Marking control method, terminal device and computer readable storage medium

A control method and marking equipment technology, applied in the field of laser marking, can solve problems such as large operation range and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

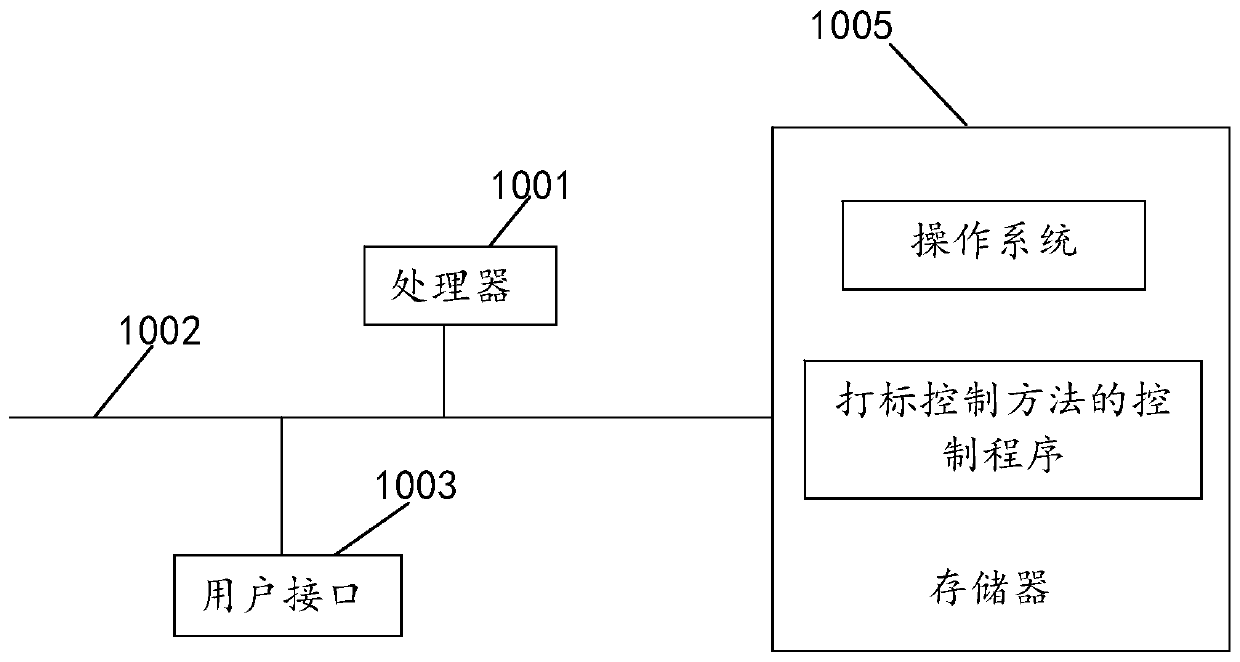

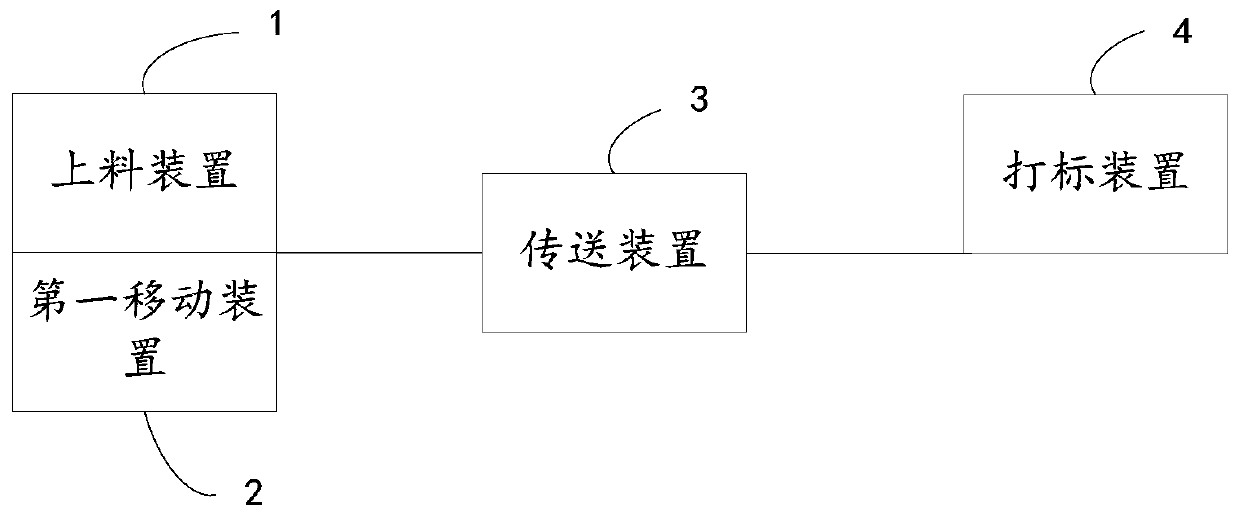

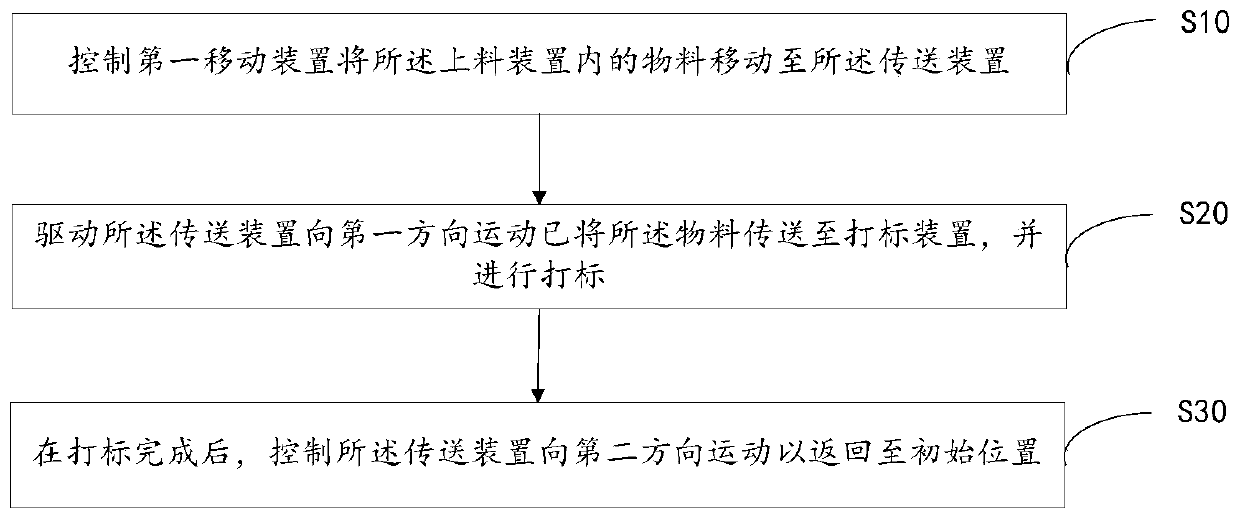

[0079] Refer to figure 2 with image 3 , figure 2 It is a schematic diagram of the hardware composition of the marking device in the first embodiment of the marking control method of the present invention, image 3 It is a flowchart of the first embodiment of the marking control method of the present invention. The marking control method includes the following steps:

[0080] Step S10, controlling the first moving device to move the material in the loading device to the conveying device;

[0081] Step S20, driving the conveying device to move in the first direction to convey the material to the marking device and marking;

[0082] In this embodiment, the conveying device is a track belt, and the track belt has a certain length in space. For ease of description, the spatial position corresponding to the track belt is divided into a front track area, a middle track area, and a rear track area. The loading device and the first moving device are located in the front track area, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com