Patents

Literature

102results about How to "Stable dielectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead And Cadmium Free, Low Temperature Fired X7R Dielectric Ceramic Composition And Method Of Making

ActiveUS20100220427A1Stable dielectric constantSmall dielectric lossFixed capacitor dielectricStacked capacitorsCeriumCadmium Cation

Multilayer ceramic chip capacitors (MLCC's) which satisfy X7R TCC requirements and which are compatible with silver-palladium internal electrodes. The MLCC's exhibit desirable dielectric properties—high capacitance, low dissipation factor, high insulation resistance, stable TCC—and excellent performance on highly accelerated life testing, and good resistance to dielectric breakdown. The dielectric layers comprise a lead-free and cadmium-free barium titanate base material doped with other metal oxides such oxides of zinc, boron, bismuth, barium, titanium, praseodymium, cerium, tungsten, neodymium, tungsten, tin, niobium, copper, and / or manganese in various combinations. The dielectric ceramic materials herein can be fired at less than 1150° C. with an inner electrode having 70 wt % or more Ag and 30 wt % or less Pd to form an MLCC.

Owner:FERRO CORP

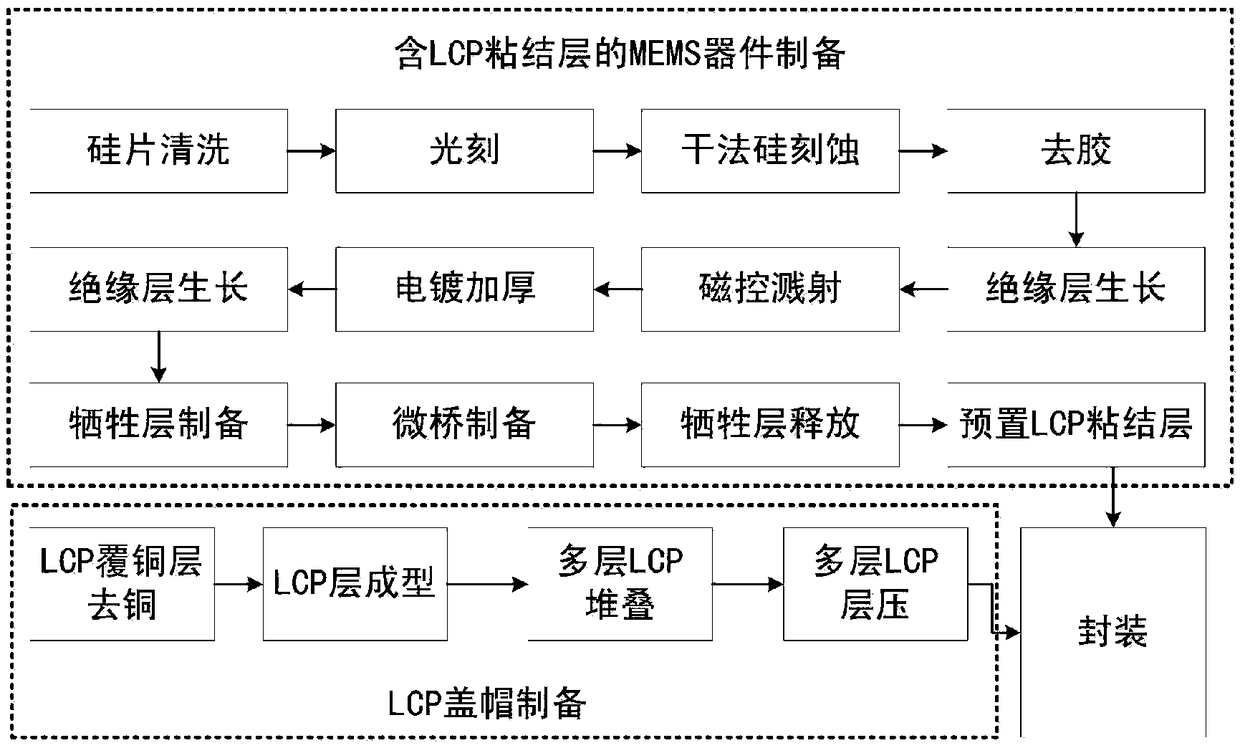

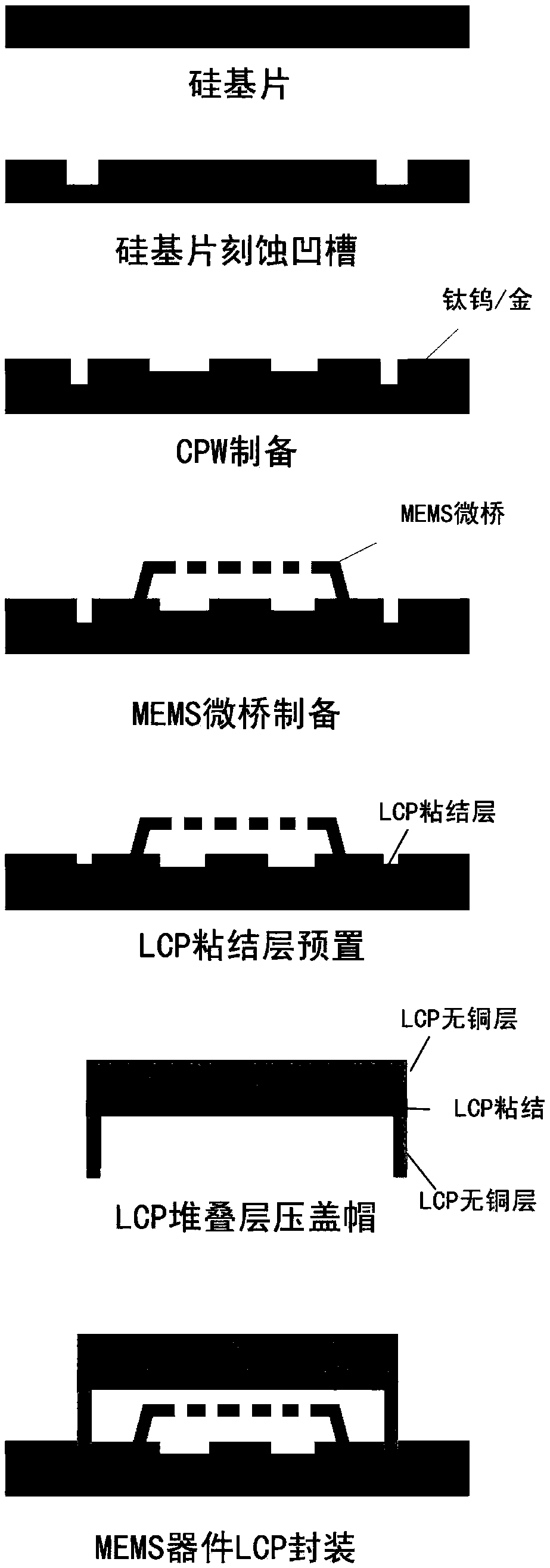

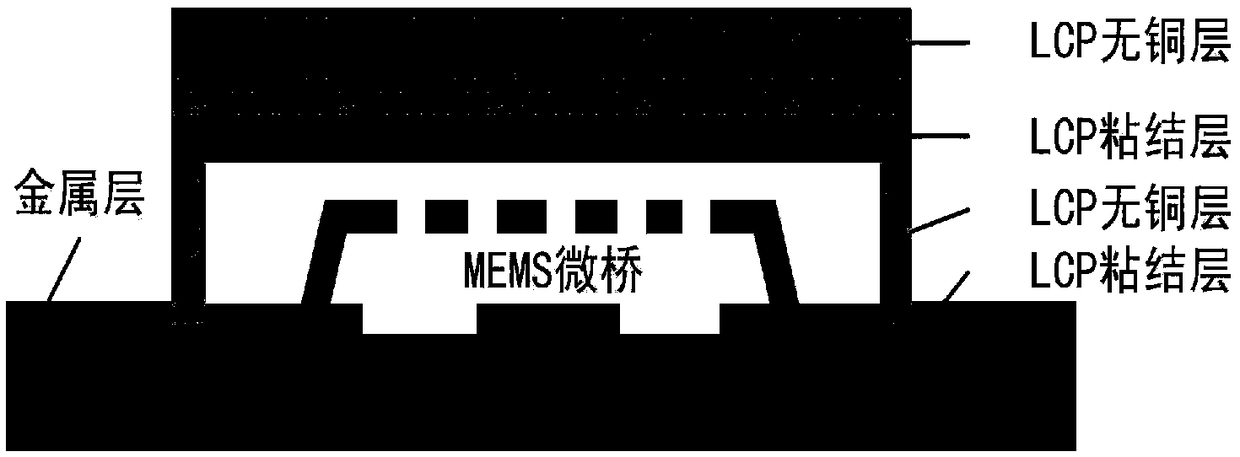

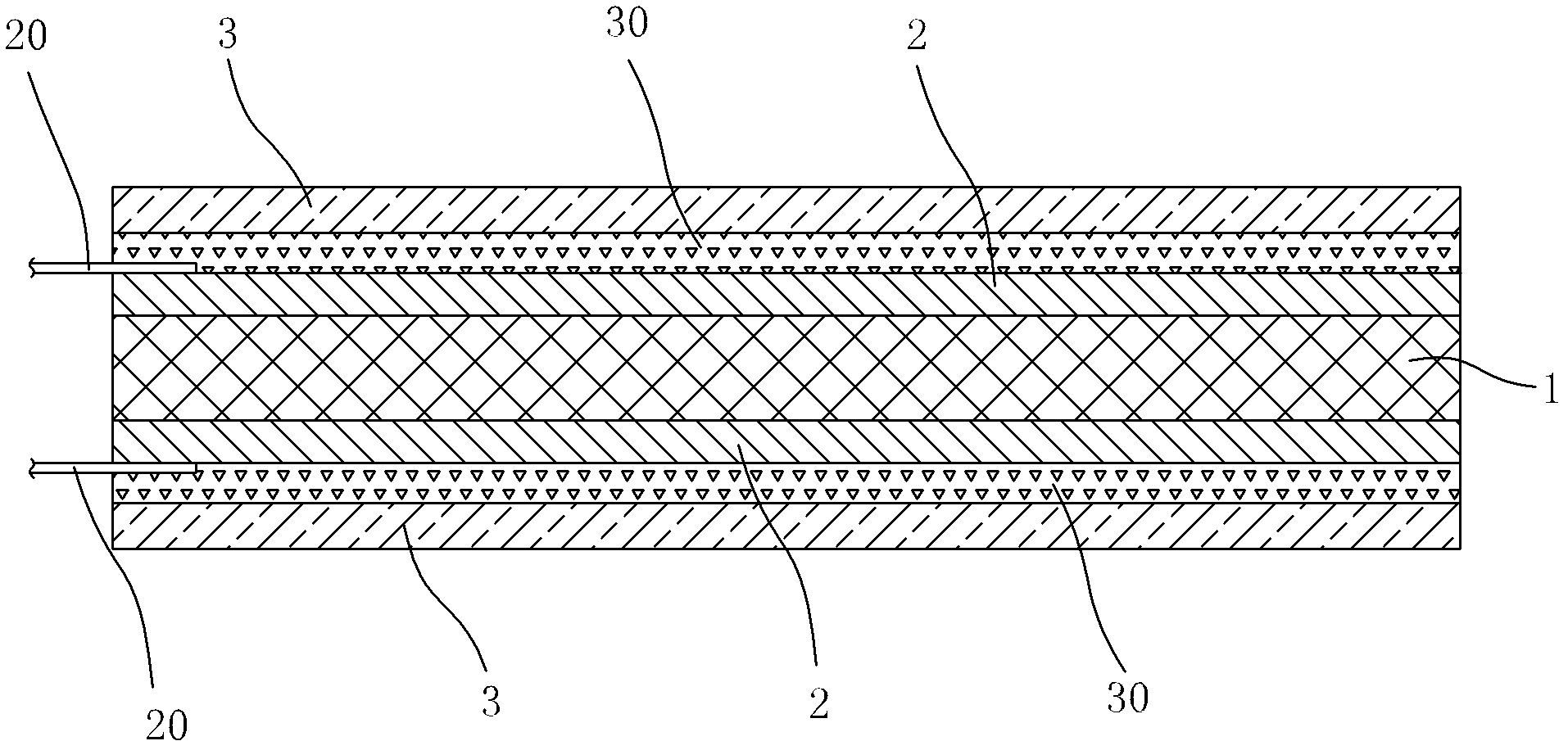

A packaging method for mems devices based on lcp multilayer stacking technology

ActiveCN107324273BImprove insulation performanceLow moisture absorptionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesRadar systemsMicrowave

The invention discloses a MEMS device packaging method based on LCP multilayer stacking technology, which is characterized in that the MEMS device is obtained by sputtering, photolithography, etching, electroplating and other processes on a double-sided polished silicon substrate, and at the same time Form silicon grooves that are easy to lead out and have accurate alignment; based on the LCP multilayer stacking technology, on the multilayer LCP substrate, the cap part of the device package is obtained through laser scribing, alignment, lamination and other processes; the device and the cap Package without assistance, high-precision integration, and obtain MEMS devices with low loss and good airtightness. The MEMS device of the invention has the advantages of low loss, high isolation and good airtightness. This method can better provide packaging protection for MEMS devices with movable parts, and is especially suitable for miniaturization applications of microwave, millimeter wave communication, radar and other systems / subsystems, and belongs to the realization of miniaturization, high performance microwave communication, radar systems / The key technology of the subsystem.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

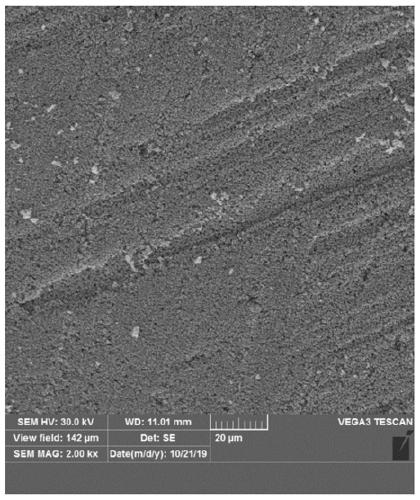

Low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and preparation method of low-temperature co-fired ceramic material

The invention discloses a low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and a preparation method of the low-temperature co-fired ceramic material. The low-temperature co-fired ceramic material is prepared by sintering the following components in percentage by mass (100% in total): 35%-50% of CaO, 30%-45% of B2O3 and 15%-25% of SiO2. The prepared low-temperature co-fired ceramic material contains a large quantity of microfine crystal grains (CaSiO3) and a small amount of glass and is typical microcrystalline glass ceramic; and the low-temperature co-fired ceramic material is low in dielectric constant and extremely low in loss, good in matching rate with high-temperature conductive silver paste, good in panel flatness and good in comprehensive property, and the dielectric constant and the loss in multiple frequency bands are stable.

Owner:昆明云基新材料有限公司

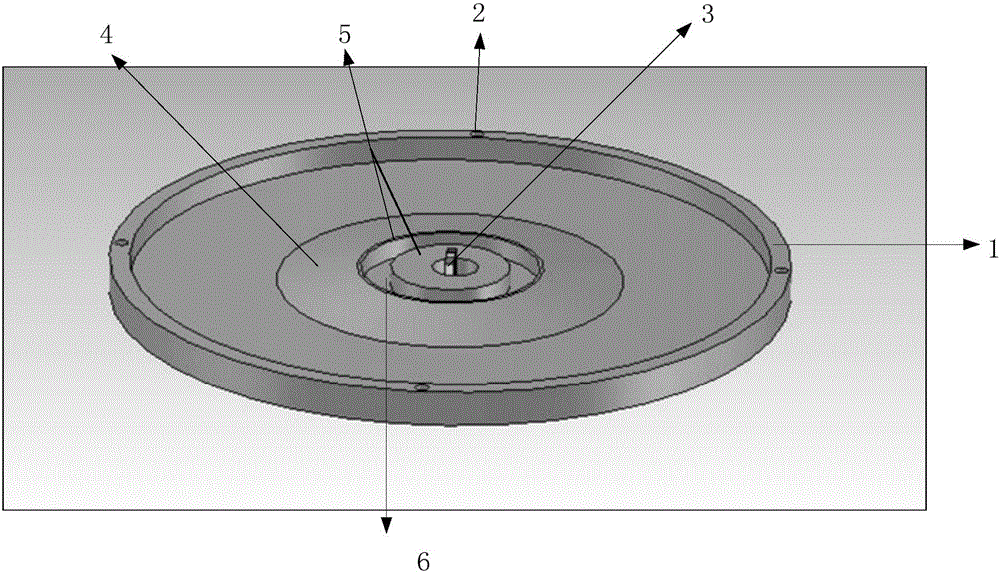

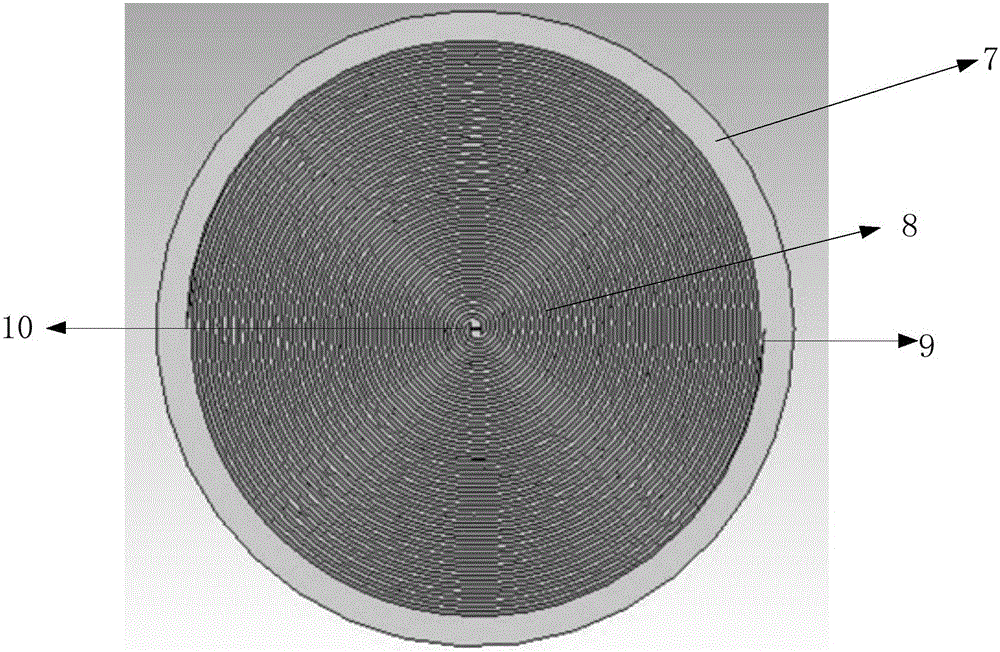

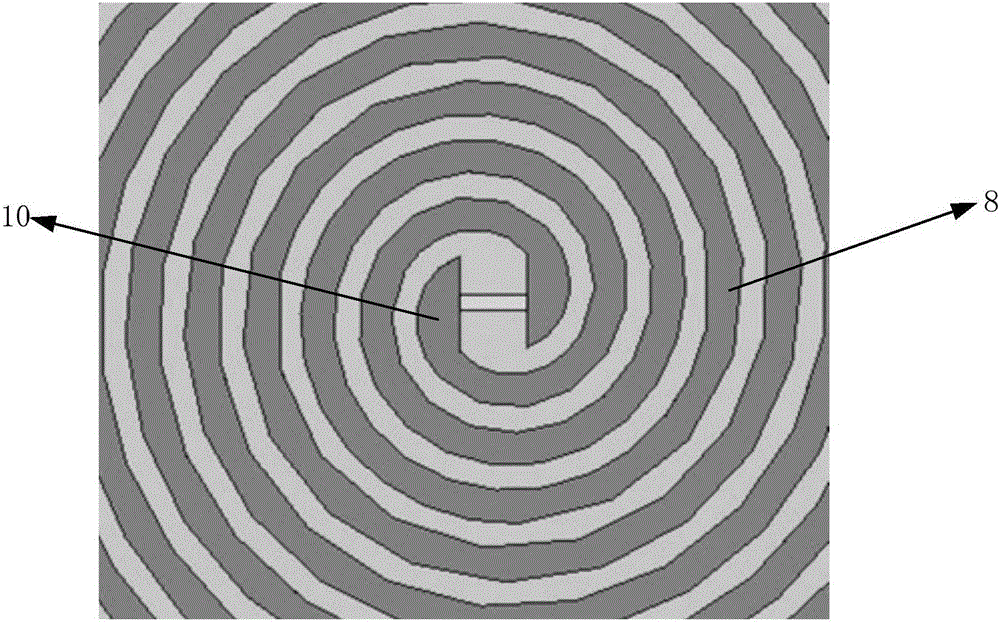

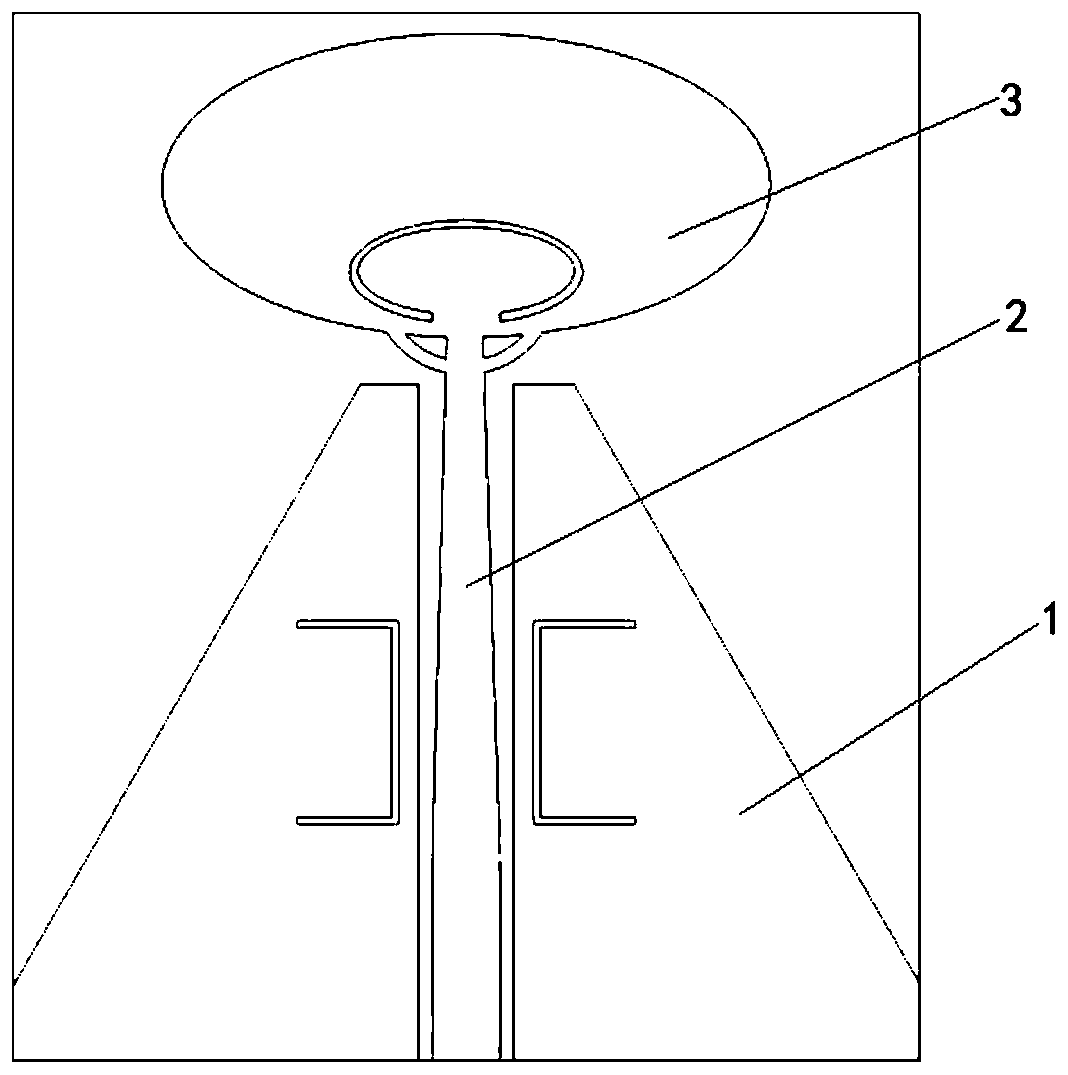

Ultra-wideband low-profile circularly-polarized two-arm spiral antenna

InactiveCN105870605ALow return lossHigh gainRadiating elements structural formsAntennas earthing switches associationUltra-widebandDielectric substrate

The invention belongs to the technical field of antennas, provides an ultra-wideband low-profile circularly-polarized two-arm spiral antenna, and aims at solving the contradiction of consideration of ultra-wideband, low profile, circular polarization and high gain development of an existing spiral antenna. The spiral antenna comprises a back cavity, a radiator dielectric substrate, an antenna spiral arm, a balun and a coaxial joint, wherein a feeding port is formed in the center of the radiator dielectric substrate; the antenna spiral arm is located on the upper surface of the radiator dielectric substrate and is connected with the upper end of the balun through the feeding port; the balun is located in the back cavity; the lower end of the balun is connected with the coaxial joint; the back cavity comprises a cylinder and a slope; the cylinder is arranged at the center of the back cavity; the slope is connected with the cylinder; the cylinder and the slope jointly form a circular truncated cone; an annular groove and a window are formed in the cylinder; and the window is used for arranging the balun. By the spiral antenna provided by the invention, the performance requirements of the wide band, low profile, circular polarization and high gain of the spiral antenna are well considered; and meanwhile, the frequency band bandwidth of the antenna is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

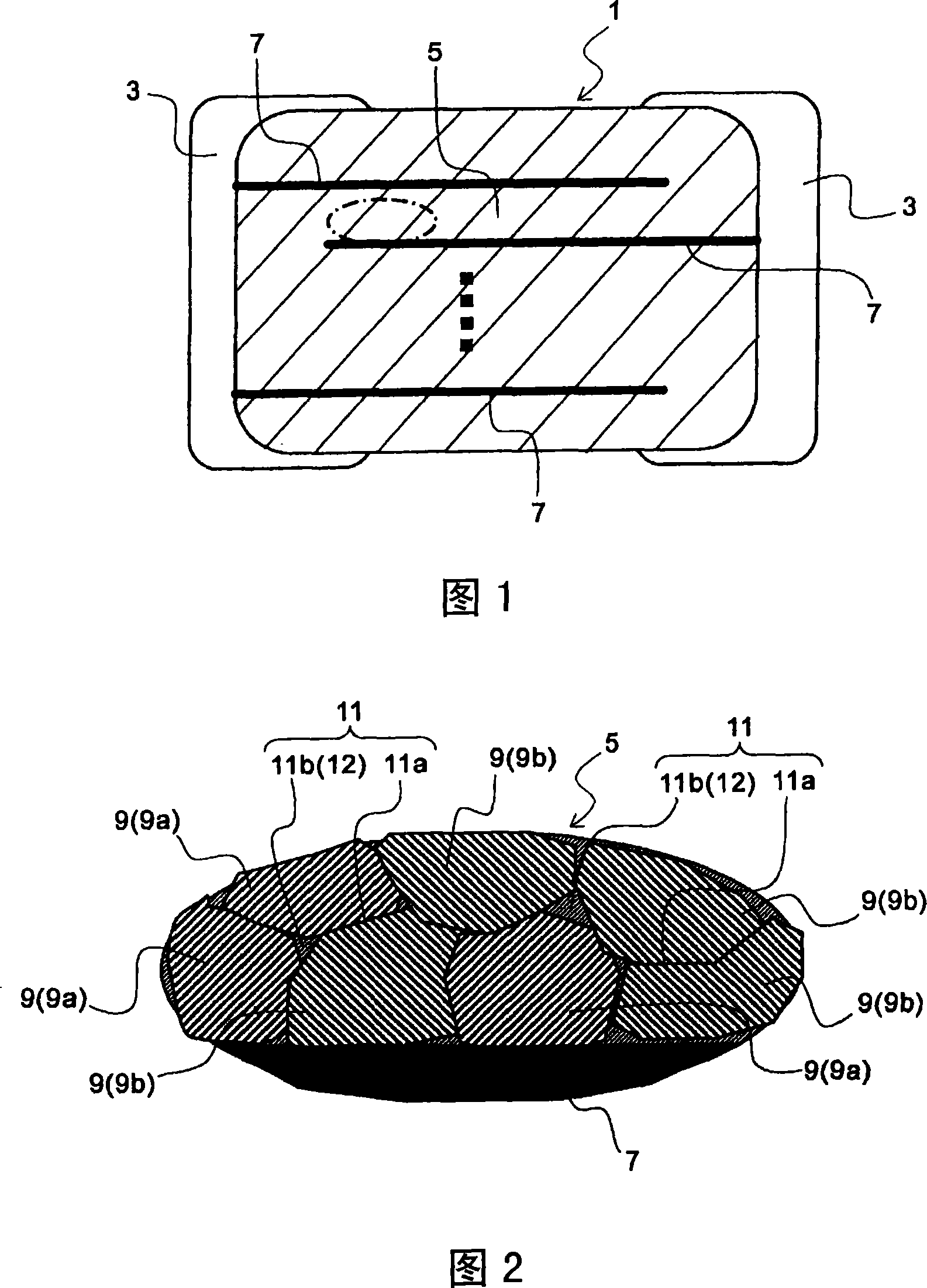

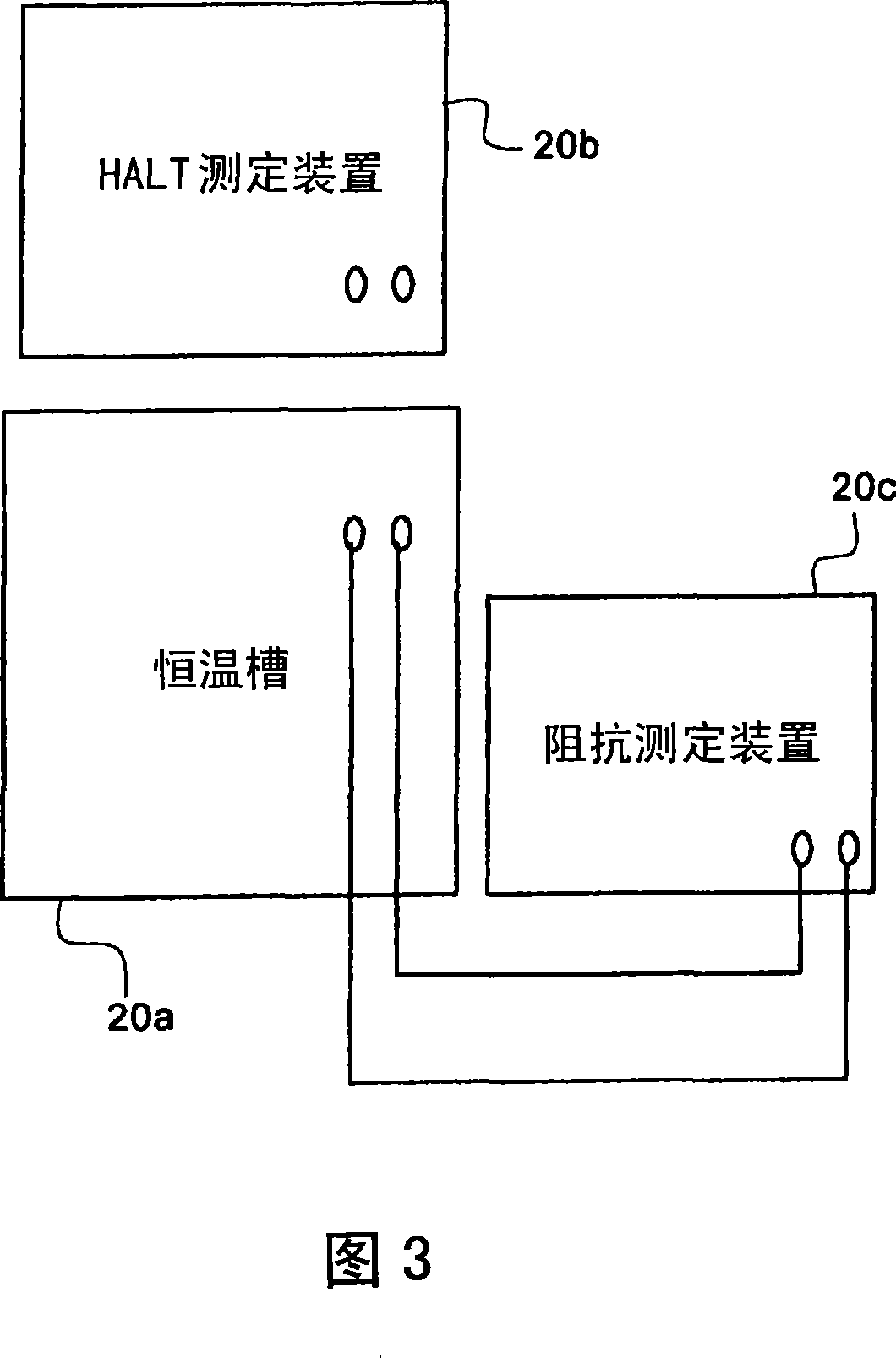

Laminated ceramic capacitor and process for producing the same

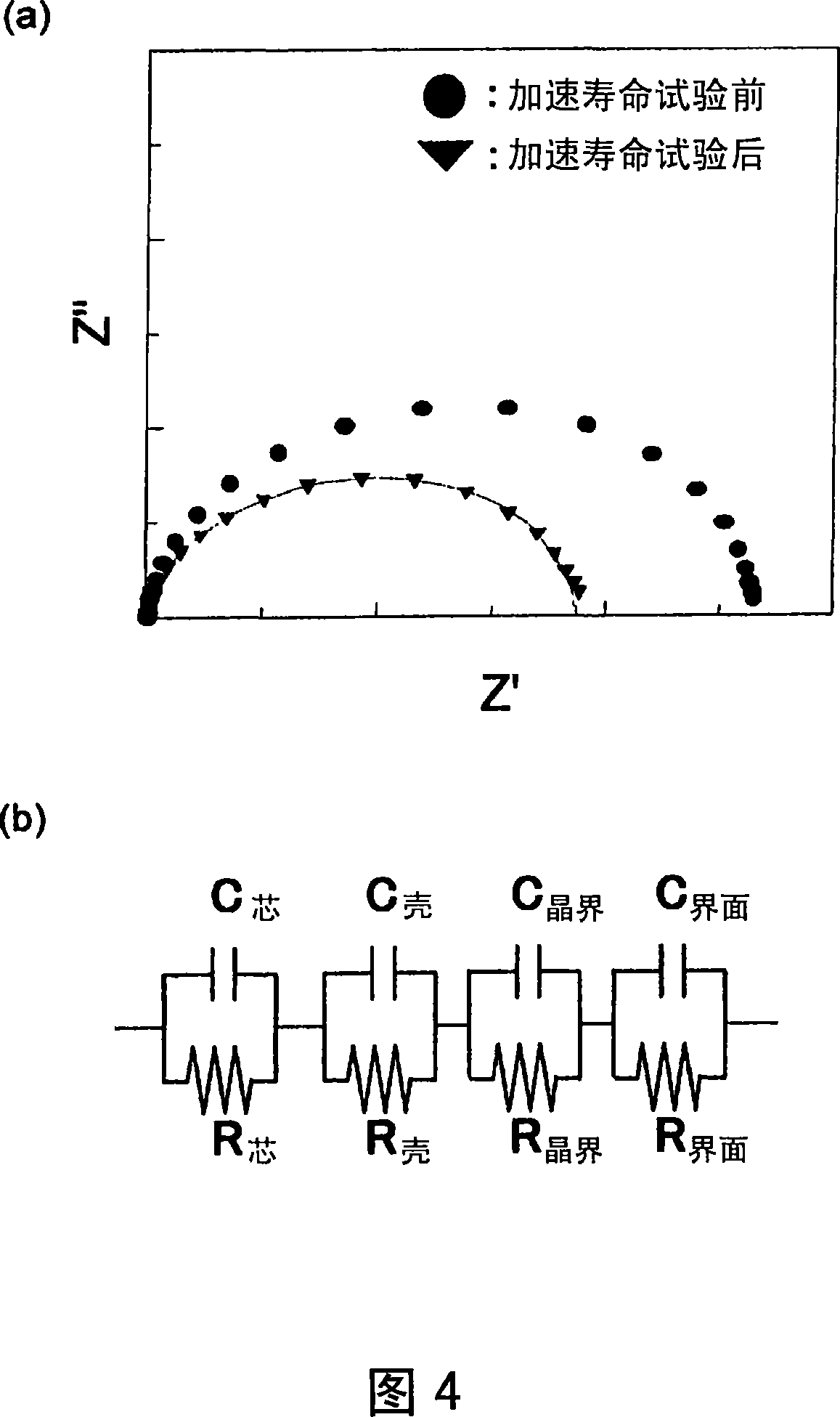

ActiveCN101147216AReduced insulation performanceImprove featuresFixed capacitor dielectricStacked capacitorsTriple pointMetallurgy

This invention provides a laminated ceramic capacitor comprising a capacitor body. The capacitor body comprises alternately stacked dielectric layers and inner electrode layers. The dielectric layer comprises a plurality of crystal grains and a grain boundary phase. The grain boundary phase comprises interfacial grain boundaries and triple point grain boundaries formed by the plurality of crystal grains adjacent to each other. An Si-Ba-O compound is formed at the triple point grain boundaries in a proportion of not less than 5% of the total number of triple point grain boundaries per unit area of the dielectric layer. Thus, a laminated ceramic capacitor, which has high specific permittivity and is excellent in temperature characteristics and high-temperature load test properties, can be provided.

Owner:KYOCERA CORP

Electronic ID tag and co-operating antenna

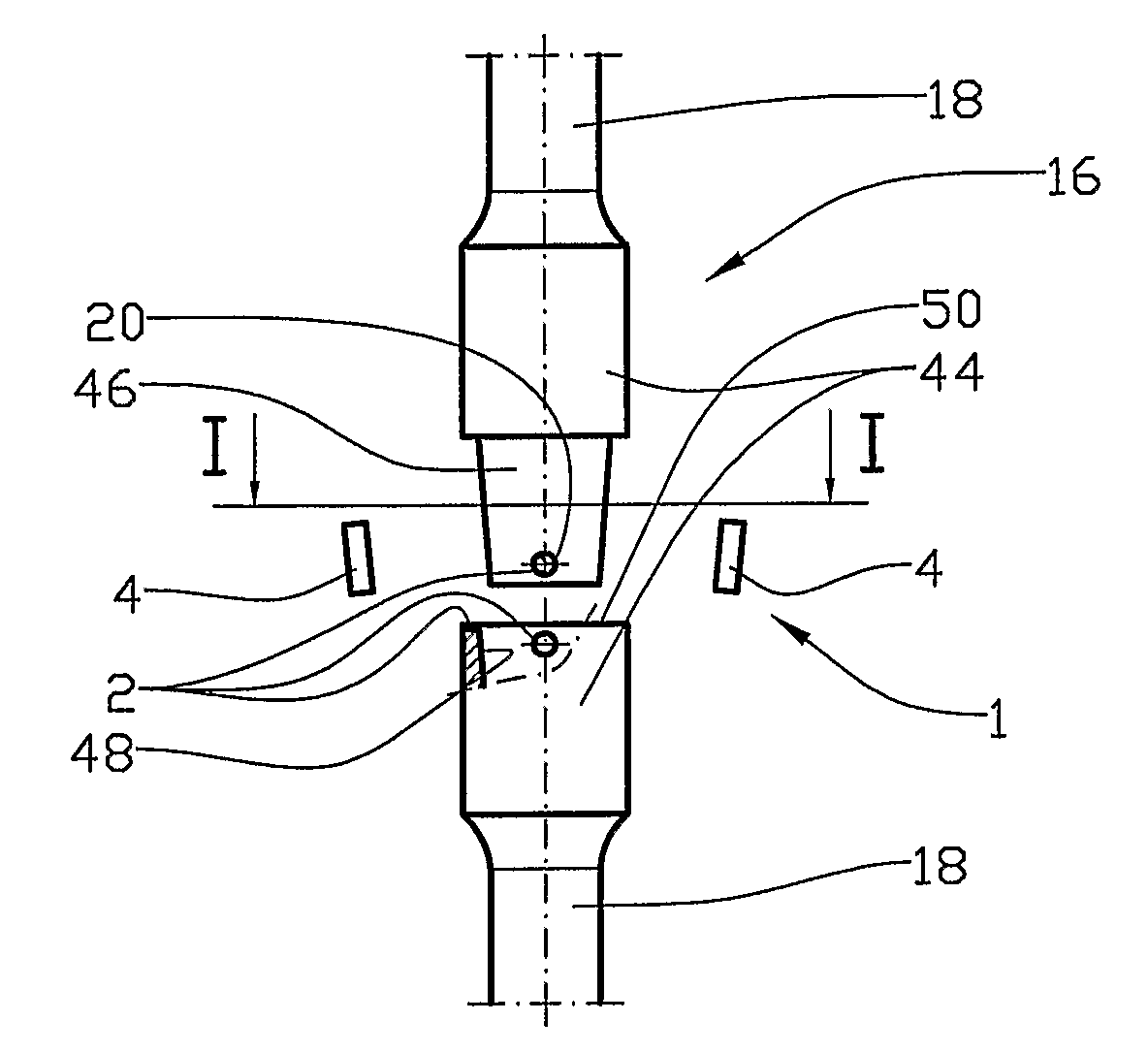

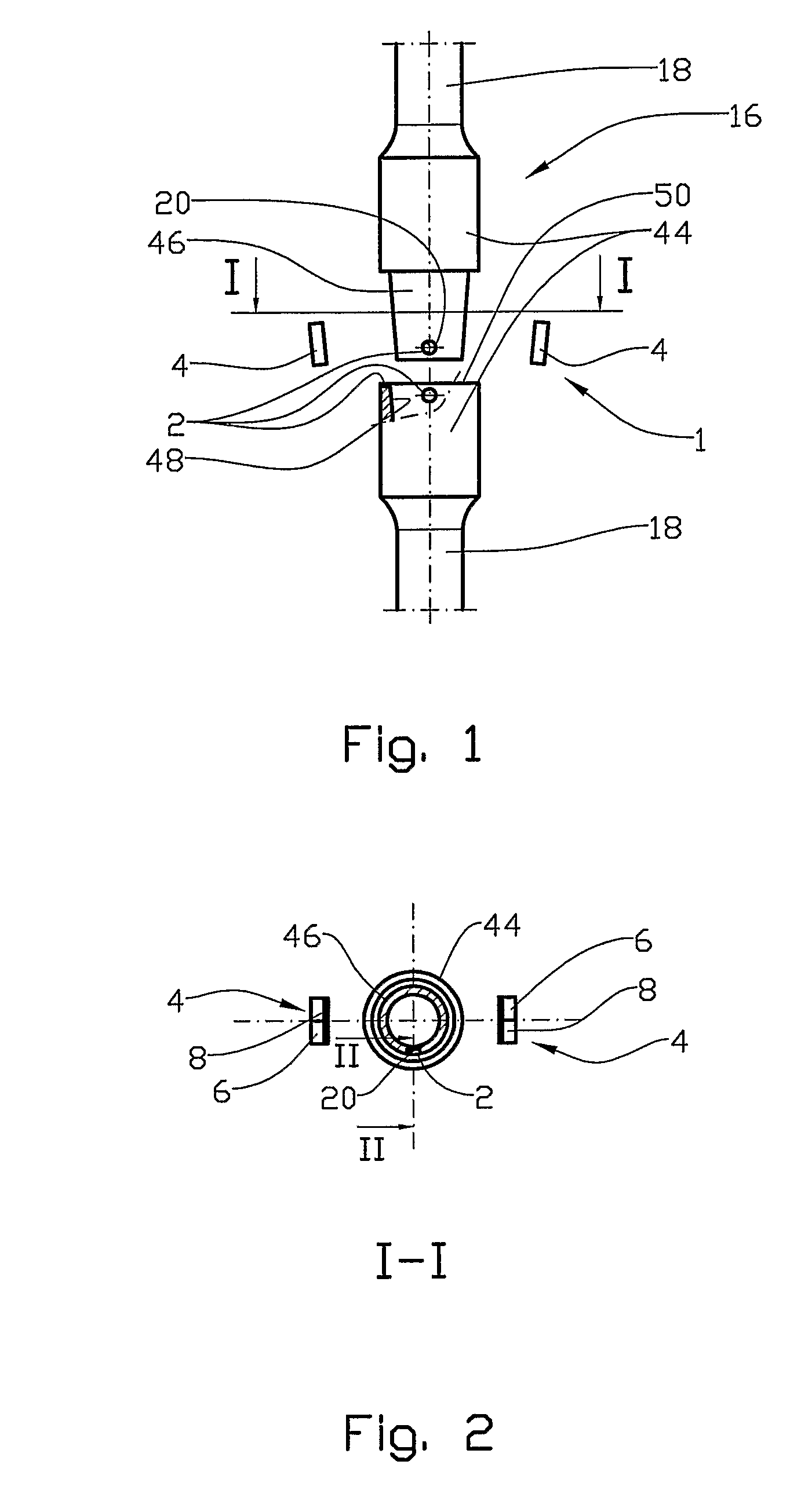

ActiveUS7688210B2Increase rangeLow dielectric lossDrilling rodsConstructionsMechanical wearGround plane

An electronic ID tag (2) for mounting in a body (18), in which at least the identity of the body (18) is to be remotely readable, the electronic ID tag (2) including an identifiable chip (24) which is electrically connected to at least one adjacent antenna (26), the identifiable chip (24) being arranged to receive energy via the adjacent antenna (26) and by means of this energy to transmit, via the adjacent antenna (26), a signal including the identity of the electronic ID tag to a distant antenna (1), and there being arranged, between the adjacent antenna (26) and the identifiable chip (24) and between the identifiable chip (24) and a ground-plane plate (28) impedance-matched inductances (34, 40), the electronic ID tag (2) being placed, with advantage, in the box portion or pin (44) of a body (18), whereby it is protected against mechanical wear.

Owner:TRAC ID SYST

Capacitive touch screen and manufacture method thereof

InactiveCN102207805AImprove efficiencySuitable for mass productionInput/output processes for data processingGlass coverHigh volume manufacturing

The invention relates to a capacitive touch screen, comprising an ITO (Indium Tin Oxide) glass substrate provided with a printed circuit layer on the front side, wherein a PET (polyethylene glycol terephthalate) film is adhered on the outer side surface of the printed circuit layer. The invention also provides a manufacture method of the capacitive touch screen, which comprises the following steps of: binding: forming the printed circuit layer on the ITO glass substrate, and then binding a flexible circuit board to the ITO glass substrate to be connected with the printed circuit layer; and film sticking: sticking an optical clear resin to the PET film, and cutting the PET film into a small piece matching to the ITO glass substrate in size, and sticking the small PET film to the outer side surface of the printed circuit layer on the ITO glass substrate. In the invention, the traditional glass cover plate is replaced by the PET film, the device and the process operation for the sticking step are simplified; and the invention has low cost and high efficiency and is suitable for the mass production. The sticking of the PET film belongs to the film-glass sticking manner, and the product yield is up to 99%. The image distortion of the product is not easy to occur during using. During assembling, the casing presses against the soft PET film having a good buffer action, and the entire capacitive screen cannot be crushed.

Owner:GANZHOU DPT TECH

Low temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and preparation thereof

InactiveCN101475371ALow costExcellent electrical performanceCeramicsDielectric antennasCeramic capacitor

The invention discloses a low-temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and a preparation method thereof. The formula of raw materials of the ceramic material comprises the following compositions: 30 to 45 percent of zinc oxide, 2 to 14 percent of magnesium oxide, 50 to 60 percent of titania and an auxiliary sintering agent. The preparation method comprises: taking the zinc oxide, basic magnesium carbonate and the titania as raw materials, mixing the raw materials, adding a grinding aid for ball milling, drying, sieving and presintering, and obtaining clinker; and mixing the obtained clinker with the titania, the auxiliary sintering agent and an additive, performing drying, granulation and press forming after secondary ball milling, finally sintering the mixture for 2 to 8 hours at a temperature of between 900 DEG C and 1,000 DEG C, and obtaining the ceramic material. The ceramic material prepared by the method has the advantages of superior microwave dielectric property, low sintering temperature, low cost and the like, and is suitable for microwave devices such as multi-layer ceramic capacitors, filters, resonators and dielectric antennas.

Owner:SOUTH CHINA UNIV OF TECH

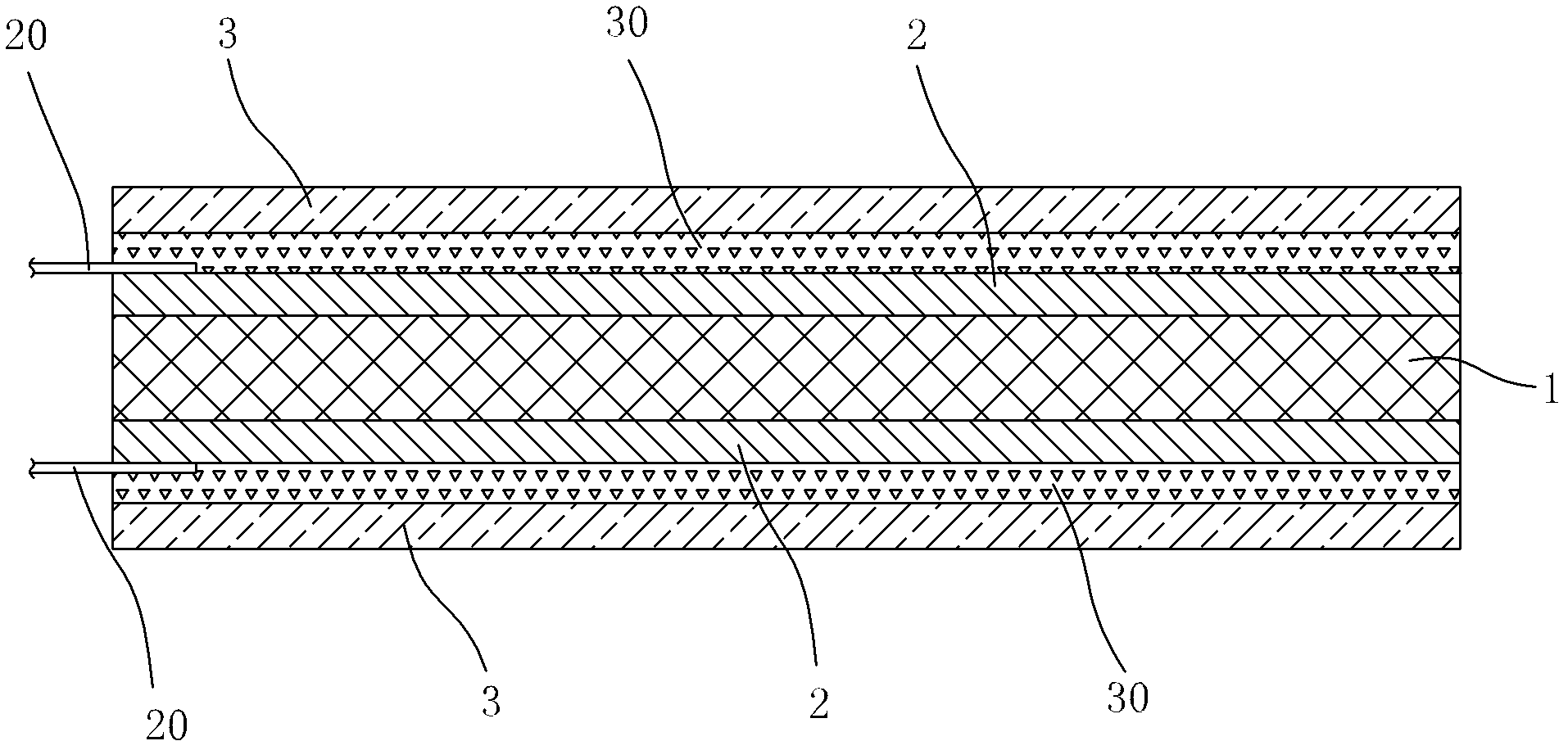

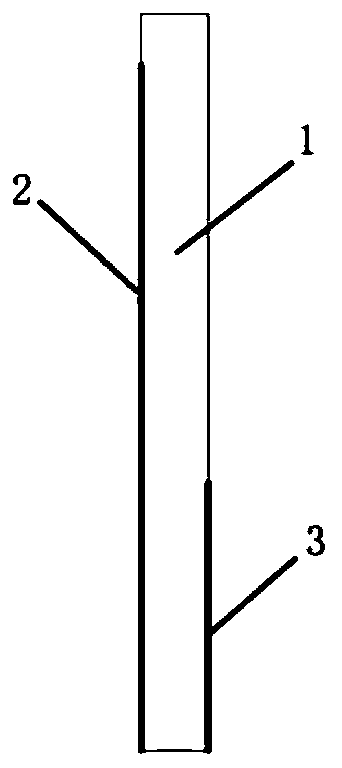

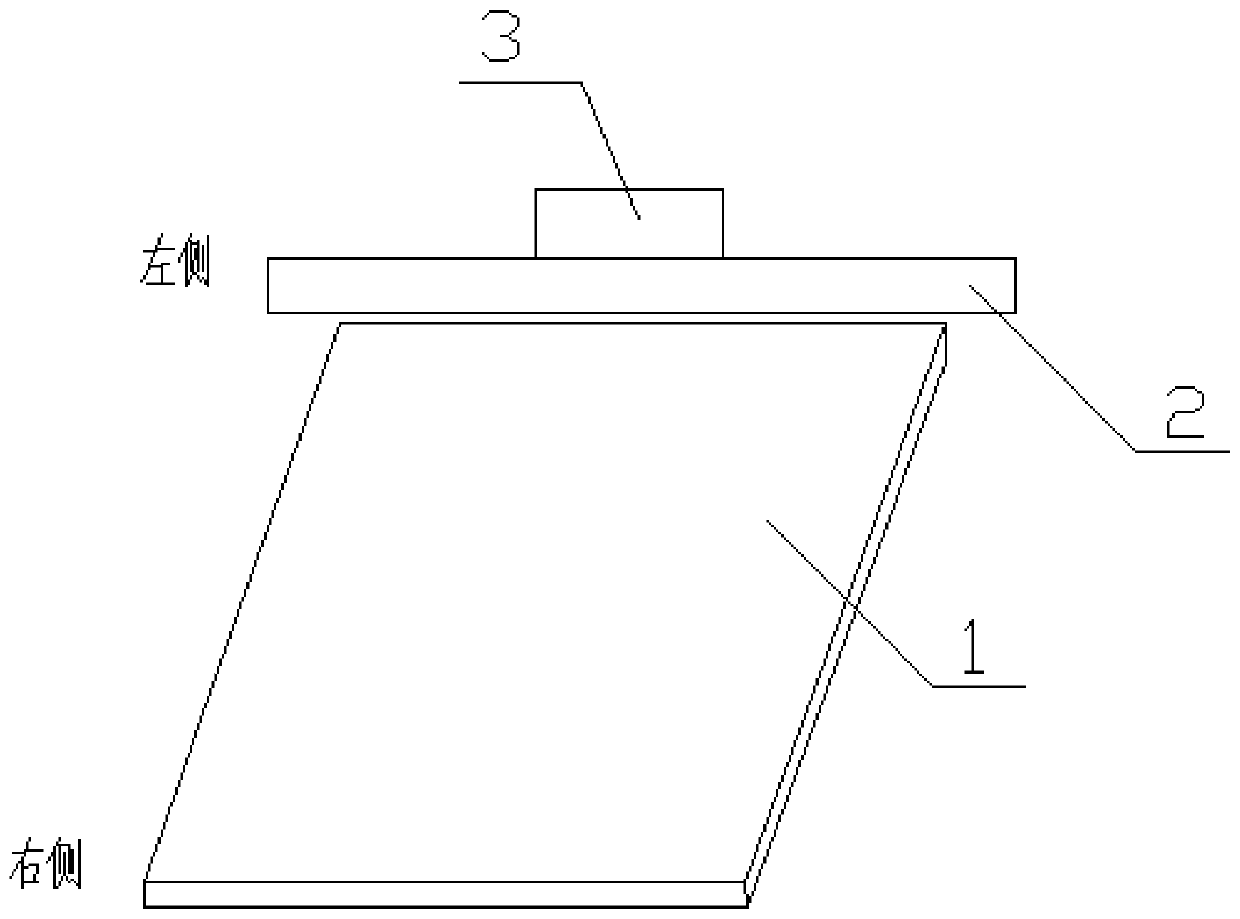

Flexible 5G multi-band antenna based on liquid crystal polymer

PendingCN109509975AImprove featuresSmall coefficient of thermal expansionSimultaneous aerial operationsRadiating elements structural formsMulti bandChinese characters

The invention relates to a flexible 5G multi-band antenna based on a liquid crystal polymer. The flexible 5G multi-band antenna include a substrate and an antenna. The substrate is a liquid crystal polymer material, the antenna comprises a main radiation patch and coplanar waveguide feeding parts, the main body of the main radiation patch and main bodies of the coplanar waveguide feeding parts arearranged in a way shaped like a Chinese character pin, and the coplanar waveguide feeding parts are positioned on the bottom left and the bottom right of the main radiation patch. The main radiationpatch is composed of two parts: one part is L-shaped and extends upwards from the left of the main body of the main radiation patch, and the other part is a rectangular radiation patch and is locatedin the center of the whole antenna. The bottom right coplanar waveguide feeding part is provided with an L-shaped branch, extending from the top to the left of the main body of the coplanar waveguidefeeding part. Compared with the prior art, the flexible 5G multi-band antenna has the advantages of flexible material, simple structure, good anti-jamming property and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

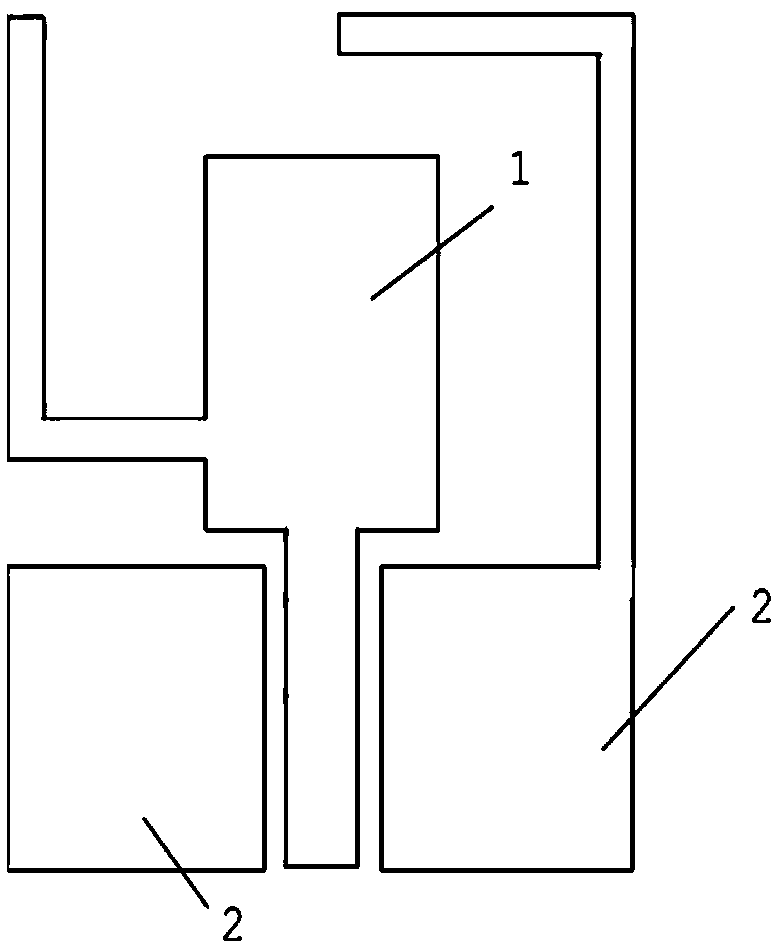

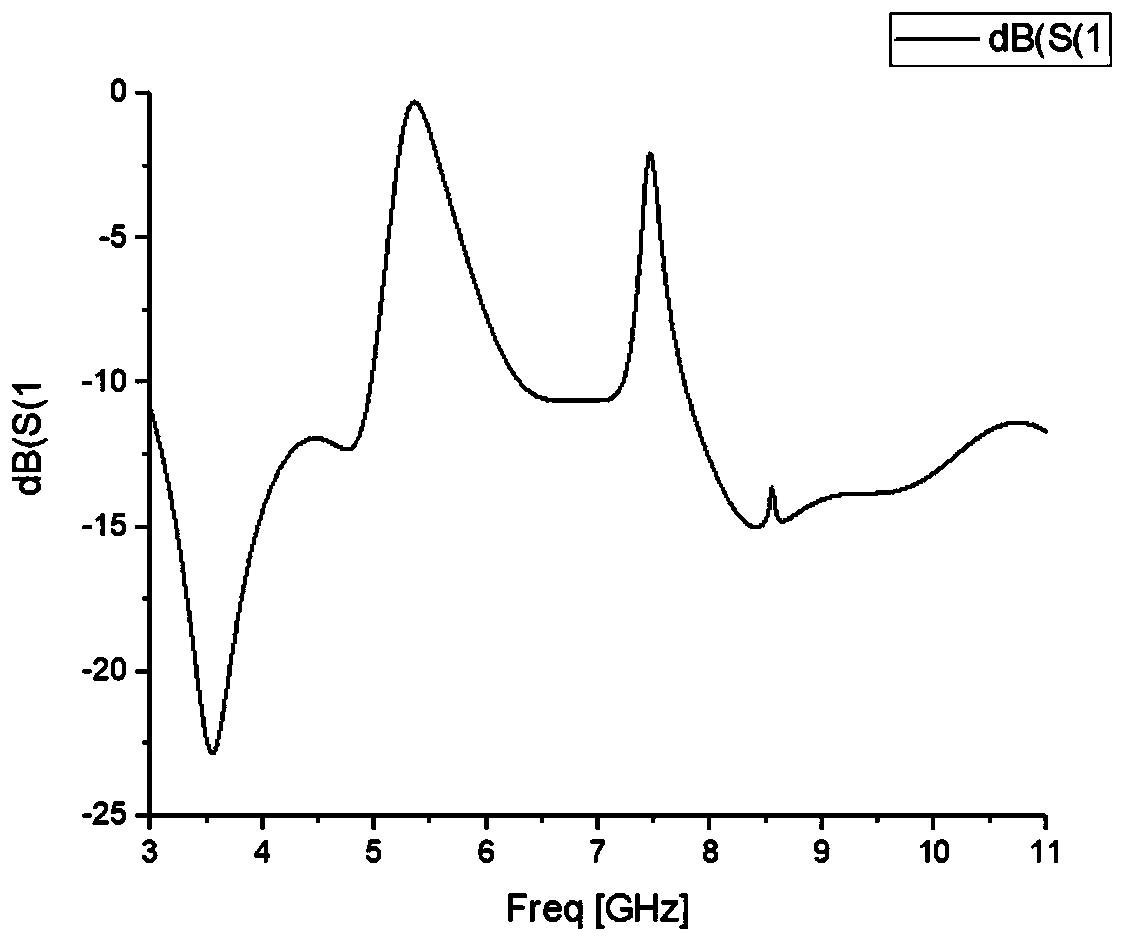

Double-notch ultra-wideband antenna based on liquid crystal polymer

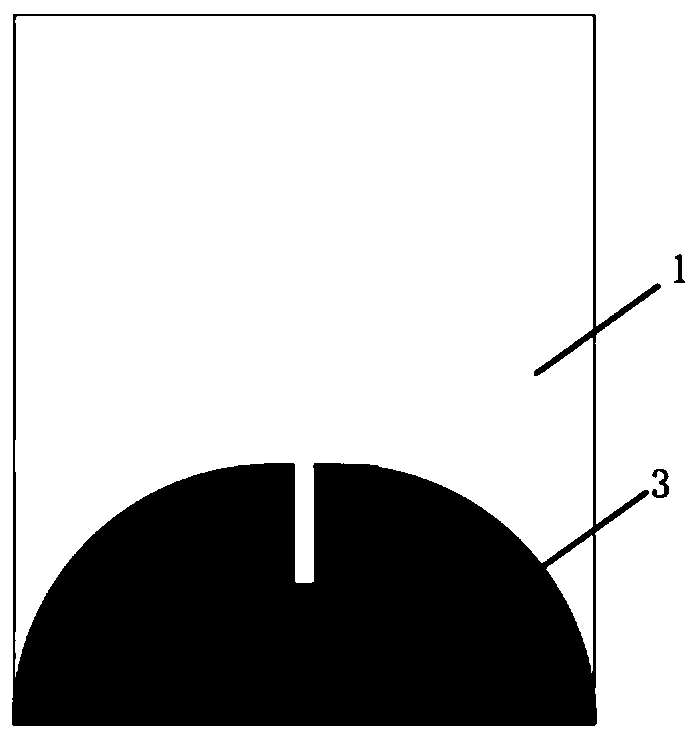

PendingCN109755733ASuppress interferenceSmall sizeRadiating elements structural formsAntenna earthingsUltra-widebandLiquid-crystal display

The invention relates to a double-notch ultra-wideband antenna based on a liquid crystal polymer. The double-notch ultra-wideband antenna comprises a substrate, a grounding plate, a feeder line and aradiation patch, wherein the grounding plate, the feeder line and the radiation patch are arranged on the substrate; the substrate is made of a liquid crystal polymer board; the radiation patch is ofan oval structure with an opening resonance ring, and the opening resonance ring is an oval with a notch, wherein the notch faces the connecting position of the radiation patch and the feeder line; and the grounding plate is located on the two sides of the feeder line. Compared with the prior art, the dielectric substrate material uses the liquid crystal polymer, the opening resonance ring is adopted on the oval patch, and a U-shaped groove structure is formed on the grounding plate, so that the antenna has the advantages of being low in cost, high in performance, small in size, double in notches and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

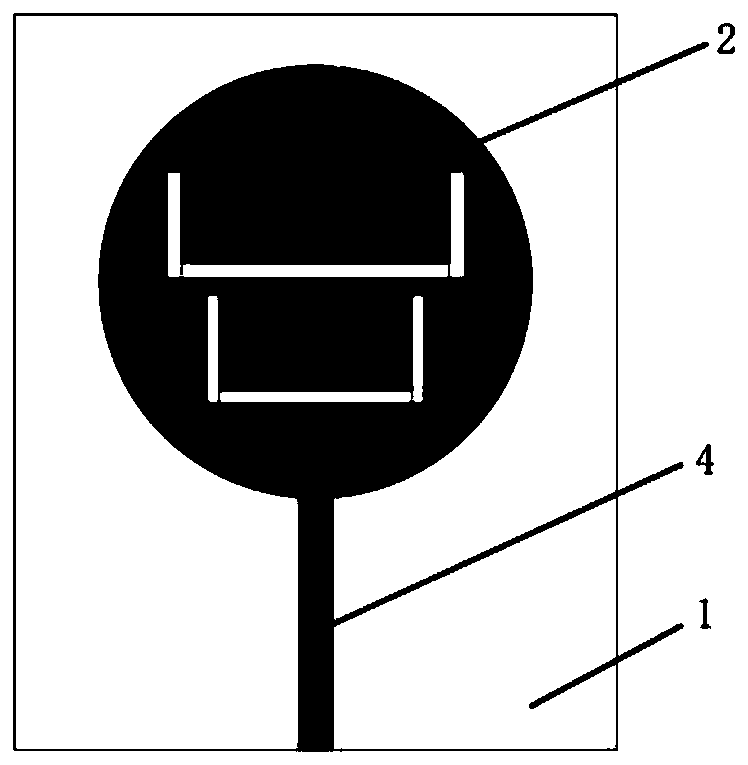

Flexible multi-frequency antenna based on liquid crystal polymer substrate

PendingCN109742534AGood flexibilityBend at willSimultaneous aerial operationsRadiating elements structural formsState of artDielectric loss

The invention relates to a flexible multi-frequency antenna based on a liquid crystal polymer substrate. The antenna comprises the substrate, an antenna body and a grounding plate; the substrate is made of a flexible material; the antenna body is a circular radiation patch located on the front surface of the substrate; two U-shaped grooves are formed in the antenna body; a feeder line is arrangedon one side of the antenna body; and the grounding plate is positioned on the back surface of the substrate. Compared with the prior art, the antenna adopts an LCP material, and has the advantages oflow dielectric loss, low hygroscopicity, high temperature resistance, chemical corrosion resistance, small thermal expansion coefficient, small thickness and the like; and the antenna is the circularradiation patch, the improved circular grounding plate is adopted, and the two U-shaped grooves are added in the round patch, so that a three-frequency working characteristic can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

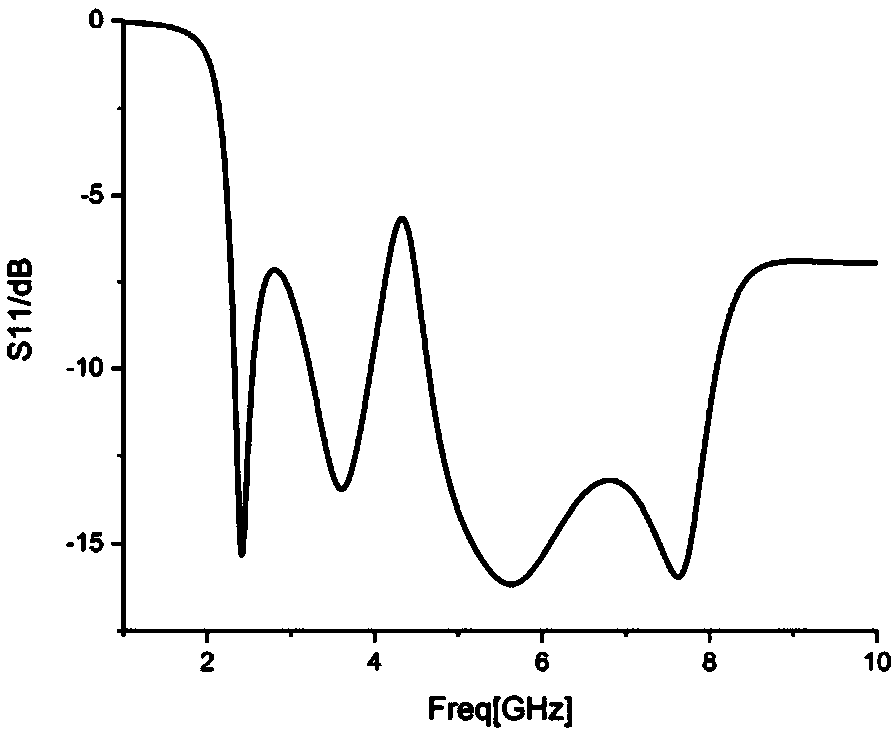

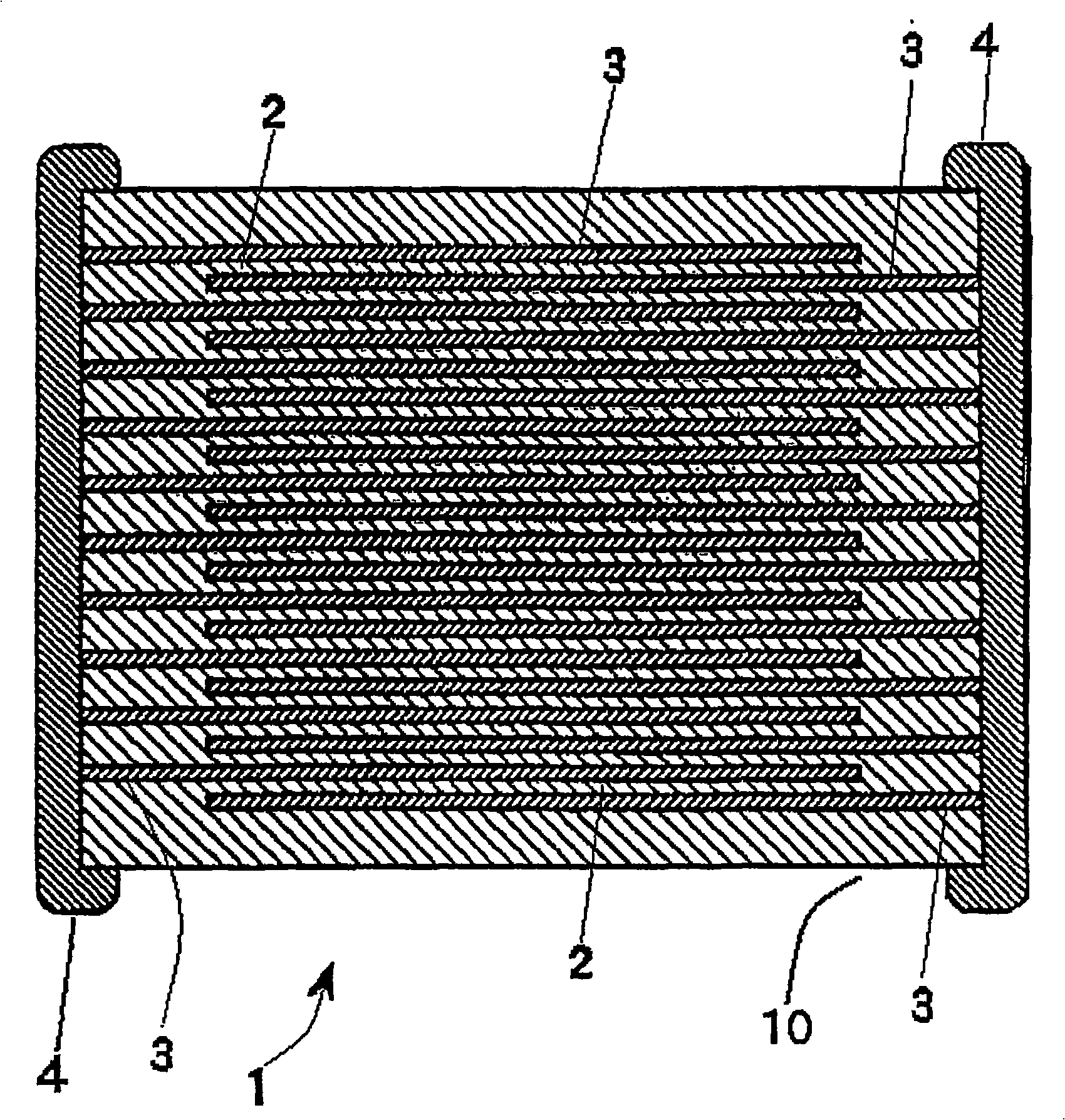

COG dielectric composition for use with nickel electrodes

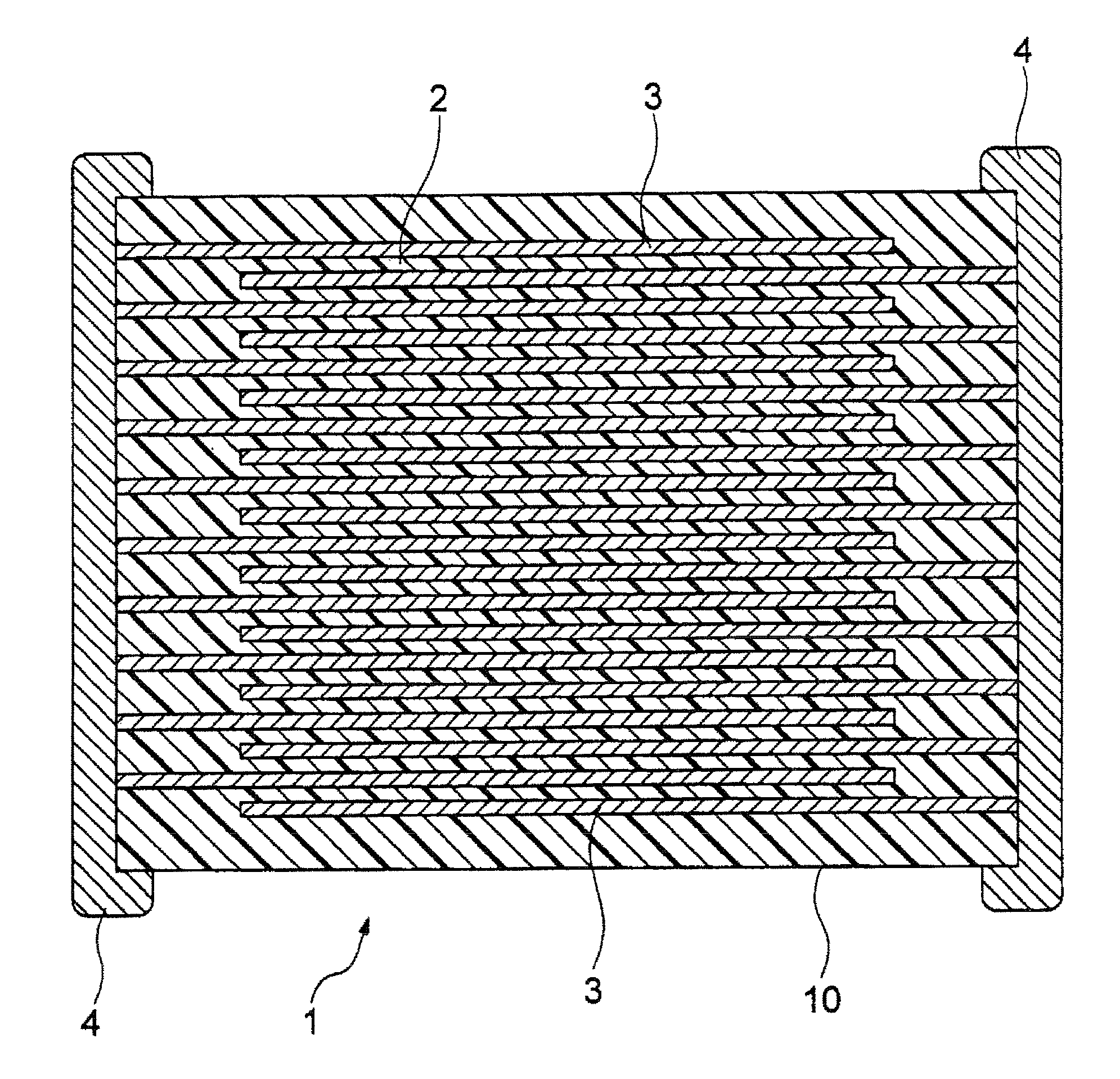

ActiveCN101272991AStable dielectric constantLow dielectric lossThin/thick film capacitorFixed capacitor dielectricLow dissipationElectrical connection

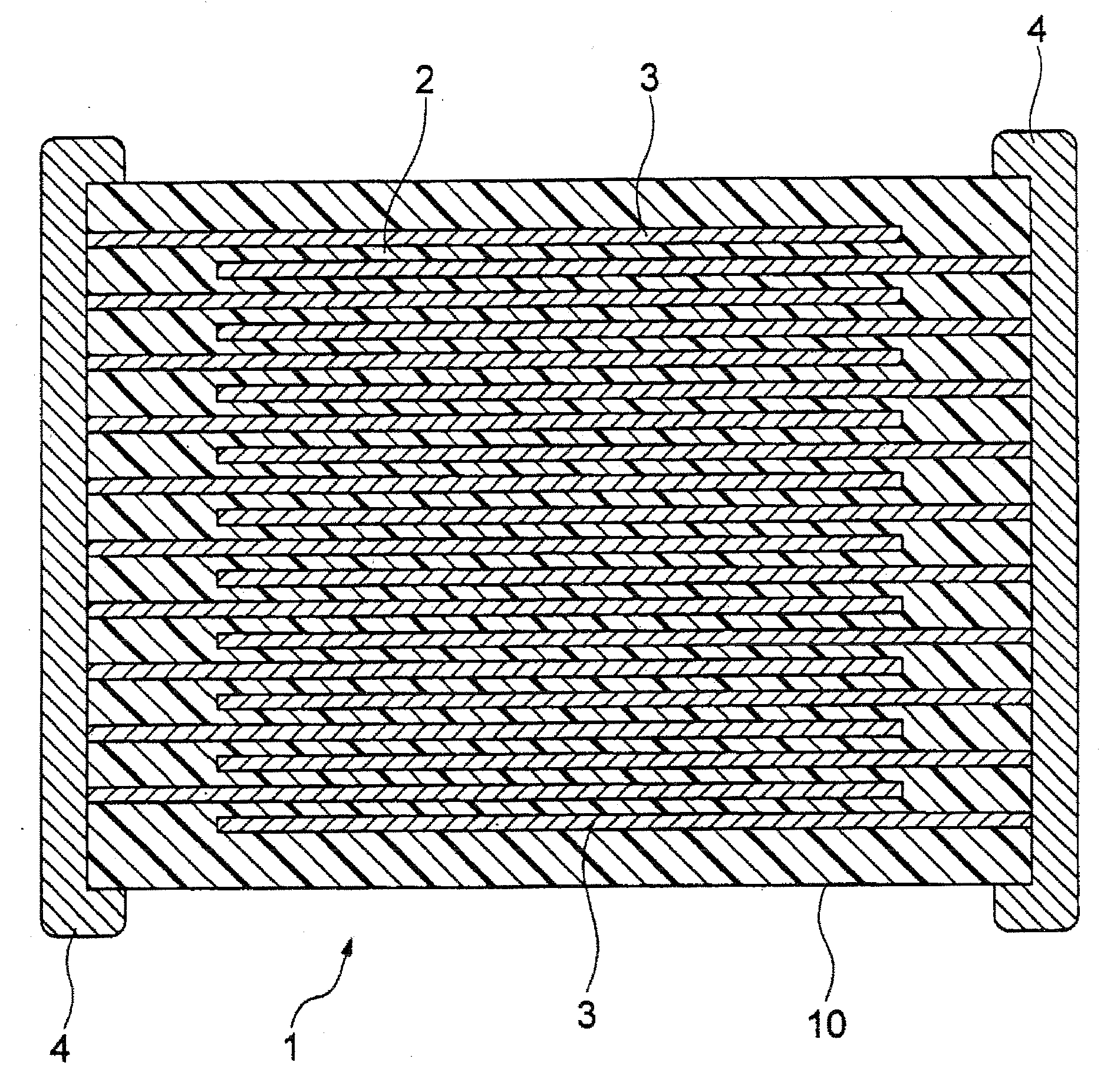

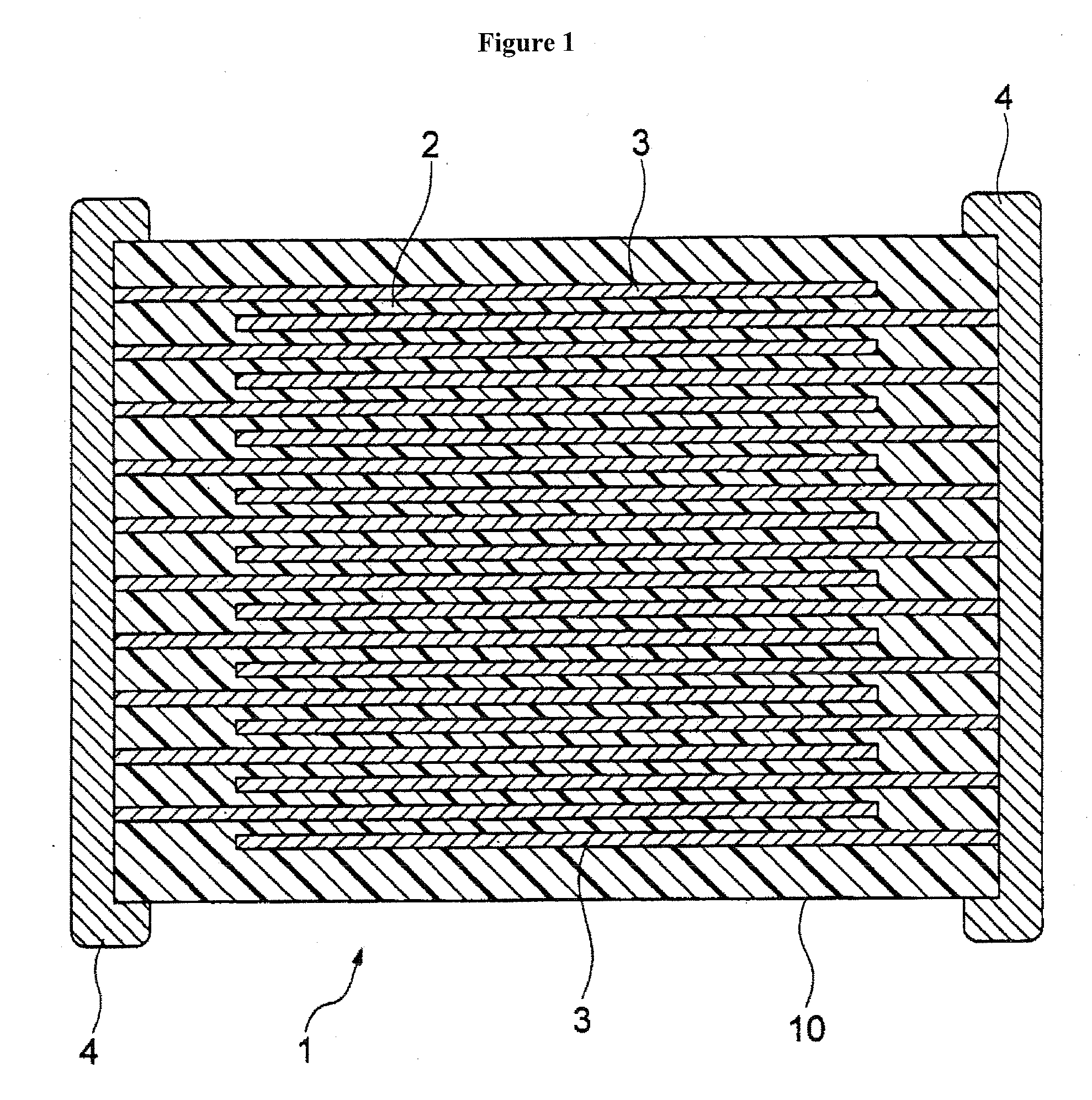

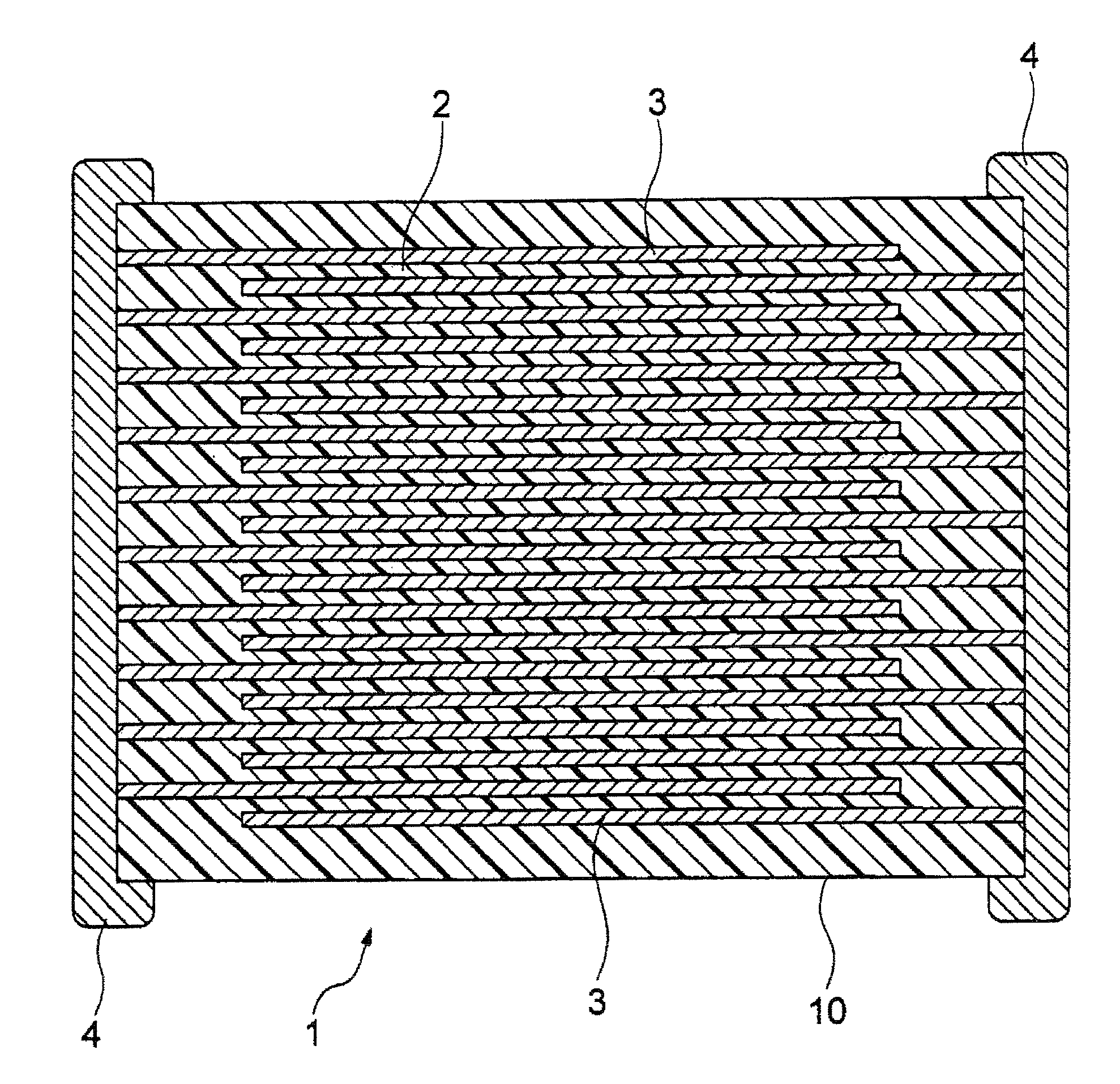

Multilayer ceramic chip capacitors which satisfy COG requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel and nickel alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a strontium ztrconate matrix doped with other metal oxides such as TiO2, MgO, B2O3, CaO, A12O3 SiO2, and SrO in various combinations. Figure 1 is a cross-sectional view of a multilayer ceramic chip capacitor (1) according to an embodiment of the invention External electrodes (4) of the capacitor (1) are disposed on side surfaces of the capacitor chip (1) and in electrical connection with internal electrode layers (3). The capacitor chip (1) has a plurality of alternately stacked dielectric layers (2).

Owner:FELLOWES INC

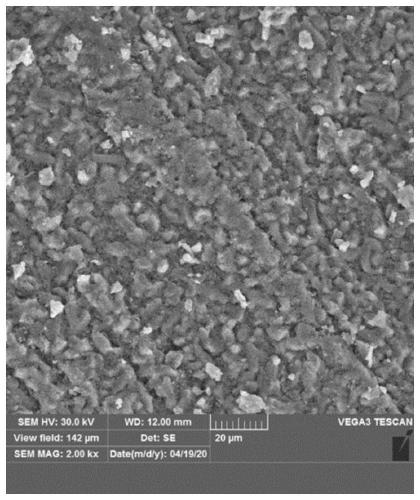

Microwave ceramic dielectric filter and processing forming method thereof

PendingCN111423239AUniform densityImprove mechanical propertiesWaveguide type devicesCeramic moldingDielectric body

The invention discloses a processing and forming method of a microwave ceramic dielectric filter and the microwave ceramic dielectric filter prepared by the method. The microwave ceramic dielectric filter comprises a ceramic dielectric body and a metal layer attached to the surface of the ceramic dielectric body, wherein the ceramic dielectric body is formed by mixing microwave ceramic powder witha ceramic forming agent at least containing a binder and then carrying out injection molding. The problems of inconsistent dry-pressing molding size shrinkage, local dielectric constant difference, incapability of molding complex shapes, non-uniform green body density and the like of the microwave ceramic dielectric filter can be solved.

Owner:SHENZHEN SUNLORD ELECTRONICS

Barium niobate sodium lead based glass ceramic material with high energy-storage density and preparation method thereof

ActiveCN110240409AHigh breakdown fieldStrong breakdown fieldFixed capacitor dielectricGlass shaping apparatusHigh energyVolumetric Mass Density

The invention relates to a barium niobate sodium lead based glass ceramic material with high energy-storage density and a preparation method thereof. The chemical ingredient of the material conforms to a chemical general formula of 21.25BaCO3-PbO-12.75Na2CO3-34Nb2O5-32SiO2. The raw materials are uniformly mixed and are dried; then, high-temperature melting is performed to obtain glass melt; the high-temperature melt is fast poured into a preheated mold; the residue stress in the glass body is removed through annealing treatment; then, the glass block body is cut into thin glass sheets with the same size and thickness; the thin glass sheets are subjected to controlled crystal separation to obtain the glass ceramic energy storage material. Compared with the prior art, the prepared glass ceramic energy storage material has the advantages of high dielectric constant, high energy storage density, low loss, high power density, good temperature stability and the like.

Owner:TONGJI UNIV

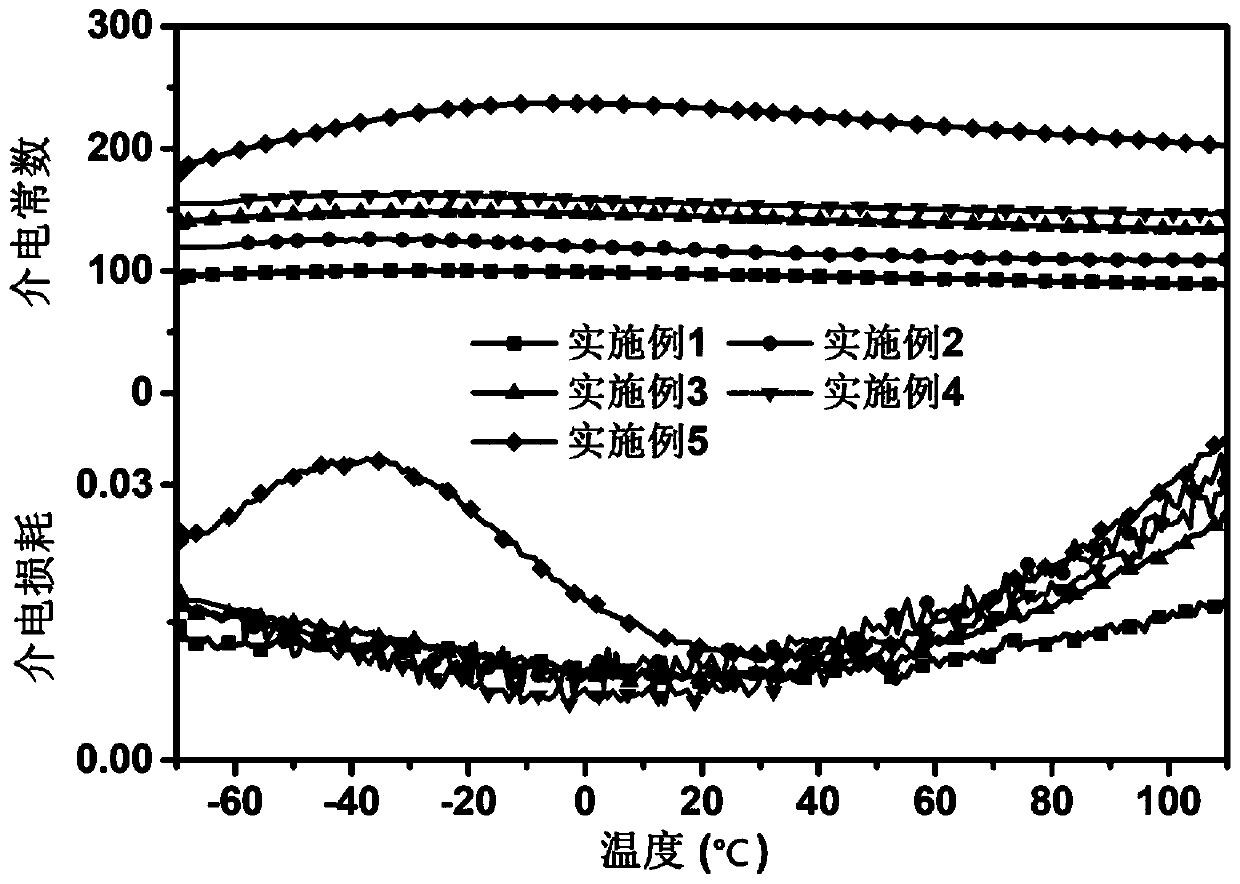

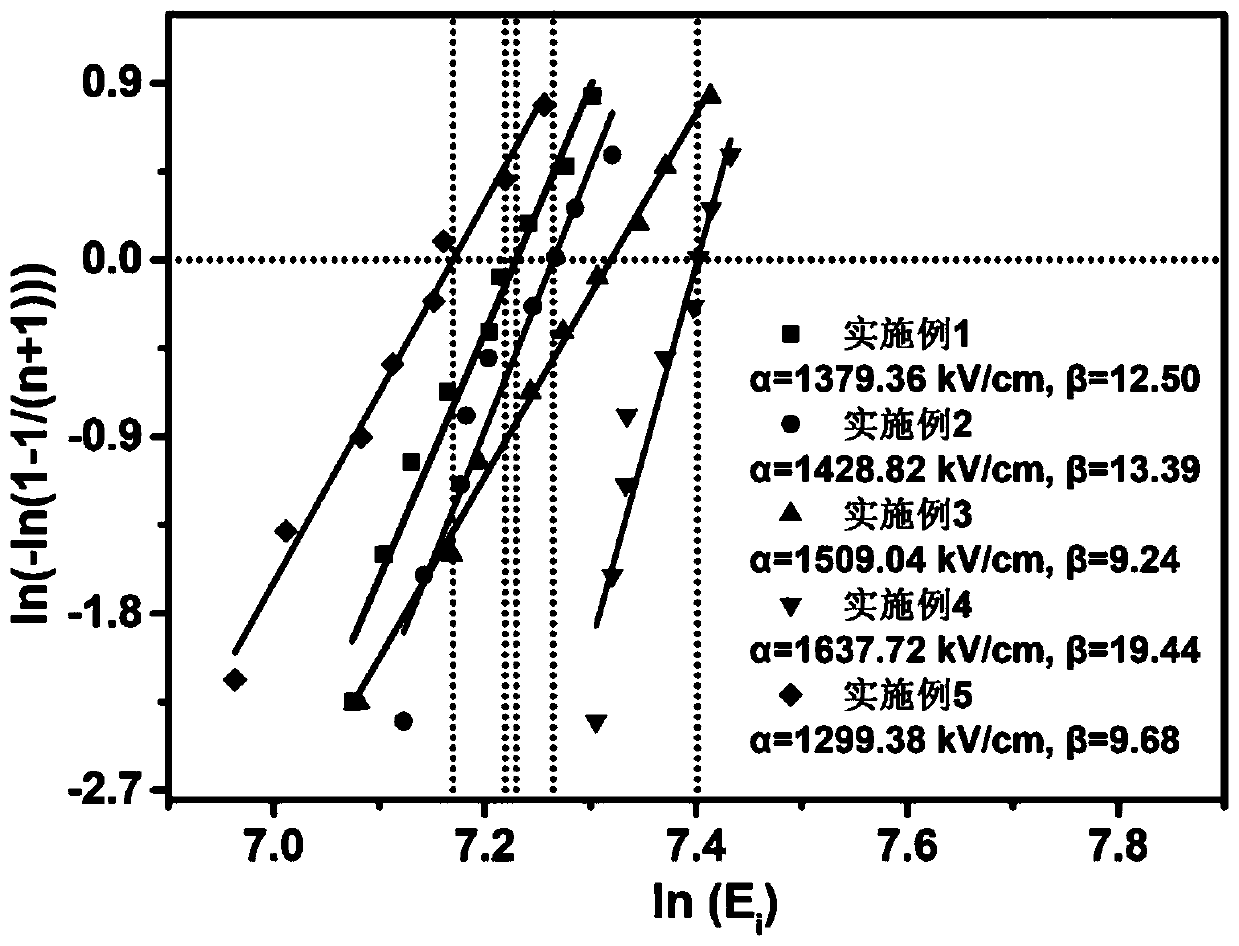

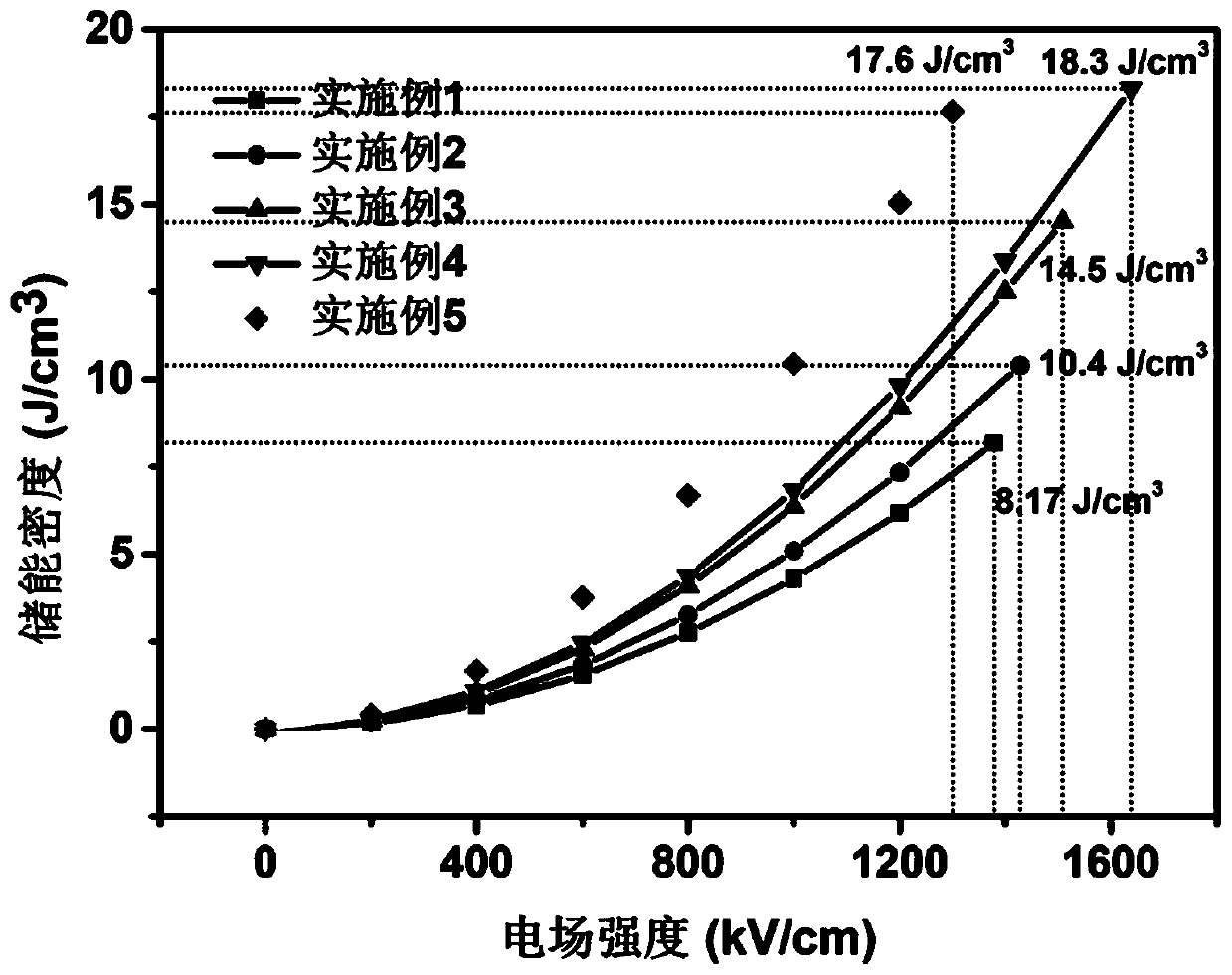

Bismuth barium sodium niobate-based glass ceramic material with high energy storage density, and preparation method and application thereof

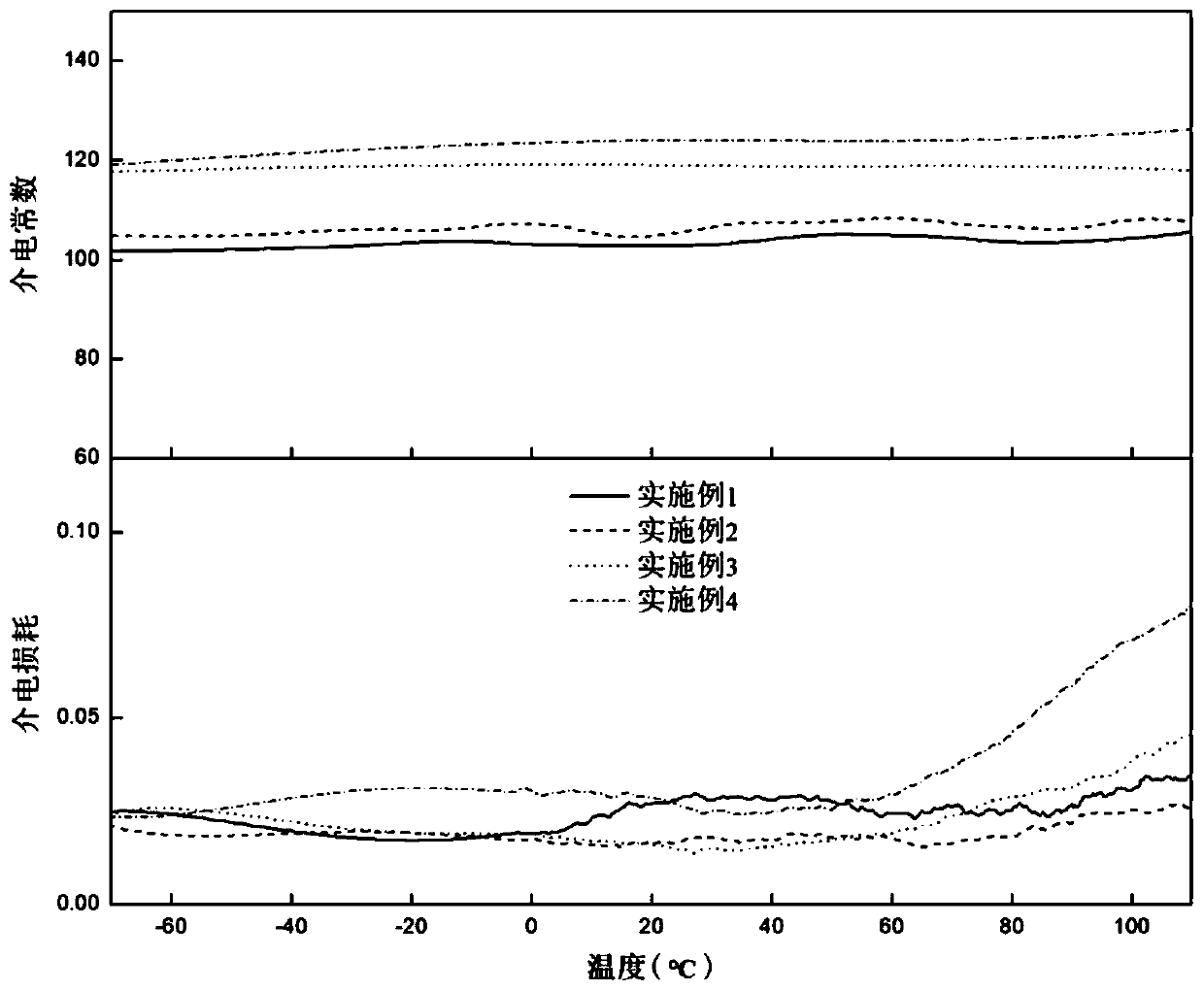

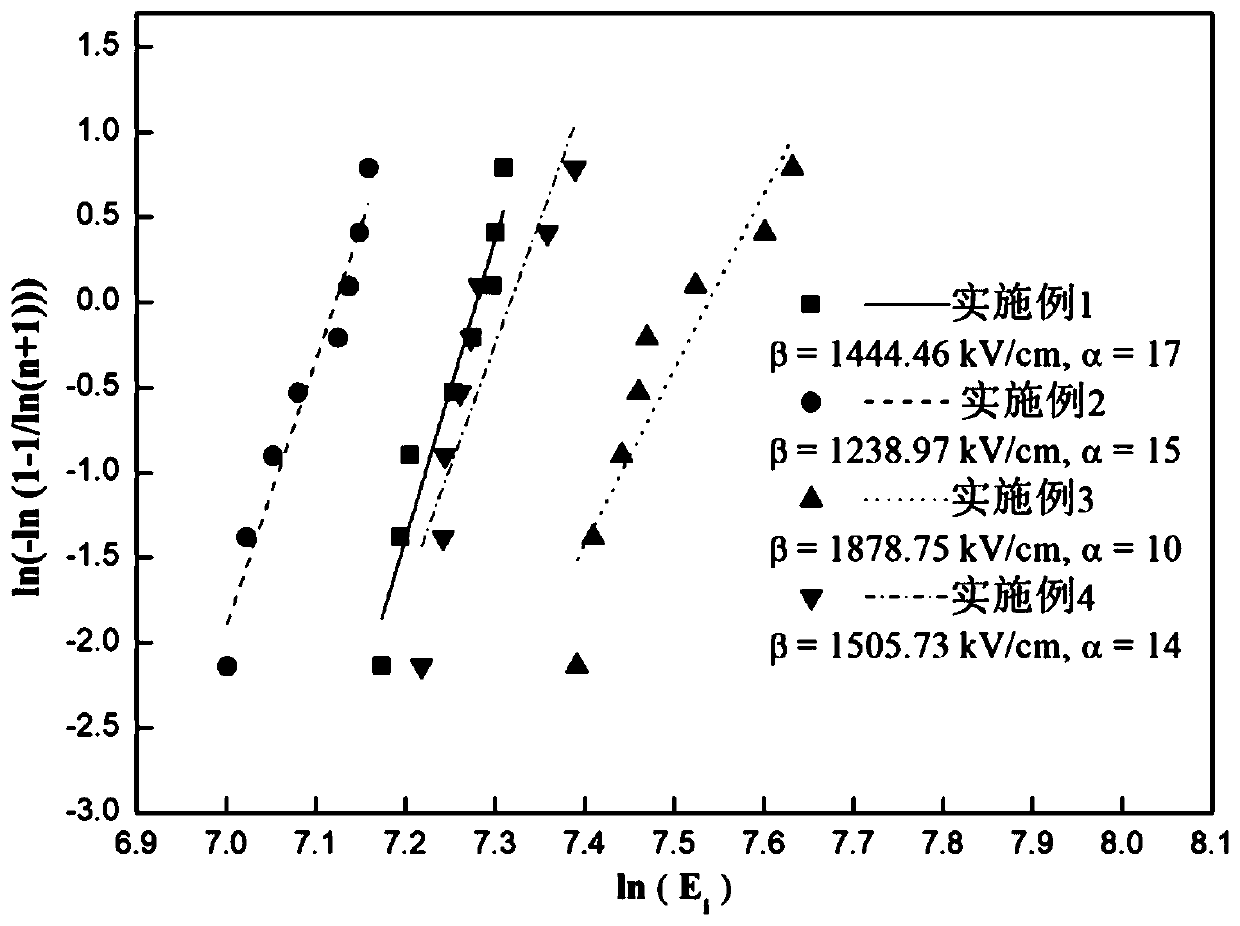

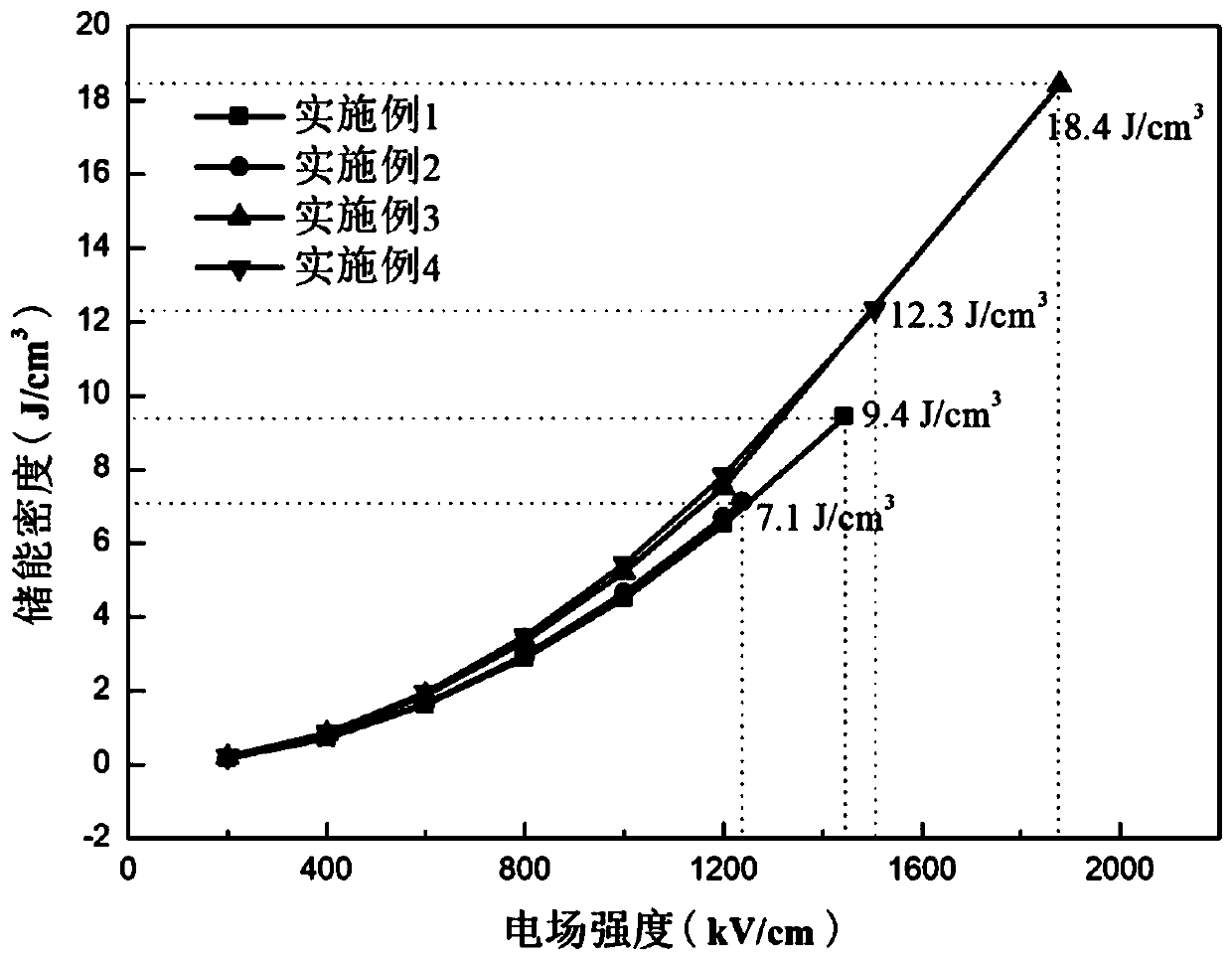

ActiveCN110451807AHigh dielectric constantHigh energy storage densityFixed capacitor dielectricGlass shaping apparatusTO-18Chemical composition

The invention relates to a bismuth barium sodium niobate-based glass ceramic material with high energy storage density, and a preparation method and application thereof. The chemical components of theglass ceramic material accord with a chemical general formula of 21.6BaCO3-2.4Bi2O3-6Na2CO3-30Nb2O5-40SiO2. The preparation method comprises the following steps: taking BaCO3, Bi2O3, Na2CO3, Nb2O5 and SiO2 as raw materials to carry out uniform mixing, then carrying out drying, carrying out melting at a high temperature to obtain a glass melt; quickly pouring the high-temperature melt into a preheated mould, removing residual stress in the glass body through annealing treatment, and then cutting the glass block body into glass sheets with a same size and thickness; and carrying out controlledcrystallization on the glass sheets to obtain the glass ceramic energy storage material. Compared with the prior art, the glass ceramic energy storage material prepared by the method has the advantages of high dielectric constant (up to 118), high breakdown field strength (up to 1878.75 kV / cm), high energy storage density (up to 18.4 J / cm<3>), low loss (low to 0.025), good temperature stability and the like.

Owner:TONGJI UNIV

Lead and cadmium free, low temperature fired X7R dielectric ceramic composition and method of making

ActiveUS8305731B2Stable dielectric constantSmall dielectric lossFixed capacitor dielectricStacked capacitorsCeriumTin

Multilayer ceramic chip capacitors (MLCC's) which satisfy X7R TCC requirements and which are compatible with silver-palladium internal electrodes. The MLCC's exhibit desirable dielectric properties—high capacitance, low dissipation factor, high insulation resistance, stable TCC—and excellent performance on highly accelerated life testing, and good resistance to dielectric breakdown. The dielectric layers include a lead-free and cadmium-free barium titanate base material doped with other metal oxides such oxides of zinc, boron, bismuth, barium, titanium, praseodymium, cerium, tungsten, neodymium, tungsten, tin, niobium, copper, and / or manganese in various combinations. The dielectric ceramic materials herein can be fired at less than 1150° C. with an inner electrode having 70 wt % or more Ag and 30 wt % or less Pd to form an MLCC.

Owner:FERRO CORP

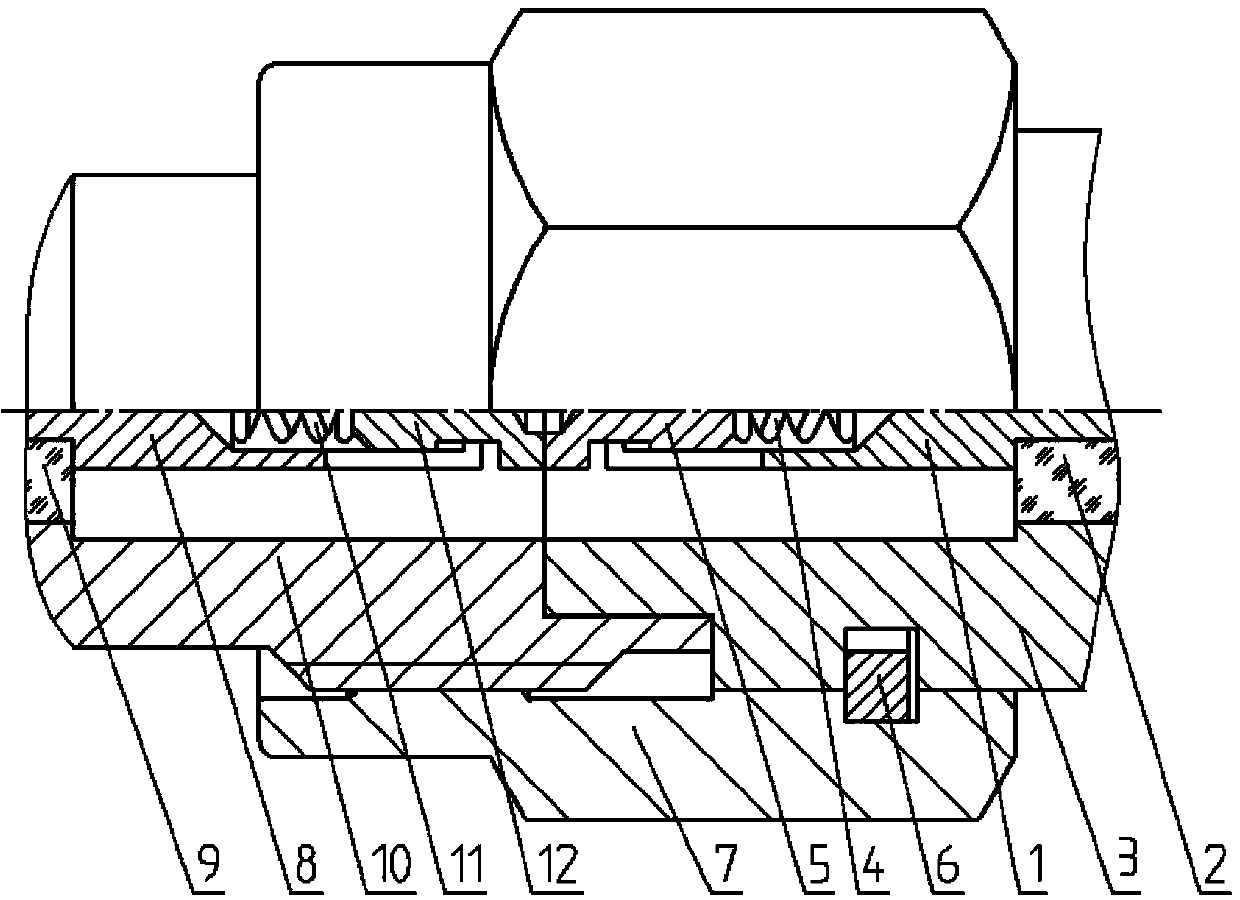

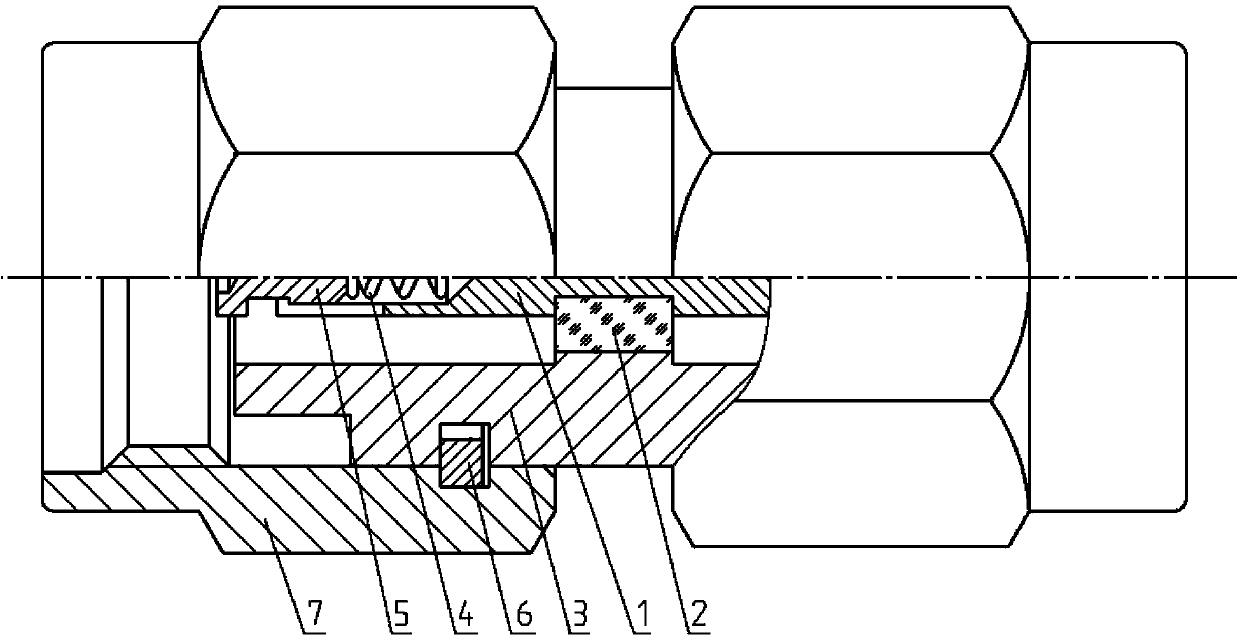

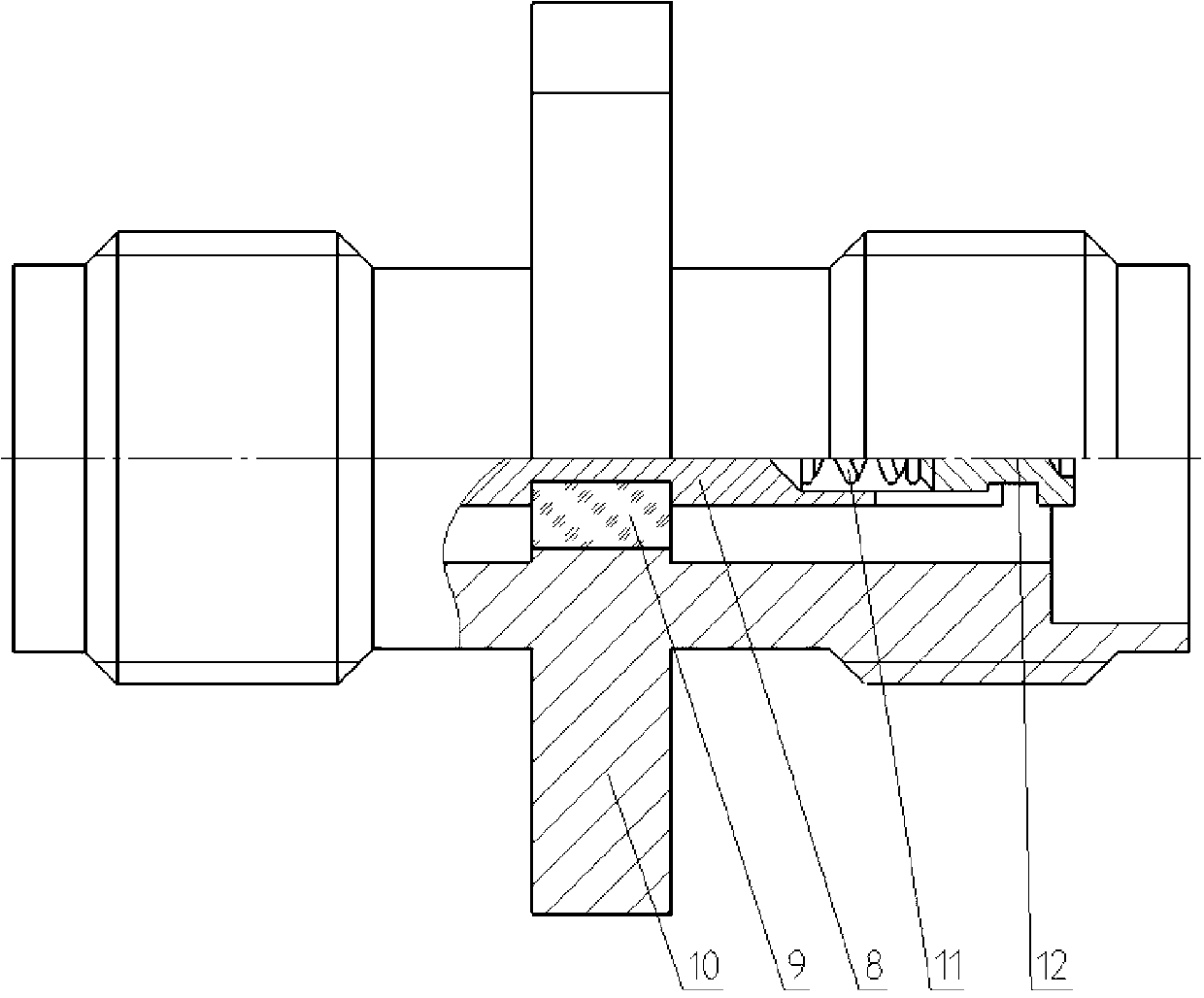

Superhigh-temperature-resistant nonpolarity radio-frequency coaxial electrical connector

InactiveCN103280677AReduce contact areaIncrease contact pressureCoupling contact membersTwo-part coupling devicesElectrical conductorElectrical polarity

A superhigh-temperature-resistant nonpolarity radio-frequency coaxial electrical connector comprises a radio-frequency connector plug and a radio-frequency connector socket; a plug inner conductor of the radio-frequency connector plug is sintered together with the middle part of a plug shell through a plug glass body; the mouth part of the plug inner conductor is provided with a plug step hole in a way of inward cutting a slot; a plug spring which is in clearance fit with the plug step hole is arranged in the plug step hole; a plug inner contact head which is in clearance fit with the plug step hole is in press fit into the plug step hole and outside the plug spring; a blind hole is formed in the outer contact end face of the plug inner contact head; a socket inner conductor of the radio-frequency connector socket is sintered together with the middle part of a socket shell through a socket glass body; the mouth part of the socket inner conductor is provided with a socket step hole in a way of inward cutting a slot; a socket spring which is in clearance fit with the socket step hole is arranged in the socket step hole; a socket inner contact head which is in clearance fit with the socket step hole is in press fit into the socket step hole and outside the socket spring; and a blind hole is formed in the outer contact end face of the socket inner contact head. The electrical connector has the characteristics that the reliability is high, and the electrical connector can meet the 650-DEG C superhigh-temperature application condition.

Owner:SHAANXI HUADA SCI TECH

Microwave dielectric ceramic material for LTCC (low temperature co-fired ceramic) and preparation method thereof

The invention discloses a microwave dielectric ceramic material for LTCC (low temperature co-fired ceramic) and a preparation method thereof. The microwave dielectric ceramic material has a structureexpressed by (1-x)Li2(Zn0.92Co0.08)(Ti0.95Nb0.05)3O8.xBaV2O6, in the formula, x is 0.1 to 0.7. According to the preparation method, Li2(Zn0.92Co0.08)(Ti0.95Nb0.05)3O8 ceramic main crystal phases withthe simultaneously substituted A and B site ions are firstly prepared; then, a BaV2O6 ceramic composite phase is prepared; next, the compounding is performed according to the mole ratio of (1-x):x (xis 0.1 to 0.7); sintering is performed at 825 to 950 DEG C. The ceramic material has the advantages that the inherent sintering temperature is low; the quality is high; the Qxf value *f reaches 90000GHZ or higher; the temperature coefficient Tau f is in a range of + / -10ppm; the LTCC low-temperature co-firing technical requirements can be met; the material can be widely applied to the manufacturingof microwave devices such as resonators, filters, oscillators, amplifiers and media antennas; important application values are realized.

Owner:HUNAN SEEDER ELECTRONICS CERAMIC TECH IND PARK DEV CO LTD

Preparation method of fluorine-containing resin mixture film and copper-clad plate

ActiveCN109880133AStable dielectric constantOvercoming thermal stabilitySynthetic resin layered productsLaminationPolymer scienceResource utilization

The invention discloses a preparation method of a fluorine-containing resin mixture film and a copper-clad plate. The preparation method comprises the following steps: preparing a uniform dispersion solution of a fluorine-containing resin mixture; and uniformly dispersing the fluorine-containing resin mixture solution on PTFE (polytetrafluoroethylene), and performing baking and drying to obtain the fluorine-containing resin mixture film of PTFE; then preparing the copper-clad plate by using the fluorine-containing resin mixture film of the PTFE; the method of invention aims to utilize PTFE with poorer performance, a unique film preparation technology is adopted, the problems of poor thermal stability, poor mechanical properties, poor cohesiveness, poor strength and the like of the copper-clad plate caused by the problems of PTFE are solved, the finally obtained copper-clad plate has low hygroscopicity, stable dielectric constant and low transmission loss, the peel strength and the adhesiveness of the product are both at a high level, meanwhile, resource utilization is achieved, and waste is avoided.

Owner:久耀电子科技(江苏)有限公司

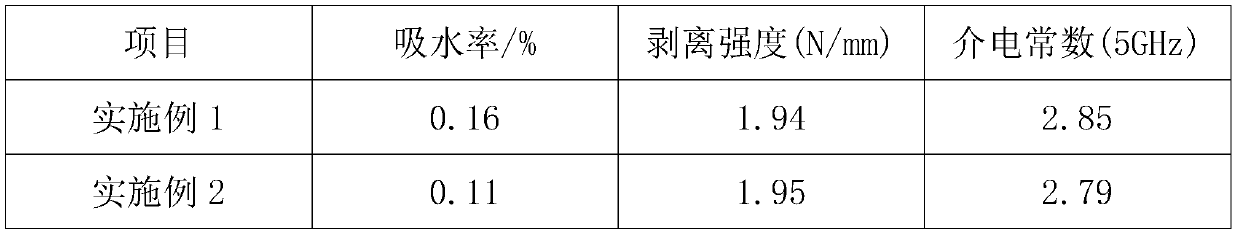

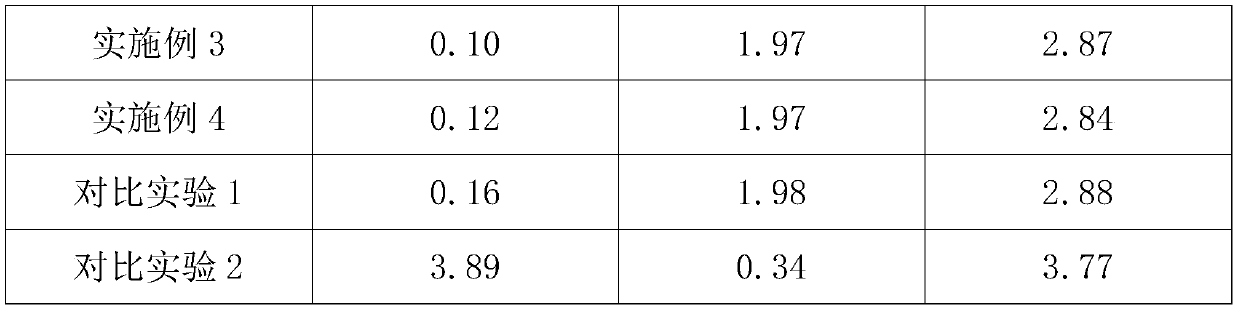

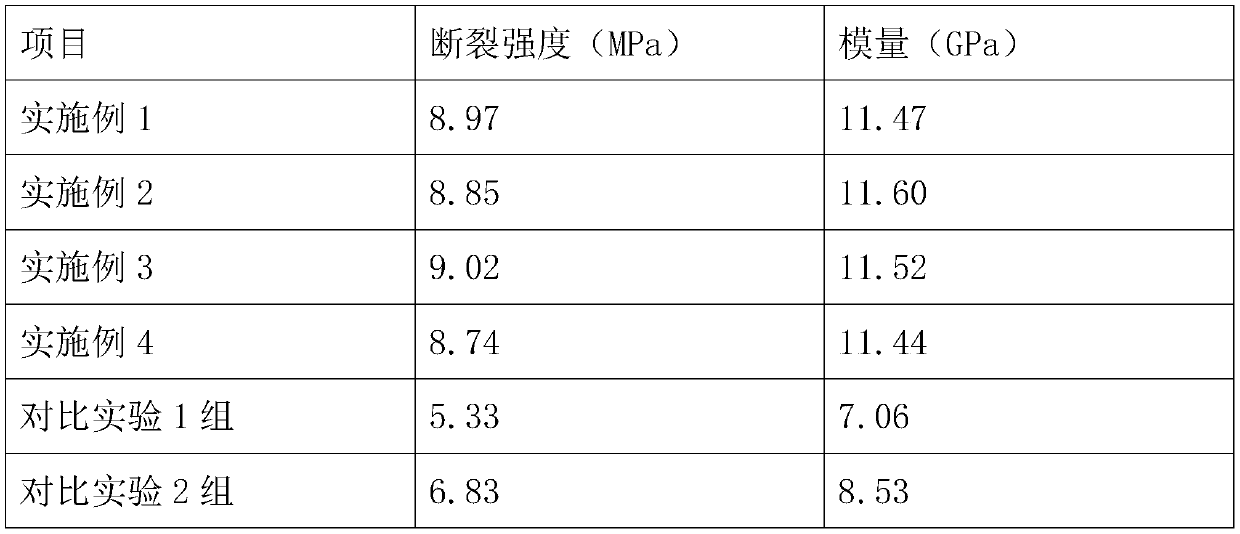

Crosslinked polystyrene, high-power pulse vacuum insulator and preparation method

InactiveCN103012646AImprove performance indicatorsComprehensive performance index of high power pulse vacuum insulator with large diameterInsulatorsPolystyreneDivinyl benzene

The invention relates to the chemical field, and in particular relates to crosslinked polystyrene, a high-power pulse vacuum insulator and a preparation method. The crosslinked polystyrene comprises the following raw materials by mass percent: 85-98% of styrene, 1-10% of divinyl benzene, and 0.5-5% of azobisisobutyronitrile; the preparation method of the crosslinked polystyrene comprises the steps of weighing the raw materials, and mixing the raw materials; injecting the mixed raw materials into a mould; placing the mould into brine so as to conduct polymerization reaction; and drying the polymerized product. The diameter of the high-power pulse vacuum insulator is greater than 1m; the thickness of the high-power pulse vacuum insulator is greater than 0.1m; and the preparation method of the high-power pulse vacuum insulator comprises the crosslinked polystyrene preparation method, the product dried is processed into a finished product according to the size of the insulator. The crosslinked polystyrene, the high-power pulse vacuum insulator and the preparation method are applicable to insulation of the high-power pulse vacuum environment.

Owner:四川中久红宇科技有限公司

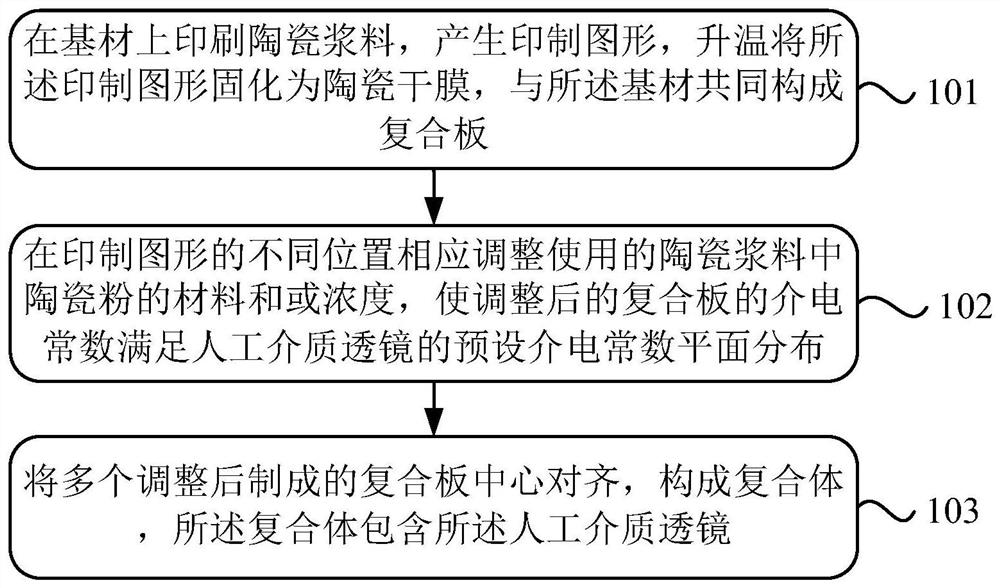

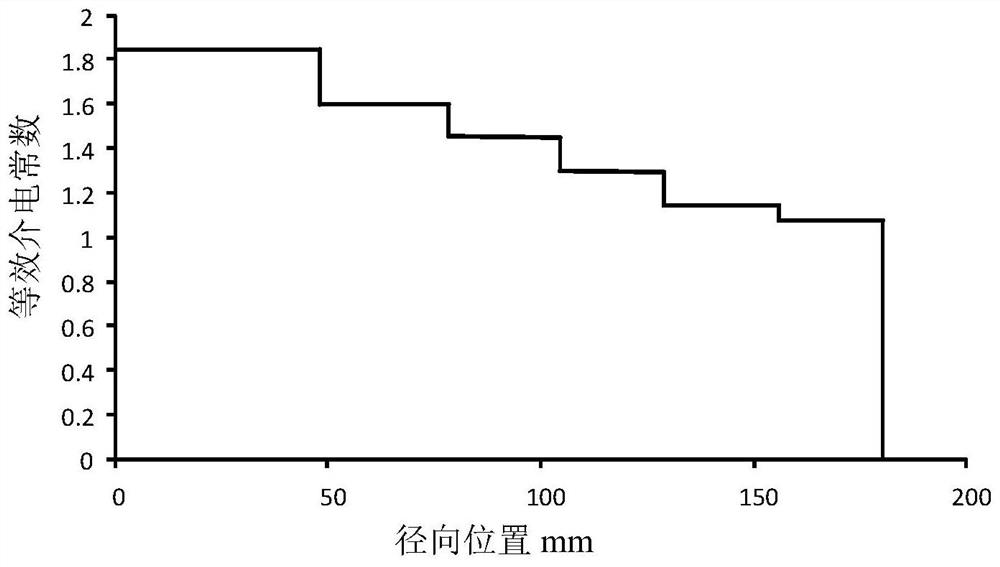

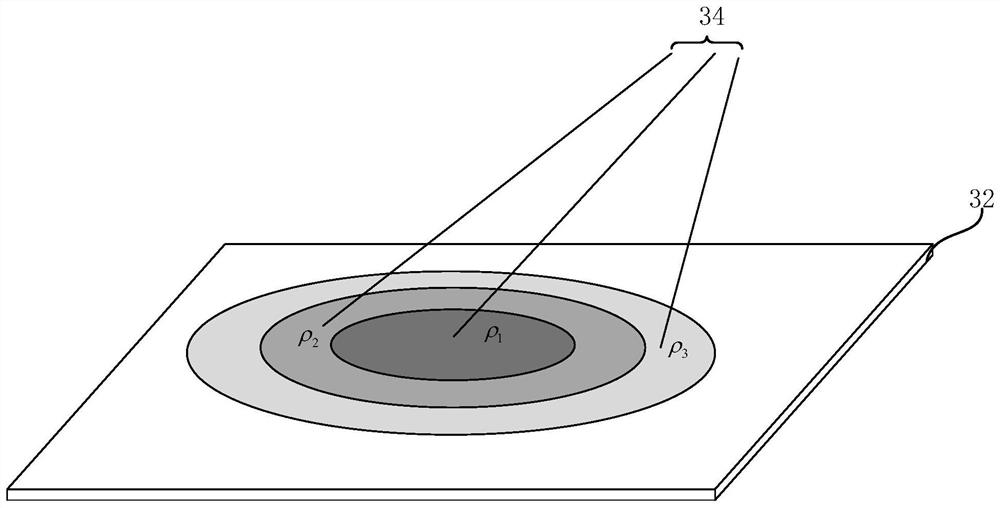

Artificial dielectric lens manufacturing method and artificial dielectric lens thereof

ActiveCN111799566APrecise change in dielectric constantThe dielectric constant can be precisely changed with any distributionAntennasAdditive manufacturing apparatusInterference (communication)Slurry

The invention discloses an artificial dielectric lens manufacturing method and an artificial dielectric lens thereof. The problems that an existing antenna is poor in parameter consistency, large in scattering and large in bidirectional communication interference are solved. The artificial dielectric lens manufacturing method comprises the following steps: printing ceramic slurry on a base material, generating a printed pattern, heating the printed pattern to be solidified into a ceramic dry film, and the ceramic dry film and the base material jointly form a composite board; correspondingly adjusting the material and / or concentration of ceramic powder in the used ceramic slurry at different positions of the printed pattern, so that the dielectric constant of the composite board manufactured after adjustment meets the preset dielectric constant plane distribution of the artificial dielectric lens; aligning the centers of a plurality of adjusted composite plates to form a composite body,and the composite body comprising the artificial dielectric lens. The artificial dielectric lens is manufactured by using the method. According to the invention, the artificial dielectric lens with stably distributed dielectric constants is realized.

Owner:BEIJING HIGH WAY TELECOMMUNICTION TECH CO LTD

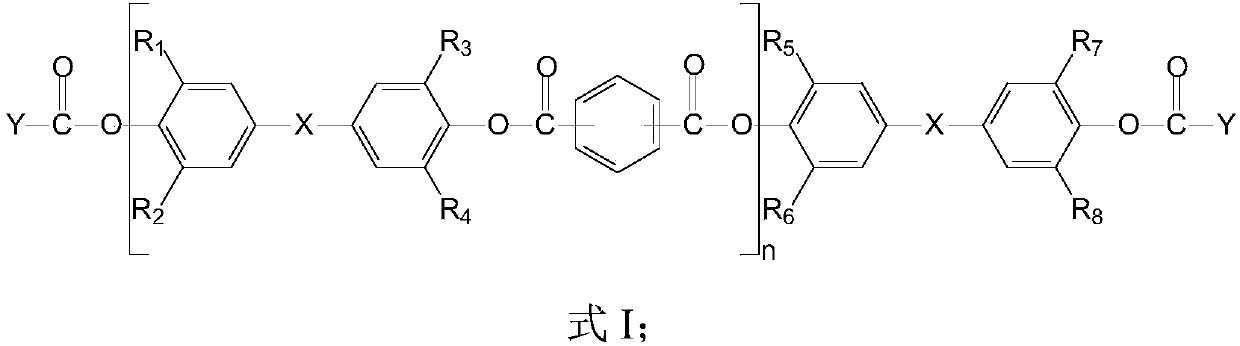

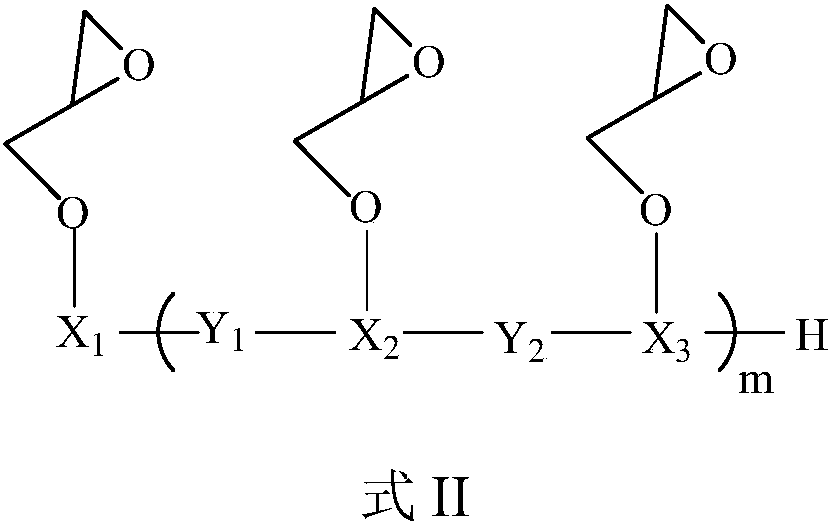

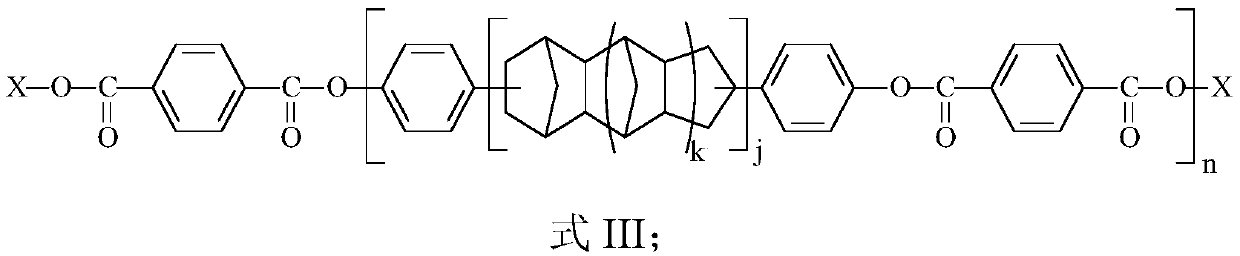

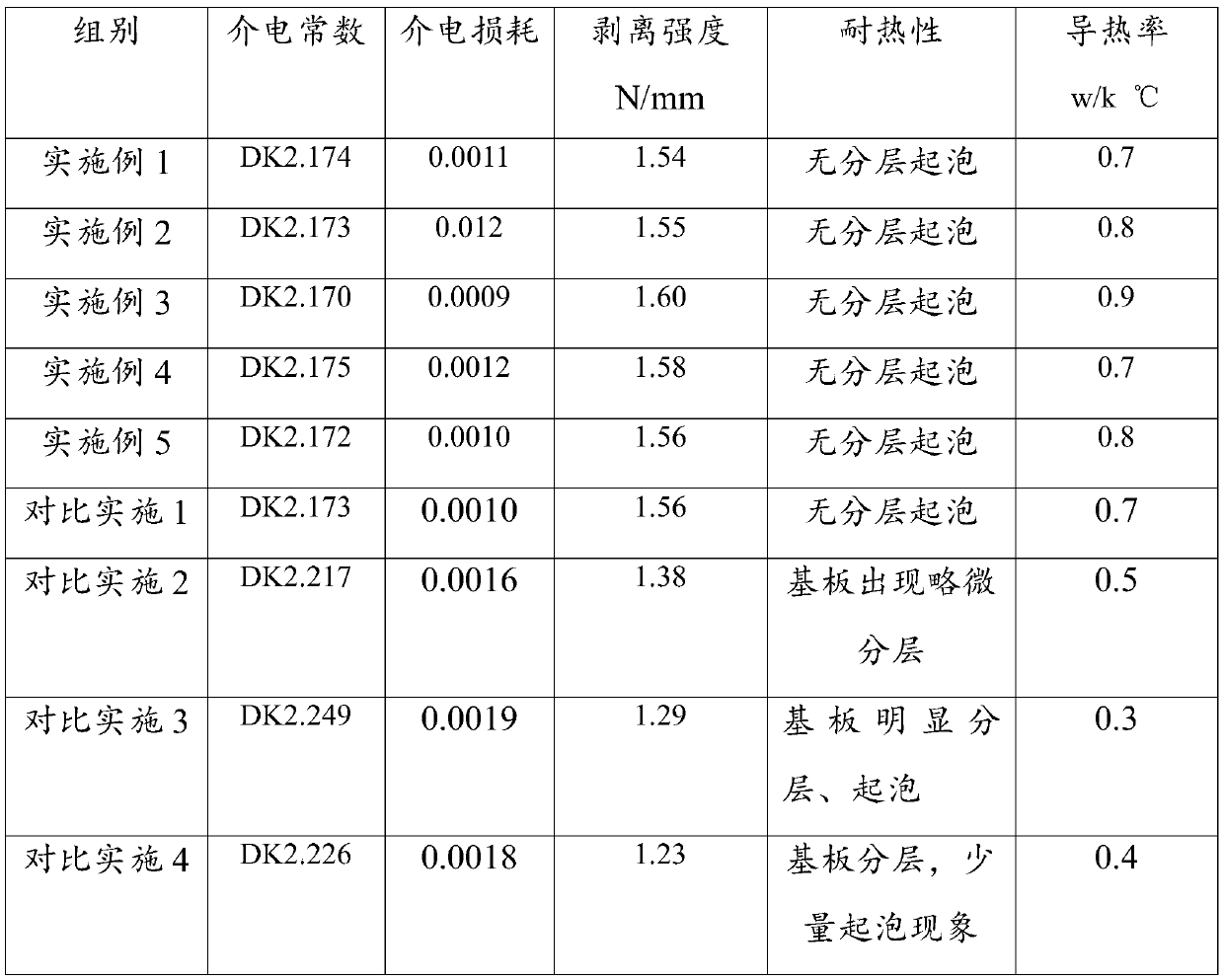

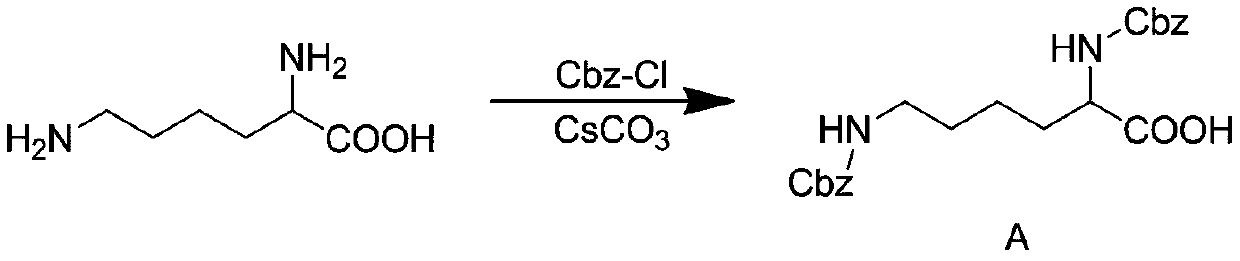

Thermosetting resin composition, and prepreg, laminated board and metal foil coated laminated board using the same

ActiveCN109651763AExcellent dielectric propertiesHigh glass transition temperatureSynthetic resin layered productsElectrical equipmentEpoxyMetal foil

The invention provides a thermosetting resin composition, and prepreg, a laminated board and a metal foil coated laminated board using the same. The composition includes epoxy resin, dicyclopentadienephenol type active ester and an ester curing agent having a structure shown as a formula I. The composition adopts the ester curing agent having the structure shown as the formula I and the dicyclopentadiene phenol type active ester to synergistically cure the epoxy resin, so that polar groups like a secondary hydroxyl group cannot be generated during curing, a large amount of hydrophobic groupsare contained in a cured product, and therefore, the cured product can be guaranteed to have higher glass-transition temperature, and water absorption rate and dielectric loss factors can be obviouslyreduced. The laminated board and the metal foil coated laminated board prepared through the composition can have good hear resistance, moisture resistance, dielectric properties, flame resistance, processability and chemical resistance.

Owner:GUANGDONG SHENGYI SCI TECH

High-performance polytetrafluoroethylene film, and manufacturing method of microwave substrate thereof

ActiveCN110746725ALow water absorptionOvercoming the problem of poor adhesionSynthetic resin layered productsElectrical equipmentGlass fiberPolymer science

The invention belongs to the field of communication, and particularly relates to a high-performance polytetrafluoroethylene (PTFE) film, and a manufacturing method of a microwave substrate thereof. The high-performance PTFE film comprises 10-70 parts of a filler and 30-90 parts of polytetrafluoroethylene resin, and the filler comprises nanometer silicon nitride, a glass fiber and a cationic polyurethane, and a mass ratio of the glass fiber to the cationic polyurethane to the nanometer silicon nitride is (3-7):(2-6):(1-4). An ultrathin high-performance PTFE film is prepared by a self-made ultrathin PTFE film device, and is used for preparing the microwave substrate. The obtained PTFE film has a low water absorption rate and a good bonding performance, and the microwave substrate has excellent thermodynamic and electrical properties.

Owner:珠海国能新材料股份有限公司

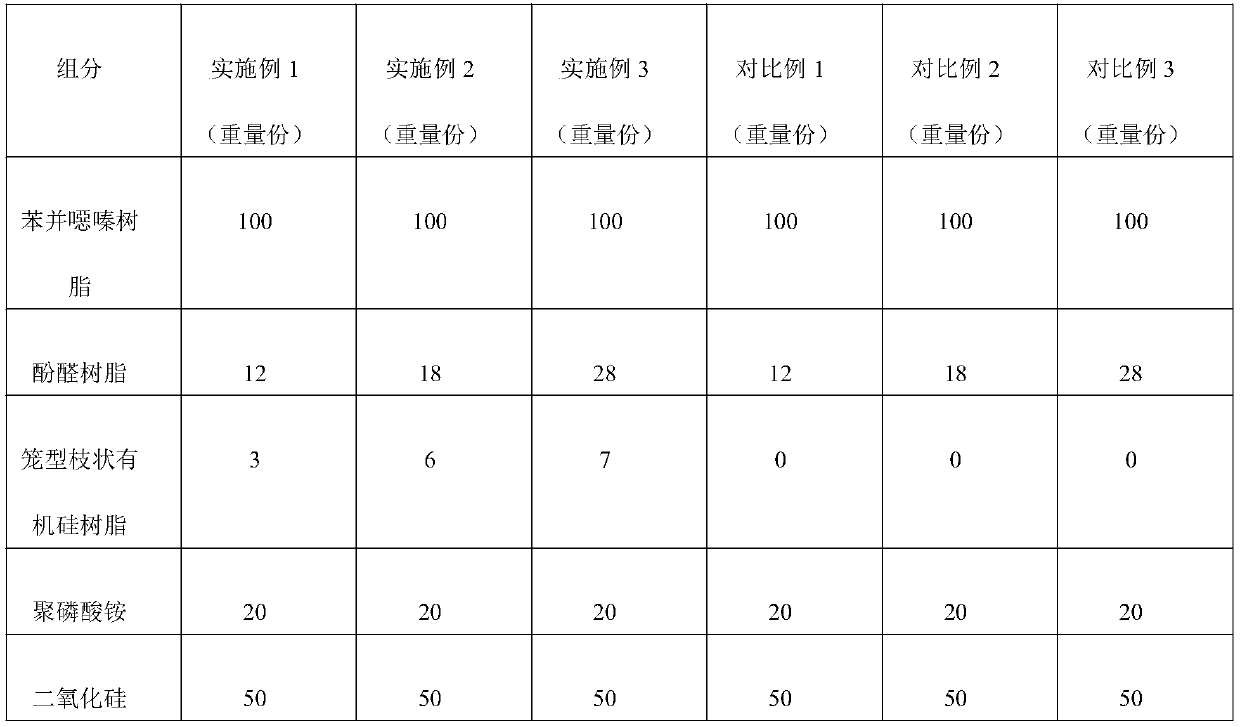

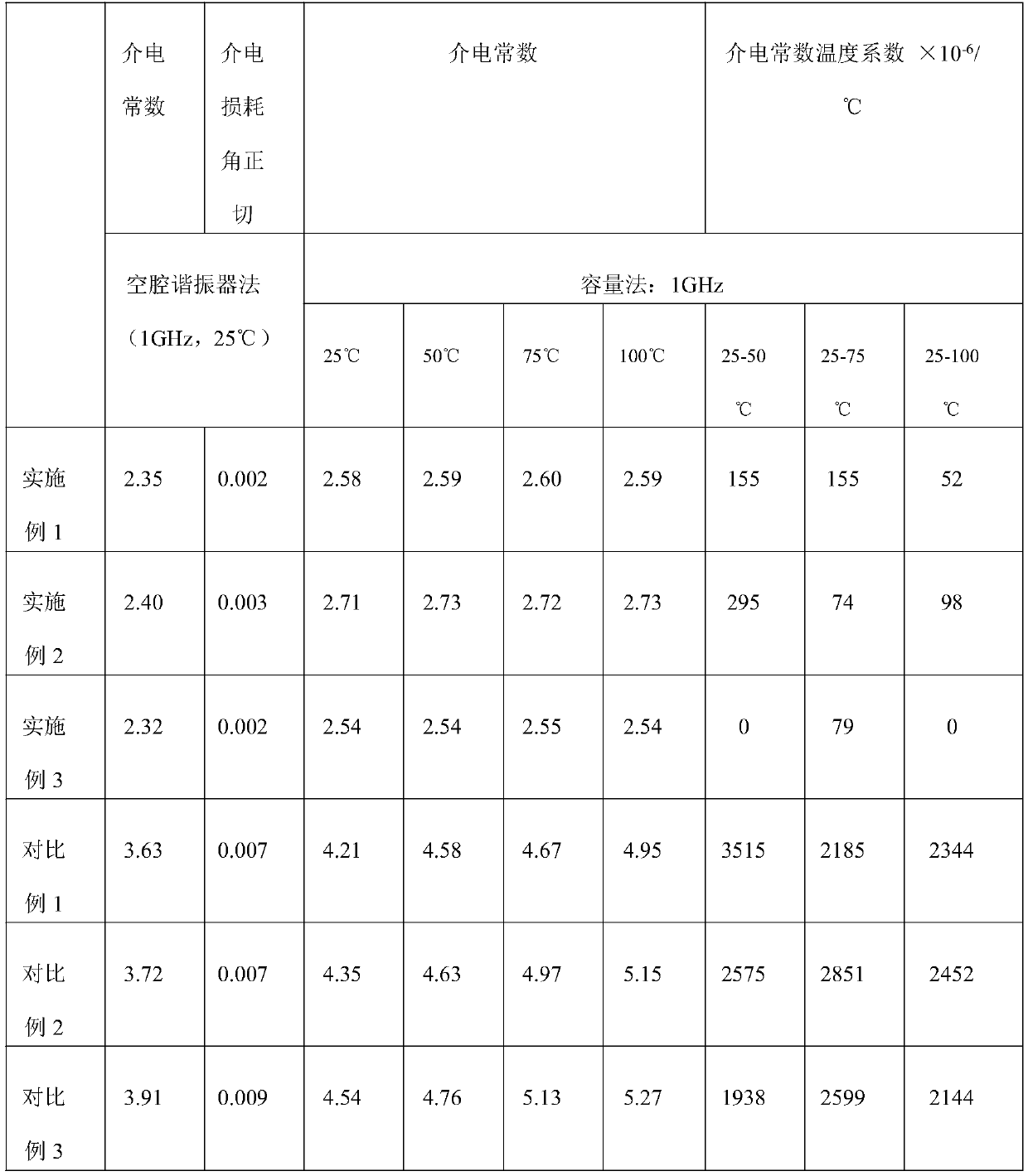

Benzoxazine resin composition, prepreg made from same, copper-clad laminate and circuit board

ActiveCN109825032ALow dielectric constantReduce the numberSynthetic resin layered productsGlass/slag layered productsDielectric lossCopper

The invention discloses a benzoxazine resin composition, comprising, by weight, 100 parts of benzoxazine resin, 10-30 parts of phenolic resin, and 1-10 parts of cage-like dendric organosilicon resin.In addition, the invention also discloses prepreg made from the benzoxazine resin composition, a copper-clad laminate comprising the prepreg, and a circuit board made with the copper-clad laminate. The benzoxazine resin composition has stable and low dielectric constant and dielectric loss even at a high temperature; the circuit board with a substrate material made from the benzoxazine resin composition has high information transmission rate and good signal transmission completeness.

Owner:ZIBO KERRBEN POLYMER NEW MATERIAL

High-frequency double-sided copper-clad dielectric board and preparation method thereof

InactiveCN110281615ASimple preparation processReduce manufacturing costLamination ancillary operationsLaminationDielectricCopper foil

The invention discloses a high-frequency double-sided copper-clad dielectric board. The high-frequency double-sided copper-clad dielectric board comprises two layers of copper foil and an insulating medium layer located between the two layers of copper foil; the insulating medium layer comprises, by weight, 60-70 parts of a resin material and 5-10 parts of a glass fiber material, wherein the resin material comprises, by weight, 40-50 parts of polytetrafluoroethylene resin, 20-30 parts of fluoropolyethylene, 10-15 parts of thermosetting cyanate resin, 2-5 parts of polyphenyl ether resin, 1-5 parts of epoxy resin, 5-10 parts of a lubricant and 1-3 parts of a curing agent. According to the high-frequency double-sided copper-clad dielectric board and a preparation method thereof, the preparation process is simple, the production cost is low, the dielectric constant during batch production is stable, and the consistency is good; the high-frequency double-sided copper-clad dielectric board has the advantages that high temperature resistance, aging resistance and radiation resistance are obtained, and the dielectric constant is precise. Finally, the dielectric constant of the obtained high-frequency double-sided copper-clad dielectric board is 2.2, and the loss tangent is 0.0009.

Owner:宁波瑞法新材料有限公司

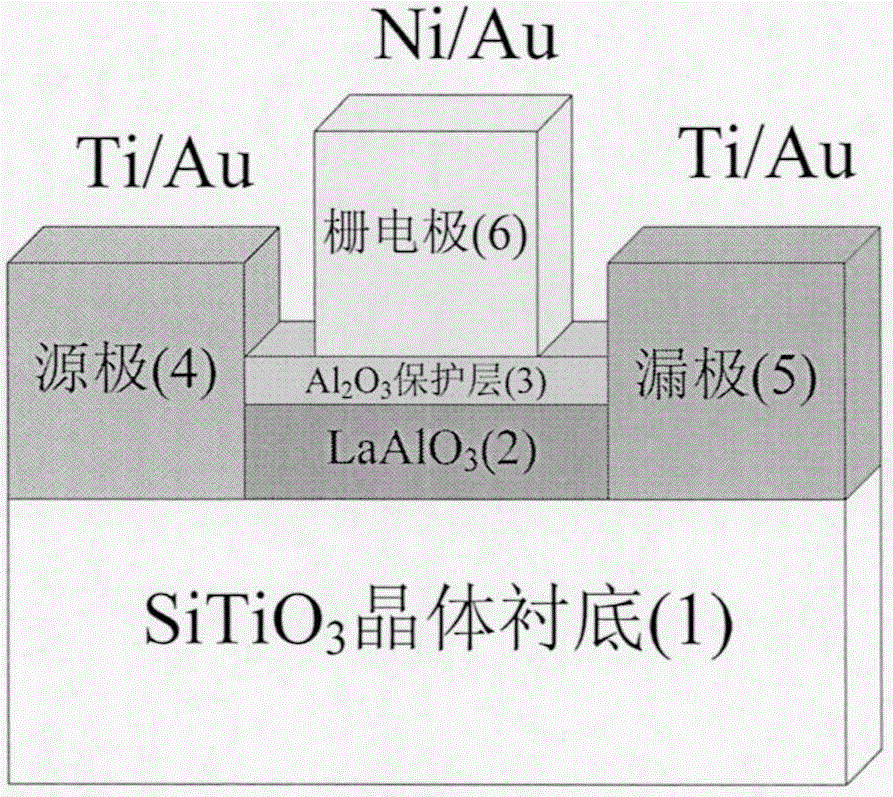

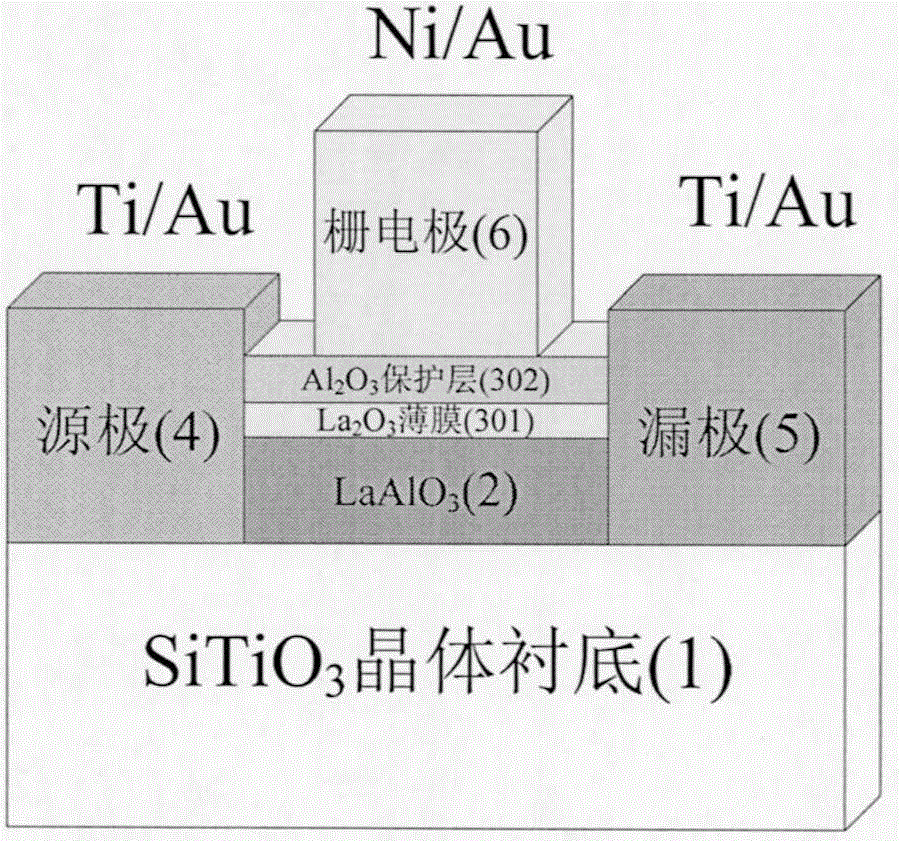

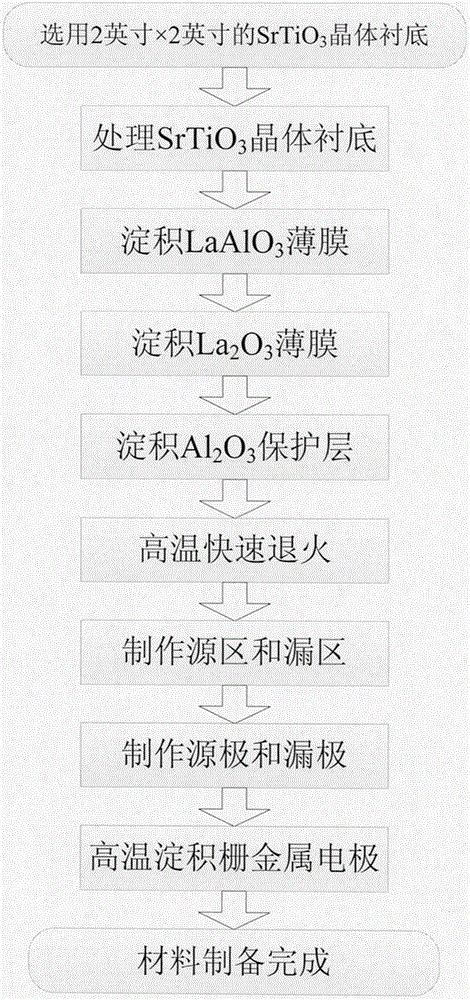

LaAlO3/SrTiO3 heterojunction field effect transistor based on La-based gate and manufacturing method

InactiveCN105470306AWide band gapHigh electrical breakdown strengthSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceGate stack

The invention discloses a LaAlO3 / SrTiO3 heterojunction field effect transistor based on a La-based gate and a manufacturing method, and mainly solves the problem in the prior art that gate capacitance has a poor control capability over device channel charges. The LaAlO3 / SrTiO3 heterojunction field effect transistor comprises a SrTiO3 crystal substrate (1) and a LaAlO3 film (2) from bottom to top, and the LaAlO3 film (2) is provided with a source electrode (4), a drain electrode (5) and a gate electrode (6). A gate medium material layer (3) is arranged between the LaAlO3 film (2) and the gate electrode (6) and forms the gate capacitance of the transistor. The gate medium material layer (3) is of a gate stacking structure formed by a La2O3 film (301) and an Al2O3 protection layer (302). According to the invention, the gate medium material is stable in performance and high in dielectric constant, the thermal stability is good, the gate capacitance control capability is high, gate electrode breakdown voltage is high, and the LaAlO3 / SrTiO3 heterojunction field effect transistor based on the La-based gate can be used for manufacturing a high-performance heterojunction field effect transistor device.

Owner:XIDIAN UNIV

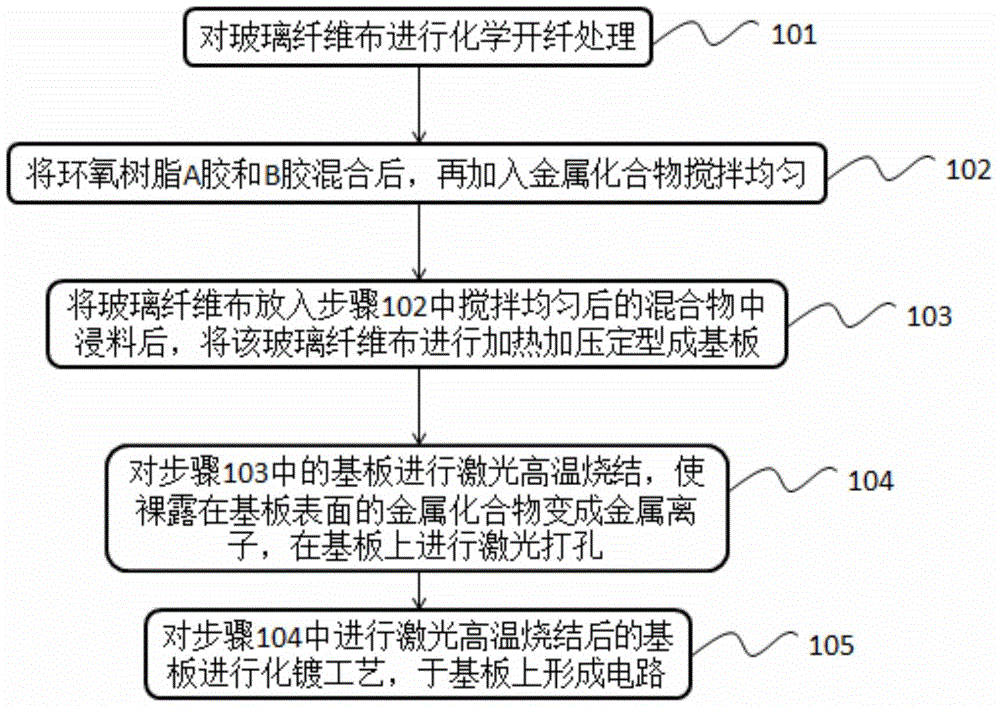

Circuit board and preparation method thereof

ActiveCN104582278AReduce pollutionSave spacePrinted circuit manufactureCircuit susbtrate materialsEpoxyGlass fiber

The invention discloses a preparation method for a circuit board. The preparation method comprises the following steps: a, performing chemical splitting treatment on fiberglass cloth; b, mixing epoxy resin adhesives A and B, and adding a metal compound for uniform stirring; c, placing the fiberglass cloth into the mixture obtained by uniform stirring in the step b for impregnation, and heating, pressing and shaping the fiberglass cloth into a substrate; d, performing high-temperature laser sintering on the substrate in the step c to convert the metal compound exposed from the surface of the substrate into metal ions, wherein multiple layers of substrates can be stacked after laser drilling on the substrate; e, carrying out a chemical plating process on the substrate subjected to high-temperature laser sintering in the step d to form a circuit on the substrate to conduct the front and back surfaces of the substrate. According to the preparation method, environment friendliness is achieved, machining time is shortened, and efficiency is improved; moreover, the metal compound is added during epoxy resin modulation, so that the resistance value and dielectric constant of the circuit board are more stable.

Owner:深圳市铭新科技有限公司

Preparation method of modified dicyclopentadiene type cyanate ester resin with low hygroscopicity

ActiveCN110372861AWater resistantTo achieve the purpose of tougheningSilicon organic compoundsBulk chemical productionWater resistantToughening

The invention discloses a preparation method of a modified dicyclopentadiene type cyanate ester resin with low hygroscopicity. Firstly, a modifier with toughening and water-resistant properties is prepared, the modifier has two amino groups, and can react with -OCN groups of a dicyclopentadiene type cyanate ester to carry out front-end polymerization, a soft segment is introduced to achieve the purpose of toughening, and at the same time, the modifier contains a large amount of organosilicone, the organosilicone is introduced by a block bonding manner, the organosilicone has a stable dielectric constant and dielectric loss in a relatively wide temperature range, has relatively high flexibility, and can greatly improve toughness of the cyanate ester, and at the same time, the organosiliconehas good oxidation resistance and low surface energy, the organosilicone is embedded in a space networking resin, and when the resin is cured, silicon atoms are released to the surface of the resin due to low surface energy of the organosilicone, so that the modified cyanate ester resin has good water resistance, and the problem that hygroscopicity is increased during a resin toughing process issolved.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

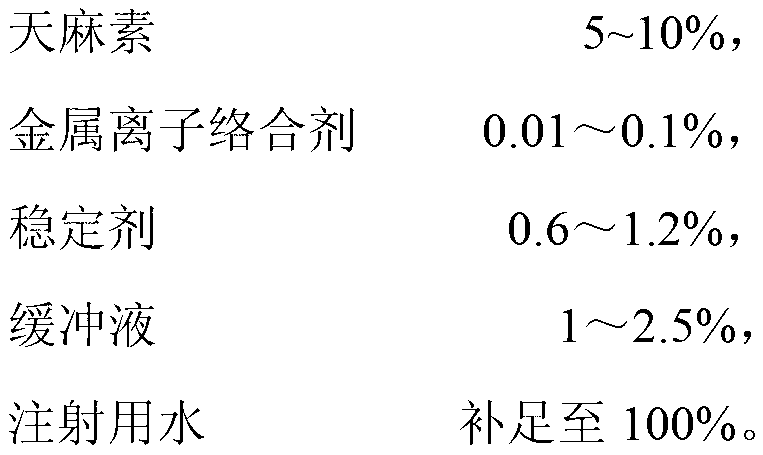

Gastrodin injection preparation and preparation method

InactiveCN103126980AReduce scrap rateStable dielectric constantOrganic active ingredientsNervous disorderBatch productionWaste product

The invention discloses a gastrodin injection preparation, which comprises the following components by weight: 5-10% of gastrodin, 0.01-0.1% of metal ion complexing agent, 0.6-1.2% of stabilizing agent, 1-2.5% of buffer and the balance of injection water. The invention also provides a preparation method of the gastrodin injection preparation. The gastrodin injection of the present invention can effectively stop the addition of visible foreign matter during a placing process of the gastrodin injection, the defective index of the visible foreign matter in a solution is reduced, the white point and white block precipitation are not generated, the expectation effect can be reached, thereby the treatment effect of gastrodin can be fully performed. The gastrodin injection preparation has the advantages of simple prescription, good stability, high clear degree, safe clinical usage, small adverse reaction and convenient industrial large batch production.

Owner:YANGZHOU ZHONGBAO PHARMA

Production process of polytetrafluoroethylene glass fiber copper-coated laminated board

InactiveCN104924721ALow dielectric constantReduce lossLaminationLamination apparatusAviationInformatization

The invention relates to the technical field of a circuit board, and particularly relates to a production process of a polytetrafluoroethylene glass fiber copper-coated laminated board. The production process comprises the steps of acquiring splicing sheets by virtue of glue preparation and glue application, then cutting and superimposing the splicing sheets, automatically combining the splicing sheets with a copper foil and a steel plate, automatically press fitting by virtue of a vacuum press under high temperature and high pressure condition, then autoamtically disassembling, and cutting the copper-foil-coated plate into the polytetrafluoroethylene glass fiber copper-coated laminated board. The production process overcomes the weaknesses that the traditional microwave circuit substrate material is difficult in hole metallization, the machinability is poor on the production line and the process is complicated and is easy for carrying out machining such as cutting, drilling and the like, the production process is also greatly simplified, the weaknesses of the existing domestic PTEE and glass cloth copper-coated plate are overcome, the current situation that the domestic high-frequency microwave substrate is mainly imported can be changed, and the demand of the highly informatization and high-speed development of the information processing in industries such as airspace, aviation, mobile phone receiving base station and the like can be satisfied.

Owner:赵国平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com