Carbon material-aluminum-based composite material with good interface bonding and preparation method

An aluminum-based composite material and interface bonding technology, which is applied in the field of composite material preparation, can solve the problems that the comprehensive performance is difficult to meet industrial needs, the functional characteristics of composite materials are deteriorated, and it is not suitable for industrial production, etc., to achieve outstanding functional characteristics and good mechanical properties , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

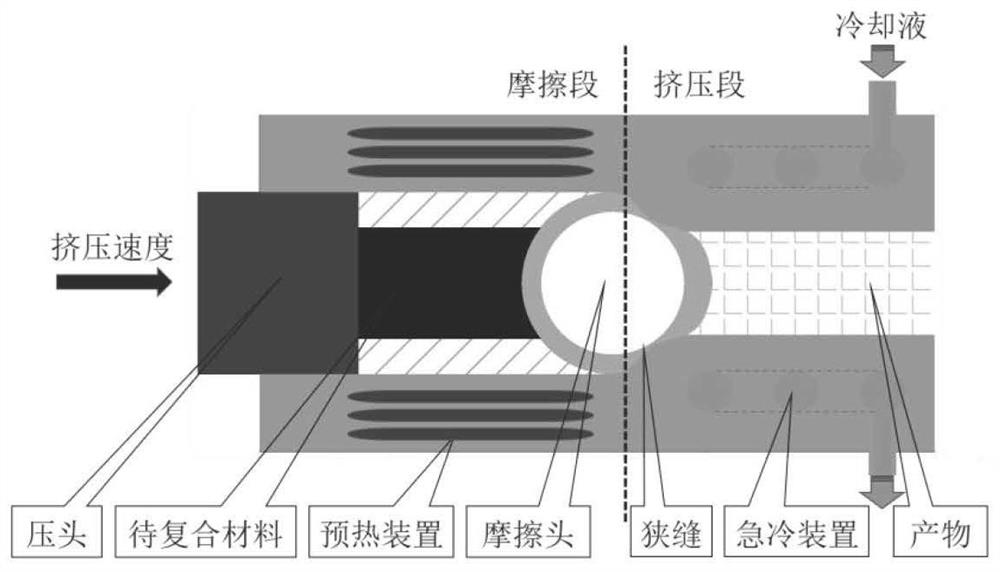

[0023] A method for preparing a carbon material-aluminum matrix composite material with good interfacial bonding provided by the invention comprises the following steps:

[0024] After mixing the carbon material to be composited with the aluminum-based material to form a composite material to be composited, preheating, friction extrusion, and rapid cooling during the extrusion process, the carbon material-aluminum-based composite material is obtained.

[0025] The present invention is provided with a preheating device and a quenching device in the process of preparing composite materials by friction extrusion; the preheating device is arranged in the front section of friction extrusion, and the composite material is preheated before friction extrusion, which can increase the material mixing temperature Promote the interdiffusion of carbon and metal atoms; install the quenching device in the rear section of friction extrusion, and use the quenching device for rapid cooling durin...

Embodiment 1

[0041] The raw materials were weighed according to the following proportions: 0.8vol.% graphene (sheet diameter 5-50 μm, thickness 3.4-8 nm) and 99.2vol.% 6061 aluminum powder (average particle size about 50 μm). Graphene and aluminum powder are mixed in the powder mixer for 2 hours and then filled into the aluminum sheath for "friction extrusion". The process parameters are set as: preheating temperature 150°C, friction head rotation speed 620r / min, 0.4mm / s, using liquid nitrogen for cooling, and T6 heat treatment after obtaining the graphene-aluminum matrix composite material.

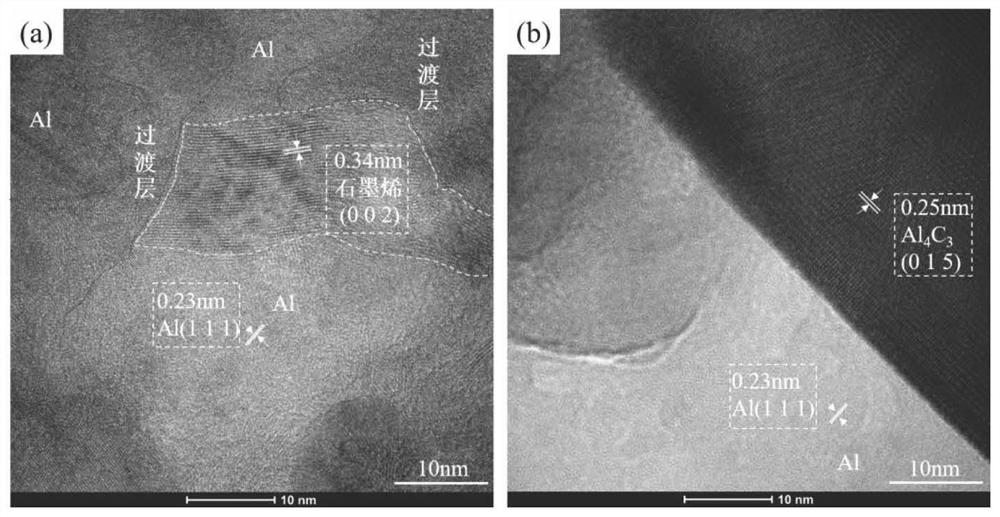

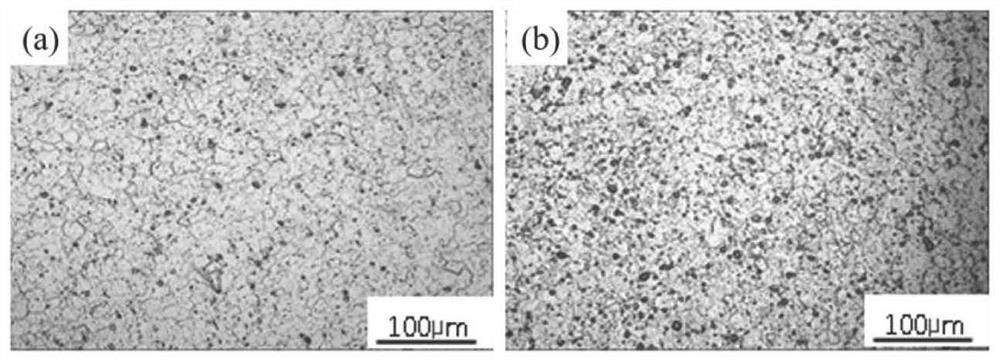

[0042] The interface microstructure and metallographic structure of the composite materials are as follows: figure 2 a and image 3 as shown in a. There is an obvious transition layer at the graphene-aluminum matrix interface of the composite material, which is formed by the interdiffusion of carbon and aluminum atoms. It is a diffusion interface, and the average grain size of the matrix is abou...

Embodiment 2

[0047] The raw materials were weighed according to the following proportions: 1vol.% graphene (sheet diameter about 2-10 μm, thickness 3nm) and 99vol.% ZL114 aluminum powder (average particle size about 50 μm). Graphene and aluminum powder are mixed in the powder mixer for 2 hours and then filled into the aluminum sheath for "friction extrusion". The process parameters are set as: preheating temperature 150°C, friction head rotation speed 620r / min, 0.3mm / s, using liquid nitrogen for cooling, and T6 heat treatment after obtaining the graphene-aluminum matrix composite material.

[0048] Tensile tests and thermal conductivity tests at room temperature showed that the average tensile strength and thermal conductivity of the composites were 318MPa and 164W / m.k, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com