Low temperature solid state bonding method through surface micro-nano structure

A micro-nano structure and bonding technology, used in semiconductor/solid-state device manufacturing, electrical solid-state devices, electrical components, etc., can solve the problems of low welding strength and high welding temperature, and achieve good bonding performance, high conductivity, and good plasticity. deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

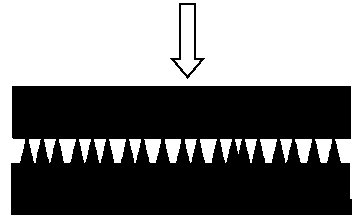

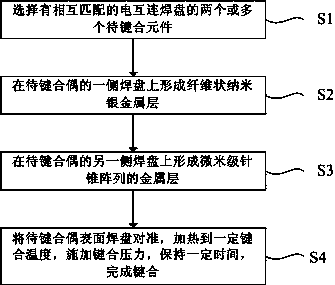

[0025] The invention provides a low-temperature solid-state bonding method utilizing surface micro-nano structures, comprising the following steps:

[0026] S1: Select two chips or substrates with matching electrical interconnection pads;

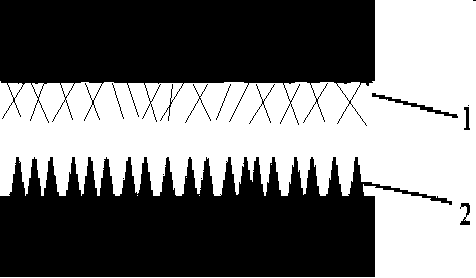

[0027] S2: Preparation of fibrous nano-silver metal layer: After degreasing the surface of the metal block in the bonding area of the chip or substrate, immerse it in 20wt.% sulfuric acid to activate it to improve the surface activity, and then place it in the chemical deposition solution for chemical deposition , thus obtaining the desired fibrous nano-silver metal layer 1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com