Low-temperature bonding method for tin-coated nano porous copper

A nanoporous copper, low temperature bonding technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that nanoporous copper is easy to oxidize, has high bonding temperature, and has no significant nanometer size effect. and other problems, to achieve the effect of facilitating the reaction process, reducing the bonding temperature, and reducing the residual thermal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

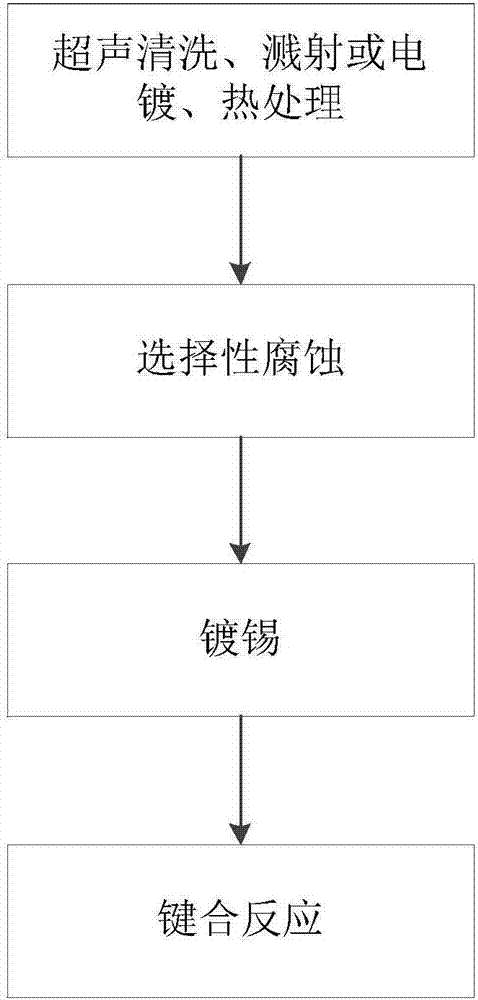

Method used

Image

Examples

Embodiment 1

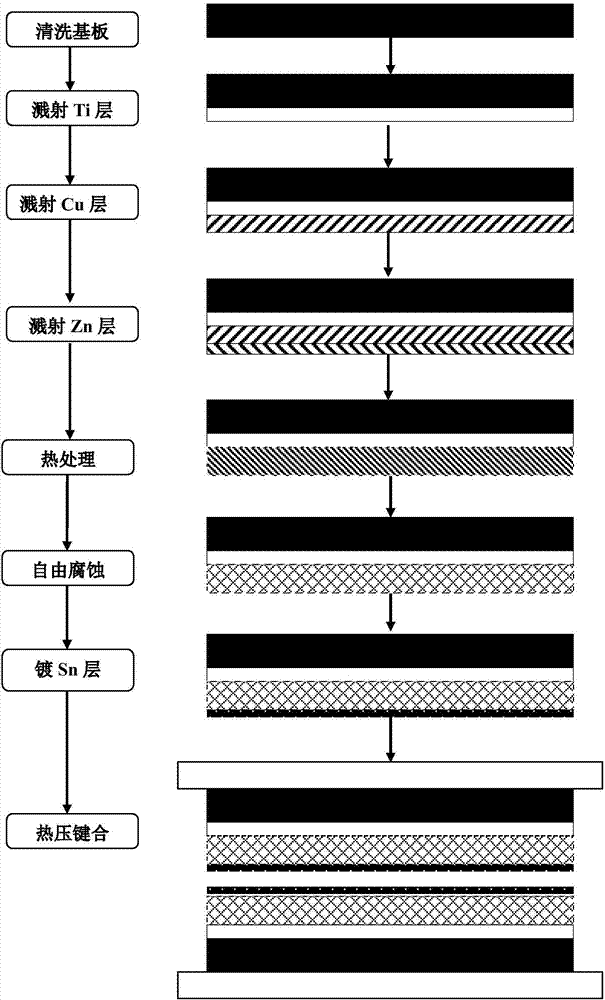

[0028] (1) Place the silicon wafer in a standard RCA cleaning solution for ultrasonic cleaning for 10 minutes, then sputter-deposit Ti layer (100nm), Cu layer (500nm) and Zn layer (1μm) in sequence, and then perform heat treatment (150°C, time 3h ) to obtain a Cu-Zn alloy layer.

[0029] (2) Place the above-mentioned silicon chip containing the Cu-Zn alloy layer in a NaOH solution with a concentration of 20%, and corrode it for 2 hours at a low temperature (-20° C.), remove the Zn element of the Cu-Zn alloy layer, and obtain on the surface of the silicon chip A nanoporous copper structure with a pore size of 20-30nm.

[0030] (3) Place the above-mentioned silicon wafer containing nanoporous copper in a tin plating solution, deposit tin on the surface of nanoporous copper by electroplating, the electroplating time is 20min, and the thickness of the tin layer is 300nm to obtain a tin-coated nanoporous copper structure.

[0031] (4) The above two silicon wafers containing tin-co...

Embodiment 2

[0033] (1) Place the aluminum nitride ceramic substrate in a standard RCA cleaning solution, clean it with ultrasonic waves for 10 minutes, then sputter and deposit a Ti layer (200nm) and a Cu layer (500nm) in sequence, electroplate a Zn layer (2μm), and then perform heat treatment (200°C, time 2h) to obtain a Cu-Zn alloy layer.

[0034] (2) Place the above-mentioned aluminum nitride ceramic substrate containing Cu-Zn alloy layer in 1% H 2 SO 4 In the solution, etch at room temperature for 2 hours, remove the Zn element in the Cu-Zn alloy layer, and obtain a nanoporous copper structure with a hole size of 60-80 nm on the surface of the aluminum nitride ceramic substrate.

[0035] (3) The above-mentioned aluminum nitride ceramic substrate containing nanoporous copper is placed in a tin plating solution, and tin is deposited on the surface of nanoporous copper by electroplating. The electroplating time is 30min, and the thickness of the tin layer is 1000nm to obtain tin-coated ...

Embodiment 3

[0038] (1) Clean the alumina ceramic substrate, then sputter-deposit Ti layer (100nm), Cu layer (500m) and Mg layer (1μm) in sequence, and then perform heat treatment (250°C, time 1h) to obtain Cu-Mg alloy layer.

[0039] (2) Place the above alumina substrate in a 1% tartaric acid solution, corrode it for 1 hour at a low temperature (-5°C), remove the Mg element of the Cu-Zn alloy layer, and obtain a pore size of 10-25nm on the surface of the alumina substrate nanoporous copper layer.

[0040] (3) The above-mentioned alumina ceramic substrate containing the nanoporous copper layer is placed in a tin plating solution, and a tin film is deposited on the surface of the nanoporous copper layer by electroless plating. The thickness of the tin plating layer is 800 nm, and the electroless plating time is 20 minutes.

[0041](4) Lay two aluminum oxide ceramic substrates whose surface is tin-coated nanoporous copper face to face, put them together on the hot plate of the bonding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com