Laser stripping method using metallic passage beds to transfer GaN substrate

A laser lift-off and transition layer technology, which is applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of affecting the current diffusion and output optical power of the device, complex device preparation process, poor thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

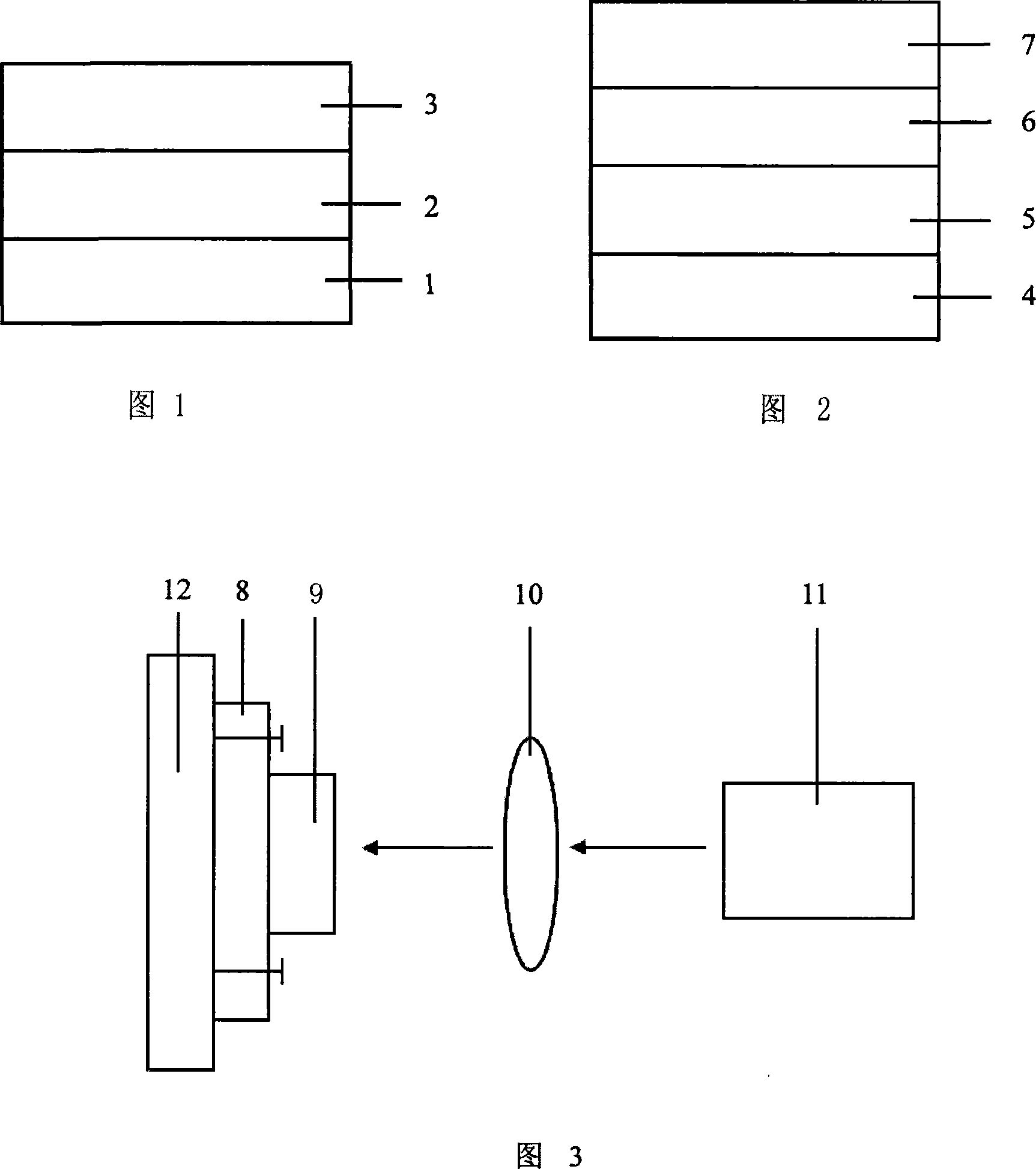

[0026] Referring to FIG. 1, a 40nm Ti layer 2 and a 200nm Au layer 3 are sputtered on a Si(001) substrate 1 in sequence to obtain a silicon wafer sputtered with Ti and Au.

[0027] Referring to FIG. 2, 40 nm Ni6 and 200 nm Au7 were sputtered sequentially on GaN5 with a sapphire substrate 4 to obtain a gallium nitride sheet sputtered with Ni and Au.

[0028] The bonding interfaces of silicon wafers sputtered with Ti and Au and gallium nitride wafers sputtered with Ni and Au are all metals. For the use of GaN-based materials to prepare light-emitting devices, metal multilayer films can also further improve reflectivity .

[0029] The silicon wafer sputtered with Ti and Au and the metal surface of the gallium nitride wafer sputtered with Ni and Au are bonded face-to-face, and then put into the inner cavity of the bonding machine, and the temperature is set to 150° C. for pre-bonding. The introduction of pre-bonding is conducive to the uneven surface of the silicon wafer sputtered wit...

Embodiment 2

[0035] Similar to Embodiment 1, the difference is that a 50nm Ti layer and a 500nm Au layer are sputtered sequentially on a Si(001) substrate to obtain a silicon wafer sputtered with Ti and Au. Sputtering 50nm of Ni and 500nm of Au on the GaN with a sapphire substrate in turn, to obtain a gallium nitride sheet sputtered with Ni and Au. The silicon wafer sputtered with Ti and Au and the metal surface of the gallium nitride wafer sputtered with Ni and Au are bonded face to face, and then put into the inner cavity of the bonding machine, and the temperature is set to 100° C. for pre-bonding. After pre-bonding, the temperature of the bonding machine is increased to 200°C, and the sapphire / gallium nitride / metal layer / silicon bonding wafer structure is formed after 1 hour of constant temperature. The laser energy density of the laser is 200mJ / cm 2 .

Embodiment 3

[0037] Similar to Embodiment 1, the difference is that a 10nm Ti layer and an 80nm Au layer are sequentially sputtered on a Si(001) substrate to obtain a silicon wafer sputtered with Ti and Au. Sputtering 10nm of Ni and 80nm of Au on the GaN with a sapphire substrate in sequence to obtain a gallium nitride sheet sputtered with Ni and Au. The silicon wafer sputtered with Ti and Au and the metal surface of the gallium nitride wafer sputtered with Ni and Au are bonded face-to-face, and then put into the inner cavity of the bonding machine, and the temperature is set to 200° C. for pre-bonding. After pre-bonding, the temperature of the bonding machine is increased to 600°C, and the sapphire / gallium nitride / metal layer / silicon bonding sheet structure is formed after 1 hour of constant temperature. The laser energy density of the laser is 300mJ / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com