Control system of fabric spreading device

A control system and cloth spreading technology, applied in the field of sewing machines, can solve the problems of time-consuming and laborious, inconvenient to suspend the machine, machine collision, etc., to avoid wasting time and manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the specific embodiments described here are only examples, and are not intended to limit the protection scope of the present invention.

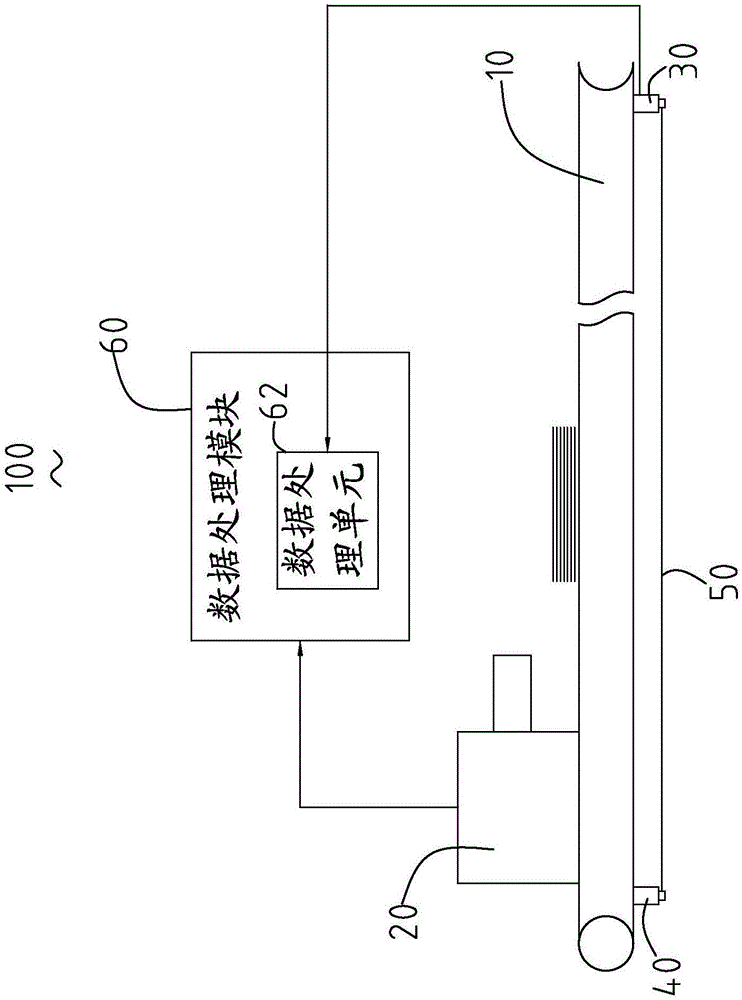

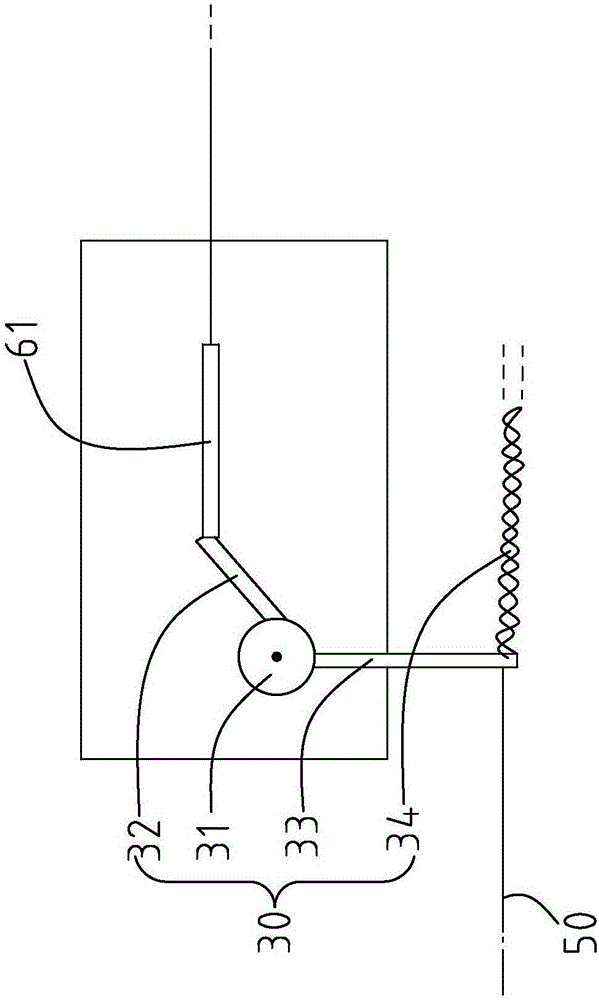

[0019] see figure 1 with figure 2 , which is a structural schematic diagram of a control system 100 of a spreading device provided by the present invention. The control system 100 of the spreading device comprises a spreading table 10, a spreading machine 20 arranged on the spreading table 10, a limit switch 30 arranged at one end of the spreading table 10, a A cable fixed end 40 arranged at the other end of the spreading table 10 relative to the limit switch 30, a cable 50 arranged between the limit switch 30 and the cable fixed end 40, and a cable fixed by The data processing module 60 controlled by the limit switch 30 is provided with the above-mentioned structure of the limit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com