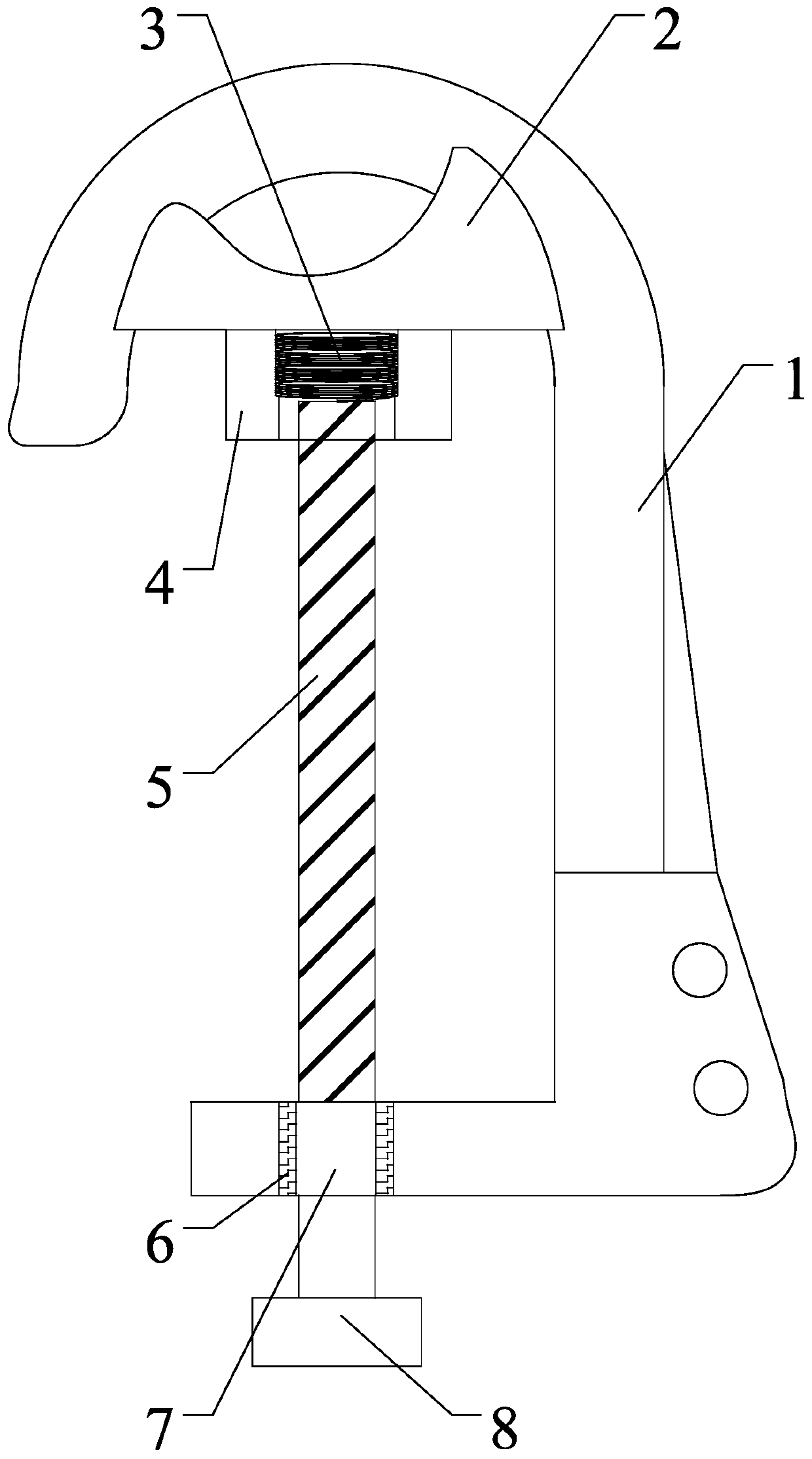

Seven-spiral grounding wire clamp

A grounding clip and screw technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of slow tightening speed and unreliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0013] figure 1 It is a structural schematic diagram of a seven-spiral ground clamp according to an embodiment of the present invention, as figure 1 As shown, the structure of the present invention includes a fixed frame 1 and a movable clamp block 2 slidingly connected to the inside of the fixed frame 1. The bottom end of the movable clamp block 2 is in contact with the top end of the screw rod 5. The screw rod 5 is a 7-thread structure, and the bottom end of the screw rod 5 passes through the After passing through the guide hole 7 opened at the bottom of the fixed frame 1, it is fixedly connected with the connecting column 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com