Sintering machine tracked by guide wheel

A sintering machine and guide wheel technology, applied in furnaces, muffle furnaces, lighting and heating equipment, etc., can solve the problems of increasing the comprehensive cost of accidents, stabbing employees' fingers, arms, and personal injuries of operators, and achieving a significant cooling effect. , The effect of preventing work-related injuries and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

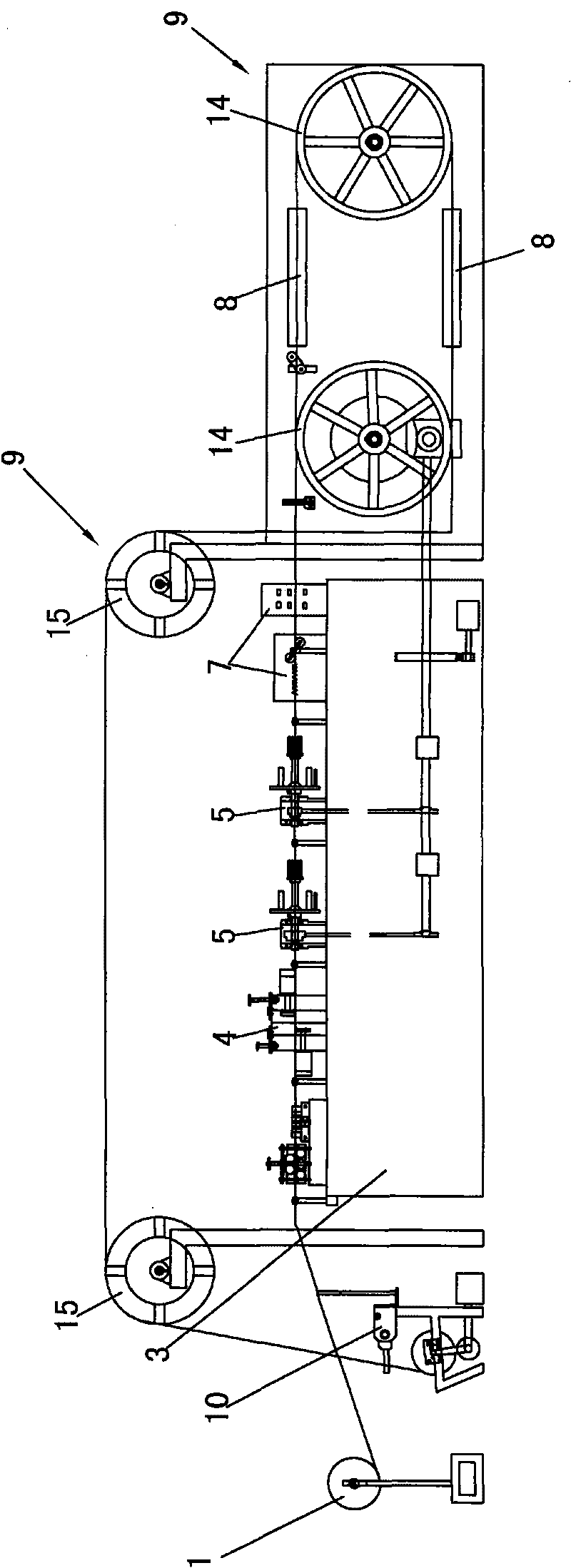

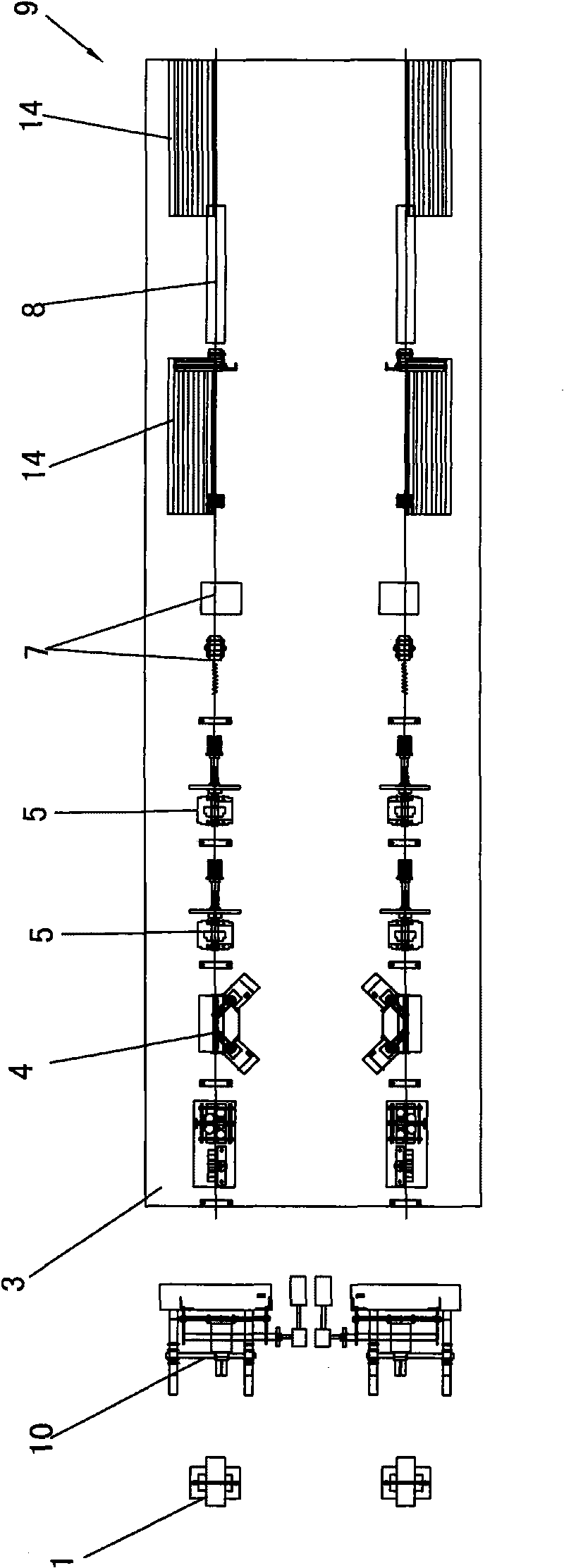

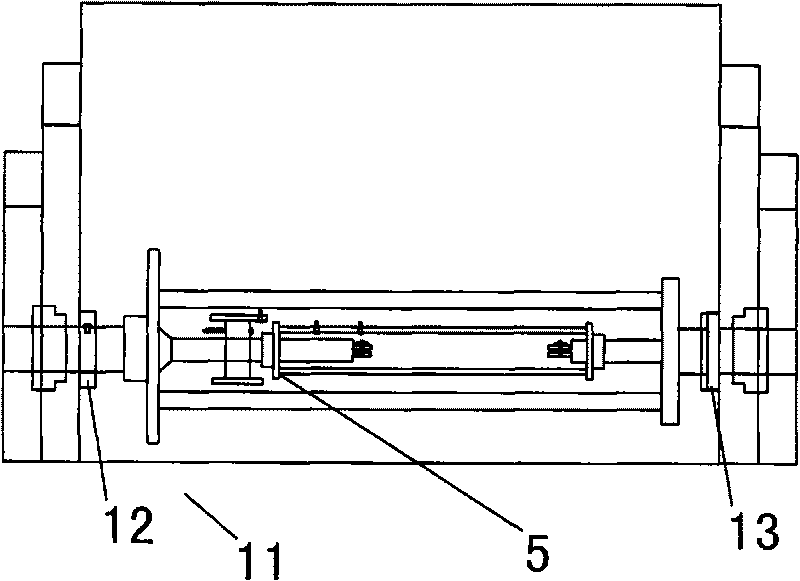

[0017] as attached figure 1 A kind of guide wheel traction sintering machine shown, it comprises pay-off stand 1, take-up machine 10, traction device, machine platform 3 and the polisher 4 that is arranged on described machine platform 3, wrapping device 5, high Frequency sintering device 7, oven 8, guide wheel 9, which can be used to produce various polyester glass sintering lines and various film sintering lines.

[0018] First, the copper conductor placed on the pay-off frame 1 passes through the pressing plate and the main line wheel set on the machine 3 to the polishing machine 4, and the polishing machine 4 throws away the burrs on the copper conductor and then reaches the wrapping device 5 to wrap the insulating layer. Wrapped over a copper conductor. The high-frequency sintering device 7 adopts high-frequency temperature control, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com