Processing technology of high-strength tin powder

A processing technology and high-strength technology, applied in the field of tin powder processing, can solve problems affecting the strength of tin powder and achieve the effect of reducing purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

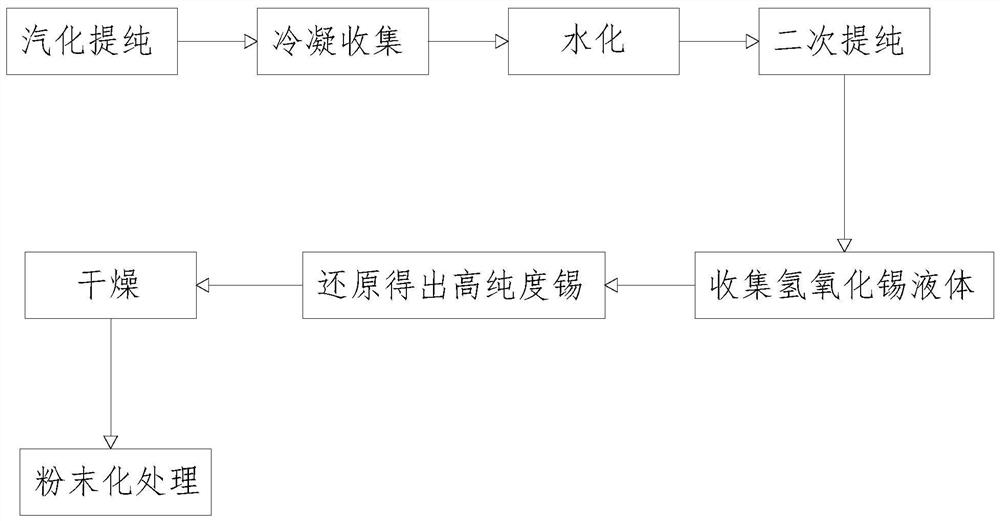

[0025] see figure 1 , the present invention provides a kind of technical scheme: a kind of processing technology of high-strength tin powder, described processing technology step is as follows:

[0026] The first step: gasification purification, prepare an appropriate amount of tin tetrafluoride raw material, put the tin tetrafluoride in the container and heat it to 705°C, and heat it for an appropriate amount of time, until the tin tetrafluoride is completely vaporized;

[0027] Tin tetrafluoride sublimates at 705°C.

[0028] The second step: condensation collection, collecting the vaporized tin tetrafluoride in a container, and cooling the vaporized tin tetrafluoride to liquid or solid state;

[0029] When collecting tin tetrafluoride, it is necessary to keep the environment dry to prevent tin tetrafluoride from dissolving in water.

[0030] The third step: hydration, heating the purified tin tetrafluoride to 705°C again, after the tin tetrafluoride is completely vaporized...

Embodiment 2

[0055] see figure 1 , the present invention provides a kind of technical scheme: a kind of processing technology of high-strength tin powder, described processing technology step is as follows:

[0056]The first step: gasification purification, prepare an appropriate amount of tin tetrafluoride raw material, put the tin tetrafluoride in the container and heat it to 705°C, and heat it for an appropriate amount of time, until the tin tetrafluoride is completely vaporized;

[0057] Tin tetrafluoride sublimates at 705°C.

[0058] The second step: condensation collection, collecting the vaporized tin tetrafluoride in a container, and cooling the vaporized tin tetrafluoride to liquid or solid state;

[0059] When collecting tin tetrafluoride, it is necessary to keep the environment dry to prevent tin tetrafluoride from dissolving in water.

[0060] The third step: hydration, heating the purified tin tetrafluoride to 705°C again, after the tin tetrafluoride is completely vaporized,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com