Automatic ring cutting machine

A technology of ring cutting machine and power mechanism, which is applied to automatic/semi-automatic lathes, metal processing machinery parts, turning equipment, etc., can solve the problems of low degree of automation, low production efficiency, increased production cost, etc., and achieves high degree of automation and saving. Production cost, the effect of avoiding work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

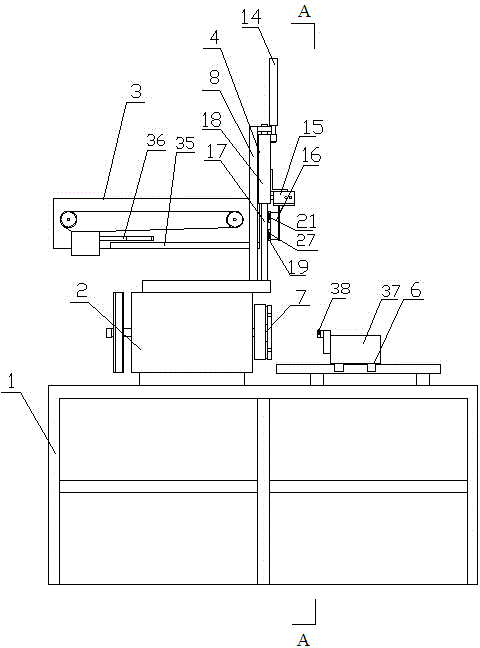

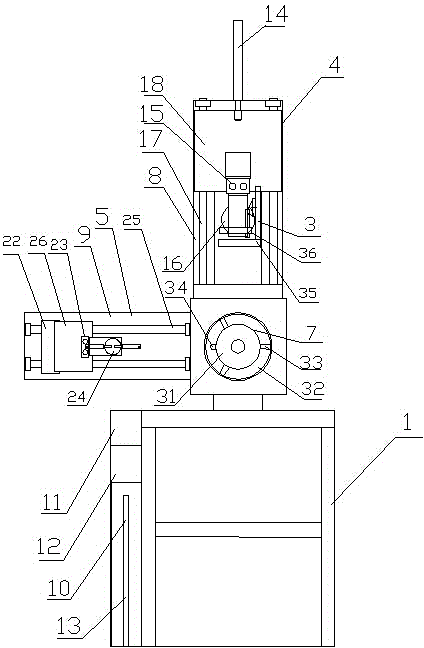

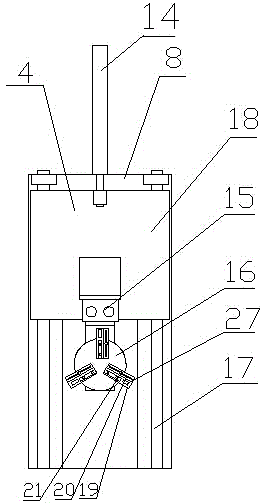

[0020] like figure 1 , 2 , 3, 4, 5, 6, 7, this automatic ring cutting machine includes frame 1, power mechanism 2, feeding mechanism 3, feeding arm 4, unloading arm 5, cutter assembly 6, power mechanism 2. The cutter assembly 6 and the feeding mechanism 3 are respectively fixed on the frame 1, the output end of the power mechanism 2 is fixedly connected to the pneumatic clamp 7, the cutter assembly 6 is arranged corresponding to the pneumatic clamp 7, and the feeding mechanism 3 is arranged in the power mechanism. Above 2, a vertical mounting plate 8 is set above the power mechanism 2, the feeding arm 4 is slidably fixed on the mounting plate 8, the feeding arm 4 slides up and down, and the grab end of the feeding arm 4 slides up to the same position as the The feeding mechanism 3 correspondingly grabs the raw material ring body, and the grab end of the feeding arm 4 slides to the corresponding pneumatic clamp 7 to feed the raw material ring body; a horizontal mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com