High-purity coating type polycrystalline silicon crucible

A technology of polysilicon and crucible, which is applied in the field of solar cell production equipment, can solve the problems that the silicon nitride layer is difficult to achieve high density and cannot meet production requirements, etc., and can prevent sintering shrinkage, high isolation, and coating coverage strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

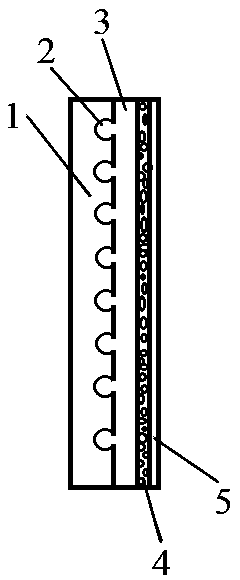

[0033] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, with several pits 2 evenly distributed on the surface of the crucible itself, and several pits 2 evenly distributed on the surface of the crucible itself. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0034] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 2mm;

[0035] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitride layer 3 that has not yet condensed in a slurry form by spraying, and the second oxide layer 4 is formed on the first The surface of the nitride layer 3 is granular;

[0036] The third nitride layer 5 is atomiz...

Embodiment 2

[0047] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, with several pits 2 evenly distributed on the surface of the crucible itself, and several pits 2 evenly distributed on the surface of the crucible itself. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0048] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 6mm;

[0049] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitride layer 3 that has not yet condensed in a slurry form by spraying, and the second oxide layer 4 is formed on the first The surface of the nitride layer 3 is granular;

[0050] The third nitride layer 5 is atomiz...

Embodiment 3

[0061] as attached figure 1 As shown: the present invention is a high-purity coated polysilicon crucible, including a crucible body 1, with several pits 2 evenly distributed on the surface of the crucible itself, and several pits 2 evenly distributed on the surface of the crucible itself. The surface is sequentially attached with a first nitride layer 3, a second oxide layer 4 and a third nitride layer 5;

[0062] The first nitride layer 3 is coated with milky silicon nitride on the surface of the crucible 1 uniformly distributed with several pits 2 by brushing, and the coating of the first nitride layer 3 The thickness range is 10mm;

[0063] The second oxide layer 4 is powdery silicon oxide, and the powdery silicon oxide is sprayed on the surface of the first nitrided layer that has not yet condensed in a slurry form by spraying, and the second oxide layer 4 is in the first nitrogen The surface of the layer 3 is granular;

[0064] The third nitride layer 5 is atomized sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com