Steel wire roll cleaning device

A cleaning device and a technology for wire coils, applied in the field of wire coil cleaning devices, can solve the problems of acid volatilization, labor consumption of workers, injury of workers, etc., and achieve the effects of avoiding physical damage, saving manpower, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The steel wire coil cleaning device of the present invention will be further described in detail through specific examples below.

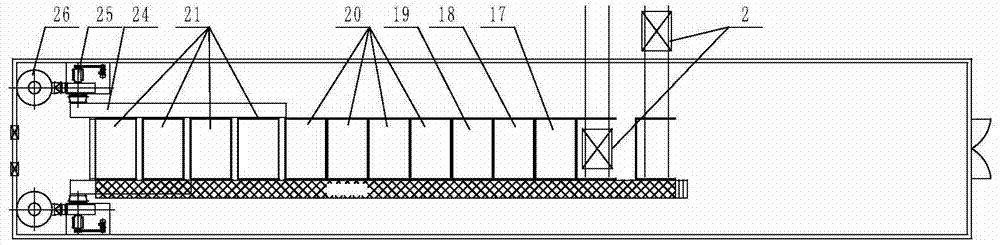

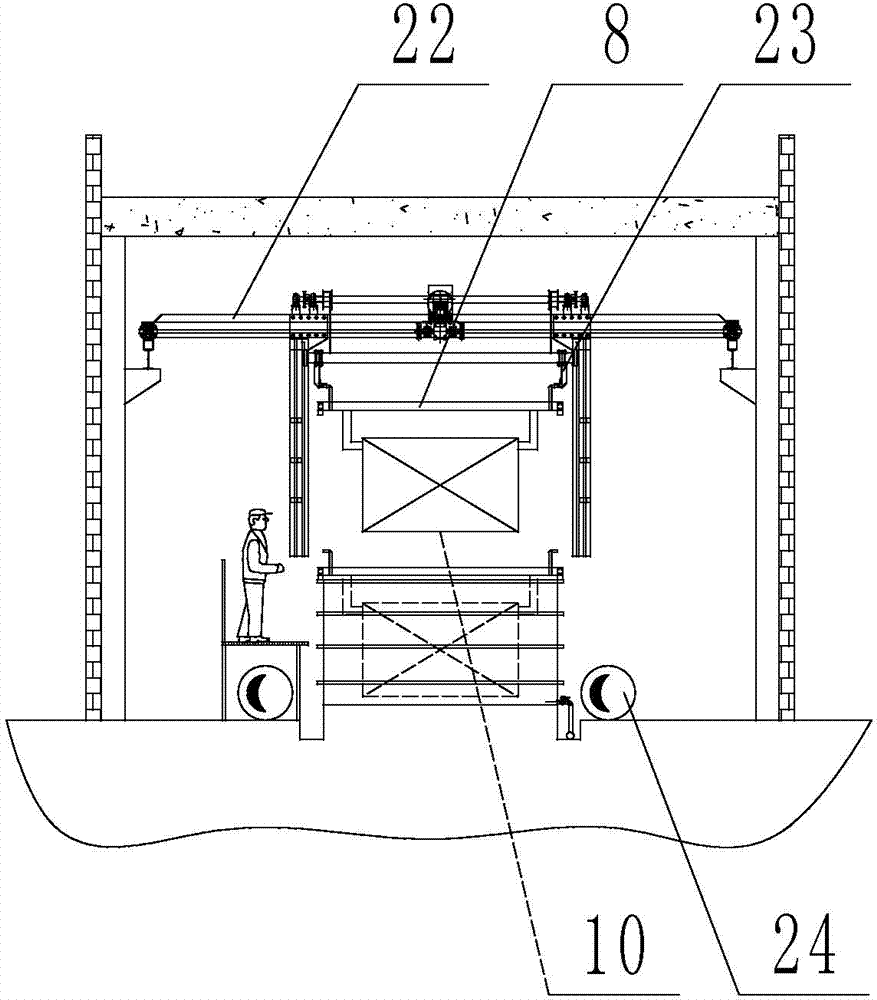

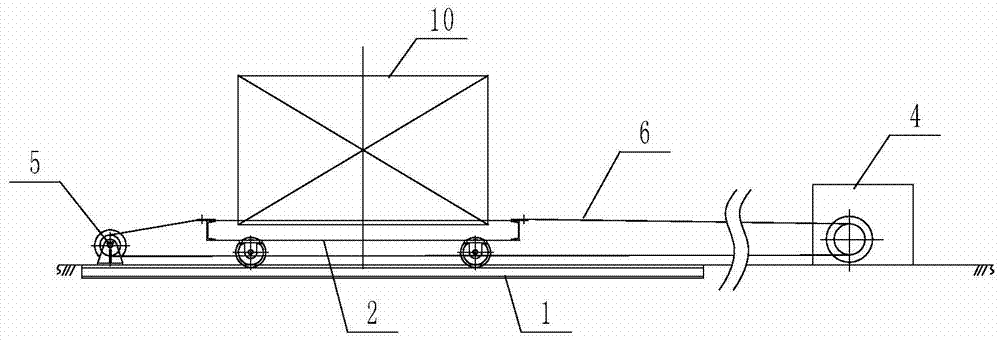

[0020] Such as figure 1 , figure 2 As shown, the steel coil cleaning device includes a hot water washing pool 17, a phosphating pool 18, a boronizing pool 19, a plurality of rinsing pools 20 and a plurality of pickling pools 21 arranged in sequence in the workshop (in this embodiment, Comprise four rinsing ponds 20 and four pickling ponds 21), described workshop is provided with crosscar 22, and the two ends of crosscart 22 are provided with hook 23, and crosscart 22 is positioned at hot water washing pond 17, phosphating pond 18, Above the boronization pool 19, a plurality of rinsing pools 20 and a plurality of pickling pools 21, the side of the hot water washing pool 17 is provided with loading and unloading equipment, such as image 3 , Figure 4 As shown, the loading and unloading equipment includes two rails 1 arranged on the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com