Solar battery component and precise superposing method

A technology of solar cell components and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of blade consumption, accidental injury of operators, high production cost, etc., and achieve the goal of saving production cost, avoiding accidental injury of personnel, and saving labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

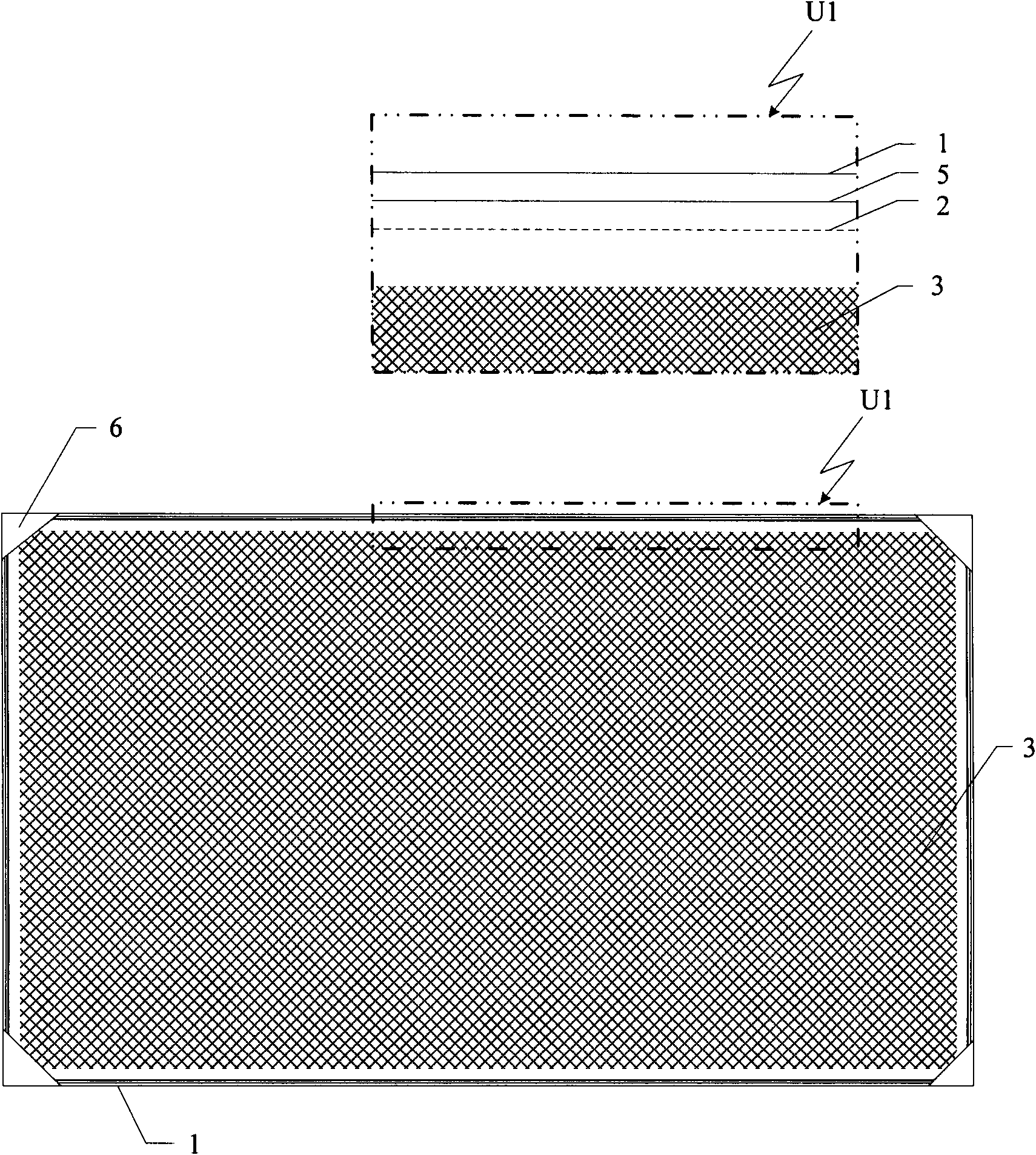

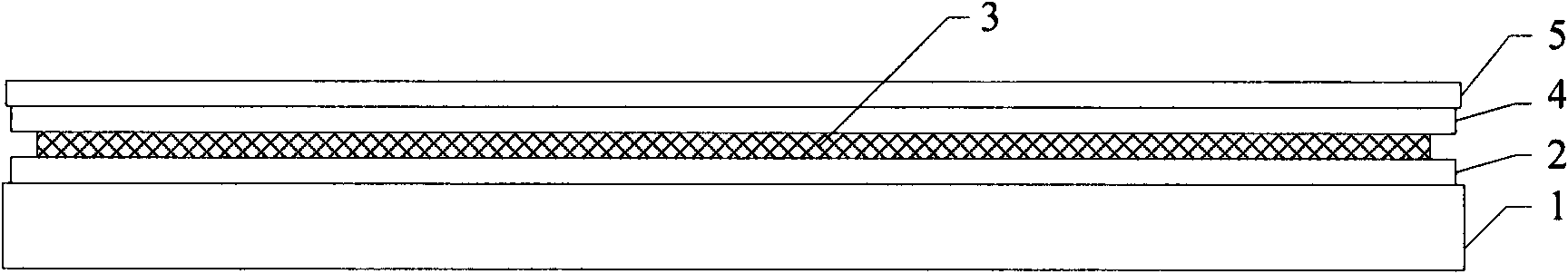

[0022] Such as figure 1 The top view of the stacked solar cell modules in this embodiment and the partial enlarged view of the upper edge (area U1) and figure 2 Shown is the front view of the stacked solar cell modules in this embodiment, wherein the size of the first layer of EVA 2 and the second layer of EVA 4 is 1570mm*798mm, and the size of TPT 5 is 1572mm*800mm.

[0023] The first layer of EVA 2 is pasted on the glass 1, its upper side is about 2 mm away from the upper side of the glass 1, and its left side is about 2 mm away from the left side of the glass 1. The solar battery string 3 is placed on the first layer of EVA 2, in the center of the glass 1, its upper side is about 20 mm away from the upper side of the glass 1, and its left side is about 16 mm away from the left side of the glass 1. The second layer of EVA4 is pasted on the solar cell string 3 , the distance between its lower side and the lower side of the glass 1 is about 2 mm, and the distance between its...

Embodiment 2

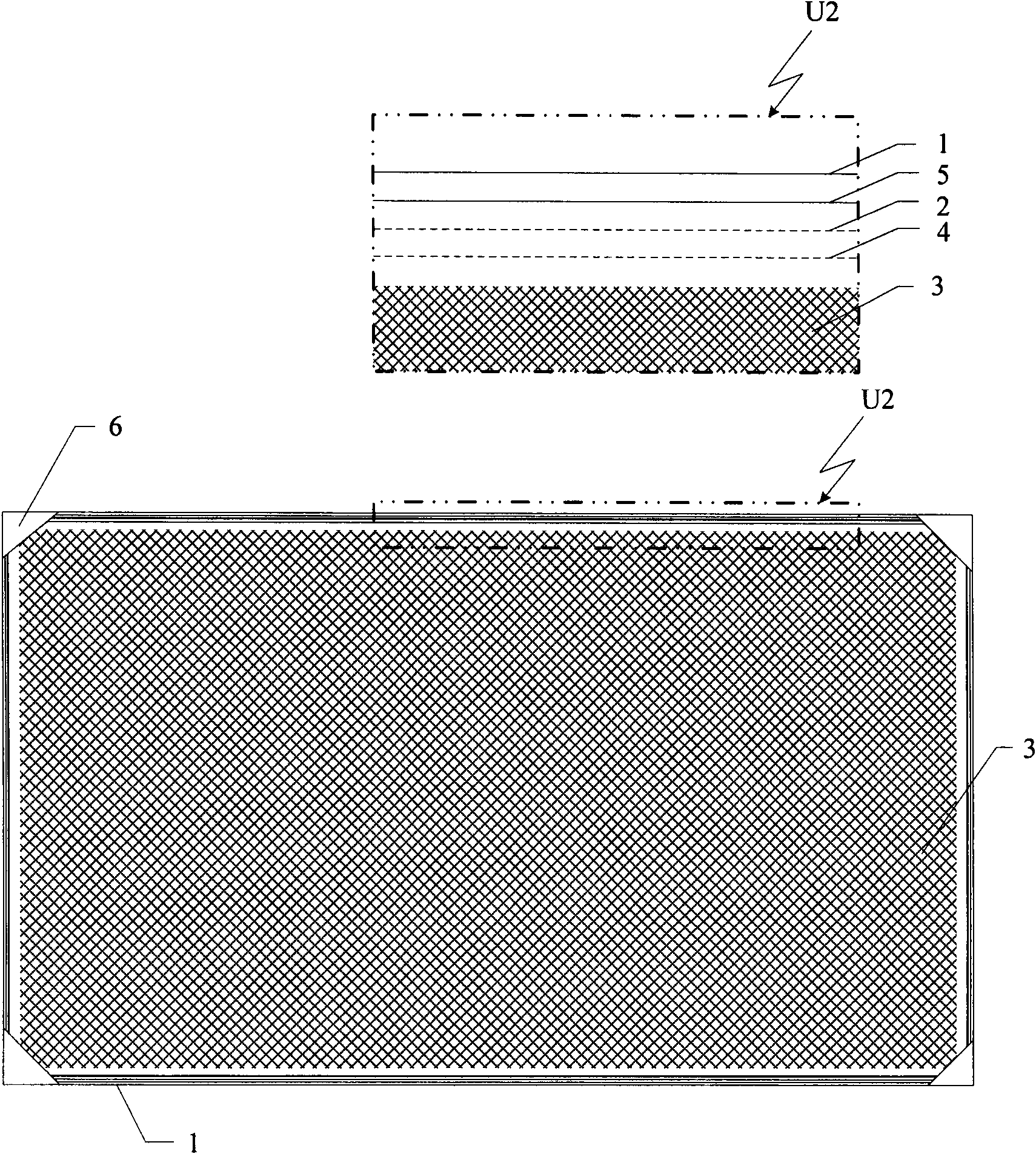

[0032] Such as image 3 The top view of the stacked solar cell module in this embodiment and the partial enlarged view of the upper edge (region U2) are shown, wherein the size of the first layer of EVA 2 and the second layer of EVA 4 is 1570mm*796mm, and the size of TPT 5 is 1572mm *800mm.

[0033] The first layer of EVA 2 is pasted on the glass 1, its upper side is about 2 mm away from the upper side of the glass 1, and its left side is about 2 mm away from the left side of the glass 1. The solar battery string 3 is placed on the first layer of EVA 2, its upper side is about 20 mm away from the upper side of the glass 1, and its left side is about 16 mm away from the left side of the glass 1. The second layer of EVA 4 is pasted on the solar battery string 3 , the distance between its lower side and the lower side of the glass 1 is about 2 mm, and the distance between its right side and the right side of the glass 1 is about 2 mm. The TPT 5 is pasted on the second layer of ...

Embodiment 3

[0039] In this embodiment, the size of the first layer of EVA 2 and the second layer of EVA 4 is 1568mm*796mm, and the size of the TPT 5 is 1573mm*801mm.

[0040]The first layer of EVA 2 is pasted on the glass 1, its upper side is about 1 mm away from the upper side of the glass 1, and its left side is about 1 mm away from the left side of the glass 1. The solar battery string 3 is placed on the first layer of EVA 2, its upper side is about 20 mm away from the upper side of the glass 1, and its left side is about 16 mm away from the left side of the glass 1. The second layer of EVA 4 is pasted on the solar cell string 3 , the distance between its lower side and the lower side of the glass 1 is about 1 mm, and the distance between its right side and the right side of the glass 1 is about 1 mm. The TPT 5 is pasted on the second layer of EVA 4 with a distance of 0.5 mm between each side and the corresponding side of the glass 1 . Between the first layer of EVA 2 and the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com