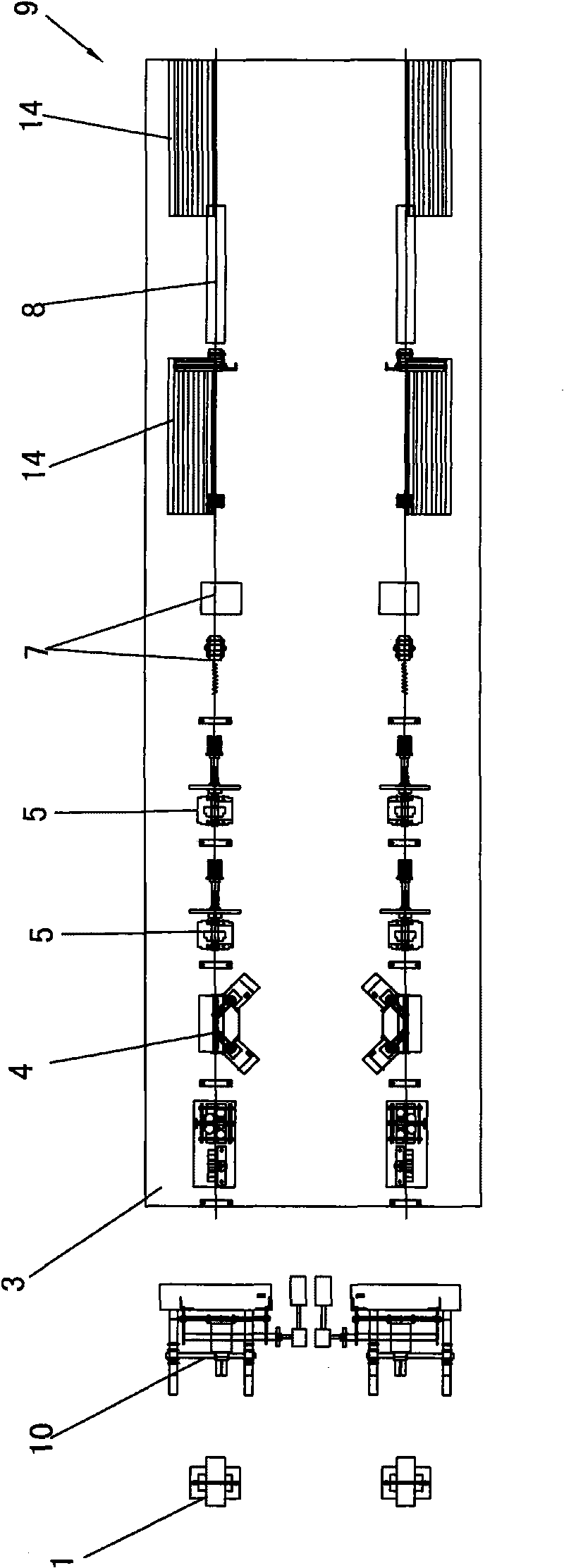

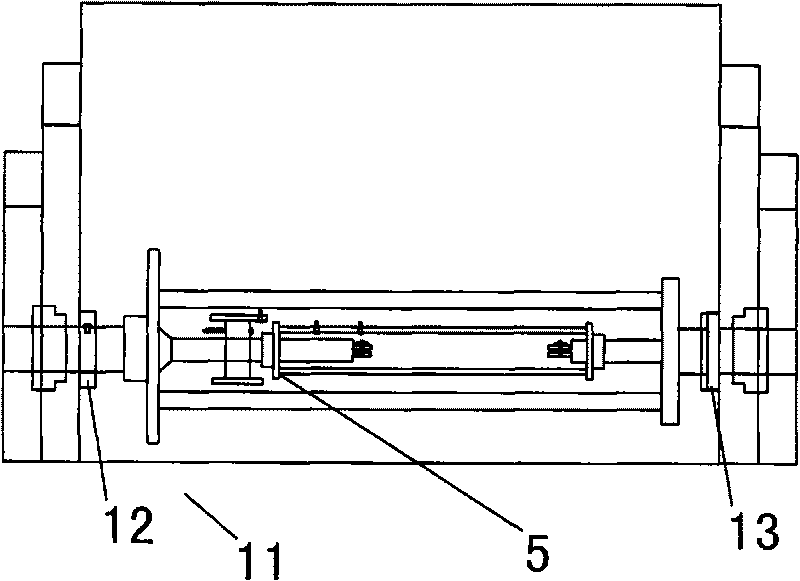

Batten arc height measuring machine

The invention discloses a batten arc height measuring machine. The batten arc height measuring machine includes a stent, a base is arranged at the lower end of the stent; a computer host and an electric cabinet are mounted on the base; a partition plate is mounted on the stent on the upper side of the control box body; a rotating mechanism is fixedly mounted on the partition plate; a workbench isarranged on the upper side of the rotating mechanism; a protective cover is mounted on the stent on the outer sides of the rotating mechanism and the workbench; the rear side of the workbench is fixedly connected with a supporting plate. An electric cylinder is fixedly mounted on the upper surface of the supporting plate; a sensor is fixedly connected to a sliding table of the electric cylinder, the bottom of the workbench is fixedly connected with the rotating mechanism, a computer display screen is installed on the outer side wall of the upper end of the stent, and a touch screen is installed on the front side of the upper left corner of the stent. The personal error is small, the machine rotates by 15-30 degrees, so that the deviation caused by manual operation is reduced; operation issimple, touch screen selection is adopted, and user-friendly layout is achieved; the universality is high, and the batten arc height measuring machine can be applied to products with the length ranging from 100 mm to 820 mm and the arc height ranging from 2 mm to 50 mm; and the precision is high, and high-precision judgment of 0.05 mm can be realized by utilizing a high-precision sensor.

Owner:长沙博途自动化工程有限公司

Sintering machine tracked by guide wheel

InactiveCN101738086AAvoid Work InjurySimple methodMuffle furnacesRetort furnacesComputer moduleMechanical engineering

The invention discloses a sintering machine tracked by a guide wheel, comprising a payoff rack, a take-up machine, a traction device, a machine bench, a polishing machine, a winding device, a high-frequency sintering device, an oven, a guide wheel and a photoelectrical safety protective device, wherein the polishing machine, the winding device, the high-frequency sintering device, the oven and the guide wheel are arranged on the machine bench; and the photoelectrical protective device is used for judging whether obstacles exist or not and provided with a photoelectric transmitting module and a photoelectric receiving module which are respectively arranged on two sides of the winding device. When an operator carelessly stretches hands into a dangerous area in which the winding device rotates during the operation, and a signal which is originally received by the photoelectrical receiving module is blocked, the photoelectrical safety protective device gives an alarm signal to enable the machine to automatically stop without pressing a stop button, thereby effectively preventing workers from being injured during the operation.

Owner:SUZHOU GUANLONG MAGNET WIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com