Acidic etching solution not generating chlorine and catalyst of acidic etching solution

An acid etching solution and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of chlorine overflow, difficulty in maintaining etching speed, etching Slow speed and other problems, to avoid industrial injuries and industrial accidents, avoid chlorine overflow, high etching coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with embodiment further detailed description.

[0067] (1) It is difficult to convert monovalent copper ions to divalent copper ions in the acid copper chloride etching solution. The reasons are:

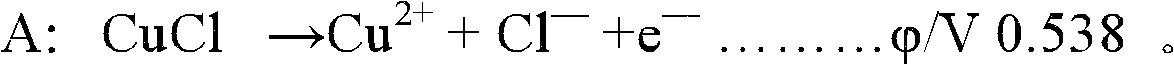

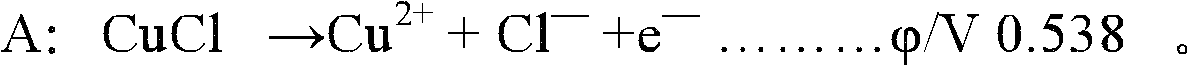

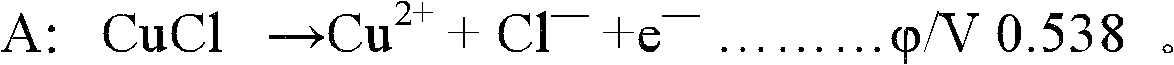

[0068] Under normal circumstances (in a neutral environment), the standard potential for conversion of monovalent copper ions to divalent copper ions is as follows:

[0069]

[0070] Under alkaline conditions:

[0071]

[0072] The reduction potential of oxygen in aqueous solution is:

[0073]

[0074] This means that in neutral and alkaline solutions, monovalent copper is more easily oxidized to divalent copper by dissolved oxygen; while in acidic and high chloride ion environments, monovalent copper ions form stable complexes with chloride ions [CuCl 2 ] - , the reaction equilibrium is sharply tilted towards the generation of monovalent copper ions. Calculated according to the Nernst equation, the actual oxidation-reduction potential is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com