Method for preparing strontium titanate nanopowder by low temperature solid phase reaction

A solid-phase reaction, nano-powder technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high reaction temperature, high cost of reaction raw materials, environmental pollution, etc., and achieve low reaction temperature and small product particles. , The effect of the process is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

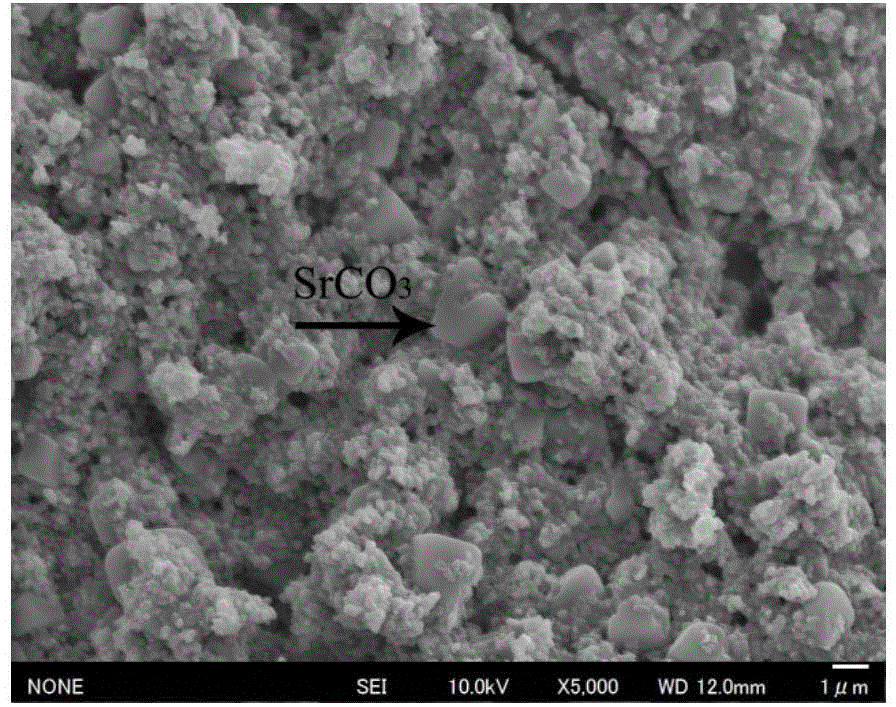

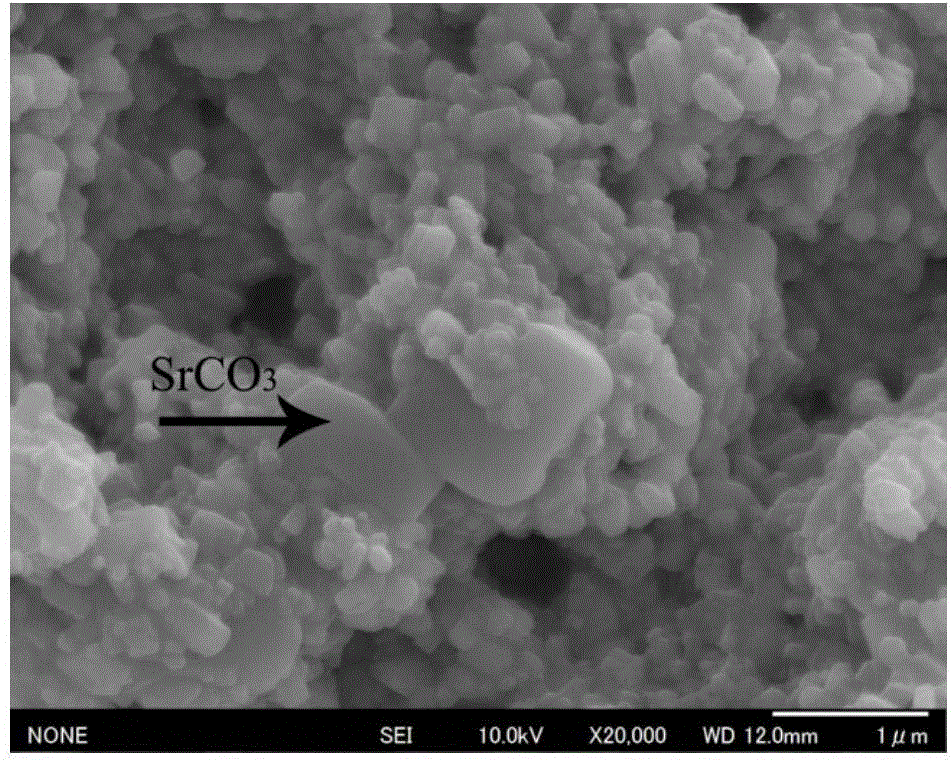

[0031] Mix strontium carbonate (Shanghai Sinopharm Chemical Reagent Co., Ltd.), titanium dioxide (Shanghai Sinopharm Chemical Reagent Co., Ltd.) and sodium chloride (Shanghai Sinopharm Chemical Reagent Co., Ltd.) according to the material ratio of 1:1:8. As a dispersant, ball mill at 280rpm for 6 hours to obtain a paste, then dry in an oven at 80°C for 6 hours, grind and sieve to obtain a powder with a particle size of 150 microns, then put the powder into a porcelain boat, put into a tube furnace, heated to 700°C in the presence of water vapor, the amount of water vapor added in the tube furnace was 1.0mL / min, reacted for 2 hours, the product was washed with water and ethanol, centrifuged and dried to obtain SrTiO 3 nanoparticles.

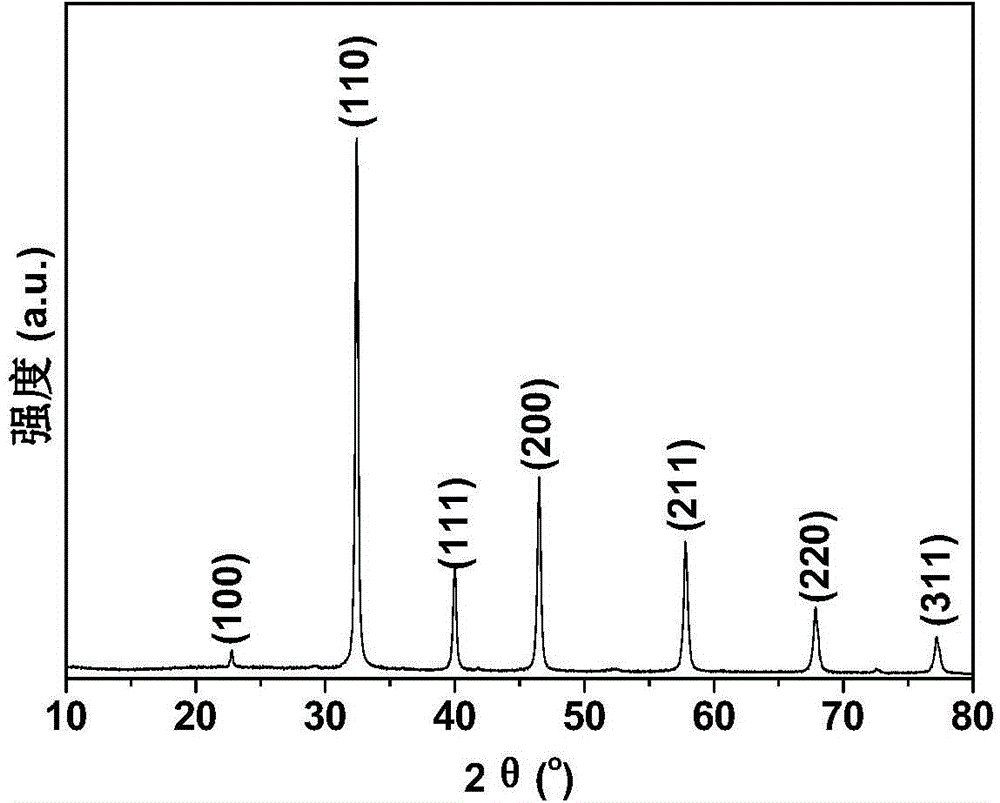

[0032] The phase analysis of the powder was carried out by a Japanese Rigaku D / max-γA X-ray powder diffraction (XRD) instrument, Cu Graphite monochromator, tube voltage and current are 40kV and 20mA, scanning speed 10.0° min -1 . figure 1 X-r...

Embodiment 2

[0036] The difference from Example 1 is that the mass ratio of strontium carbonate, titanium dioxide and sodium chloride is mixed at 1:1:0, and then a solid phase reaction is carried out, which needs to be reacted at 900 ° C for 2 hours, SrCO 3 and TiO 2 can be completely converted into SrTiO 3 Nano powder, SrTiO 3 The average particle size of nanoparticles is about 200nm, but the agglomeration is particularly serious, and the nanoparticles are assembled into particles with a size of about 50 microns, such as Figure 6 shown.

Embodiment 3

[0038] The difference from Example 1 is that the mass ratio of strontium carbonate, titanium dioxide and sodium chloride is mixed at 1:1:1, and then a solid phase reaction is carried out, which needs to be reacted at 750 ° C for 2 hours, SrCO 3 and TiO 2 can be completely converted into SrTiO 3 Nano powder, SrTiO 3 The average particle size of nanoparticles is about 200 nanometers, but the agglomeration is serious, and the nanoparticles are assembled into particles with a size of about 20 microns, such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com