High-purity coating type polycrystalline silicon crucible and brushing method of coating of high-purity coating type polycrystalline silicon crucible

A polysilicon and crucible technology, which is applied in the field of solar cell production equipment, can solve the problems that the silicon nitride layer is difficult to achieve a high degree of density and cannot meet production requirements, and can prevent sintering shrinkage, high isolation, and prevent participation in the reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

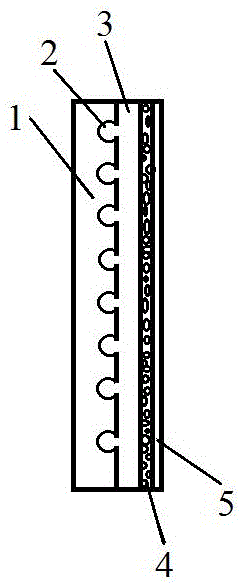

[0042] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, a plurality of pits 2 are evenly distributed on the surface of the crucible 1, and a plurality of pits 2 are evenly distributed on the surface of the crucible 1. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0043] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 2mm;

[0044] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitrided layer 3 that has not been condensed by spraying, and the second oxide layer 4 is formed on the first surface of the first nitride layer 3. The surface of the nitride layer 3 is granular;

[0045] The t...

Embodiment 2

[0066] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, a plurality of pits 2 are evenly distributed on the surface of the crucible 1, and a plurality of pits 2 are evenly distributed on the surface of the crucible 1. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0067] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 6mm;

[0068] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitrided layer 3 that has not been condensed by spraying, and the second oxide layer 4 is formed on the first surface of the first nitride layer 3. The surface of the nitride layer 3 is granular;

[0069] The t...

Embodiment 3

[0090] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, a plurality of pits 2 are evenly distributed on the surface of the crucible 1, and a plurality of pits 2 are evenly distributed on the surface of the crucible 1. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0091] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 10mm;

[0092] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitrided layer that has not yet condensed in a slurry form by spraying, and the second oxide layer 4 is in the first nitrogen The surface of the layer 3 is granular;

[0093] The third nitride layer 5 is atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com