Patents

Literature

80results about How to "Lower bonding temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

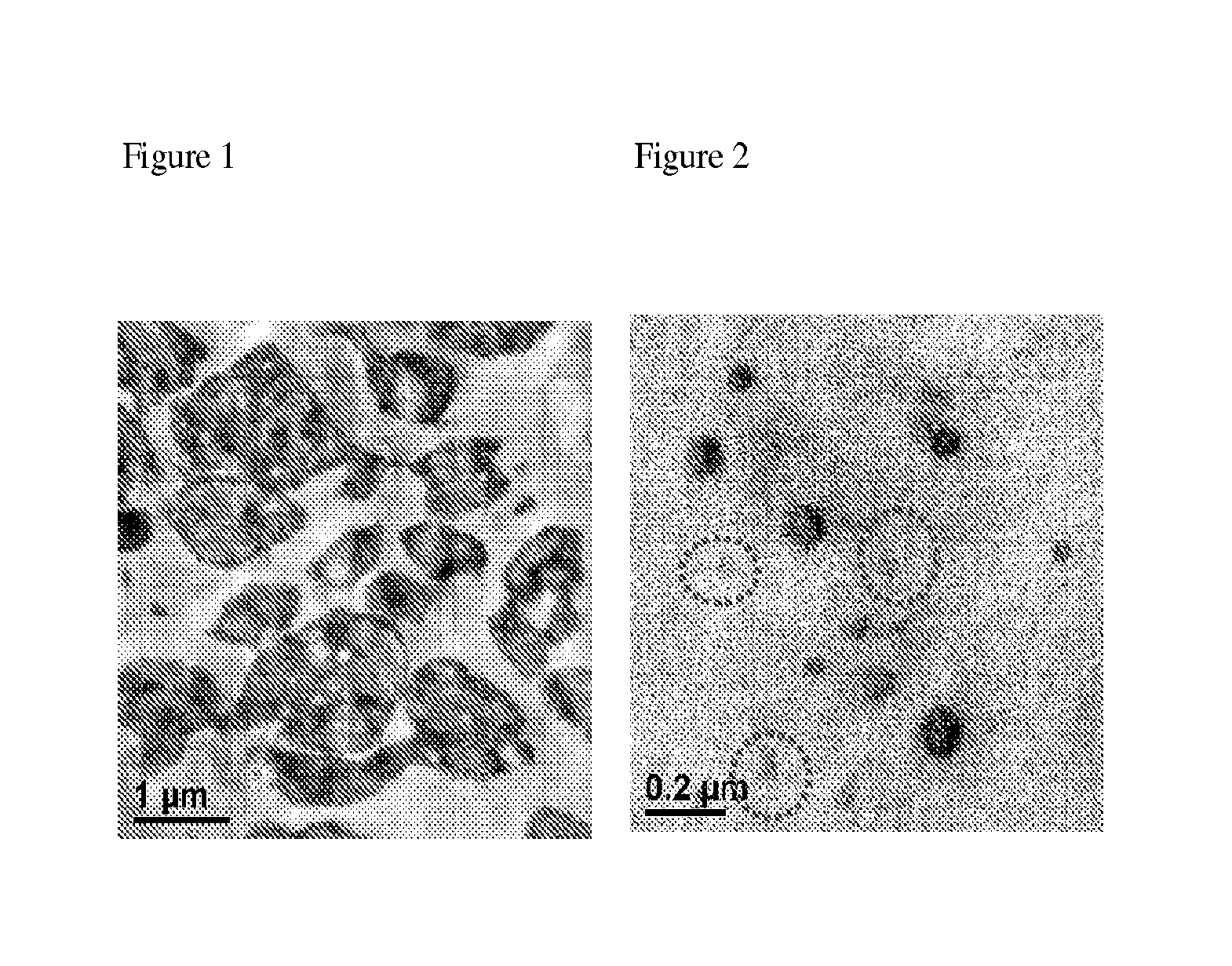

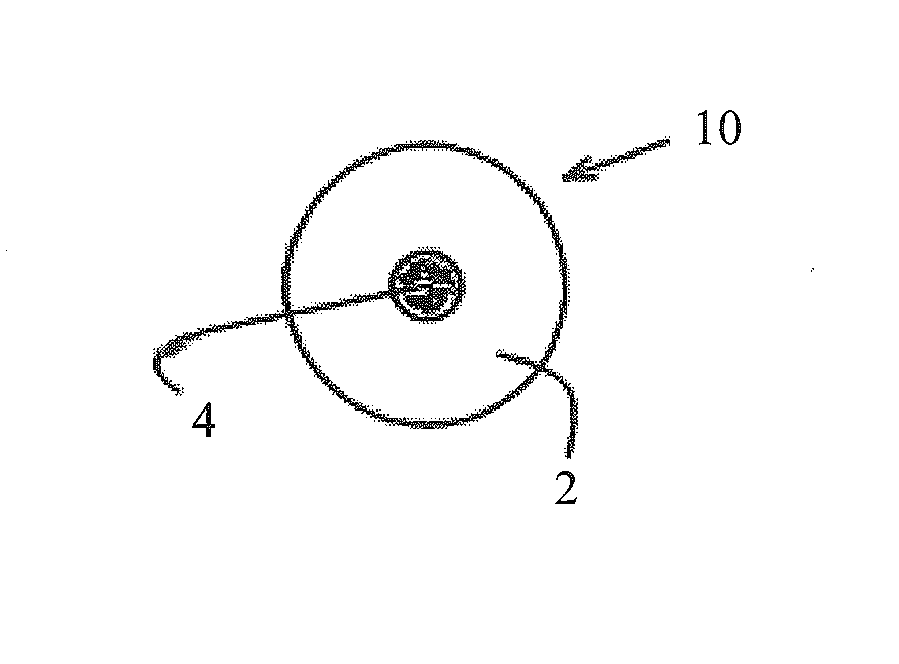

Nanoscale metal paste for interconnect and method of use

ActiveUS20090162557A1Broaden applicationEasy to handleTransportation and packagingPrinted circuit aspectsMicrometerMetal particle

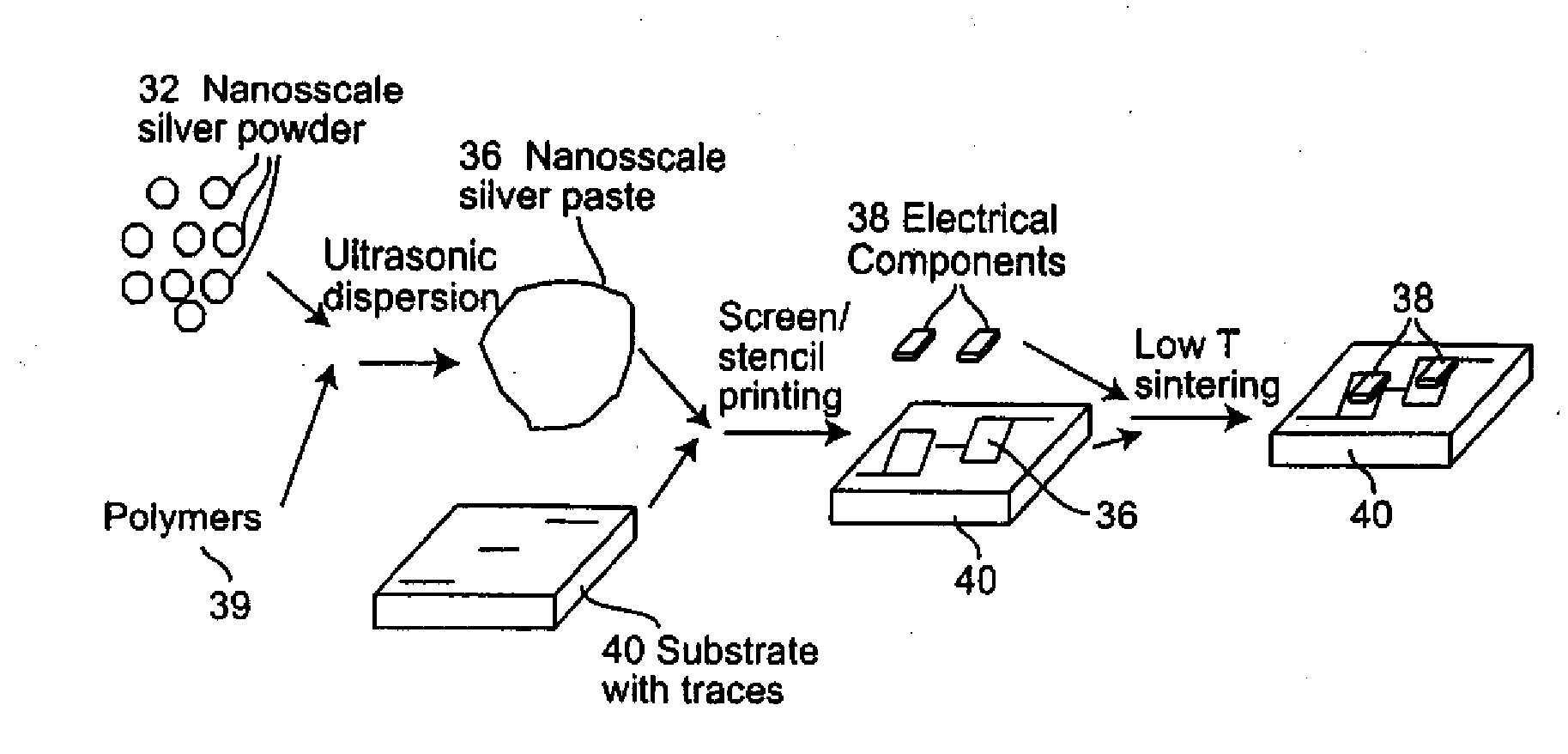

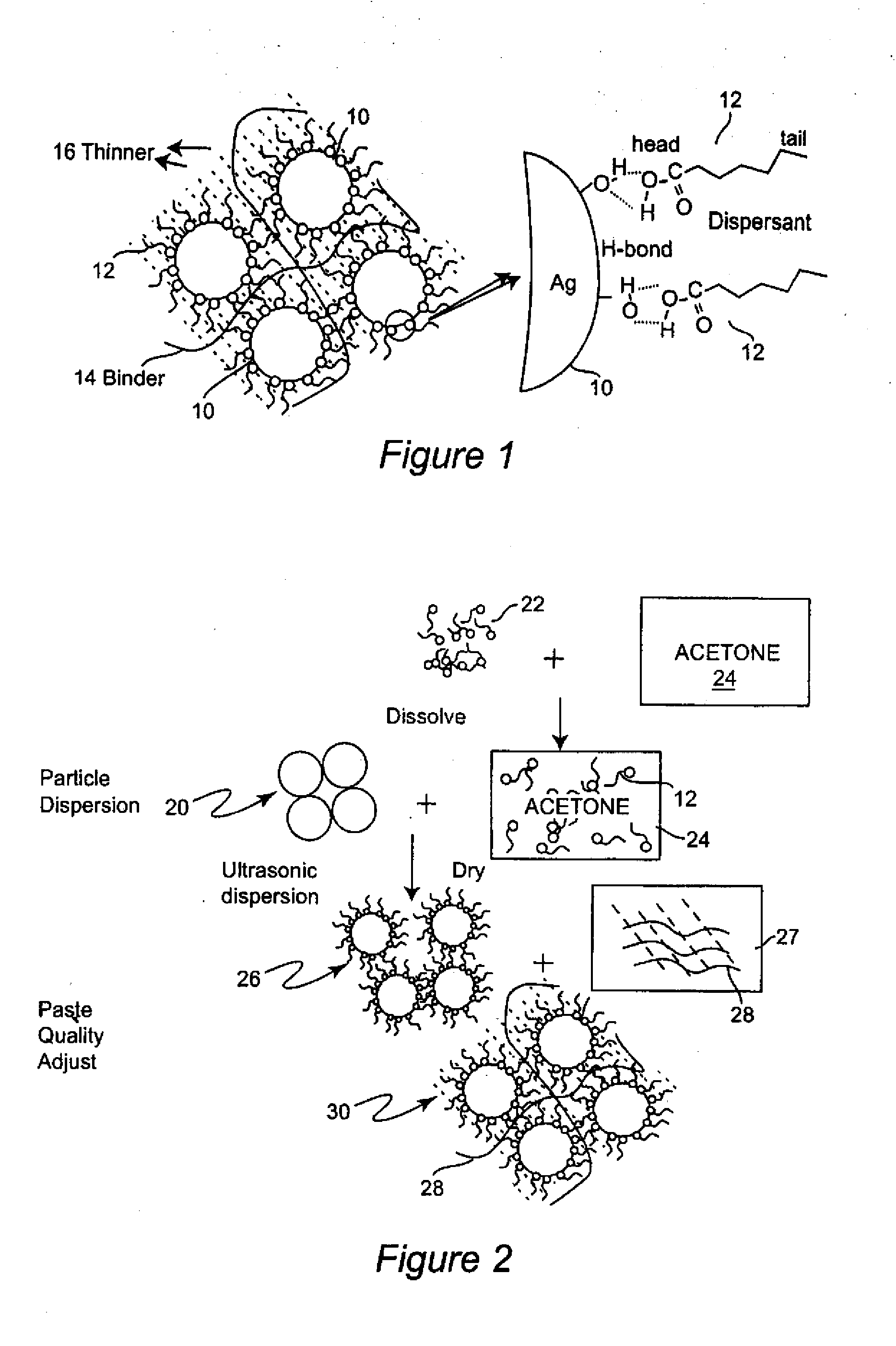

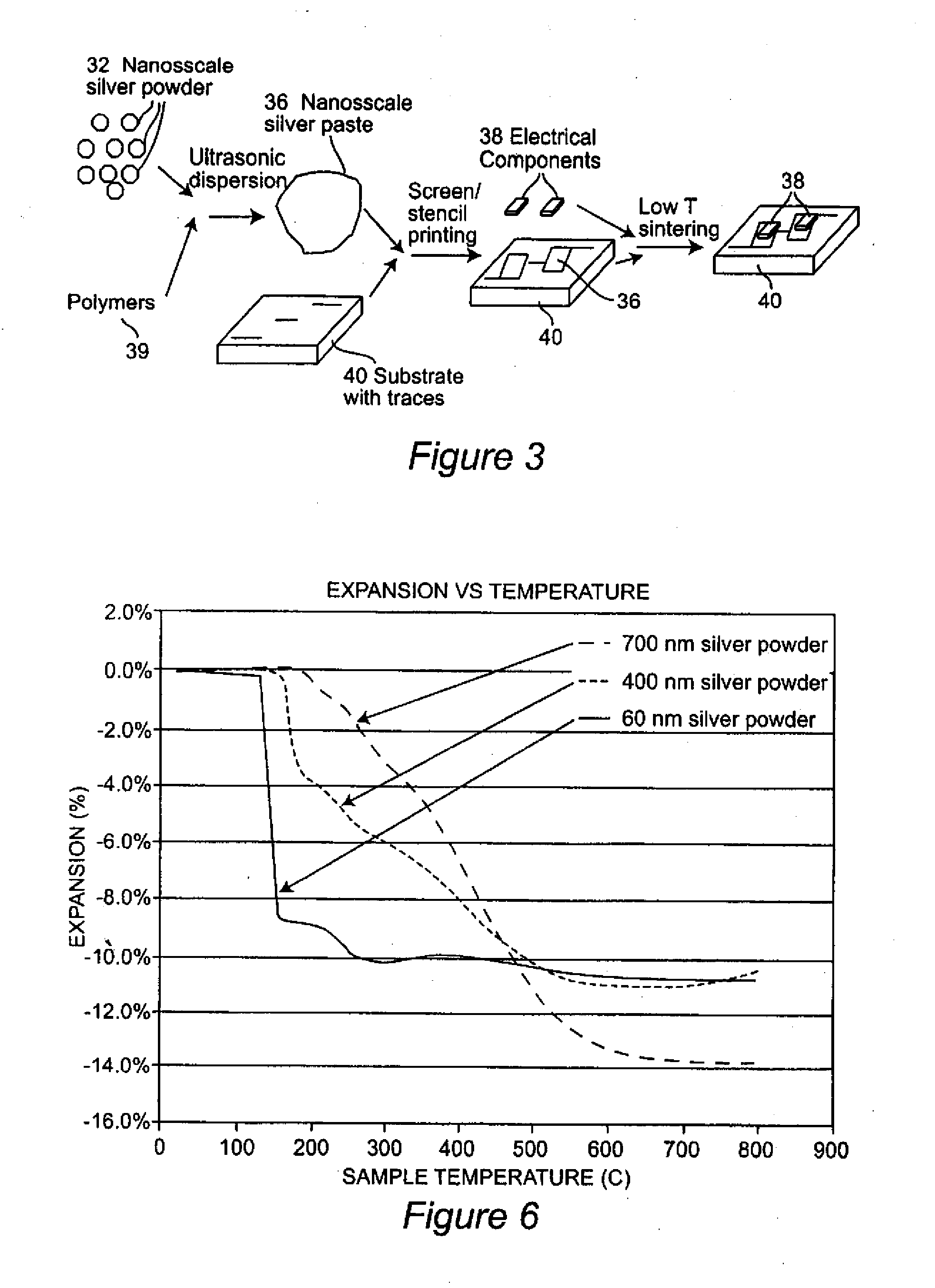

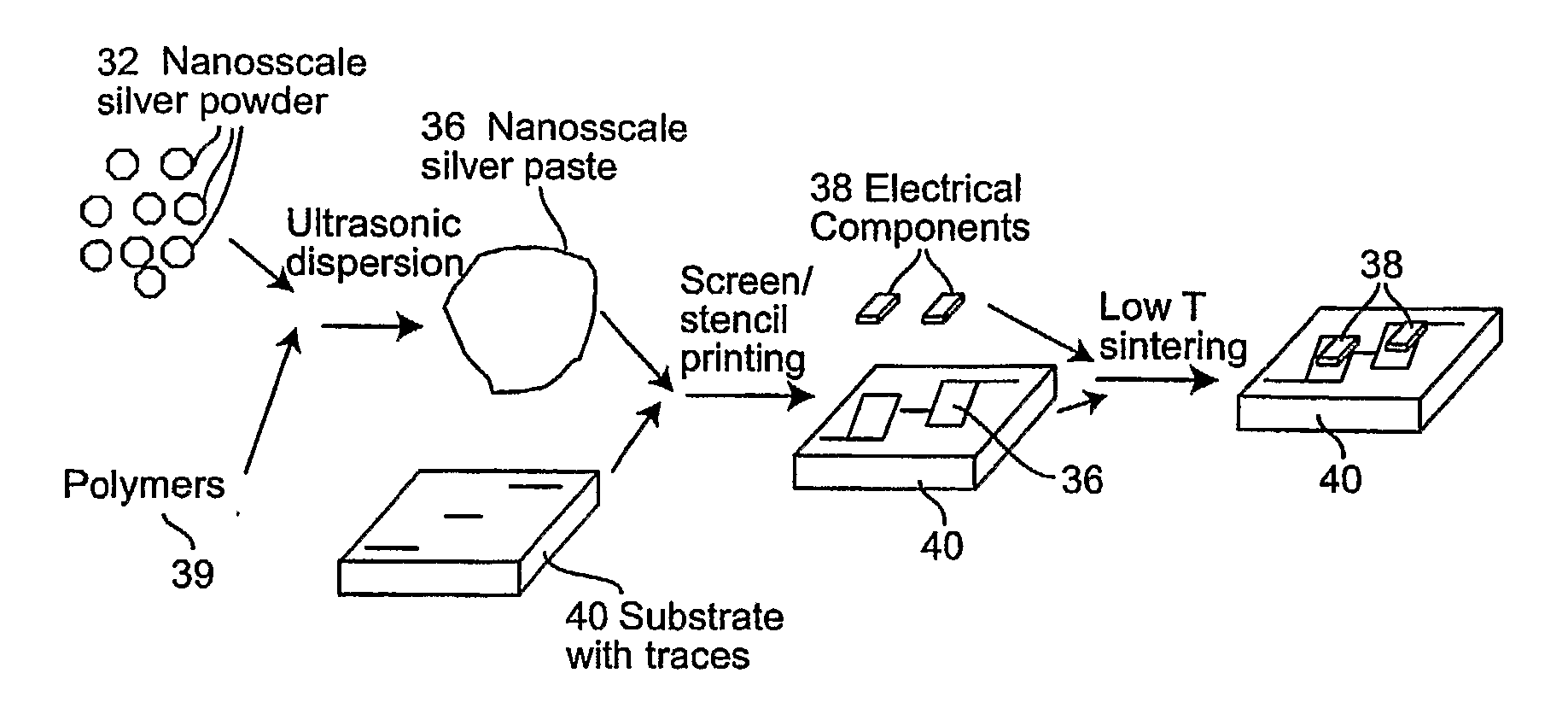

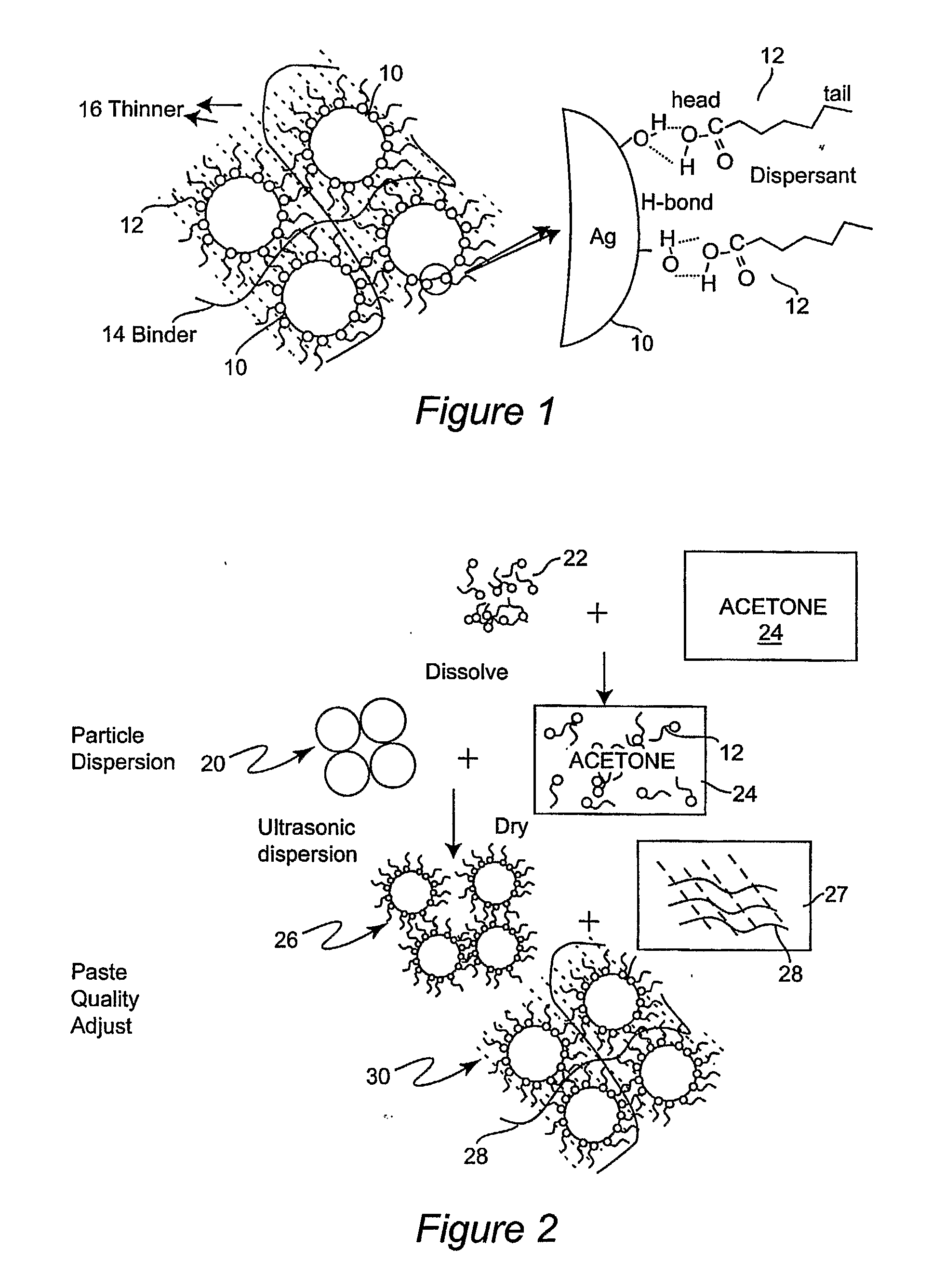

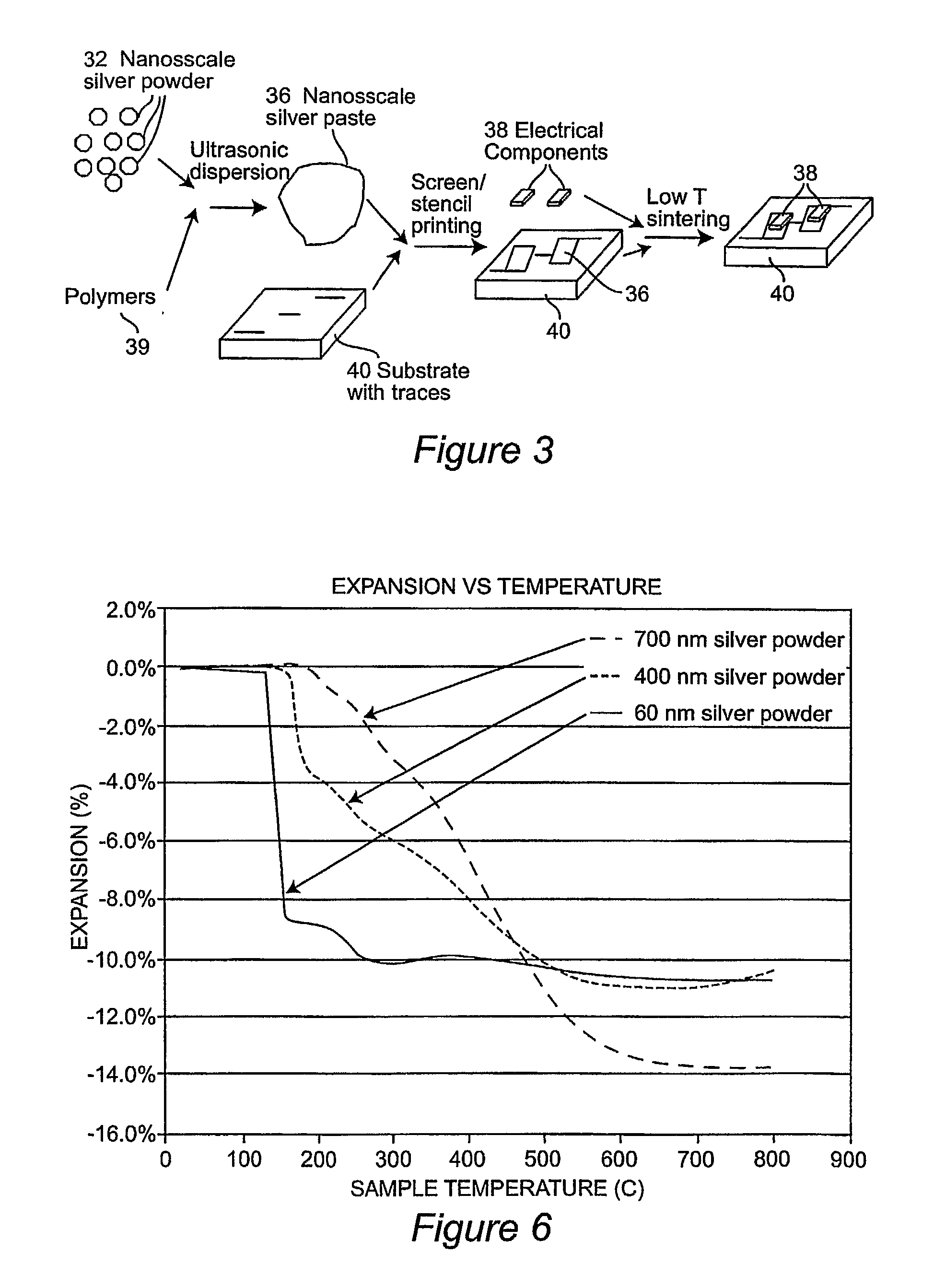

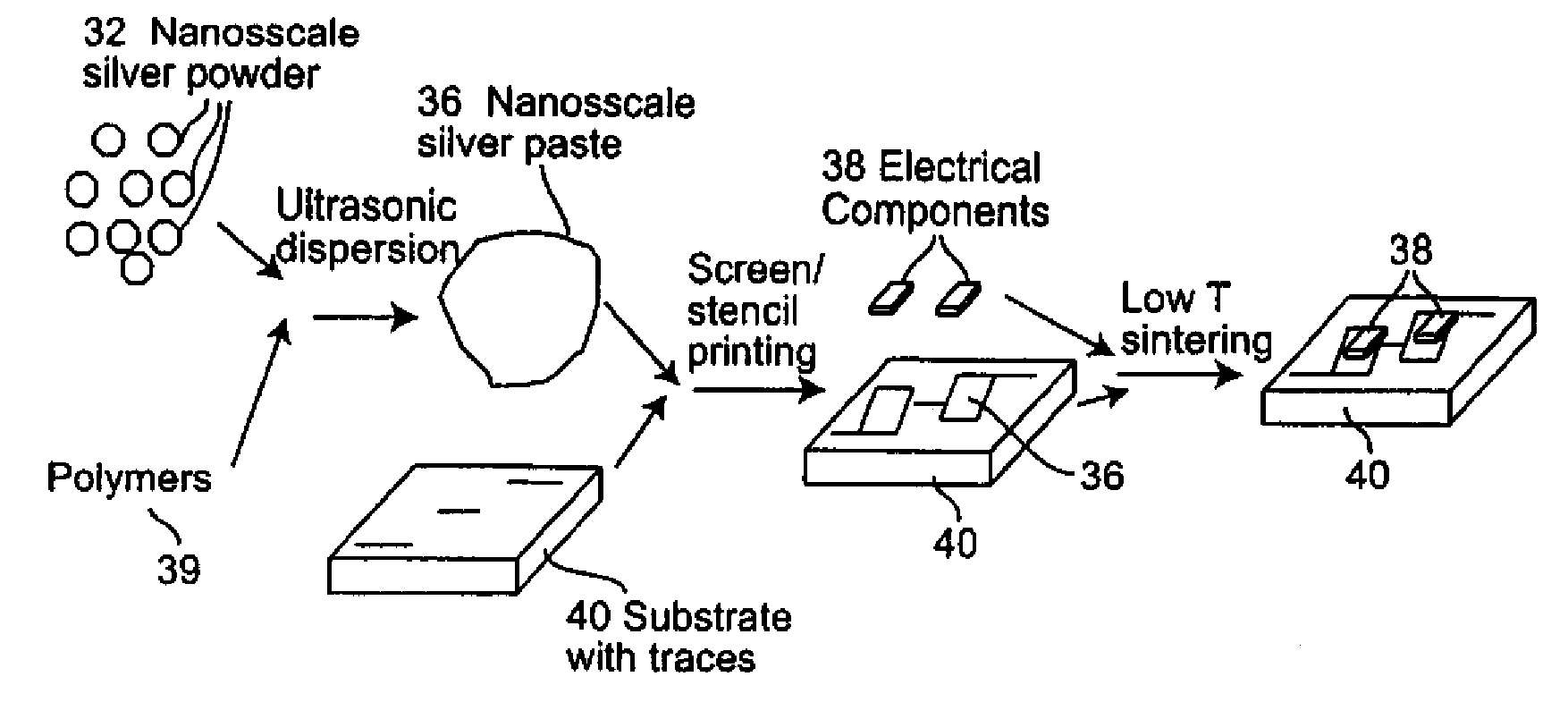

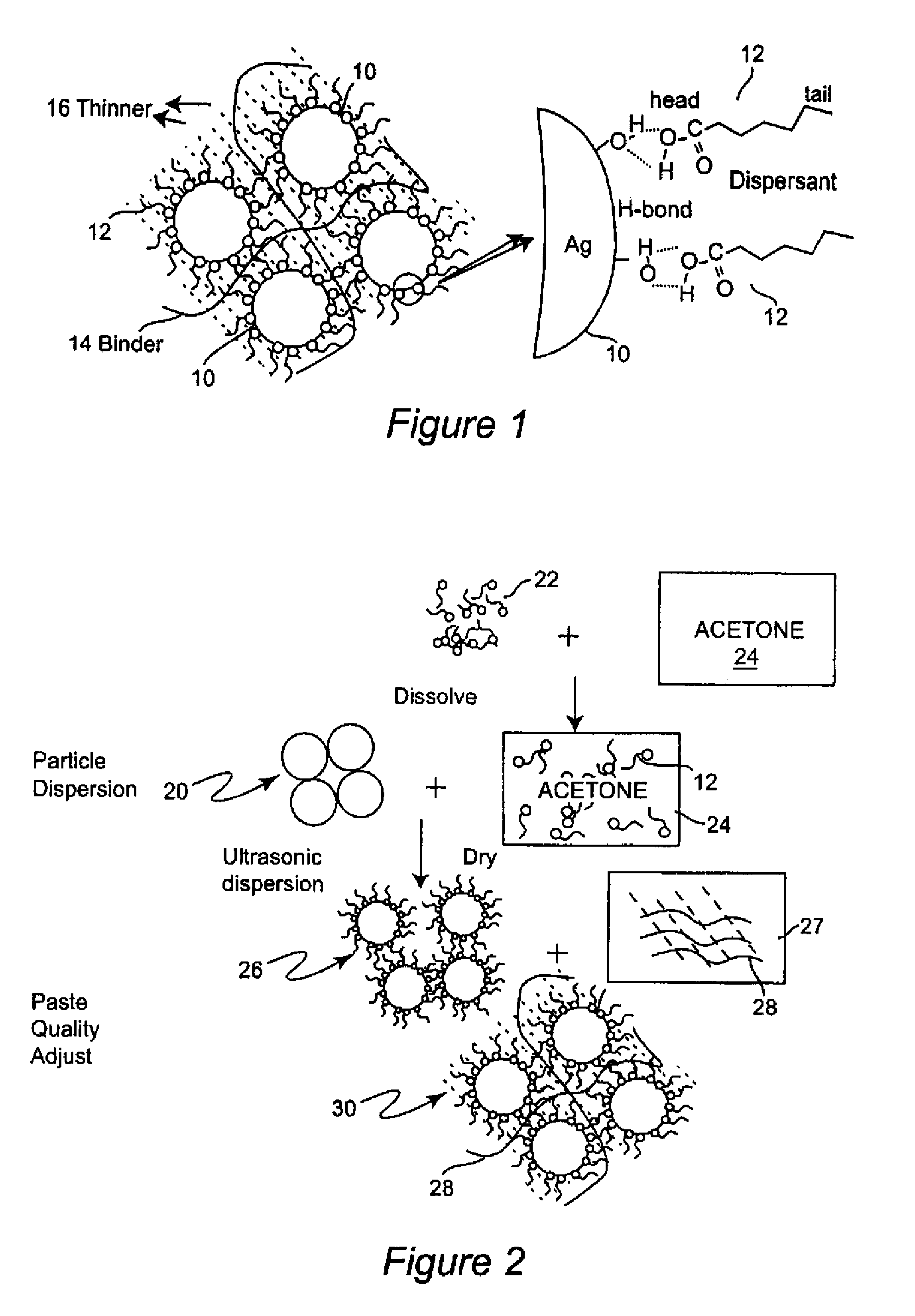

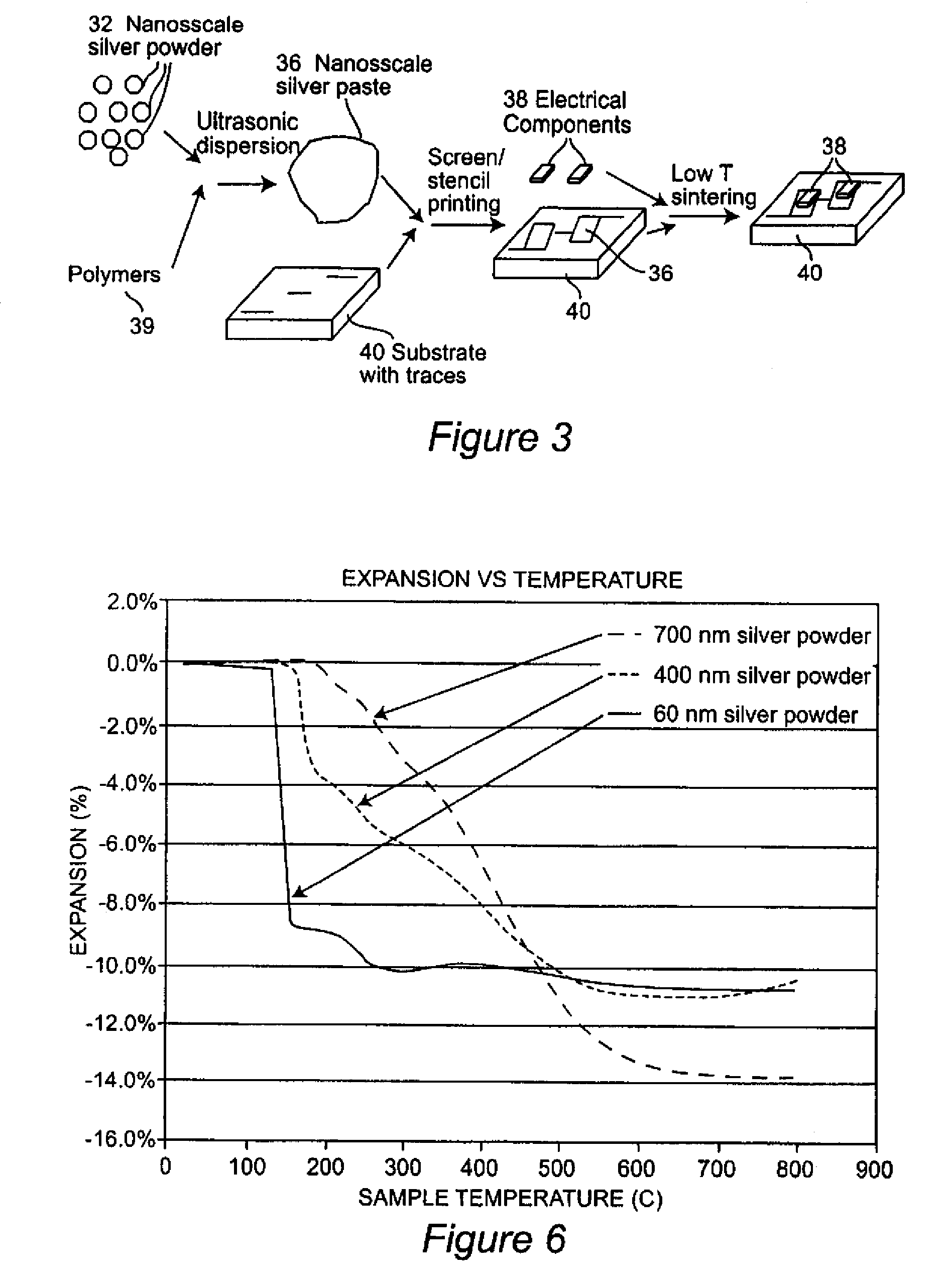

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

Nanoscale metal paste for interconnect and method of use

InactiveUS20070183920A1Lower bonding temperatureReduce and eliminate needTransportation and packagingMetal-working apparatusElectric heatingMicrometer

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

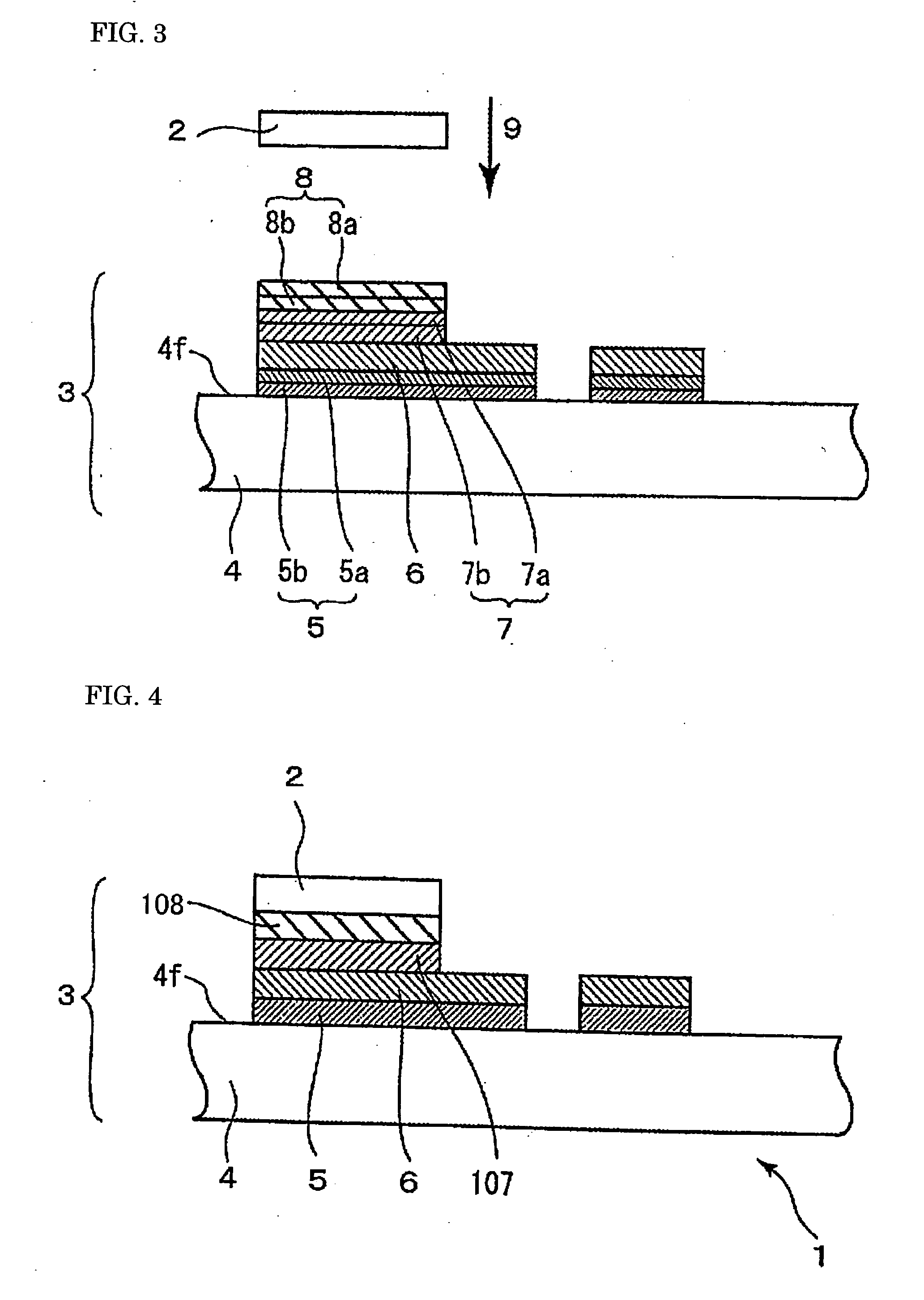

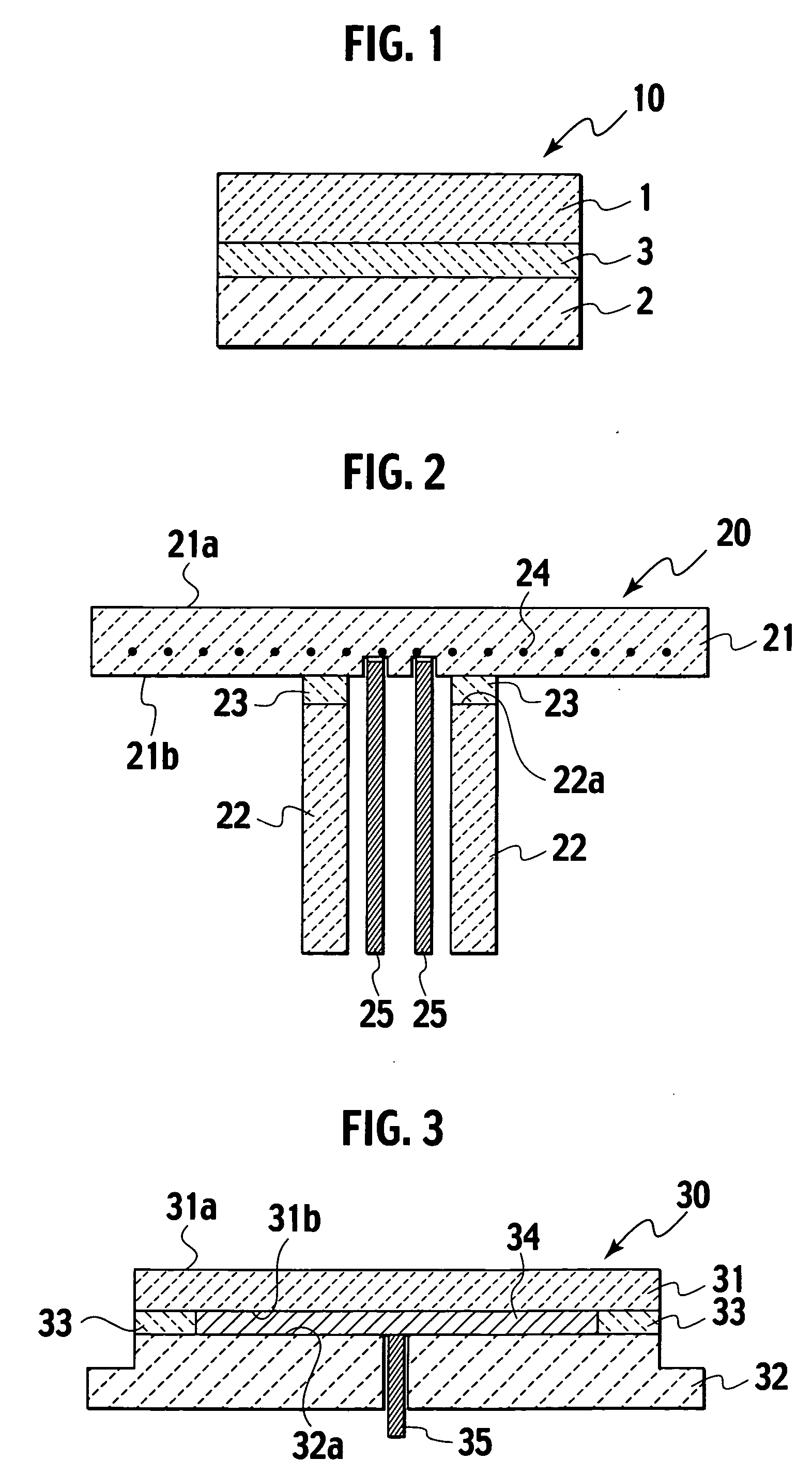

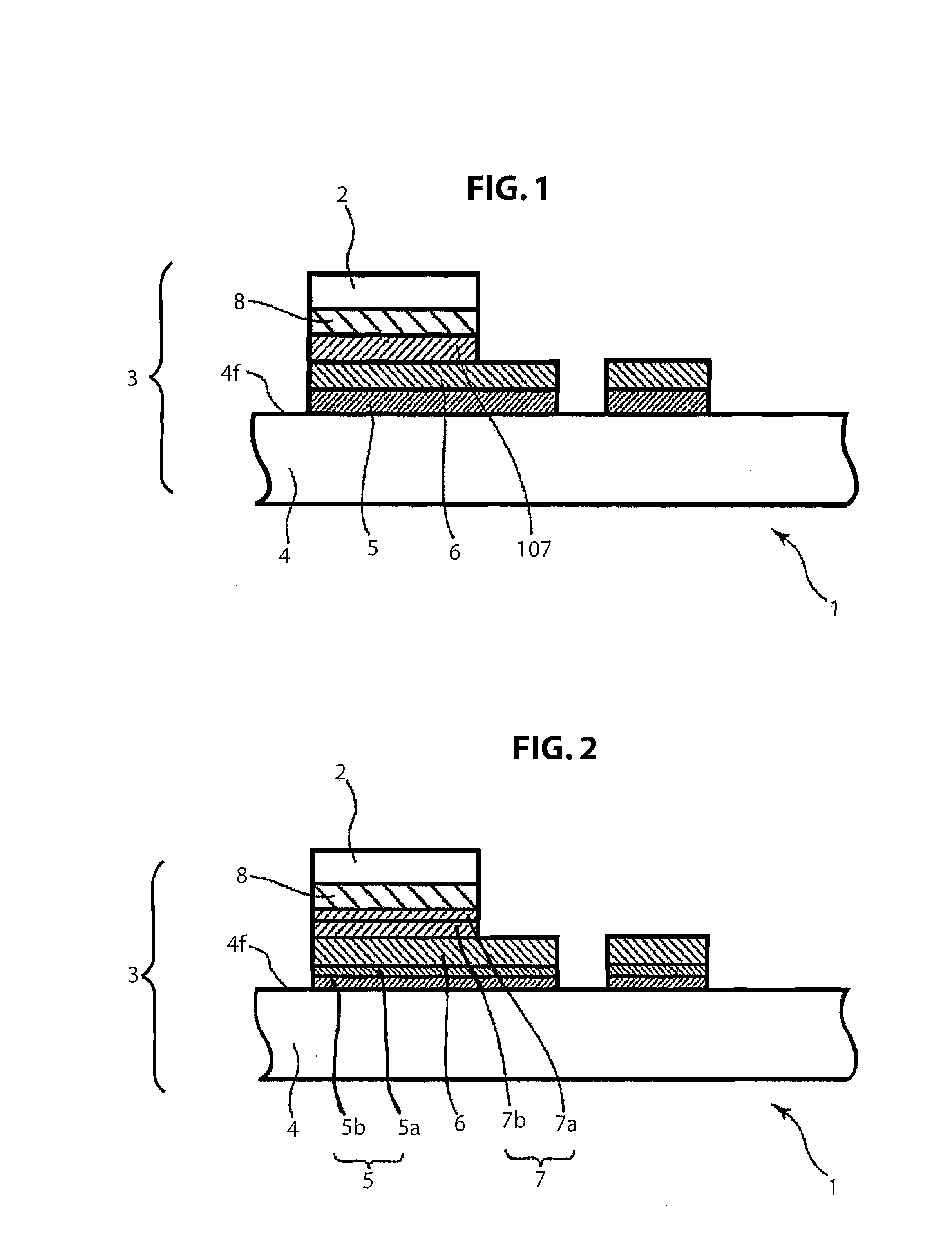

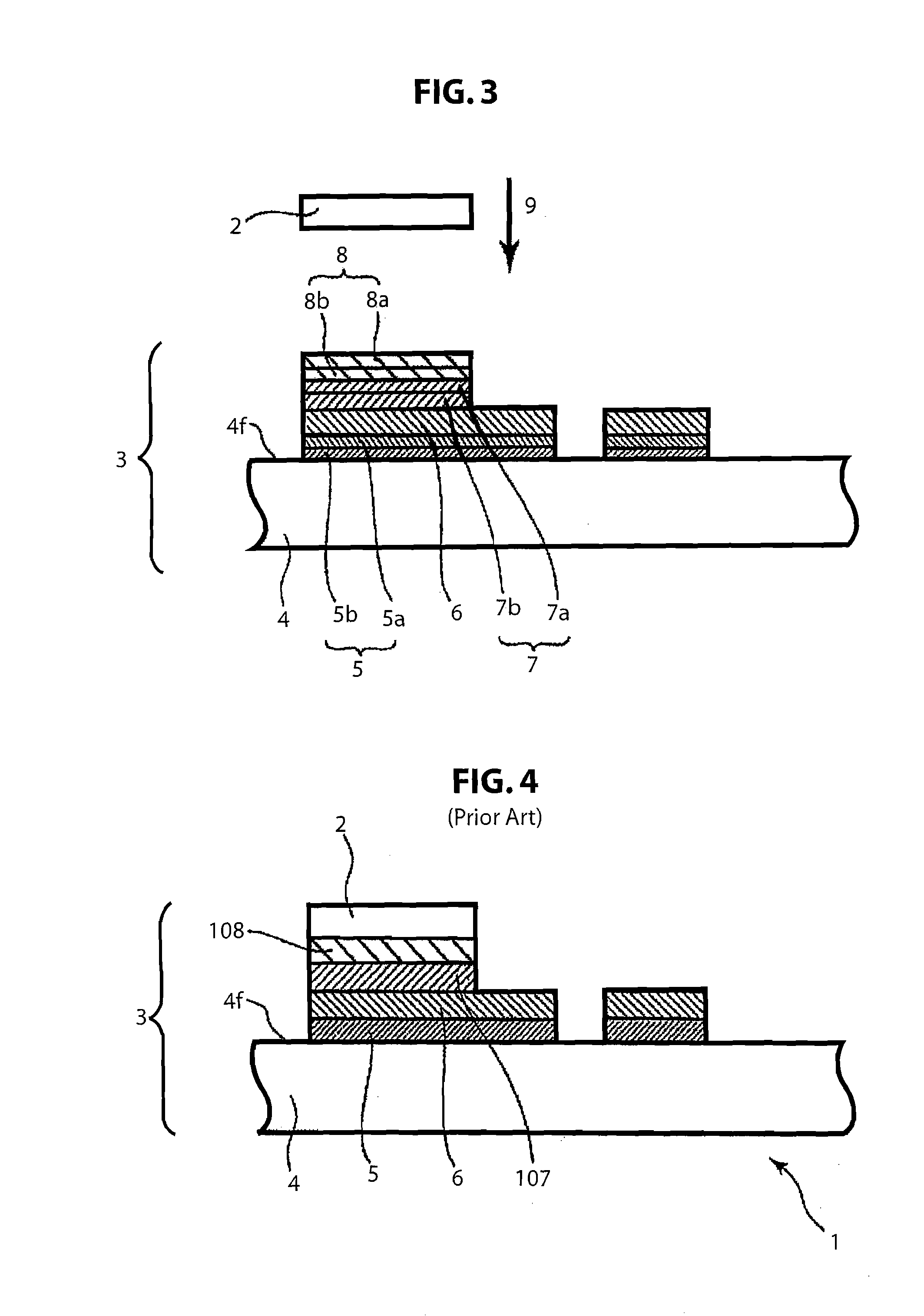

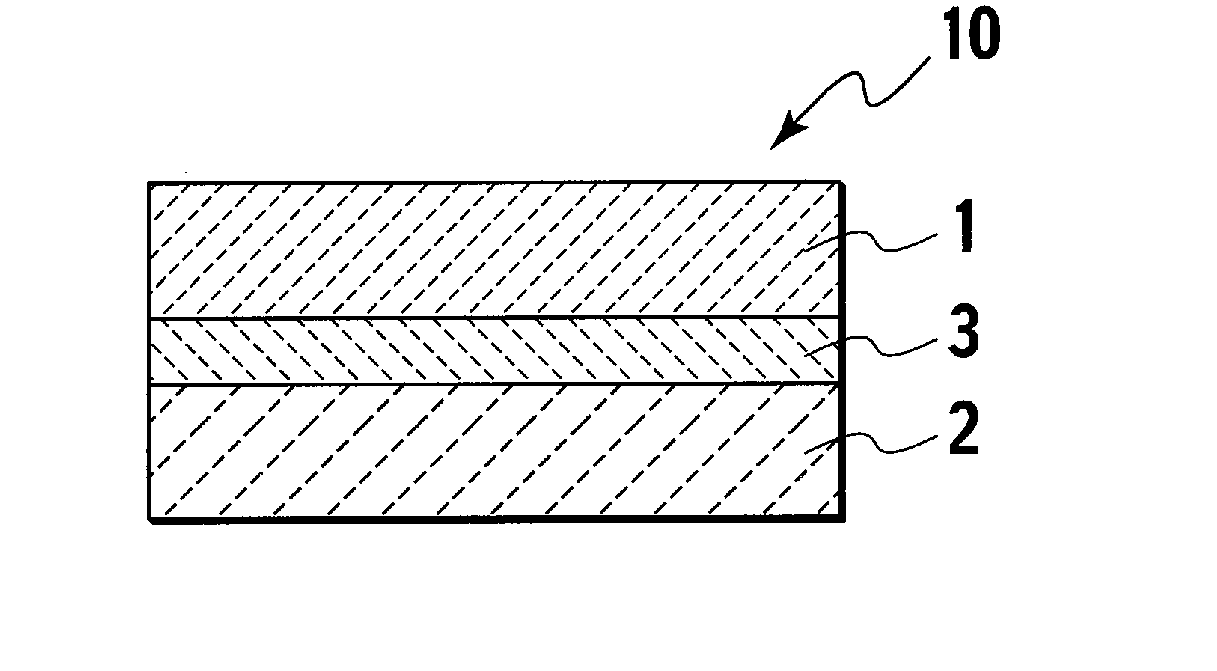

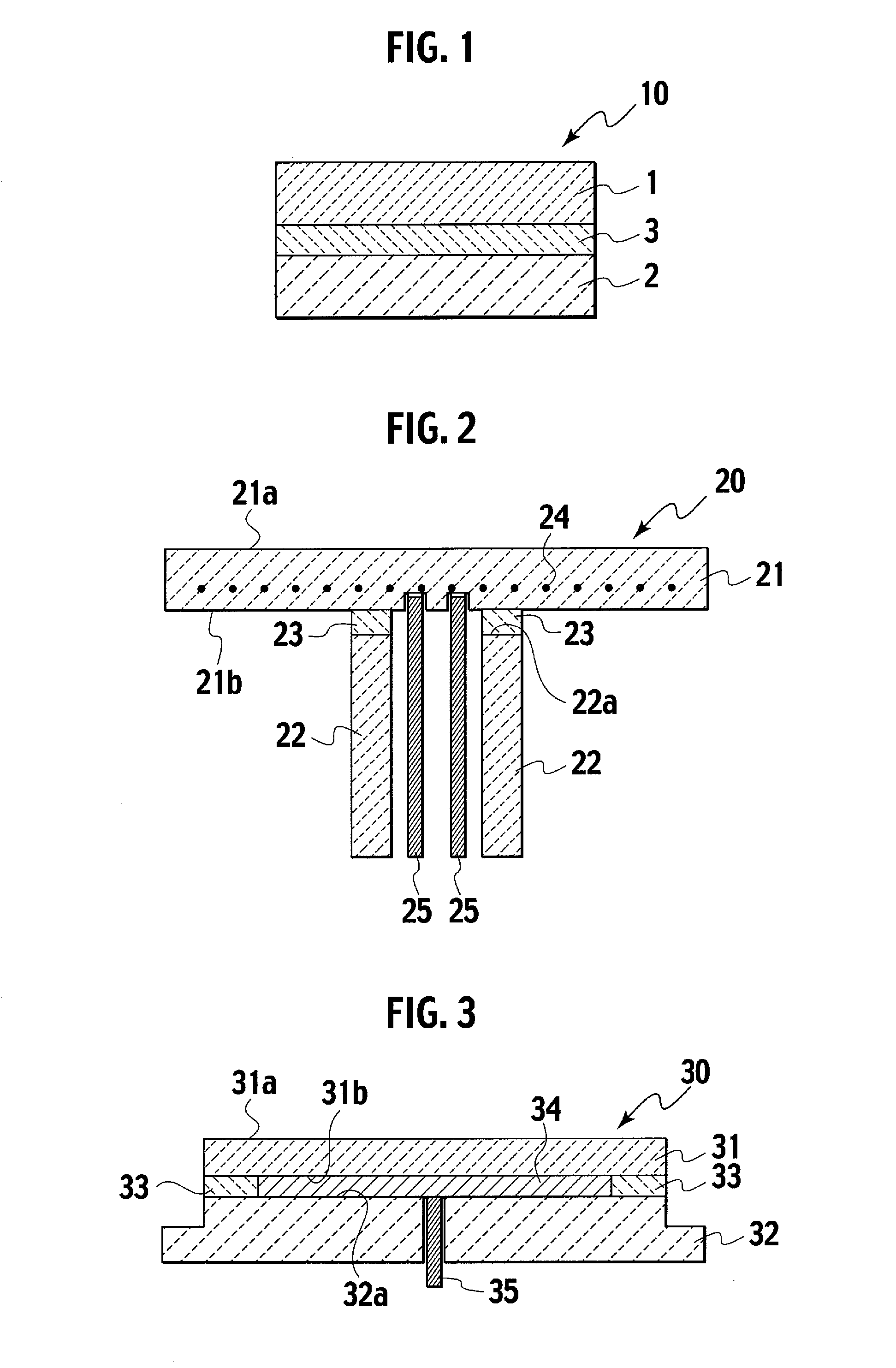

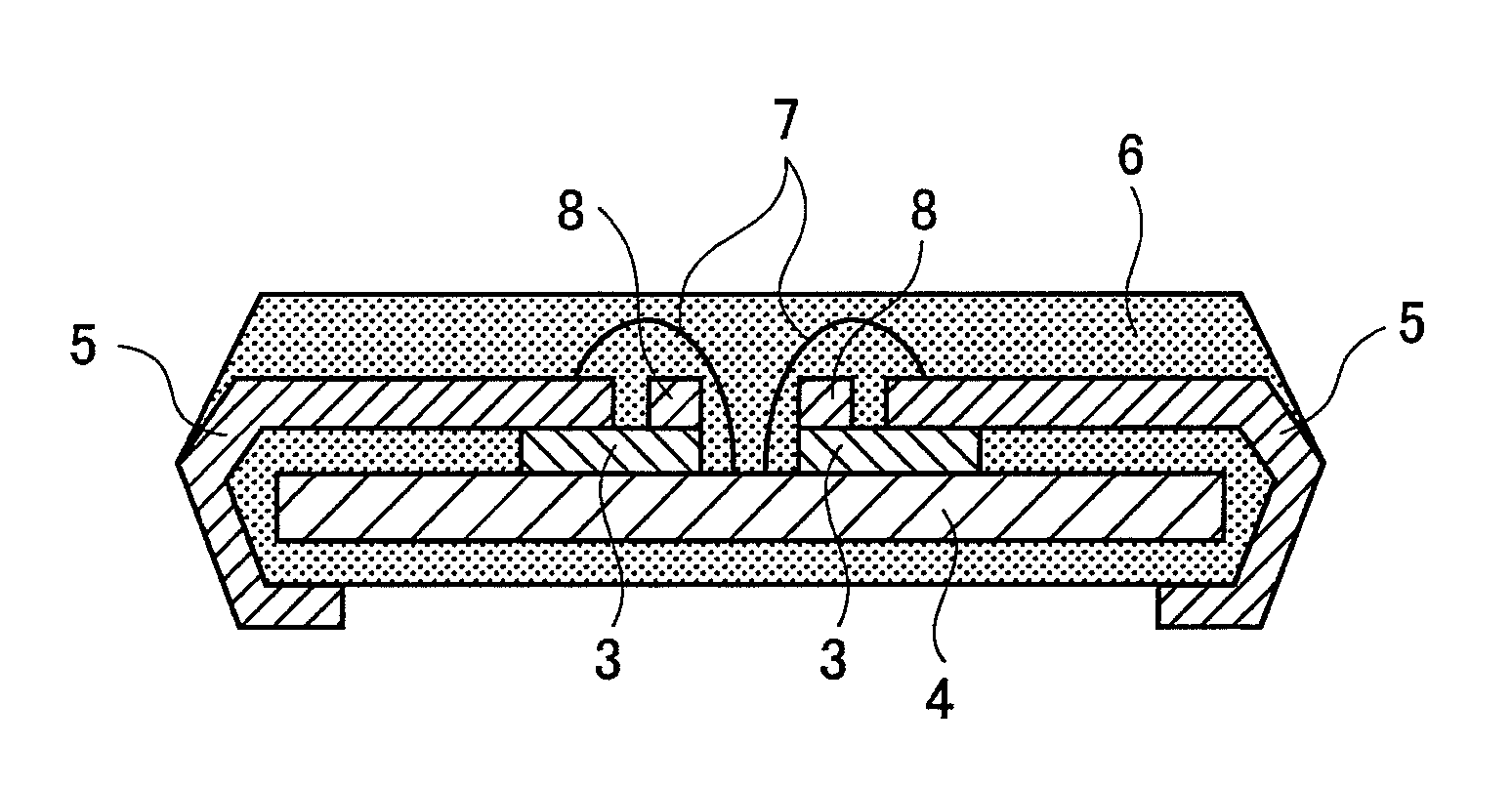

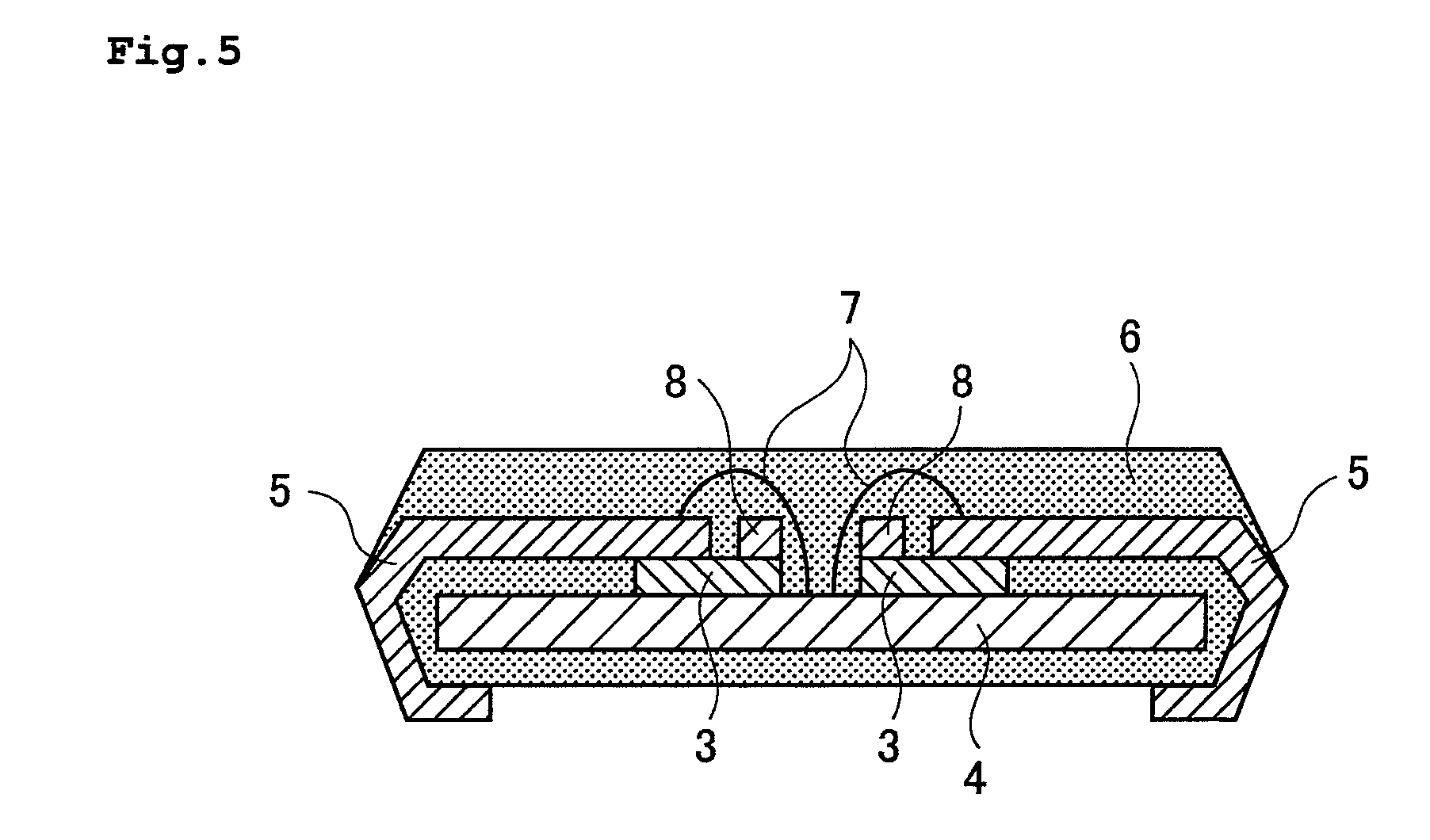

Submount and semiconductor device

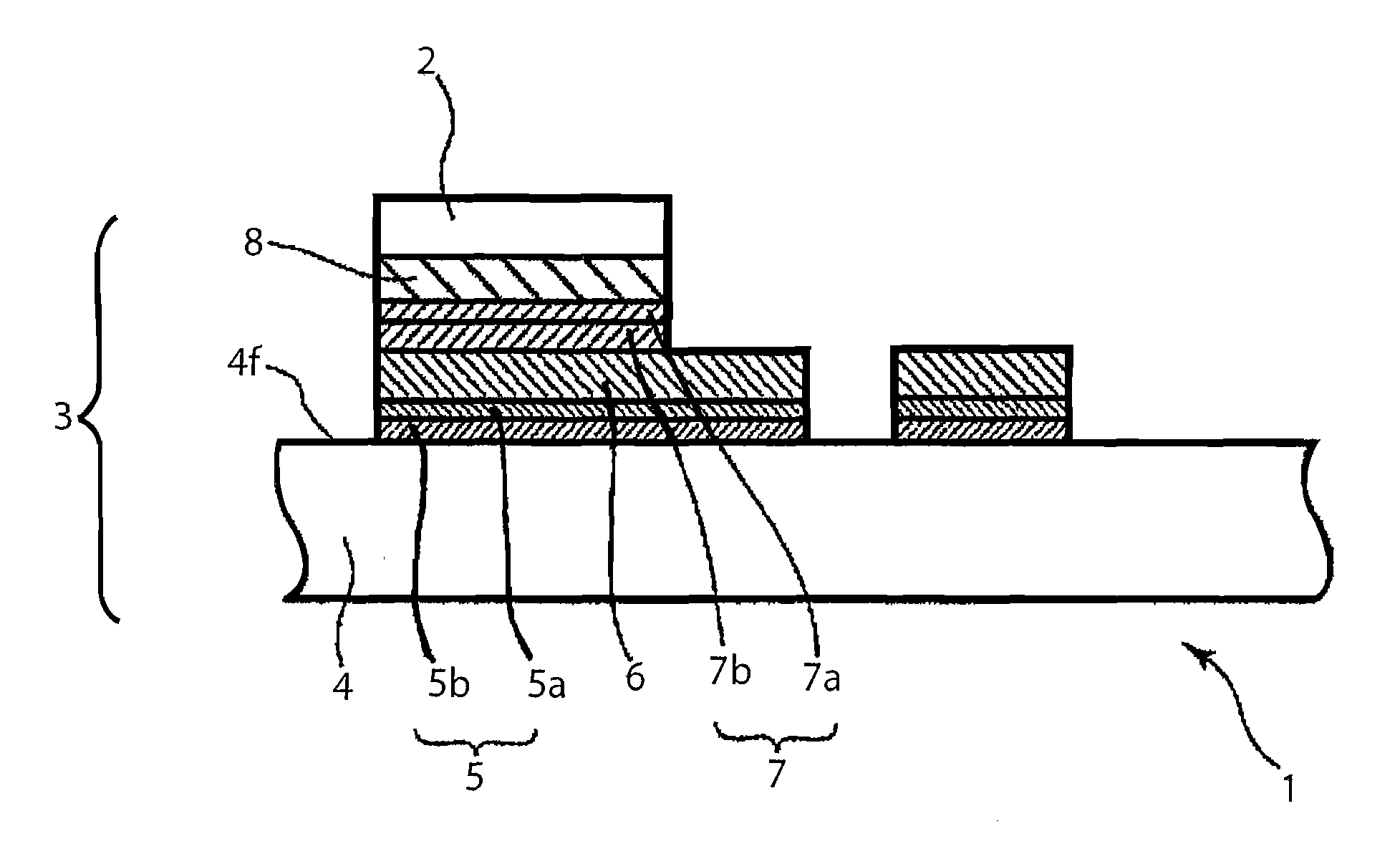

ActiveUS20050194690A1Preventing heat-related damageLower bonding temperatureLaser detailsSemiconductor/solid-state device detailsDevice materialSemiconductor

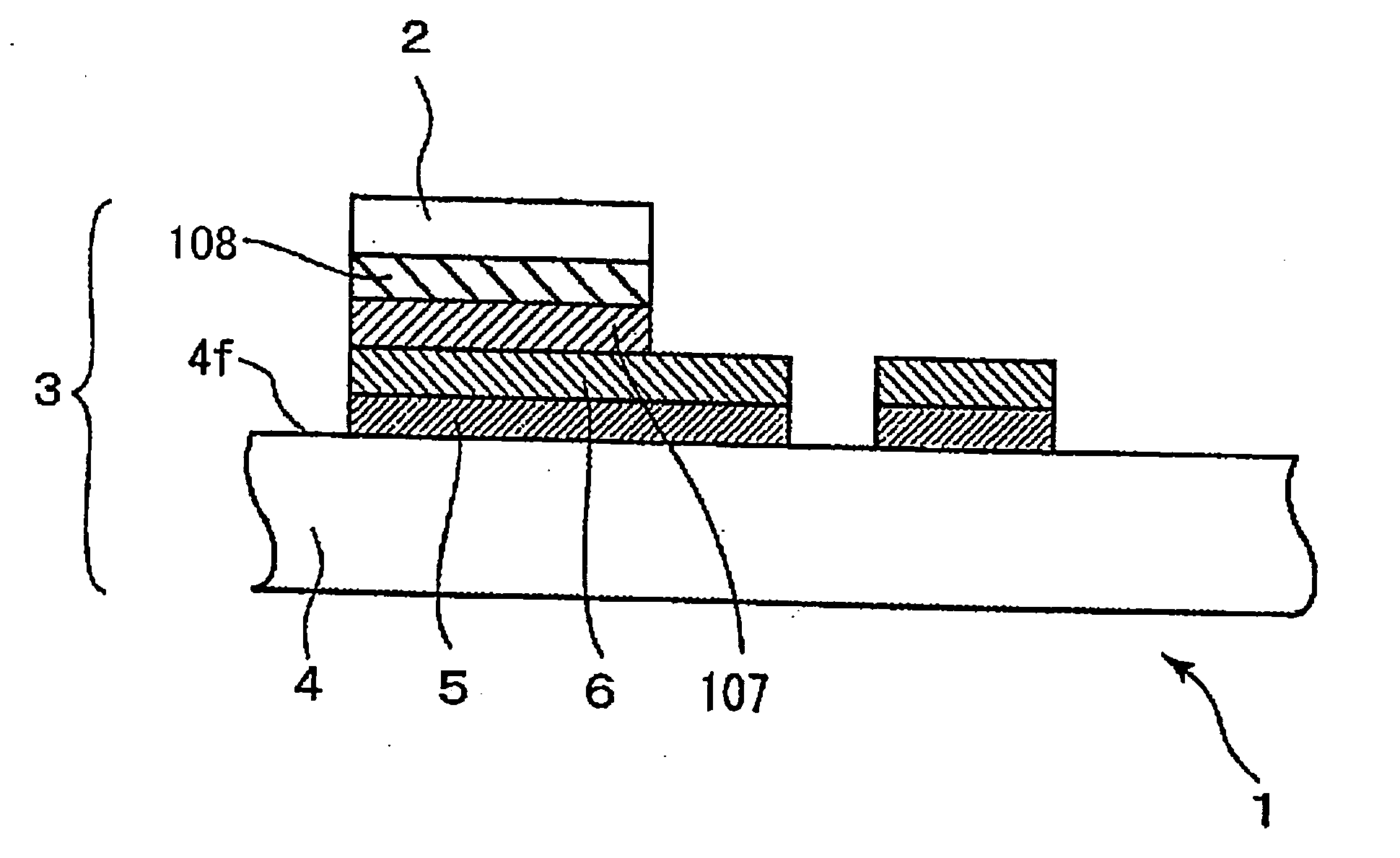

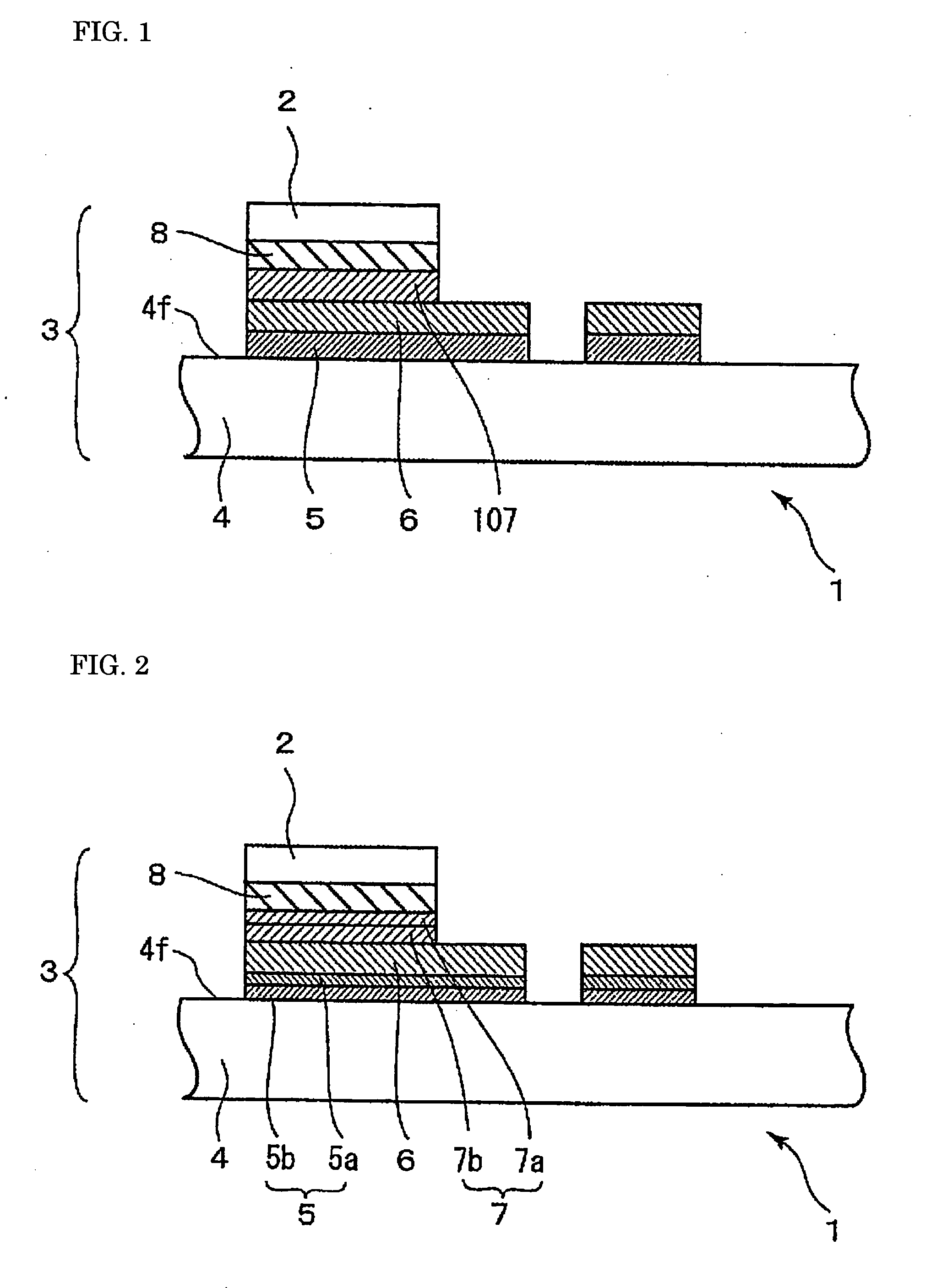

The present invention provides a submount that allows a semiconductor light-emitting element to be attached with a high bonding strength. A submount 3 is equipped with a substrate 3 and a solder layer 8 formed on a primary surface 4f of the substrate 4. The density of the solder layer 8 is at least 50% and no more than 99.9% of the theoretical density of the material used in the solder layer 8. The solder layer 8 contains at least one of the following list: gold-tin alloy; silver-tin alloy; and lead-tin alloy. The solder layer 8 before it is melted is formed on the substrate 4 and includes an Ag film 8b and an Sn film 8a formed on the Ag film 8b. The submount 3 further includes an Au film 6 formed between the substrate 4 and the solder layer 8.

Owner:SUMITOMO ELECTRIC IND LTD

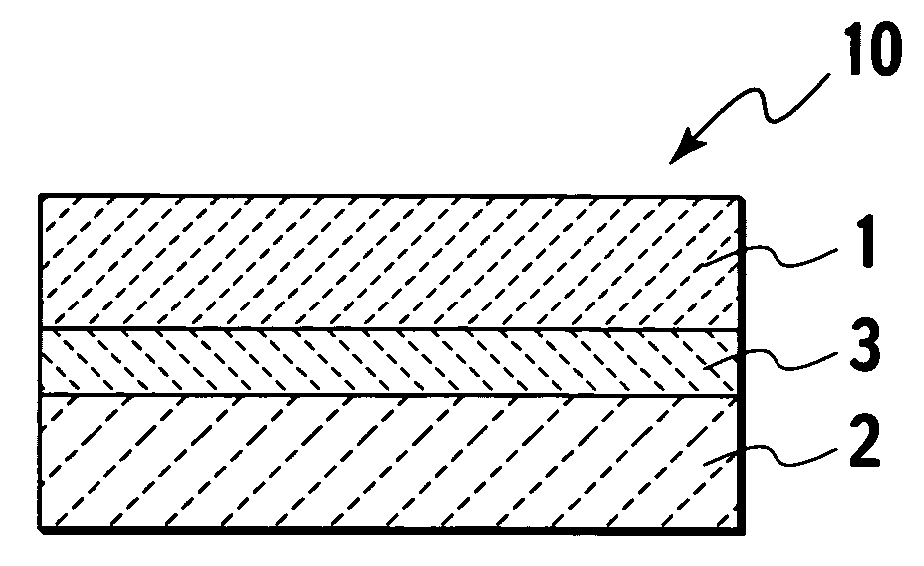

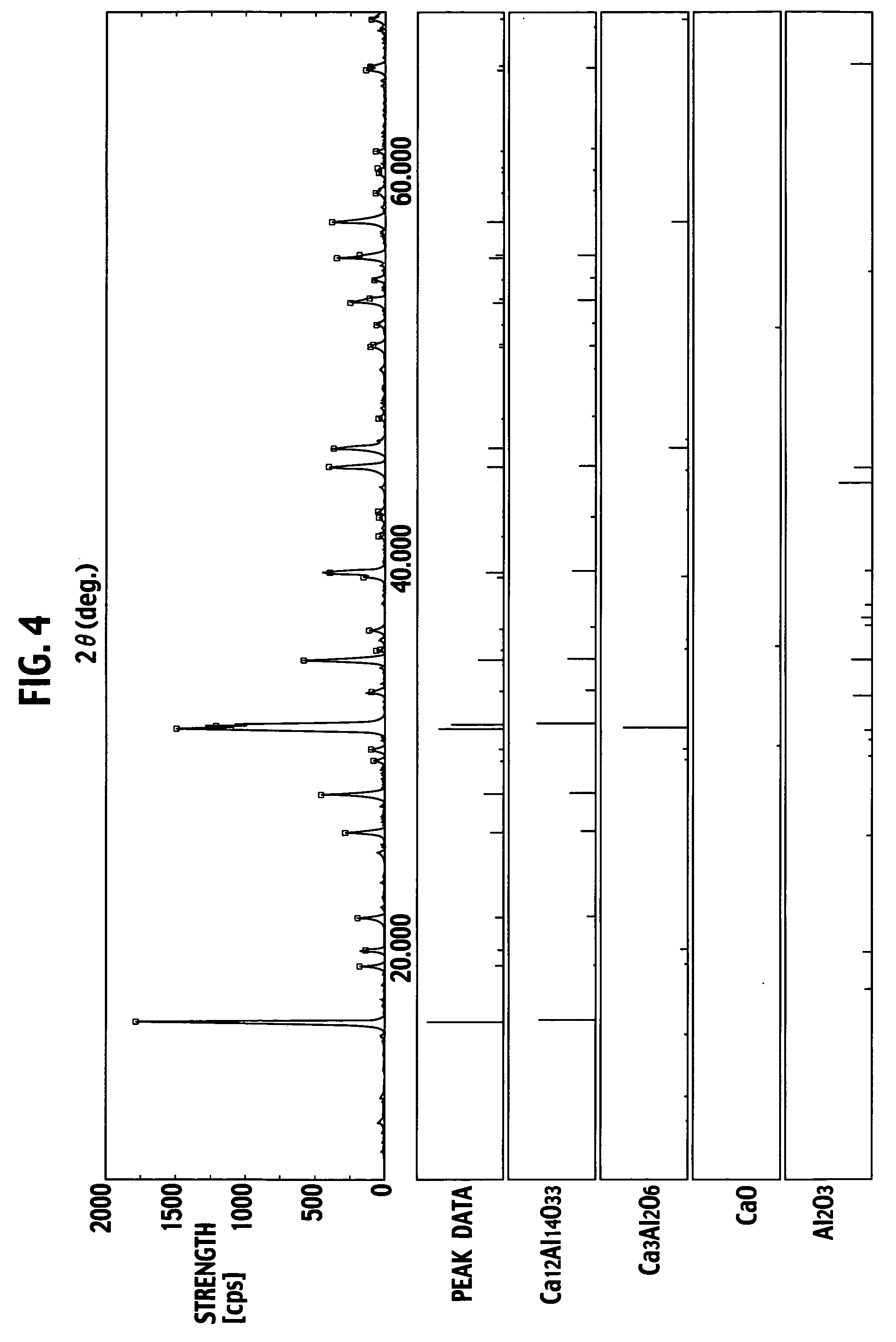

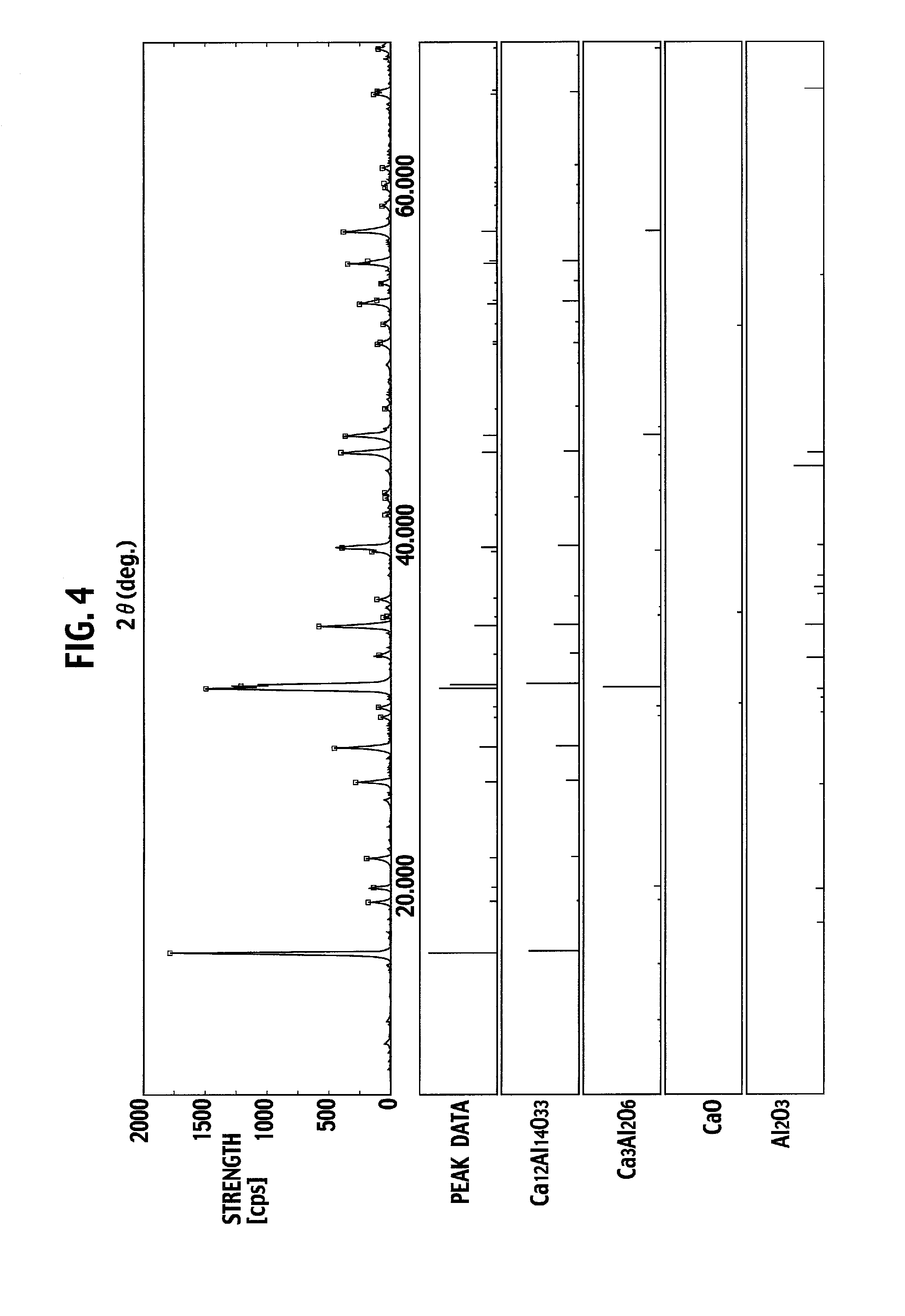

Bonding agent, aluminum nitride composite body, and manufacturing method of the same

InactiveUS20060110624A1Improve abilitiesLower bonding temperatureCeramic layered productsInorganic adhesivesRare-earth elementCalcium aluminates

Owner:NGK INSULATORS LTD

Nanoscale metal paste for interconnect and method of use

ActiveUS8257795B2Reduce and eliminate needReduce reunionTransportation and packagingPrinted circuit aspectsMicrometerMetal particle

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

Submount and semiconductor device

InactiveUS7196356B2Preventing heat-related damageLower bonding temperatureLaser detailsSemiconductor/solid-state device detailsSemiconductorBonding strength

The present invention provides a submount that allows a semiconductor light-emitting element to be attached with a high bonding strength.A submount 3 is equipped with a substrate 3 and a solder layer 8 formed on a primary surface 4f of the substrate 4. The density of the solder layer 8 is at least 50% and no more than 99.9% of the theoretical density of the material used in the solder layer 8. The solder layer 8 contains at least one of the following list: gold-tin alloy; silver-tin alloy; and lead-tin alloy. The solder layer 8 before it is melted is formed on the substrate 4 and includes an Ag film 8b and an Sn film 8a formed on the Ag film 8b. The submount 3 further includes an Au film 6 formed between the substrate 4 and the solder layer 8.

Owner:SUMITOMO ELECTRIC IND LTD

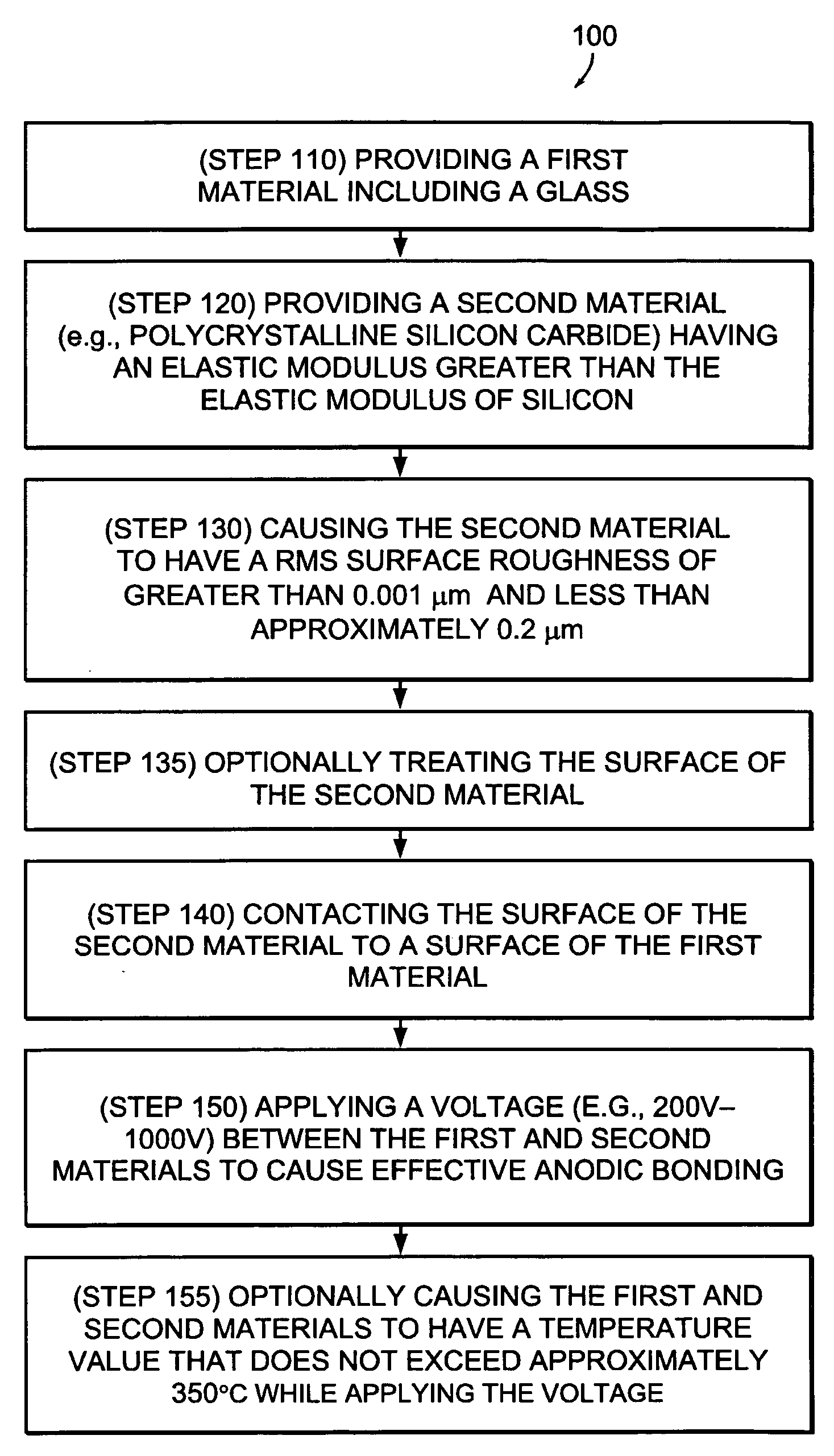

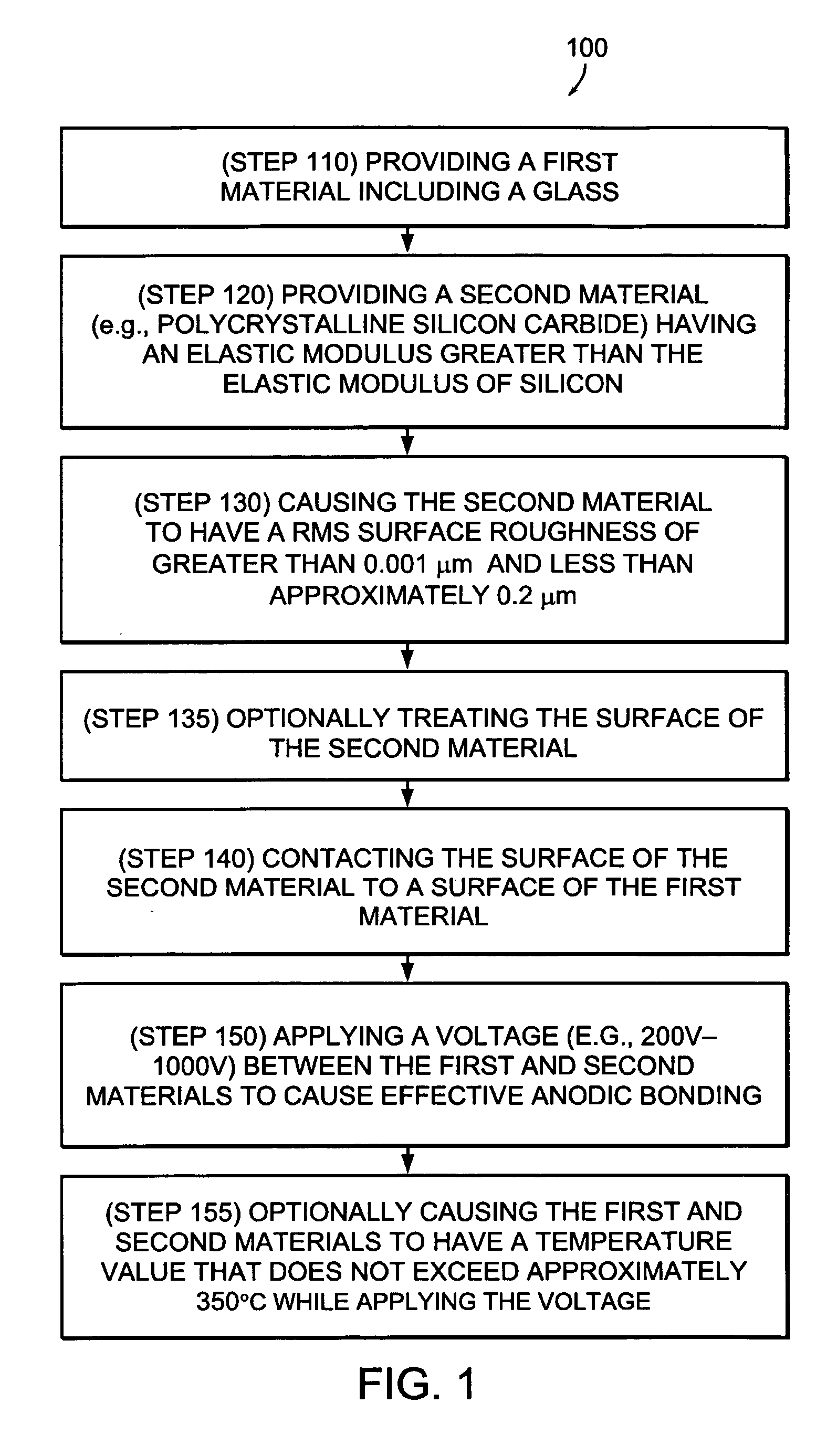

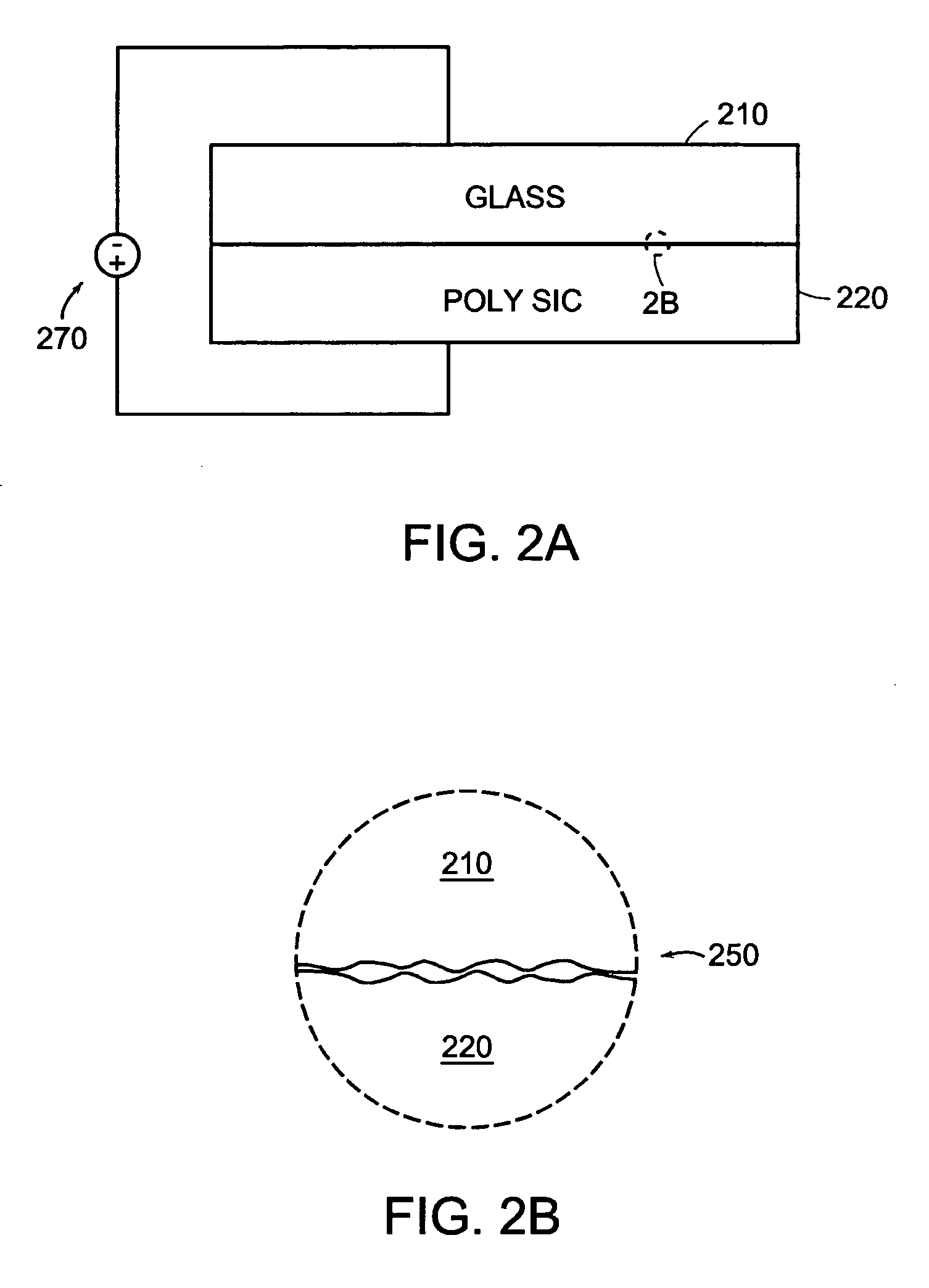

Anodic Bonding of silicon carbide to glass

InactiveUS20050072189A1Large elastic modulusLower bonding temperaturePrecision positioning equipmentLamination ancillary operationsSurface roughnessAnodic bonding

MEMS and microelectronic devices and fabrication methods feature providing a first material including a glass, providing a second material having an elastic modulus greater than the elastic modulus of silicon, causing the second material to have a surface with a RMS surface roughness of greater than 0.001 μm and less than approximately 0.15 μm, contacting the surface of the second material to a surface of the first material, and applying a voltage between the first and second materials to cause an anodic bond to form.

Owner:CHARLES STARK DRAPER LABORATORY

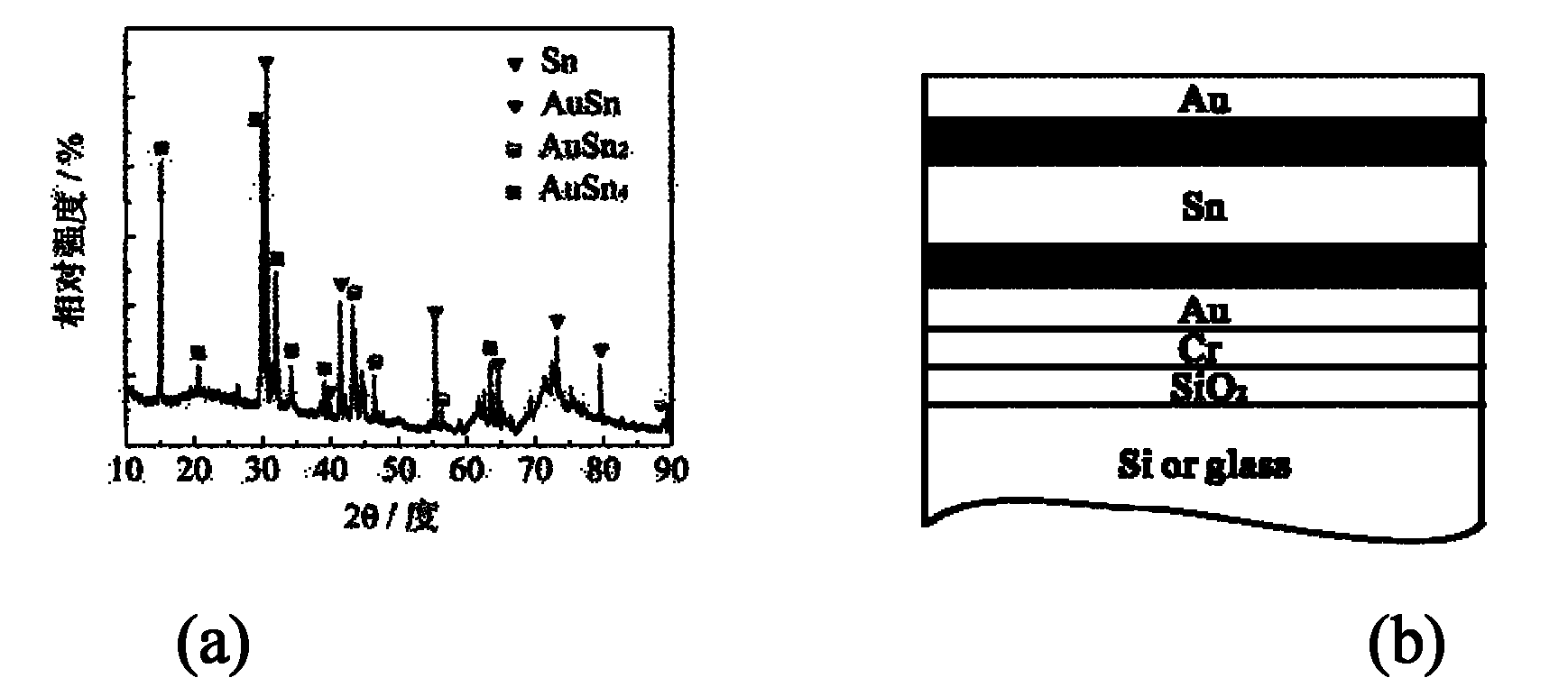

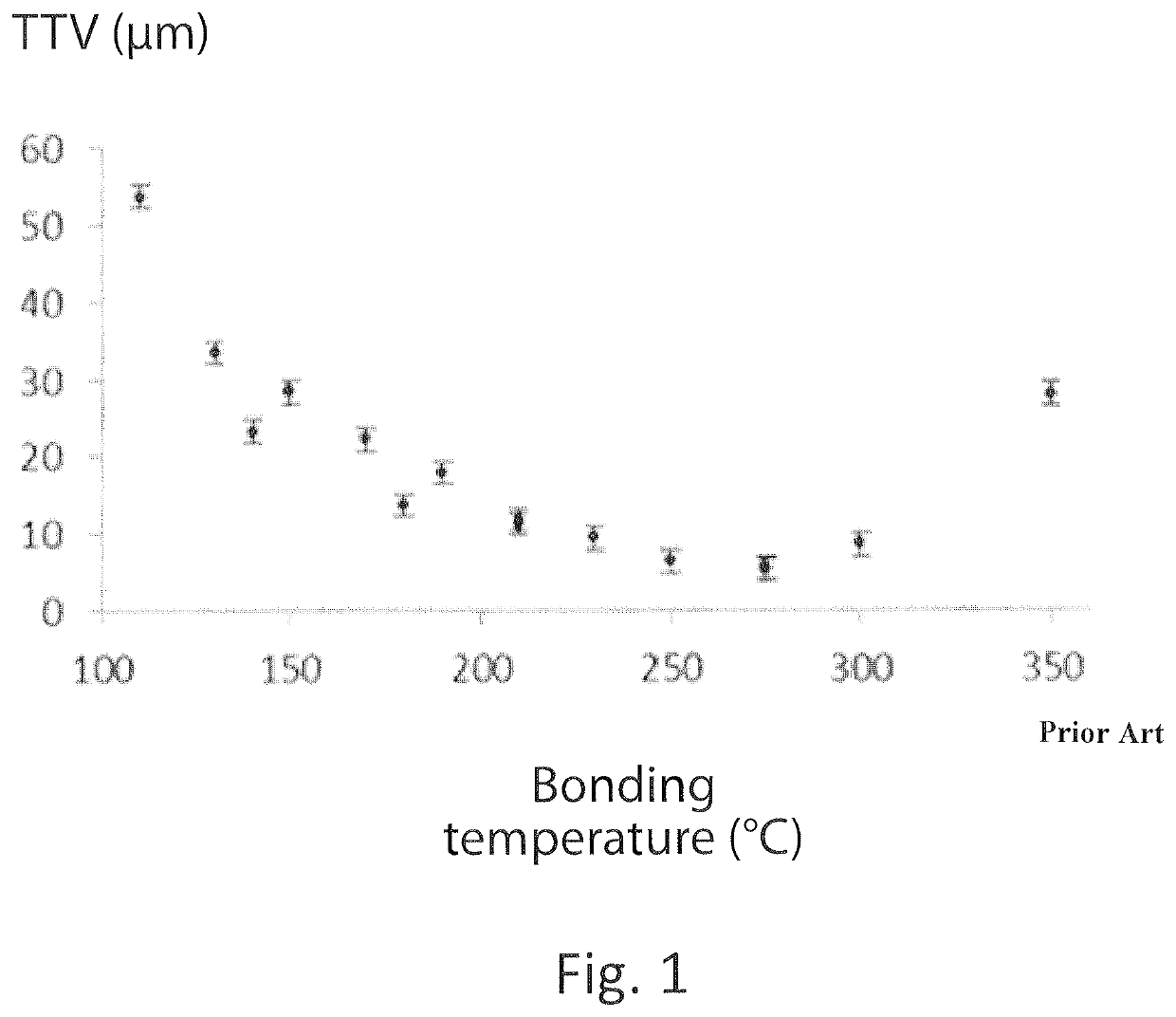

Wafer-level low-temperature packaging method based on gold-tin alloy bonding

ActiveCN102130026AHigh bonding strengthReduce weight percentageDecorative surface effectsSemiconductor/solid-state device manufacturingHardnessAlloy

The invention discloses a wafer-level low-temperature packaging method based on gold-tin alloy bonding, a tin-rich (Sn) alloy component is selected, Sn content is equal to 54%-71%, the gold thickness and the tin thickness are designed to be less than 2.1 mu m and 0.7 mu m respectively, and the gold-tin alloy bonding is performed at a certain pressure and a certain temperature within certain time, thereby forming an intermediate layer which is based on an AuSn2 phase (that is an epsilon phase) with high Vickers hardness and realizing the wafer-level low-temperature packaging method with low cost and high bonding strength. The bonding temperature is 140-310 DEG C, and the bonding strength as high as 20-64MPa can be realized. The wafer-level low-temperature packaging method which has the advantages of low cost and high bonding strength can be applied in packaging of devices on any substrates.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

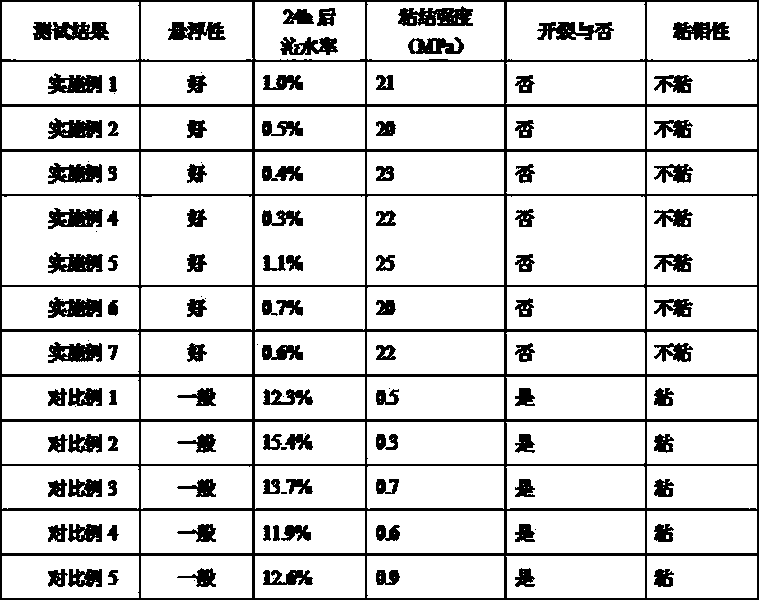

Aqueous boron nitride coating capable of binding at low temperature and being used at high temperature

ActiveCN109021628AGood adhesionImprove stabilityCoatingsEnvironmental resistanceHexagonal boron nitride

The invention discloses an aqueous boron nitride coating capable of binding at a low temperature and being used at a high temperature. The coating is prepared from 15-60 wt% of hexagonal boron nitride, 2-15 wt% of a composite high temperature binder, 1 wt% of carboxymethyl cellulose, 0.5 wt% of a thickener, 1 wt% of cobalt aluminate, 0.2 wt% of isooctanol, and the balance is demineralized water. Apreparation method of the coating comprises the following steps: mixing and stirring carboxymethyl cellulose used as a dispersant, the high-temperature binder, the thickener, cobalt aluminate used asa high-temperature pigment and demineralized water at a normal temperature to form a uniform solution, adding the hexagonal boron nitride and isooctanol used as a defoamer to the solution, and performing stirring until a uniform system is formed. The coating adopts an aqueous system, has no harmful substance volatilization during use, is clean and environmentally friendly, has good adhesion, anddoes not crack or spall in order to effectively block direct contact between a metal melt and the surface of a refractory material. Additionally, the coating has excellent stability and suspension capacity, and the stability and the suspension capacity do not change under high dilution.

Owner:SHANGQIU NORMAL UNIVERSITY

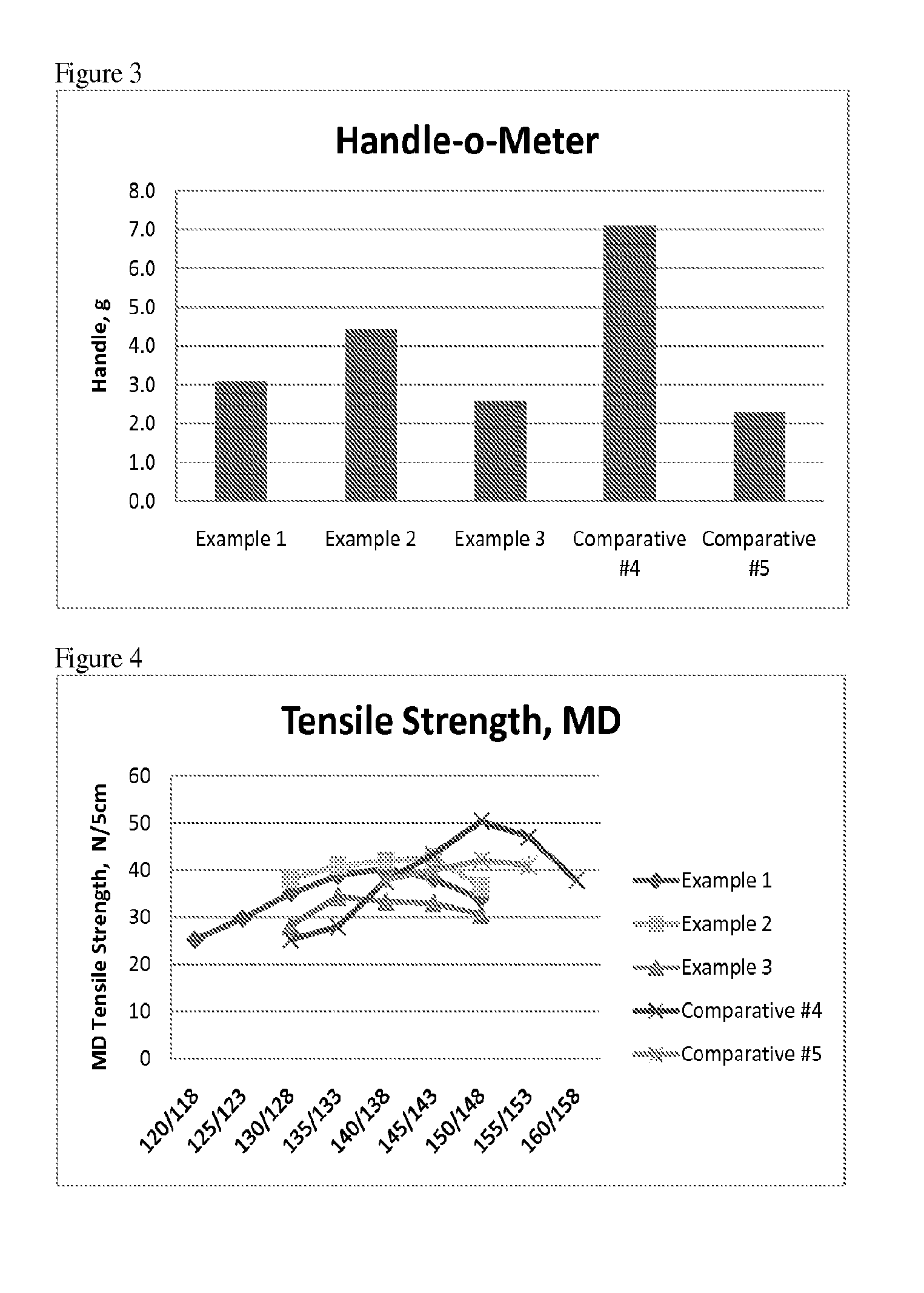

Compositions for enhanced thermal bonding

InactiveUS6946195B2Lower bonding temperatureSynthetic resin layered productsWoven fabricsFiberCopolyester

A composition including an aromatic polyester and a copolyester having a lower melting point than the aromatic polyester. The aromatic polyester and the copolyester can be blended together to form fibers and fibrous webs. The composition can be thermally bonded at a temperature below the melting point of the aromatic polyester.

Owner:KIMBERLY-CLARK WORLDWIDE INC

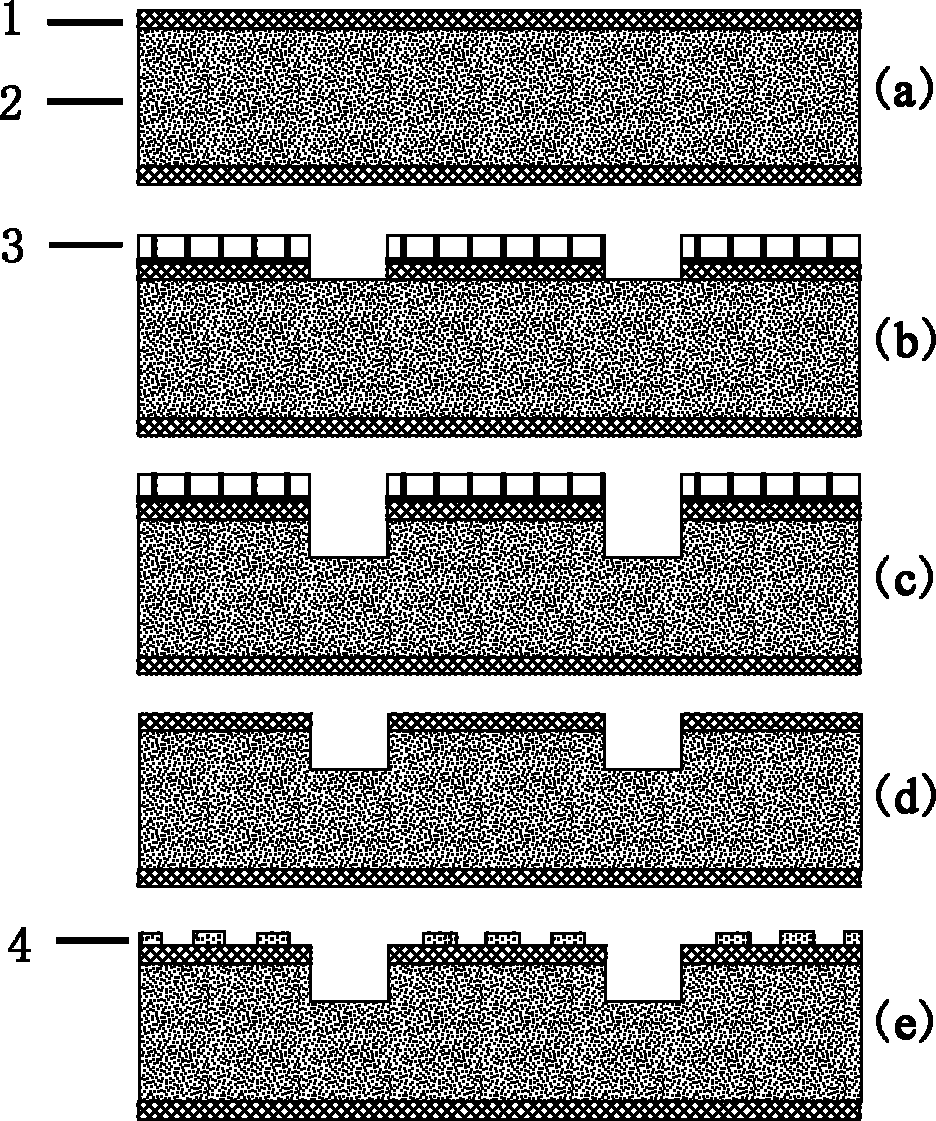

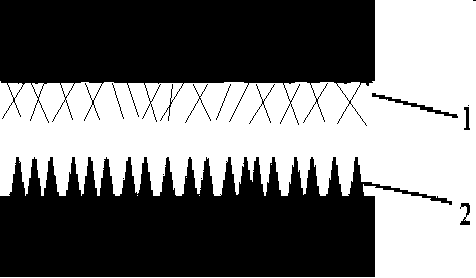

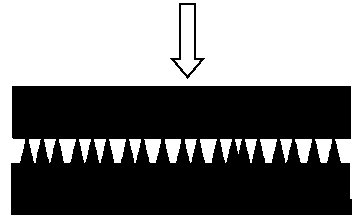

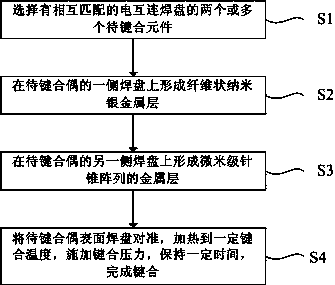

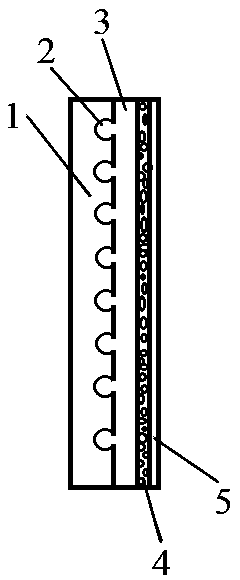

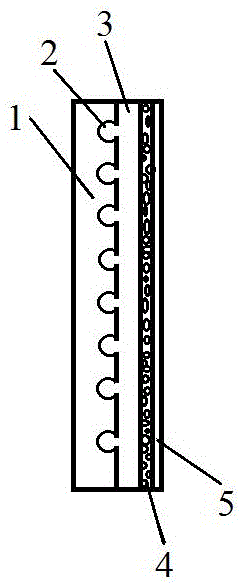

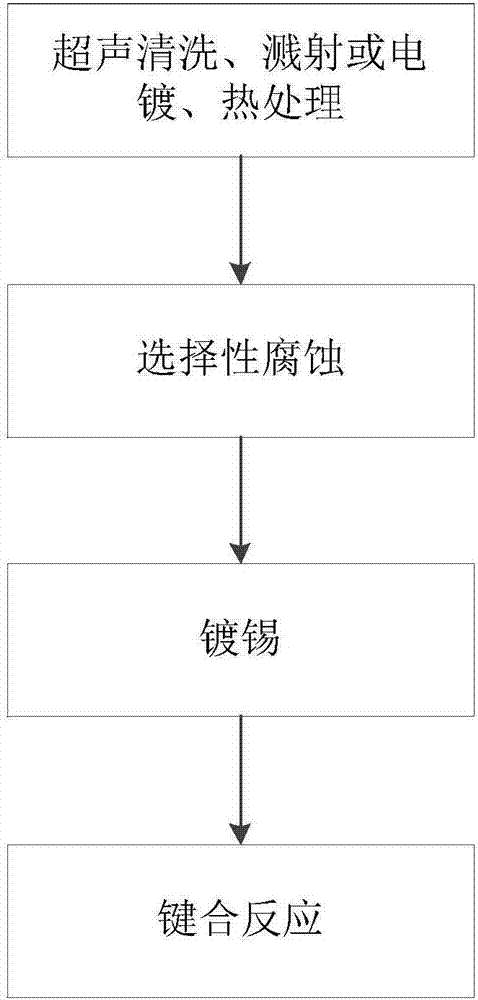

Low temperature solid state bonding method through surface micro-nano structure

InactiveCN104201123AImprove plastic deformation abilityImprove bindingSolid-state devicesSemiconductor/solid-state device manufacturingFiberElectricity

The invention discloses a low temperature solid state bonding method through a surface micro-nano structure. The low temperature solid state bonding method through the surface micro-nano structure comprises choosing two or more elements to be bonded with matching electrical interconnecting pads, wherein every two elements forms a to-be-boned couple; forming fiber-shaped nano silver metal layers on pads on one side of the to-be-boned couples; forming a metal layer of a micron size cone array structure on the pads of the other sides of the to-be-boned couples; aligning pads on the surfaces of the to-be-boned couples, and heating contact areas to a certain temperature lower than a metal melting point and meanwhile applying pressure to one or two sides of the to-be-boned couples and maintaining the state for a certain period to enable the fiber-shaped nano silver metal layers to be in solid state bonding with the metal layers of the micron size cone array structure. According to the low temperature solid state bonding method through the surface micro-nano structure, the conductivity and the electrical conductivity are higher, temperature of thermocompression bonding can be greatly reduced and bonding strength is improved.

Owner:SHANGHAI JIAO TONG UNIV

Fabricated articles comprising polyolefins

InactiveUS20130237111A1Good flexibilityLower bonding temperatureSynthetic resin layered productsMixingPolyolefinAlpha-olefin

Fabricated articles are disclosed which comprise a polypropylene impact copolymer. The propylene impact copolymer composition comprises from 60 to 90 percent by weight of the impact copolymer composition of a matrix phase, which can be a homopolymer polypropylene or random polypropylene copolymer having from 0.1 to 7 mol percent of units derived from ethylene or C4-C10 alpha olefins. The propylene impact copolymer composition also comprises from 10 to 40 percent by weight of the impact copolymer composition of a dispersed phase, which comprises a propylene / alpha-olefin copolymer having from 6 to 40 mol percent of units derived from ethylene or C4-C10 alpha olefins, wherein the dispersed phase has a comonomer content which is greater than the comonomer content in the matrix phase. The propylene impact copolymer composition is further characterized by having the ratio of the matrix MFR to the dispersed phase MFR being 1.2 or less. The fabricated articles of the present invention can be made at high speeds and are characterized by their soft feel, as compared to fabricated articles made from other propylene impact copolymers.

Owner:BRASKEM AMERICA

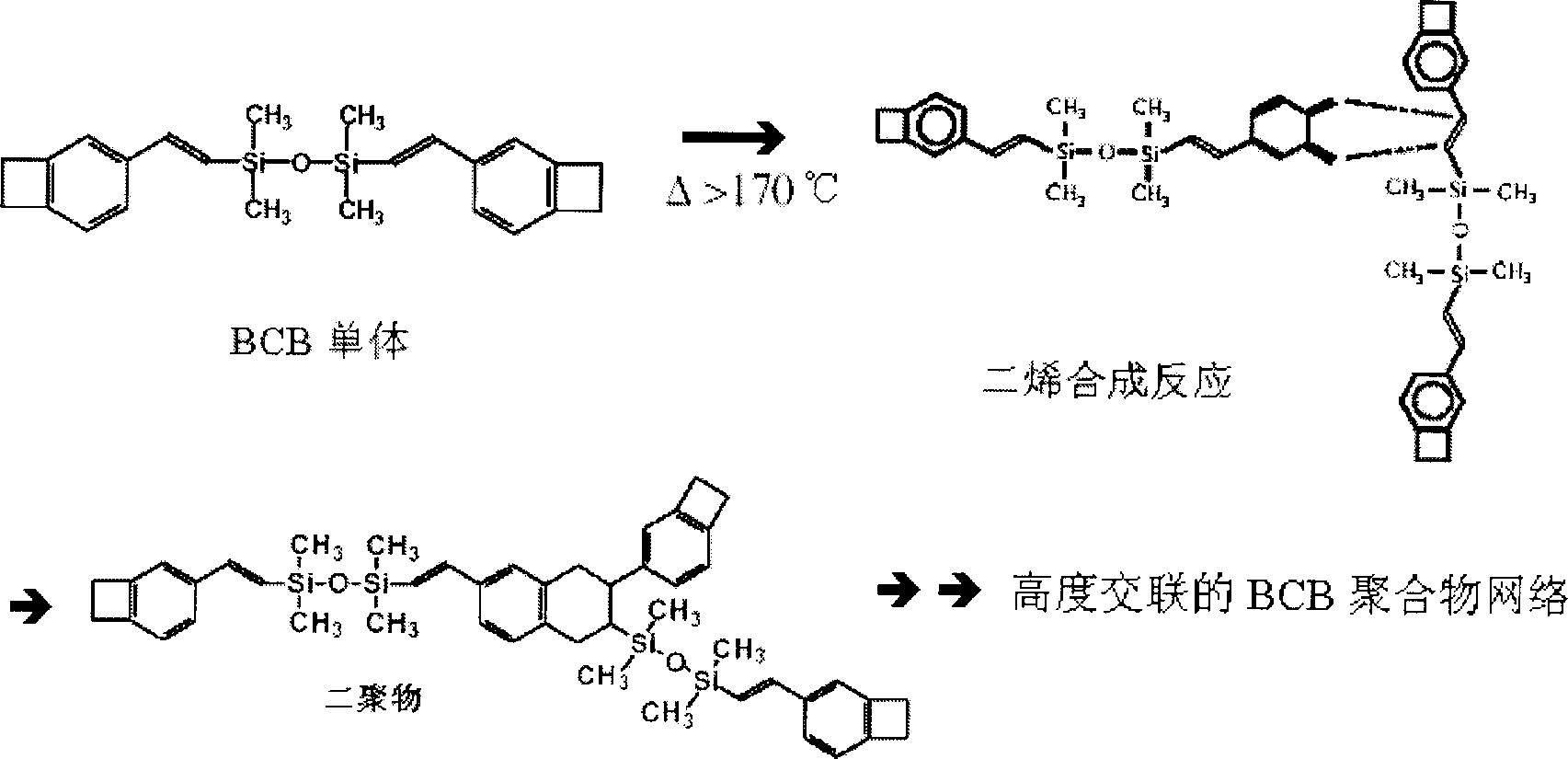

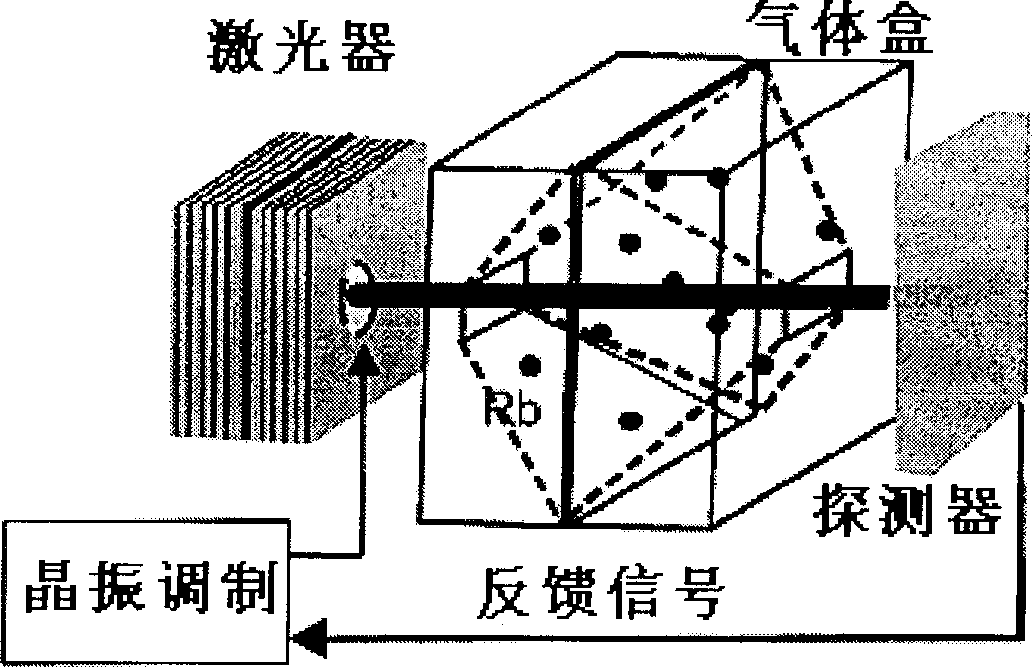

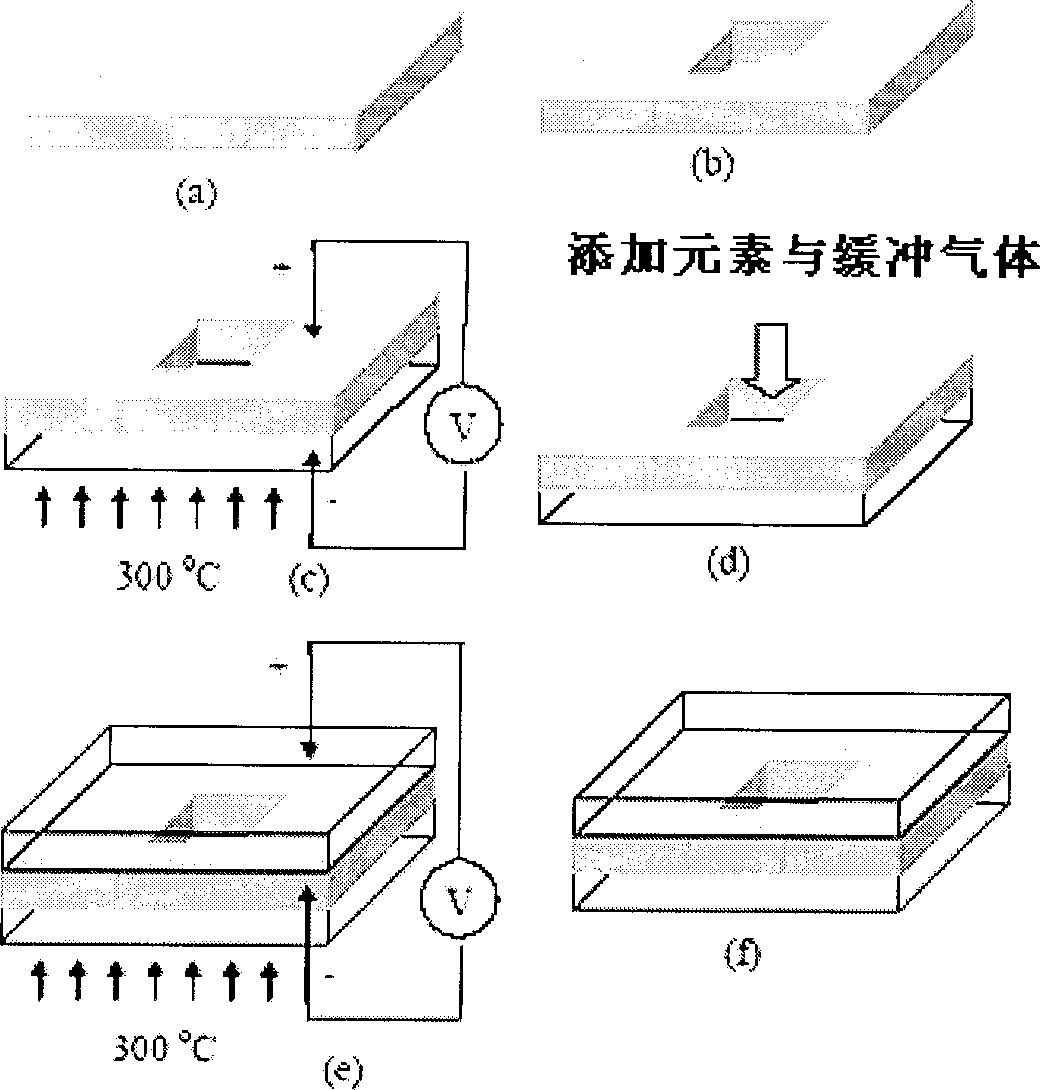

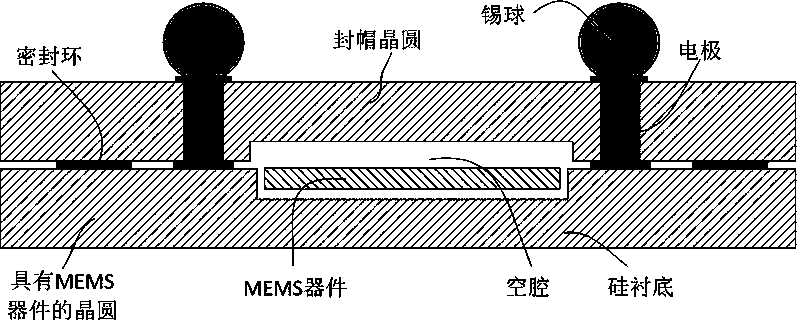

Process for preparing low-temperature wafer-level mini-sized gas container

InactiveCN1827522AMeet packaging requirementsAvoid lostNanostructure manufactureSemiconductor materialsAir tightness

The invention relates to a method for producing low-temperature circle sheet micro gas box, which is characterized in that: the benzocyclobutene is used to process material linkage with humid etching or dry etching technique of semi-conductor in 250Deg. C, to realize the circle sheet air-tightness sealing linkage of chip-level gas box. The invention comprises a atom gas box containing a chip-level atom clock gas box, a high-precision magnetic field sensor gas box, a atom feedback glimmer frequency stabilizer; a atom gas box containing a atom light filter, with glimmer Fabry-Perot chamber. The linked BCB glue is in 0.2ª–m thickness, the air-tightness of sealed He gas can reach 2.1-5.9X10-4Pa cm3 / s, and the linkage strength is higher than 4.65MPa, while the thermal cycle reliability can fully reach the packing standard of micro electric device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Bonding agent, aluminum nitride composite body, and manufacturing method of the same

ActiveUS20090242101A1Small overall deformationImprove relationshipLamination ancillary operationsSynthetic resin layered productsAluminium oxideAluminium nitride

Owner:NGK INSULATORS LTD

Multicomponent aliphatic polyester blend fibers

InactiveUS20140272362A1Increased melt flow rateLow viscosityFilament/thread formingAbsorbent padsFiberPolyester

The present invention provides multicomponent thermoplastic fibers that are biodegradable and that are capable of forming strong bonds in air bonding processes. In various embodiments, the multicomponent fibers can include a first polymer component that includes a first aliphatic polyester, and a second polymer component also including an aliphatic polyester, wherein the first polymer component comprises at least a portion of an exposed surface of the multicomponent fiber. The first polymer component can be a fully amorphous polylactic acid and the second polymer component can be a semicrystalline polylactic acid. The multicomponent fiber can have cross-sectional area comprising the first polymer component and the second polymer component in about a 1:1 ratio, wherein the first polymer component and the second polymer component are configured in a sheath / core arrangement.

Owner:FIBER INNOVATION TECH

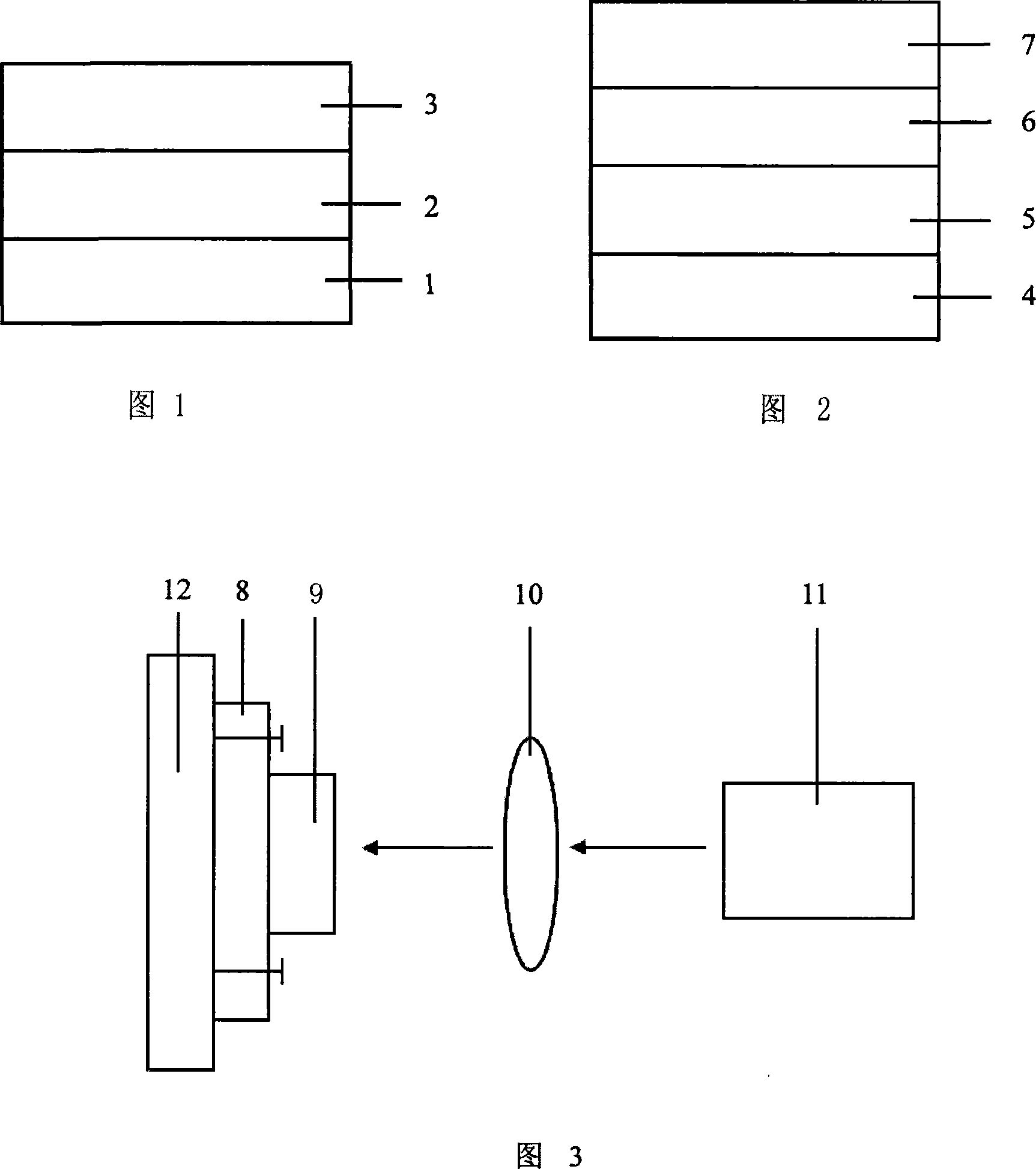

Laser stripping method using metallic passage beds to transfer GaN substrate

InactiveCN101118850AChange structureAchieve strippingSemiconductor/solid-state device manufacturingSputteringLaser scanning

The present invention relates to a laser lift-off method to transfer the GaN liner by using a metal transition layer, in particular to a method of bonding silicon and GaN by using the metal transition layer and transferring GaN on a sapphire liner to a Si liner by combining the laser lift-off technology; and provides a method for transferring the GaN liner by using the metal transition layer. The Si liner is sputtered with Ti and Au in sequence to form a silicon chip sputtered with Ti and Au; GaN on the sapphire liner is sputtered with Ni and Au in sequence to obtain a GaN chip sputtered with Ni and Au; the silicon chip and the GaN chip are jointed front to front and then put into a bonding machine under 100 to 200 DEG C. After pre-bonding, the temperature of the bonding machine is raised to 200 to 600 DEG C. Then, the bonding machine anneals and a GaN / metal / Si bonded chip forms. After that, the GaN / metal / Si bonded chip gets adhesively connected onto a glass piece and fixed on an electric-driven platform. Laser wave with 365nm above are to radiate the bonded piece from one side of the sapphire.

Owner:XIAMEN UNIV

High-purity coating type polycrystalline silicon crucible

InactiveCN105133007APrevent participation in responsePrevent sintering shrinkagePolycrystalline material growthSingle crystal growth detailsCrucibleSpray coating

The invention relates to a high-purity coating type polycrystalline silicon crucible, which comprises a crucible body, wherein a plurality of concave pits or annular grooves are uniformly distributed on the surface of the crucible body; a first nitriding layer, a second oxidation layer and a third nitriding layer are sequentially attached to the surface; according to the first nitriding layer, whey type silicon nitride coats the surface of the crucible body provided with uniformly distributed concave pits or annular grooves in a brush coating mode; the second oxidation layer is powder silicon oxide; the powder silicon oxide is spayed onto the surface of the whey type first nitriding layer which is not coagulated in a spraying mode; the second oxidation layer forms particle type on the surface of the first nitriding layer; the third nitriding layer is mist silicon nitride; the mist silicon nitride is sprayed and coated on the surface of the second oxidation layer in a spray coating mode until the particles of the second oxidation layer are covered; the third nitriding layer forms a smooth surface. The crucible has the characteristics that the coating coverage capability is high; the stability is high; a coating layer has a high isolation degree; the crucible body can be prevented from participating in the reaction in the polycrystalline silicon preparation process, and the like.

Owner:WUXI SHUNYANG NEW ENERGY

Thermosetting reaction type EVA hot-melt adhesive

InactiveCN101070455AImprove heat resistanceImprove cohesive strengthNon-macromolecular adhesive additivesHeat resistanceCohesive strength

The present invention relates to a hot-set reactive EVA thermo sol. The weight proportion of this material: EVA gum (55-85 shares), increase dimension agent (25-45 shares), crummy peroxide (0.01-0.6 shares), benzoic peroxide (0.01-0.5 shares), 1, 2-divinylbenzene (0.01-0.5 shares). Comparing to normal EVA thermo sol, the present invention obviously increases heat endurance, cohesive strength, bonding action and refractoriness of the EVA thermo sol. The technical level of the EVA thermo sol is increased, and in some aspects, it can replace the PA, PUR, PET thermo sols.

Owner:杭州仁和热熔胶有限公司

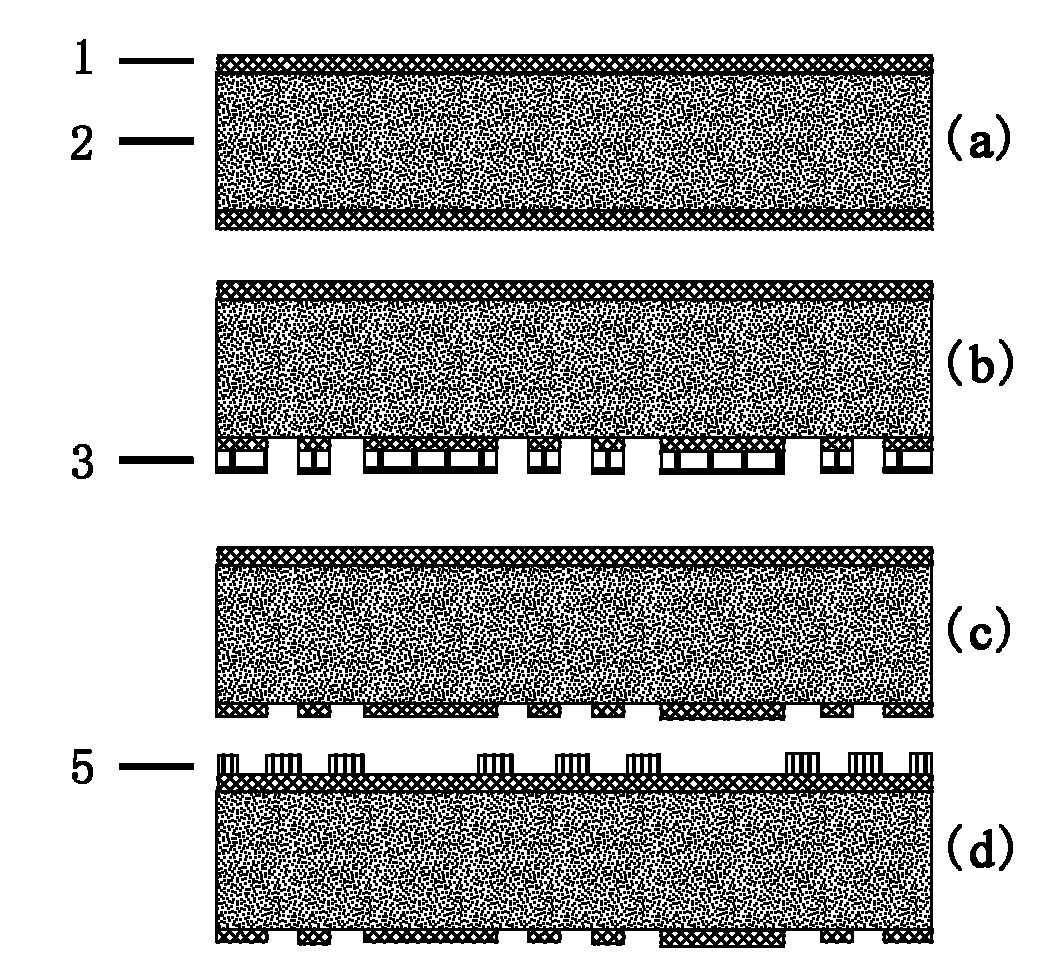

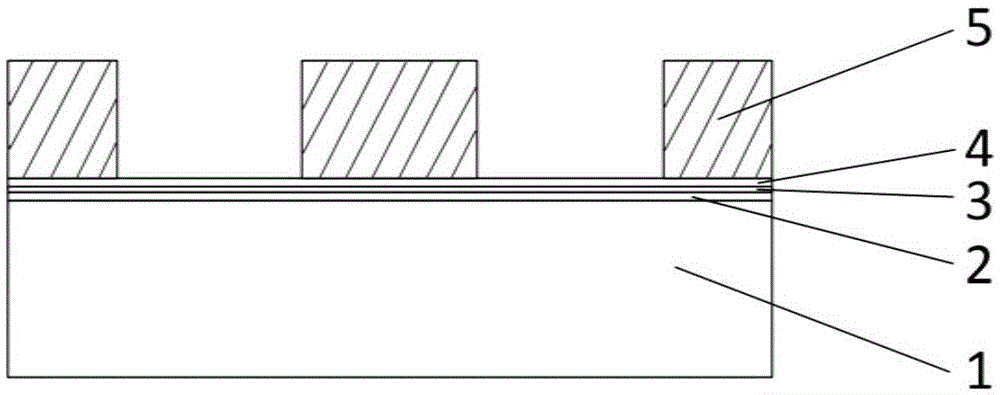

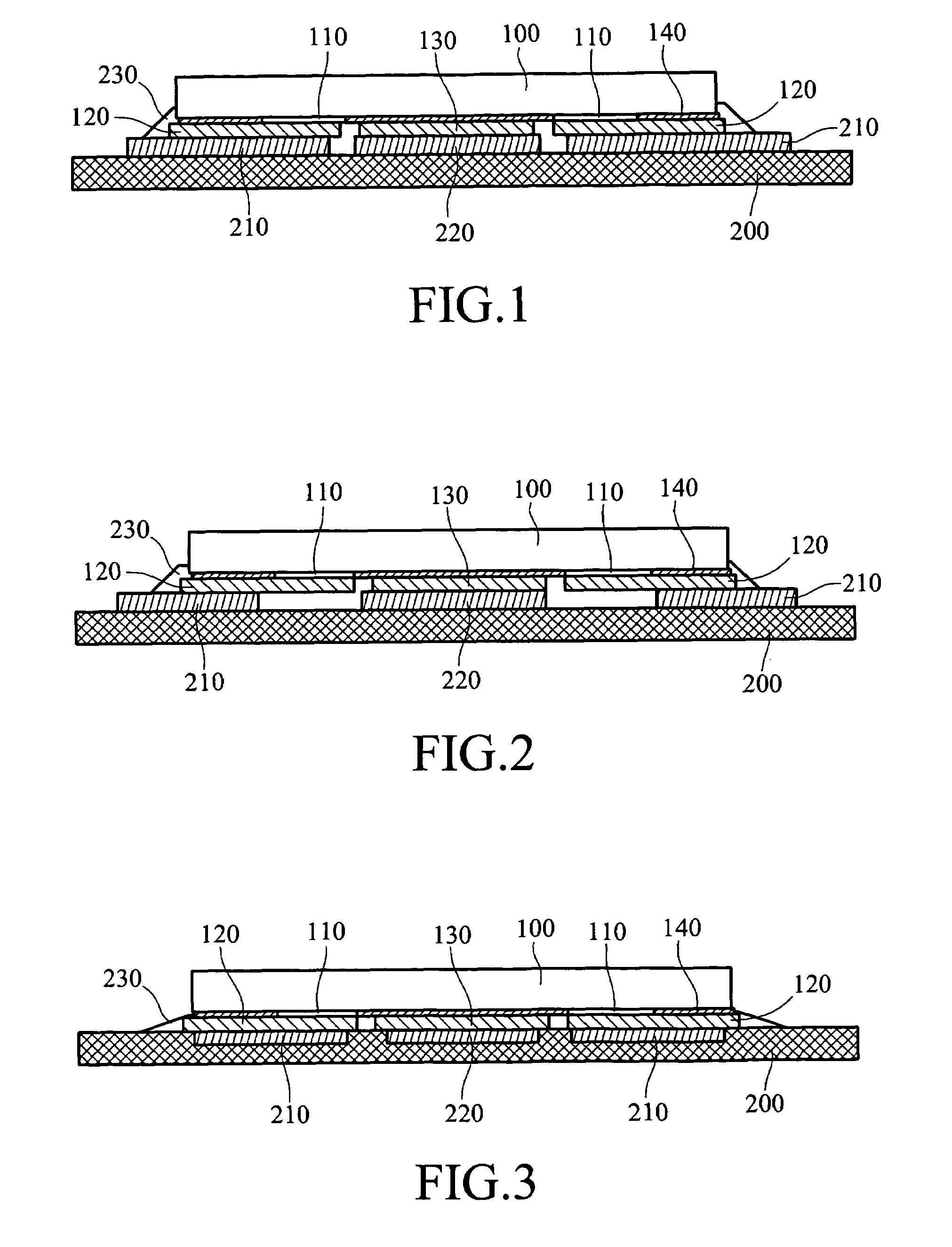

Copper nanorod based copper-tin-copper bonding process and structure

ActiveCN105679683ALower requirementLower bonding temperatureMaterial nanotechnologySemiconductor/solid-state device detailsBonding processCopper

The invention discloses a copper nanorod based copper-tin-copper bonding process and structure. The process comprises the following steps of sequentially depositing an insulation layer, an adhesion layer and a seed layer on the surface of a substrate; spin-coating a layer of photoresist on the seed layer, and fabricating round holes in the photoresist; electroplating copper in the round holes to obtain copper convex points; removing the photoresist, and removing the exposed seed layer and the exposed adhesive layer; spin-coating the photoresist on the surfaces and the peripheries of the copper convex points, and exposing the upper surfaces of the copper convex points; electroplating tin convex points on the copper convex points of one of two substrate units obtained according to the above steps, and removing the photoresist; depositing copper nanorods on the copper convex points of the other substrate unit, and removing the photoresist; and bonding the two substrate units by a hot-pressing mode. The copper-tin-copper bonding structure is acquired according to the bonding process. According to the bonding process and the bonding structure, the copper nanorods are applied to copper-tin-copper bonding, the bonding temperature can be effectively reduced, and a tight bonding surface is obtained; and the preparation process is simple and controllable, is low in cost, and has great application value.

Owner:HUAZHONG UNIV OF SCI & TECH

Non-formaldehyde waterproof plastic film reinforced flexible decorative veneer and preparation method thereof

ActiveCN106272804AReduce heat stressLower bonding temperatureElectric wood treatmentSynthetic resin layered productsEngineeringPlastic film

The invention discloses a non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. Composting faces of a rotary cut or sliced decorative veneer and a plastic film are subjected to low-temperature plasma modification treatment, the treated composite faces of the decorative veneer and the plastic film are stacked to form composite blanks, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer is obtained through hot-press gluing. The invention further discloses a preparation method of the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. The product prepared by adopting the method releases no formaldehyde, no adhesive or gluing procedure is omitted, the production cost is lowered, the product suppleness is good, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer has the enough transverse tensile strength, will not cause glue penetration, is good in water resistance, saves energy, and is environmentally friendly, easy and convenient to operate and high in efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

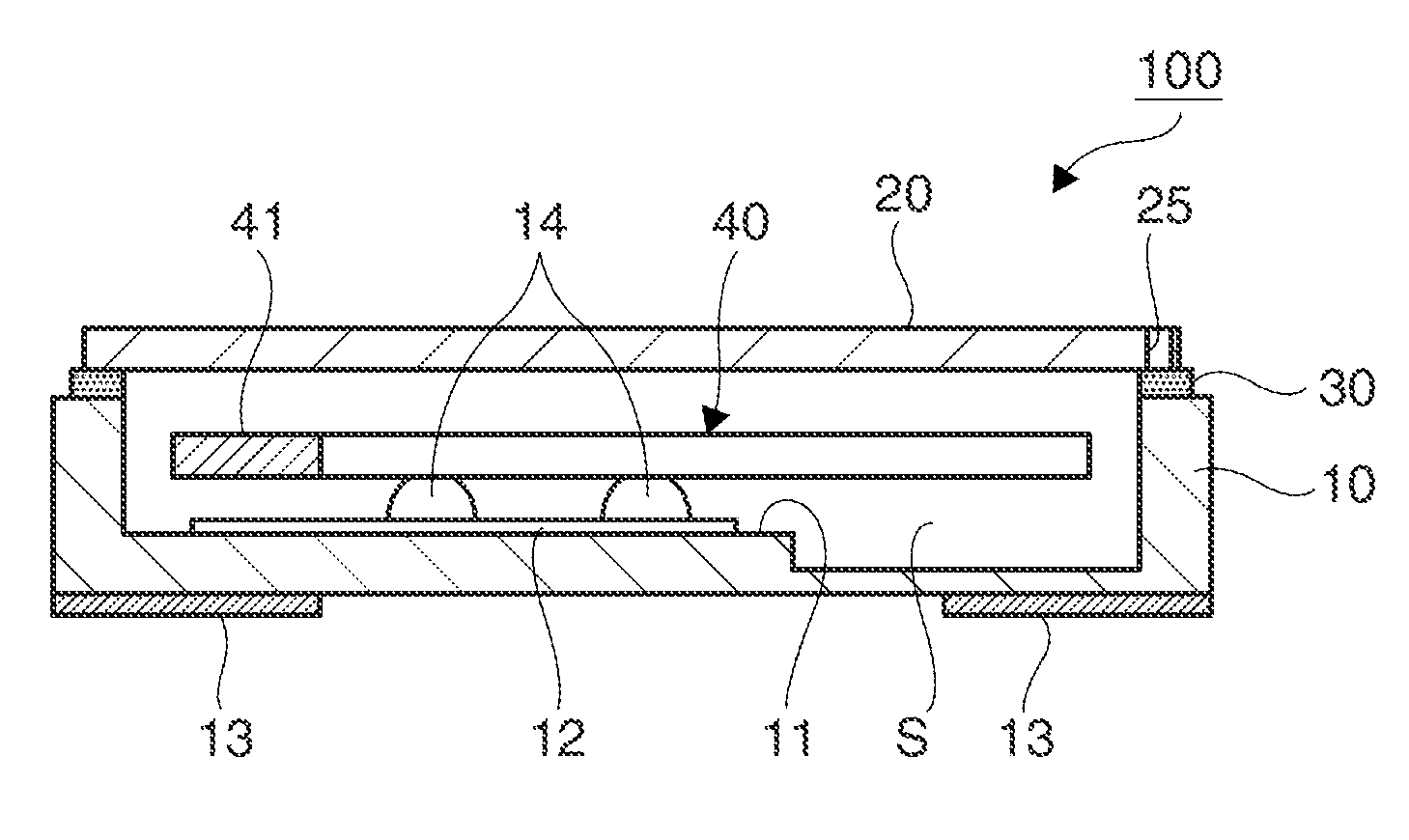

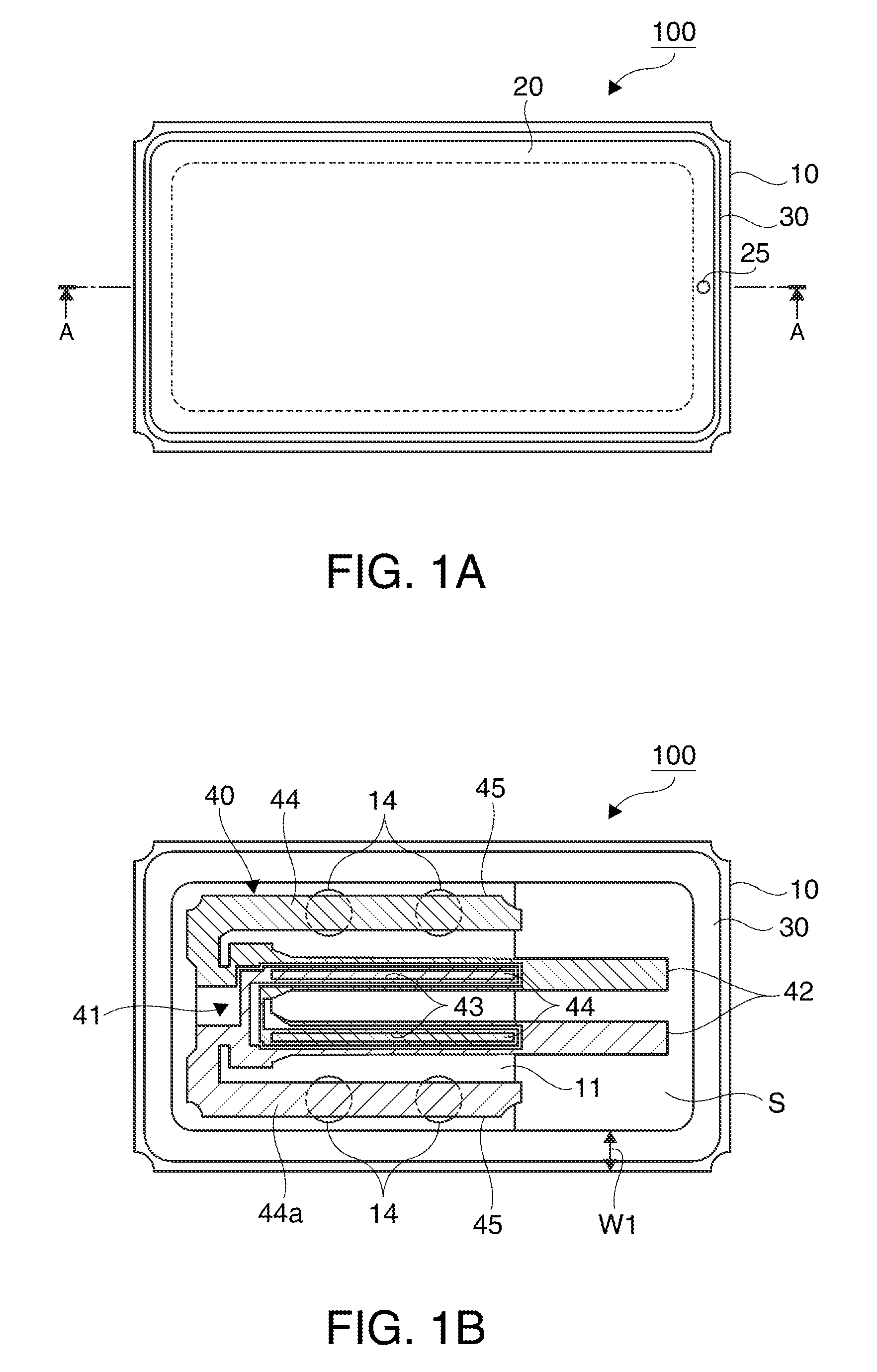

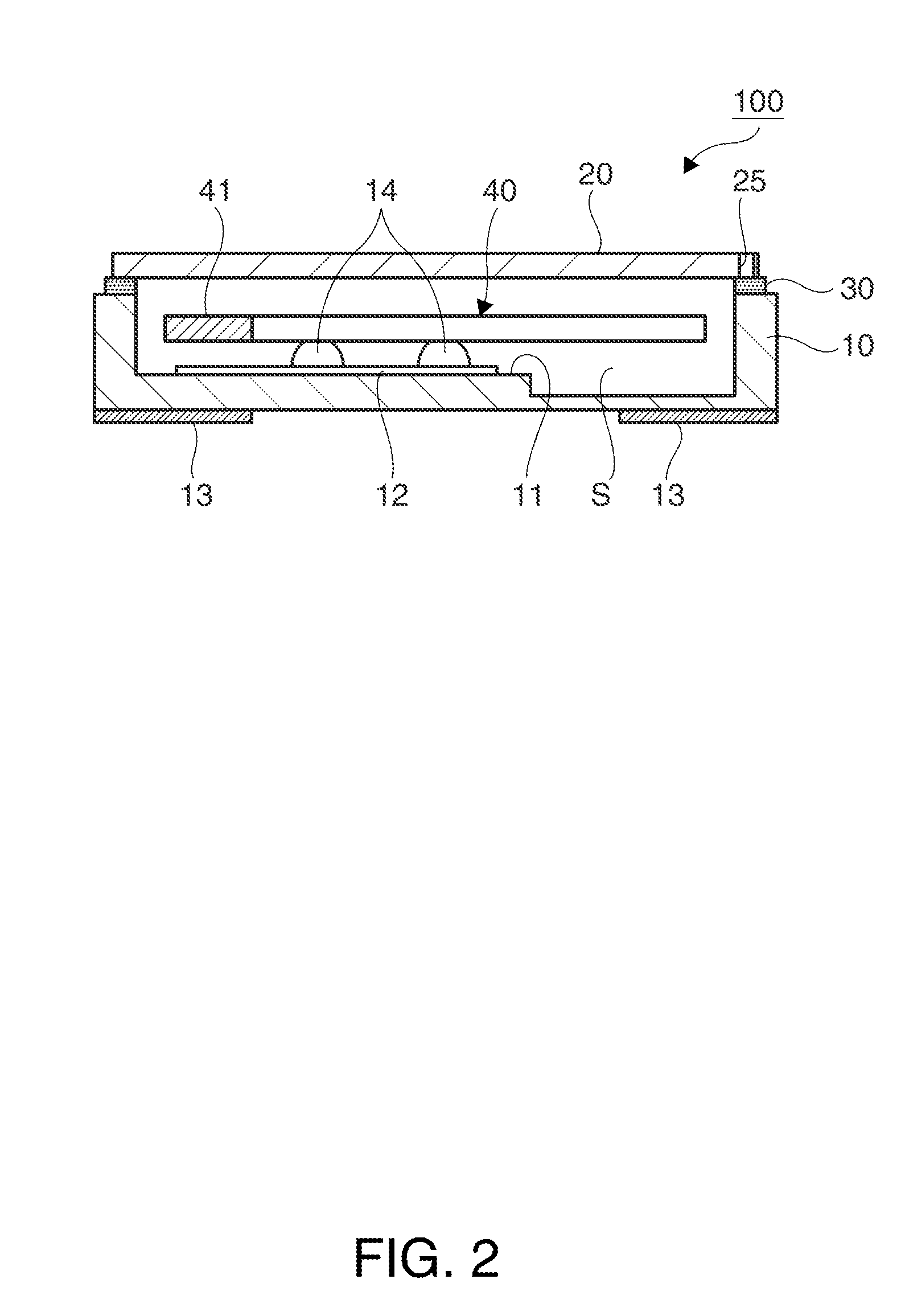

Method of manufacturing electronic device, electronic device, electronic apparatus, and mobile object

InactiveUS20140043779A1Simple processLower bonding temperaturePrinted circuit assemblingImpedence networksEngineeringElectronic component

A method of manufacturing an electronic device includes preparing a lid having a seal hole, a package having a seam ring (metalization portion) and constituting an internal space along with the lid, and a crystal vibrating piece (electronic component), mounting the crystal vibrating piece in the package, placing the lid on the package such that the seal hole and the seam ring overlap each other in plan view, seam-welding the outer circumferential portion of the lid and the package, and irradiating an energy beam to bond the seal hole and the seam ring and sealing the seal hole and the internal space.

Owner:SEIKO EPSON CORP

High-purity coating type polycrystalline silicon crucible and brushing method of coating of high-purity coating type polycrystalline silicon crucible

InactiveCN105154971APrevent participation in responsePrevent sintering shrinkagePolycrystalline material growthSingle crystal growth detailsSmooth surfaceSilicon nitride

The invention relates to a high-purity coating type polycrystalline silicon crucible and a brushing method of a coating of the high-purity coating type polycrystalline silicon crucible. The high-purity coating type polycrystalline silicon crucible comprises a crucible body, wherein a plurality of pit or annular grooves are uniformly formed in the surface of the crucible body, and the surface of the crucible body is sequentially adhered with a first nitration layer, a second oxidization layer and a third nitration layer; the surface of the crucible body is brushed with the whey-state first nitration layer, powdery silicon oxide of the second oxidization layer is ejected to the surface of whey, vaporous silicon nitride is sprayed to the surface of the second oxidization layer until particles of the second oxidization layer are covered, and a smooth surface is formed on the third nitration layer. The high-purity coating type polycrystalline silicon crucible and the brushing method have the characteristics that the coating is strong in covering capacity and high in stability and isolation degree, and the crucible body is prevented from reacting during the preparation of polycrystalline silicon.

Owner:WUXI SHUNYANG NEW ENERGY

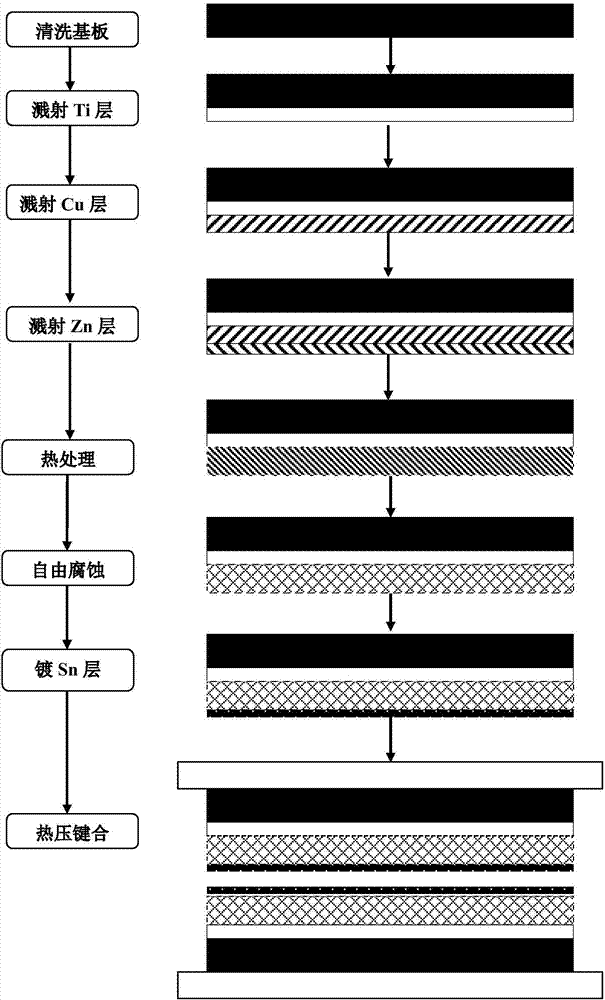

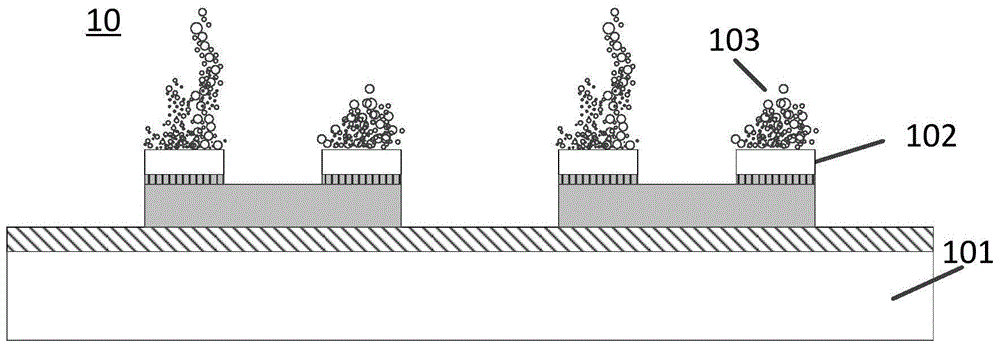

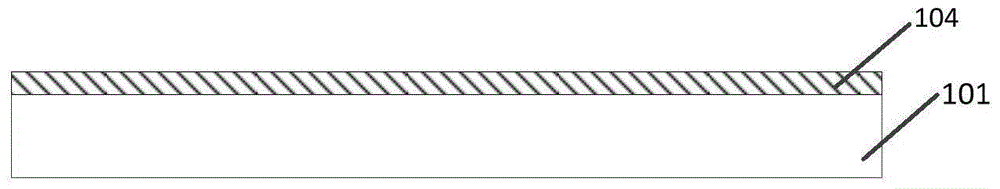

Low-temperature bonding method for tin-coated nano porous copper

InactiveCN107195559AReduce the characteristics of easy oxidationPromote interdiffusionMaterial nanotechnologySolid-state devicesBonding processElectron

The invention belongs to the field of electronic manufacturing, and discloses a low-temperature bonding method for tin-coated nano porous copper. The low-temperature bonding method comprises the steps of: firstly, preparing a copper alloy thin film on an initial substrate by means of ultrasonic cleaning, sputtering or electroplating, and thermal treatment; secondly, preparing a nano porous copper structure by adopting a selective corrosion process; thirdly, depositing tin on the surface of the nano porous copper structure to form a tin-coated nano porous copper structure; and utilizing the tin-coated nano porous copper structure as a bonding layer to realize bonding at low temperature and low pressure. The low-temperature bonding method is simple in process, can realize low-temperature and low-pressure bonding, serves at high temperature, reduces thermal stress generated by adopting the bonding process, and has wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

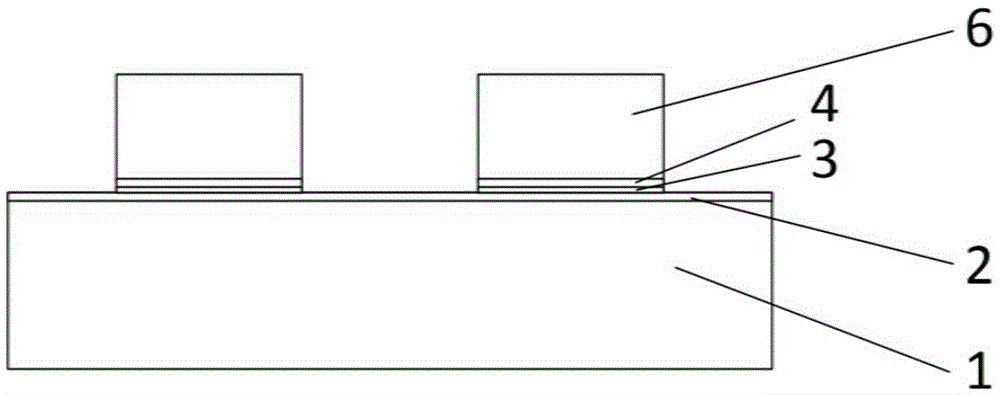

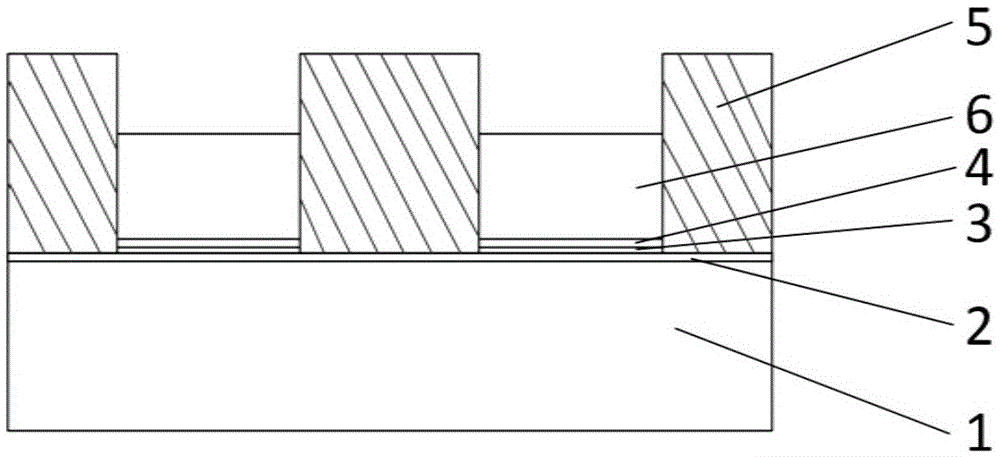

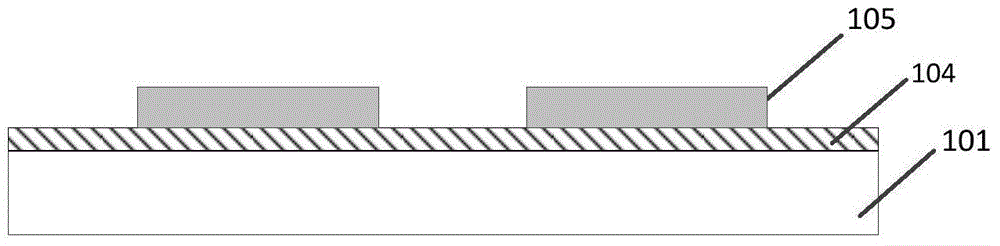

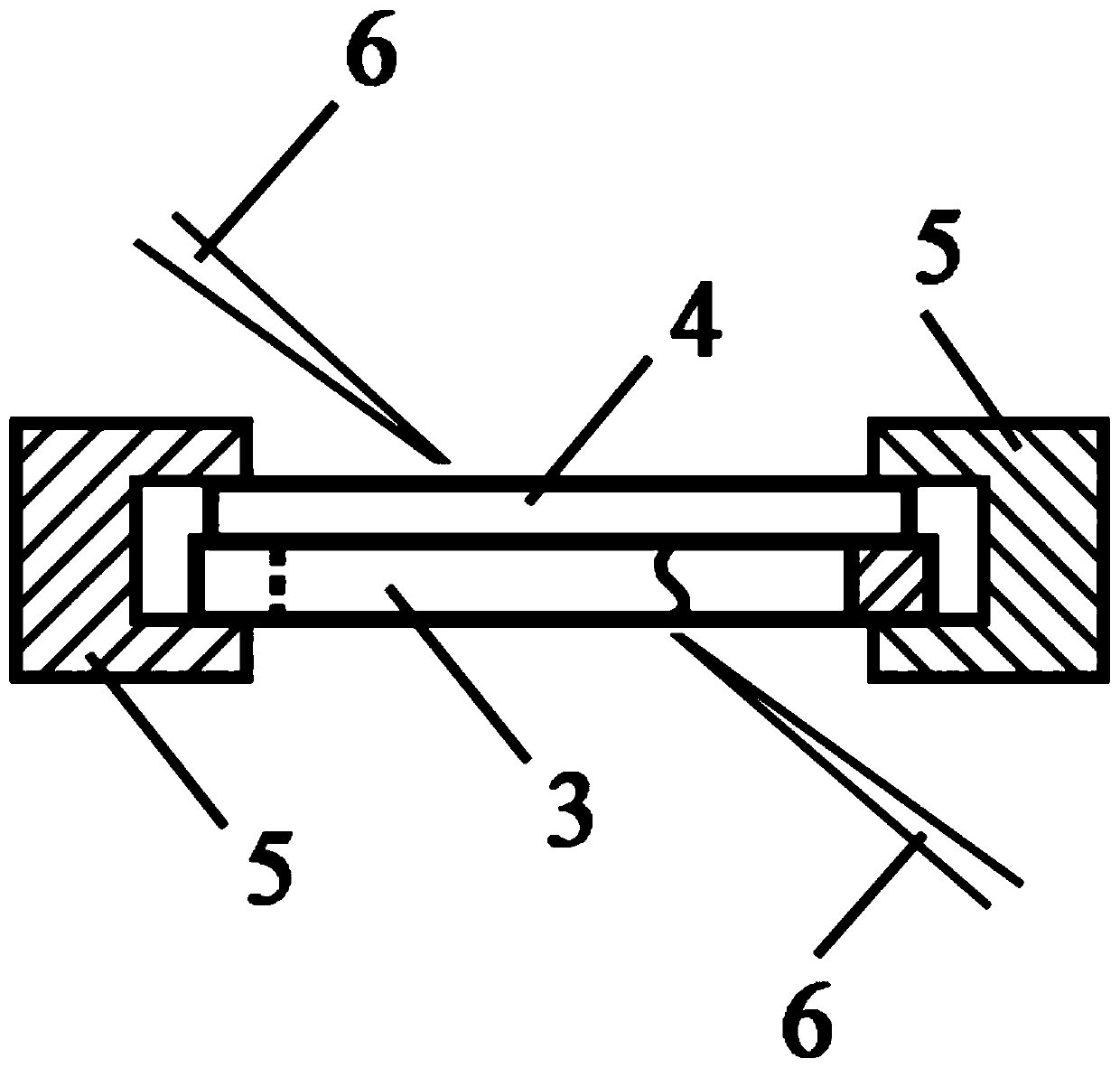

Inter-chip interconnection structure, manufacturing method of inter-chip interconnection structure and packaging structure

InactiveCN106158828ALower bonding temperatureHighly integratedFixed microstructural devicesSemiconductor/solid-state device detailsInterconnectionEngineering

The invention discloses an inter-chip interconnection structure, a manufacturing method of the inter-chip interconnection structure and a packaging structure. The inter-chip interconnection structure comprises a substrate, and first bonding bumps formed on the substrate, and is characterized by also comprising a first three-dimensional nanostructure which is deposited on the first bonding bumps and has the conductivity. Therefore, continuous reduction of an interlayer pitch can be achieved, the bonding temperature is reduced and the integration level is improved.

Owner:TSINGHUA UNIV

Thermoplastic resin composition for semiconductor, adhesion film, lead frame, and semiconductor device using the same, and method of producing semiconductor device

InactiveUS7843045B2Tight adhesionLower bonding temperatureOrganic chemistryOrganic compound preparationBenzeneSemiconductor chip

Owner:RESONAC CORPORATION

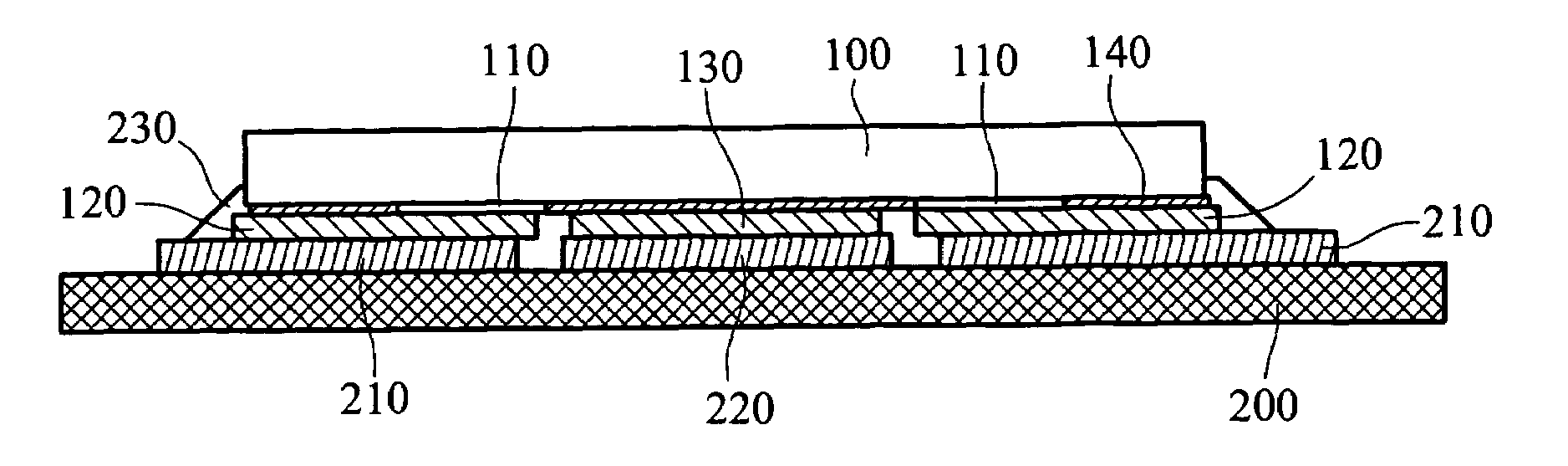

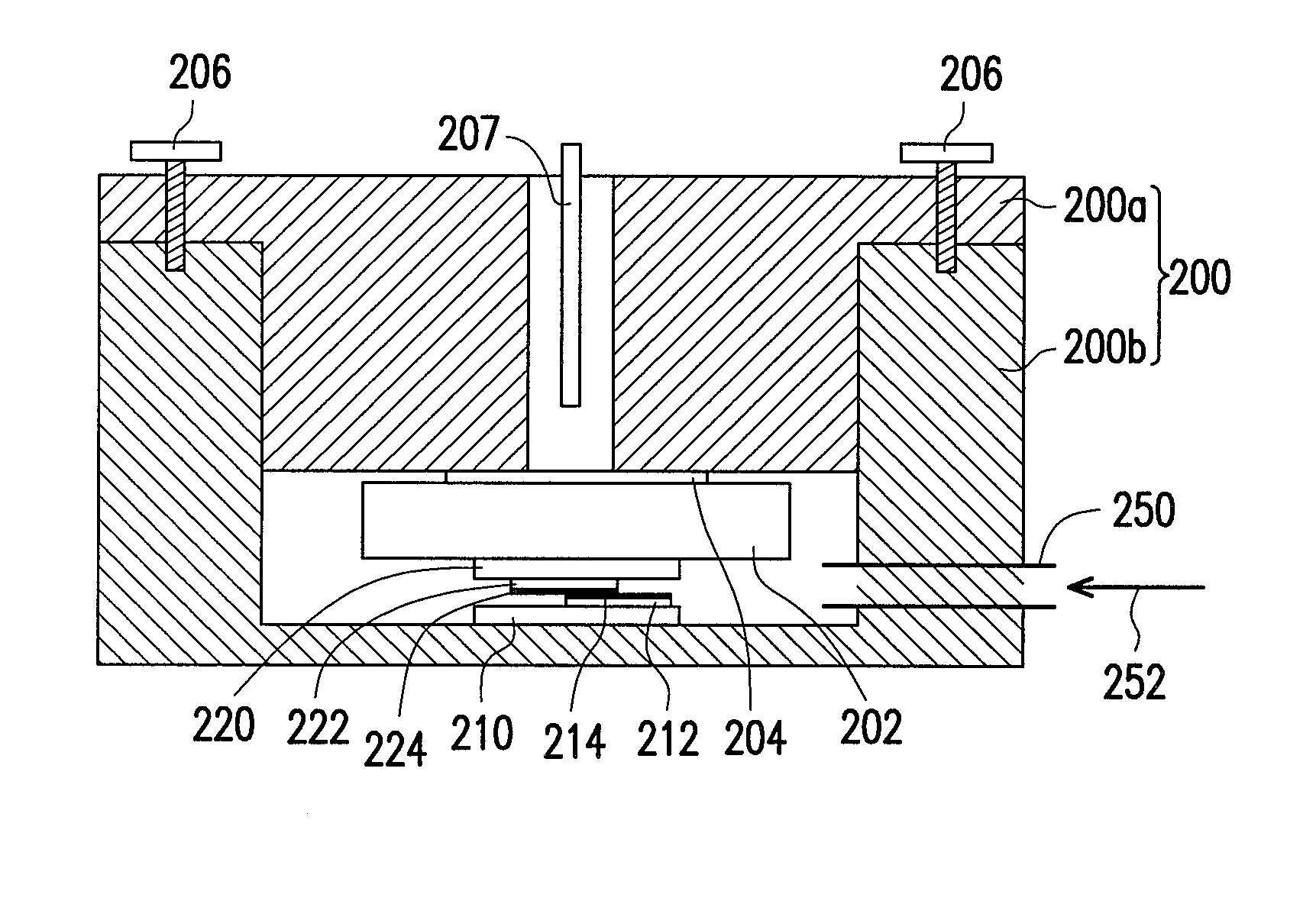

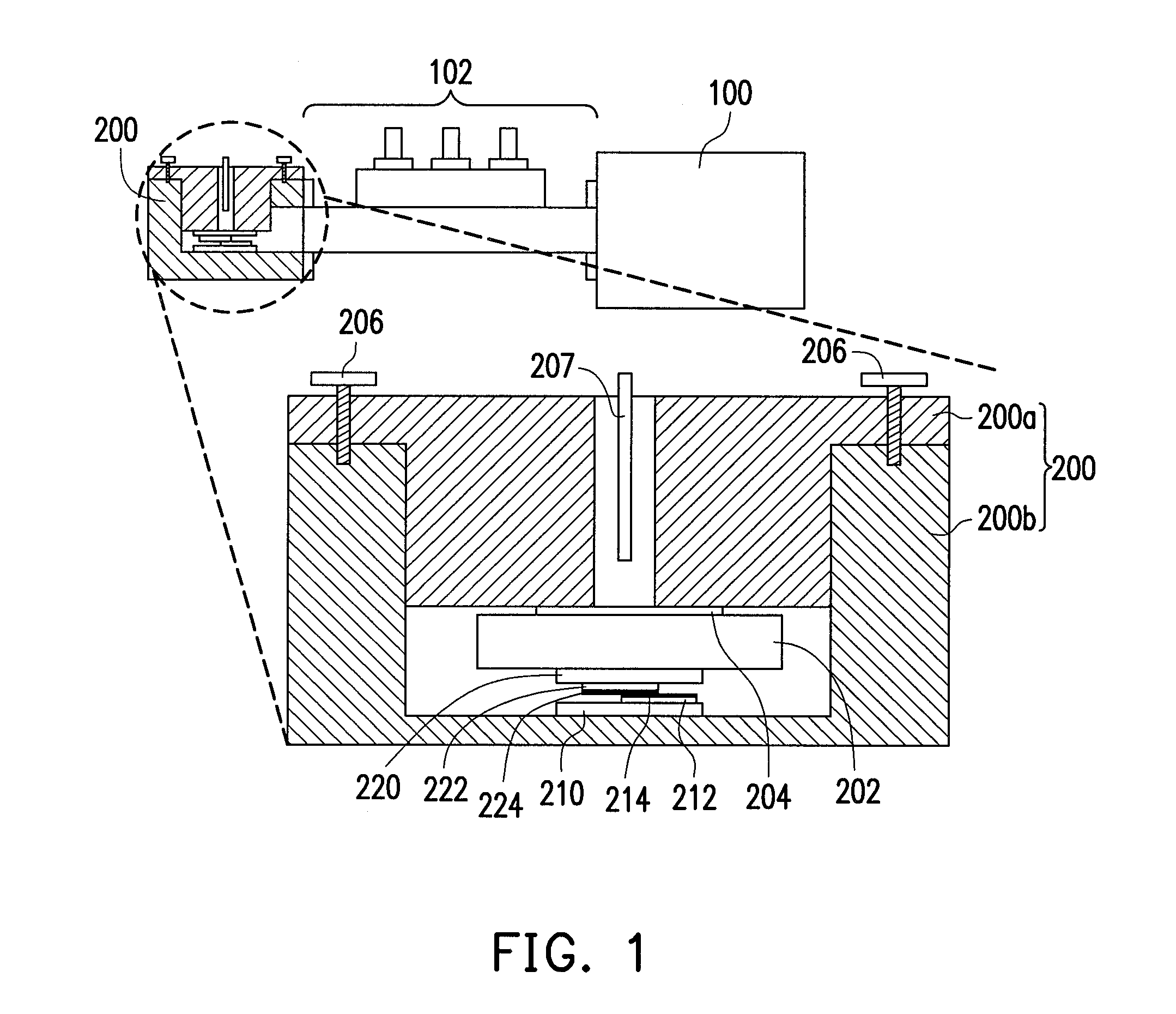

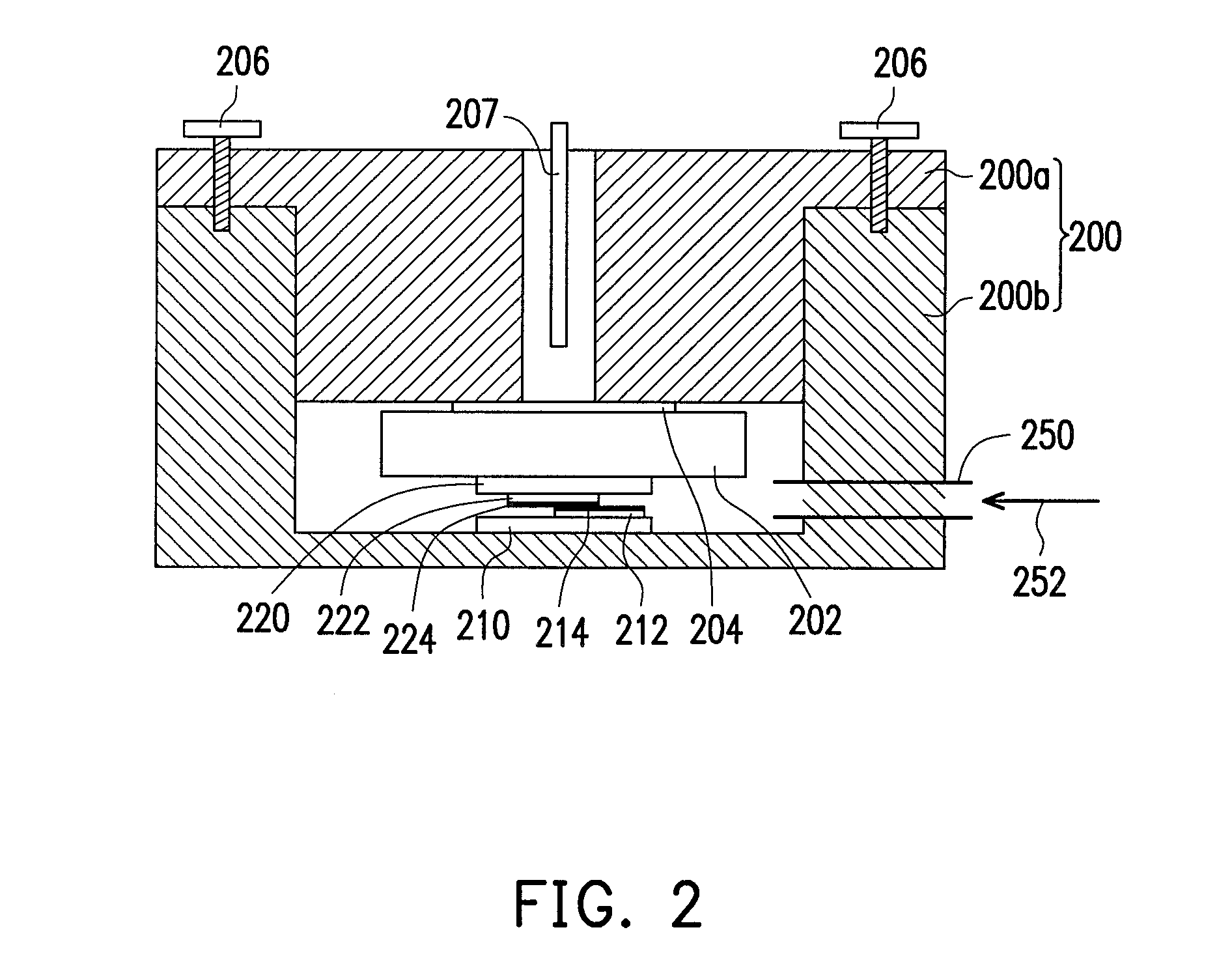

Bonding structure of device packaging

InactiveUS7239027B2Lower bonding temperatureSemiconductor/solid-state device detailsPrinted circuit aspectsMetalElectrical and Electronics engineering

A bonding structure of device packaging includes a first substrate and a second substrate. The surfaces of the first substrate have metal pads and a first bonding layer connected to the second substrate whose surfaces have a second bonding layer and electrodes. The first bonding layer is combined with the second bonding layer, and the metal pads are in electrical communications with the electrodes. The second substrate may be a flexible substrate to decrease the strain between the first substrate and the second substrate.

Owner:IND TECH RES INST

Preparation method of electron beam sensitive brittle material transmission electron microscope sample

PendingCN110926898ALower bonding temperatureAvoid destructionPreparing sample for investigationMaterial analysis by transmitting radiationCarbon filmMicrostructure

The invention discloses a preparation method of an electron beam sensitive brittle material transmission electron microscope sample. The preparation method comprises the following steps: A, preparinga sheet sample; B, carrying out water milling pre-thinning on the sheet sample; C, performing low-temperature ion sputtering thinning on the pre-thinned sheet sample; and D, carrying out carbon spraying treatment on the surface of the sheet sample subjected to low-temperature ion sputtering thinning, so as to deposite a layer of amorphous carbon film on the surface of the sheet sample. According to the method, measures such as liquid nitrogen cooling, carbon spraying treatment and the like are adopted, so that the influence of adverse factors such as charge accumulation and the like on the microstructure of the sample in the TEM sample preparation process is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

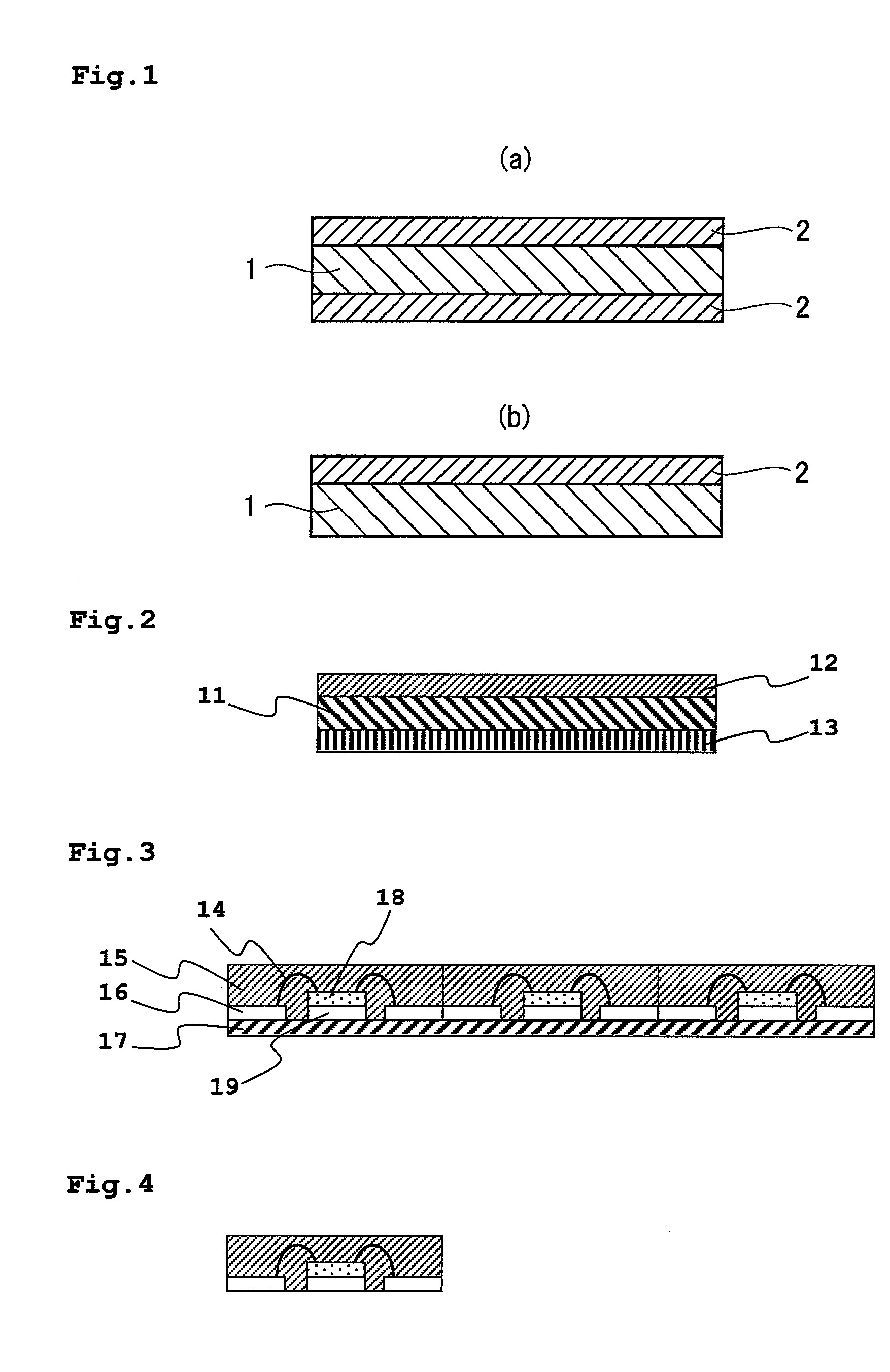

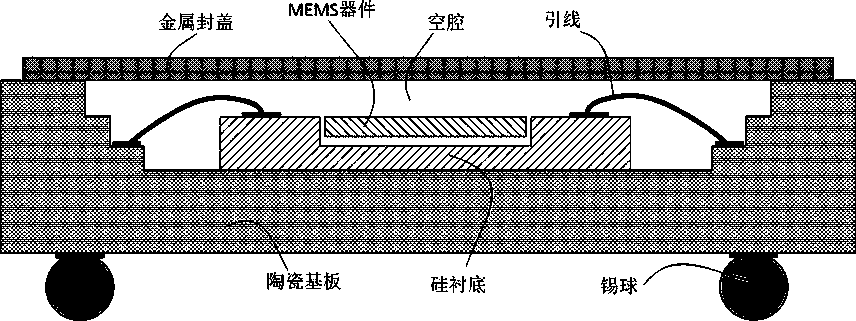

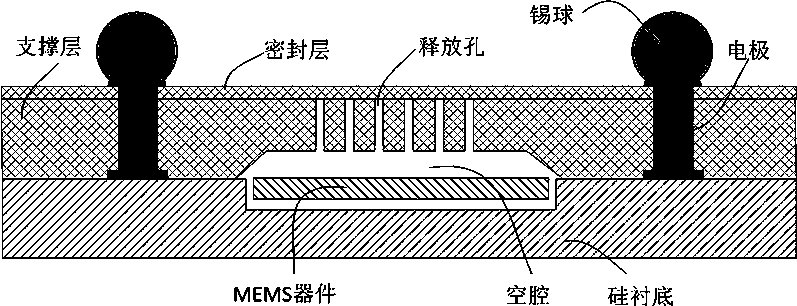

A wafer level packaging method of an MEMS device

InactiveCN109809357AEasy to handleReduce the chance of damageTelevision system detailsPrecision positioning equipmentEngineeringWafer-level packaging

The invention discloses a wafer level packaging method of an MEMS device. Firstly, an MEMS device is manufactured on an MEMS wafer, and a packaging structure is attached to a bearing wafer through a temporary bonding material. Secondly, the packaging structure on the bearing wafer and the MEMS wafer are bonded together, and the MEMS device is enclosed by the packaging structure and the MEMS waferin a sealed mode; Thirdly, the temporary bonding material is removed, so that the bearing wafer is stripped from the packaging structure, and packaging of the MEMS device is completed. According to the invention, the manufacturing process of the packaging structure does not influence or damage the MEMS device, the damage probability of the MEMS device in the packaging process is reduced, the optional range of the packaging material is wide, and the packaging cost is reduced.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

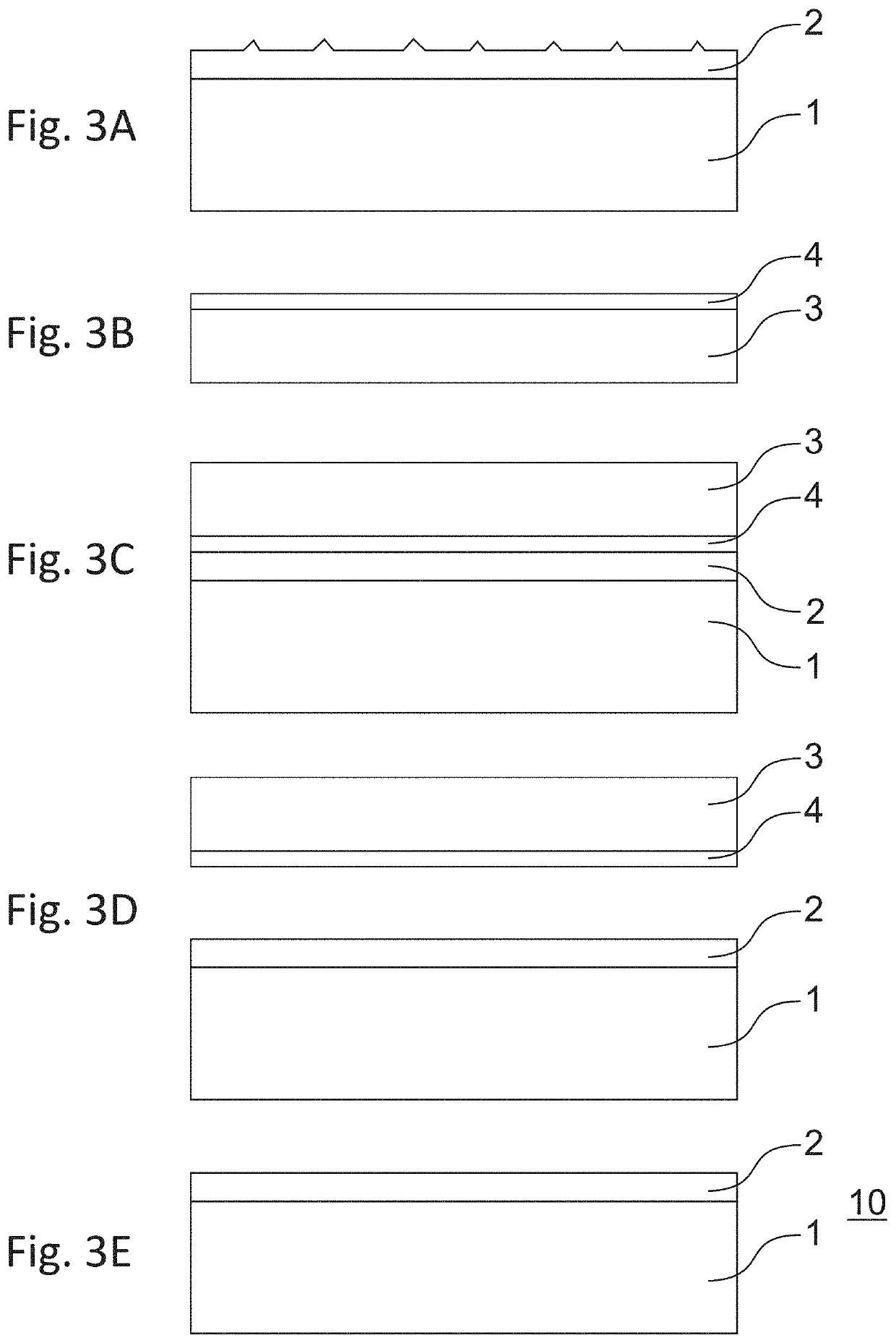

Method for manufacturing a handling device and method for reversible bonding using such a device

ActiveUS10854493B2Lower glass transition temperatureLower bonding temperatureSolid-state devicesSemiconductor/solid-state device manufacturingWaferingAdhesive

A method for manufacturing a handling device includes depositing a single layer of an adhesive on a first surface of a first wafer; depositing an antiadhesive layer on a first surface of a second wafer different from the first wafer; bringing into contact the first wafer and the second wafer, the bringing into contact taking place at the level of the single adhesive layer of the first wafer and the antiadhesive layer of the second wafer; separating the first wafer and the second wafer; the first wafer including the single adhesive layer forming a handling device. The bringing into contact of the first wafer and the second wafer is carried out at a temperature TC such that TC>Tg+100° C. where Tg is the glass transition temperature of the material composing the single adhesive layer of the first wafer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method of joining superconductor materials

ActiveUS8808492B2Lower bonding temperatureLarge resistance valueLamination ancillary operationsLaminationThermal energyMicrowave power

A method of joining superconductor materials is described. A microwave chamber including a first heat absorption plate and a second heat absorption plate corresponding to the first absorption plate is provided. A first superconductor material and a second superconductor material are disposed between the first heat absorption plate and the second heat absorption plate in the microwave chamber. The first superconductor material and the second superconductor material have an overlapping region therebetween, and a pressure is applied to the first heat absorption plate and the second heat absorption plate. Microwave power is supplied to the microwave chamber. The first heat absorption plate and the second heat absorption plate transform the microwave power into thermal energy so as to join the first superconductor material and the second superconductor material at the overlapping region.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com