Patents

Literature

78results about How to "Reduce prolapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refractory metal alloy ultrathin plate and foil, as well as producing method of plate

ActiveCN102950286AGuaranteed purityAdd stepsTurbinesOther manufacturing equipments/toolsIron powderAlloy

The invention discloses a refractory metal alloy ultrathin plate, a foil, and a producing method of the plate. The method for producing the ultrathin plate comprises the following steps of: (1) uniformly mixing the raw material, namely 50-99% of tungsten powder or molybdenum powder and 50-1% of one or more of the following materials of iron powder, nickel powder and copper powder with ethanol so as to obtain a mixture, wherein the usage of the ethanol is relatively lower than 0.5% of the total weight of the raw material; (2) preheating the mixture at 120-140 DEG C, and pressing after uniform heating, so that a raw slab with the thickness of 0.3-0.9millimeter is produced; and (3) sintering and cooling the raw slab under an anaerobic condition, so that the refractory metal alloy ultrathin plate is obtained. According to the producing method, a binding agent is not added, so that a step for removing the binding agent during the subsequent processes is reduced, the material purity is ensured, moreover, the production cost is also greatly lowered, and the production efficiency is increased. The refractory metal alloy ultrathin plate has a uniform internal organizational structure and has the thickness of 0.25-0.8millimeter, and one to six passes of rolling or short-time grinding only needs to be carried out subsequently, so that a high-specific-gravity foil product with the thickness of 10-50mu m can be produced.

Owner:上海瑞钼特科技股份有限公司

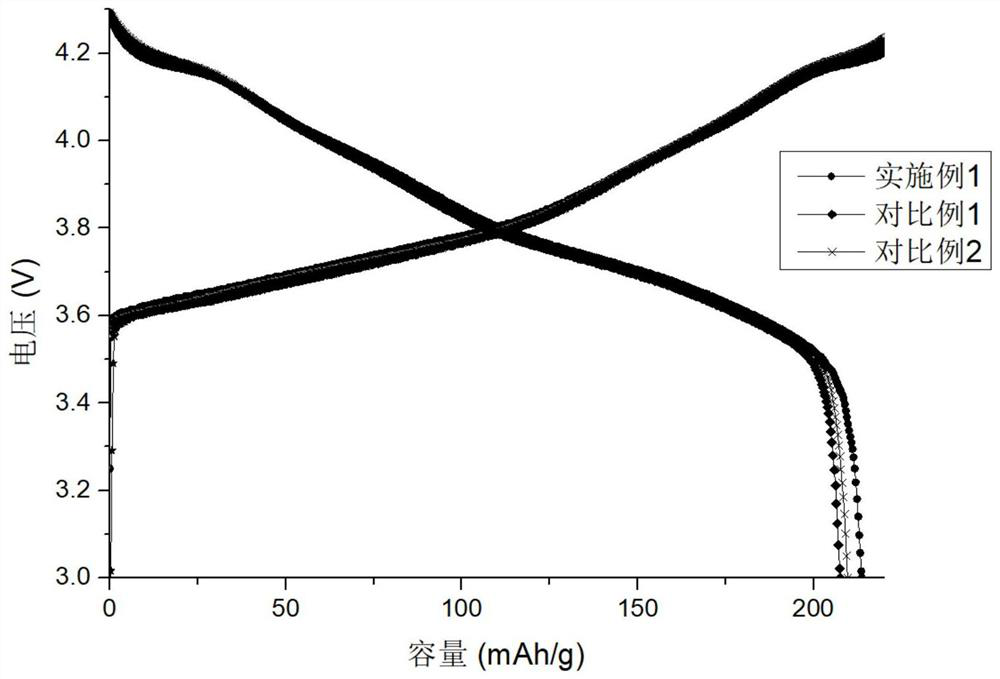

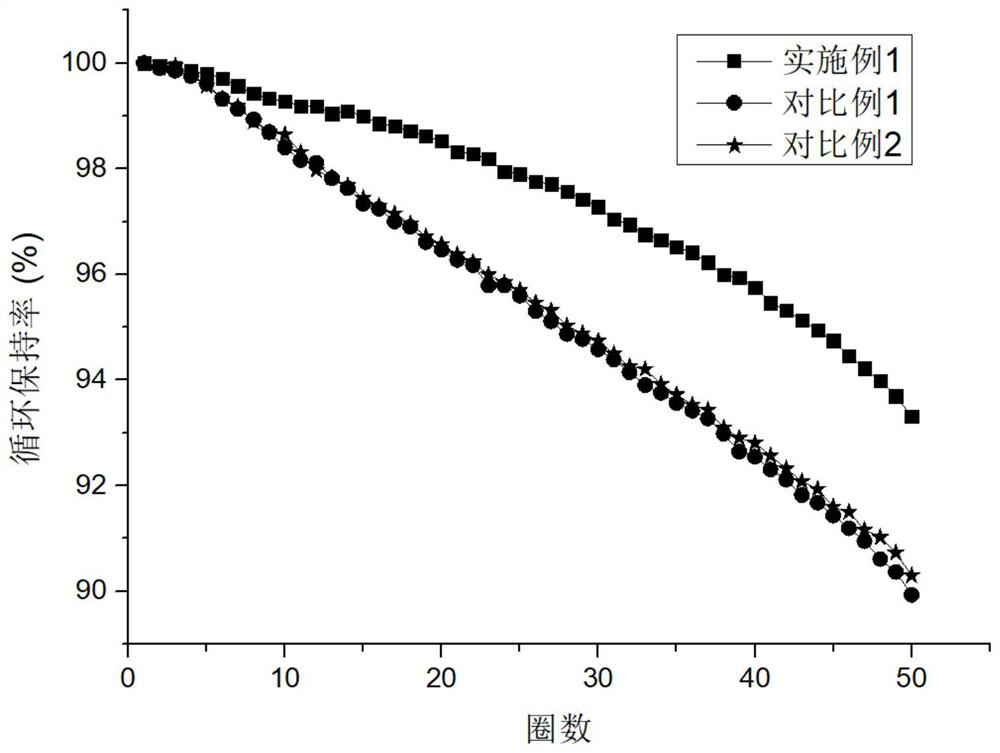

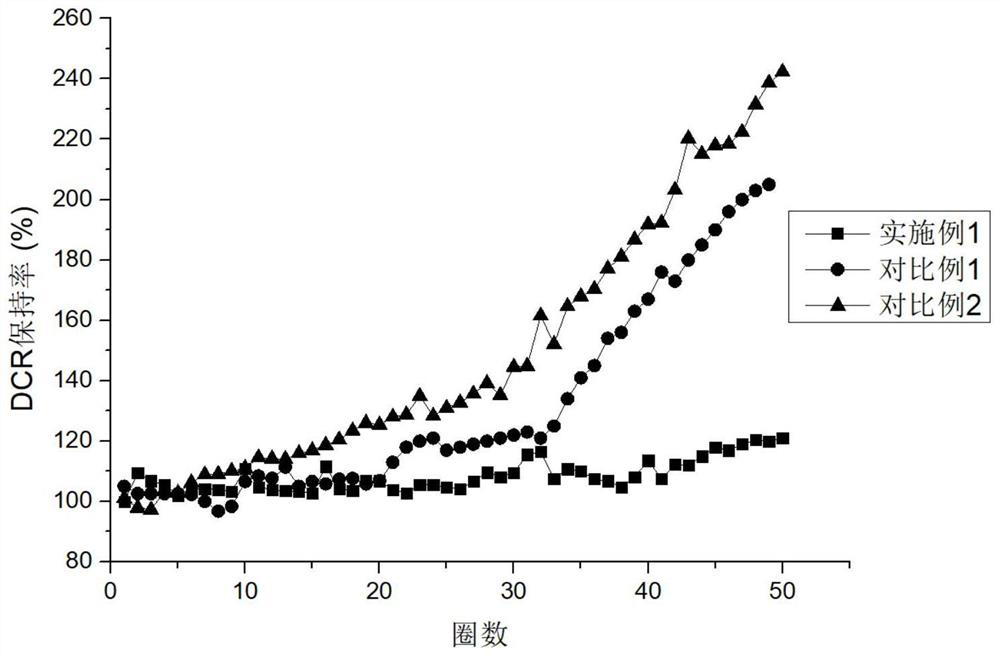

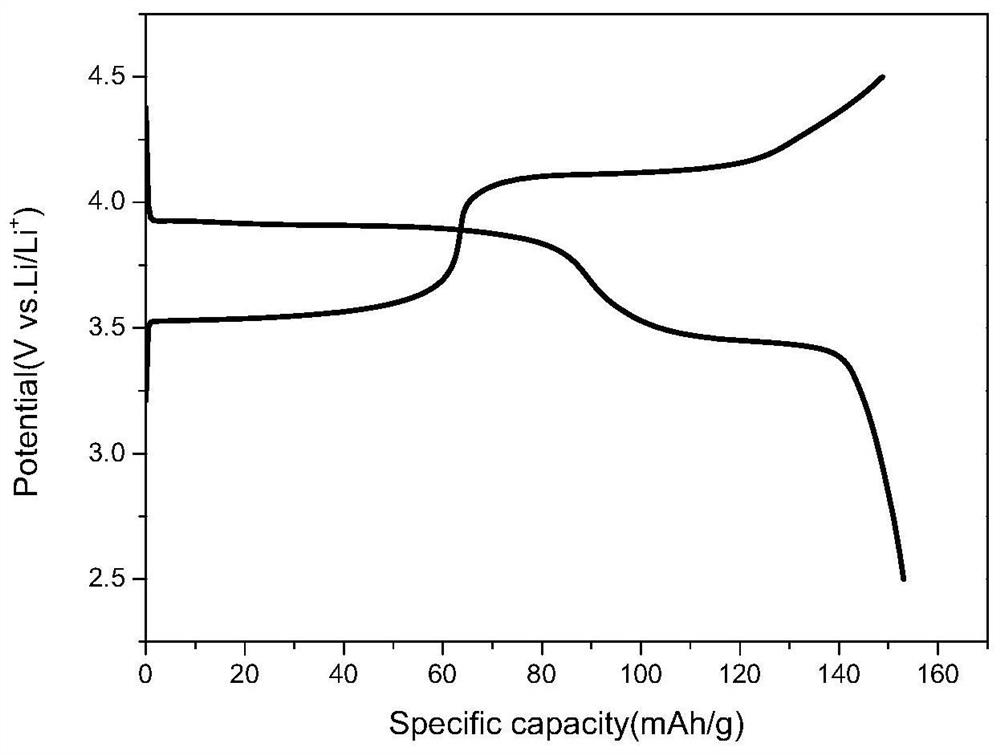

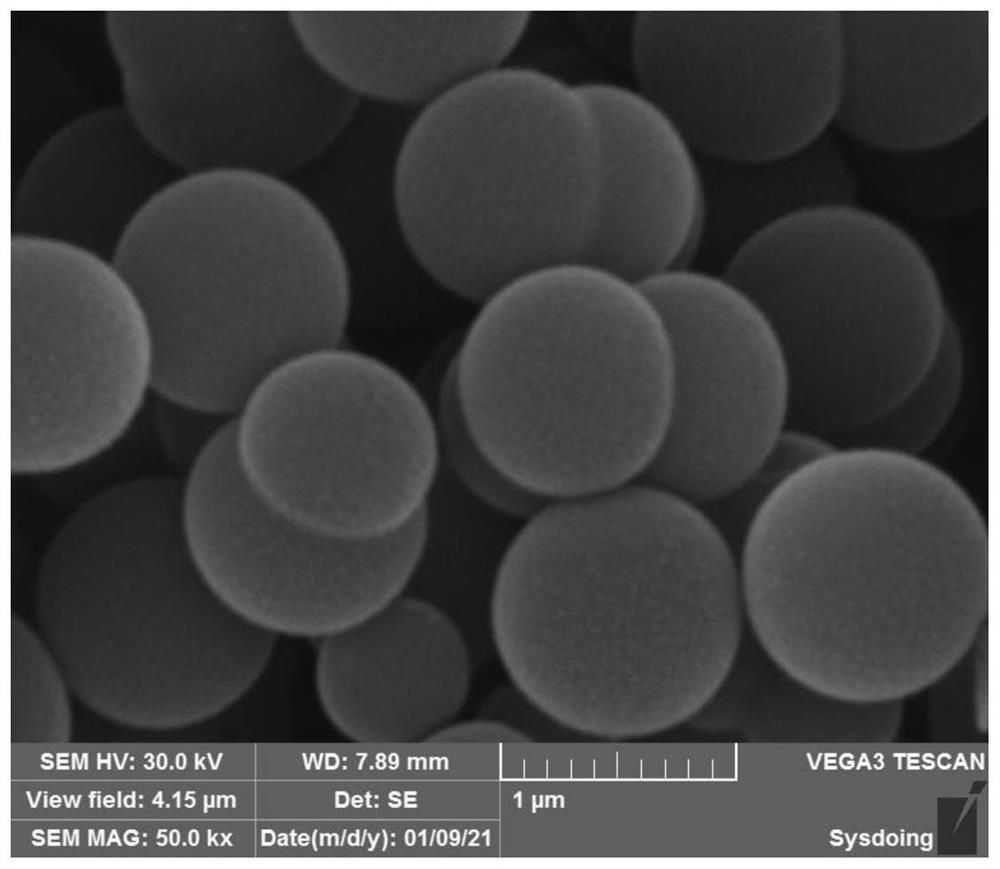

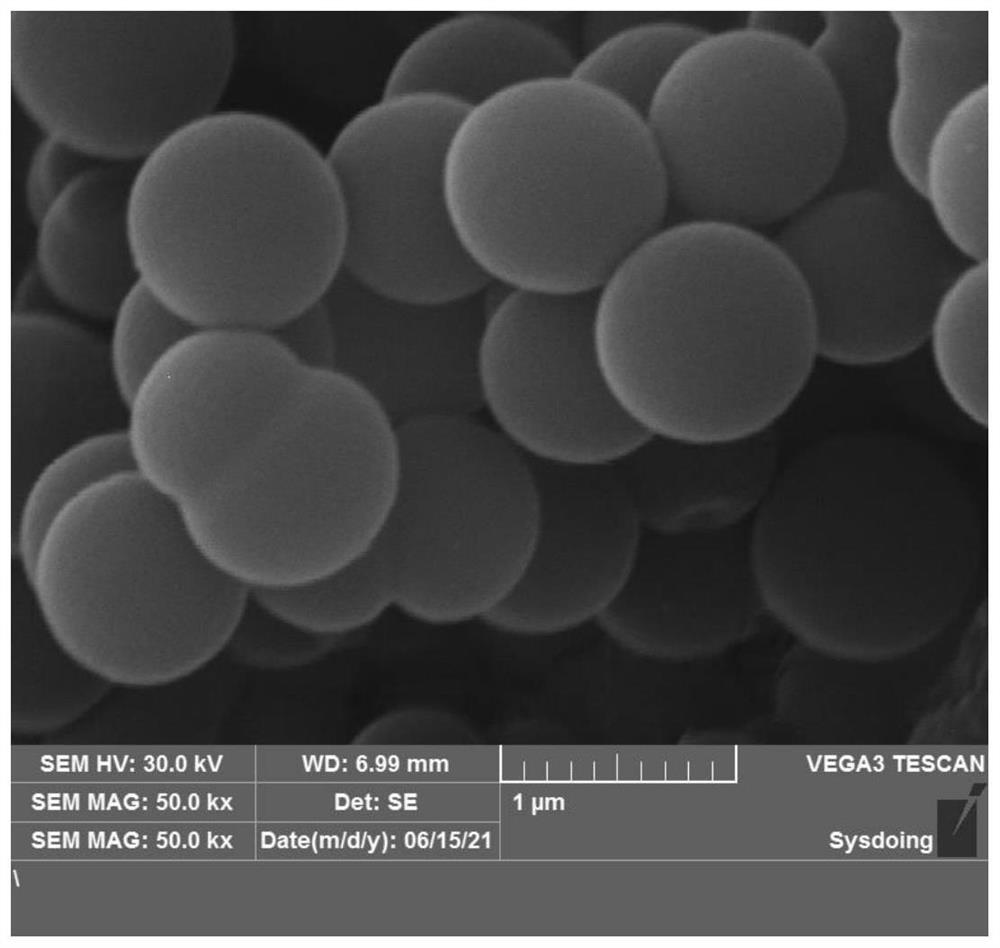

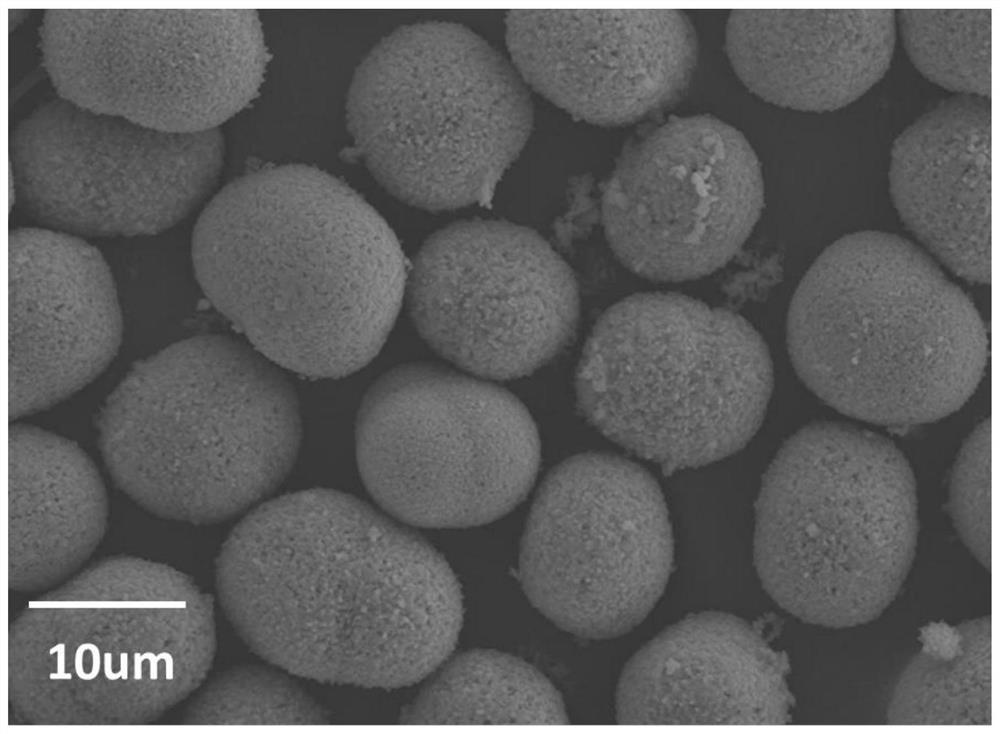

Modification method for reducing residual alkali on surface of high-nickel ternary positive electrode material, prepared high-nickel ternary positive electrode material and lithium ion battery

InactiveCN112340783AReduce surface residual alkaliReduce prolapseFinal product manufactureCell electrodesElectrical batteryPhysical chemistry

The invention discloses a modification method for reducing residual alkali on the surface of a high-nickel ternary positive electrode material, which comprises the following steps of (1) uniformly mixing the high-nickel ternary positive electrode material with a solvent to form slurry, and (2) rapidly leaching the slurry with a solvent, then carrying out filter pressing and drying, and sintering the dried product to obtain the high-nickel ternary positive electrode material with low residual alkali, The solvent is selected from one or a mixture of more of deionized water, ammonia water and alcohol. According to the method, the high-nickel ternary positive electrode material is pulped, and then residual alkali on the surface of the material is reduced by a rapid leaching method, so that theresidual alkali on the surface of the material is further reduced; under the condition that the specific surface area is not obviously increased, LiOH and Li2CO3 on the surface of the material are reduced; meanwhile, the removal of lattice lithium is reduced, the first specific discharge capacity of the high-nickel ternary positive electrode material is not reduced due to water washing, the high-temperature cycle performance and the high-temperature storage performance of the high-nickel ternary positive electrode material are further improved, and the increase of high-temperature cycle DCR is reduced.

Owner:宜宾锂宝新材料有限公司

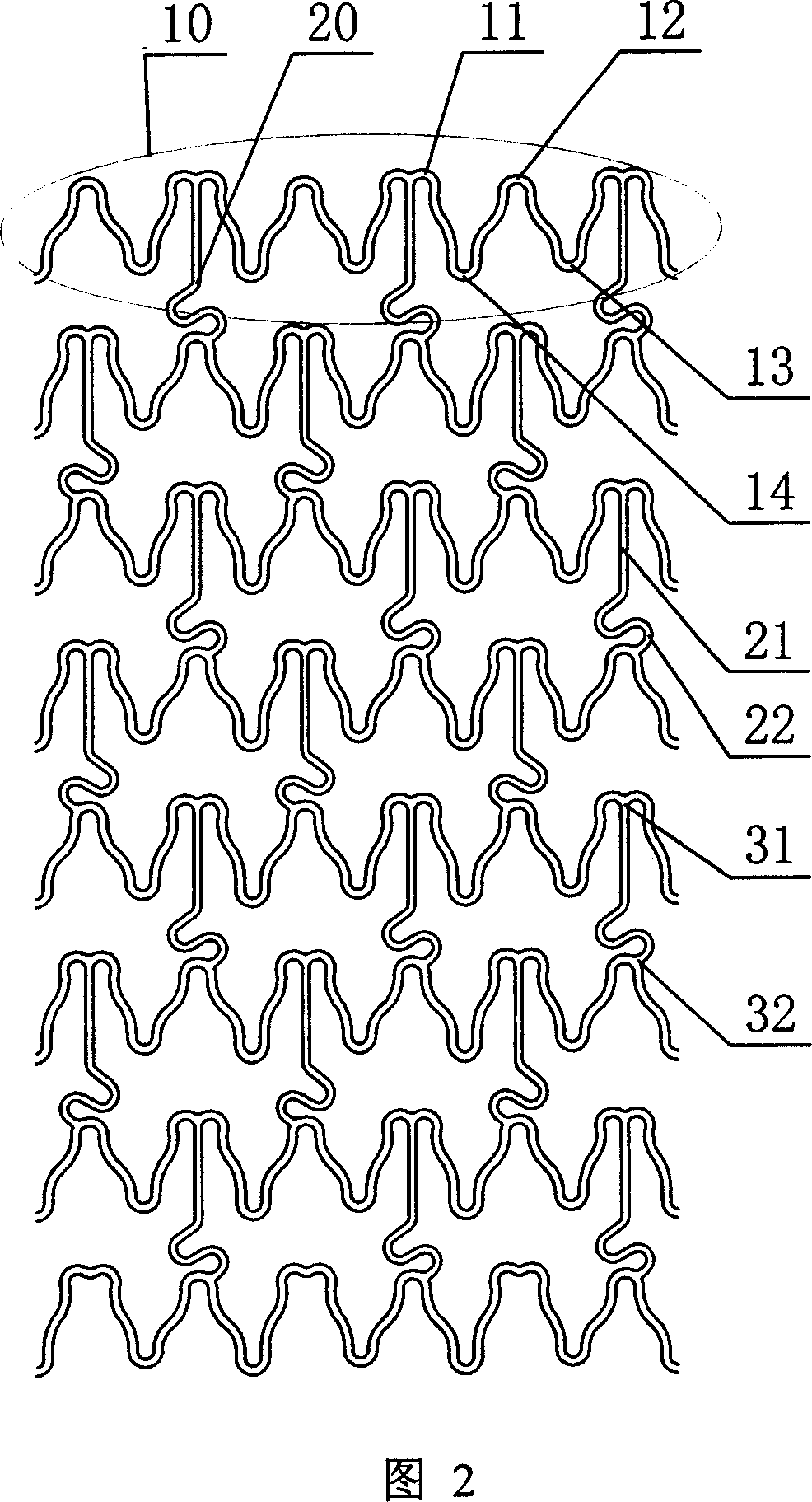

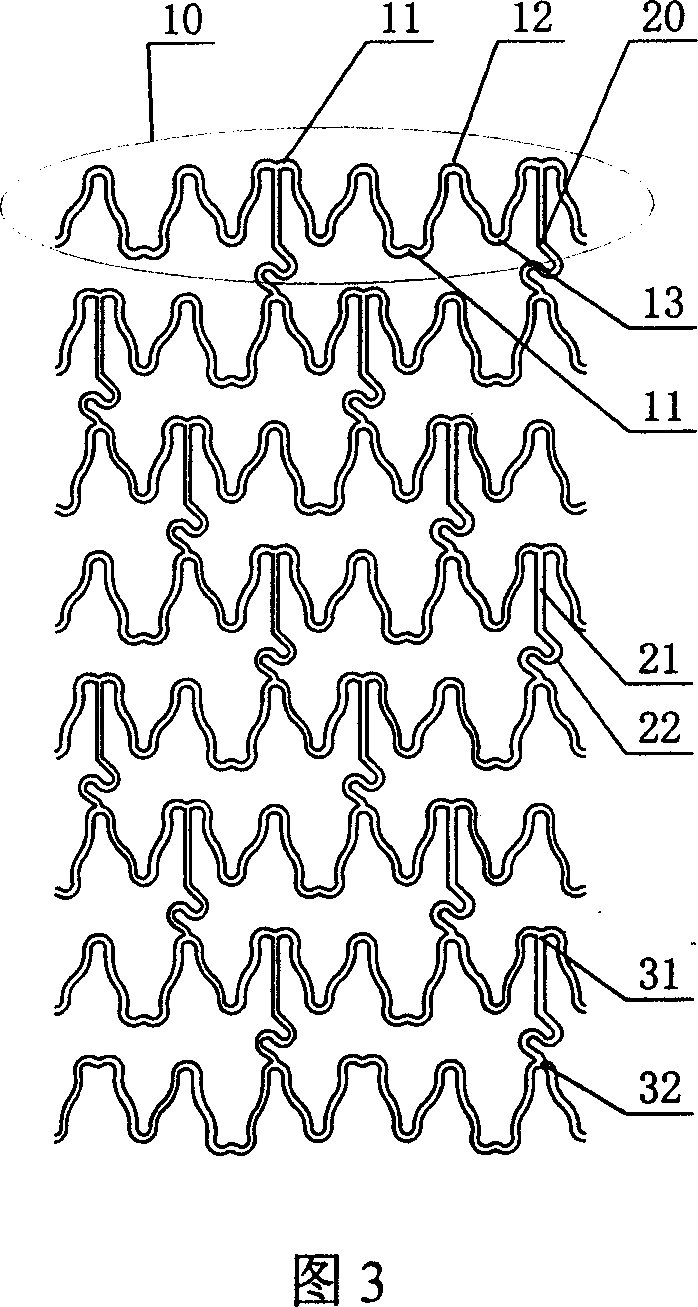

Blood vessel support bracket with little tissue prolapsus after implantation

InactiveCN1923154AEvenly distributedReduce prolapseStentsBlood vesselsBlood vessel occlusionReticular formation

The invention relates to a blood vessel support with less drop organism after being planted into organism, used to treat blood vessel block in puncture shaping surgery. Wherein, said support can be used in heart blood vessel, and outer blood vessels, via thin micro tube and laser to be carved into network structure; and the invention is formed by several groups of wave support rings (10) connected by connecting rods (20); each support ring (10) is formed by 2-5 groups of unit waves; nearby support rings (10) are connected by 2-10 connecting rods; the invention can avoid the support rod interfere the clamping and expanding, to improve flexibility, and the drug coat will not form web and the drug density will be uniform.

Owner:SOUTHEAST UNIV

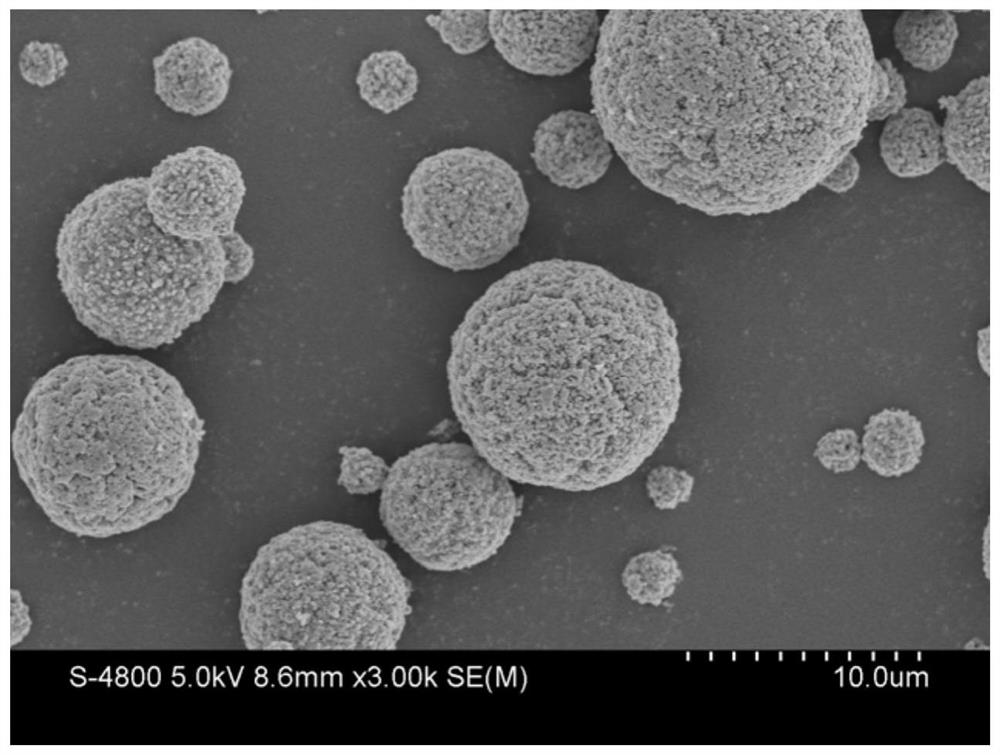

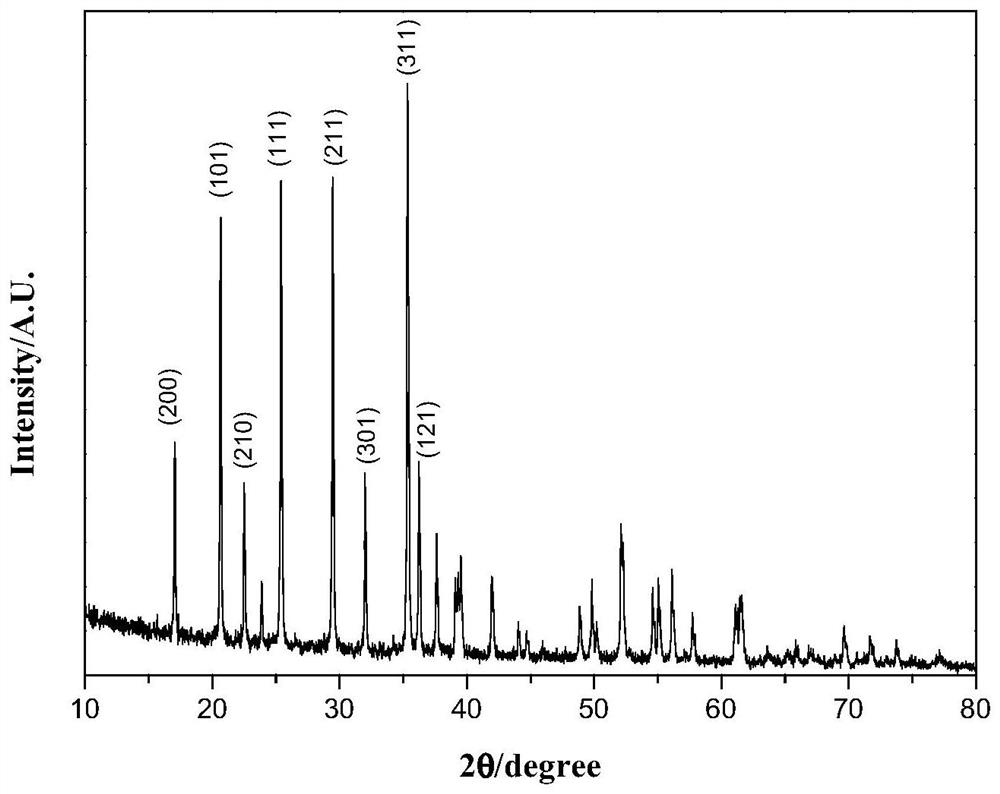

Preparation method of high-compaction-density lithium manganese iron phosphate/carbon composite positive electrode material

ActiveCN113072049AGood performance repeatabilityReaction conditions are easy to controlMaterial nanotechnologyCarbon compoundsCarbon compositesPhosphoric acid

The invention discloses a preparation method of a high-compaction-density lithium manganese iron phosphate / carbon composite positive electrode material. The chemical general formula of the material is LiMnxFeyPO4 / C, wherein x is more than or equal to 0.5 and less than or equal to 0.9, and x + y is equal to 1. The preparation method comprises the following steps: diluting phosphoric acid for later use, adding a manganese source, an iron source, a dispersing agent and deionized water into a sealable container, and introducing shielding gas; adding diluted phosphoric acid into the sealed container, aging until the pH value is 2.0-5.0, and uniformly nucleating; cleaning the formed precipitate, drying in vacuum, and sintering for the first time at high temperature to form spherical particles A; preparing a solution from lithium hydroxide monohydrate, adding the spherical particles A into the solution, performing spray drying, and performing high-temperature secondary sintering to obtain spherical particles B; and preparing a glucose solution, adding the spherical particles B into the glucose solution, performing spray drying, and performing high-temperature third sintering to obtain the nano spherical lithium manganese iron phosphate / carbon composite material. The electrochemical performance and the compaction density of the material are greatly improved.

Owner:天津斯科兰德科技有限公司

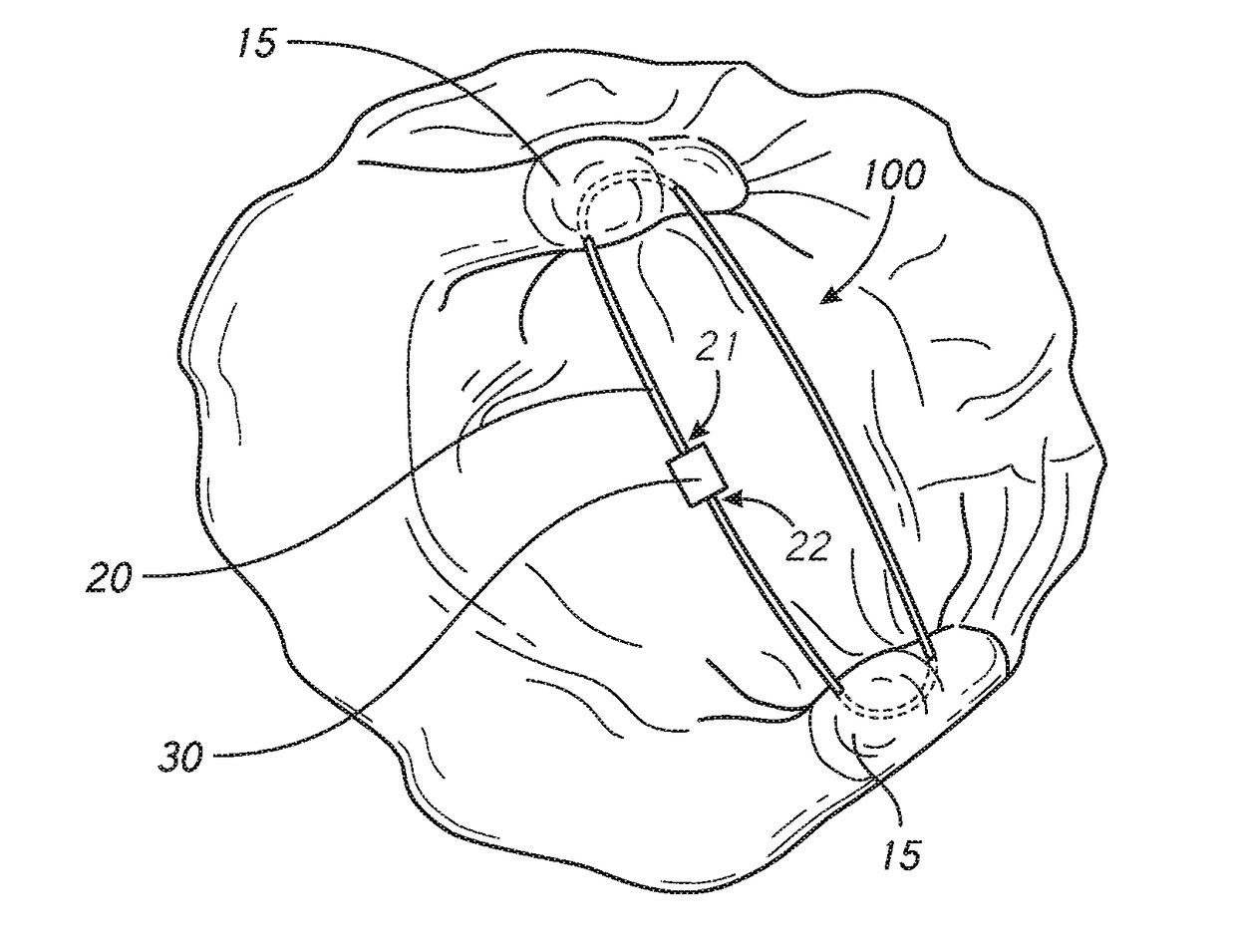

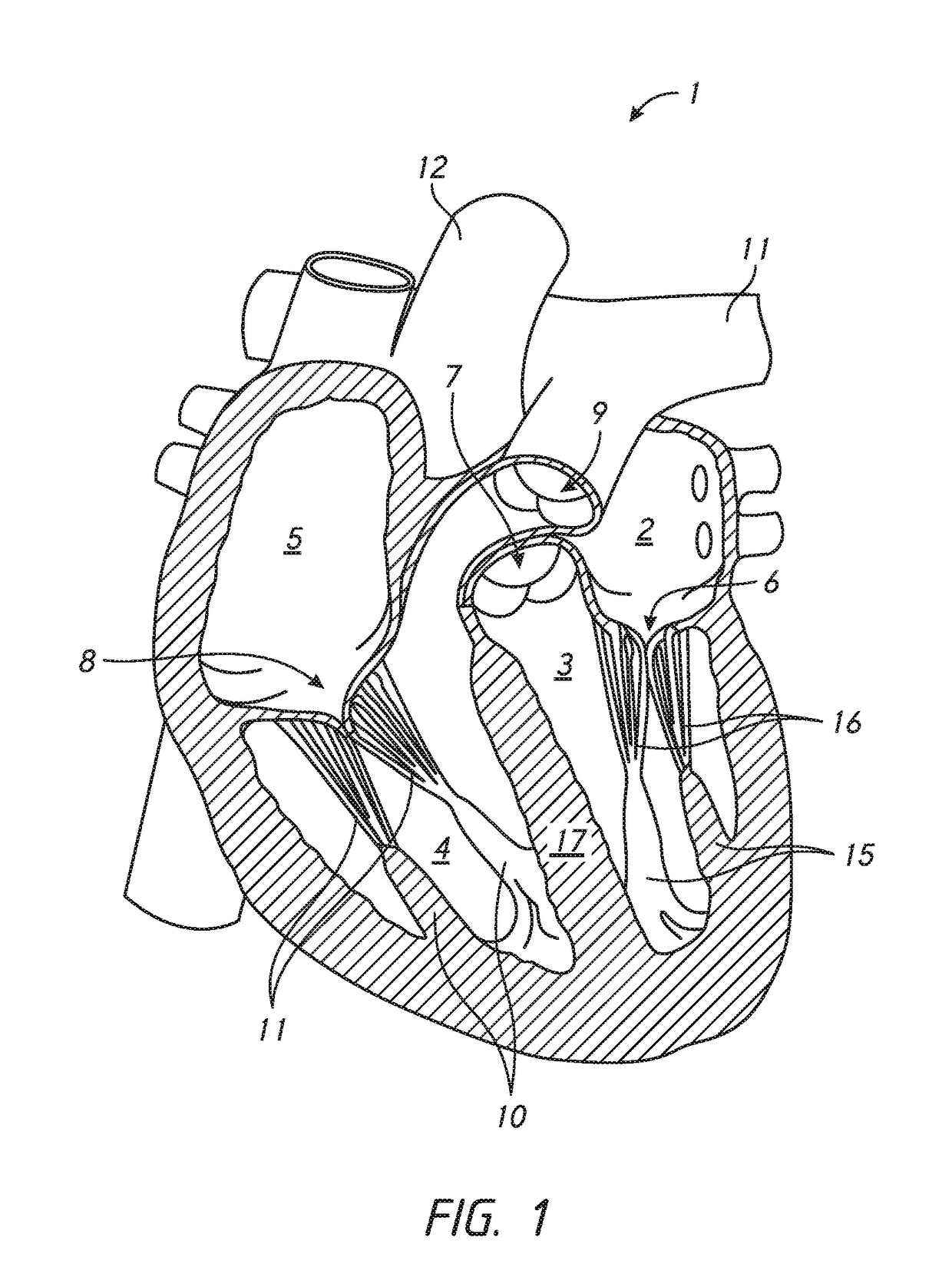

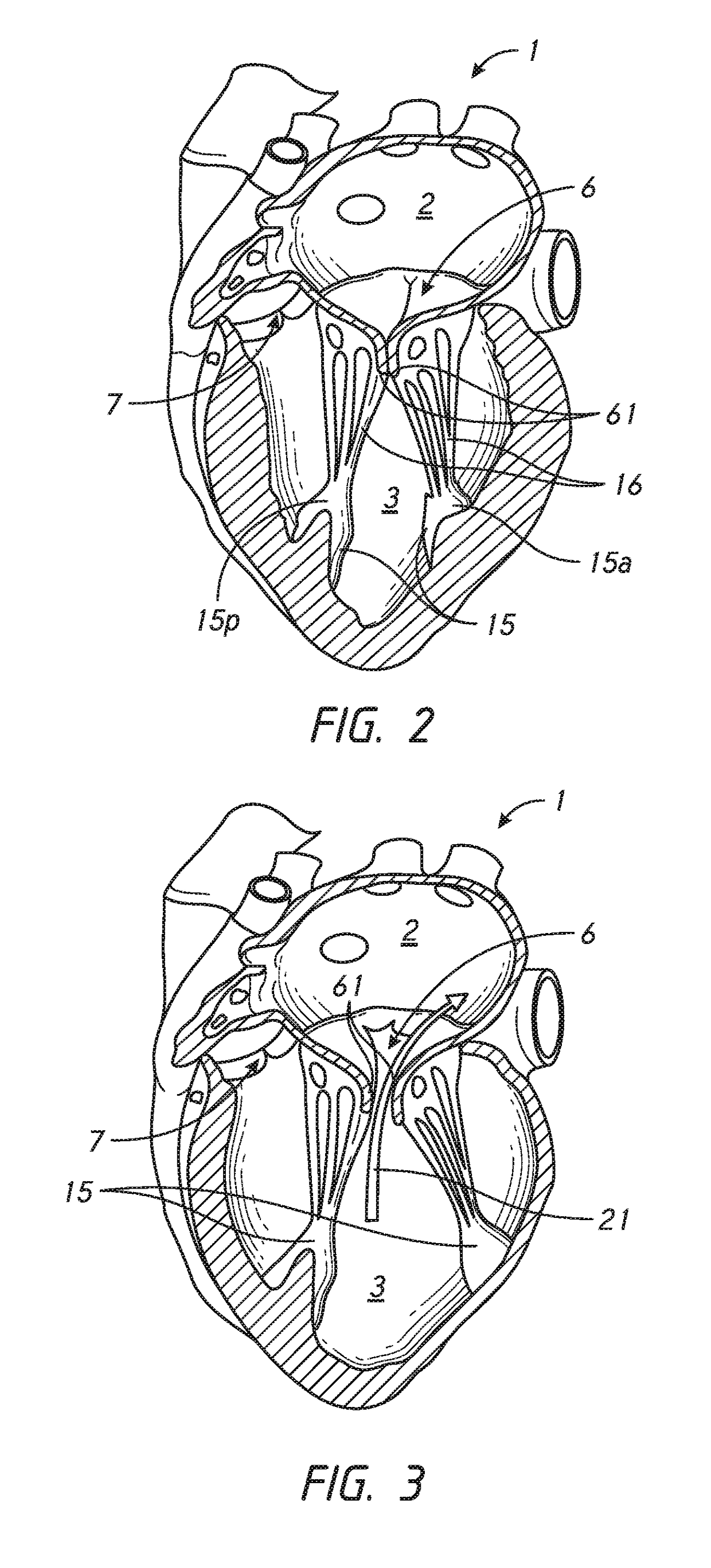

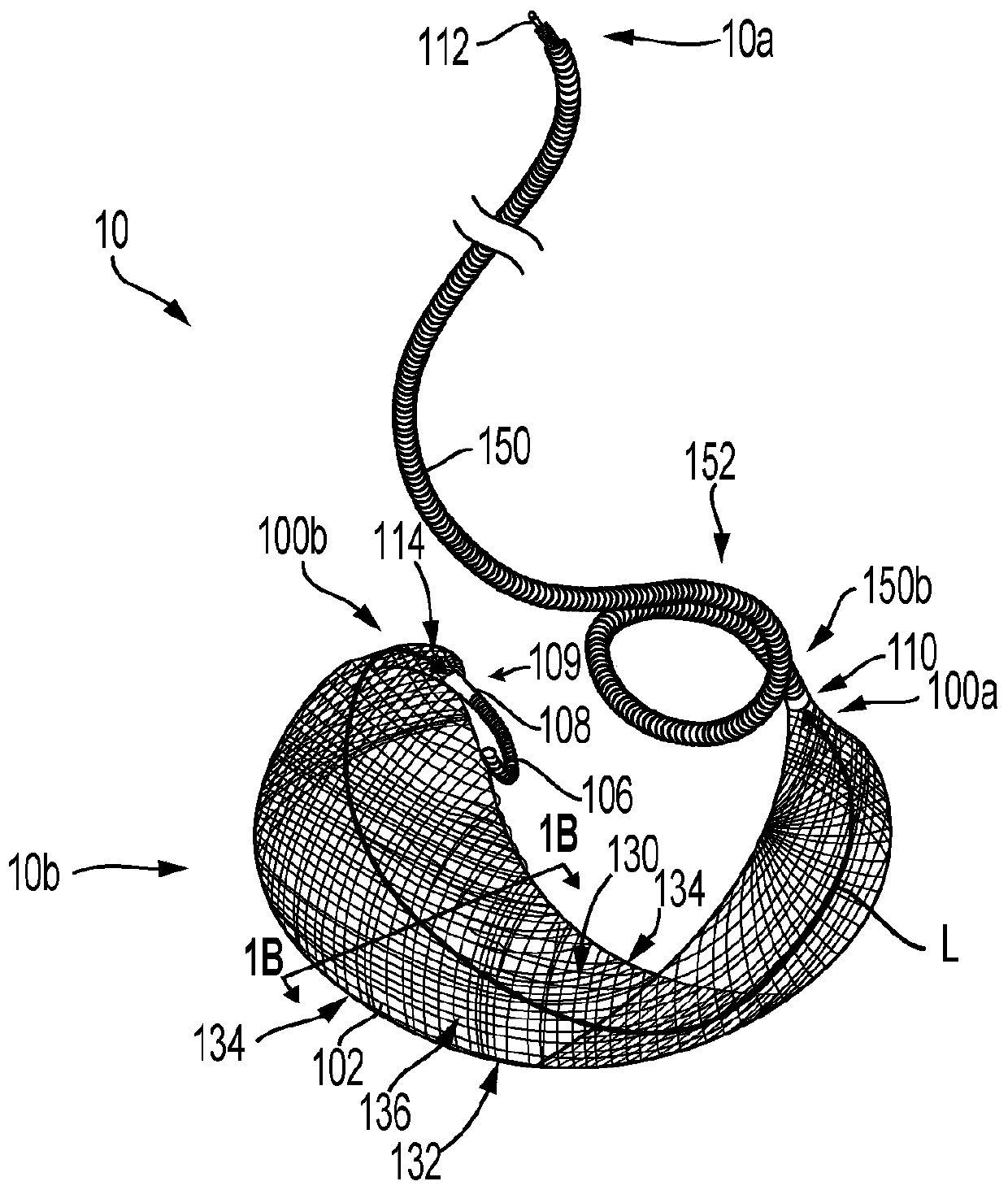

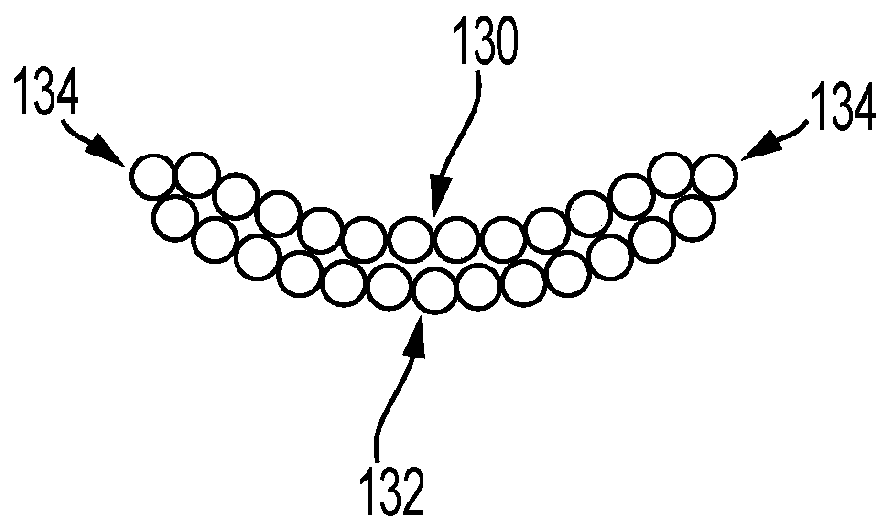

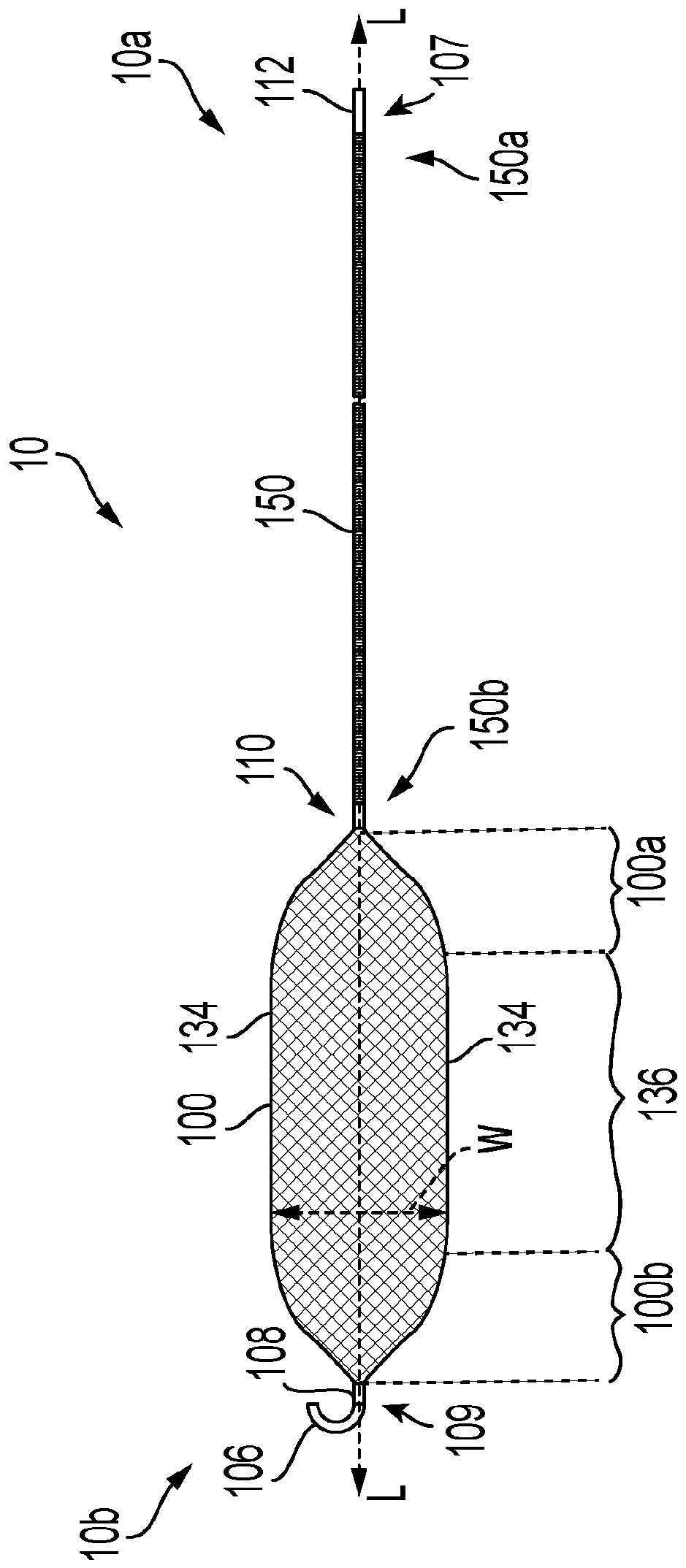

Papillary muscle binding

InactiveUS20180318082A1Improve heart valve performanceReduce regurgitationSuture equipmentsSurgical needlesPapillary muscleLoop of Henle

A method for improving leaflet prolapse and / or valve regurgitation associated with a heart valve involves delivering a catheter into a ventricle of a heart, attaching a cord to a first papillary muscle disposed in the ventricle, the first papillary muscle being connected to a first leaflet of an atrioventricular heart valve, attaching the cord to a second papillary muscle, the second papillary muscle being connected to a second leaflet of the heart valve, secure first and second portions of the cord in a fixed relative position to form a loop attached to both the first and second papillary muscles, and releasing the cord from the catheter.

Owner:EDWARDS LIFESCIENCES CORP

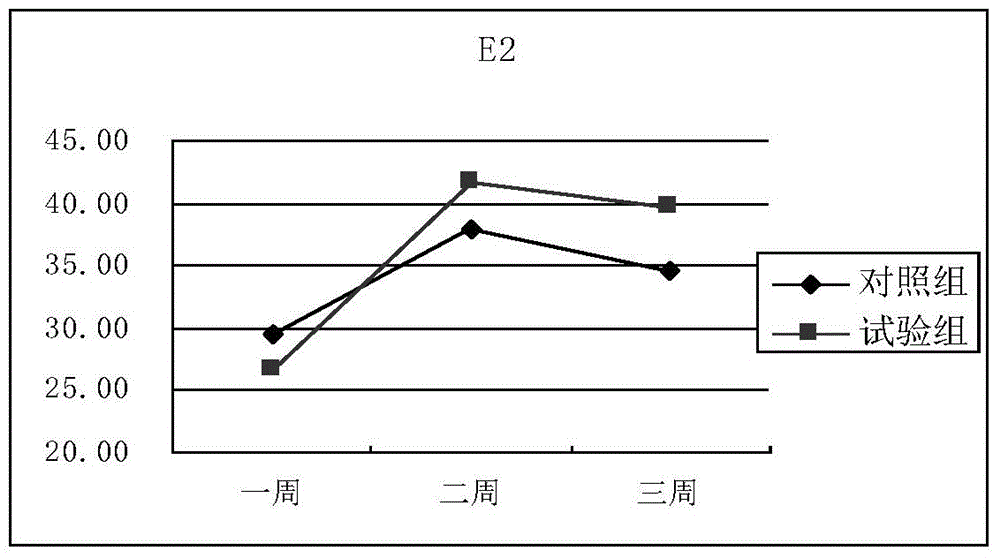

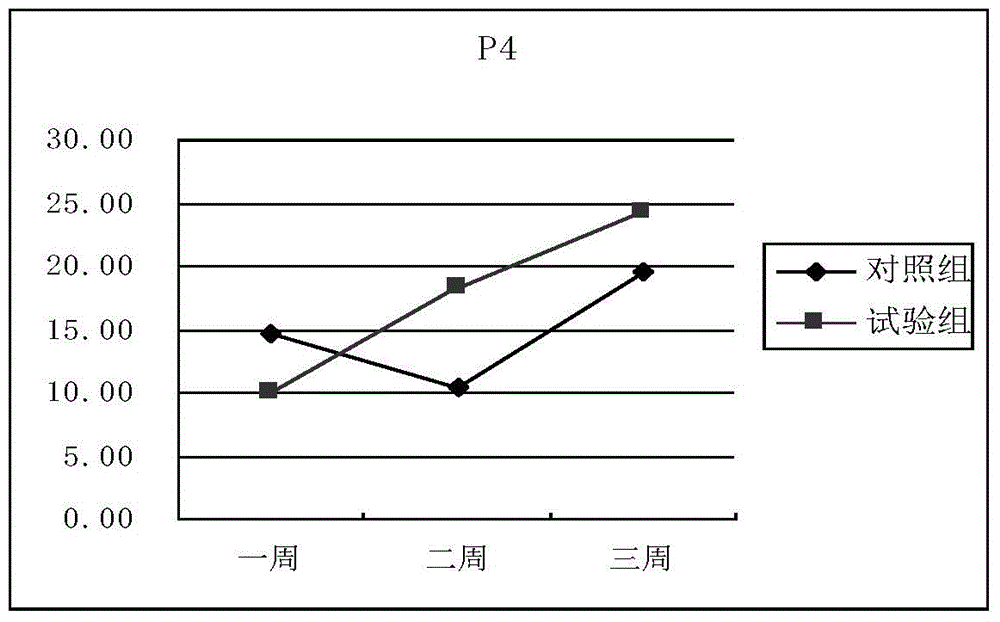

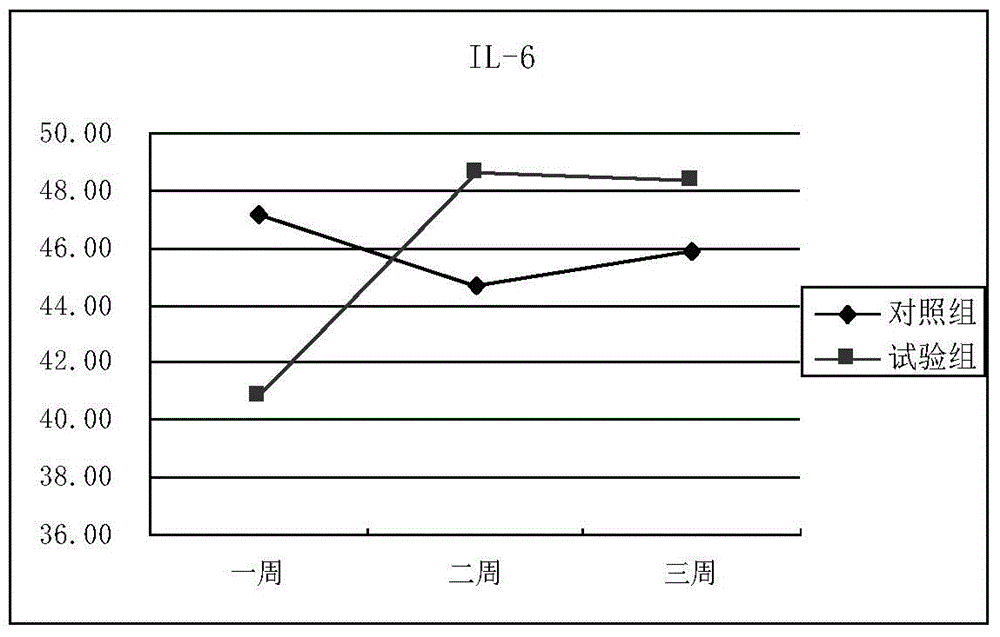

Chinese medicine probiotic compound preparation and preparation method thereof for poultry ovarian maintenance

ActiveCN104825718AEnhance immune functionPromote growthOrganic active ingredientsUnknown materialsReproductive systemCompounded preparations

The invention discloses a Chinese medicine probiotic compound preparation for the poultry ovarian maintenance, which comprises the following raw materials in part by weight: 10-20 parts of Radix Astragali, 5-15 parts of Radix Codonopsis, 5-10 parts of acanthopanax, 4-8 parts of Astragali Complanati Semen, 2-5 parts of Cyperus Rotundus L, 1-5 parts of corydalis tuber, 5-15 parts of isatis roots, 15-25 parts of epimeddium, 10-15 parts of motherwort, 4-8 parts of Radix Ranunculi Ternati, 0.001-0.1 part of lactic acid bacteria, 0.001-0.1 part of Bacillus spp, 7-15 parts of selenium yeast, and 2-5 parts of decavitamin. The invention also discloses a preparation method of the Chinese medicine probiotic compound preparation. The Chinese medicine probiotic compound preparation significantly improves the immunity of laying hens, improves the ovarian function, eliminates the genital system damage, promotes the follicular development and ovulation, prolongs the peak period of egg production, and improves the egg quality. The Chinese medicine probiotic compound preparation has the health-care effect on ovaries and low in cost, thus being suitable for the egg-production poultry.

Owner:山东宝来利来生物工程股份有限公司

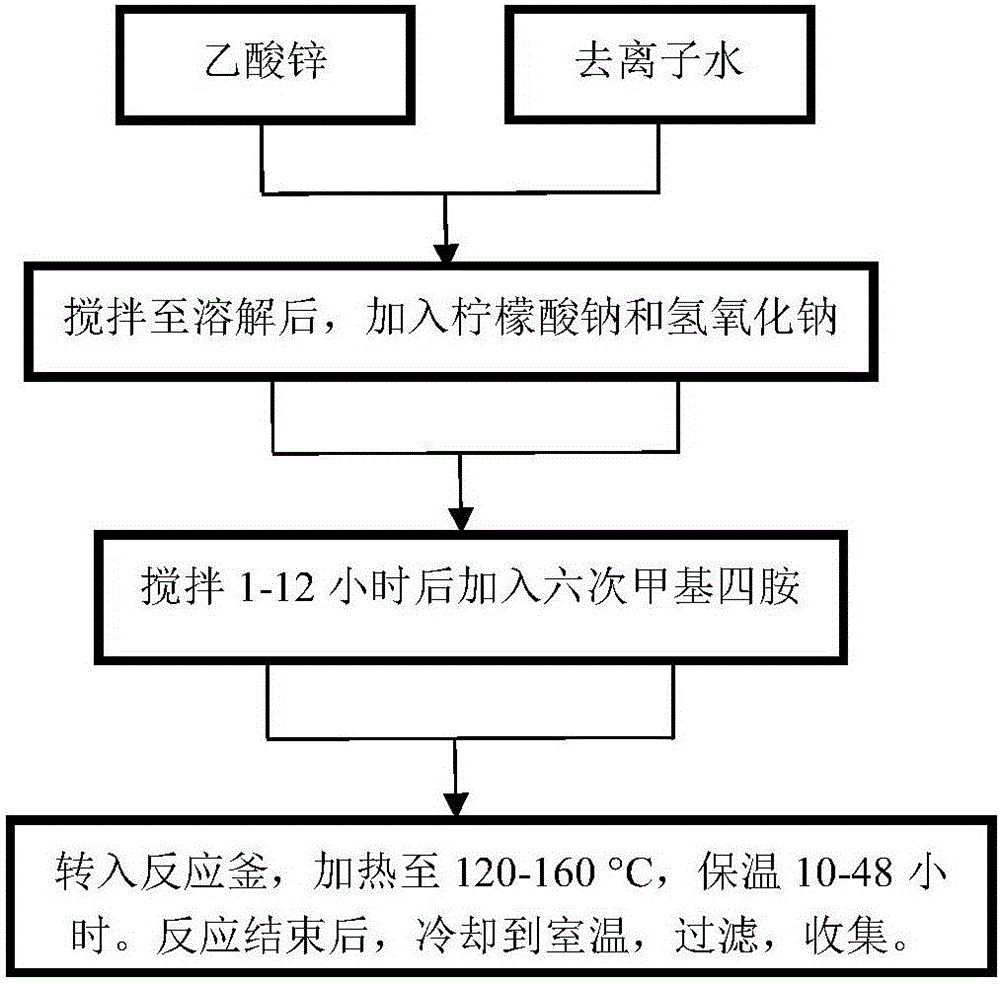

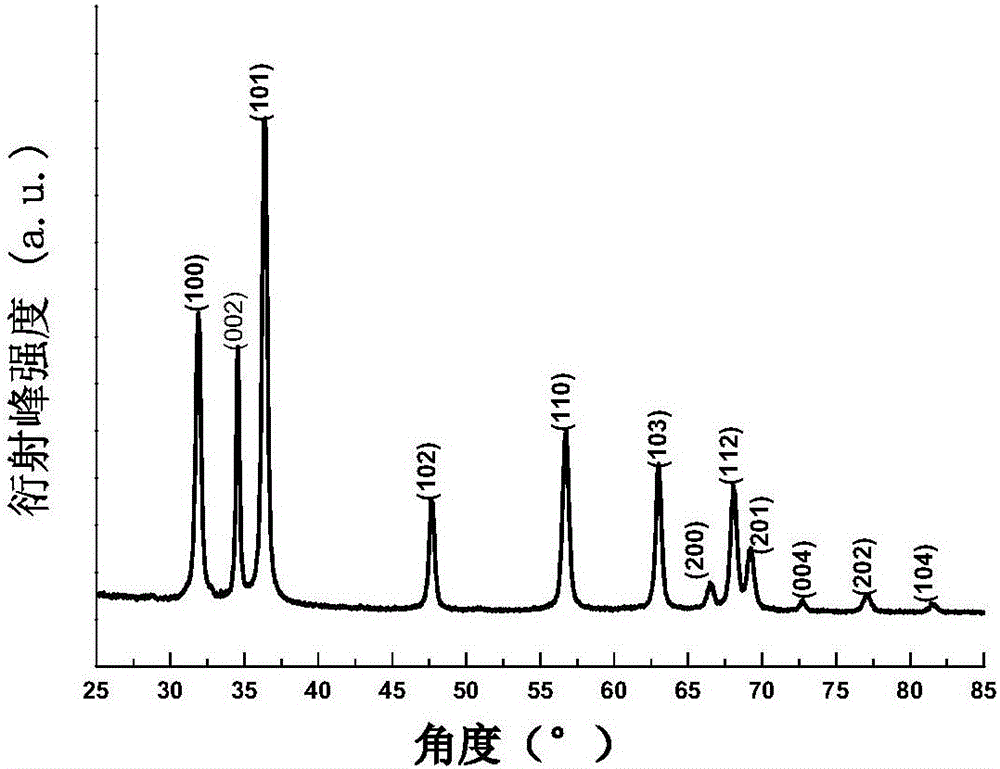

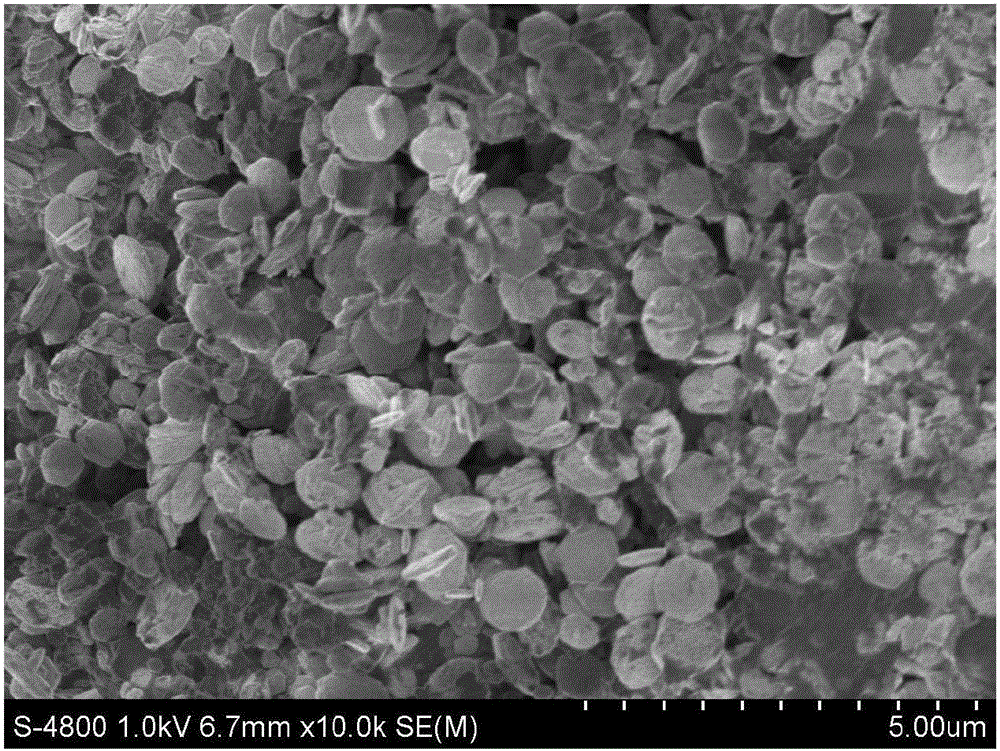

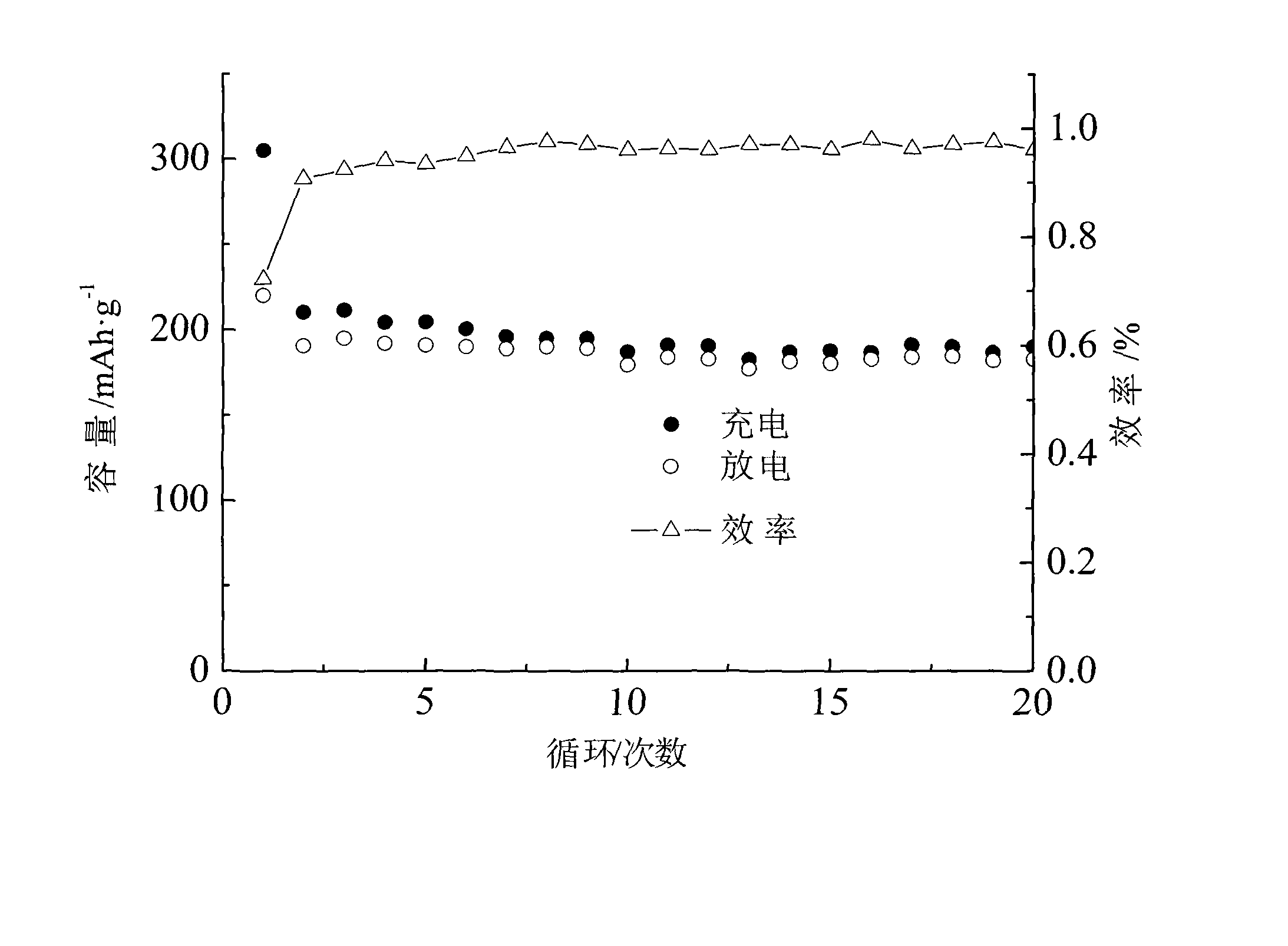

Preparation method of zinc oxide nanosheet for negative electrode of lithium-ion battery

InactiveCN105789602ASimple contact areaIncrease contact areaMaterial nanotechnologyZinc oxides/hydroxidesHexamethylenetetramineElectrochemistry

The invention provides a preparation method of a zinc oxide nanosheet for a negative electrode of a lithium-ion battery. The method comprises the following steps: (1) dissolving zinc acetate into deionized water as a precursor at a room temperature; (2) sequentially adding sodium citrate and sodium hydroxide to the solution prepared in the step (1) for stirring for 1-12 hours; (3) adding hexamethylenetetramine to the solution obtained in the step (2) and stirring and dissolving the hexamethylenetetramine, wherein the molar ratio of the zinc acetate to the sodium citrate to the sodium hydroxide to the hexamethylenetetramine is 1 to (1.8-2.1) to (1.8-2.1) to 1; and (4) transferring the solution into a reaction kettle, heating the solution to 120-160 DEG C, carrying out heat preservation for 10-48 hours, cooling the solution to a room temperature after reaction is ended, and filtering and collecting the solution to obtain a target material. The preparation method is simple to operate and low in cost; the zinc oxide nanosheet can be obtained through a one-step hydrothermal synthesis method; the contact area of the obtained zinc oxide nanosheet and an electrolyte is large; and the lithium-ion battery has relatively good electrochemical properties.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

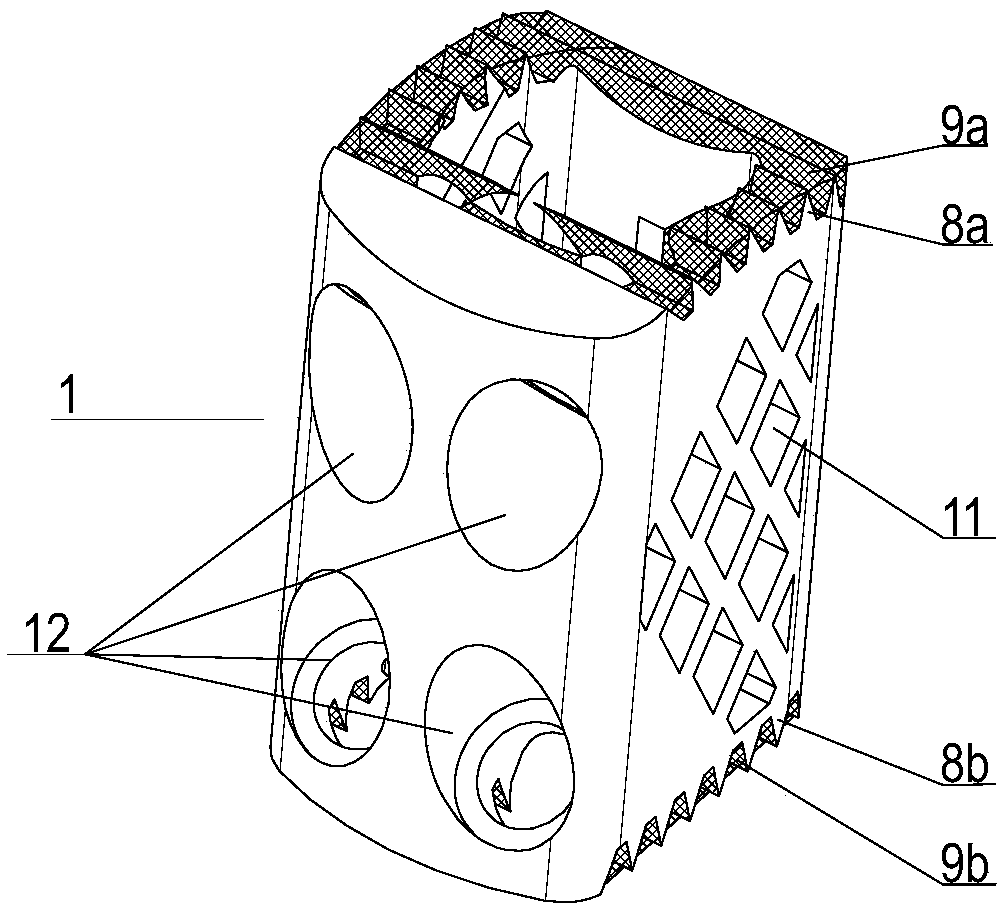

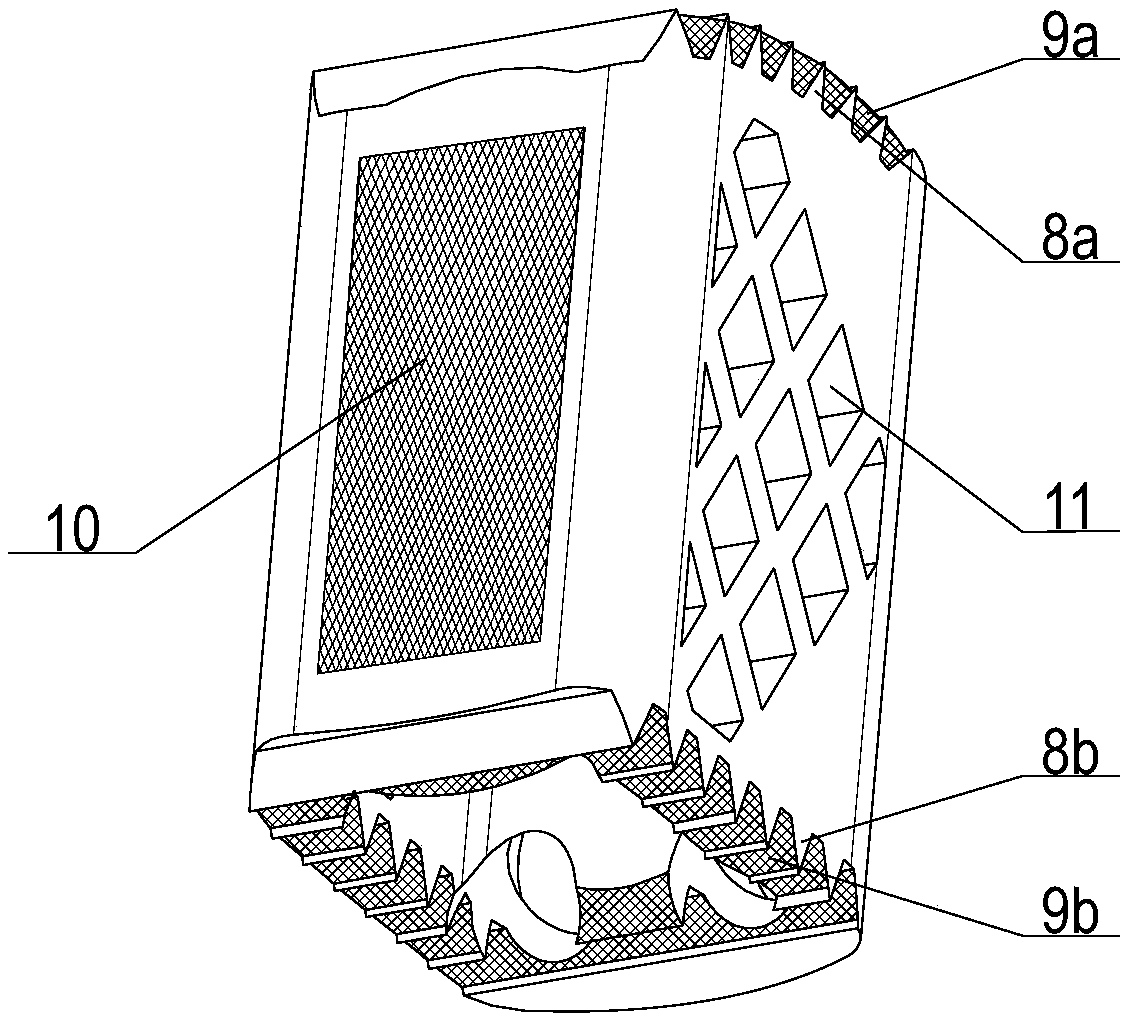

Anterior cervical approach self-fixation artificial centrum

PendingCN109481101AAvoid displacementIncrease frictionSpinal implants3D printingSpinal columnBiomechanics

The invention discloses an anterior cervical approach self-fixation artificial centrum and belongs to the technical field of medical centrum manufacturing. The anterior cervical approach self-fixationartificial centrum is composed of an integrated centrum part and is mainly characterized by comprising an upper-end cambered surface, a lower-end oblique plane, an end face sawtooth structure, an endface micro-hole structure, a side wall rhombus hole, a back wall micro-hole structure, a front wall cambered surface structure, a back wall cambered surface structure and a screw hole structure for front wall self-fixing. A traditional anterior cervical approach titanium plate is removed on the premise that the stability of postoperative spine segments is ensured, the complexity degree of sub-total ectomy fusion of an anterior cervical approach cervical vertebra body is effectively reduced, the surgical time is shortened, the bleeding during surgery is decreased, a biomechanical conduction mode of an anterior cervical approach implantation instrument is optimized, and lots of complications caused by anterior cervical approach steel sheets are avoided. By adopting the above design, the anterior cervical approach self-fixation artificial centrum can effectively decrease lots of complications of a traditional titanium cage and improves prognosis of a patient suffering from the sub-totalectomy fusion of the anterior cervical approach cervical vertebra body.

Owner:SECOND AFFILIATED HOSPITAL OF COLLEGE OF MEDICINEOF XIAN JIAOTONG UNIV

Ti<4+>, Al<3+>, Fe<3+> and F-co-doped with composite lithium-rich anode material and preparation method thereof

InactiveCN103066273AReduce oxygen deficiency concentrationImprove surface stabilityCell electrodesLithium compoundNickel salt

The invention discloses a Ti<4+>, Al<3+>, Fe<3+> and F-co-doped layer-layer composite lithium-rich anode material xLi2MnO3. (1-x) LiMn0.5Ni0.5O2 (x is not less than 0 and not more than 0.5). The anode material is characterized in that the chemometry formula is xLi2MnO3. (1-x)Li1-n-y (Mn0.5Ni0.5)1-m-npAlm TinFepO2-yFy, wherein x is not less than 0 and not more than 0.5, m is not less than 0.01 and not more than 0.05, n is not less than 0.01 and not more than 0.05, p is not less than 0.01 and not more than 0.05, and y is not less than 0.01 and not more than 0.06. The anode material is obtained by adding soluble lithium compound, soluble manganese salt, soluble nickel salt, butyl titanate, Al (NO3)3.9H2O, soluble iron salt and lithium fluoride in deionized water according to stoichiometric ratio of the above molecular formula with the amount of added substance for 2.5-4.0 times of total metal ion, fully and uniformly stirring with tartaric acid to completely dissolve; and concentrating, gelling, drying, grinding, decomposing, performing and calcining the solution. The prepared anode material has excellent hold ability of circulating capacity and magnification characteristic.

Owner:NINGBO UNIV

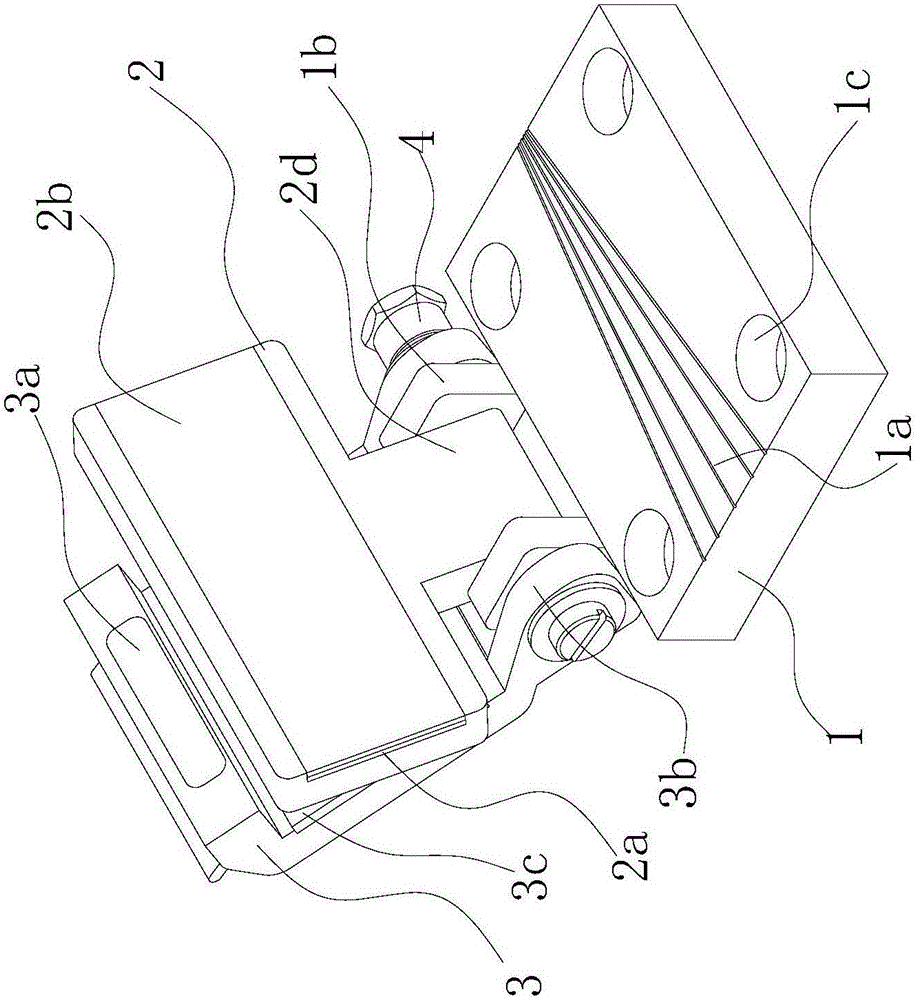

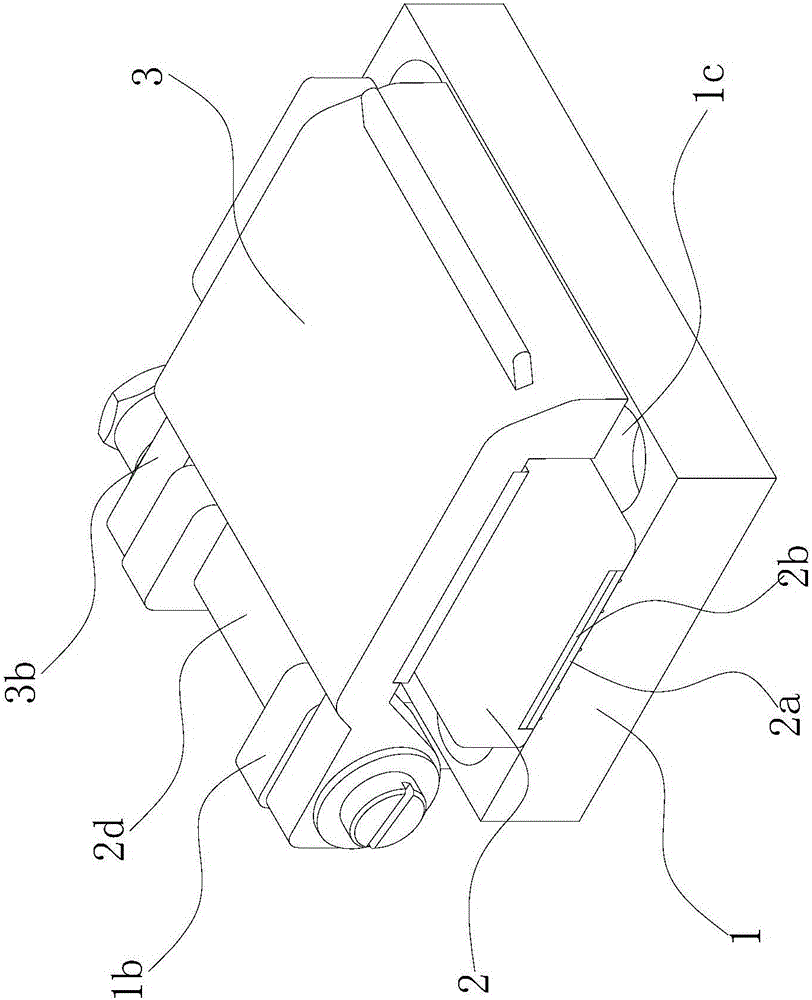

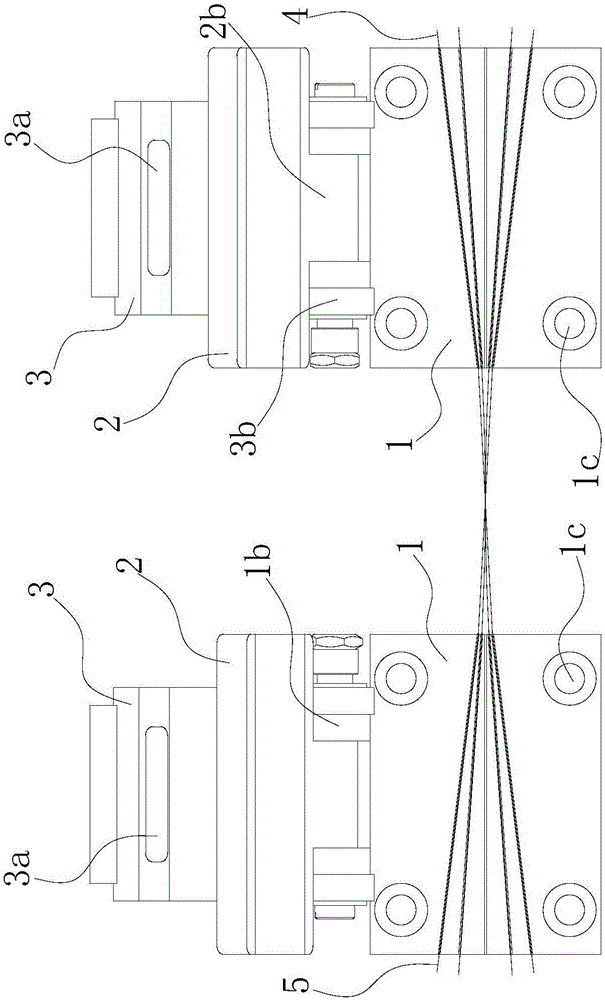

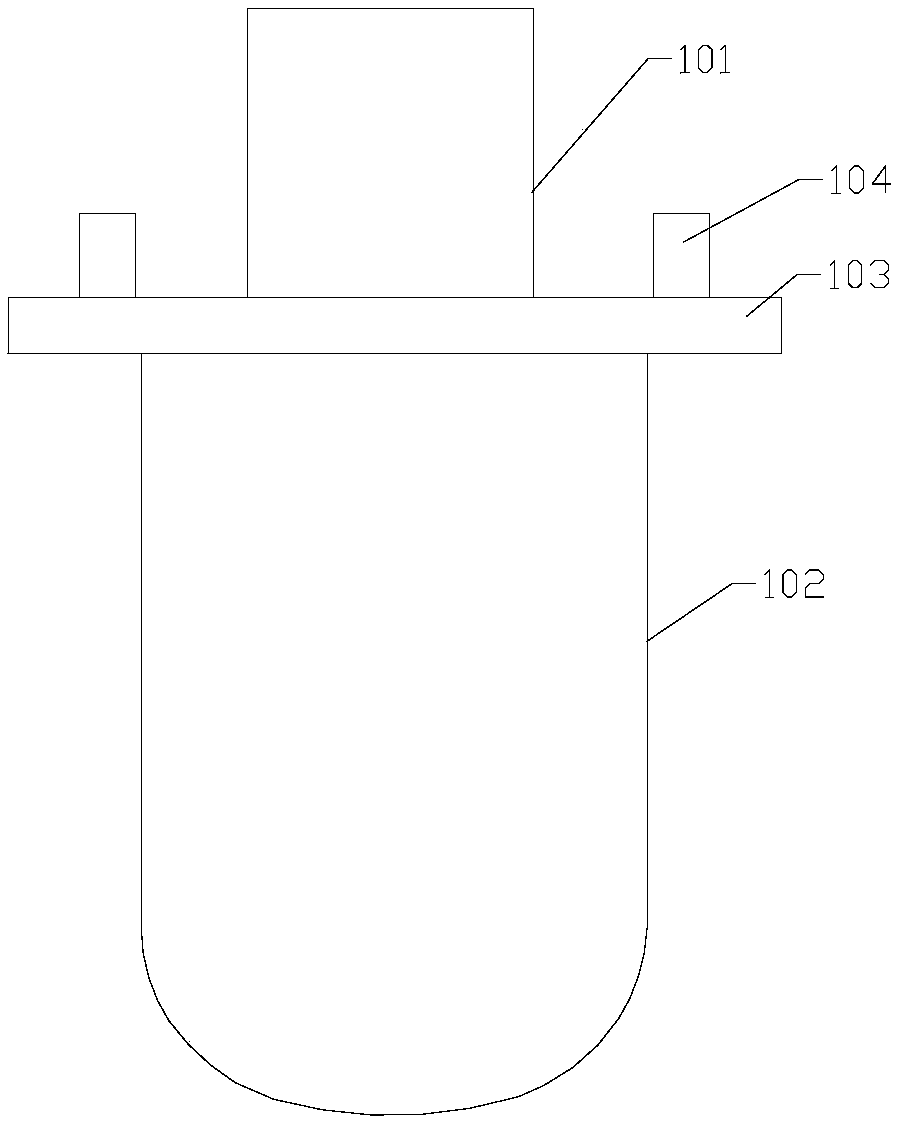

Fiber combining clamp for multi-channel optical fiber splitter

The invention relates to a fiber doubling fixture for a multi-channel optical fiber splitter, which comprises a metal base, a middle laminated fiber board and an upper laminated board. There are at least two optical fiber receiving grooves on the upper surface of the metal base, and the optical fiber receiving grooves are radial distribution; the middle laminated fiberboard is hinged on the back side of the metal base, and the bottom of the middle laminated fiberboard is provided with an inverted U-shaped groove, and a flexible magnet is arranged in the groove; the bottom of the upper laminated board has a compressed fiberboard receiving groove, and the pressed The accommodating groove of the fiberboard is in an inverted U shape, the rear side of the upper laminate is hinged to the metal base, and the front side is fixed with a magnetic body. The fiber doubling fixture for multi-channel optical fiber splitter of the present invention is used in conjunction with the middle laminated fiber board with a smaller magnetic force and the upper laminated board with a larger magnetic force to prevent the optical fiber from coming out of the optical fiber receiving groove during the process of artificially adjusting the optical fiber , which simplifies the operation process and increases the fault tolerance rate.

Owner:蚌埠道生精密光电科技有限公司

La<3+>, Al<3+>, Fe<3+> and F<-> co-doped composite lithium-rich anode material and preparation method thereof

InactiveCN103078104AReduce prolapseImprove ionic conductivityCell electrodesLithium compoundChemistry

The invention discloses a La<3+>, Al<3+>, Fe<3+> and F<-> co-doped composite lithium-rich anode material xLi2MnO3.(1-x)LiMn0.5Ni0.5O2 (x is not less than 0 and not more than 0.5). The anode material is characterized in that a chemical stoichiometric equation is xLi2MnO3.(1-x)Li1-y(Mn0.5Ni0.5)1-m-n-pAlmLanFepO2-yFy, wherein x is not less than 0 and not more than 0.5, m is not less than 0.01 and not more than 0.05, n is not less than 0.01 and not more than 0.05, p is not less than 0.01 and not more than 0.05 and y is not less than 0.01 and not more than 0.06. A preparation method for the anode material comprises the steps as follows: dissolving a soluble lithium compound, soluble magnesium salt, soluble nickel salt, La(NO3)3.6H2O, Al(NO3)3.9H2O, soluble iron salt and lithium fluoride in de-ionized water according to the chemical stoichiometric equation of the molecular formula; adding tartaric acid which is 1.2-2.0 times of the total amount of all metal ions; fully and uniformly stirring until tartaric acid is fully dissolved; and concentrating, gelling, drying, grinding, decomposing, tabletting and calcining a solution to obtain the anode material. The prepared anode material is excellent in cyclic capacity retention capability and rate performance.

Owner:NINGBO UNIV

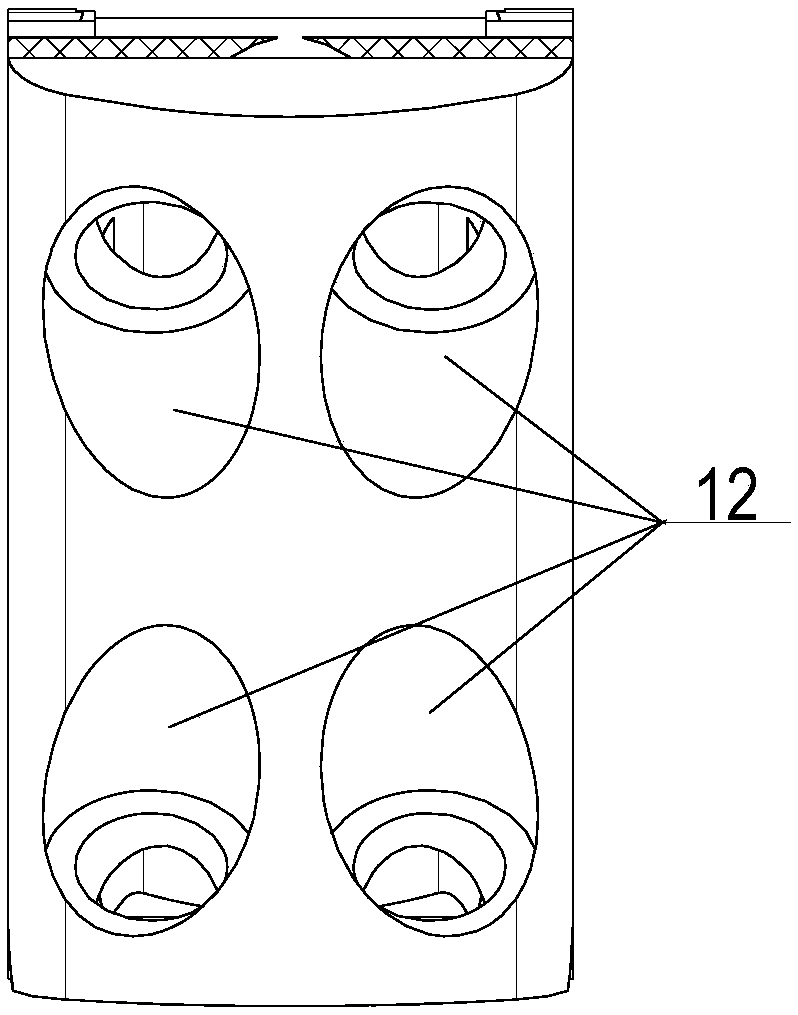

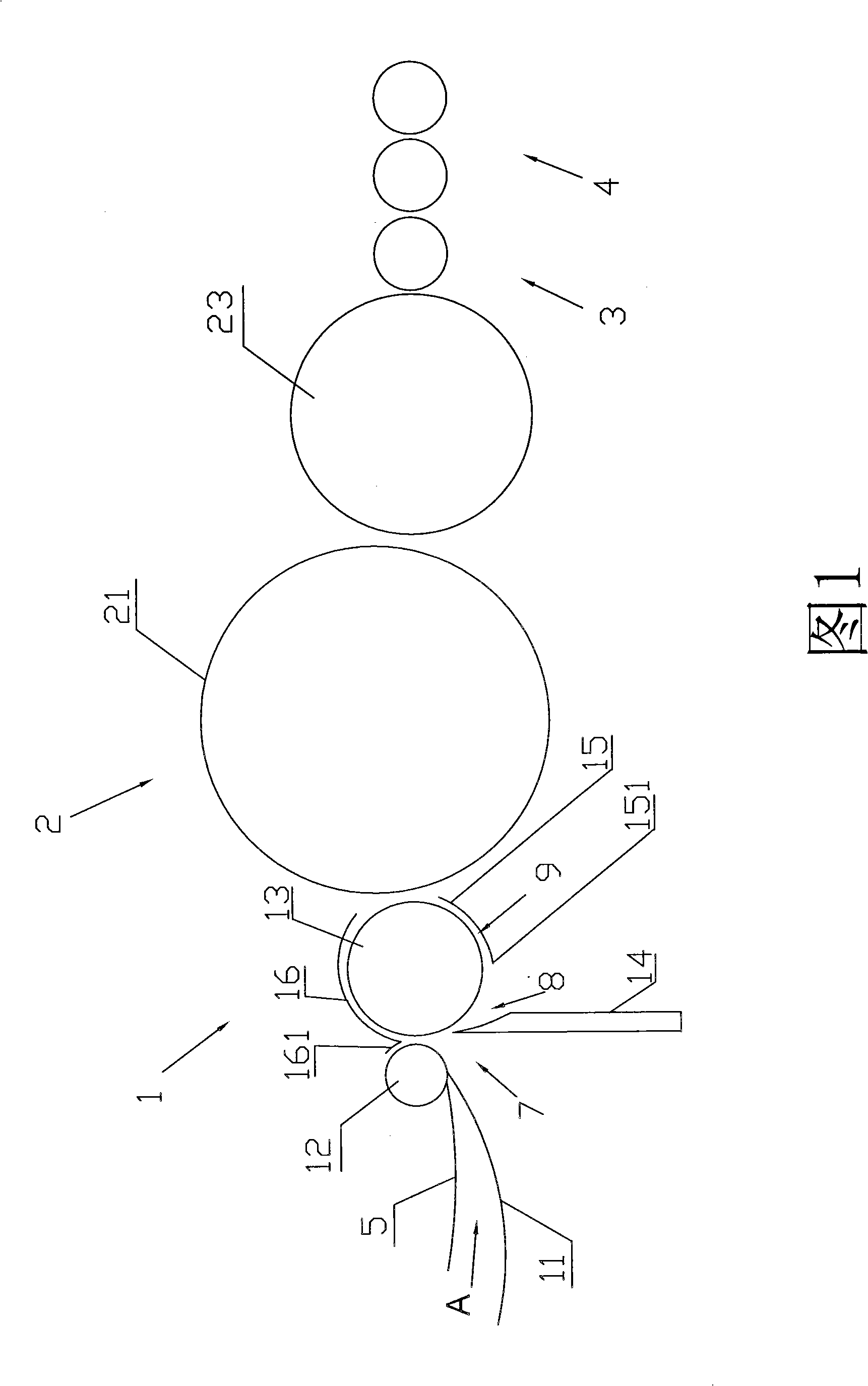

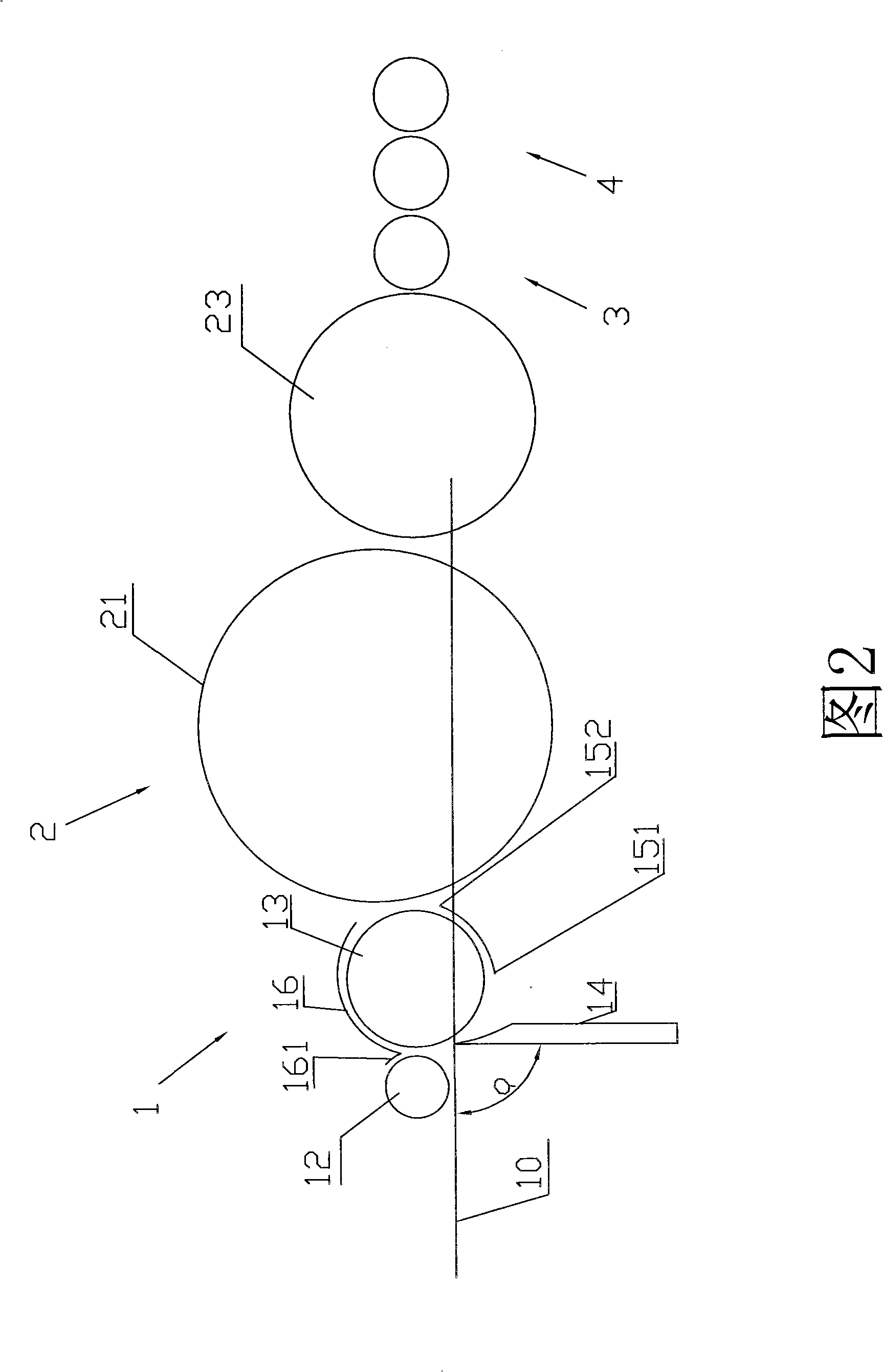

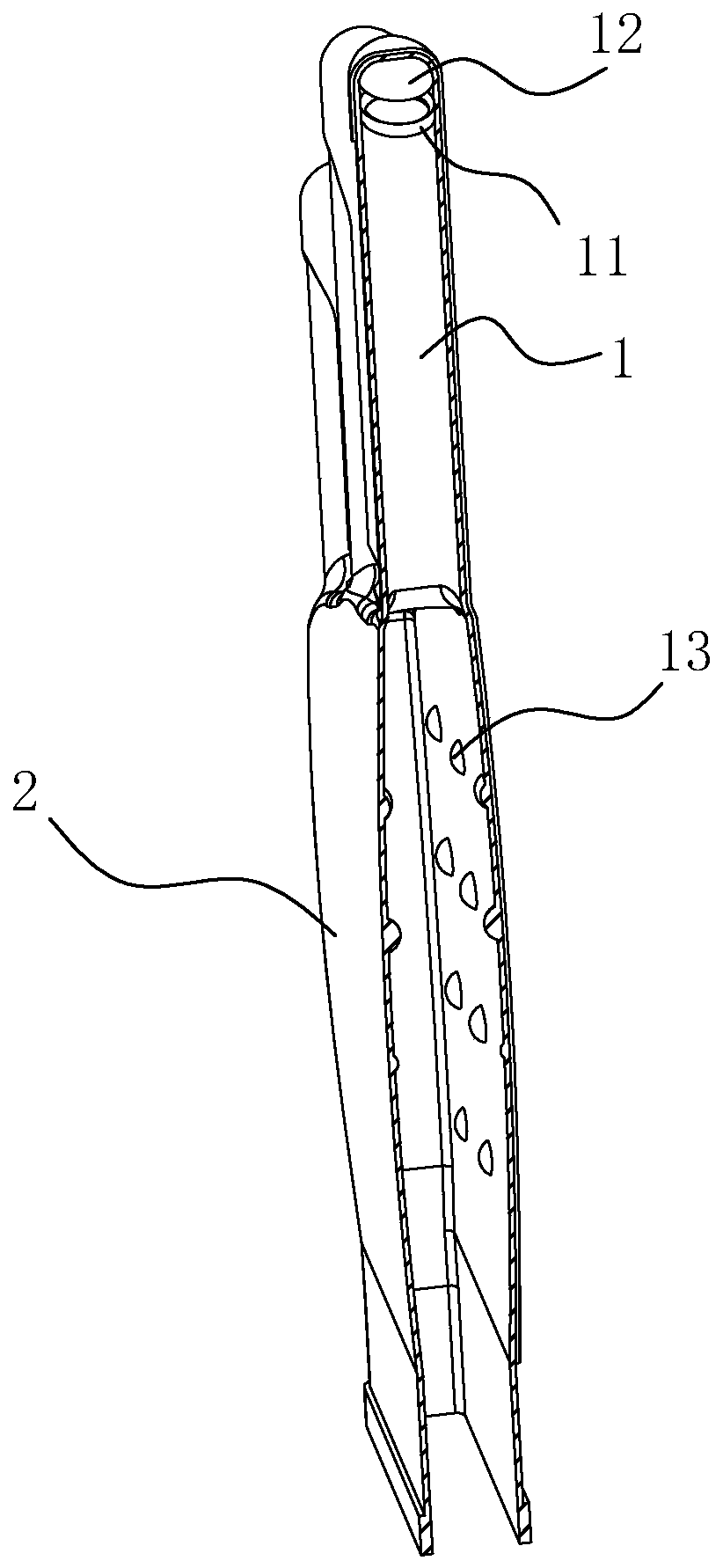

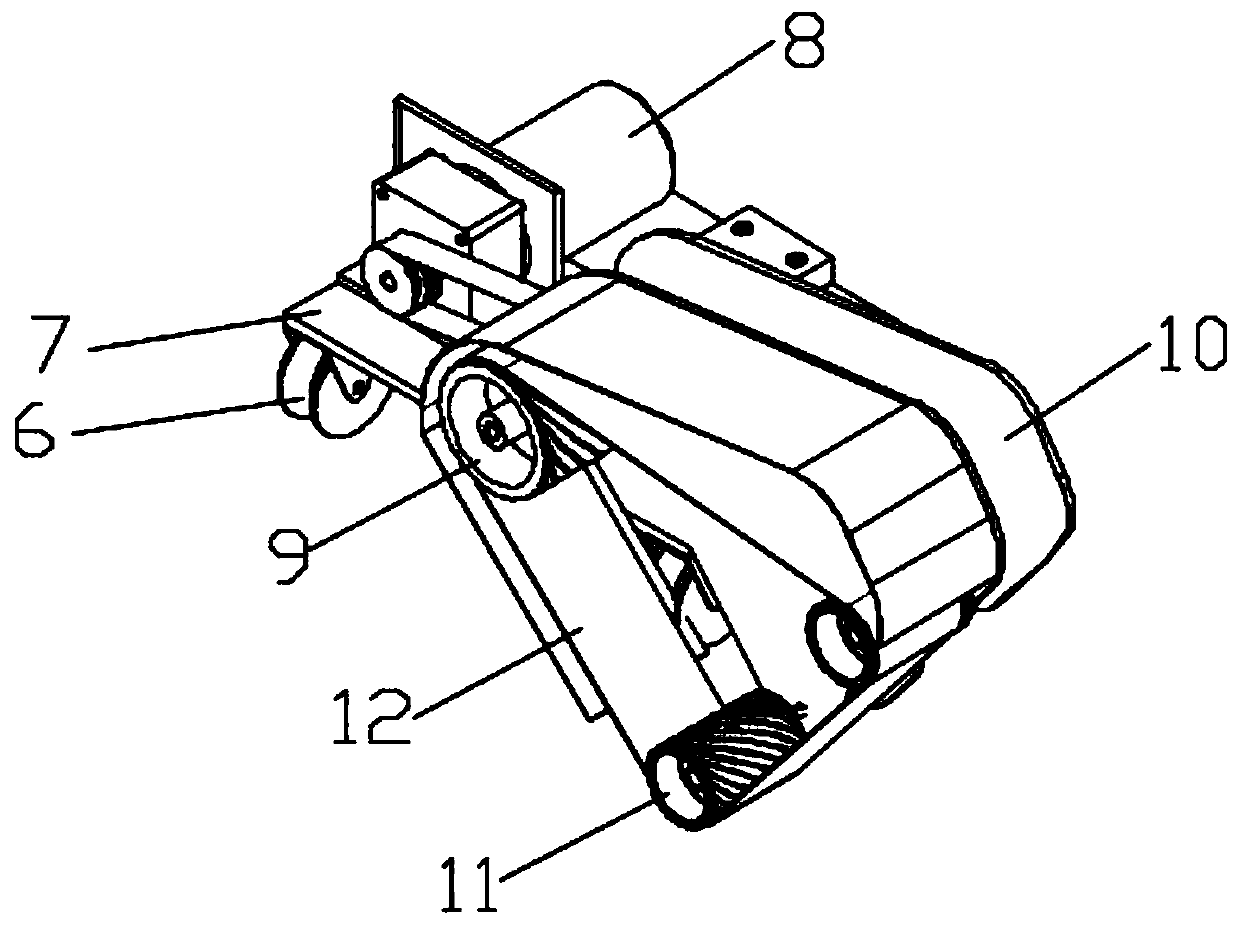

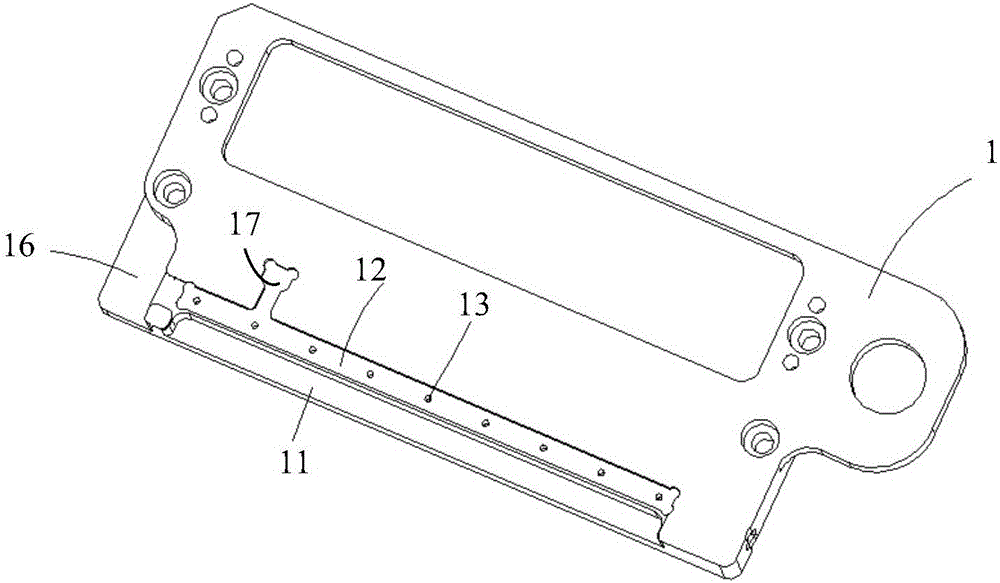

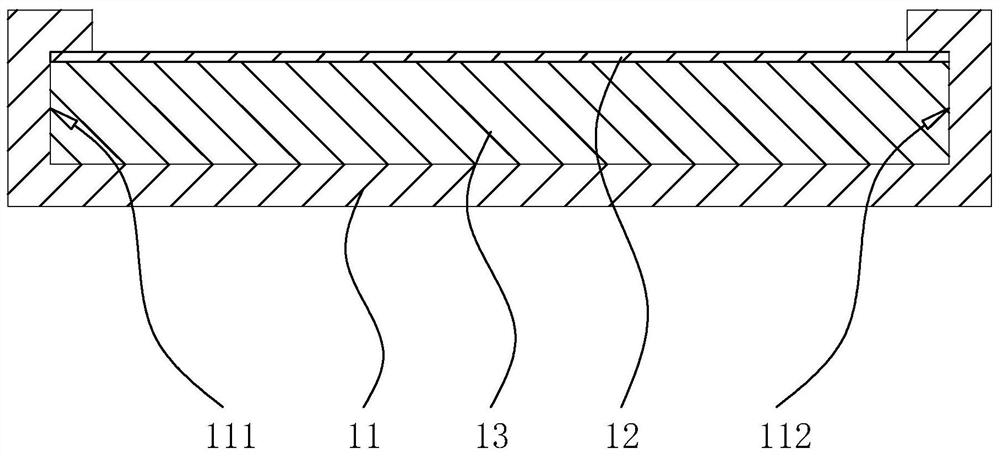

Cotton-feeding cubing-roll device of cover plate type carding machine

The invention provides a cotton-feeding cubing-roll device for a cover plate type carding machine, comprising a roller (12), a fiber feeding board (11), a cubing roll (13) and a cubing-roll housing plate (16), wherein the fiber feeding board (11) is arranged under the roller (12); the cubing roll (13) is arranged on one side of the roller; the cubing-roll housing plate (16) is arranged above the roller (13); a mote knife (14) and a small screen (15) are arranged under the cubing roll (13); the mote knife (14) is arranged on one side of the cubing roll (13) close to the roller (12); and a wrapping angle a of the small screen (15) is between 109 and 140 degrees. The cotton-feeding cubing-roll device for the cover plate type carding machine can effectively improve the utilization rate of fibrilia, and ensure even slivering, good quality of final yarn, and stabilize the blending ratio with cotton and other fibers.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

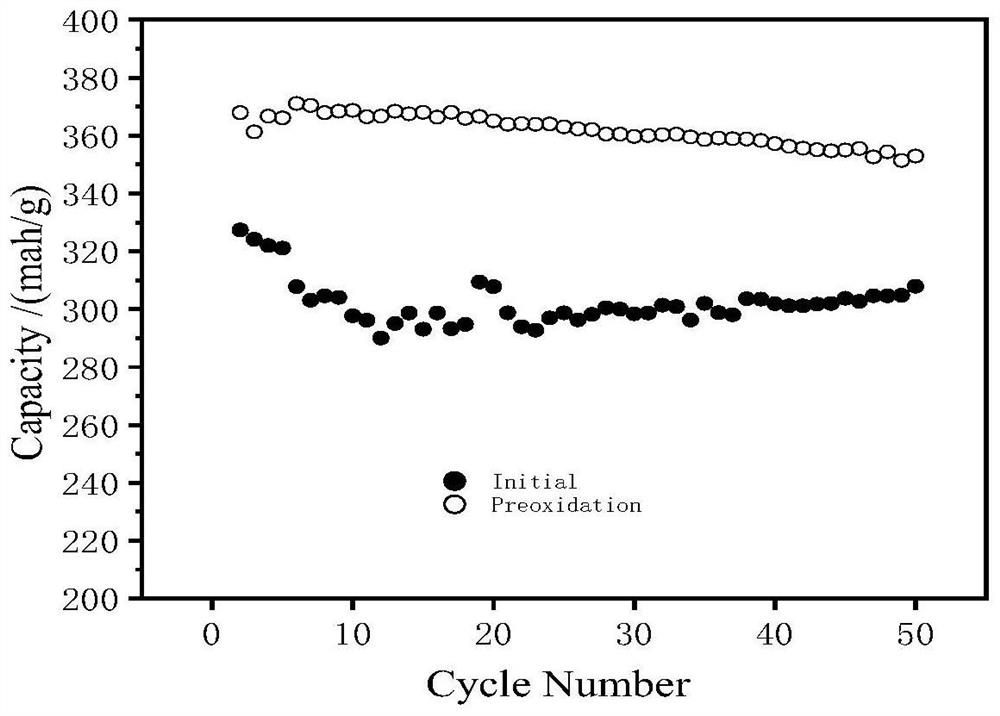

Hard carbon material and preparation method and application thereof

ActiveCN114436237AGrowth inhibitionInhibition orientationCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention relates to a preparation method of a hard carbon material. The preparation method comprises the following steps: S100, pre-oxidizing a hard carbon precursor; s200, grinding the pre-oxidized hard carbon precursor into powder; s300, the powder is subjected to microwave treatment; and S400, calcining the powder obtained in S300 to obtain the hard carbon material. The hard carbon material is prepared by the preparation method. The hard carbon material prepared by the preparation method is applied to the negative electrode of the sodium-ion battery. The method has the advantages that the prepared hard carbon material serves as a sodium ion battery negative electrode material to be assembled into a sodium half-battery pair, within the voltage range of 0-2 V, the cycling stability is good, the initial reversible capacity reaches up to 370 mAh / g, the capacity retention rate reaches 95.9% after 50 cycles under the current density of 20 mA / g, compared with a traditional preparation method, the hard carbon specific capacity is obviously improved, and the method is simple and easy to implement. The method is low in cost and suitable for large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

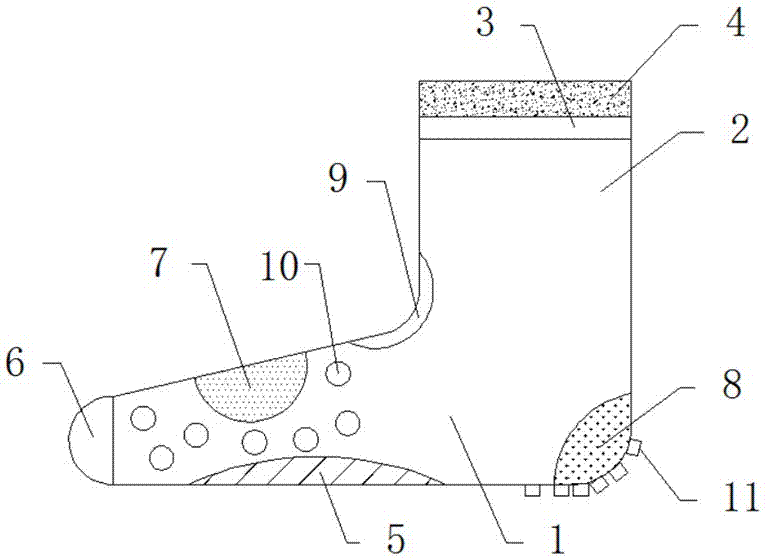

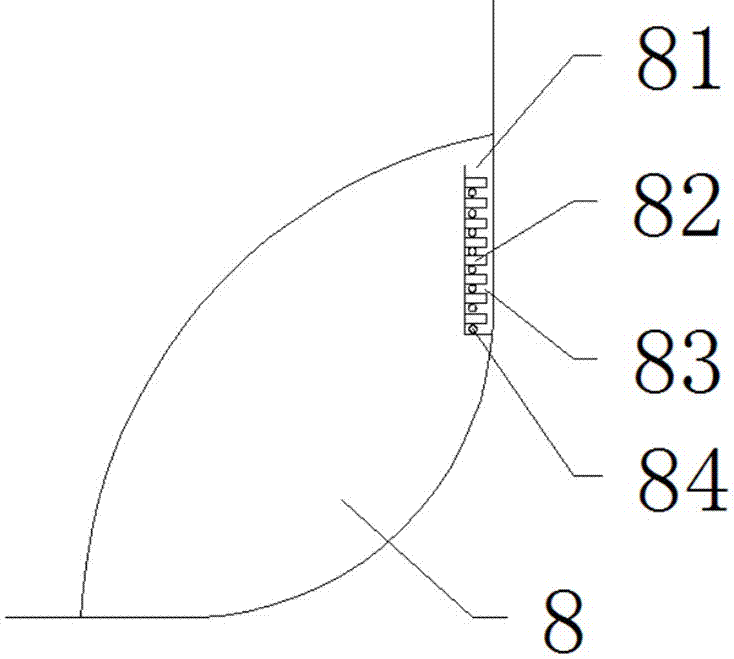

Anti-corrosion thickening sock

InactiveCN107173860AExtended service lifeWear dryHandkerchiefsBaby linensWear resistantMoisture absorption

The invention discloses an anti-corrosion thickening sock which comprises a sock body and a sock leg, wherein the sock body meets the shape of a foot; the sock leg is integrally woven with the sock body; a wear-resistant layer covering toe joints in an annular manner is woven at the toe part of the sock body; a moisture absorption layer covering sole joints in the annular manner is woven in the middle of the sole part of the sock body; vent holes covering the sole joints in the annular manner are formed in the sole part of the sock body; an antibacterial additive is fixedly connected with a part covering the back part of the sock body; an ankle elastic ribbon covering an ankle joint in the annular manner is woven at the connecting part of the sock body and the sock leg; an elastic ribbon is woven at the tail end at the upper part of the sock leg; a withdrawing hole is woven at the upper part of the elastic ribbon; the heal part of the sock body is covered by a heal wear-resistant device; and anti-sliding convex points are fixedly connected below the heal wear-resistant device. The anti-corrosion thickening sock is scientific and reasonable in design, the service life of the sock is prolonged, and relatively high market popularization values are achieved.

Owner:HAINING RANDY SOCKS

La<3+>, Co<3+>, Fe<3+> and F<-1> co-doped composite lithium-rich positive material and preparation method thereof

InactiveCN103107326AReduce prolapseReduce oxygen deficiency concentrationCell electrodesNickel saltLithium compound

The invention discloses an La<3+>, Co<3+>, Fe<3+> and F<-1> co-doped layer-by-layer composite lithium-rich positive material xLi2MnO3.[1-x]LiMn0.5Ni0.5O2 (x is smaller than or equal to 0.5 and greater than or equal to 0). The La<3+>, Co<3+>, Fe<3+> and F<-1> co-doped layer-by-layer composite lithium-rich anode material is characterized in that the stoichiometric equation is xLi2MnO3.[1-x]Lil-y(Mn0.5Ni0.5)[1-m-n-p]ComLanFepO2-yFy, wherein x is smaller than or equal to 0.5 and greater than or equal to 0; m is smaller than or equal to 0.05 and greater than or equal to 0.01; n is smaller than or equal to 0.05 and greater than or equal to 0.01; p is smaller than or equal to 0.05 and greater than or equal to 0.01; and y is smaller than or equal to 0.06 and greater than or equal to 0.01. The method comprises the steps of adding soluble lithium compound, soluble manganese salt, soluble nickel salt, La(NO3)3.6H2O, Co(NO3)2.6H2O, soluble ferric salt, and lithium fluoride into deionized water according to the stoichiometric proportion of the molecular formula; adding tartaric acid which is 1.2-2.0fold of total mass of all metal ions to fully and evenly agitate until the tartaric acid is completely dissolved; and concentrating, condensing, drying, grinding, decomposing, pressing and burning the solution to obtain the positive material. The prepared positive material has excellent circulation capacity keeping ability and ratio characteristics.

Owner:NINGBO UNIV

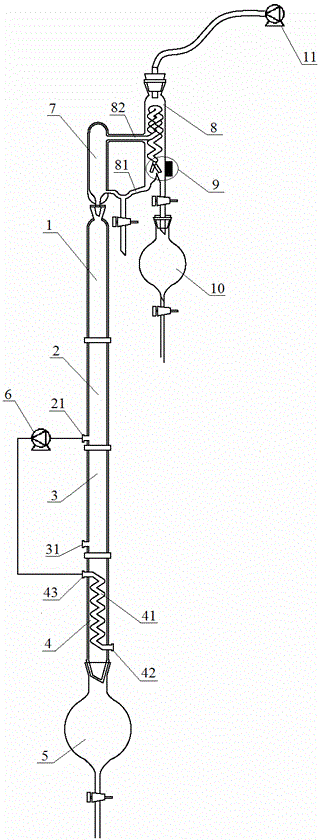

Device and method for eliminating and recycling organic solvent from cathode electrophoresis emulsion

ActiveCN104906822AAchieve strippingRealize rectification recoverySteam distillationElectrophoresesEmulsion

The invention relates to a device and a method for eliminating and recycling organic solvent from cathode electrophoresis emulsion. The device comprises an upper tower section, a middle tower section and a lower tower section, wherein a carrier gas inlet is formed at the lower part of the lower tower section, the lower end of the lower tower section is connected with a heat exchanger of which the bottom is connected with an emulsion recover kettle, the lower end of a heat exchange tube in the heat exchanger is provided with a cold emulsion feeding hole, the upper end of the heat exchange tube is provided with an emulsion discharge hole, the emulsion discharge hole is communicated with the emulsion feeding hole at the lower end of the middle tower section by a charging pump, the upper end of the upper tower section is connected with a tower top, the tower top is externally connected with a condenser, a reflux ratio controller is arranged on the condenser, the bottom of the condenser is connected with a solvent recovery kettle, and the upper end of the condenser is connected with a vacuum pump. The method comprises the following steps: (1) vacuumizing and introducing water vapor; (2) performing reversed current heat exchange to the cathode electrophoresis emulsion, and then performing gas-liquid mass transfer in a packed tower; and (3) adjusting the reflux ratio controller and collecting emulsion and a solvent. According to the device and the method, the removal rate of organic solvent is high, zero emission is realized, the process control is stable, the operation is simple, and the recovery products have excellent performances.

Owner:湖南湘江关西涂料有限公司

Cr3<+>, Mg<2+>, Fe<3+> and F<-> co-doped composite lithium-rich anode material and preparation method thereof

InactiveCN103078101AReduce oxygen deficiency concentrationImprove surface stabilityCell electrodesLithium compoundNickel salt

The invention discloses a Cr3<+>, Mg<2+>, Fe<3+> and F<-> co-doped layer-layer composite lithium-rich anode material xLi2MnO3.(1-x)LiMn0.5Ni0.5O2(x is not less than 0 and not more than 0.5). The Cr3<+>, Mg<2+>, Fe<3+> and F<-> co-doped layer-layer composite lithium-rich anode material is characterized in that a stoichiometric equation of the anode material is xLi2MnO3.(1-x)Li1+n-y(Mn0.5Ni0.5)1-m-n-pCrmMgnFepO2-yFy, wherein x is not less than 0 and not more than 0.5, m is not less than 0.01 and not more than 0.05, n is not less than 0.01 and not more than 0.05, p is not less than 0.01 and not more than 0.05 and y is not less than 0.01 and not more than 0.06. The preparation method comprises the following steps: adding soluble lithium compound, soluble manganese salt, soluble nickel salt, soluble magnesium salt, soluble chromium salt, soluble iron salt and lithium fluoride into deionized water according to the stoichiometric ratio of the molecular formula; adding tartaric acid of which the mol ratio is 1.5-2.5 times of the total amount of metal ions and uniformly and fully stirring until the mixture is dissolved; and condensing, gelating, drying, grinding, decomposing, tabletting and calcining the solution to obtain the Cr3<+>, Mg<2+>, Fe<3+> and F<-> co-doped layer-layer composite lithium-rich anode material. The prepared anode material has excellent circulation capacity holding capacity and magnification characteristic.

Owner:NINGBO UNIV

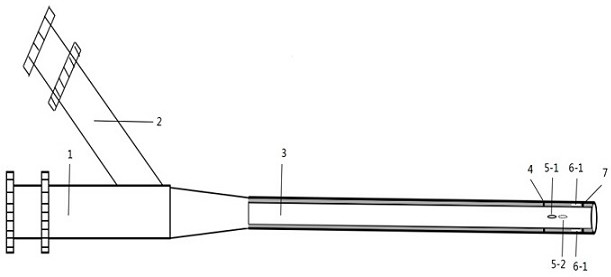

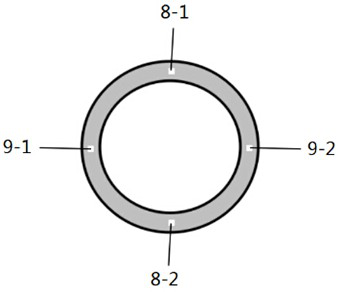

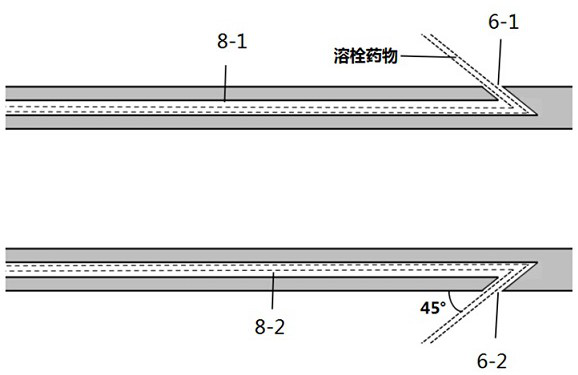

Multifunctional thrombolysis and thrombus breaking large-caliber suction catheter

PendingCN112754601AClear locationIncreased ability to aspirate blood clotsSurgeryInternal cavityBiomedical engineering

The invention discloses a multifunctional thrombolysis and thrombus breaking large-caliber suction catheter, which comprises a thrombus suction connector, a thrombolysis medicine connector and a catheter, wherein the thrombus suction connector is provided with the thrombolysis medicine connector; the right end of the thrombus suction connector is provided with the catheter; the inner cavity of the catheter is a suction inner cavity; the catheter is provided with an X-ray-proof marker point A and an X-ray-proof marker point B; in addition, positions which are near the front position and the back position of the X-ray-proof marker point A, are independently provided with a first near-end ejection hole and a second near-end ejection hole; a position, which is near the left side of the top end of the X-ray-proof marker point B, is provided with a first far-end ejection hole; a position, which is near the left side of the bottom end of the X-ray-proof marker point B, is provided with a second far-end ejection hole; and the first near-end ejection hole communicates with a first near-end ejection hole medicine conveying channel. The multifunctional thrombolysis and thrombus breaking large-caliber suction catheter can efficiently and quickly remove thrombus, quickly recovers unobstruction of blood vessels, also can reduce a thrombolysis bleeding risk, reduces postoperative complications and improves a clinical effect.

Owner:深圳市联科翰微医疗科技有限公司

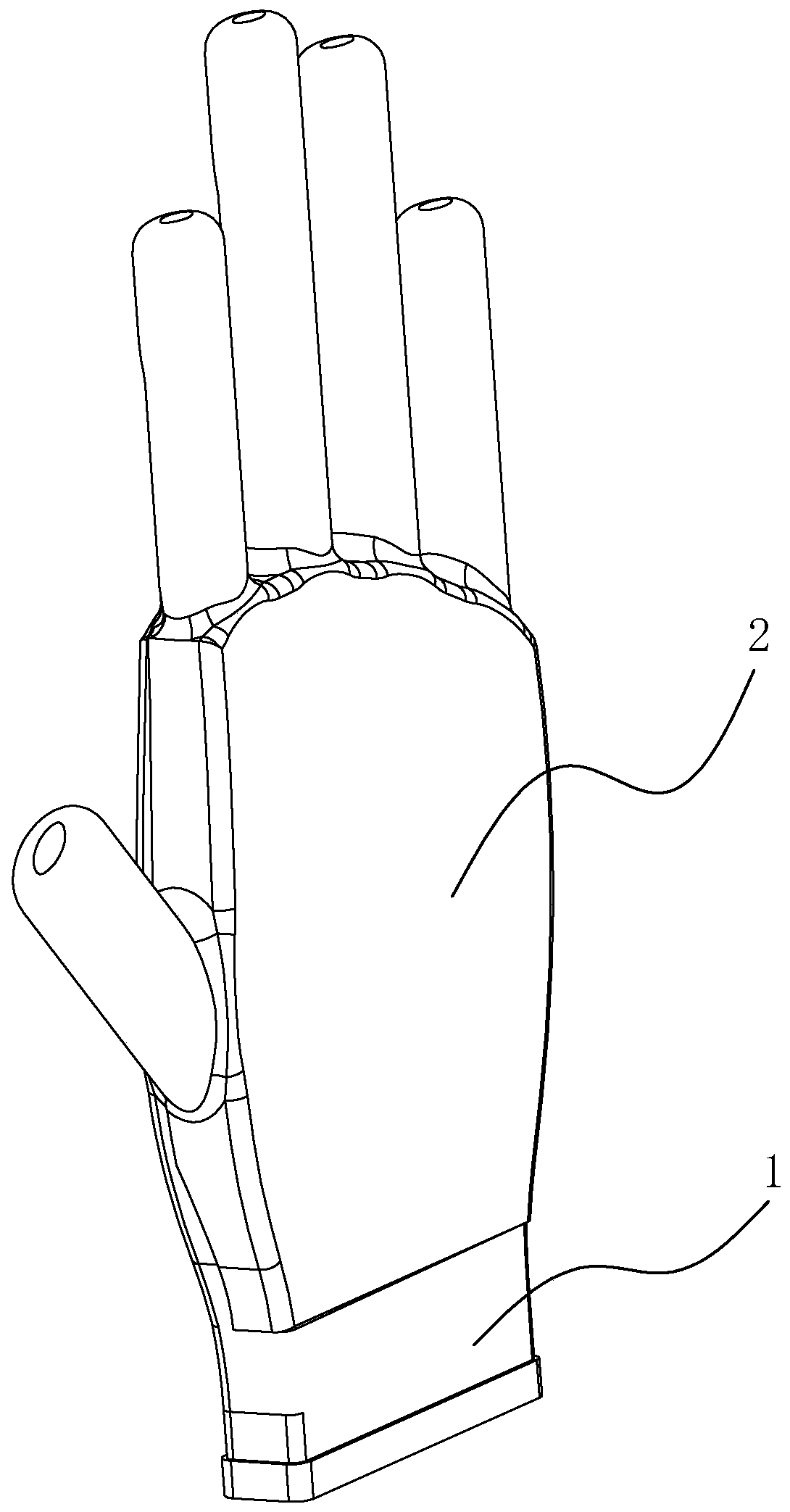

Gum dipping glove and manufacturing process thereof

InactiveCN111391207AReduce prolapseImprove production efficiencyGlovesDomestic articlesEngineeringProcess engineering

The invention discloses a gum dipping glove and a manufacturing process thereof, relates to the technical field of gum dipping glove manufacturing, and aims at solving the technical problems that in the operation steps of an existing gum dipping glove, the gum dipping glove needs to be soaked into a coagulator again after gum dipping, the coagulator is cleaned away in the later period, and the operation steps are tedious. According to the technical scheme, the manufacturing process of the gum dipping gloves is characterized by comprising the following steps that a glove mold is preheated through a drying oven; a glove core is manually sleeved on the glove mold; the surface temperature of the glove core is waited to be cooled; a palm of the glove core faces a dipping cylinder, fingers of the core incline by 30-45 degrees towards the dipping cylinder, the glove core enters the dipping cylinder, and parts of the palm and the fingers of the glove core are gum dipping; the glove core aftergum dipping is placed above a hanging drop groove for hanging drops; the dripped glove core is fed into a drying oven for steam heating; the product is cooled after the product is discharged from theoven; and a glove demolding machine performs demolding treatment and arranges and warehouses the gloves, so that the operation steps of the gum dipping gloves can be simplified.

Owner:南通金斯顿防护用品有限公司

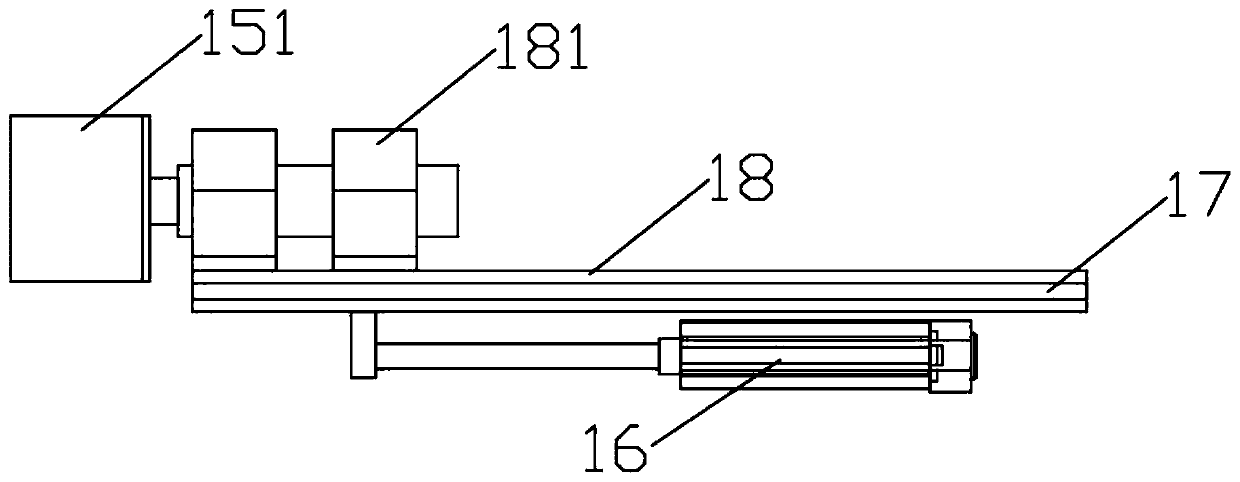

Preparation method of high-temperature-resistant and impact-resistant UPVC pipe fitting

InactiveCN110669300AImprove thermal stabilityExtended service lifeTubular articlesHydraulic cylinderPipe fitting

The invention discloses a preparation method of a high-temperature-resistant and impact-resistant UPVC pipe fitting. The Vicat softening temperature of the prepared high-temperature-resistant and impact-resistant UPVC pipe fitting measured according to GB / T 8802-2001 is 105-113 DEG C, and the impact strength measured according to GB / T 19712-2005 is 38-43 KJ / m<2>. A semi-finished pipe fitting is put into a traction opening at one side of a traction box, the output shaft of a sixth motor drives traction belts to transmit through a commutator, the two traction belts drive the semi-finished pipe fitting to be pulled out from a traction opening in the other side and pulled to a position between two arc-shaped sleeves, the piston rod of a hydraulic cylinder pushes a cutting blade, and the cutting blade cuts the semi-finished pipe fitting, so the technical problems of failed automatic fixation and poor fixation effect of the pipe fitting after cutting in the prior art are solved.

Owner:安徽玉发塑业有限公司

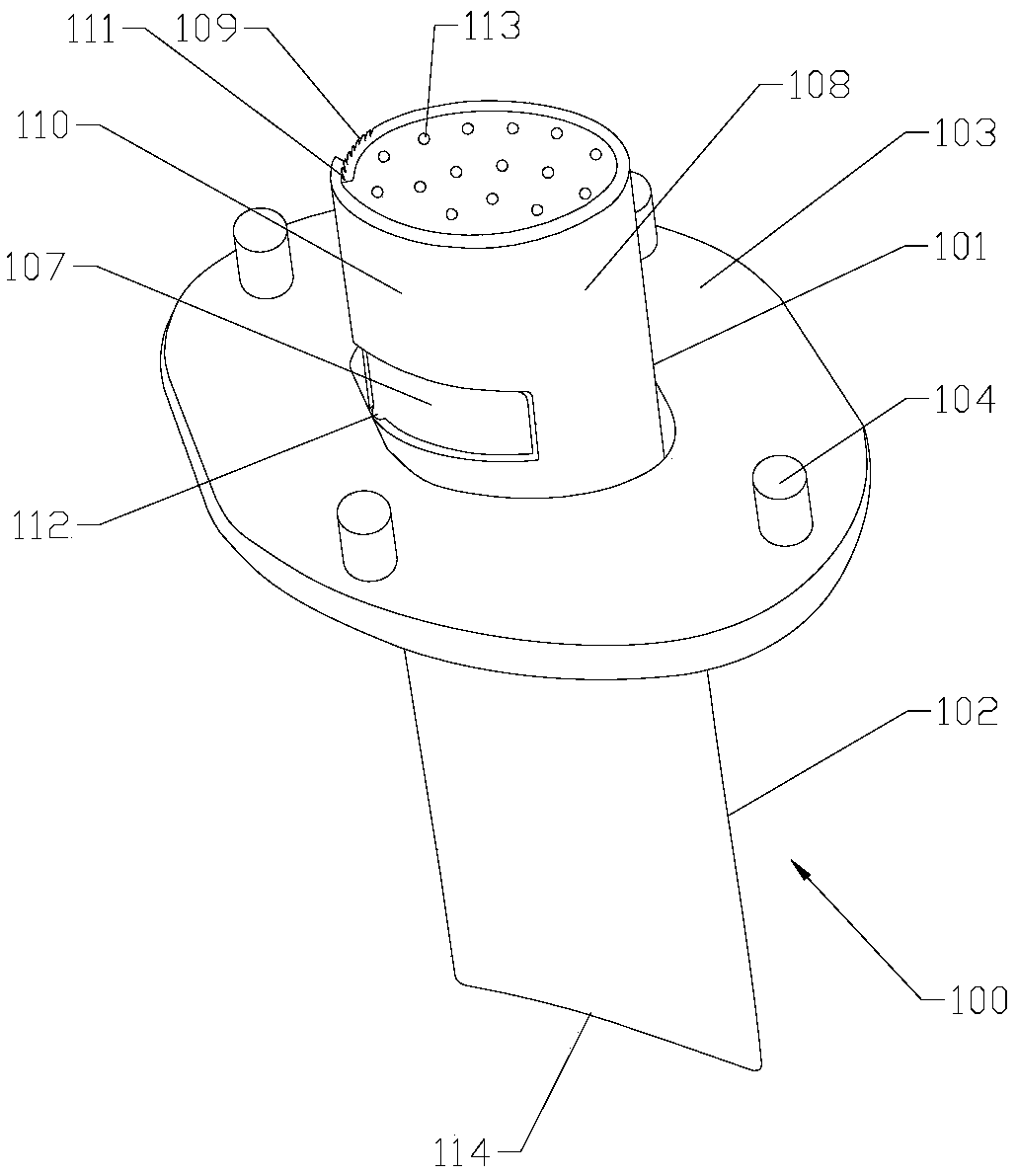

Mouth-shaped spreader capable of fixing oropharyngeal cannula and using method thereof

The invention relates to a mouth-shaped spreader capable of fixing an oropharyngeal cannula and a using method thereof. The spreader comprises a spreading fixator body and a fixing strap, wherein thespreading fixator body comprises a tube body part, a positioning part and a hoop body part; the tube body part is an oval tube body internally provided with three cavities, the three cavities comprisea circular middle tube oropharyngeal cannula cavity and two suction catheter cavities; the top end of the tube body part extends to the periphery to form the oval positioning part, and the positioning part is provided with a protrusion; the hoop body part comprises a fixing section and an extension section, and a gap is reserved between the tail end of the extension section and the top end of thecircular middle tube; an anti-slip structure is arranged at the inner side of the fixing section, a plurality of hook grooves are formed in the outer side of the fixing section, and the inner side ofthe fixing section is provided with clamping hooks matched with the hook grooves. The mouth-shaped spreader is placed at a joint of the oropharyngeal cannul before used, when the mouth-shaped spreader is used, the oropharyngeal cannu is inserted through the oral cavity of a patient, the hoop body part is loosened, the tube body part is pushed in the oral cavity of the patient, and the positioningpart fits the lip of the patient; the hoop body part is adjusted so that the clamping hooks are meshed with the hook grooves, so that the oropharyngeal cannul is fixed. Not only is the nursing cost reduced, but also the success rate of patient rescue treatment is greatly improved.

Owner:冯玉玺

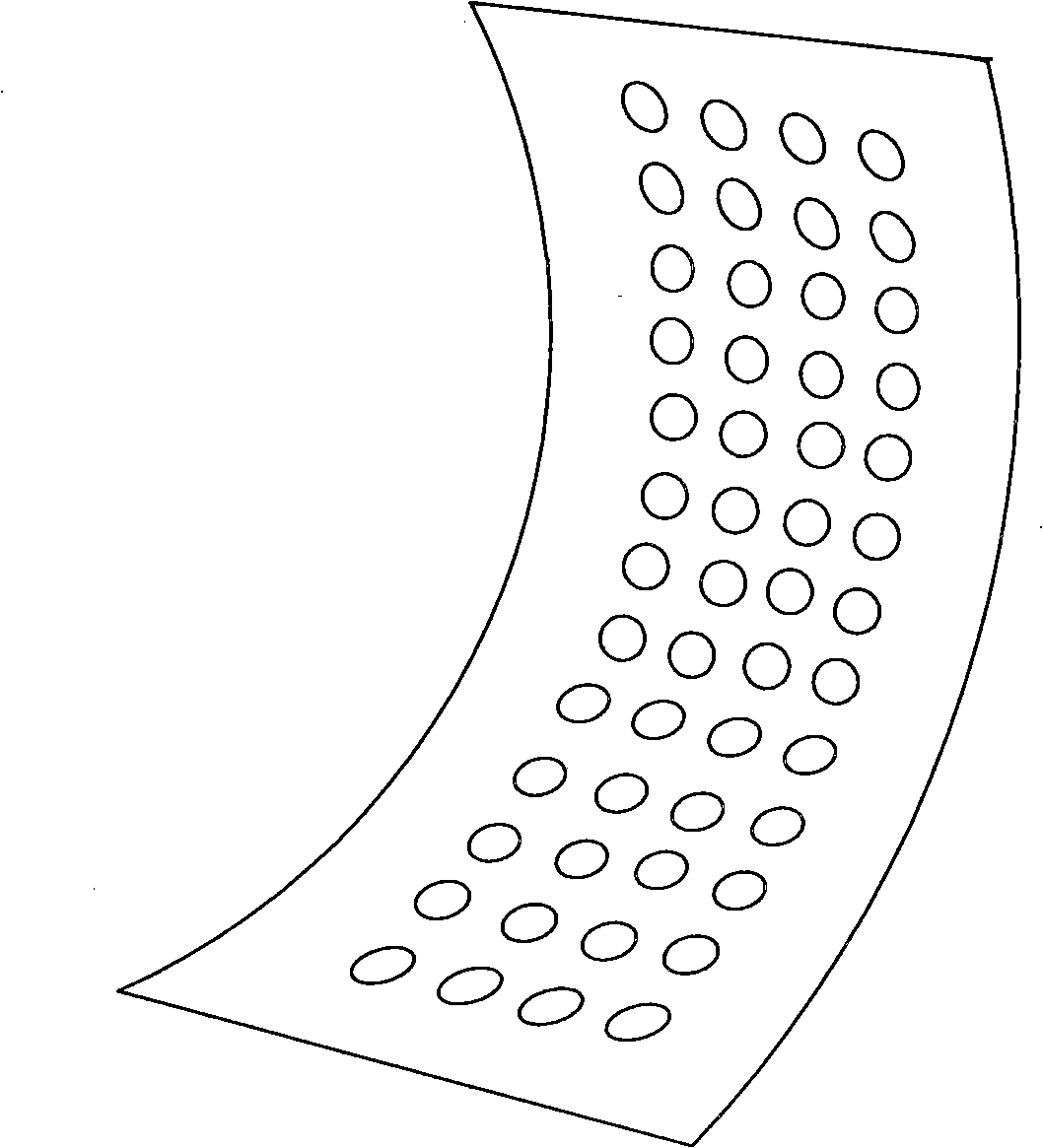

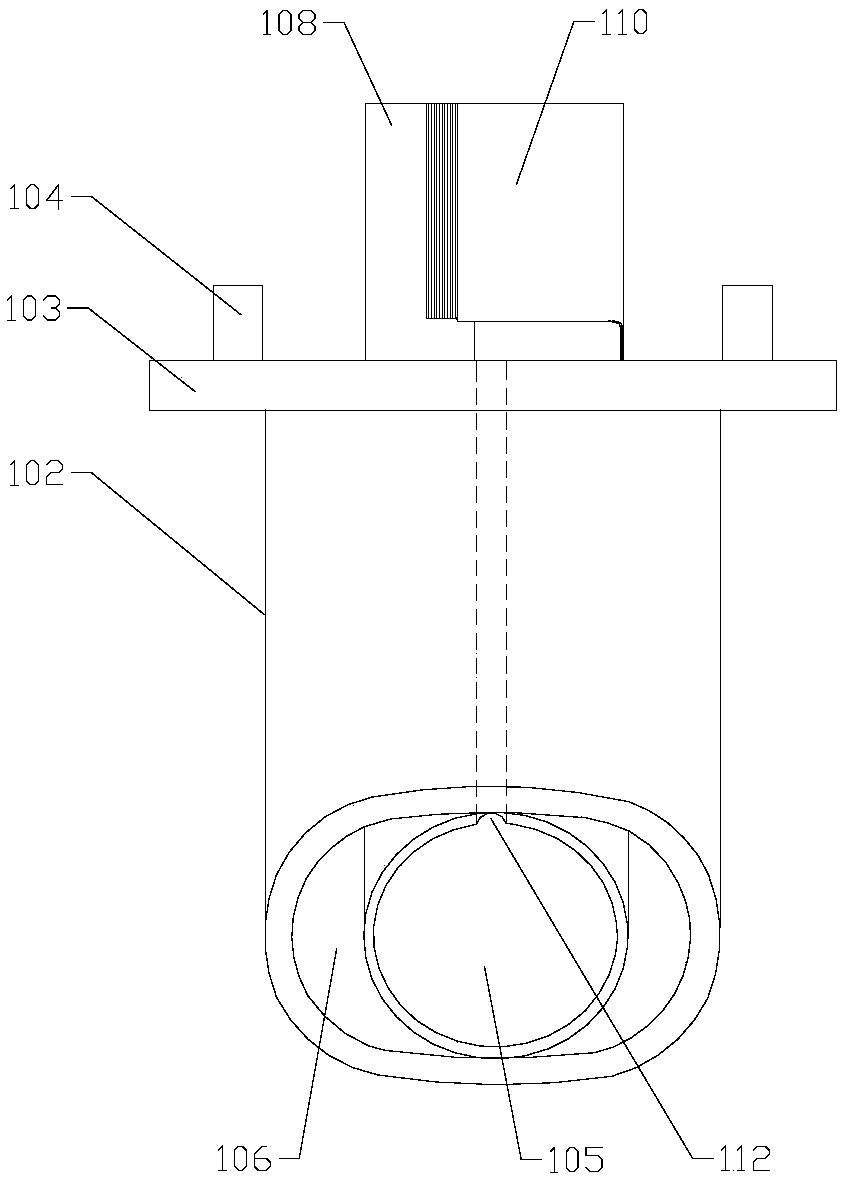

Occlusion device

InactiveCN111388045ALarge packing densitySmall package densityDiagnosticsOcculdersInternal iliac aneurysmBrain aneurysm

The invention discloses an occlusion device for treating intracranial aneurysm or cerebral aneurysm. The occlusion device comprises a mesh, the mesh has an expanded state and a low configuration statefor intravascular delivery to an aneurysm, the mesh includes a first end portion, a second end portion, and a length extending between the first and second end portions, and a first lateral edge, a second lateral edge, and a width extending between the first and second lateral edges. The mesh may have a predetermined shape in the deployed state, wherein (a) the mesh is curved along its width, (b)the mesh is curved along its length, and (c) the mesh has an undulating profile across at least a portion of one or both of its length or its width. The mesh is configured to be placed within the aneurysm in the deployed state such that the mesh extends over a neck of the aneurysm.

Owner:TYCO HEALTHCARE GRP LP

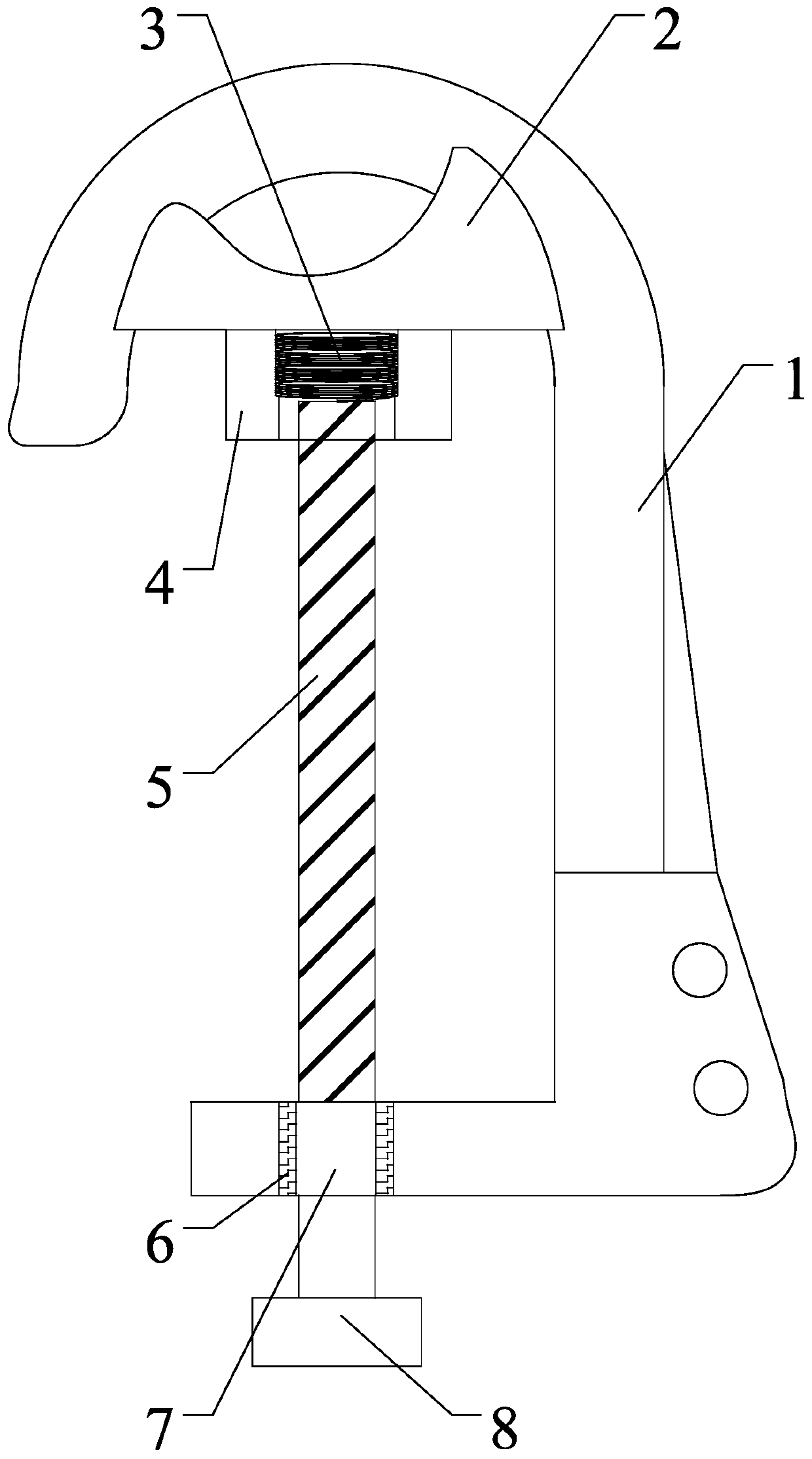

Seven-spiral grounding wire clamp

PendingCN111525299AReduce prolapseImprove connection reliabilityElectric connection structural associationsClamped/spring connectionsPhysicsEngineering

The invention discloses a seven-spiral grounding wire clamp, which comprises a fixed frame and a movable clamping block slidably connected with the inner side of the fixed frame, wherein the bottom end of the movable clamping block makes contact with the top end of a screw rod, the screw rod is of a seven-threaded structure, and the bottom end of the screw rod penetrates through a guide hole formed in the bottom end of the fixed frame and then is fixedly connected with a connecting column. According to the seven-spiral grounding wire clamp adopting the structure, the screwing efficiency (the rotating speed of the seven-spiral grounding wire clamp is seven times that of a conventional single thread) is improved by arranging the screw rod with the seven-threaded structure, and the connectingreliability between the screw rod and the positioning cylinder is improved by arranging the positioning spring in the positioning cylinder connected with the screw rod so as to reduce the possibilitythat the screw rod is disengaged from the positioning cylinder.

Owner:保定瑞隆电力器材有限公司

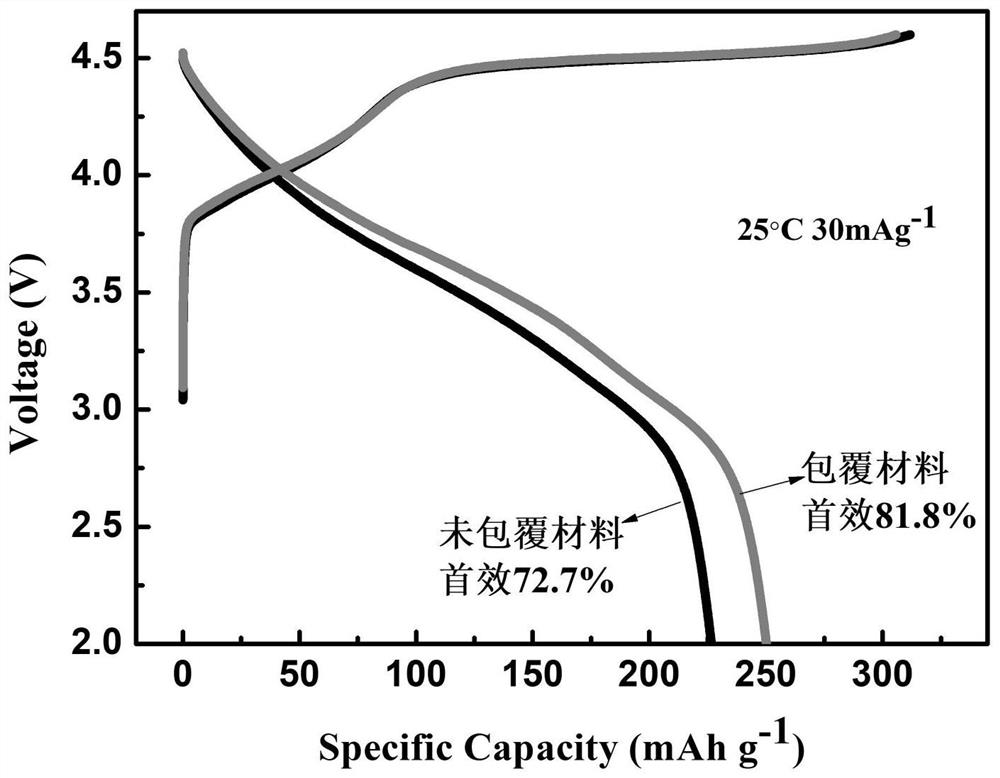

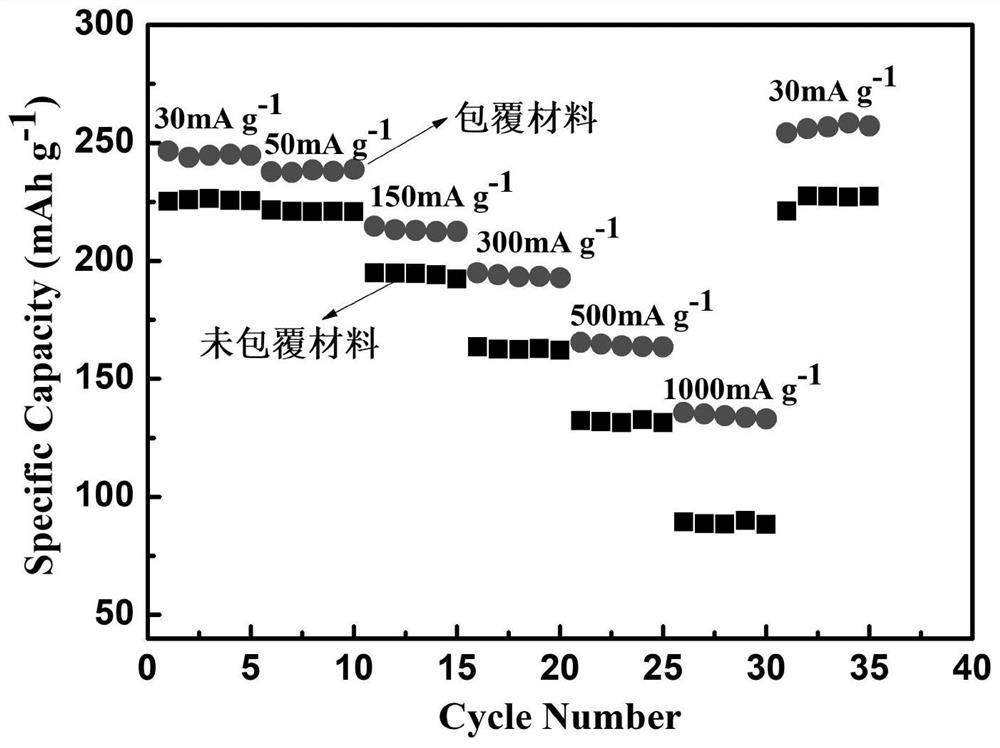

Method for improving coulombic efficiency and cycling stability of lithium-rich positive electrode material

ActiveCN113363484ALow priceImprove the first Coulombic efficiencySecondary cellsPositive electrodesOrganic groupOrganic compound

The invention belongs to the technical field of preparation of positive electrode materials, and particularly relates to a method for improving the coulombic efficiency and cycling stability of a lithium-rich positive electrode material, and the surface of the lithium-rich positive electrode material is coated with a lithium-intercalated organic compound by adopting any one of a dry-method mixing mode and a wet-method mixing mode; and the mass of the lithium-intercalated organic group compound is 0.2-10% of the mass of the lithium-rich positive electrode material. The method is simple and convenient to operate, the raw materials are low in price, the manufacturing cost is low, industrial production is facilitated, the first coulombic efficiency, the capacity and the cycling stability of the lithium-rich positive electrode material can be effectively improved by utilizing the method, and meanwhile, other side effects cannot be introduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Traditional Chinese medicine for treating uterus prolapsus and proctoptosia

InactiveCN103385916AGood curative effectAlleviate the pain of anal prolapse pain treatmentDigestive systemSexual disorderSide effectIrritation

The invention discloses a traditional Chinese medicine for treating uterus prolapsus and proctoptosia, which comprises the following raw materials: 40-80g of nosema cochinchinensis, 50-100g of red castor bean, 50-100g pig intestines, 1-2 tortoise heads and 15-20 river snails or field snails. The traditional Chinese medicine is prepared by natural raw materials, and has no special smell, no excitant and toxic and side effect, can be taken for external use and for oral use, and can be used for treating uterus prolapsus and proctoptosia. The traditional Chinese medicine can be used conveniently, and can control the condition in a short time. By clinic application, the traditional Chinese medicine can be used for treating uterus prolapsus, proctoptosia with a substantial curative effect, and the uterus and the proctoptosia have a fast contraction.

Owner:罗寿康

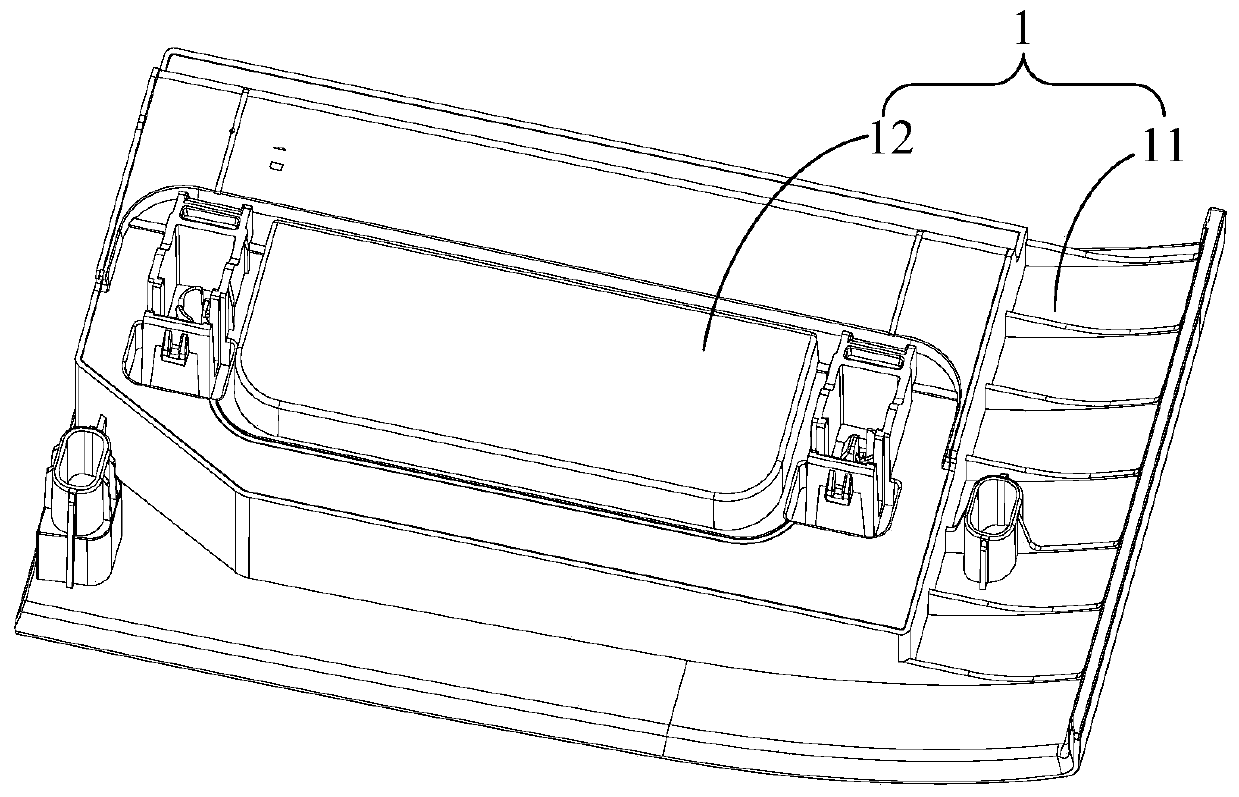

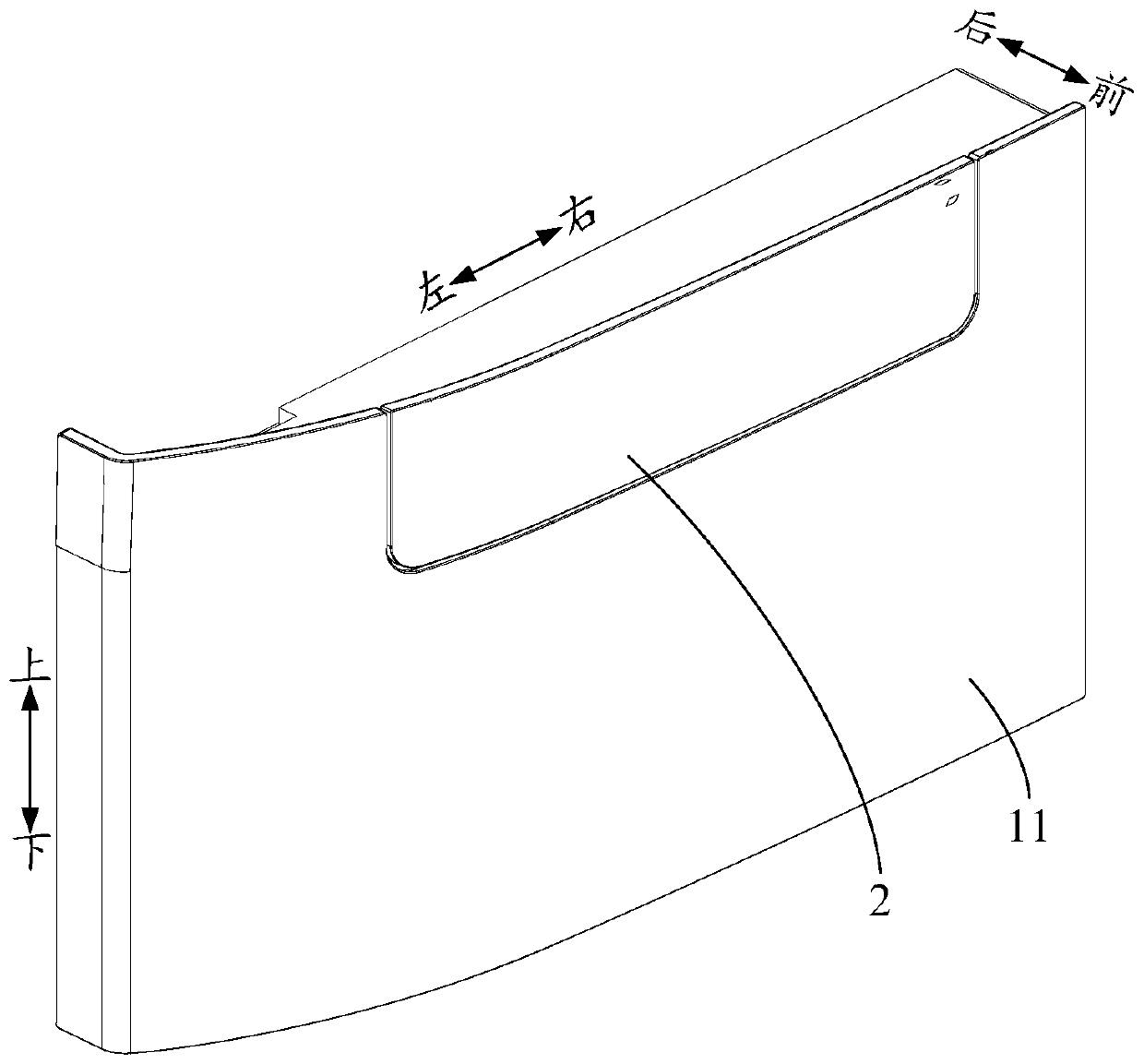

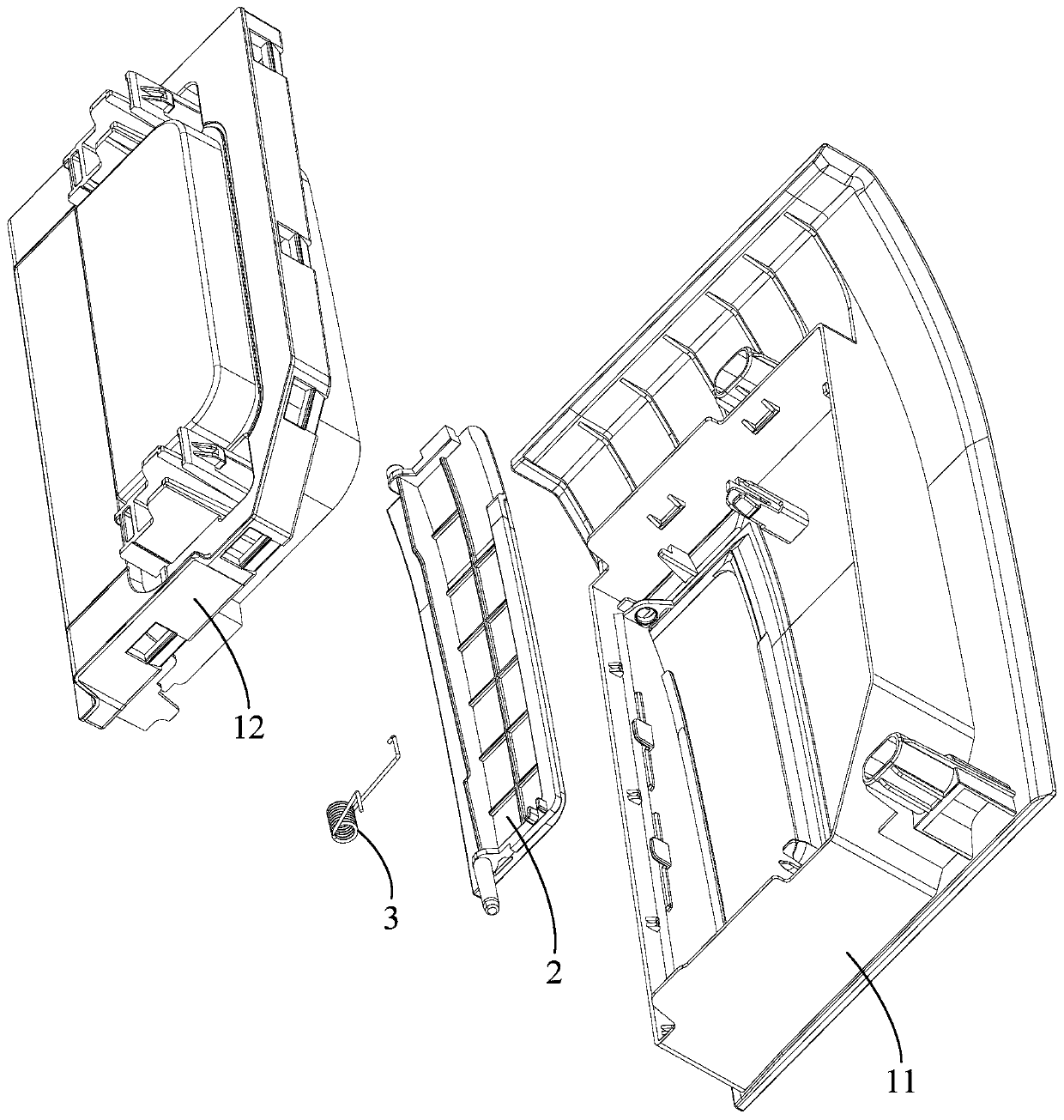

Handle assembly, distributor, detergent box assembly and clothes treatment equipment

ActiveCN109972355AImprove cleanlinessIntegrity guaranteedOther washing machinesTextiles and paperPush and pullEngineering

The invention provides a handle assembly, a distributor, a detergent box assembly and clothes treatment equipment. The handle assembly comprises a handle body and a decorating part, wherein the handlebody is provided with a clasp groove penetrating through the appearance face of the handle body; the decorating part is arranged in the clasp groove and is connected with the handle body through a movable connection structure, and the size of the decorating part is adaptive to the size of the clasp groove, and is used for sealing the clasp groove under the natural state and flush with the appearance face. The handle assembly, the distributor, the detergent box assembly and the clothes treatment equipment have the advantages that the decorating part is added in the clasp groove of the handle body, since the size of the decorating part is adaptive to the size of the clasp groove, the decorating part can seal the clasp groove under the natural state, thereby avoiding the situation that the dirt is hidden in the clasp groove, improving the cleanliness of the product, not only ensuring the integrity of the appearance face of the handle body, but also ensuring the smoothness of the appearance face of the handle body, and playing a good decorative role. In addition, the decorating part is movably connected with the handle body to trigger the decorating part, so that the clasp groove is exposed for a user to push and pull the handle assembly, thereby achieving the normal operation of the distributor.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

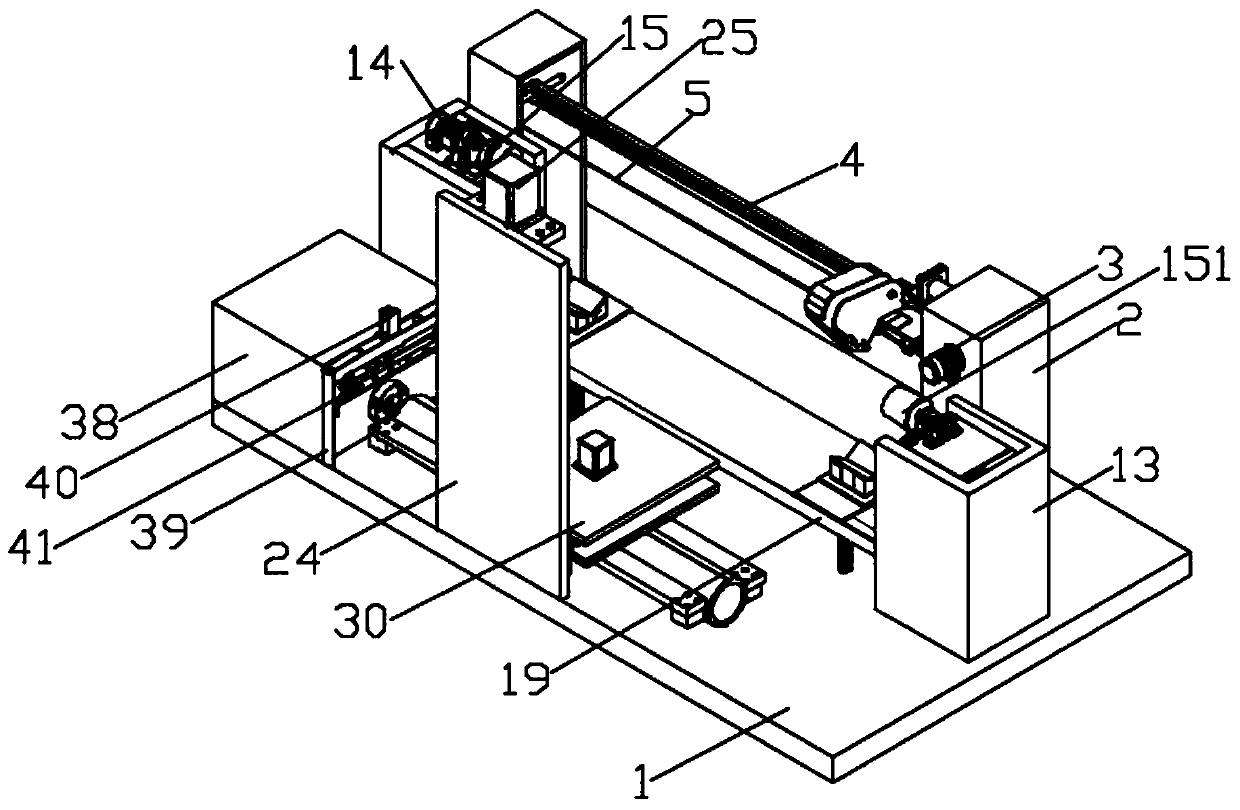

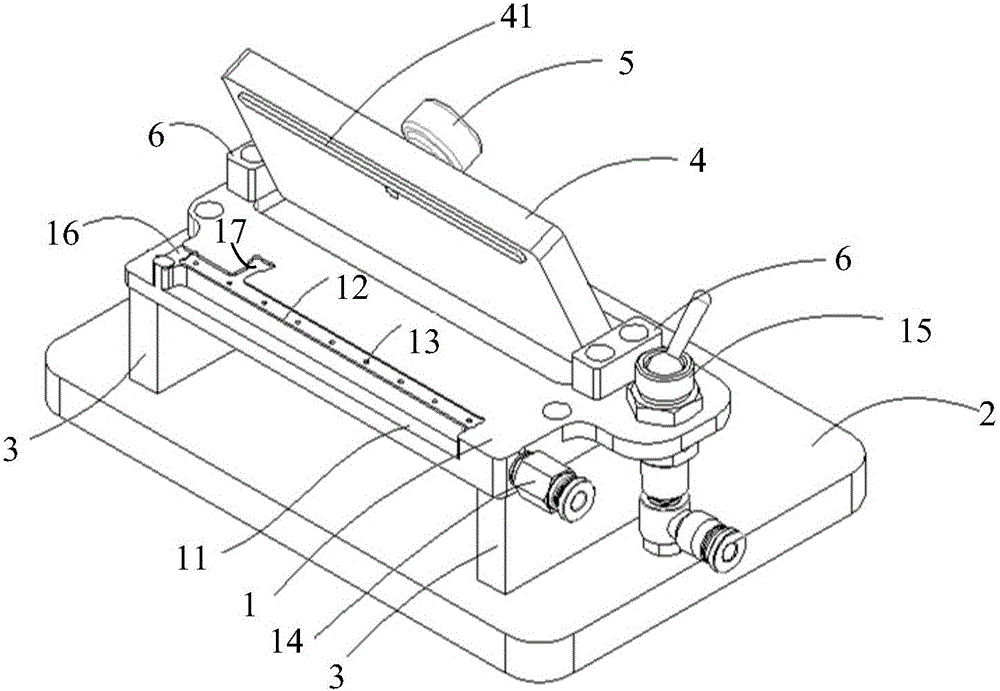

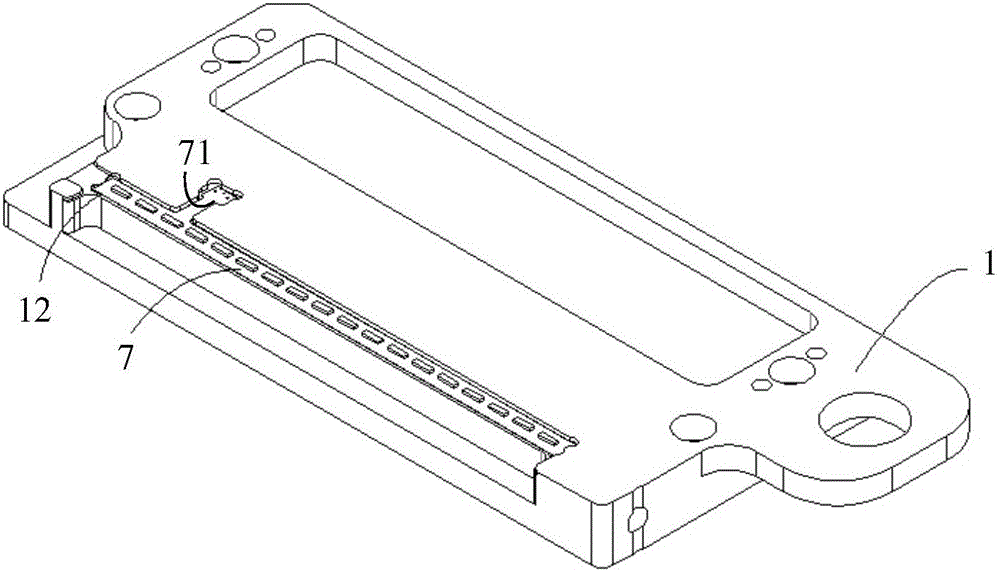

Light bar and light guide plate assembling jig

PendingCN106402807AFixed flatLess bendingElongate light sourcesLight fasteningsLight guideDisplay device

The invention relates to the technical field of display device manufacturing, and discloses a light bar and light guide plate assembling jig. The light bar and light guide plate assembling jig comprises a bearing table and a pressing plate; the bearing table is provided with a positioning assembling groove for containing a light bar and a light guide plate, and a step protrusion used for supporting the light bar is arranged in the positioning assembling groove and is provided with an attraction unit used for attracting the light bar; and the pressing plate is rotationally connected with the bearing table and used for tightly pressing a pasting layer of the light bar and the light guide plate. When the light bar and light guide plate assembling jig is used, the light bar and the light guide plate can be positioned through the positioning assembling groove, the light bar can be tightly attached to the light entering side of the light guide plate through the pressing plate, and the attraction unit is arranged so that the light bar can be smoothly fixed to the step protrusion. By means of the light bar and light guide plate assembling jig, the phenomenon of light bar bending and the phenomenon that the light bar is separated from the light bar and light guide plate assembling jig are avoided, and the accuracy of light bar and light guide plate assembling is improved.

Owner:BOE OPTICAL SCI & TECH +1

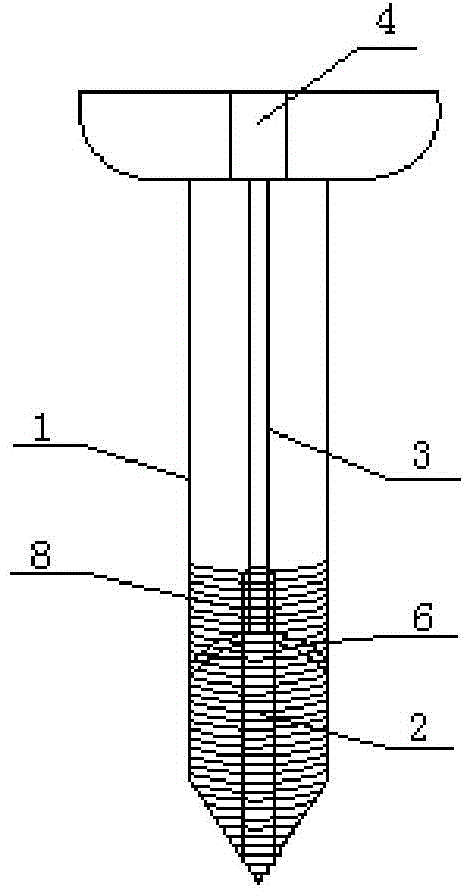

Hollow nail

InactiveCN104905866AReduce loosenessReduce prolapseInternal osteosythesisFastenersScrew threadCancellous bone

The invention provides a hollow nail pertaining to the field of medical equipment for the department of orthopaedics. The hollow nail comprises a nail body with a hollow structure. The head portion of the nail body is symmetrically provided with two U-shaped grooves. Openings of the U-shaped grooves are located at the head portion of the nail body. The interior of the nail body is provided with a hollow rod, the top end of which is provided with a positioning block. The positioning block is in threaded connection with the tail of the nail body. The bottom end of the hollow rod is connected with an arc elastic sheet which protrudes upwardly. Two ends of the arc elastic sheet are fixed into an inner wall of the head portion of the nail body. The hollow nail has following beneficial effects: the hollow nail is simple in structure and reasonable in design; after the nail body is screwed into a fracture part and internally provided with the arc elastic sheet, deformation of the arc elastic sheet is produced under effect of the hollow rod; the downwardly-pressed arc elastic sheet enables the head portion of the nail body to expand outwardly for deformation so that looseness of the nail body is reduced or even occurrence rate of separation is decreased; and stability and reliability of cancellous bone fracture fixation are effectively enhanced.

Owner:BEIJING BEST BIO TECHN

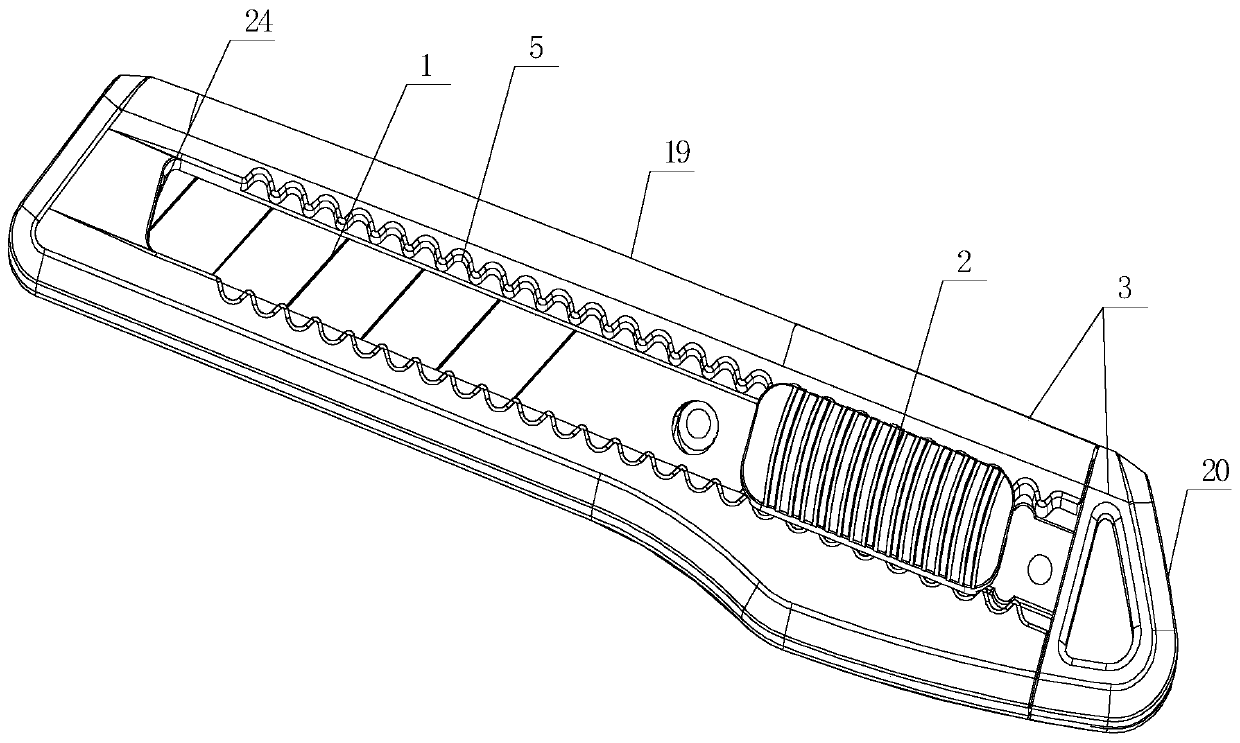

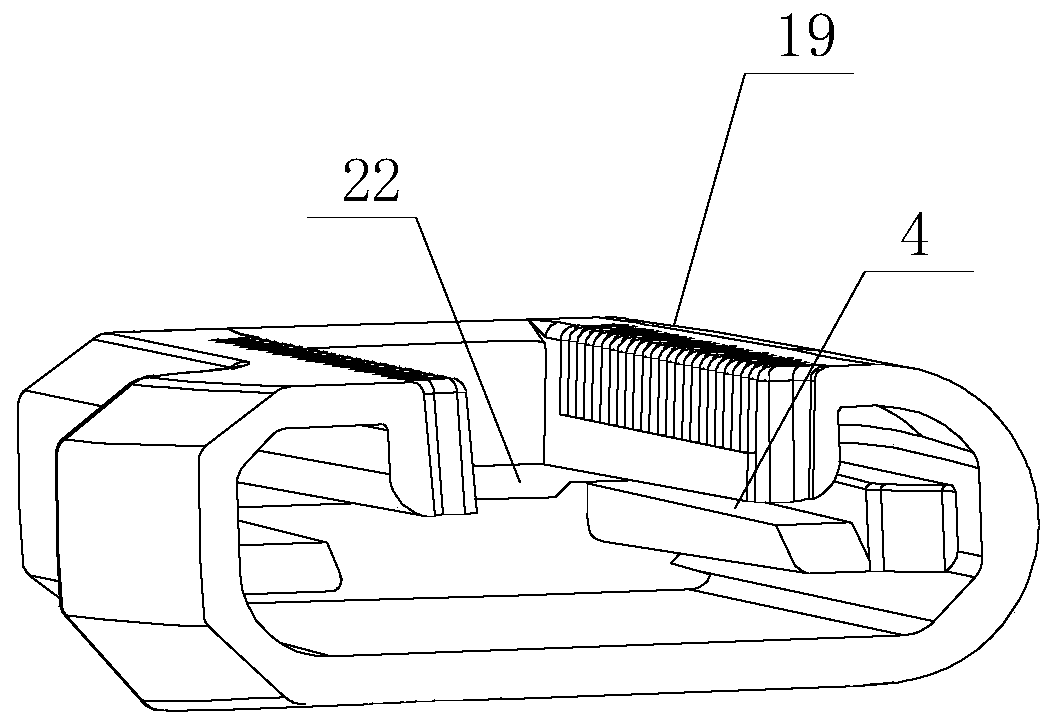

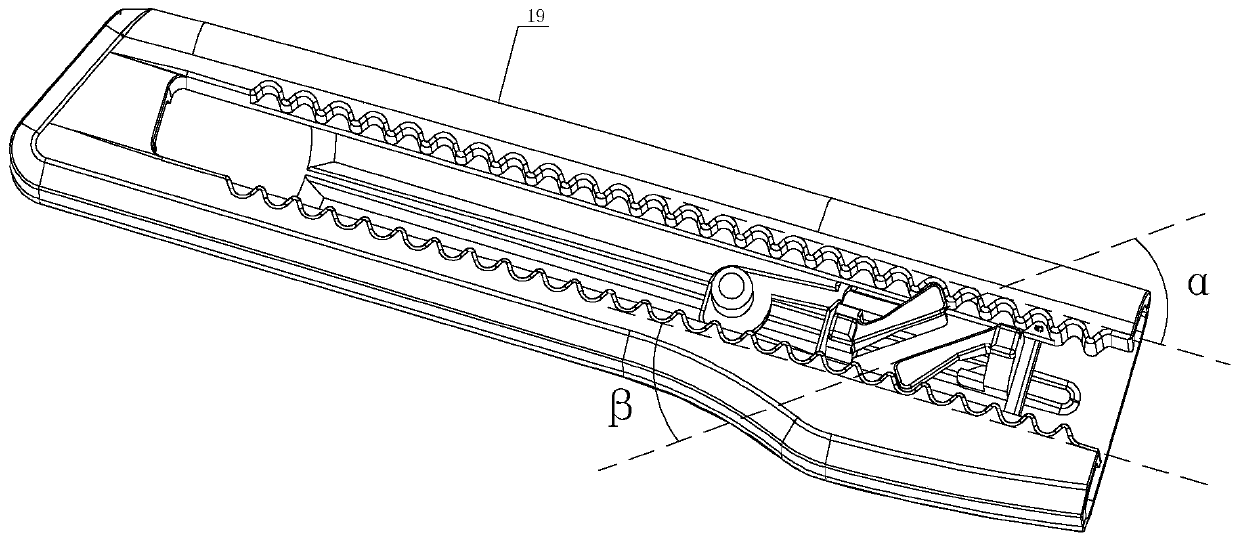

Art knife

The invention discloses an art knife. The art knife comprises a blade (1), a handle switch (2) and a knife housing (3); a knife groove (4) for sliding fit of the blade (1) is formed in the knife housing (3); the knife housing (3) is provided with an opening (24) for sliding fit of the handle switch (2); the blade (1) is connected with that handle switch (2); a plurality of grooves (5) are formed in the knife housing (3); the grooves (5) are arranged in two rows basically in parallel; a first elastic buckle (6) and a second elastic buckle (7) are arranged on the two sides of the handle switch (2) correspondingly; the first elastic buckle (6) can be embedded into each of the grooves (5) in one row; the second elastic buckle (7) can be embedded into each of the grooves (5) in the other row; and the handle switch (2) is internally provided with a locking and unlocking structure which can enable the first elastic buckle (6) or the second elastic buckle (7) to escape from the grooves (5). The art knife is low in cost, high in working reliability and high in safety.

Owner:DELI GROUP CO LTD

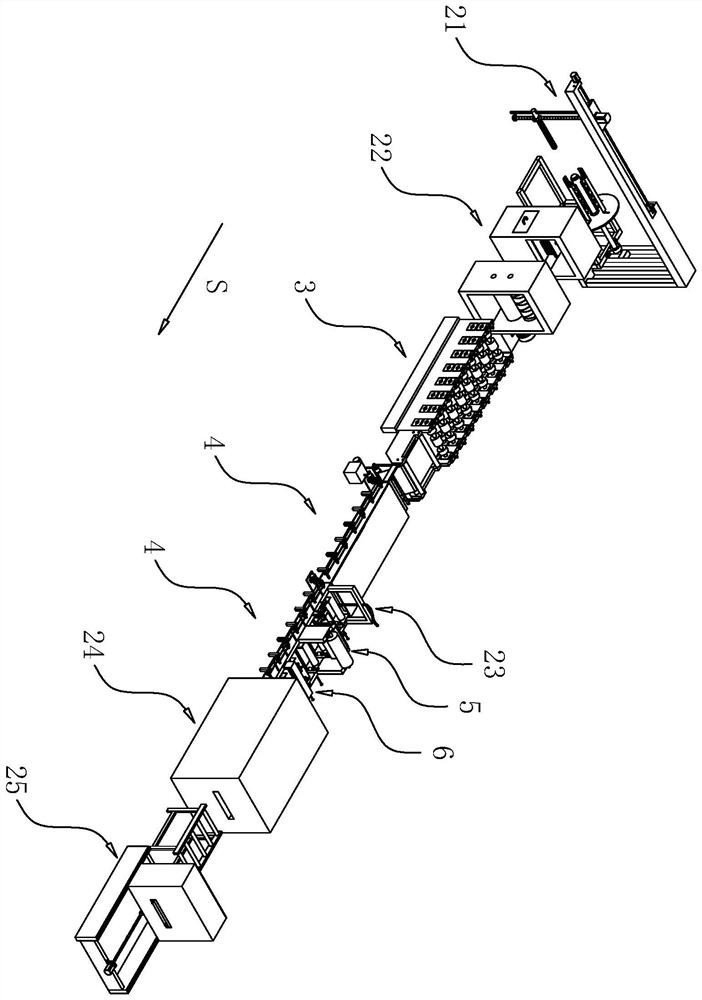

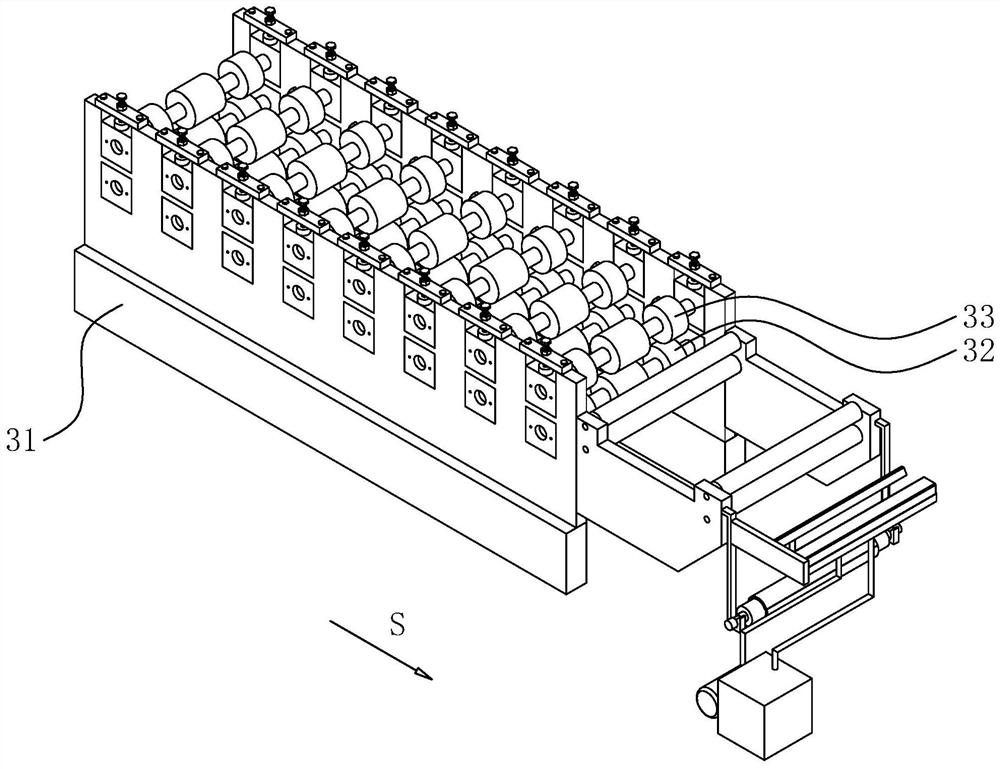

Polyurethane insulation board and production line thereof

ActiveCN111906987ANot easy to fall offMutual protectionHeat proofingFlat articlesProduction linePolymer science

The invention relates to a polyurethane insulation board and a production line thereof, and relates to the technical field of insulation board manufacturing. The polyurethane insulation board comprises a base plate, aluminum foil cloth and polyurethane foam, wherein one end of the base plate in the width direction is bent to form a first clamping groove, and the other end of the base plate in thewidth direction is bent to form a second clamping groove; the two ends of the aluminum foil cloth are embedded in the first clamping groove and the second clamping groove respectively; the polyurethane foam is filled between the base plate and the aluminum foil cloth; the production line comprises an uncoiling machine, an embossing machine, a forming machine, a foaming machine, a cloth paving machine, a cloth embedding machine and a laminating machine, and further comprises a conveying device used for conveying the base plate; and the foaming machine, the cloth paving machine and the cloth embedding machine are sequentially arranged on the conveying device. Compared with the prior art, the aluminum foil cloth is not prone to falling off from the polyurethane foam, then the polyurethane foam can be protected by the aluminum foil cloth, mutual protection between the aluminum foil cloth and the polyurethane foam is achieved, the service life of the insulation board is prolonged, and meanwhile, the thermal insulation performance of the insulation board after long-time use is improved.

Owner:济南建诚新型保温材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com