Wood plate processing assembly line device and working method thereof

A wood plank and flowing water technology, which is applied in the field of wood plank processing flow devices, can solve the problems of not being able to guarantee the large dust of wood planks and sawdust, and processing errors, and achieve the effects of simple structure, high safety factor, and improved mechanic precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

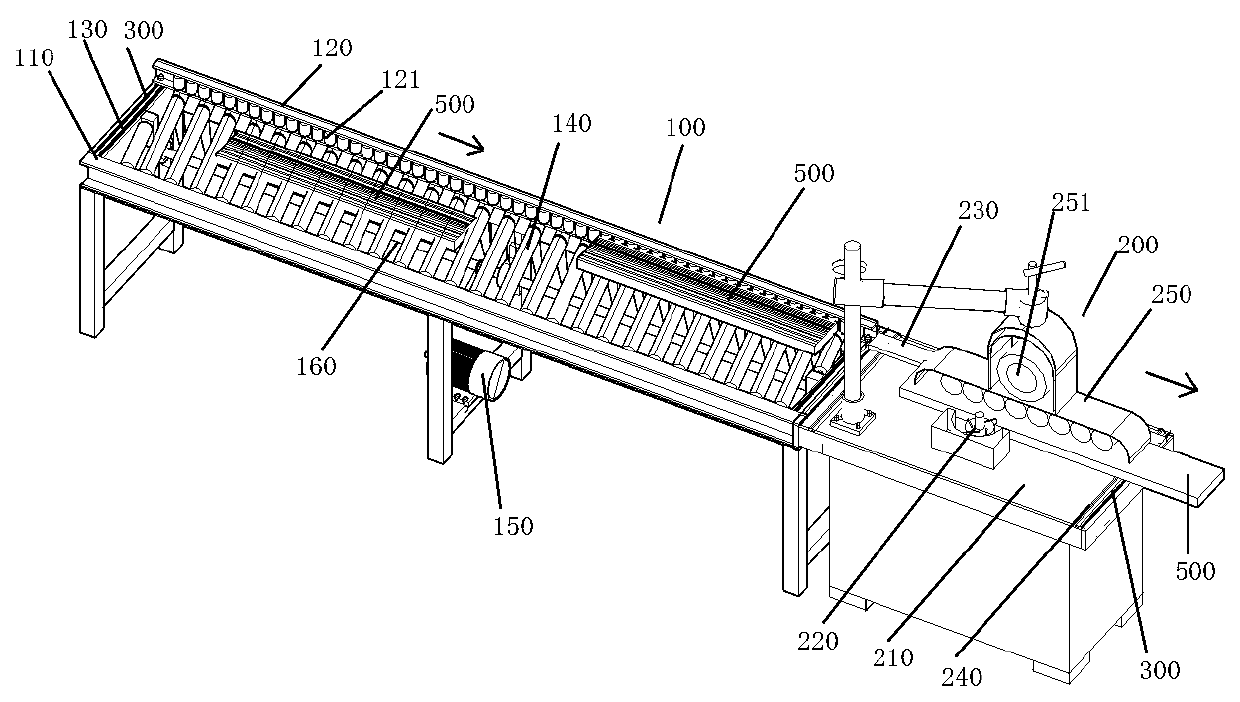

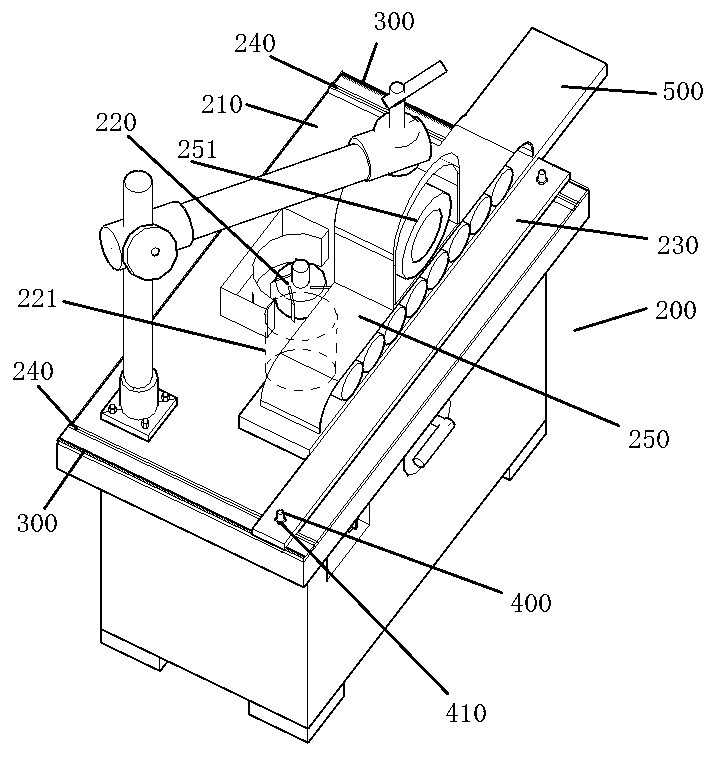

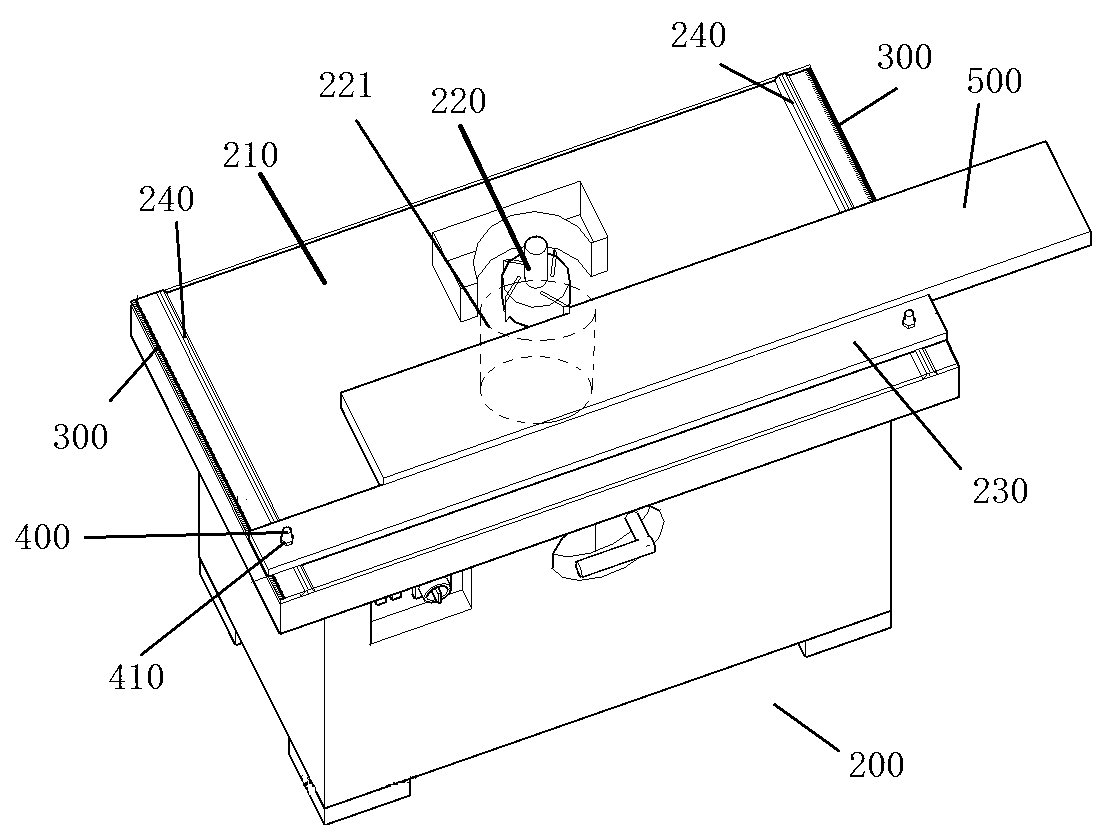

[0031] Such as Figure 1~7 As shown, a wood board processing flow device is provided with a wood board conveying mechanism and a wood board processing mechanism along the wood board conveying direction. The other side of the table is provided with a first guide backer seat for guiding the board and adjusting the processing size of the wood board, and a first installation groove for adjusting the distance between the first guide backer seat and the tool is provided on the upper surface of the machine table. A first motor for driving the cutter to rotate is arranged in the machine table, and the plank conveying structure includes a frame on which a device is provided to guide the plank into the feed end of the plank washing mechanism and make the plank and the first guiding backer seat The attached second guide seat is provided with a second installation groove on the upper end of the frame to adjust the installation position of the second guide seat, and there is also a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com