Polyurethane insulation board and production line thereof

A polyurethane insulation board and production line technology, which is applied in insulation, other household appliances, building components, etc., can solve the problems of inability to protect foam materials, aluminum foil composite glass fiber cloth falling off, and reducing the thermal insulation performance of aluminum foil insulation boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

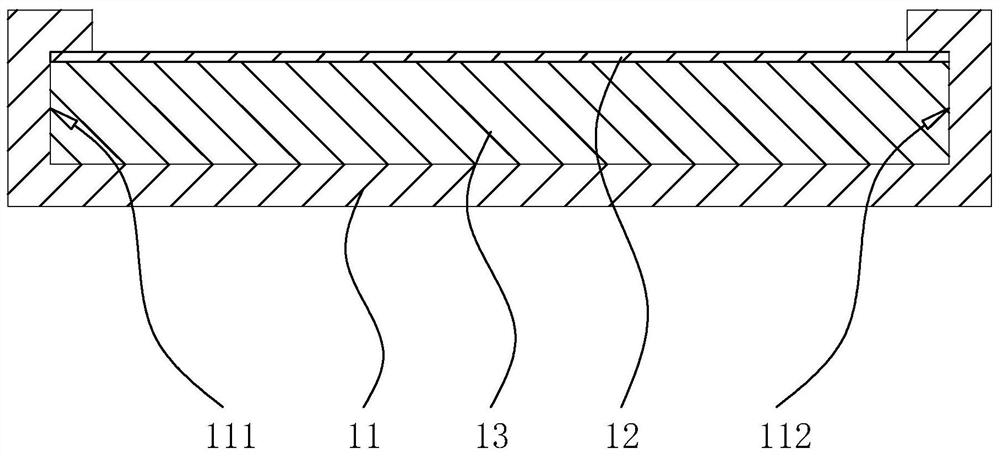

[0047] The embodiment of the present application discloses a polyurethane insulation board. refer to figure 1 The polyurethane insulation board includes a base plate 11, an aluminum foil cloth 12 and a polyurethane foam 13, wherein the base plate 11 is bent in a C shape, so that the two ends of the base plate 11 in the width direction form a first slot 111 and a second slot 112. The two ends of the aluminum foil cloth 12 are respectively embedded in the first card slot 111 and the second card slot 112, so that a foam cavity is formed between the substrate 11 and the aluminum foil cloth 12, and the polyurethane foam 13 is filled in the foam cavity, so that the polyurethane foam 13 will Both ends of the aluminum foil cloth 12 in the width direction are fastened in the first slot 111 and the second slot 112 of the substrate 11 .

[0048] The implementation principle of a kind of polyurethane insulation board in the present embodiment is:

[0049]After the aluminum foil cloth 12...

Embodiment 2

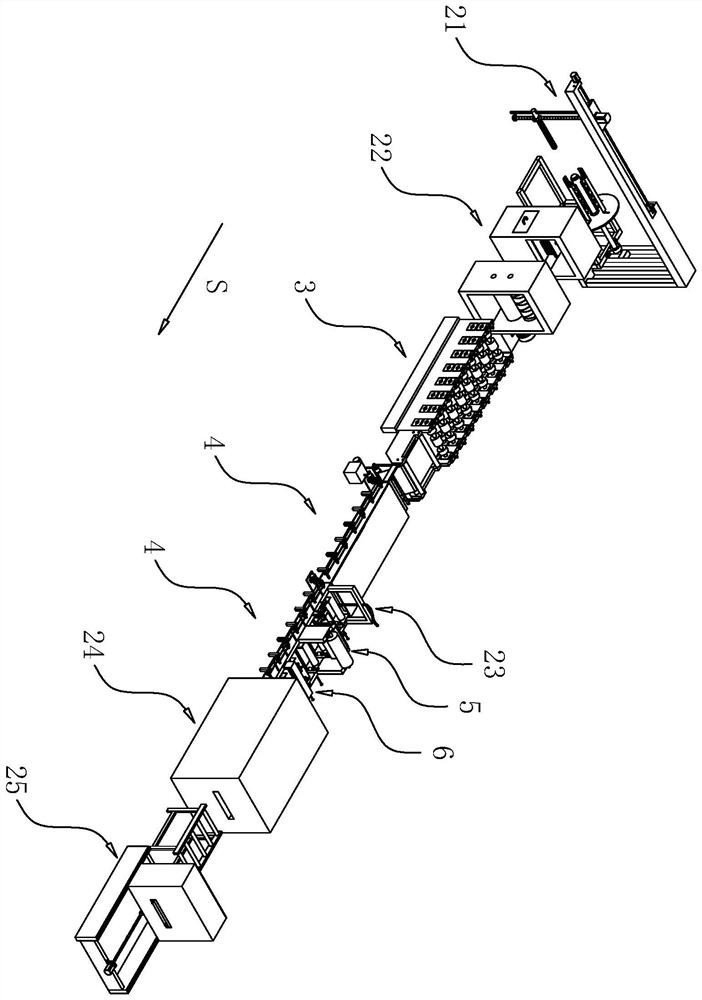

[0051] The embodiment of this application discloses a production line. refer to figure 2 , the production line includes an uncoiler 21 for uncoiling the coil into a sheet, an embossing machine 22 for embossing the sheet, a forming machine 3 for extruding the sheet into a substrate 11, a foaming machine 23 for A foaming machine 23 sprayed on the substrate 11, a spreader 5 for laying the aluminum foil cloth 12 on the substrate 11, a cloth embedding machine 6 for embedding the aluminum foil cloth 12 in the substrate 11, and a machine for conveying the substrate 11 The conveying device 4 and the laminator 24 for compacting the insulation board 442 . Wherein the uncoiler 21, the embossing machine 22, the forming machine 3, the conveying device 4 and the laminating machine 24 are arranged in sequence, and the foaming machine 23, the spreading machine 5 and the cloth inserting machine 6 are arranged on the conveying device 4 in sequence.

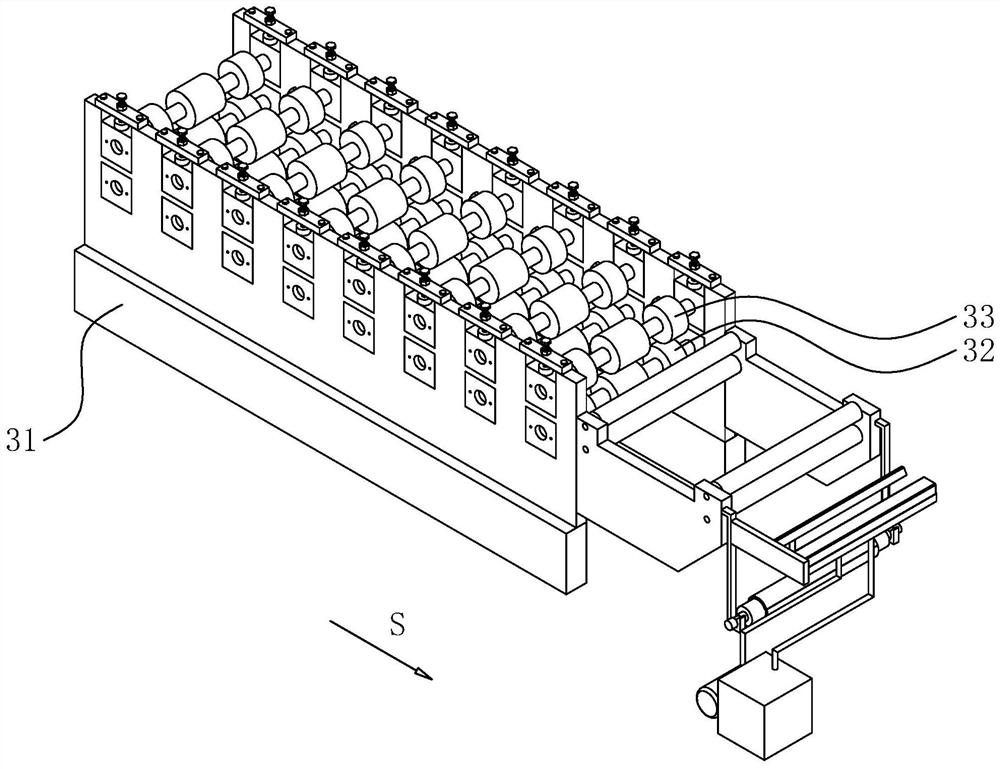

[0052] refer to image 3 and Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com