L-shaped trolley

A trolley, L-shaped technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of dropped boards, scrapped boards, personnel injuries, etc., and achieves the effect of preventing board dropping, simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

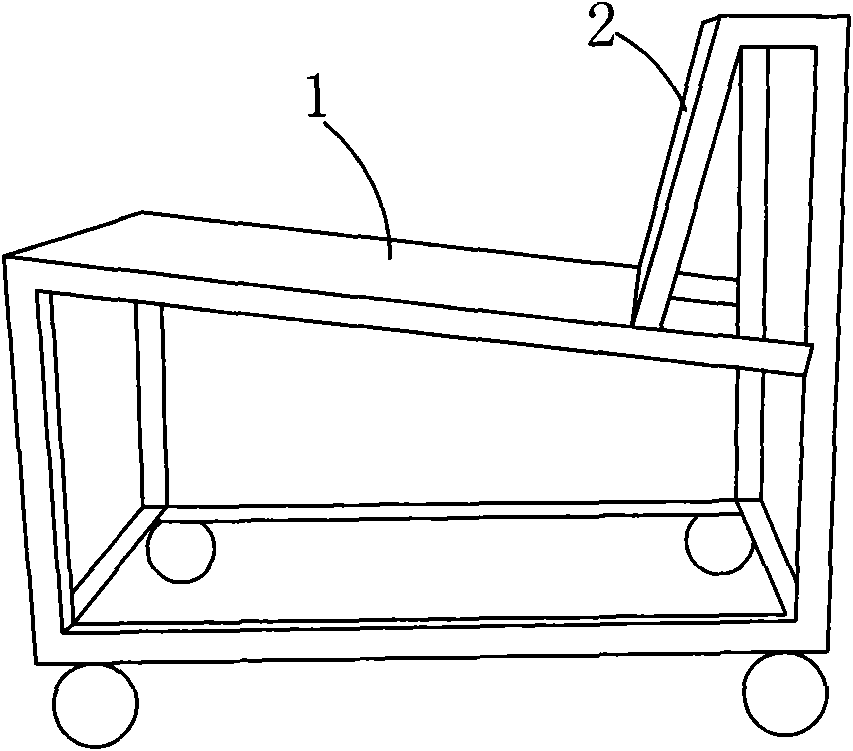

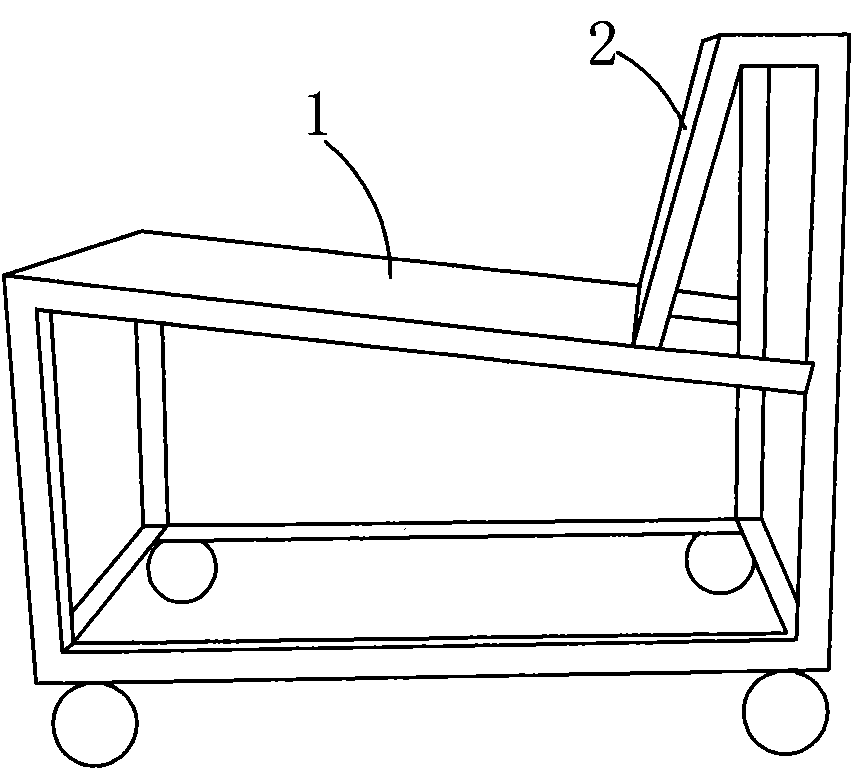

[0011] Embodiment: an L-shaped trolley, a table top 1 with a load plate, based on the use direction, there is an angle between the table top 1 and the horizontal plane, and the lowest side of the table top is provided with a baffle plate 2 upwards, The baffle and the table form an L-like shape.

[0012] Based on the direction of use, the table top is high at the front and low at the back.

[0013] Based on the direction of use, the angle between the table and the horizontal plane is 15°.

[0014] Since the table top and baffle plate of the L-shaped trolley form an L-like shape, and the angle between the table top and the horizontal plane is 15°, the L-shaped trolley can effectively prevent the board from falling during the board feeding process, thereby avoiding the The scrap caused by the board and the work-related injury of the personnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com