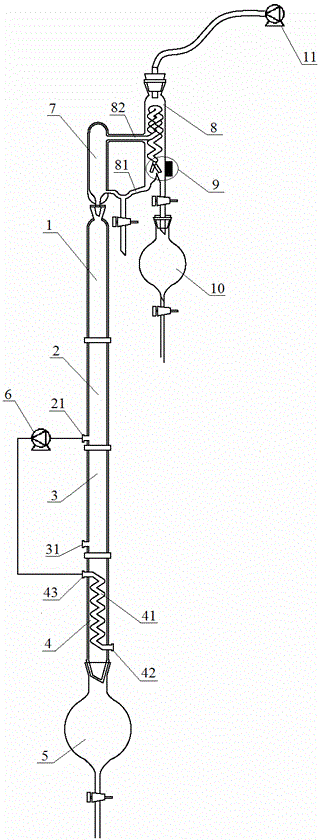

Device and method for eliminating and recycling organic solvent from cathode electrophoresis emulsion

A cathodic electrophoresis, organic solvent technology, applied in steam distillation and other directions, can solve the problems of difficult operation stability control, large loss of effective solvent, imperfect solvent recovery, etc., to avoid low removal efficiency, zero-emission process operation, effective Stabilizing effect of solvent content and other conventional physical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Vacuumize the system continuously to keep the system pressure at 10±1kPa, continuously feed water vapor from the carrier gas inlet at the lower part of the lower tower section, and the water vapor flow rate is 180g / h;

[0040] (2) Start the peristaltic pump, feed cathodic electrophoretic emulsion 1 into the heat exchanger through the cold emulsion inlet at the lower end of the heat exchanger at a feed flow rate of 3500g / h, and flow out from the emulsion outlet of the heat exchanger after countercurrent heat exchange. The emulsion feed port of the middle tower section enters the packed tower for gas-liquid mass transfer;

[0041] (3) Adjust the reflux ratio of the electromagnetic pendulum controller to 3. After the system is preheated, collect the emulsion in the emulsion recovery kettle and the solvent in the solvent recovery kettle.

[0042] After the cathodic electrophoretic emulsion 1 passes through the heat exchanger for heat exchange, the feed temperature rises...

Embodiment 2

[0044] (1) Vacuumize the system continuously to keep the system pressure at 10±1kPa, continuously feed water vapor from the carrier gas inlet at the lower part of the lower tower section, and the water vapor flow rate is 200g / h;

[0045] (2) Start the peristaltic pump, feed cathodic electrophoretic emulsion 1 into the heat exchanger through the cold emulsion inlet at the lower end of the heat exchanger at a feed flow rate of 4000g / h, and flow out from the emulsion outlet of the heat exchanger after countercurrent heat exchange. The emulsion feed port of the middle tower section enters the packed tower for gas-liquid mass transfer;

[0046] (3) Adjust the reflux ratio of the electromagnetic pendulum controller to 3. After the system is preheated, collect the emulsion in the emulsion recovery kettle and the solvent in the solvent recovery kettle.

[0047] After the cathodic electrophoretic emulsion 1 passes through the heat exchanger for heat exchange, the feed temperature rises...

Embodiment 3

[0049] (1) Vacuumize the system continuously to keep the system pressure at 10±1kPa, continuously feed water vapor from the carrier gas inlet at the lower part of the lower tower section, and the water vapor flow rate is 200g / h;

[0050] (2) Start the peristaltic pump, feed cathodic electrophoretic emulsion 1 into the heat exchanger through the cold emulsion inlet at the lower end of the heat exchanger at a feed flow rate of 3500g / h, and flow out from the emulsion outlet of the heat exchanger after countercurrent heat exchange. The emulsion feed port of the middle tower section enters the packed tower for gas-liquid mass transfer;

[0051] (3) Adjust the reflux ratio of the electromagnetic pendulum controller to 3. After the system is preheated, collect the emulsion in the emulsion recovery kettle and the solvent in the solvent recovery kettle.

[0052]After the cathodic electrophoretic emulsion 1 passes through the heat exchanger for heat exchange, the feed temperature rises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com