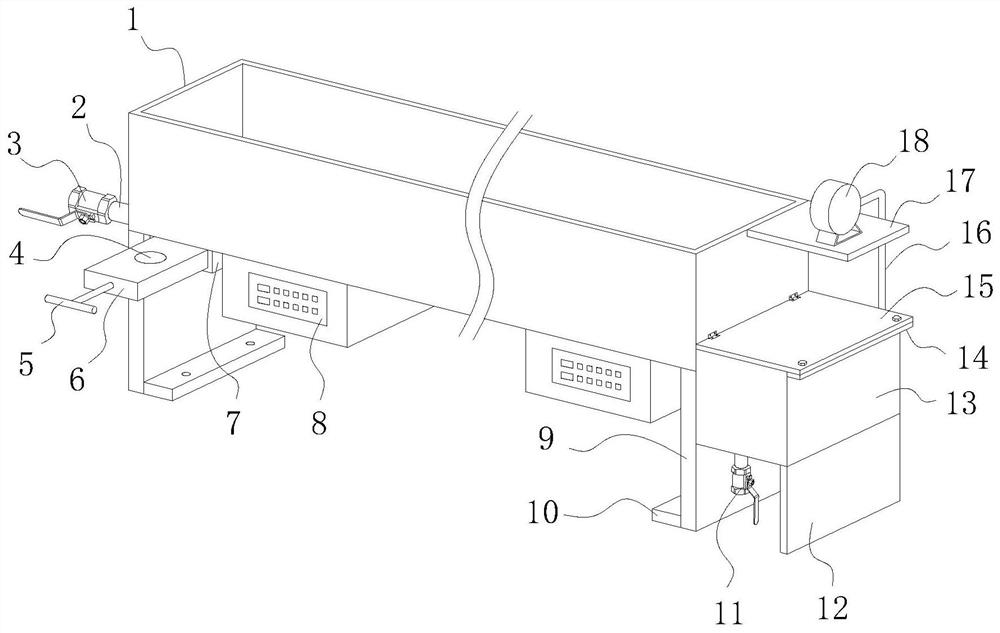

An integrated machine for automatic surface derusting treatment of h-shaped steel

A technology of H-shaped steel and integrated machine, which is applied in the field of steel processing, can solve the problems of people walking back and forth, increasing labor intensity, and low cleaning efficiency, so as to reduce labor intensity, avoid walking back and forth, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

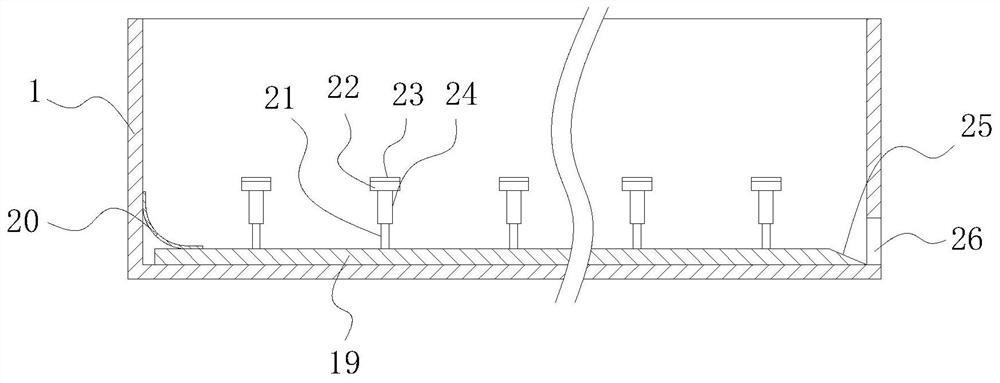

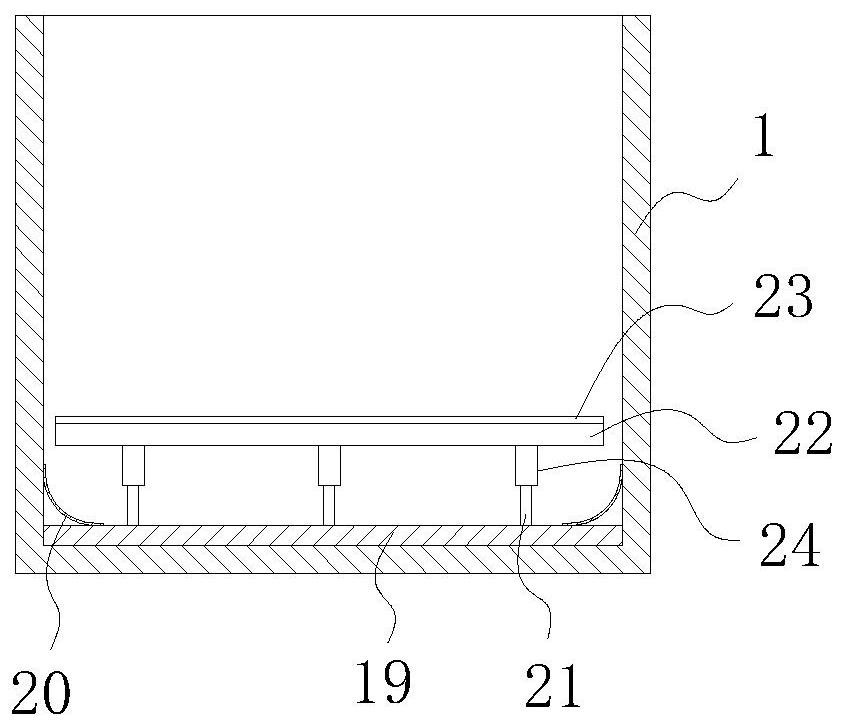

[0040] DETAILED DESCRIPTION: A U-shaped rubber strip 29 is installed between the movable bottom plate 19 and the inner wall of the liquid storage tank 1, which plays the role of movably connecting the movable bottom plate 19 and the liquid storage tank 1, and is convenient for the movable bottom plate 19 to be in the position of the rubber strip 29. It can move within the deformation range, and at the same time, it can prevent rust and other solid debris from falling on the lower side of the movable bottom plate 19. When it is necessary to clean up the sediment deposited at the bottom of the liquid storage tank 1, insert the plug board 6 in the slot 7 until the first A magnet block 4 is aligned with the second magnet block 28, and then under the action of the repulsive force of the first magnet block 4 and the second magnet block 28, the end of the movable bottom plate 19 away from the discharge opening 26 is lifted upwards. 19 is inclined, and then the sediment deposited on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com