Patents

Literature

92results about How to "Improve tightening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

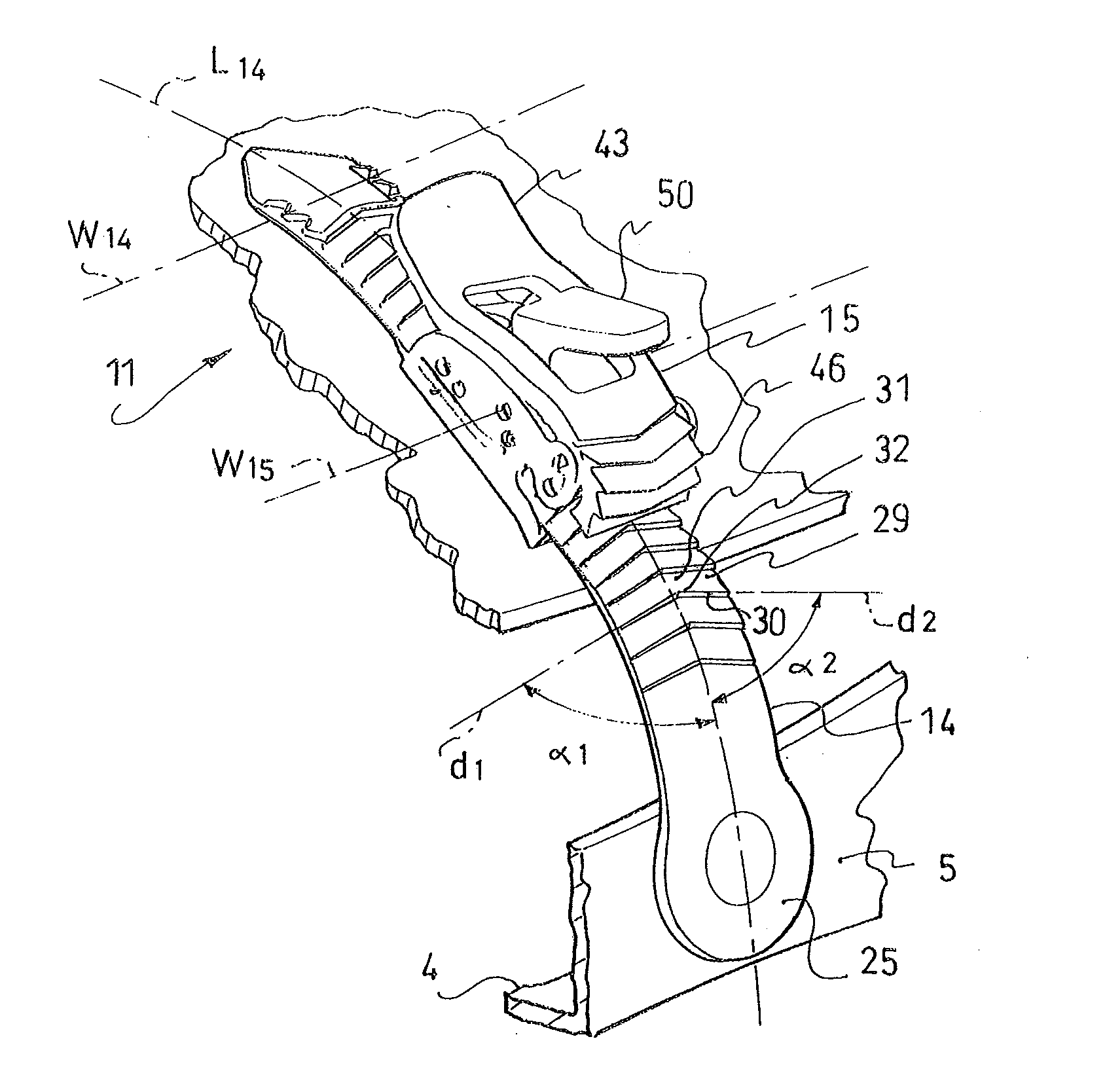

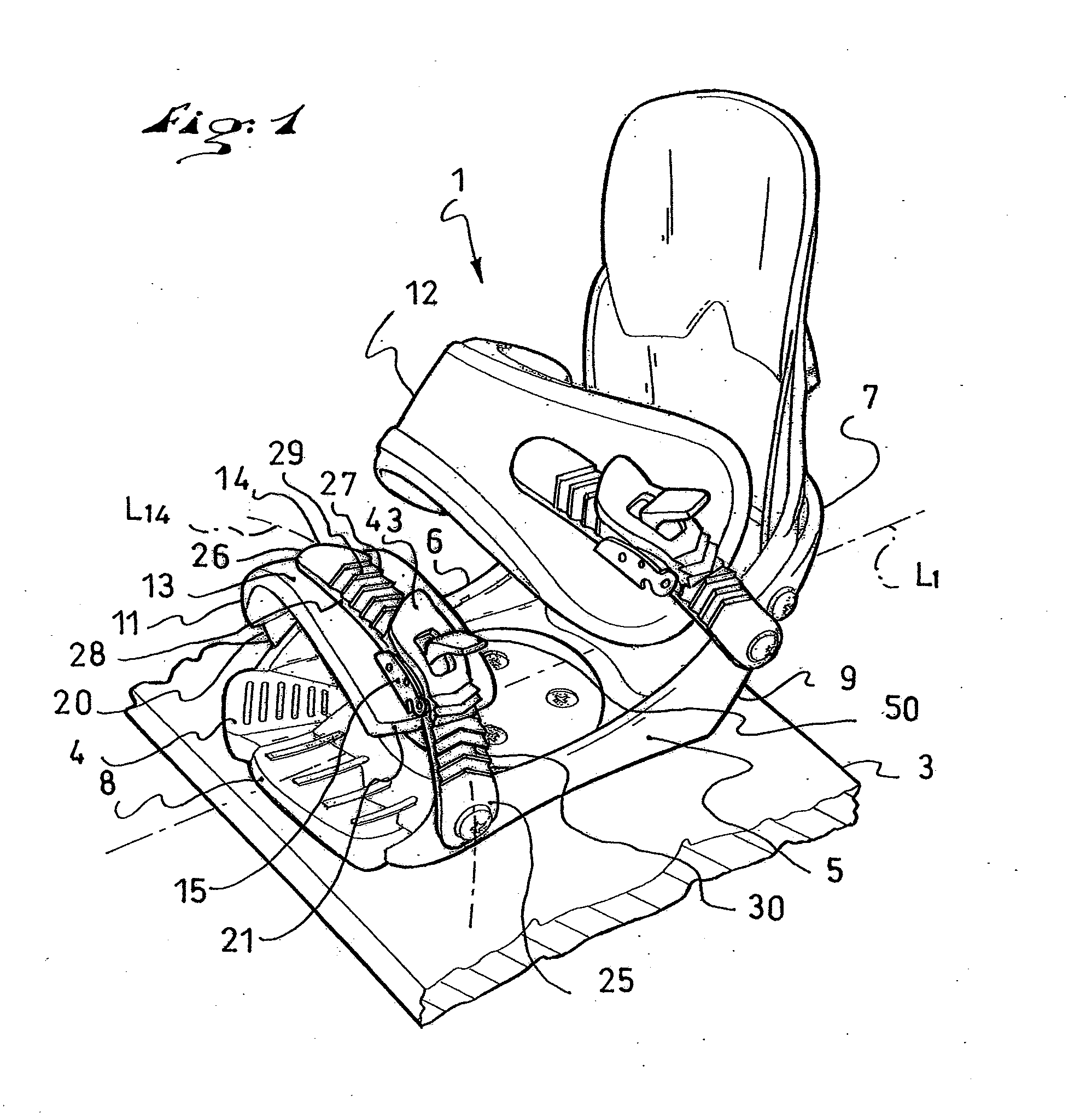

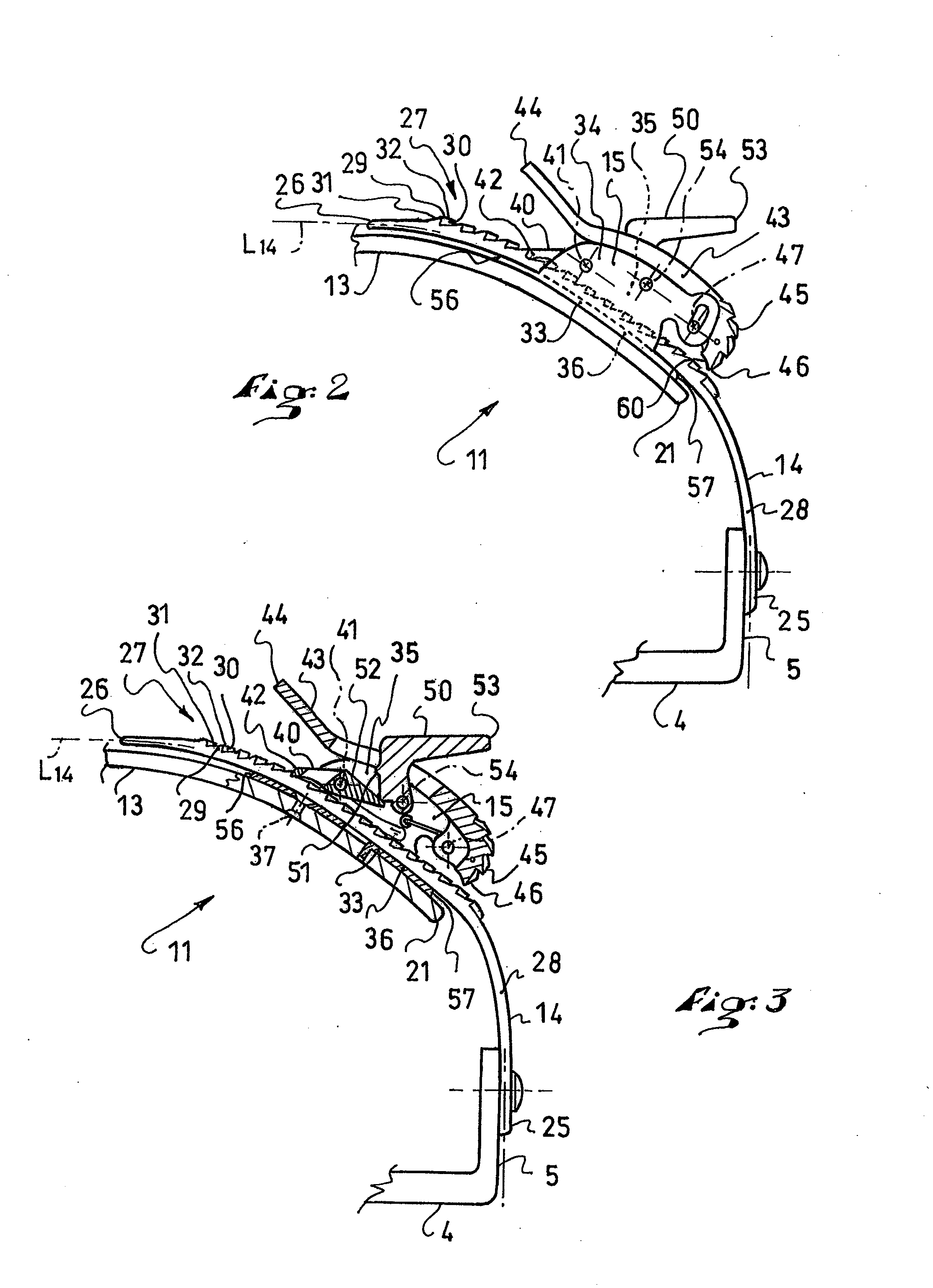

Assembly including a ratchet device and a tightening strap

InactiveUS20100162539A1Reduce wearImproves tighten efficiencySnap fastenersSki bindingsEngineeringSerration

An assembly including a ratchet tightening device and a band. The device includes a base, a driving lever, and a pawl. For at least one tooth of a series of serrations of the band, at least one straight line tangent to the meshing surface of the tooth and parallel to the band, forms, together with the longitudinal direction of the band, an angle that is less than 90 degrees. A driving end of the lever is configured to cooperate with the serrations of the band. A retaining zone of the pawl is configured to cooperate with the serrations of the band.

Owner:SALOMON SA

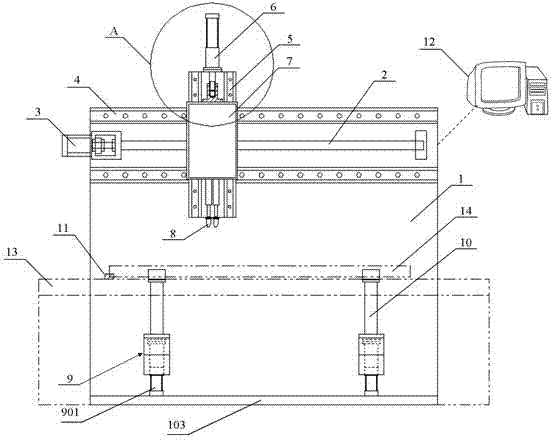

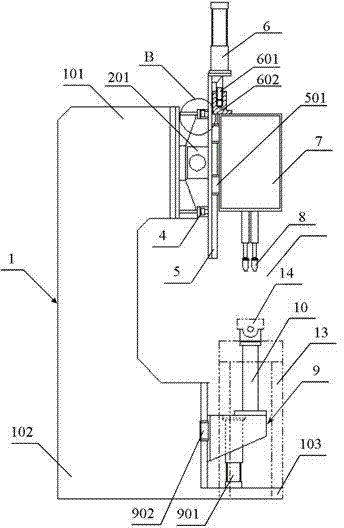

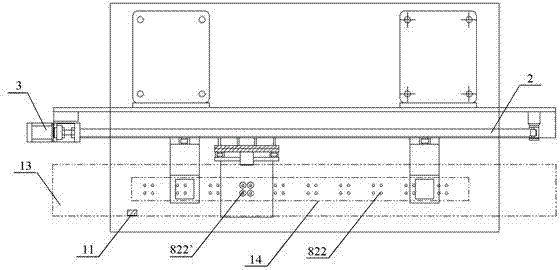

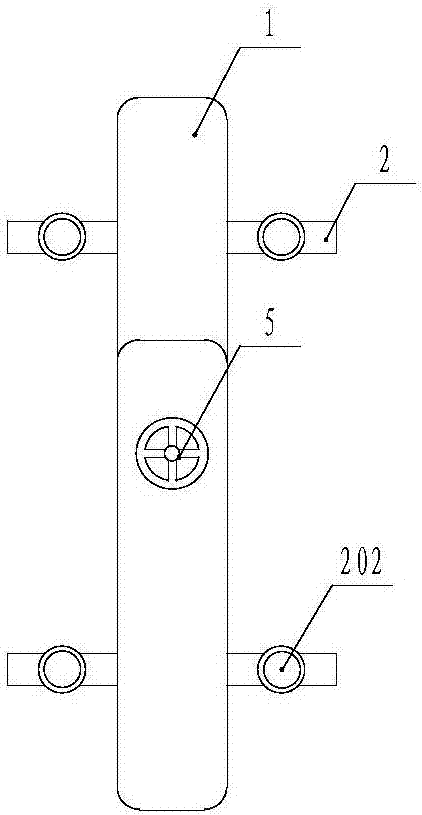

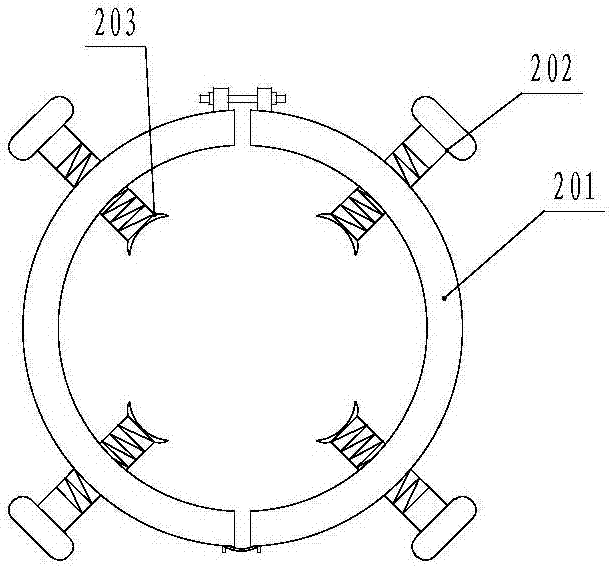

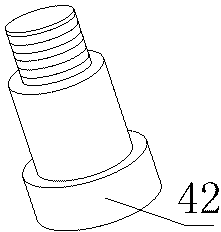

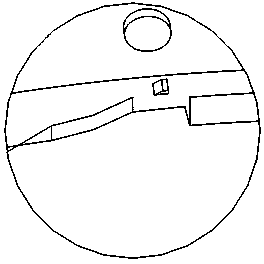

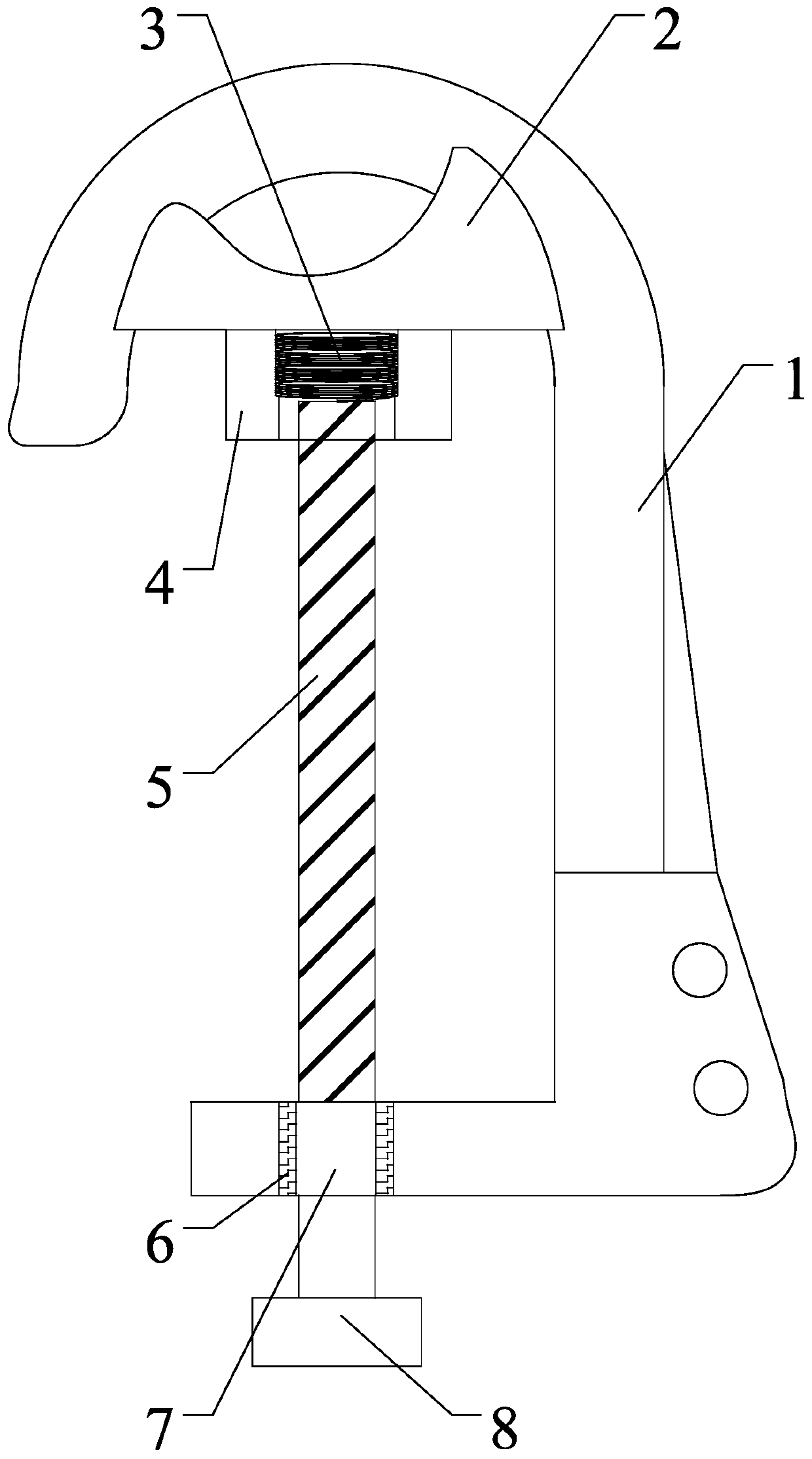

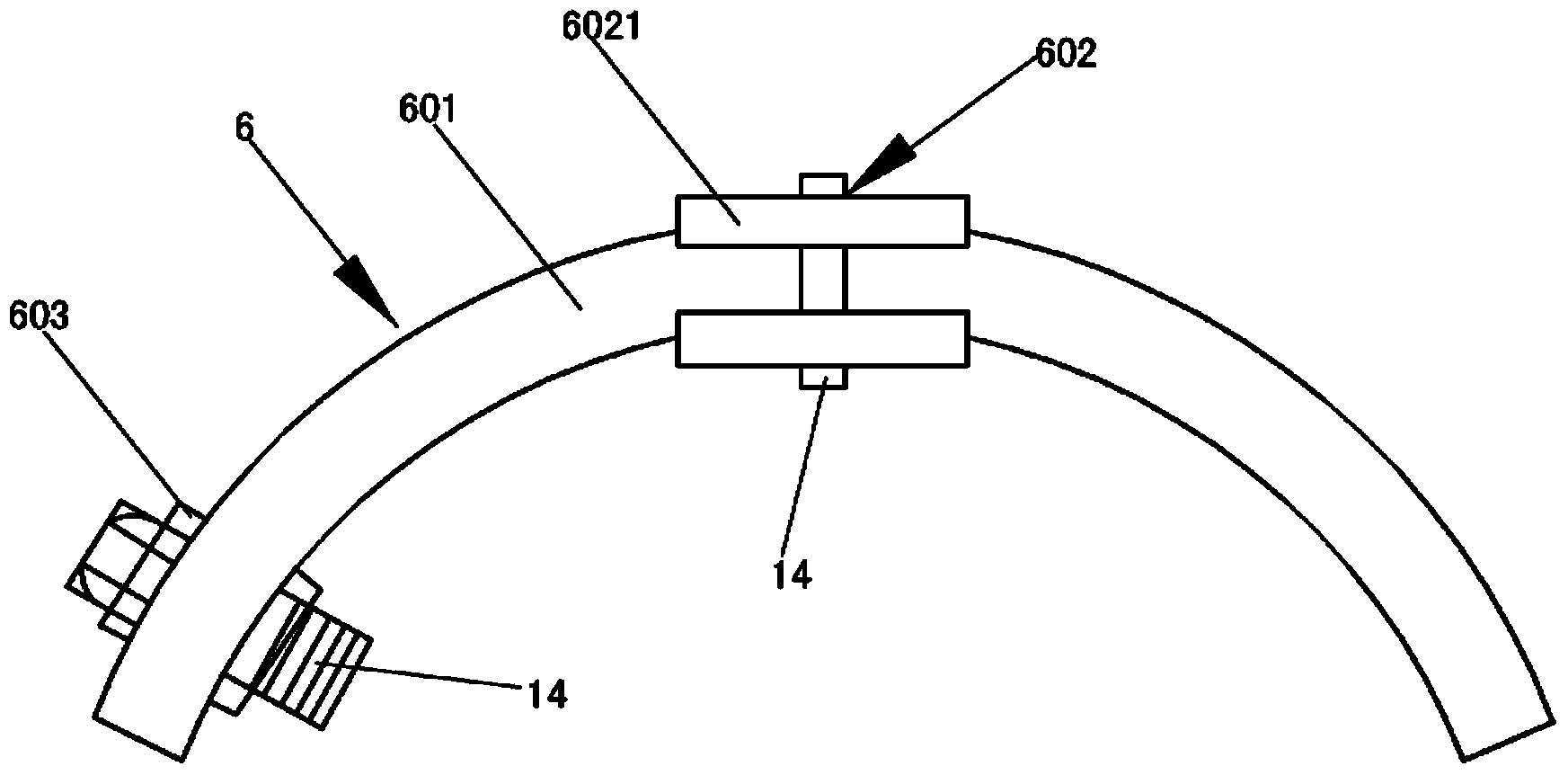

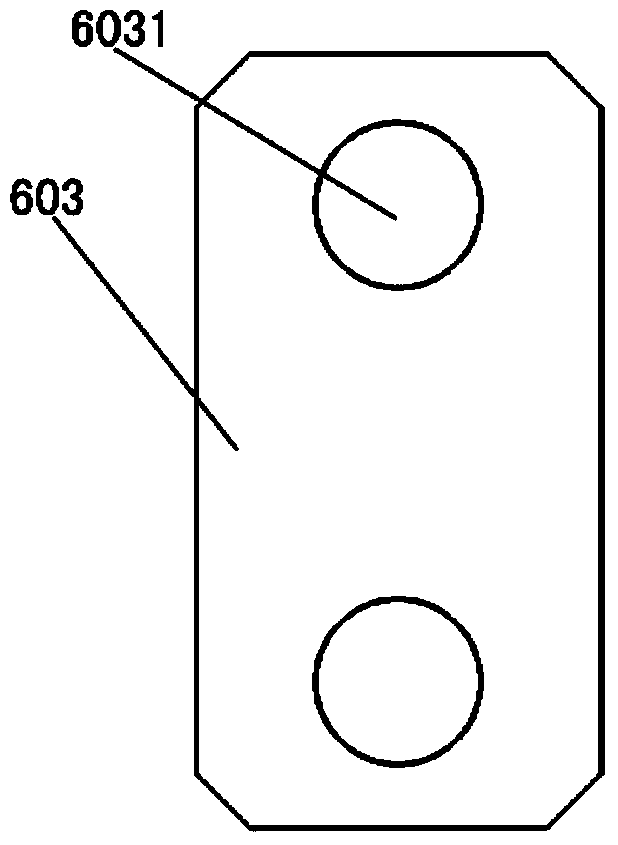

Automatic tightening device for double-end studs and nuts

InactiveCN103495860AAutomatic tighteningRealize automatic hat recognitionMetal working apparatusCircular segmentElectrical and Electronics engineering

The invention discloses an automatic tightening device for double-end studs and nuts. The automatic tightening device comprises an arch-shaped support, a lead screw, transverse guide rails, a motor, longitudinal guide rails, a tightening air cylinder, lifting-up devices and supporting claws, the lead screw and the transverse guide rails are arranged on the upper portion of the support, the motor is connected with the lead screw, the longitudinal guide rails are distributed to be perpendicular to the transverse guide rails, the tightening air cylinder is arranged on the upper portion of the longitudinal guide rails, and the air cylinder shaft of the tightening air cylinder is connected with a tightening mechanism through a connecting piece. The drive rod of the tightening mechanism is connected with a tightening head. The automatic tightening device for the double-end studs and the nuts is used for automatically tightening batched double-end studs or nuts regularly distributed on a narrow workpiece, the reliability, the precision and the interference resisting capacity of a tightening system are ensured, and tightening consistency and tightening efficiency can be improved.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

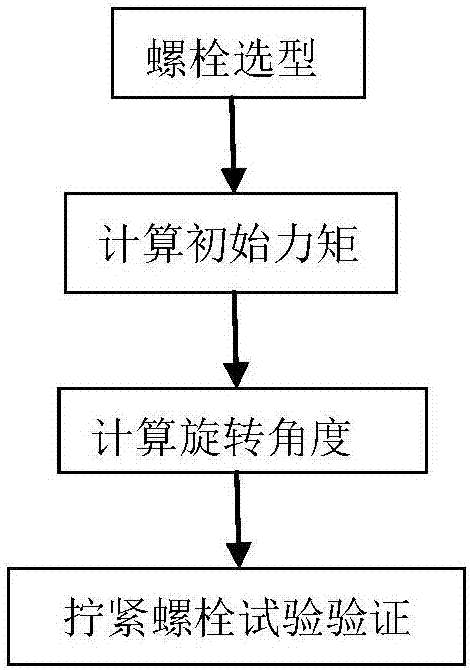

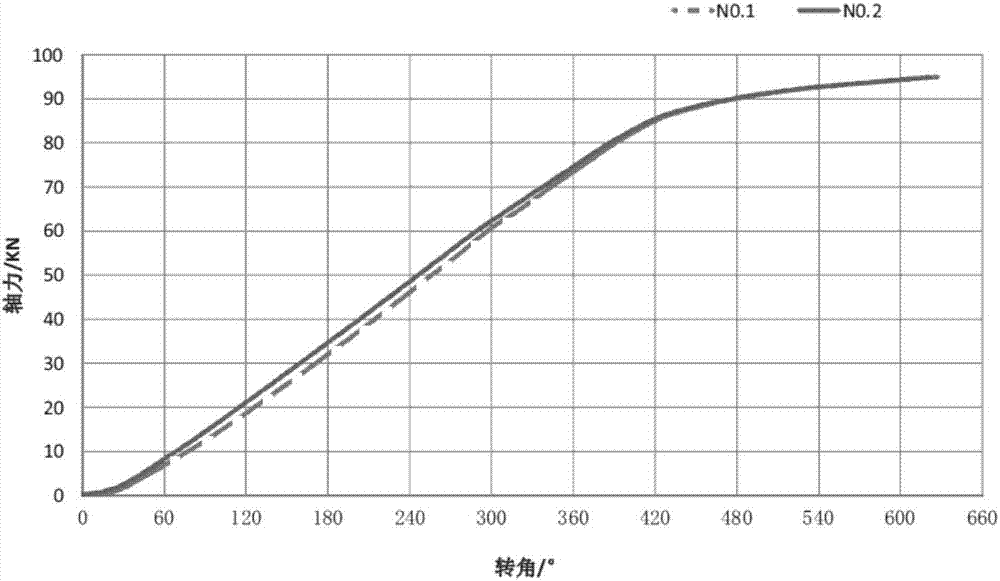

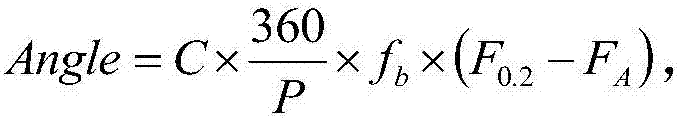

Calculation method for bolt rotation angle method-based tightening process

InactiveCN107341280AImprove tightening efficiencyGuaranteed reliabilityGeometric CADSpecial data processing applicationsRotation methodEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

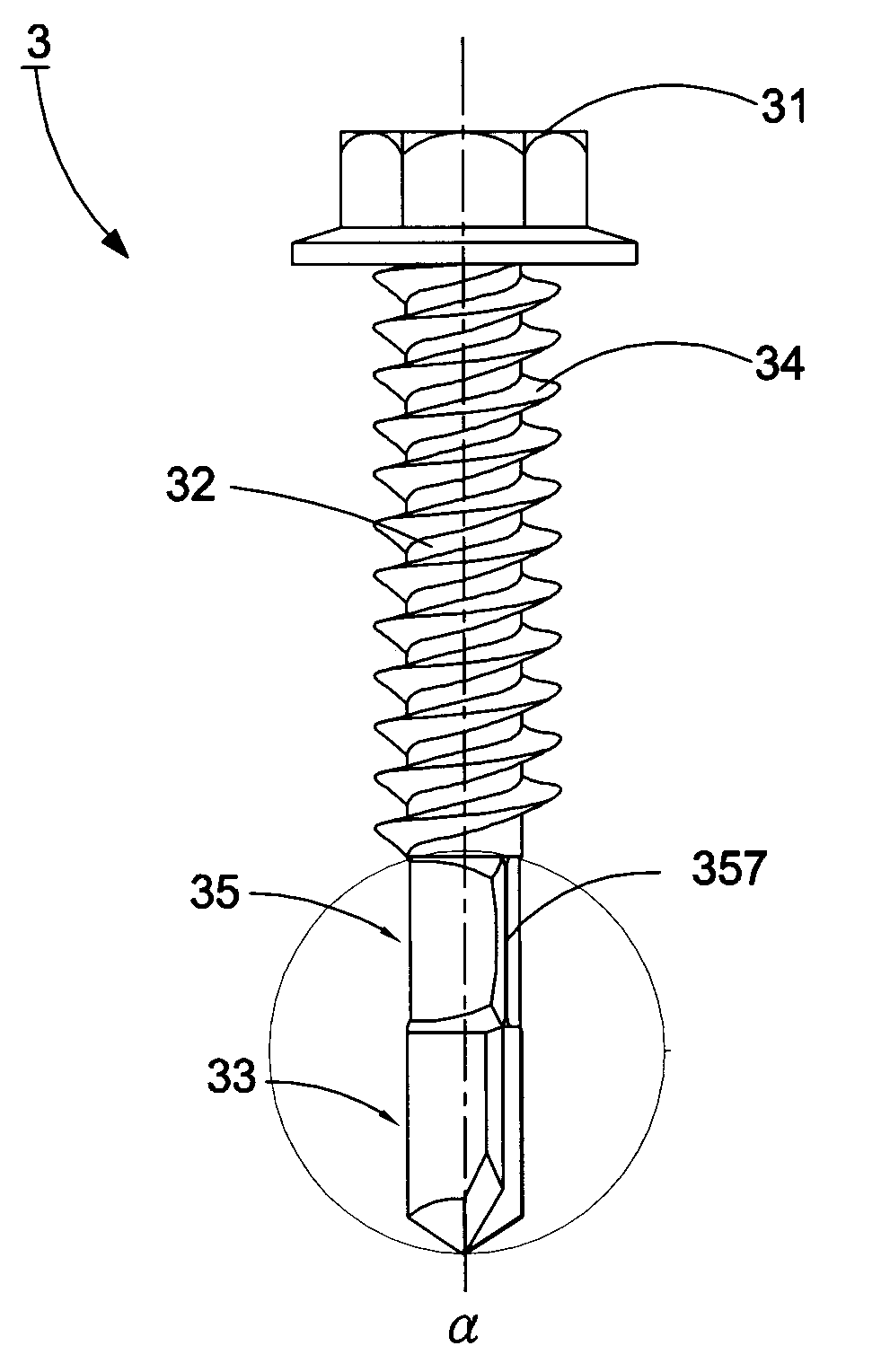

Self-drilling screw with multi-drilling portions

A self-drilling screw with multi-drilling portions mainly comprises a shank, a head and a drilling portion separately disposed on both ends of the shank, and a thread section spiraled on the shank. Wherein, at least one sub-drilling portion formed amid the drilling portion and the thread section further defines a sequence of indentations and prominent areas, and each indentation generates a cutting surface outwardly extended from one side thereof so as to converge the cutting surface with the adjacent prominent area at a cutting ridge. Accordingly, the application of the cutting ridges and the indentations facilitates the drilling portion with the chipping capability and renders an appropriate guidance to redundant debris, thereby efficiently achieving a swift screwing and the lowered screwing resistance to promote the screwing efficiency.

Owner:CHAN LIANG ENTERPRISE

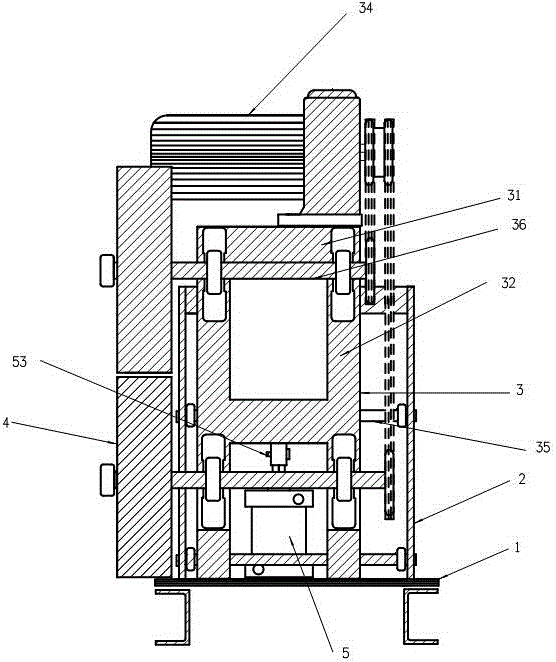

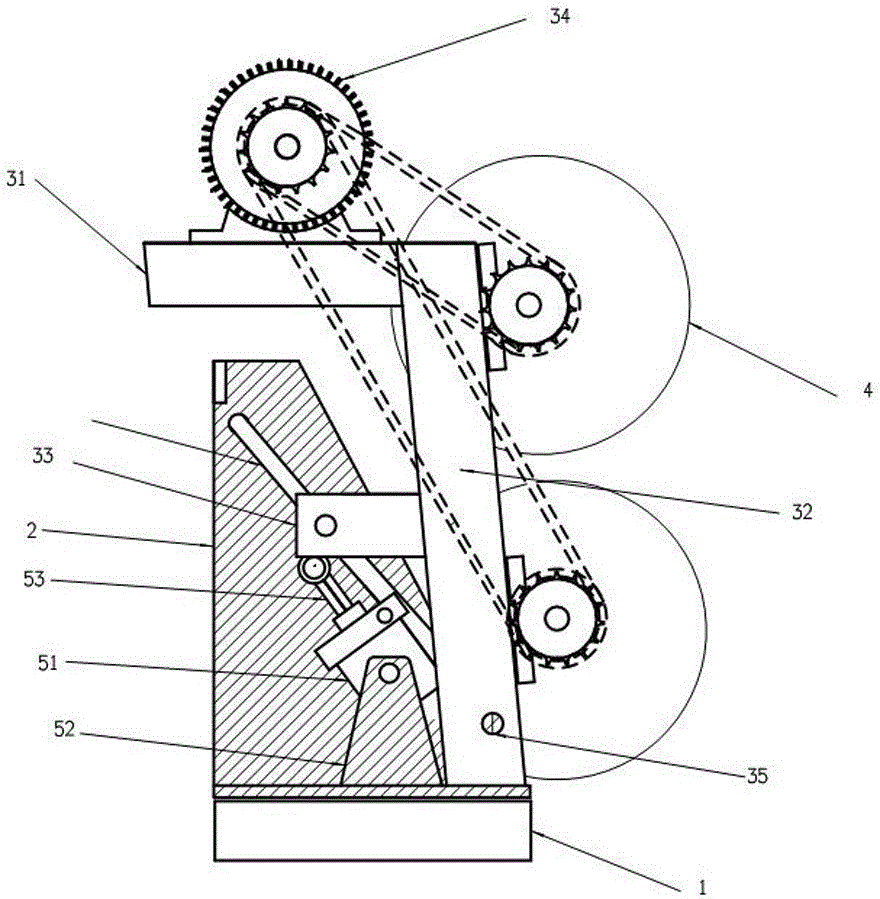

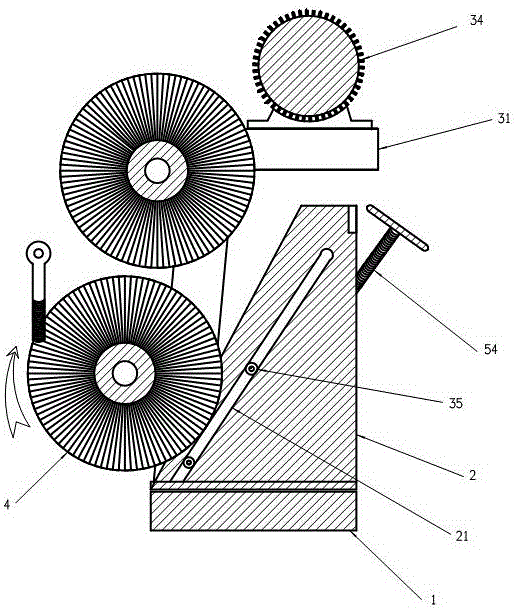

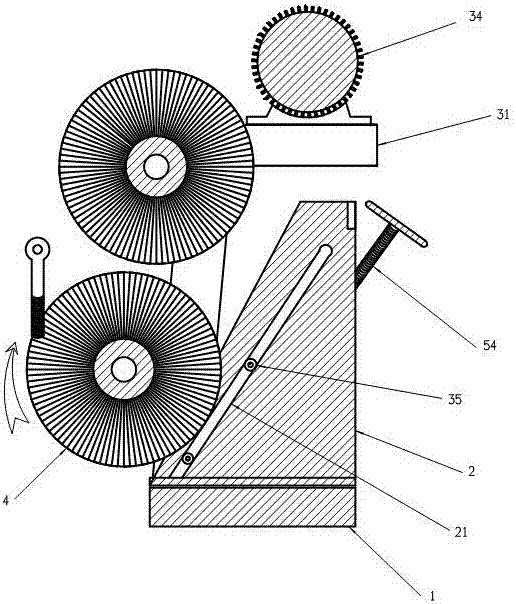

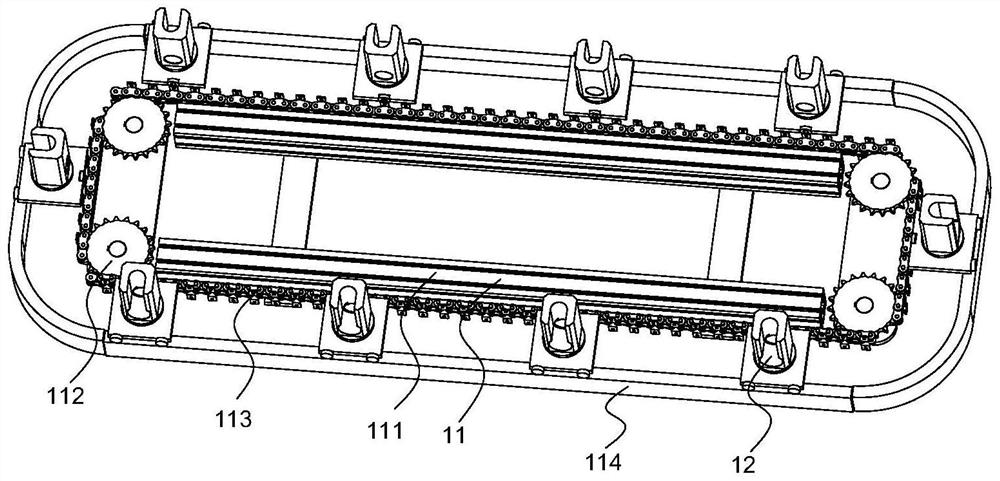

Automatic turnover system of die assembly bolt of pipe pile

InactiveCN106003414AAchieve rotationImprove tightening efficiencyCeramic shaping apparatusDrive motorEngineering

The invention relates to an automatic turnover system of a die assembly bolt of a pipe pile. According to the innovation point, the turnover system comprises a supporting base, guide plates, a mounting rack, nylon brushes and an adjusting mechanism; the automatic turnover system of the die assembly bolt of the pipe pile is mounted on the two sides of a pipe pile die rail; the nylon brush on the lower portion of the turnover system is obliquely located below the die assembly bolt in a vertical state and is closely attached to the die assembly bolt; and when a die assembly procedure is carried out after pipe pile dies are filled with concrete, a drive motor drives the nylon brushes to rotate, the nylon brush on the lower portion enables the die assembly bolt to rotate around the lower pipe pile die and then ascend to be in contact with the nylon brush on the upper portion of the turnover system, and therefore the die assembly bolt is driven by the nylon brush on the upper portion to continue to rotate, 180-degree rotation is achieved, and the die assembly bolt can be screwed down by workers conveniently.

Owner:国鼎(南通)管桩有限公司

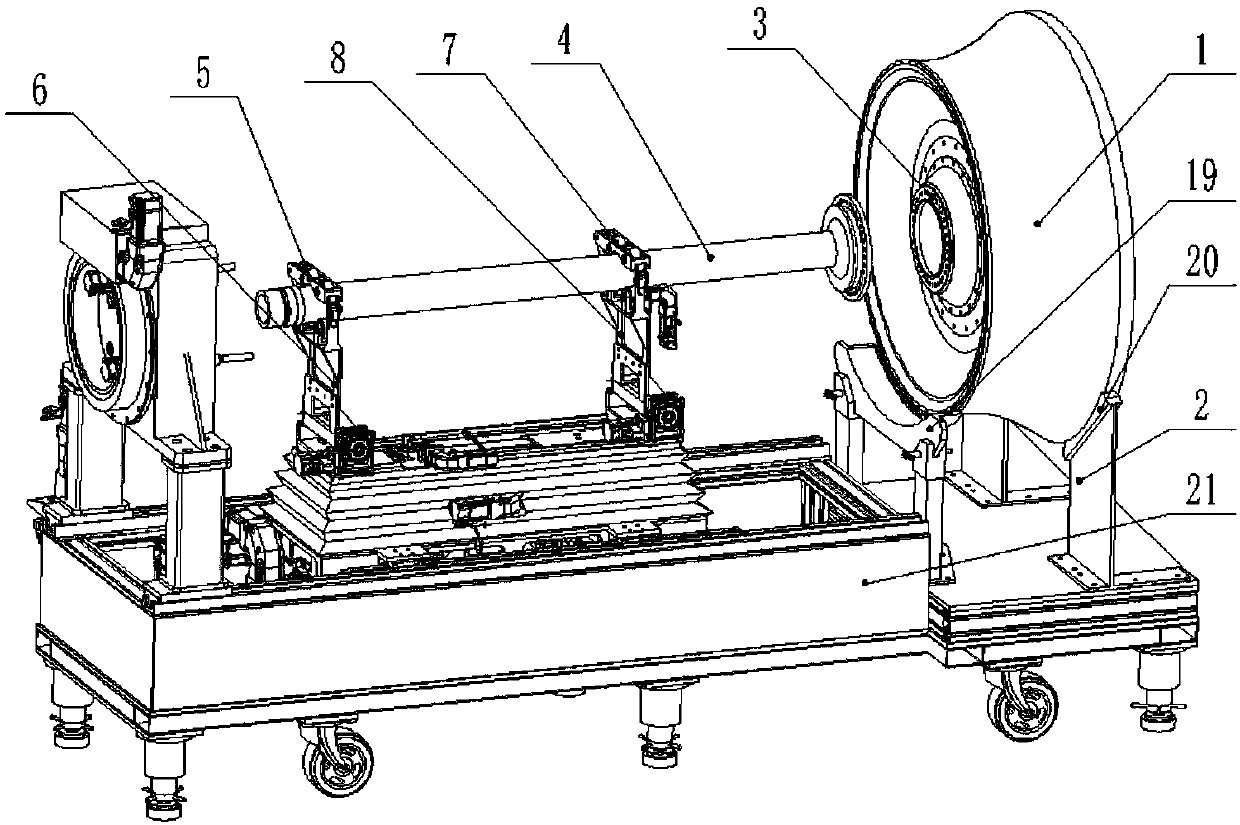

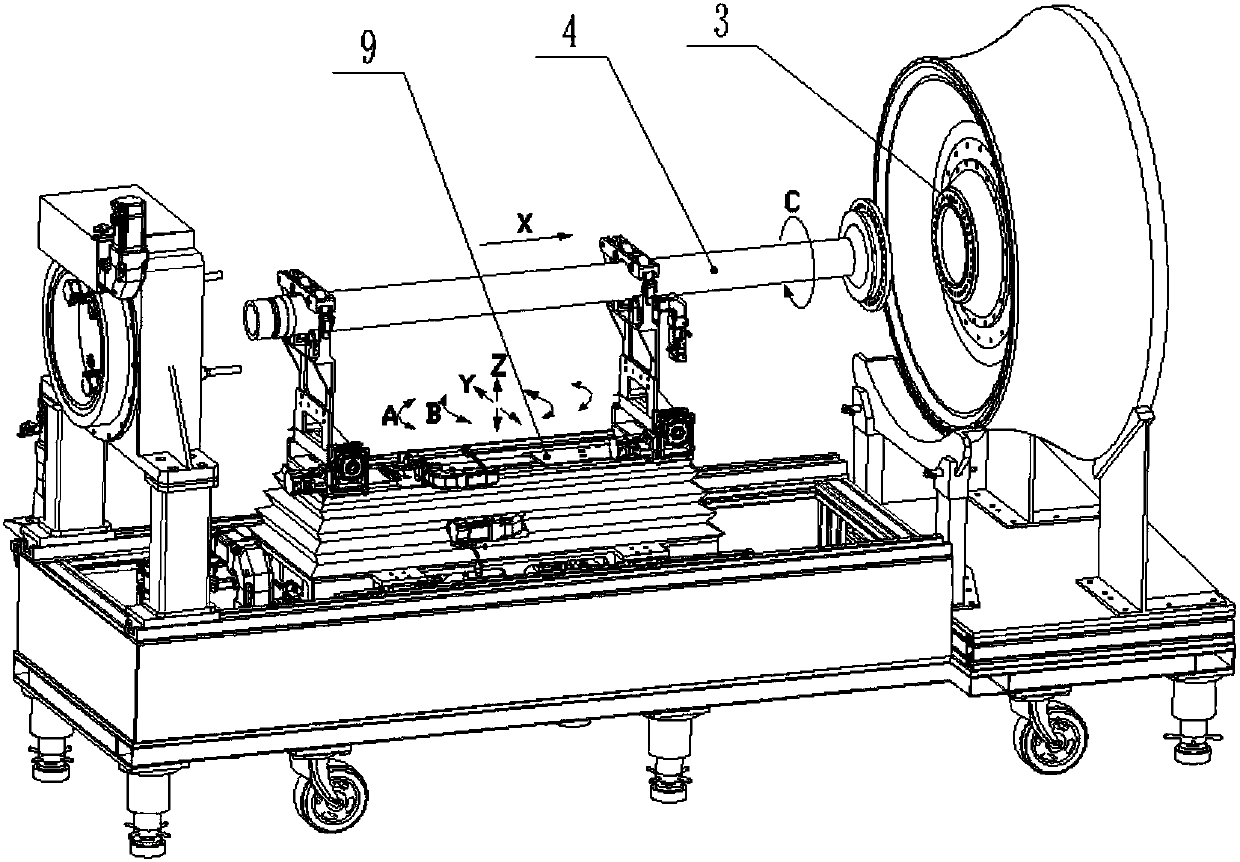

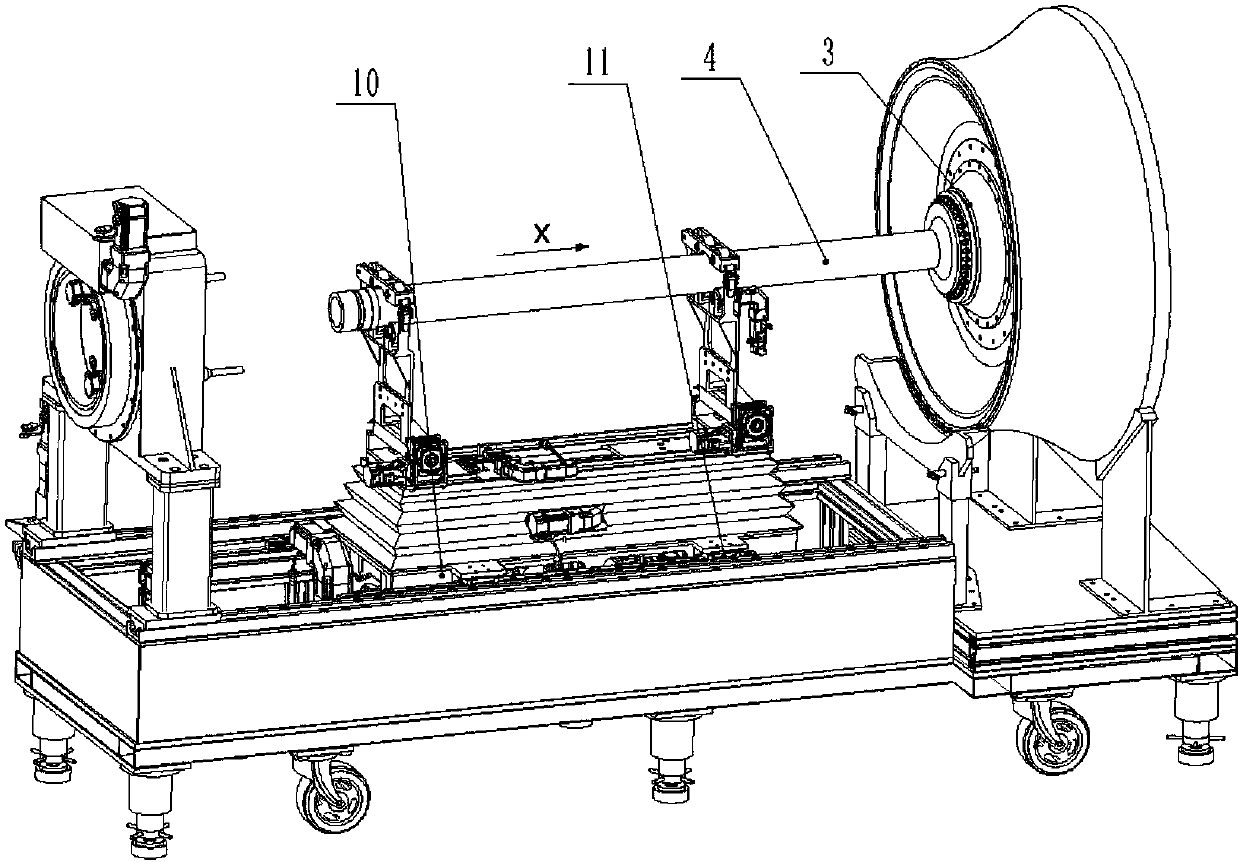

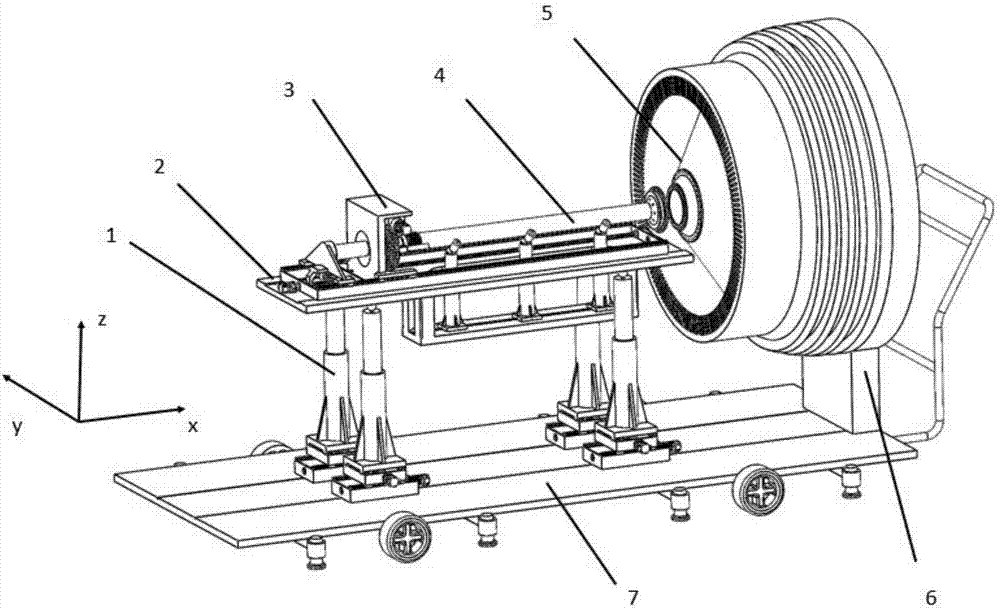

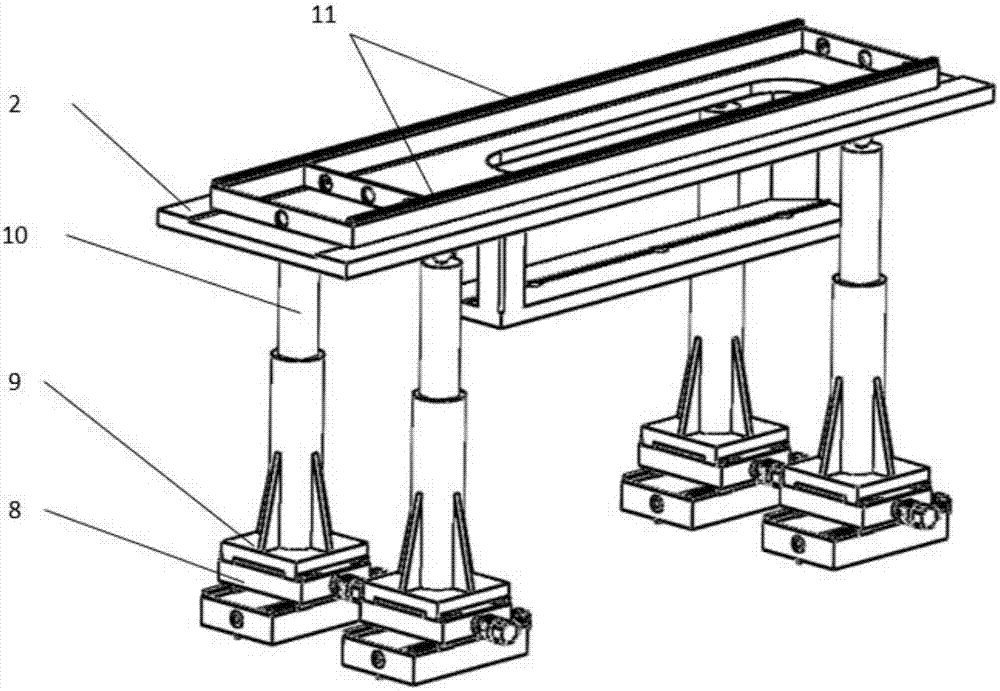

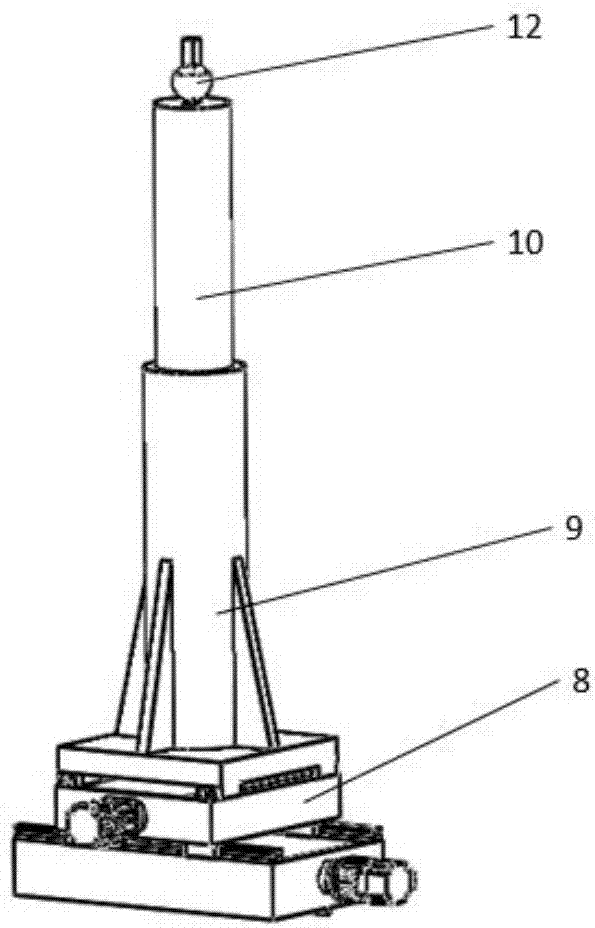

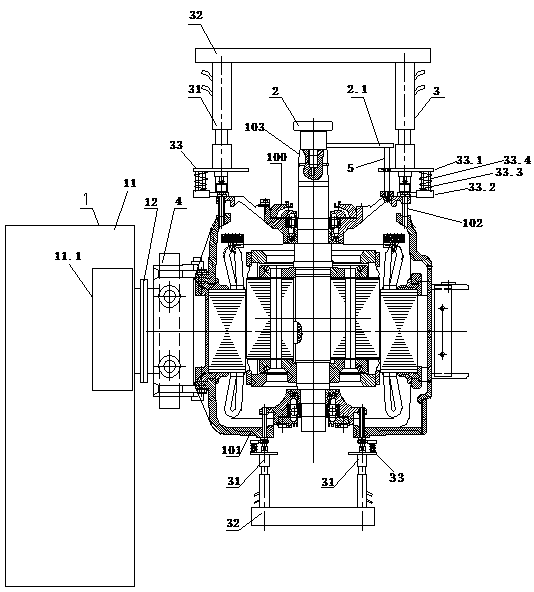

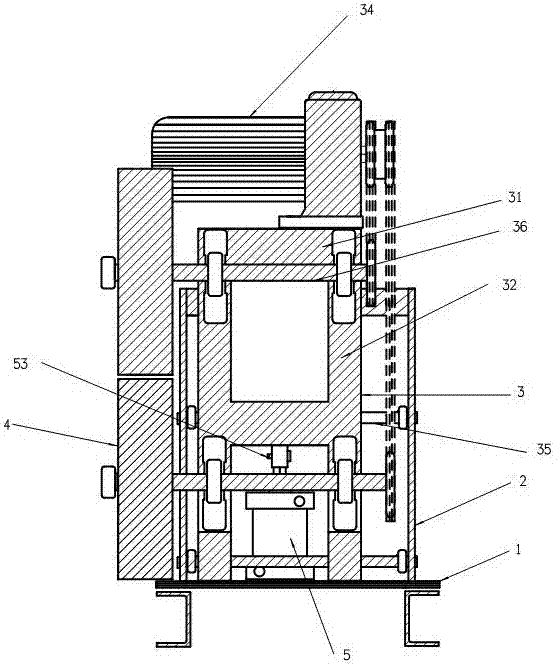

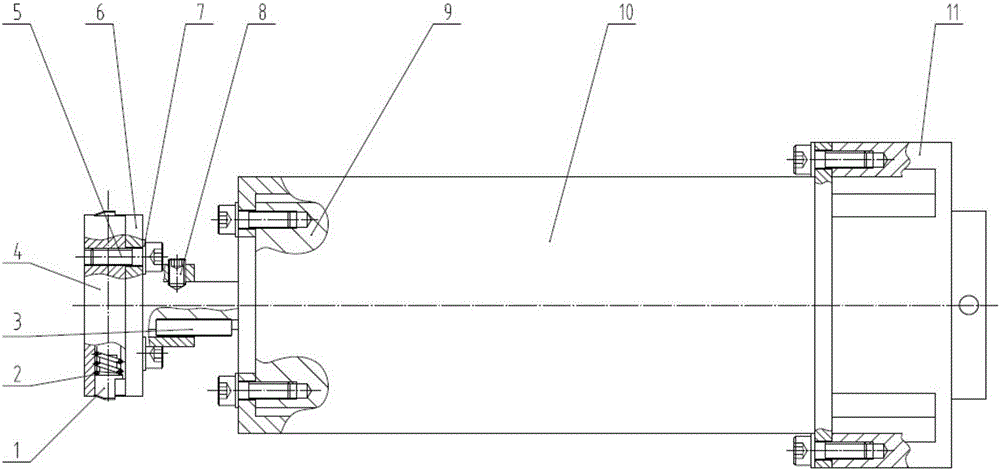

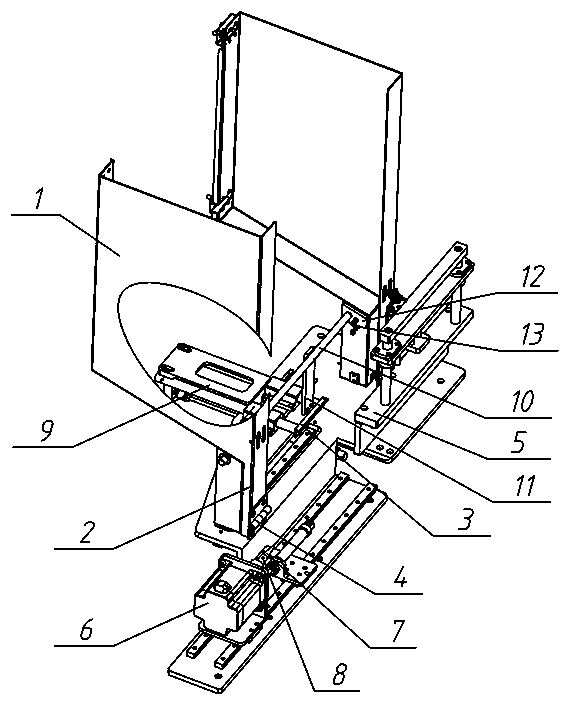

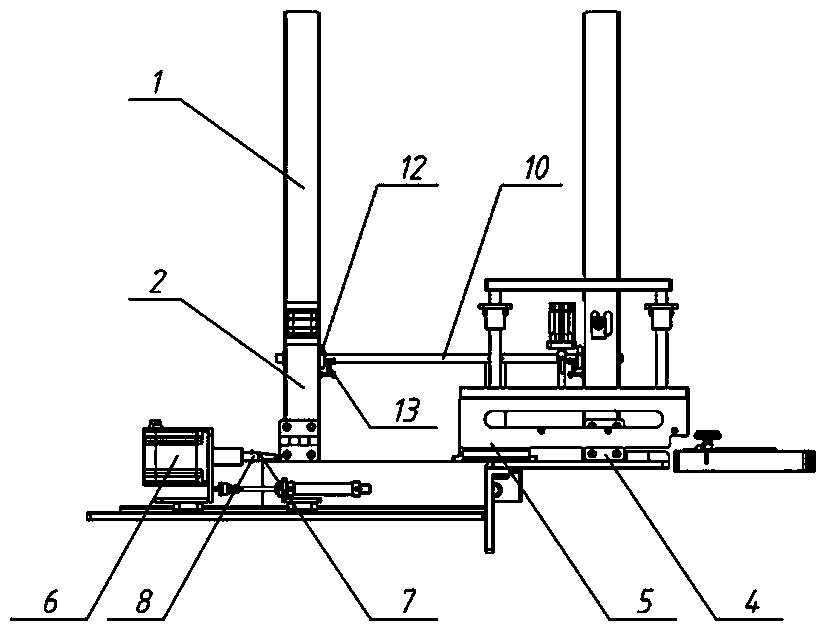

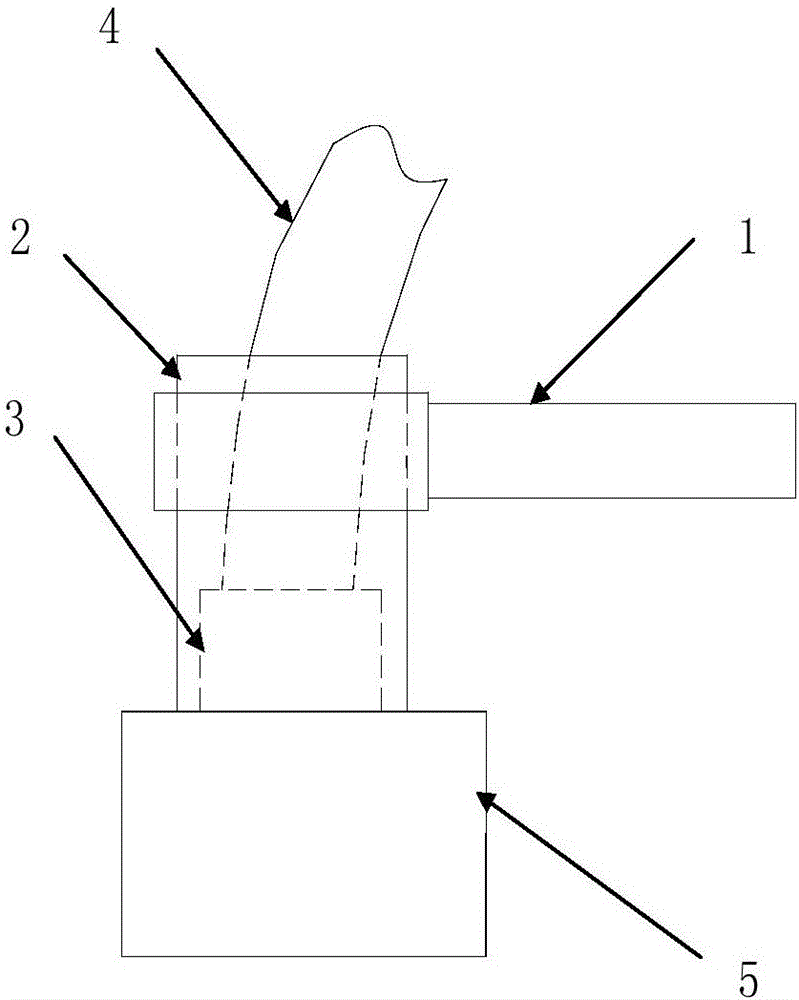

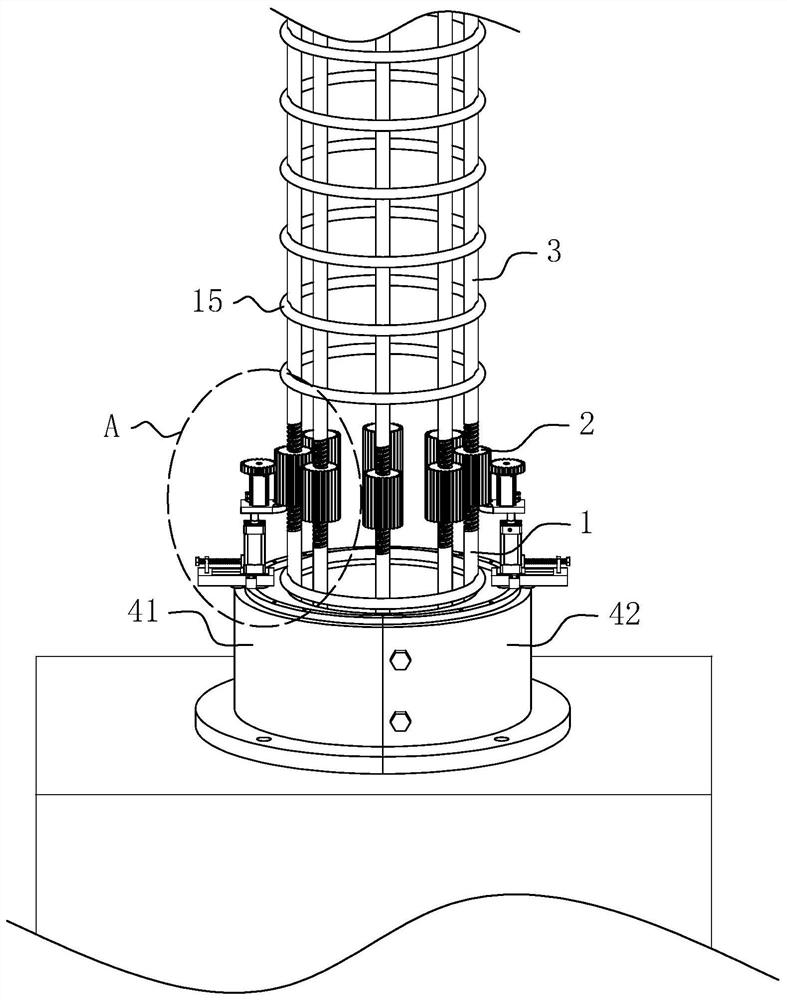

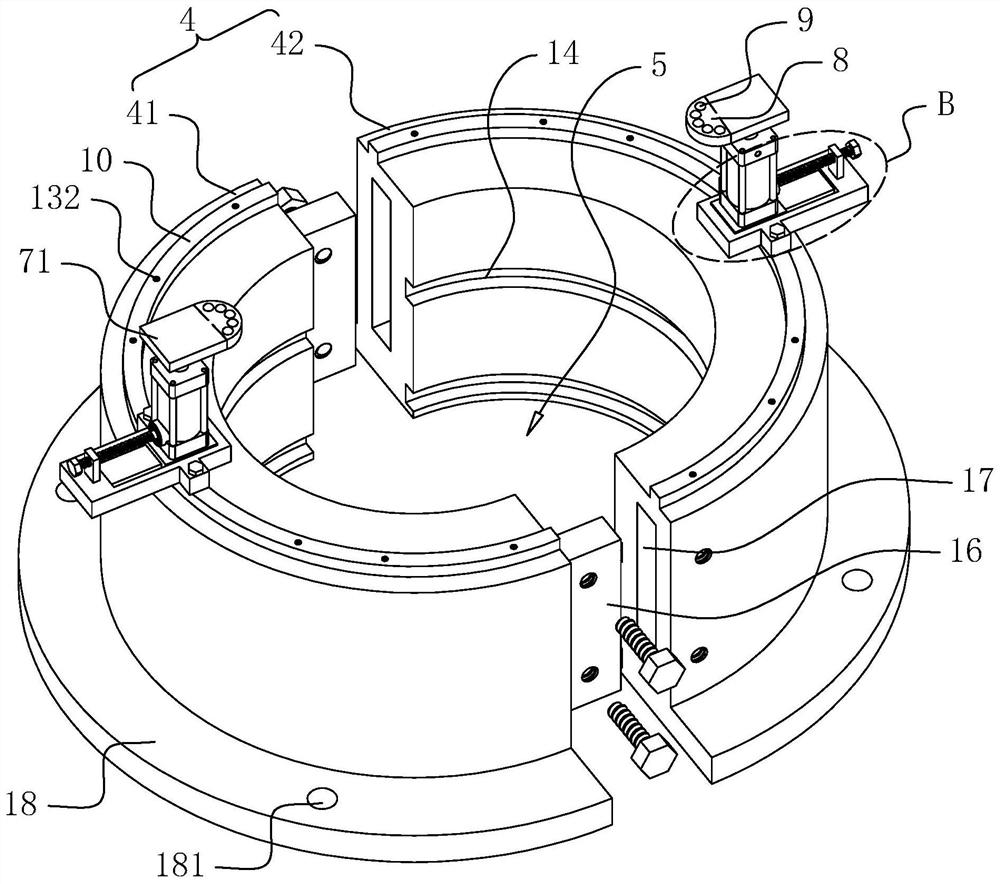

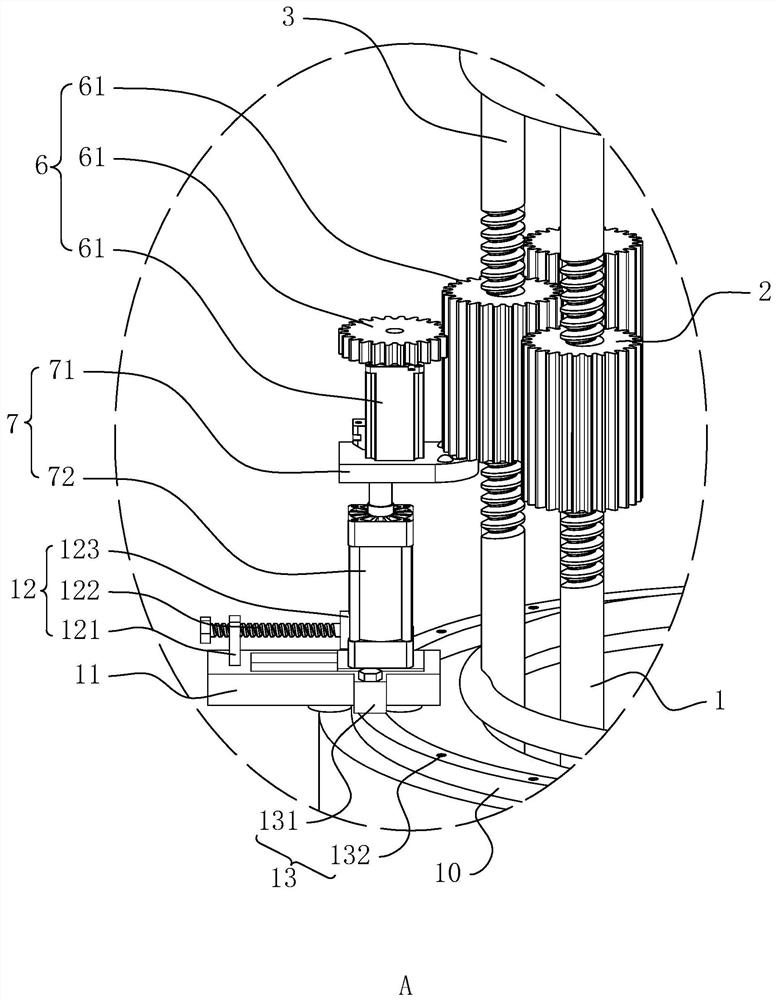

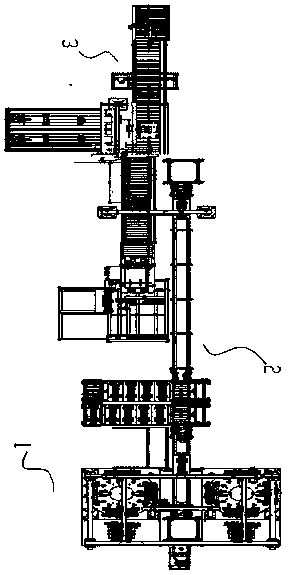

Assembling method for low-pressure turbine shaft-disc assembly of aero-engine

The invention discloses an assembling method for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembling method comprises the following steps that workpieces are installed, the position and the posture of a turbine shaft are adjusted; the turbine shaft butts joint and is pre-installed; an indexable tightening system is fed to a front end operation area; a tightening shaft is tightened; and the indexable tightening system returns back. According to the assembling method for the low-pressure turbine shaft-disc assembly of the aero-engine, an assembly mode that an axis of a low-pressure turbine shaft-disc is horizontal is adopted, the position and the posture of the low-pressure turbine shaft with the large length are adjusted precisely and advantageously in the butt-joint process, centering positioning alignment and end face correct close fitting of the turbine shaft relative to a connecting disc are achieved, and the butt-joint and assembling precision is improved;a turbine shaft position and posture adjusting table is applied, quantitative position and posture adjusting is conducted on the low-pressure turbine shaft through a mechanical way, experiential methods such as traditional manual hanger operating are replaced, manual repeated trial assembly and correction are avoided, the butt-joint efficiency is improved, and assembly consistency requirements ofassemblies are met; and the indexable tightening system is adopted, worker skill requirements and the labor intensity are reduced, and the tightening efficiency is improved.

Owner:DALIAN UNIV OF TECH

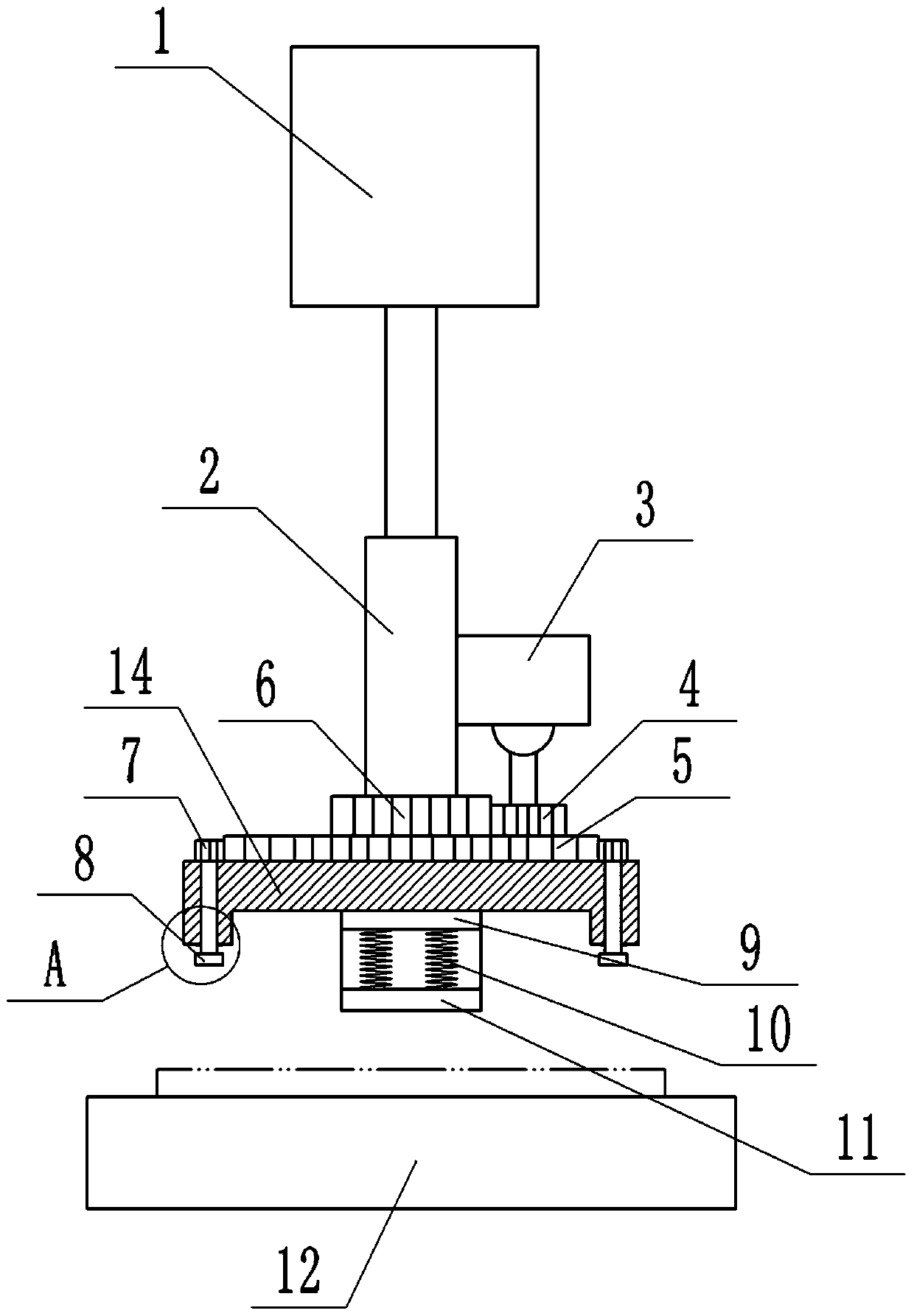

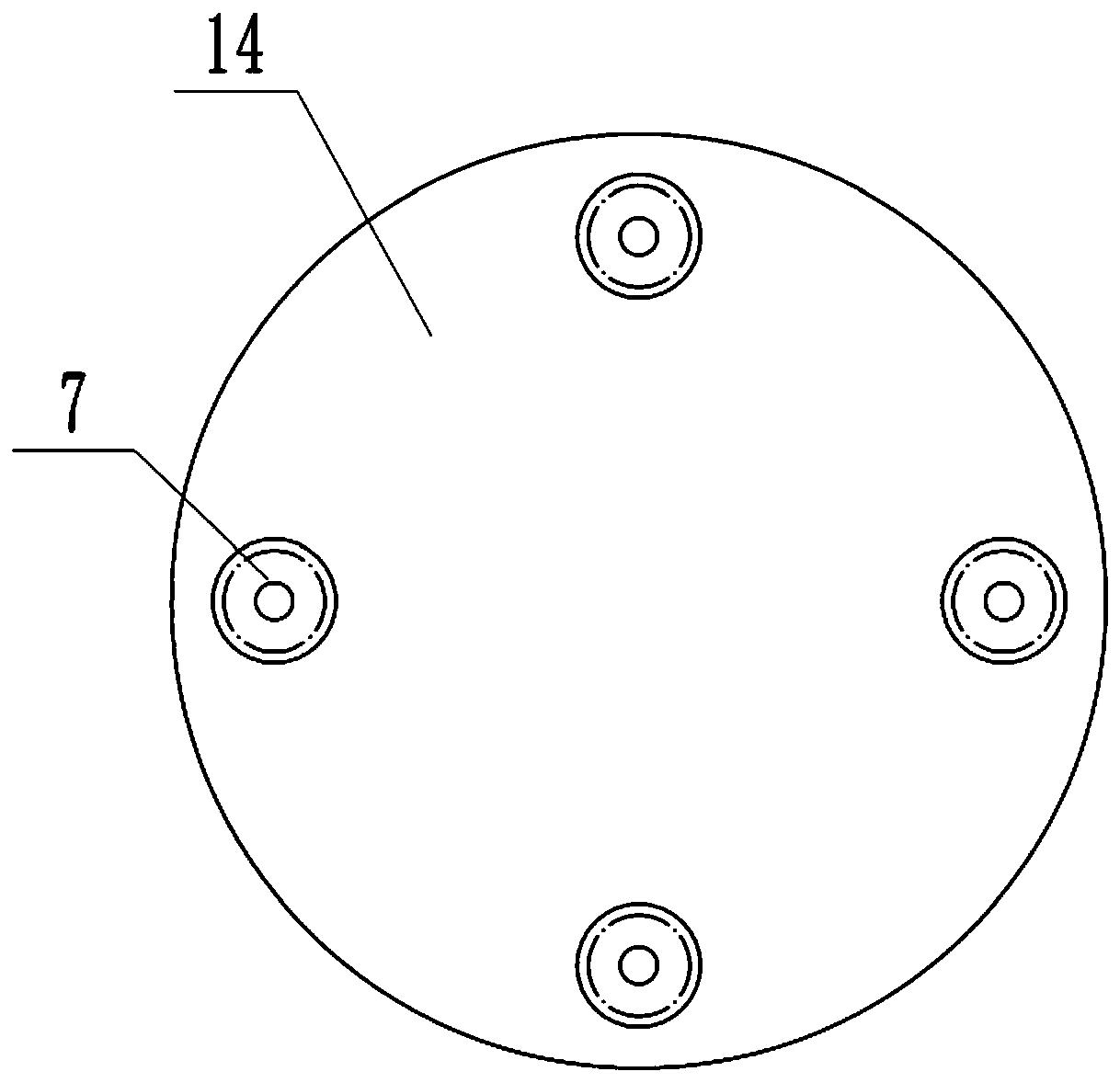

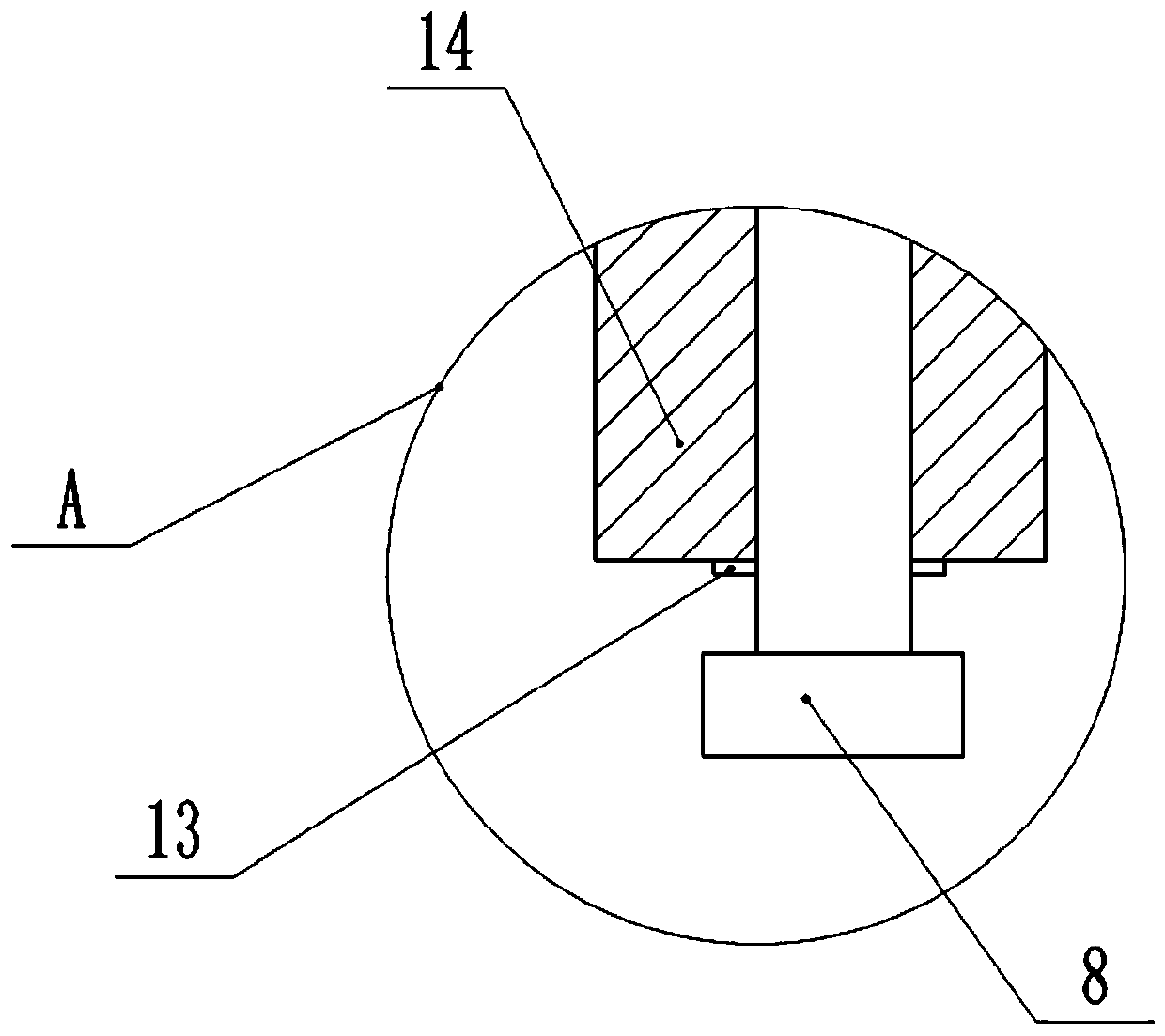

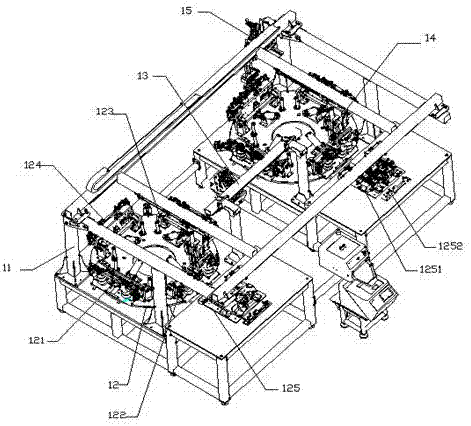

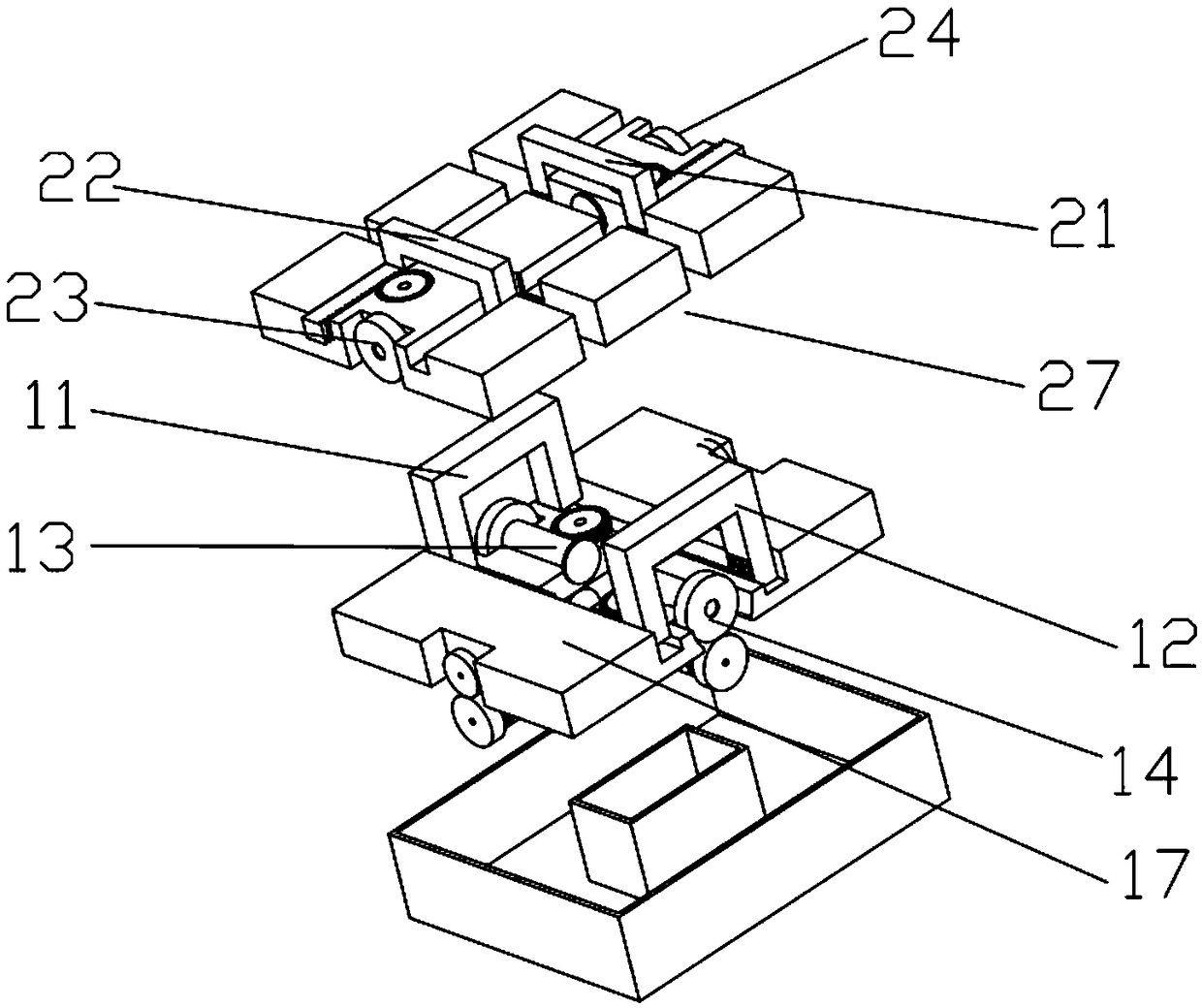

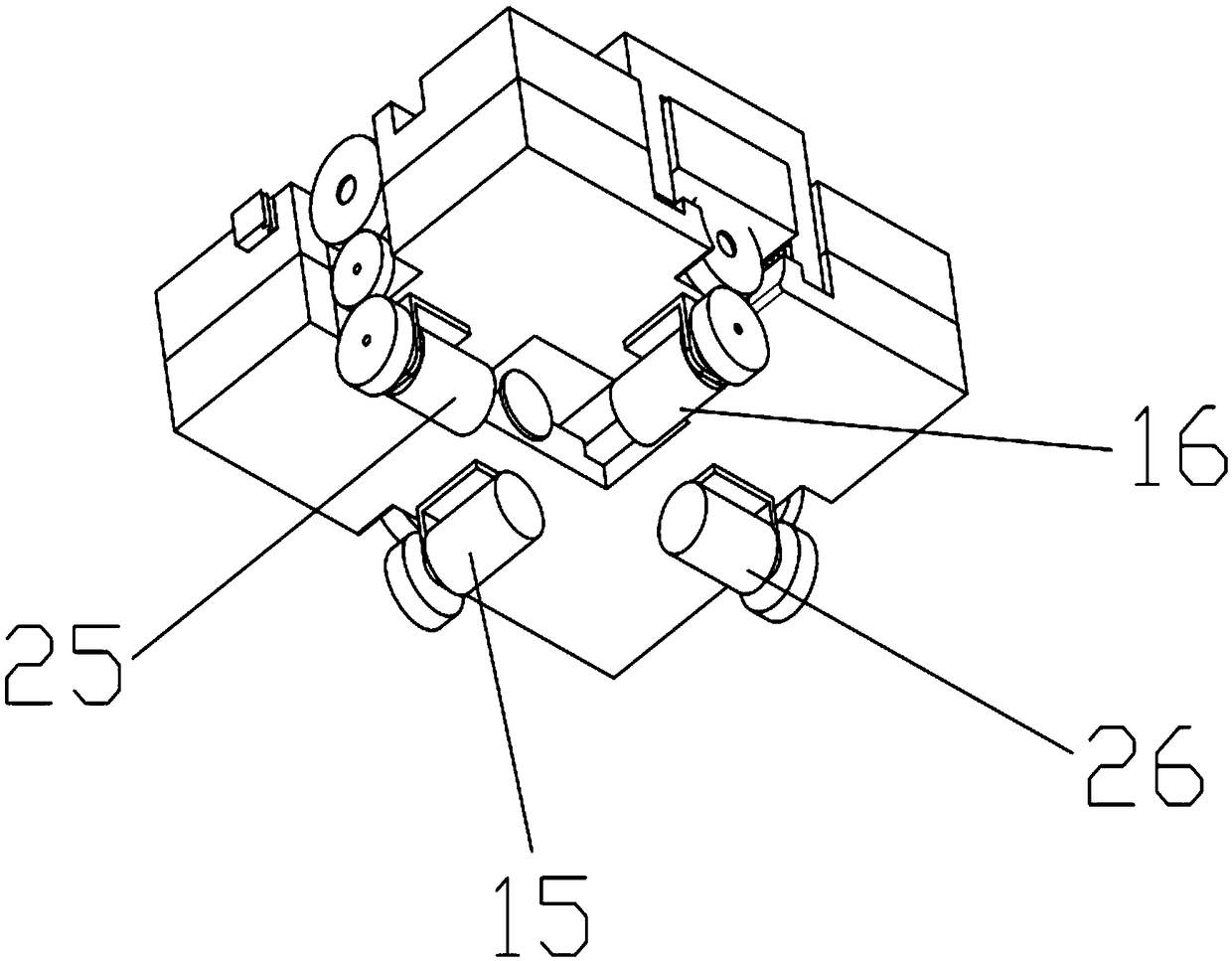

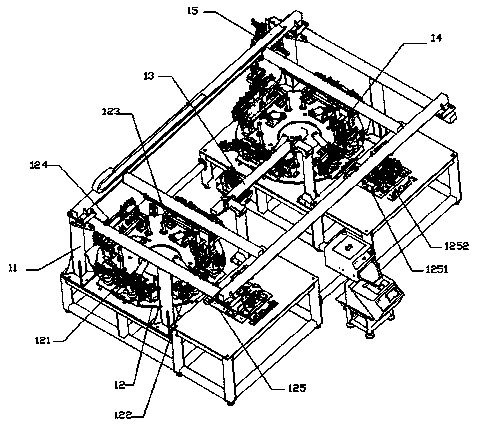

Automatic assembly equipment with collaborative gesture adjustment, collision prevention and tightening functions

ActiveCN107984203AStrong posture adjustment abilityHigh precision in posture adjustmentWork benchesMetal working apparatusButt jointSimulation

The invention discloses automatic assembly equipment with collaborative gesture adjustment, collision prevention and tightening functions. The automatic assembly equipment comprises at least two pairsof POGO column mechanisms arranged on a base through two-dimensional motion mechanisms, and gesture adjustment movable platforms and screw tightening devices arranged on the POGO column mechanisms, wherein parts to be assembled are arranged in the screw tightening devices, and are aligned to fixed parts. The automatic assembly equipment has the advantages of high gesture adjustment motion capacity, high gesture adjustment motion precision, high bolt tightening efficiency and full automation, and can realize precise butt joint of the parts and bolt fastening. The automatic assembly equipment greatly reduces the part assembly difficulty and potential safety hazards, improves the butt joint efficiency, and meets the assembly process requirements.

Owner:SHANGHAI JIAO TONG UNIV

Expansion device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

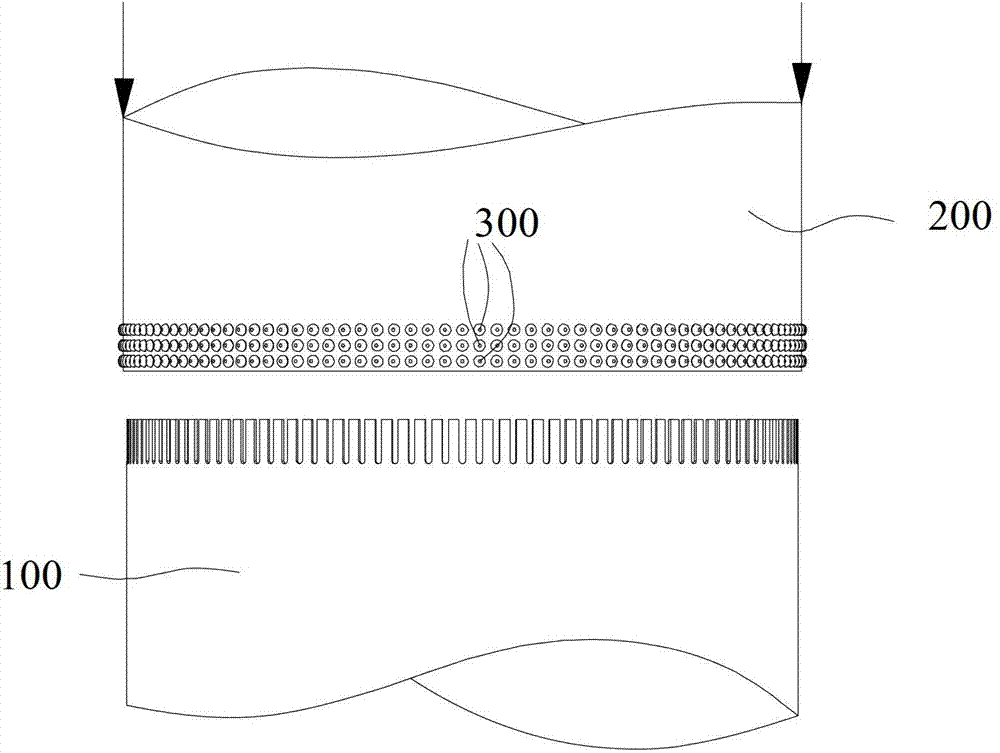

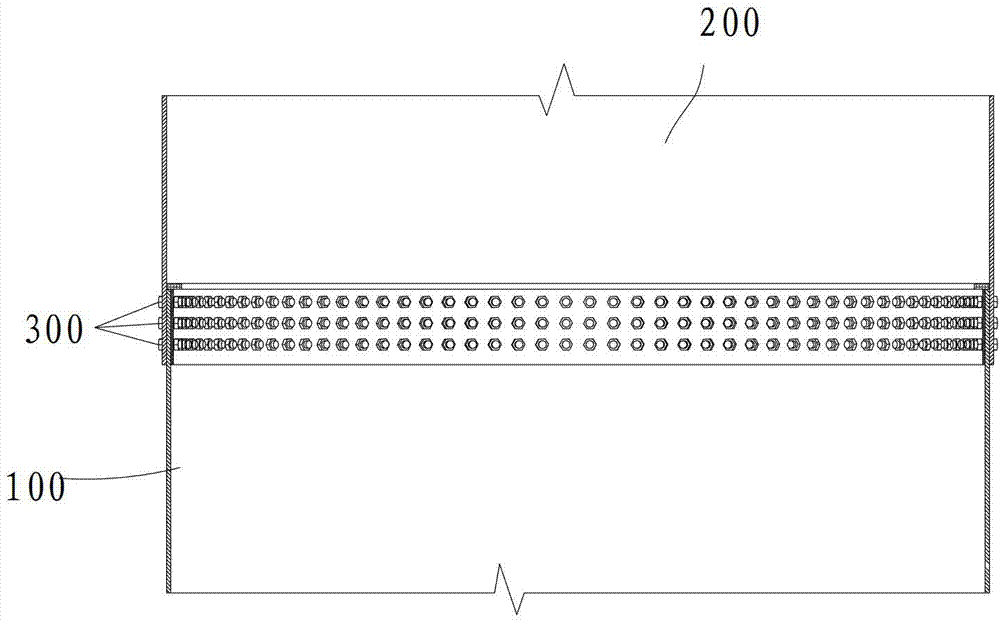

Motor stator-rotor co-assembly device and method

PendingCN110336428ACombined to achieveIncrease the level of automationManufacturing stator/rotor bodiesCentering/balancing rotorsInterference fitEngineering

The invention discloses a motor stator-rotor co-assembly device and method. The motor stator-rotor co-assembly device comprises a stator displacement device for driving a stator to rotate to change the axial direction of the stator, a grabbing hanger for hanging a rotor and a bolt automatic tightening device for automatically tightening a connecting bolt between a rotor end cover and a stator stock, wherein the stator displacement device is connected with the stator stock; the grabbing hanger is connected with a rotor shaft extending end; the bolt automatic tightening device is in matched connection with the connecting bolt; the rotor is assembled to the stator along with tightening of the connecting bolt; and the rotor end cover is in interference fit with the stator stock along with tightening of the connecting bolt. Automatic transposition of the stator and positioning after transposition can be realized, the stator and the rotor are ensured to complete vertical co-assembly along avertical direction, when the connecting bolt is completely tightened, stator-rotor co-assembly is realized, interference fit assembly between the rotor end cover and the stator stock is also realized,and the stator-rotor co-assembly automation level is improved, and the universality and the practicability are high.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

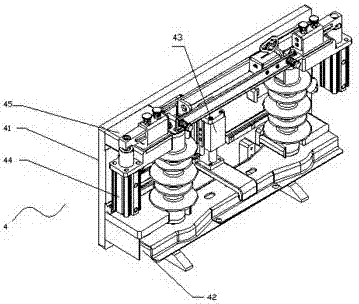

Clutch press fitting device

ActiveCN110977397ARealize press fitImprove assembly efficiencyMetal working apparatusHydraulic cylinderGear wheel

The invention belongs to the field of clutch assembly and relates to a clutch press fitting device. The device comprises a placing table, a pressing head located above the placing table and a hydraulic cylinder used for driving the pressing head to vertically move; the pressing head comprises a fixing part and an extruding part; an elastic piece is connected between the extruding part and the fixing part; the extruding part is located below the fixing part; a fixing disc is fixedly connected to the fixing part; a plurality of tightening gears are distributed on the circumference of the fixingdisc; the tightening gears are rotationally connected to the fixing disc; tightening blocks detachably connected with the head of bolts are fixedly connected to the tightening gears; and the tightening blocks are located below the fixing disc; a first gear is rotationally connected to the fixing disc; the multiple tightening gears are engaged with the first gear at the same time; and the clutch press fitting device further comprises a driving mechanism used for driving the first gear to rotate. According to the clutch press fitting device provided by the technical schemes of the invention, thebolts can be automatically screwed into a clutch in a press fitting process.

Owner:贵州友擘机械制造有限公司

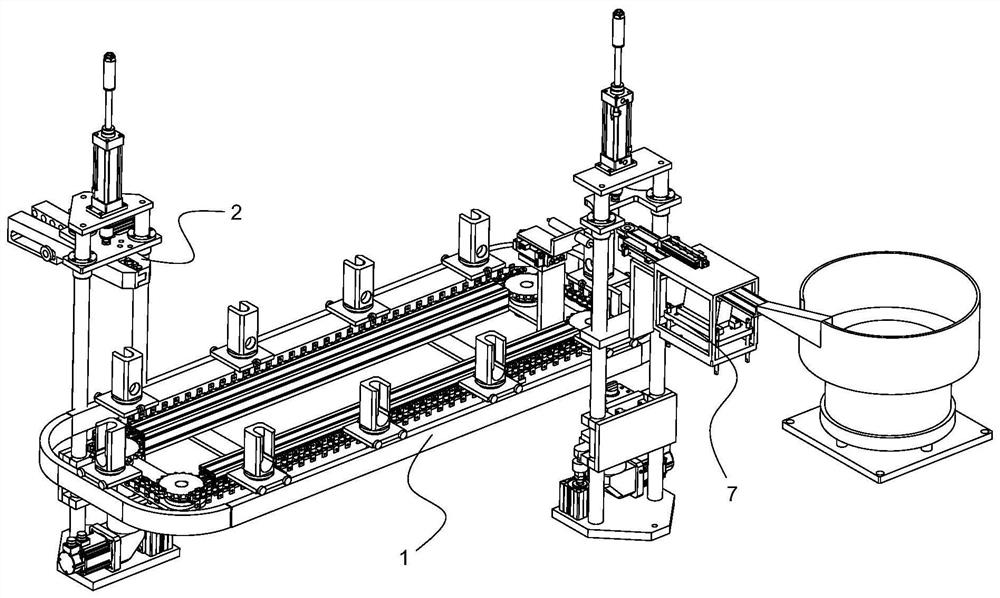

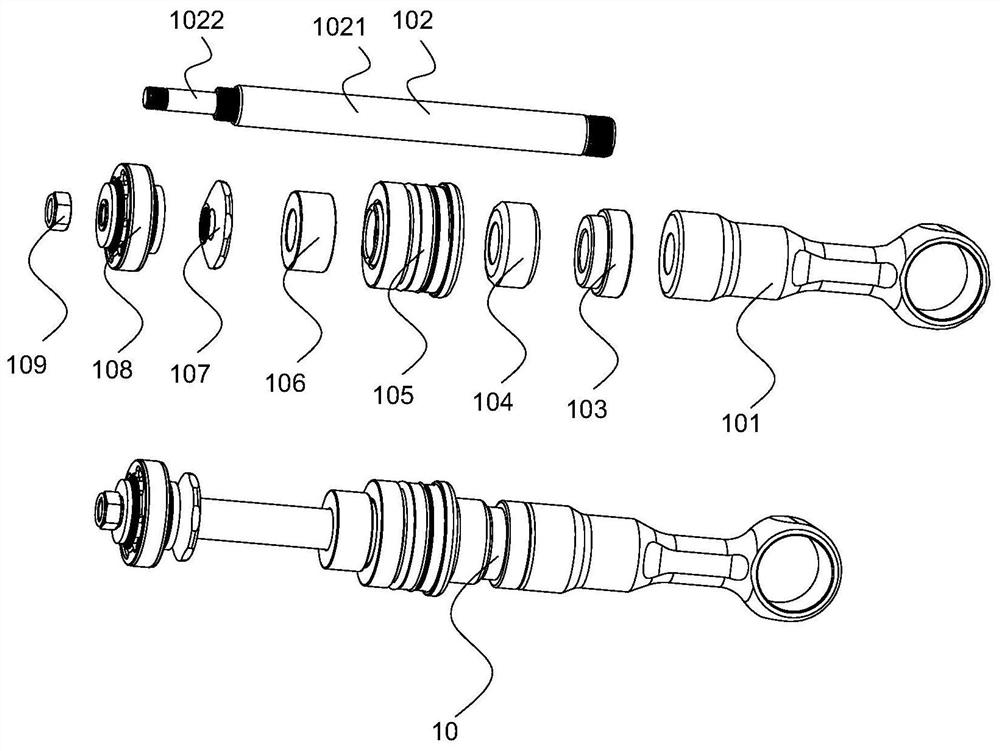

Limiting nut feeding and tightening device for producing piston assembly and piston assembly assembling equipment

InactiveCN112247543ARapid positioningSimple structureMaterial gluingAssembly machinesControl theoryMechanical engineering

The invention relates to the field of piston assembly assembling, and discloses a limiting nut feeding and tightening device for producing a piston assembly. A limiting nut feeding mechanism comprisesa limiting nut feeding rail, a limiting nut pushing air cylinder, a limiting nut feeding air cylinder, a limiting nut lifting air cylinder and a limiting nut limiting plate; and the limiting nut pushing air cylinder is horizontally installed above the limiting nut feeding rail, the output end of the limiting nut pushing air cylinder is located at the discharging end of the limiting nut feeding rail, a limiting nut feeding air cylinder is horizontally installed on the lower portion of the limiting nut feeding rail, a limiting nut lifting air cylinder is vertically installed at the output end of the limiting nut feeding air cylinder, the limiting nut limiting plate is installed at the output end of the limiting nut lifting air cylinder, the limiting nut pushing air cylinder pushes a limiting nut to the limiting nut limiting plate, and a limiting nut positioning groove is formed in the limiting nut limiting plate. According to the limiting nut feeding and tightening device, the feeding structure is simplified, and the feeding efficiency is improved.

Owner:陈美香

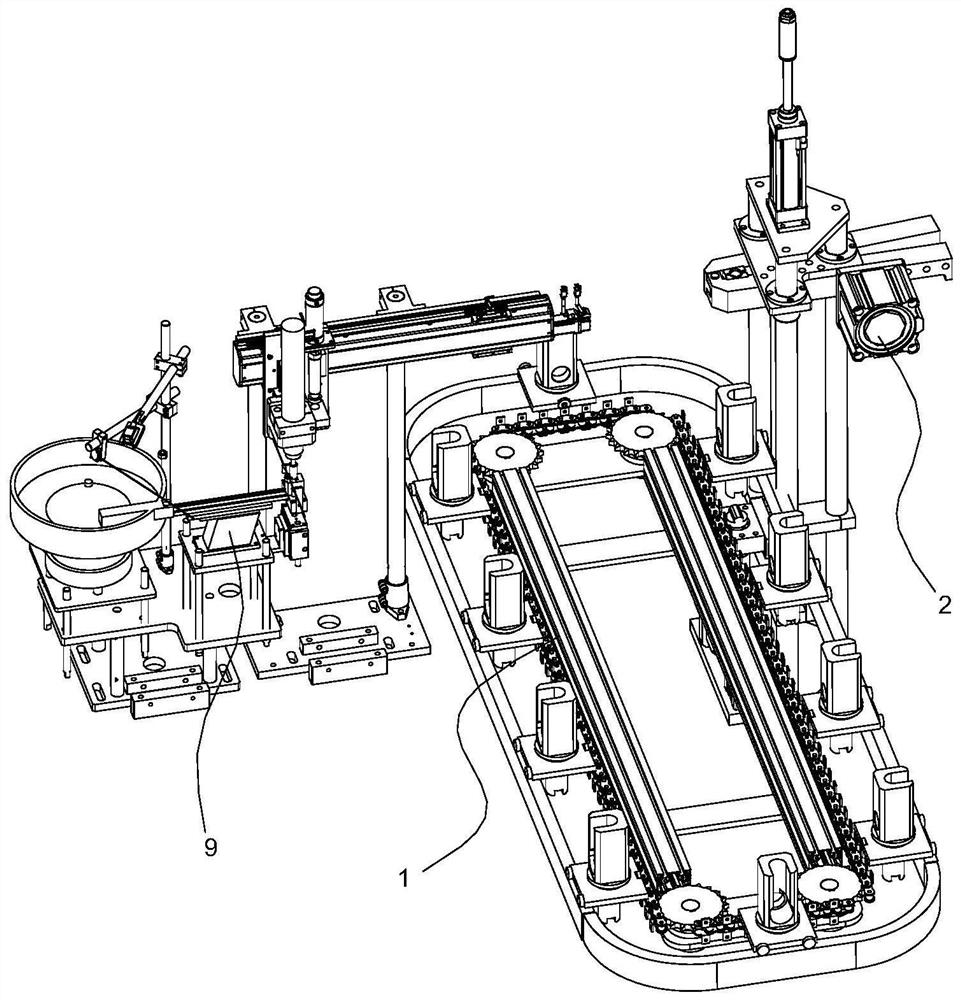

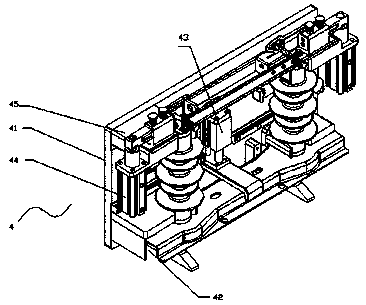

Isolating switch production system

ActiveCN107507719AImprove tightening efficiencyReduce labor intensityElectric switchesUltimate tensile strengthElectrical and Electronics engineering

The present invention relates to an isolating switch production system. An isolating switch comprises a base plate, an insulator and a conductive base; the conductive base is installed at one end of the insulator through a connection rack, and the other end of the insulator is installed on the base plate; and the system is characterized in that the comprises an assembling system, a sorting system and a package system which are arranged in order. The worker labor intensity is reduced, the work efficiency is improved, and the semi-automation production of the isolating switch is realized.

Owner:JIANGSU RUGAO HIGH VOLTAGE ELECTRIC APP

Automatic overturning system for building pipe pile mold clamping bolt

The invention relates to an automatic overturning system for a building pipe pile mold clamping bolt. The automatic overturning system is innovatively characterized by comprising a supporting base, guide mold plates, an installation bracket, nylon brushes and an adjusting mechanism; the automatic overturning system for the building pipe pile mold clamping bolt is installed on the two side edges of a pipe pile mold track; the nylon brush on the lower portion of the overturning system is obliquely located under the mold clamping bolt in a vertical state and closely attached to the mold clamping bolt; and when the mold clamping process is conducted after a pipe pile mold is filled with concrete, a driving motor drives the nylon brushes to rotate, the mold clamping bolt is rotated around a pipe pile lower mold body through the nylon brush on the lower portion and then rises and makes contact with the nylon brush on the upper portion of the overturning system, thus, the nylon brush on the upper portion drives the mold clamping bolt to continuously rotate, 180-degree rotation is achieved, and a worker can conveniently tighten the mold clamping bolt.

Owner:如皋市磨头建设开发有限公司

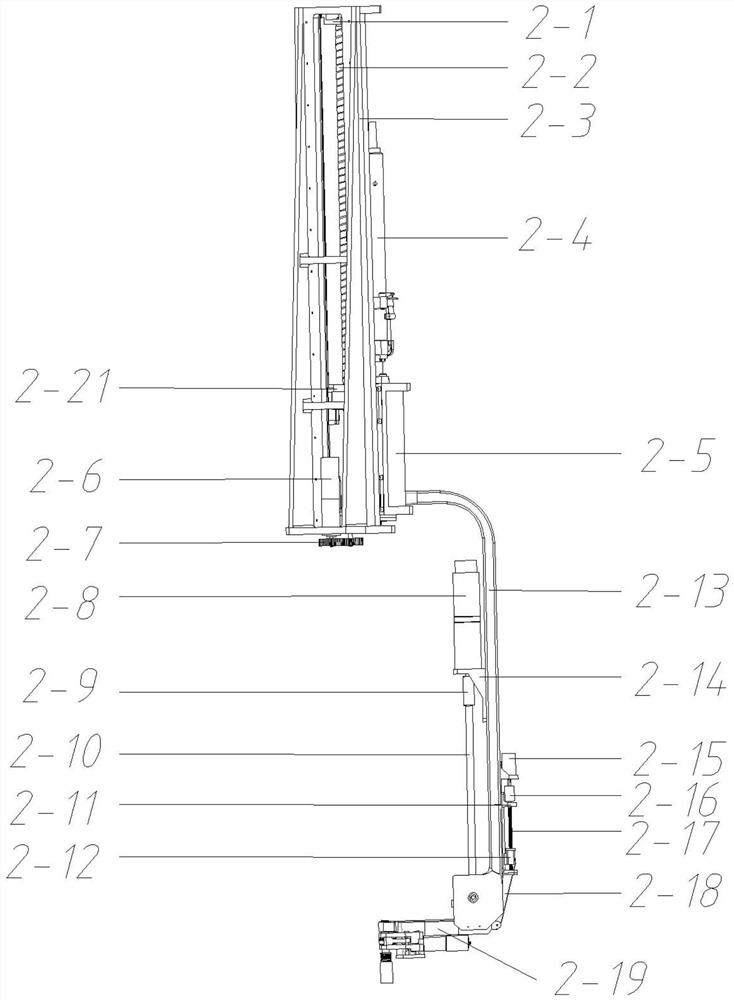

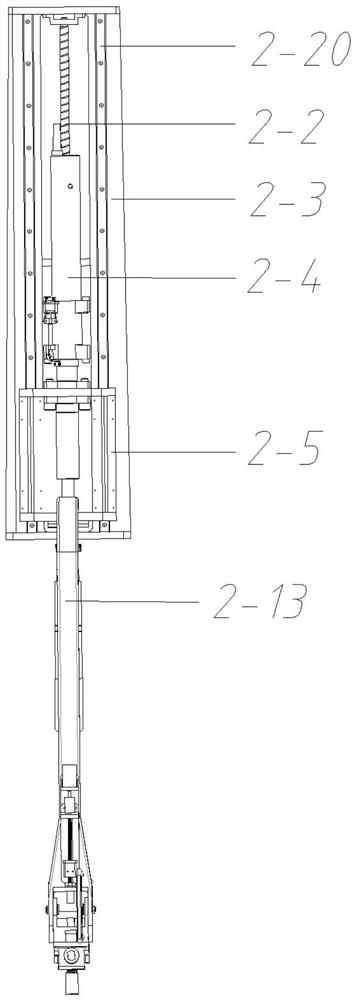

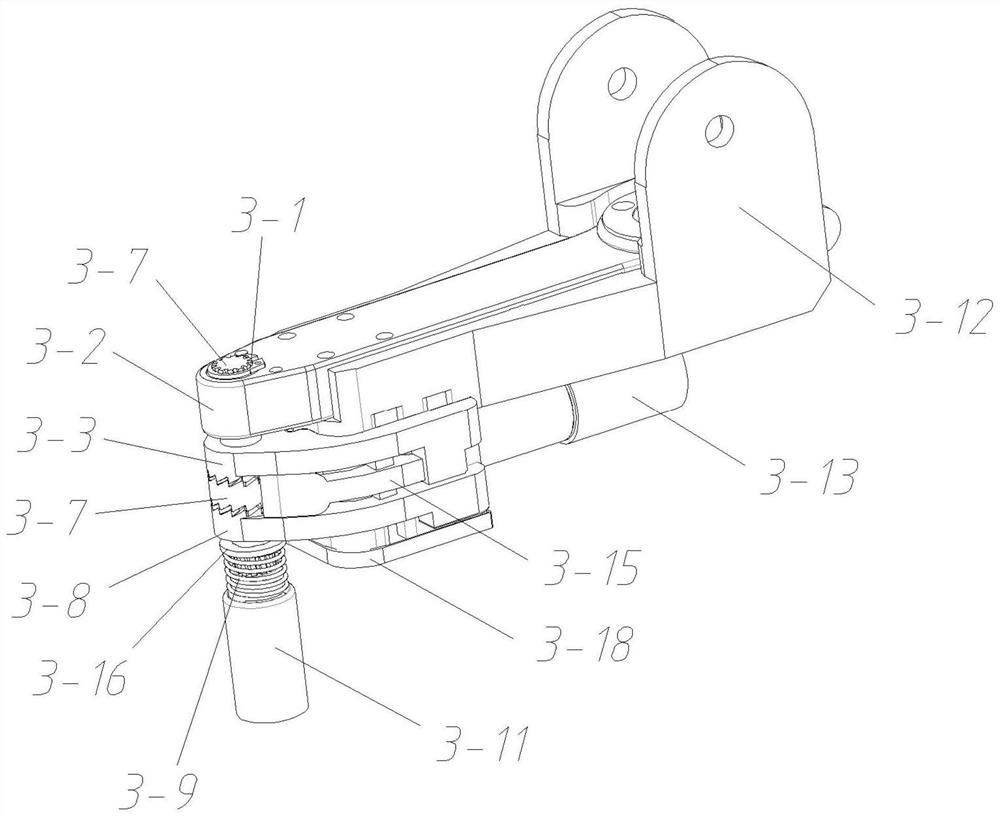

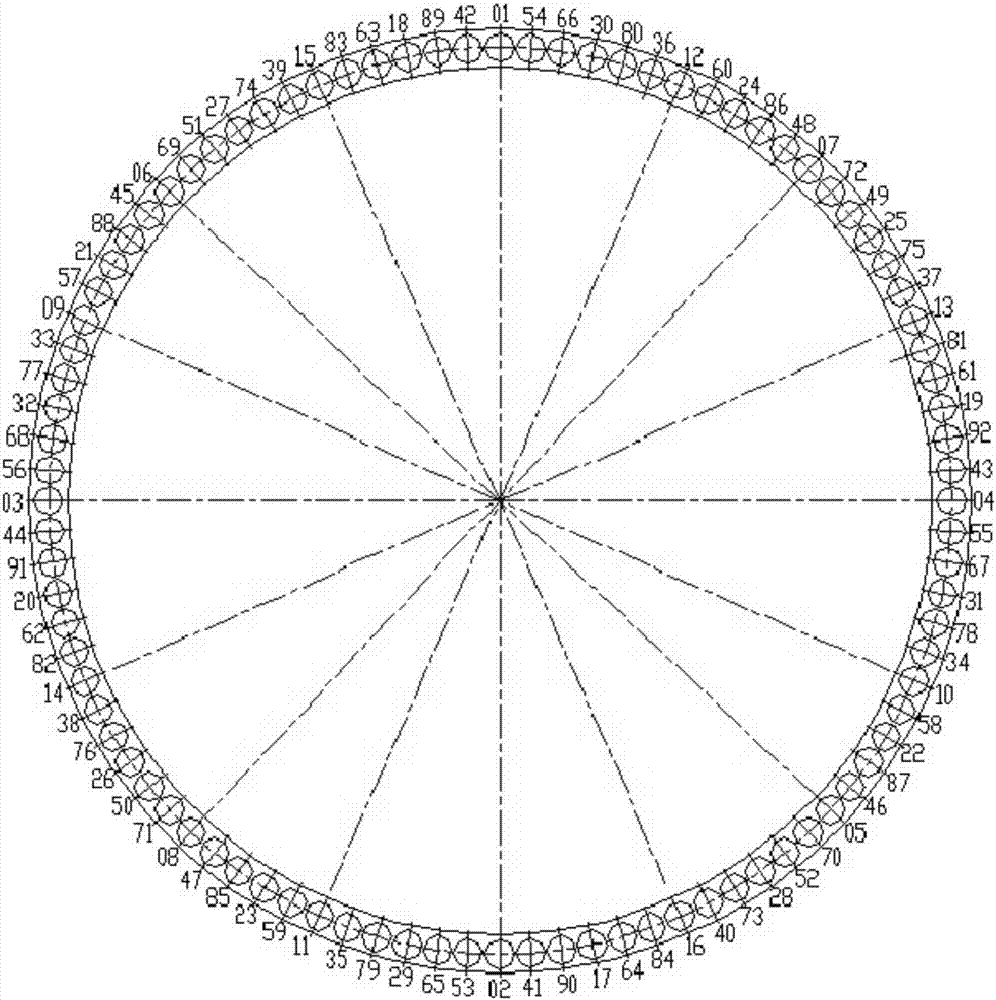

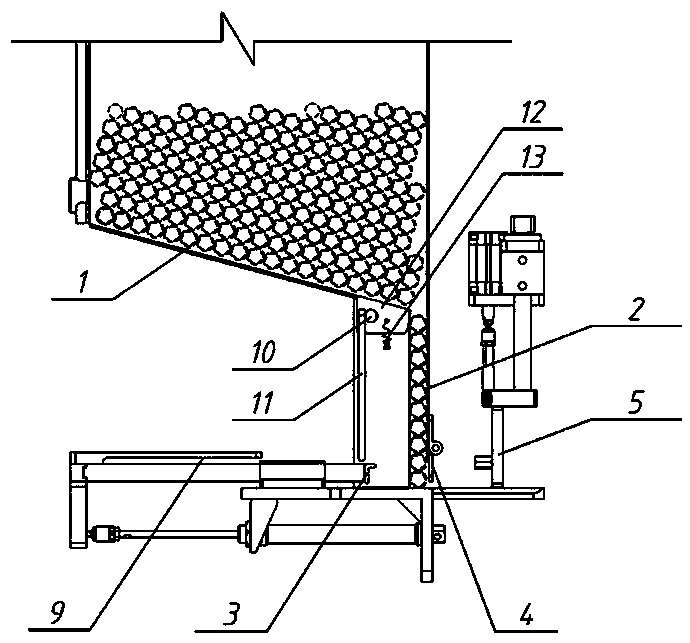

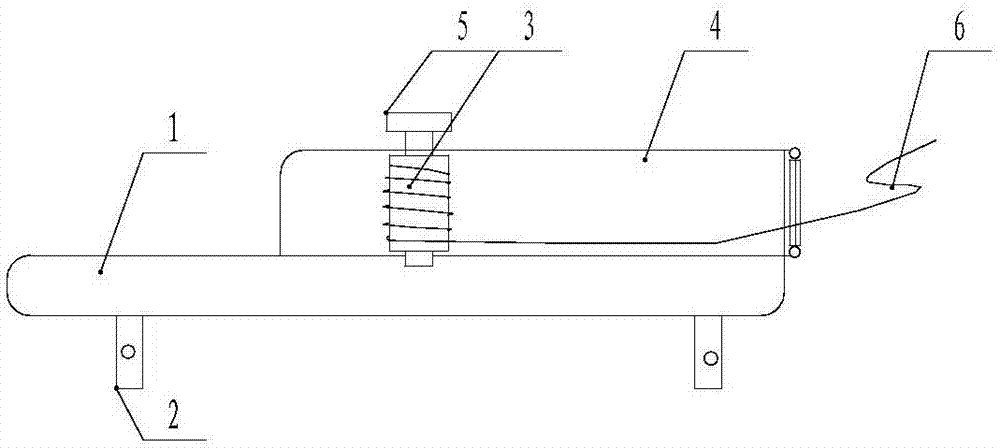

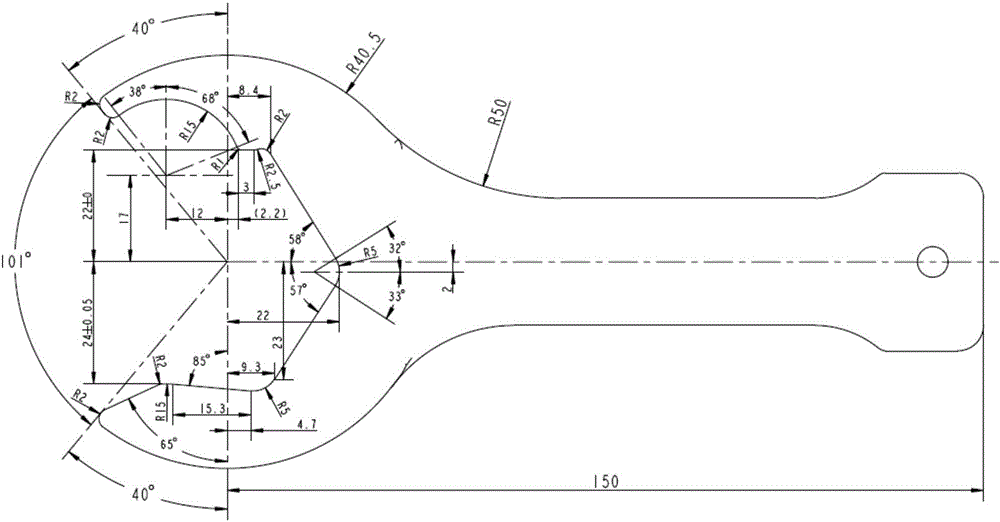

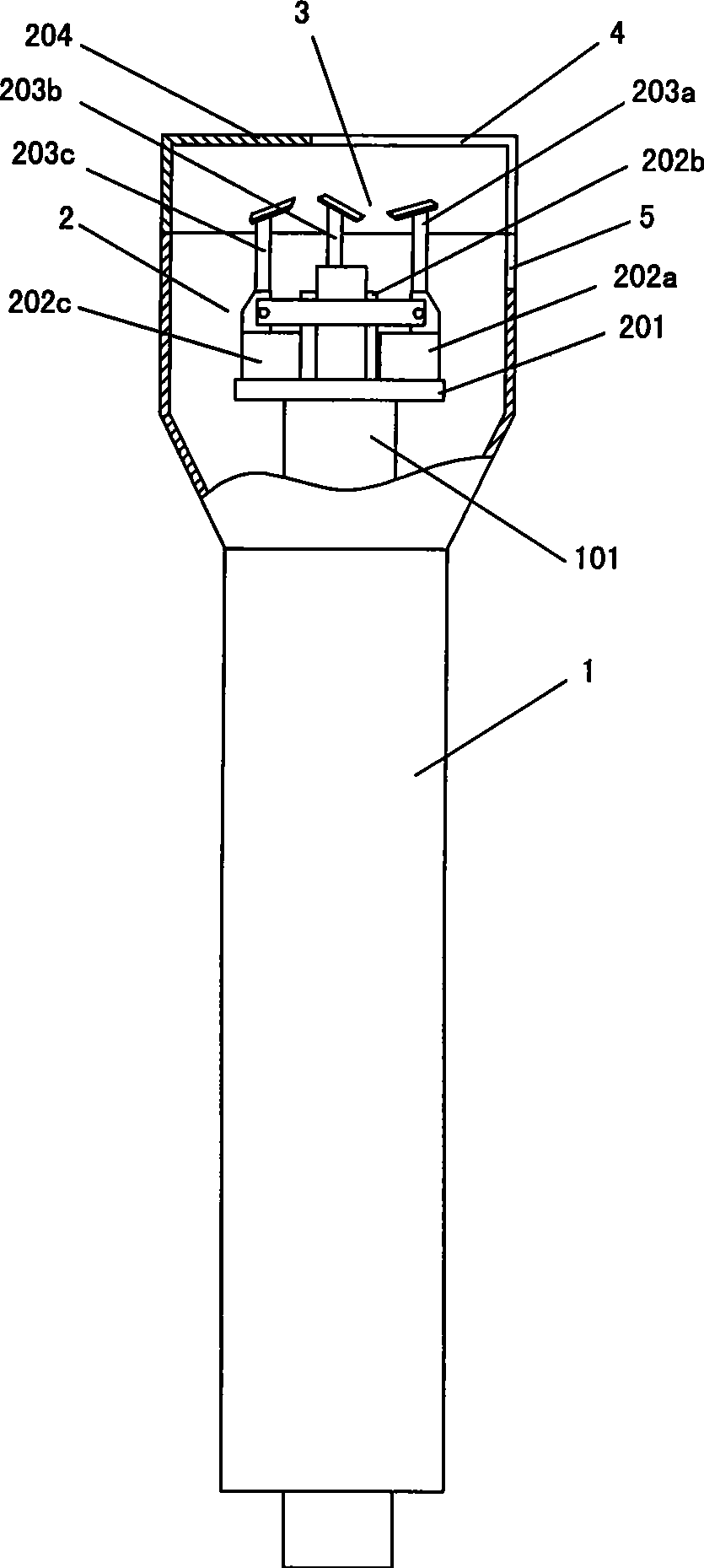

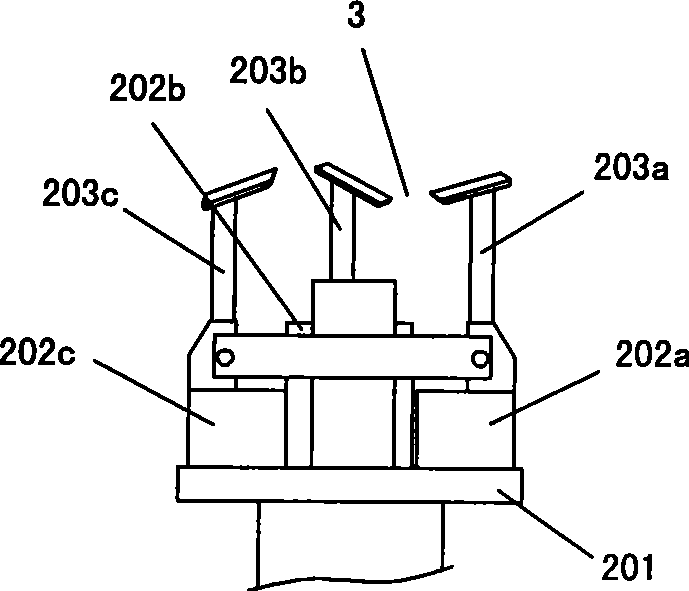

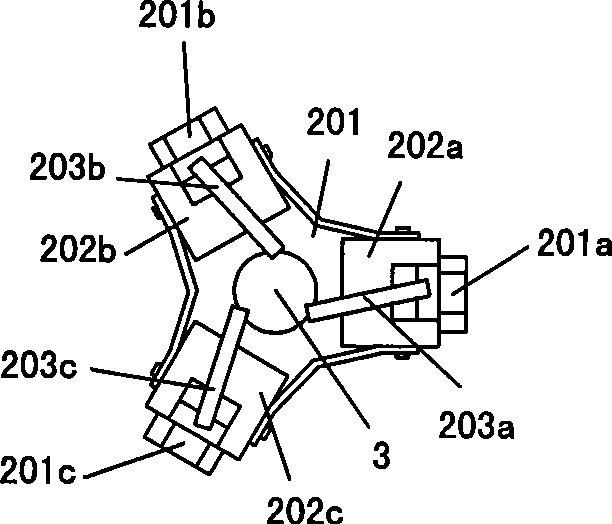

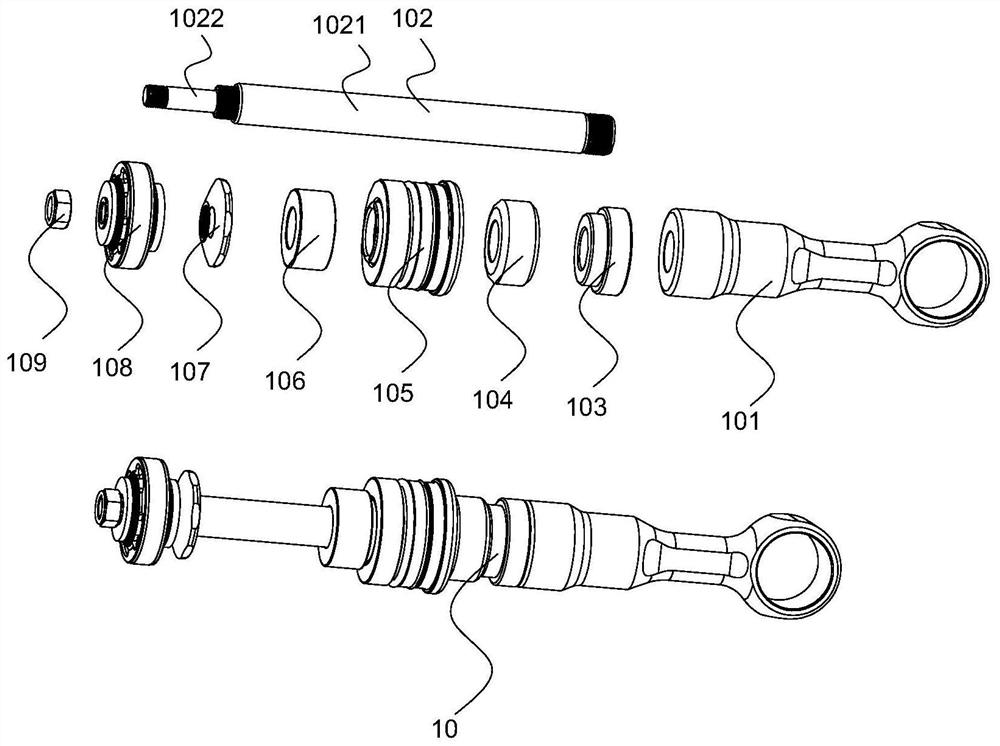

Rapid large-torque tightening device and method for narrow long-space blind cavity

PendingCN112045405AImprove tightening efficiencyHigh tightening precisionMetal working apparatusReciprocating motionEngineering

The invention relates to a rapid large-torque tightening device and method for a blind cavity in a narrow and long space. The device comprises an automatic pushing mechanism and an automatic folding and unfolding tightening mechanism connected with the automatic pushing mechanism, and the automatic pushing mechanism enables a tightening head to be conveyed into or withdrawn from a tightening station, so as to achieve the positioning work before tightening; and the automatic folding and unfolding tightening mechanism is used for folding when the tightening head enters a tightening cavity, torsion transmission during rapid tightening, reciprocating motion during high-torque tightening and switching between the tightening direction and the loosening direction, and rapid tightening and high-torque reciprocating bidirectional composite integrated tightening motion is achieved. The automatic pushing mechanism is driven by a lead screw to do linear motion and is matched with the automatic folding and unfolding tightening mechanism to achieve pushing and folding in a narrow and long space, and the position is adjusted in the nut tightening process.

Owner:SHENYANG AEROSPACE UNIVERSITY +1

Special terminal actuator for industrial robot for grabbing and screwing steel-drum large-thread cover

InactiveCN106826175ASimple mechanical structureReduce load requirementsProgramme-controlled manipulatorMetal working apparatusSet screwProduction line

The invention discloses a special terminal actuator for an industrial robot for grabbing and screwing a steel-drum threaded cover. The special terminal actuator for the industrial robot consists of an actuator wedge-shaped pusher, a spring, a flat key, an actuator terminal, a hexagon socket head cap screw M5*16, an actuator terminal cover plate, a shim, a hexagon socket set screw M5*8, a pneumatic motor, an actuator sleeve and an actuator connecting plate. The grabbing of a steel-drum large-thread cover is realized through the actuator wedge-shaped pusher and the spring; the screwing of the steel-drum threaded cover is realized through the pneumatic motor and the actuator terminal fitted with the inner wall of the steel-drum large-thread cover. The special terminal actuator for the industrial robot can be applied to the screwing of the steel-drum large-thread cover in a steel-drum production line, is simple in mechanical structure, small in size, low in control difficulty and high in efficiency, and has a quite good application prospect.

Owner:JIANGNAN UNIV

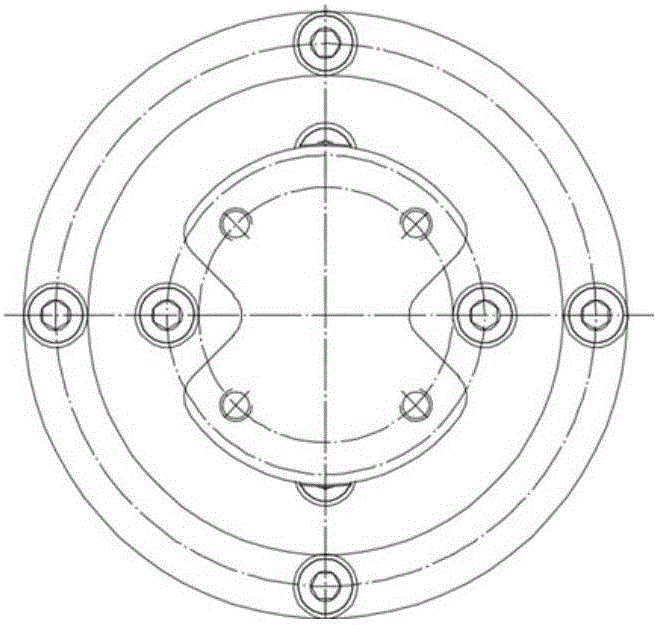

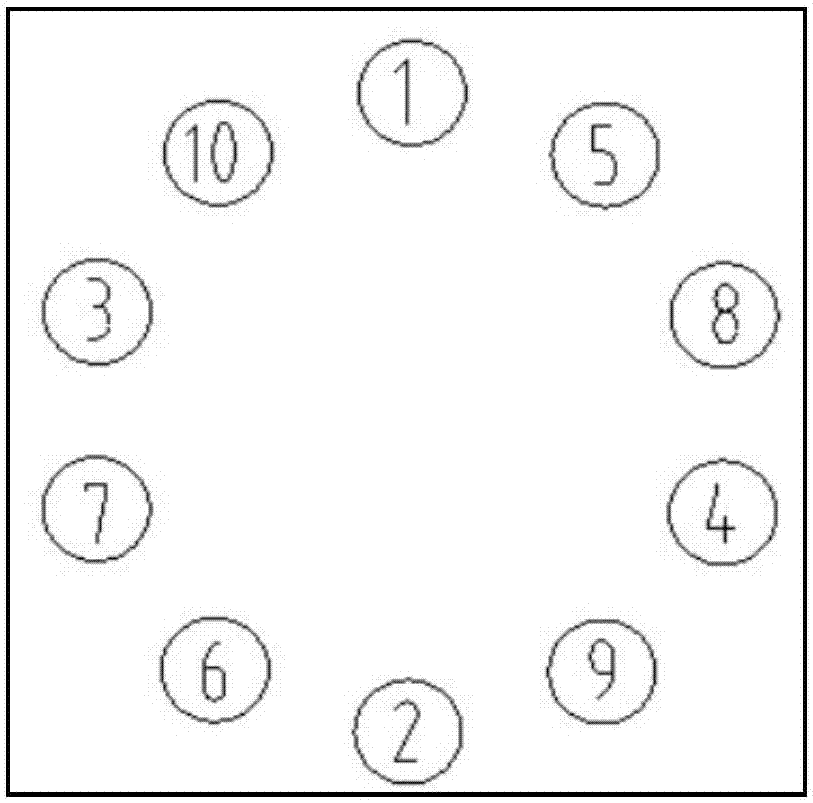

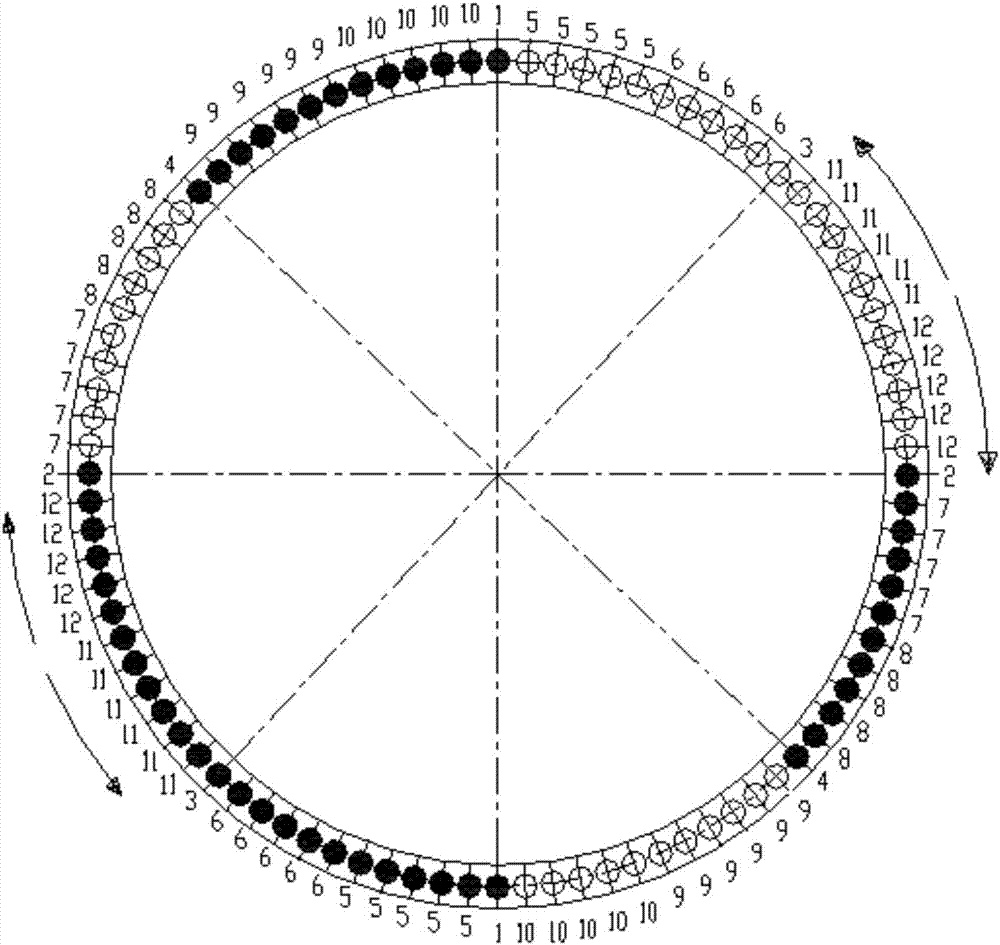

Wind turbine generator variable-pitch bearing bolt tightening method

ActiveCN107091197AImprove tightening efficiencyReduce labor intensityWind motor controlMachines/enginesEngineeringUltimate tensile strength

The invention discloses a wind turbine generator variable-pitch bearing bolt tightening method. The method includes the steps that (1) eight bolts at the 0-degree position, 45-degree position, 90-degree position, 135-degree position, 180-degree position, 225-degree position, 270-degree position and 315-degree position of a variable-pitch bearing are subject to first-time tightening according to the crossing method sequence; (2) the eight bolts on the variable-pitch bearing are averagely divided into eight zones through eight bolts; (3) the bolts in the eight zones are subject to regionalization first-time tightening according to the crossing method sequence; and (4) after first-time tightening of all bolts on the variable-pitch bearing is completed, second-time tightening of all the bolts is completed according to the sequence in the step (1) and the step (3), and finally final tightening of all bolts is completed according to the sequence in the step (1) and the step (3). According to the wind turbine generator variable-pitch bearing bolt tightening method, the regionalization tightening measure is taken, while the bolt tightening quality is guaranteed, the process is optimized, the labor intensity of workers is reduced, and potential safety hazards are eliminated.

Owner:GUODIAN UNITED POWER TECH

Installation mechanism for handle material guide pipe of fire extinguisher

PendingCN108673113ASimple structureEasy to useMetal working apparatusProduction lineFire extinguisher

The invention discloses an installation mechanism for a handle material guide pipe of a fire extinguisher. The installation mechanism disclosed by the invention comprises a workbench provided with a material bin, wherein the material bin comprises a material storage groove with a bottom which is of a slope surface structure, and a single-pipe material guide groove vertically connected to the lowest part of the slope surface; a material push plate driven by a horizontal cylinder and making direct contact with the material guide pipe is arranged at the rear side of the single-pipe material guidegroove; a single-pipe material feeding baffle is hinged to the bottom of the front panel of the single-pipe material guide groove; a lifting limit plate is arranged at the front side of the single-pipe material feeding baffle at an interval; a pipe screwing area is formed between the lifting limit plate and the single-pipe material feeding baffle; a pipe screwing motor connected with a push-pullcylinder is arranged at one end of the pipe screwing area; a pipe screwing shaft connected with the material guide pipe in a sleeving manner is connected to the pipe screwing motor; and the pipe screwing shaft comprises a conical head and a limit bulge. According to the installation mechanism disclosed by the invention, automatic installation for the handle material guide pipe is realized throughthe cooperation of a material push mechanism and a pipe screwing mechanism, so that the labor amount of workers is greatly reduced, and the screwing efficiency for the material guide pipe is effectively increased; and the installation mechanism is quite suitable for the production takt of an automatic production line for fire extinguishers.

Owner:HENAN LVBO ENERGY EQUIP CO LTD

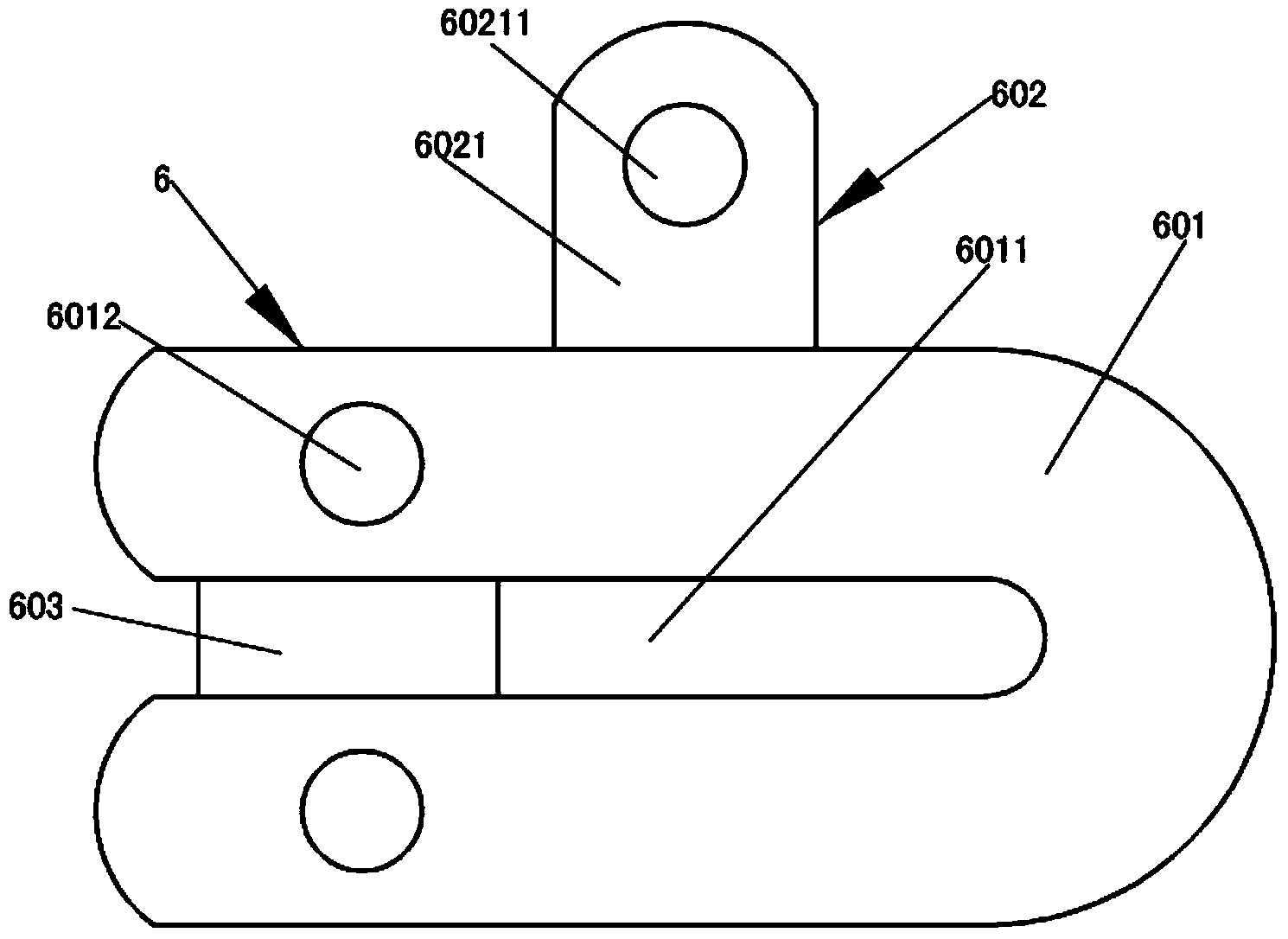

Combined wire tightening tool for tightening conductive wire of circuit

ActiveCN107465146AIncrease frictionReduce relative motionApparatus for overhead lines/cablesInverted uOverhead line

The invention discloses a combined wire tightening tool for tightening a conductive wire of a circuit, relates to mounting and maintaining equipment for an overhead line or cable, and is used for solving the problems of low wire tightening efficiency and damage to the conductive wire caused by insecure connection of the existing wire tightening device. The combined wire tightening tool for tightening the conductive wire of the circuit comprises a bottom plate and hoops which are arranged on the bottom plate; a rope wheel and an outer protective cover with an inverted U-shaped cross section are arranged on the bottom plate; a rotating shaft of the rope wheel extends out of the outer protective cover and is driven through a rotating disc; rolling shafts are arranged on three edges of the tail part of the outer protective cover; a roller is arranged outside each rolling shaft; the rolling shafts are arranged at the tail part of the outer protective cover of the bottom plate; the rollers are arranged outside the rolling shafts; a traction rope is arranged on the rope wheel; the traction rope extends out of the outer protective cover through the tail part of the outer protective cover. The combined wire tightening tool for tightening the conductive wire of the circuit is used for tightening the wire of the overhead line, is high in wire tightening efficiency, and can reduce the damage to a cable.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

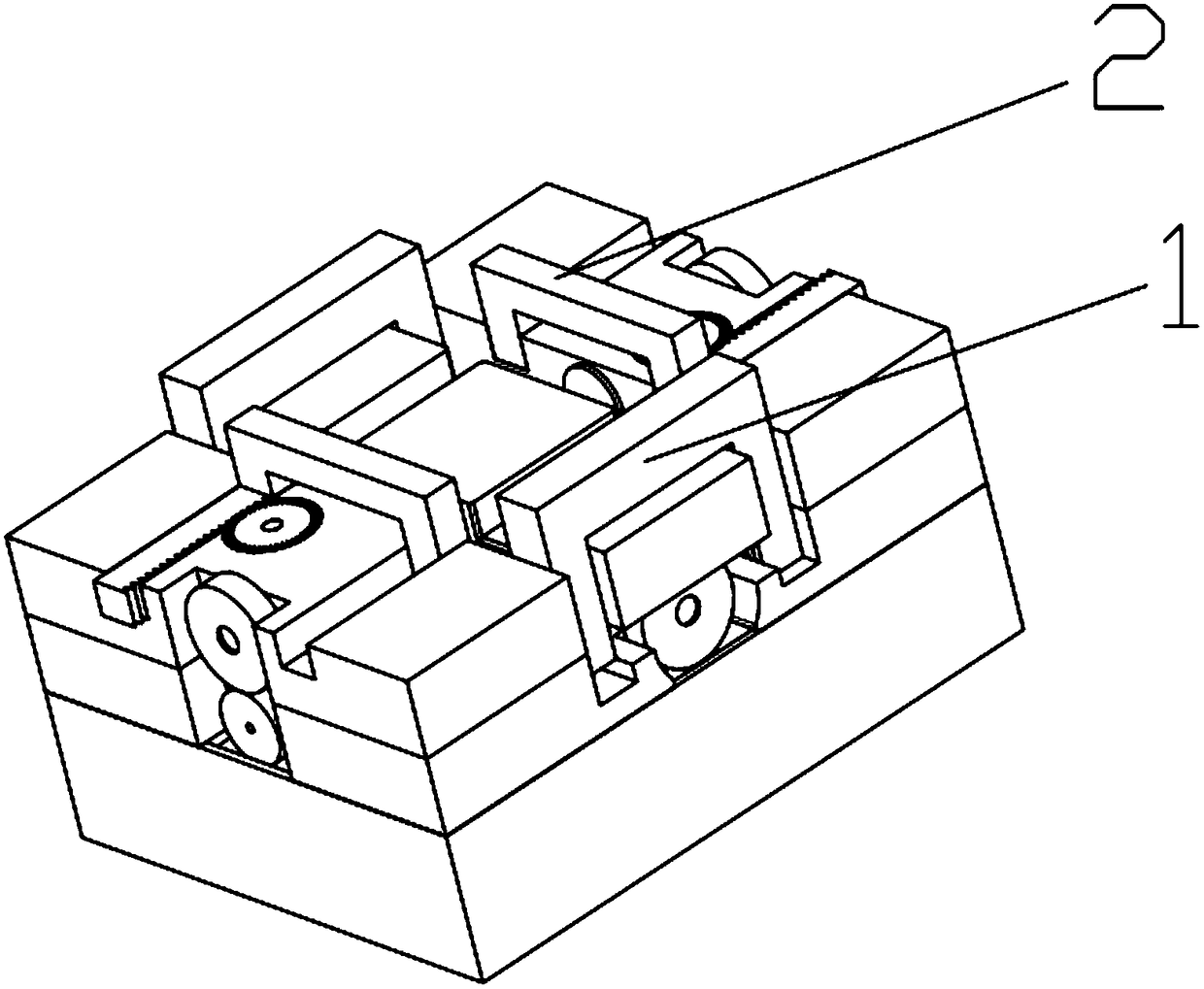

Clamp capable of adjusting workpiece position

ActiveCN109483265AThe stepping up process is quick and easyImprove tightening efficiencyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a clamp capable of adjusting the workpiece position, and relates to the field of clamp equipment. The clamp capable of adjusting the workpiece position comprises a first adjusting clamp and a second adjusting clamp; the first adjusting clamp is used for fixing the X-axis direction of a workpiece, and can drive the workpiece to move in the X-axis direction, the second adjusting clamp is used for fixing the Y-axis direction of the workpiece, and the second adjusting clamp can drive the workpiece to move in the Y-axis direction. According to the clamp capable of adjustingthe workpiece position, a fixing method for fixing a workpiece through extrusion to the middle from four faces is adopted, when the workpiece is fixed, the workpiece is more stable and is not prone todeviating, the workpiece clamping precision is improved, the workpiece is subject to precise adjusting in the X-axis direction and the Y-axis direction, the clamping position of the workpiece can beactively adjusted, and a machine tool does not need to carry out tool alignment again.

Owner:宁波碧达机械科技有限公司

Fast tightening device for screw pair in small space

A fast tightening device for a screw pair in small space comprises a sleeve and a fast dismounting wrench and is used for tightening and dismounting a redundant tube self-sealing nut between two servo mechanisms in a new-generation carrier rocket servo system. In a new-generation carrier rocket servo product, mounting space for a redundant tube self-sealing joint is small, then one open transfer sleeve is designed skillfully, a redundant tube is avoided, the sleeve is clamped to the nut conveniently, and the tightening space for the wrench is increased; meanwhile, opening appearance and size of the fast tightening wrench are designed specially, so that the nut can be tightened when the wrench clamps the transfer sleeve once, the position of the wrench relative to the sleeve is changed counterclockwise, and the nut is tightened clockwise. During dismounting, the wrench direction is changed, the position of the wrench relative to the sleeve is changed clockwise, and the nut is dismounted counterclockwise. The fast tightening device can be extensively applied to other conditions of fast mounting and dismounting of nuts in small space.

Owner:北京实验工厂有限责任公司 +1

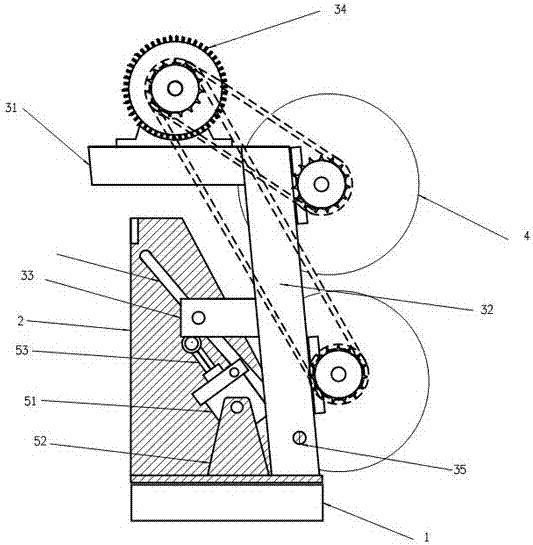

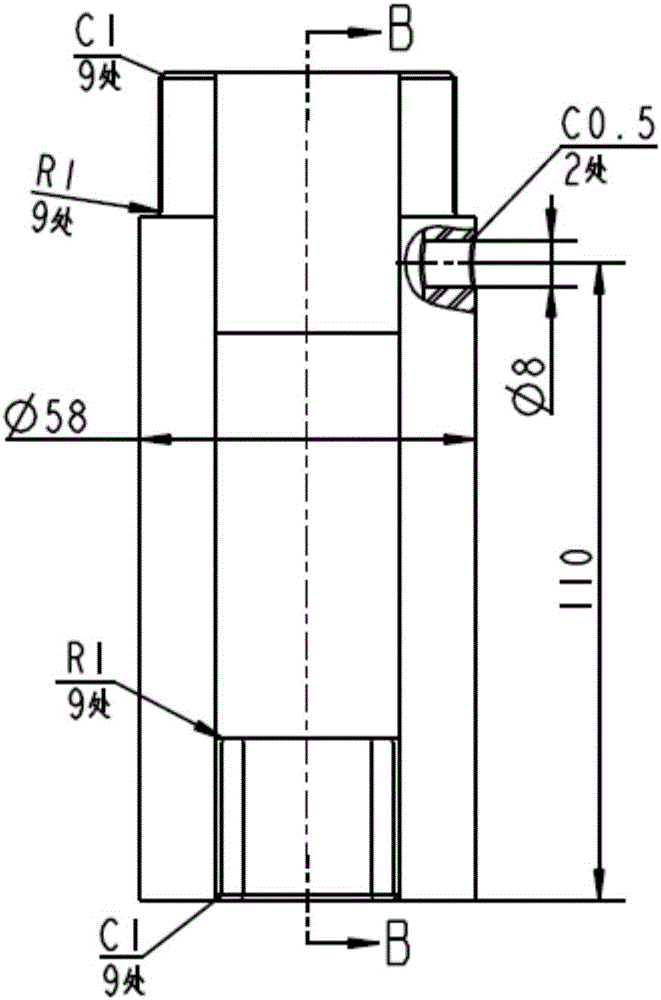

Prefabricated reinforcement cage rapid butt joint device and construction method thereof

ActiveCN112112154AImprove tightening efficiencyLiberate workloadBuilding reinforcementsBuilding material handlingGear wheelClassical mechanics

The invention relates to a prefabricated reinforcement cage rapid butt joint device. The device comprises a plurality of vertically-arranged lower main reinforcements, threaded sleeves arranged at thetop ends of the lower main reinforcements and vertically-arranged upper main reinforcements, and further comprises a limiting clamping base which comprises a left clamping base and a right clamping base which are symmetrically arranged. Limiting cavities used for limiting the position of a lower reinforcement cage are formed in the left clamping base and the right clamping base correspondingly, the left clamping base and the right clamping base are detachably connected, and screwing assemblies used for automatically screwing the threaded sleeves are arranged on the upper surface of the limiting clamping base. Each screwing assembly comprises a driving motor vertically arranged on the upper surface of the limiting clamping base, a driving gear fixedly arranged on an output shaft of the driving motor and a driven gear ring arranged on the circumferential side wall of the corresponding threaded sleeve, the driving gears are meshed with the driven gear rings, and the driving motors are detachably connected to the upper surface of the limiting clamping base. The device has the effect of improving the butt joint construction efficiency of a reinforcement cage to a great extent.

Owner:昆山市城乡建设有限公司

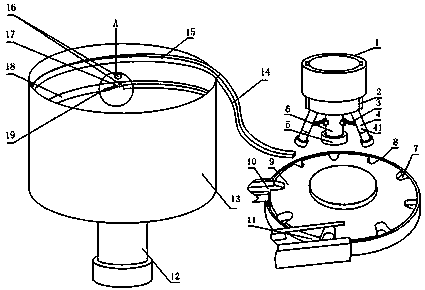

Wire twisting device for conductive wire terminal

InactiveCN101459310AImprove tightening efficiencyImprove pass rateLine/current collector detailsPass rateWire twister

The invention discloses a wire end twister, which comprises a drive device, a twister head which can tighten bare wire ends is mounted at an output end of the drive device, wherein the twister head comprises a rotary seat, interlocked seats and twister arms, the lower portion of the rotary seat is equipped with a drive interface for inserting the output end of the drive device, the upper portion of the rotary seat is fixed with a plurality of circumferentially arranged interlocked seats, the L-like twister arms are fixed on the interlocked seats, and a wire twister mouth is formed in a gap among the twister arms. When twisting a wire, one end of a bare wire without a casing is inserted into the wire twister mouth, then the drive device is started to directly drive the rotary seat to rotate in high speed to further drive the twister arms to rotate, and because the top ends of the twister arms are inclined, the bare wire end inserted in the wire twister mouth can be twisted tightly. The wire end twister has simple and easy operation in the whole process, effectively increases twisting effect and pass rate of wires, and can reduce labor cost and meet requirements of batch production.

Owner:孔星

Aluminum foil cap packing mechanism

ActiveCN104030207ASimple structureConducive to package transfer efficiencyFlanged caps applicationEngineeringAluminum foil

The invention discloses an aluminum foil cap packing mechanism which comprises a bottle conveying mechanism, a bottle cap tightening mechanism and a cap conveying mechanism. The bottle conveying mechanism comprises a rotary disk barrel, a rotary disk and a bottle containing bayonet. The bottle cap tightening mechanism comprises a rotating shaft, a tightening wheel, a first rotating shaft, an elastic portion and a pull rod. The tightening wheel comprises a tightening wheel base and a rolling wheel. The cap conveying mechanism comprises a cylindrical cap conveying barrel. A spiral cap-discharge guide rail is fixedly connected to the inner wall of the cap conveying barrel. The bottom of the cap conveying barrel is further provided with a power output device used for braking the motion of a bottle cap. The exit end of the spiral cap-discharge guide rail is further connected with a cap-discharge guide rail. The tail end of the cap-discharge guide rail is located over the rotary disk. The aluminum foil cap packing mechanism is high in working efficiency, and a simple structural form enables the aluminum foil cap packing mechanism to be easy to operate and maintain.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

Seven-spiral grounding wire clamp

PendingCN111525299AReduce prolapseImprove connection reliabilityElectric connection structural associationsClamped/spring connectionsPhysicsEngineering

The invention discloses a seven-spiral grounding wire clamp, which comprises a fixed frame and a movable clamping block slidably connected with the inner side of the fixed frame, wherein the bottom end of the movable clamping block makes contact with the top end of a screw rod, the screw rod is of a seven-threaded structure, and the bottom end of the screw rod penetrates through a guide hole formed in the bottom end of the fixed frame and then is fixedly connected with a connecting column. According to the seven-spiral grounding wire clamp adopting the structure, the screwing efficiency (the rotating speed of the seven-spiral grounding wire clamp is seven times that of a conventional single thread) is improved by arranging the screw rod with the seven-threaded structure, and the connectingreliability between the screw rod and the positioning cylinder is improved by arranging the positioning spring in the positioning cylinder connected with the screw rod so as to reduce the possibilitythat the screw rod is disengaged from the positioning cylinder.

Owner:保定瑞隆电力器材有限公司

Lock nut feeding and tightening device for piston assembly production

InactiveCN112247558AEasy loadingEasy to absorbAssembly machinesMetal working apparatusControl engineeringMechanical engineering

The invention relates to the field of hydraulic buffer production and assembly, in particular to a lock nut feeding and tightening device for piston assembly production. The lock nut feeding and tightening device comprises a lock nut feeding mechanism. The lock nut feeding mechanism comprises a lock nut material disc, a lock nut feeding rail, a lock nut vibrator, a lock nut positioning block, a positioning block installation base and a positioning block lifting air cylinder. The discharging end of the lock nut material disc is connected with the feeding end of the lock nut feeding rail. The lock nut vibrator is installed at the lower portion of the lock nut feeding rail. The discharging end of the lock nut feeding rail is connected with the lock nut positioning block. The lock nut positioning block is provided with a lock nut positioning groove. The end, close to the lock nut feeding rail, of the lock nut positioning groove is provided with a guide part. The end, away from the lock nutfeeding rail, of the lock nut positioning groove is provided with a sharp corner. According to the lock nut feeding and tightening device, lock nuts are positioned through the sharp corner, the placement forms of the nuts on the lock nut positioning block are consistent, and suction of an electric screwdriver is facilitated.

Owner:陈美香

A production system for isolating switches

ActiveCN107507719BImprove tightening efficiencyReduce labor intensityElectric switchesEngineeringElectrical and Electronics engineering

The present invention relates to an isolating switch production system. An isolating switch comprises a base plate, an insulator and a conductive base; the conductive base is installed at one end of the insulator through a connection rack, and the other end of the insulator is installed on the base plate; and the system is characterized in that the comprises an assembling system, a sorting system and a package system which are arranged in order. The worker labor intensity is reduced, the work efficiency is improved, and the semi-automation production of the isolating switch is realized.

Owner:JIANGSU RUGAO HIGH VOLTAGE ELECTRIC APP

Tackle fixing plate for overhead line stringing

ActiveCN103594975ASimple structureImprove efficiencyApparatus for overhead lines/cablesTransmission lineArchitectural engineering

The invention discloses a tackle fixing plate for overhead line stringing. The tackle fixing plate comprises a plate-shaped body, a tackle fixing structure and a backup plate. A U-shaped through groove which penetrates through the plate-shaped body in the thickness direction of the plate-shaped body is formed in the plate-shaped body. The plate-shaped body is provided with two first through holes which are formed in the two sides of the U-shaped through groove respectively. Two second through holes are formed in the backup plate. The two second through holes correspond to the two first through holes in position. The backup plate is fixed to the plate-shaped body through two bolts. The tackle fixing structure is arranged at the top end of the plate-shaped body. The tackle fixing structure comprises two vertical plates, wherein the two vertical plates are arranged in parallel, each vertical plate is provided with a third through hole, and a bolt sequentially penetrates through the third through holes of the two vertical plates and is fixed in the two third through holes. The tackle fixing plate for overhead line stringing can improve safety and reliability of electric transmission line conductor stringing, improve stringing efficiency and the like.

Owner:XUANCHENG POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER

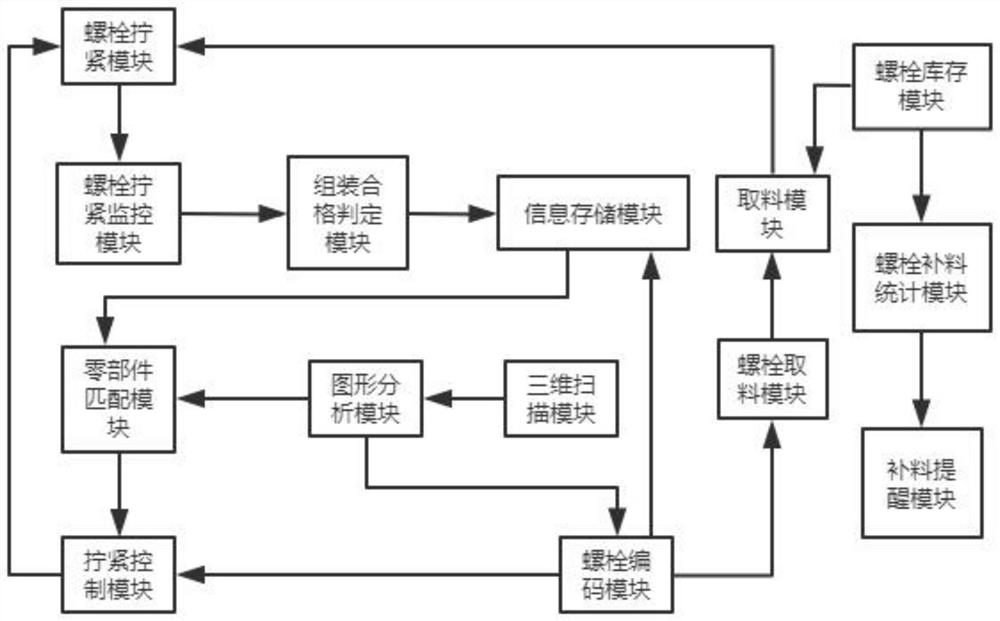

Bolt tightening system

InactiveCN112372282AImprove the uniformity of forceAvoid warpingDigital data information retrievalCharacter and pattern recognitionGraphicsCode module

The invention discloses a bolt tightening system which comprises a three-dimensional scanning module, a graphic analysis module, a bolt coding module, an information storage module, a bolt taking module, a bolt inventory module, a taking module, a bolt tightening module, a tightening control module, a bolt tightening monitoring module, a part matching module, an assembly qualification judgment module, a bolt supplementing statistics module and a supplementing reminding module. The bolt tightening system has the following advantages that the universality of the tightening system is greatly improved through on-site identification and analysis of parts and setting of the tightening sequence; the tightening efficiency is improved; due to a cross-shaped tightening route, the pressure distribution in the tightening operation is uniform, and the convex warping phenomenon is avoided; in the operation step of the tightening control module, a geometric center and a horizontal reference line arearranged to further reasonably plan an operation route; and through the arrangement of the part matching module, the parts of the same specification can directly call corresponding information from aninformation storage center for direct operation, and the system is suitable for rapid operation of the parts with stable and unchanged specifications.

Owner:苏州锐凯标准件有限公司

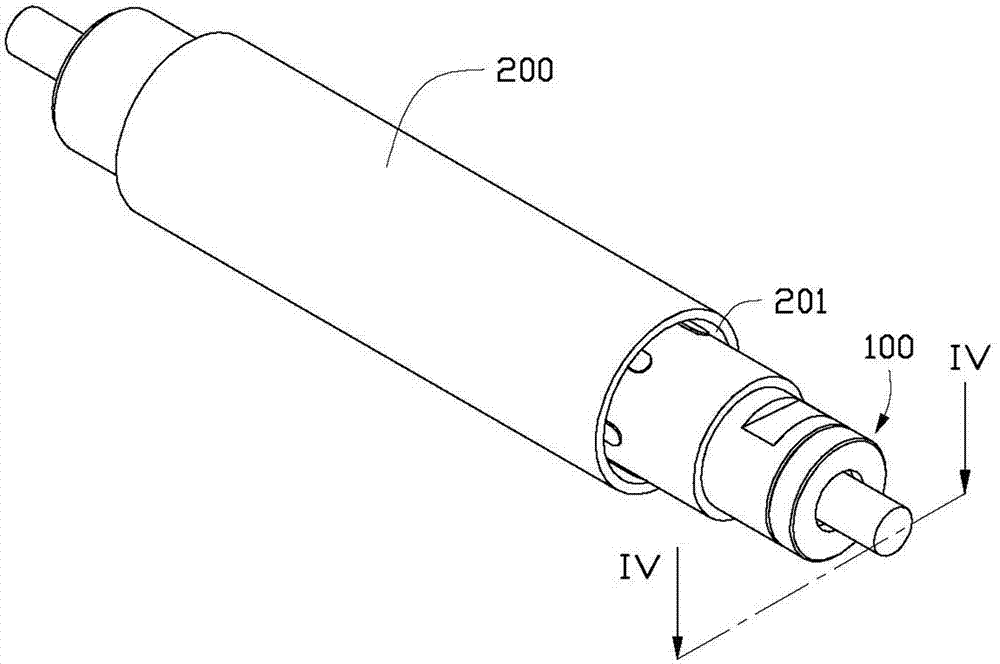

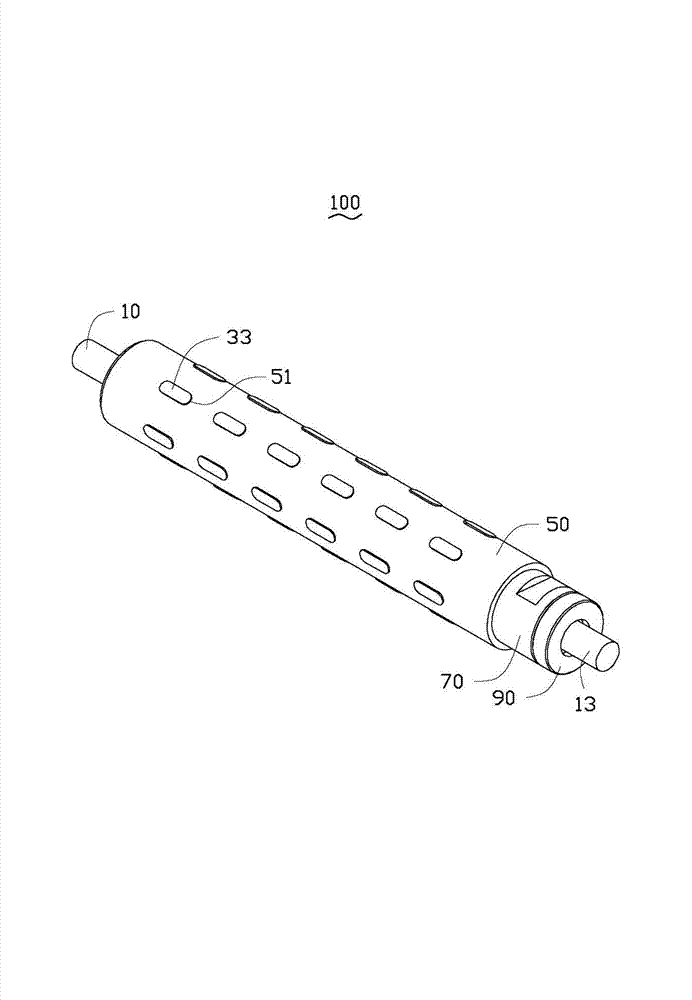

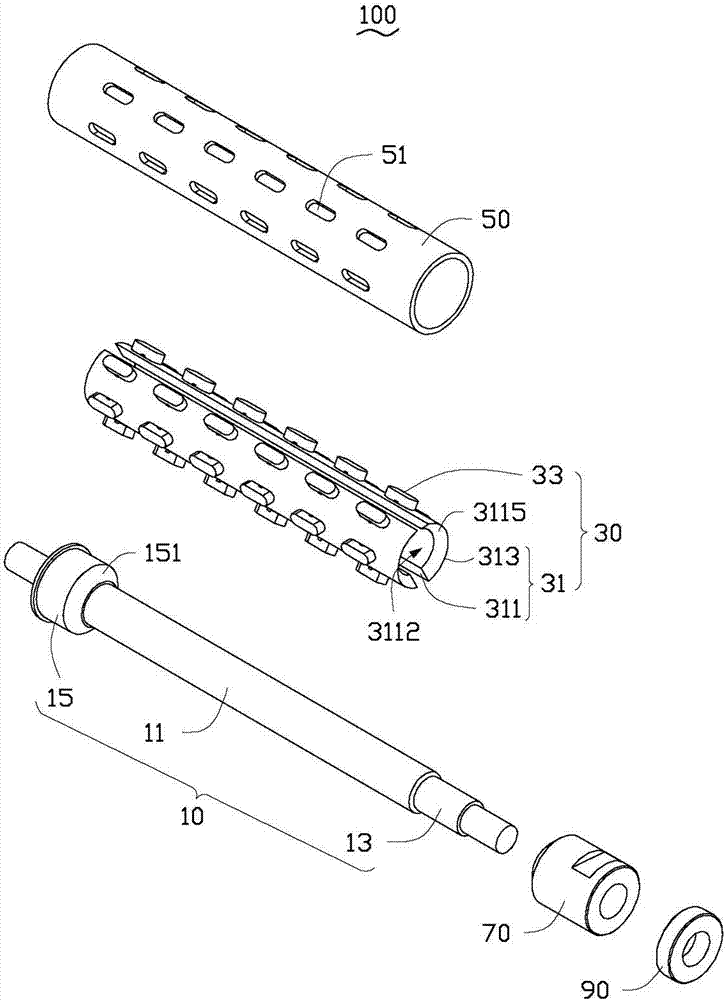

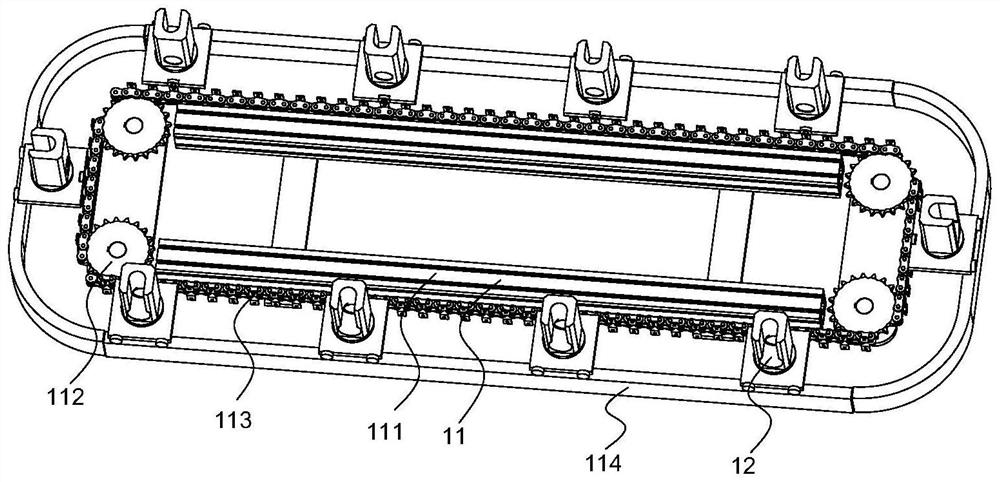

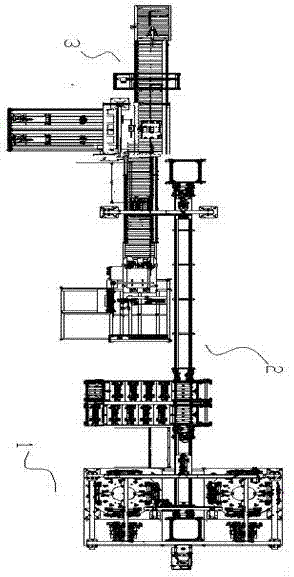

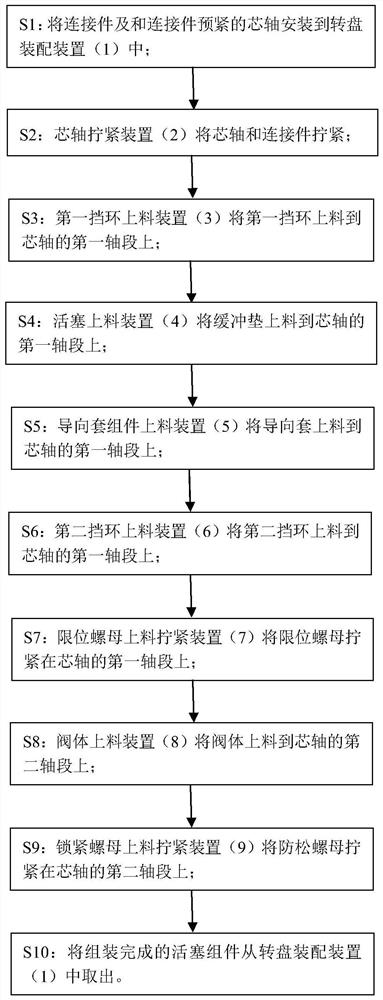

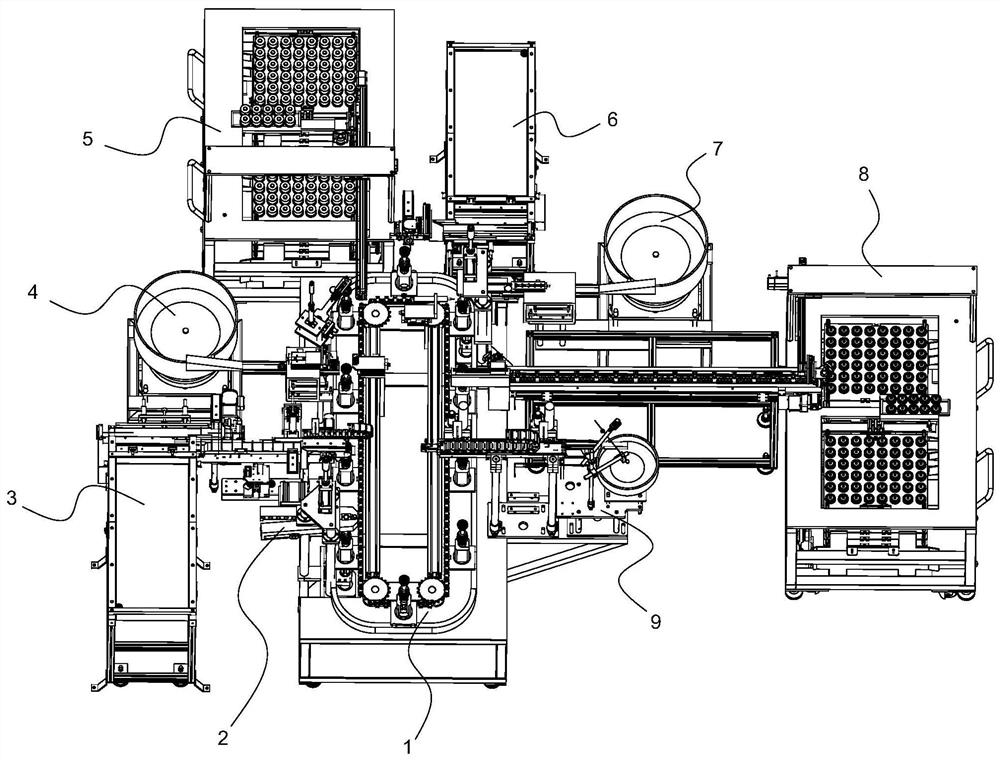

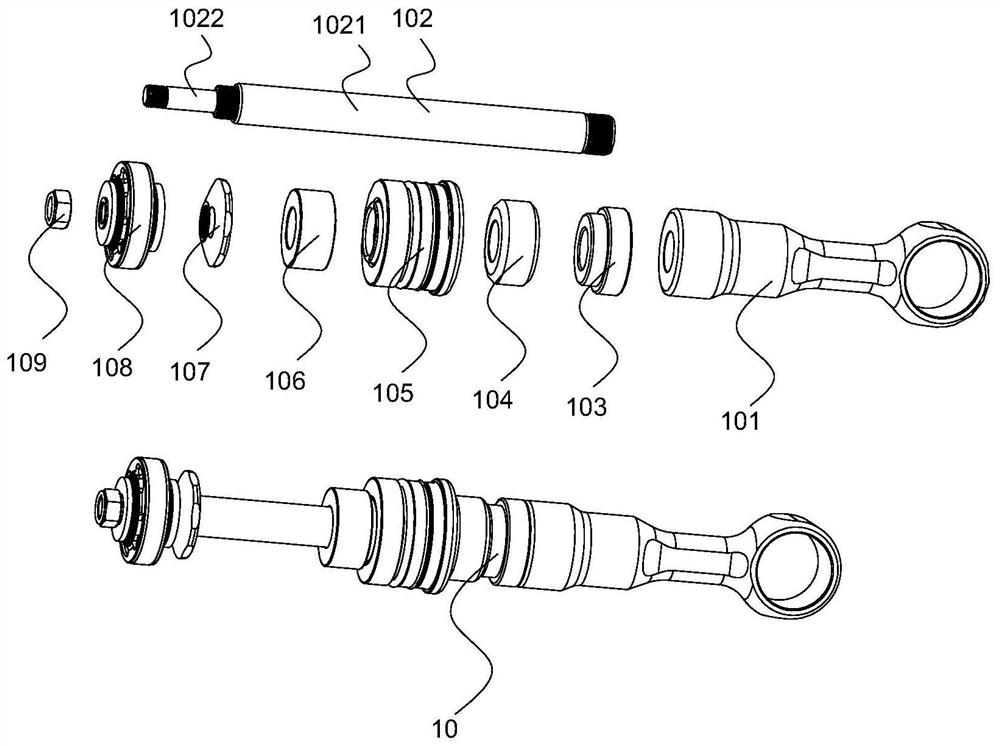

Hydraulic buffer assembly production system equipment and production process thereof

InactiveCN112338520APrecise positioningRapid positioningAssembly machinesMetal working apparatusEngineeringStructural engineering

The invention relates to the field of hydraulic buffer assembly production. The invention provides a hydraulic buffer assembly production system. The system comprises piston component assembly production equipment. The equipment comprises a rack, and a turntable assembling device, a mandrel tightening device, a first baffle ring feeding device, a piston feeding device, a guide sleeve component feeding device, a second baffle ring feeding device, a limiting nut feeding tightening device, a rebuilt valve feeding device and a locking nut feeding tightening device which are mounted on the rack, ajig mechanism used for vertically fixing a connecting piece is installed on an assembling frame mechanism in a sliding manner, and the jig mechanism continuously and annularly circulates on the assembling frame mechanism. The mandrel tightening device, the first baffle ring feeding device, the piston feeding device, the guide sleeve component feeding device, the second baffle ring feeding device,the limiting nut feeding tightening device, the rebuilt valve feeding device and the locking nut feeding tightening device are sequentially arranged at the periphery of the turntable assembling device, so that the devices act at the same time, and the assembling efficiency is improved.

Owner:陈美香

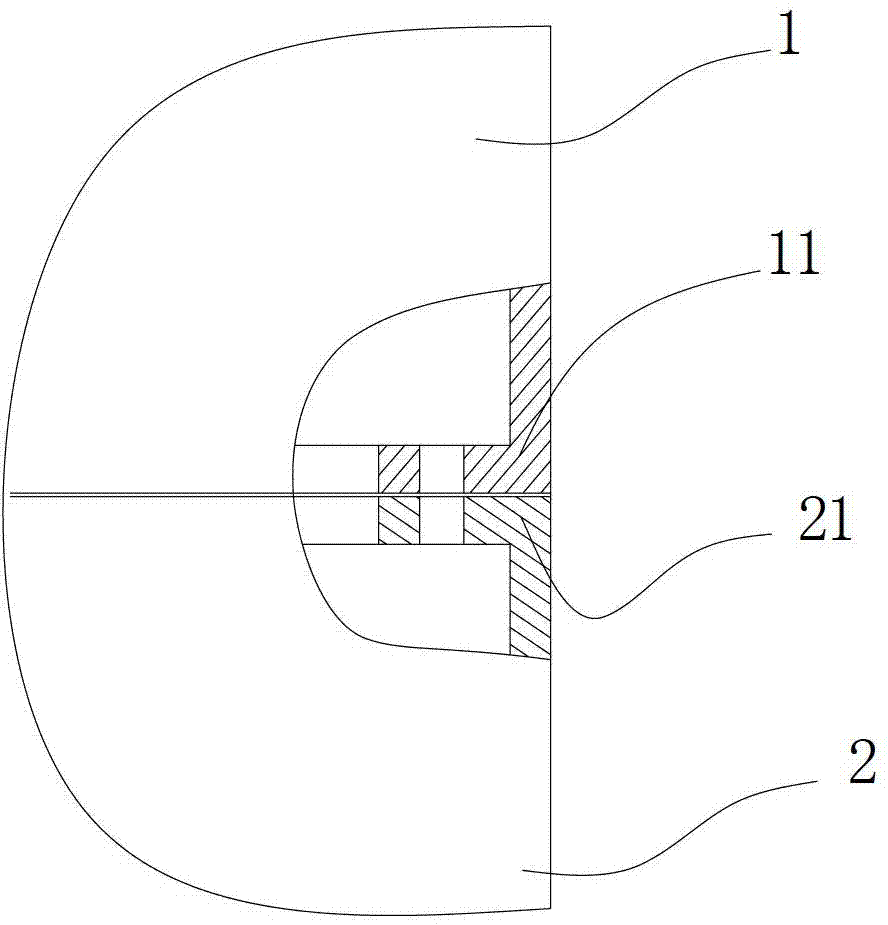

Tower drum frame

InactiveCN102758554AEasy to assembleImprove assembly efficiencyTowersBulk storage containerArchitectural engineeringTower

The invention discloses a tower drum frame, which comprises at least two sections of tower drums that are connected in sequence in an upper-lower direction. In the tower drums, the outer circumference of an inner connecting end of the first tower drum props against the inner circumference of an outer connecting end of the second tower drum; the inner connecting end of the first tower drum is provided with a plurality of inner connecting holes penetrating through the drum wall of the first tower drum, and the outer connecting end of the second tower drum is provided with a plurality of outer connecting holes penetrating through the drum wall of the second tower drum; the tower drum frame further comprises a plurality of connecting assemblies, wherein each connecting assembly comprises a connecting rod and two fastening components; each connecting rod passes through one inner connecting hole and one outer connecting hole; the two fastening components of each connecting assembly are respectively connected with two ends of each connecting rod and respectively supported on the inner circumference surface of the inner connecting end of the first tower drum and the outer circumference of the outer connecting end of the second tower drum. The tower drum frame disclosed by the invention has lower manufacturing cost and corresponding strength.

Owner:北京中水新能工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com